Investigation of Conductive Mechanism of Amorphous IGO Resistive Random-Access Memory with Different Top Electrode Metal

Abstract

1. Introduction

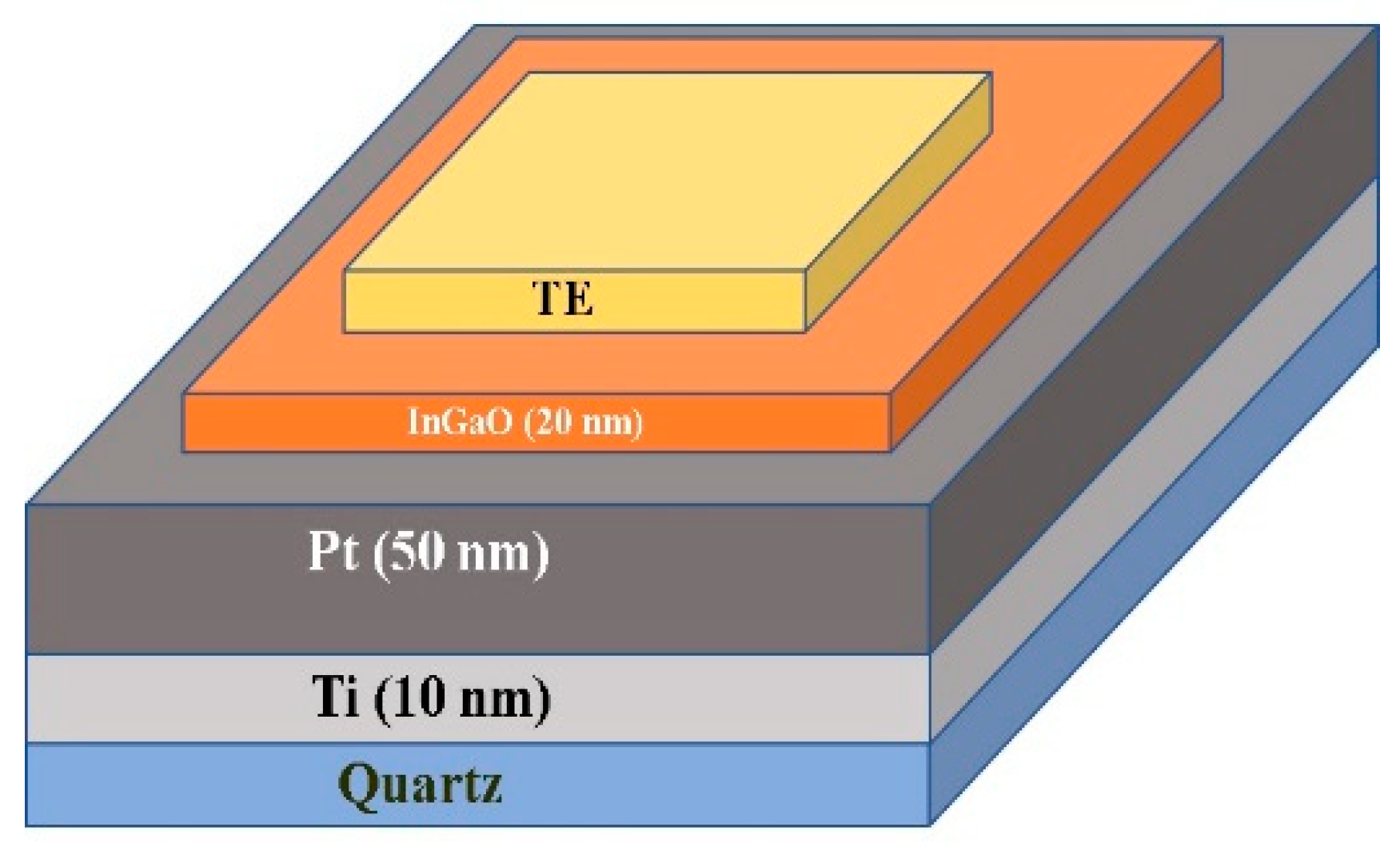

2. Experimental Details

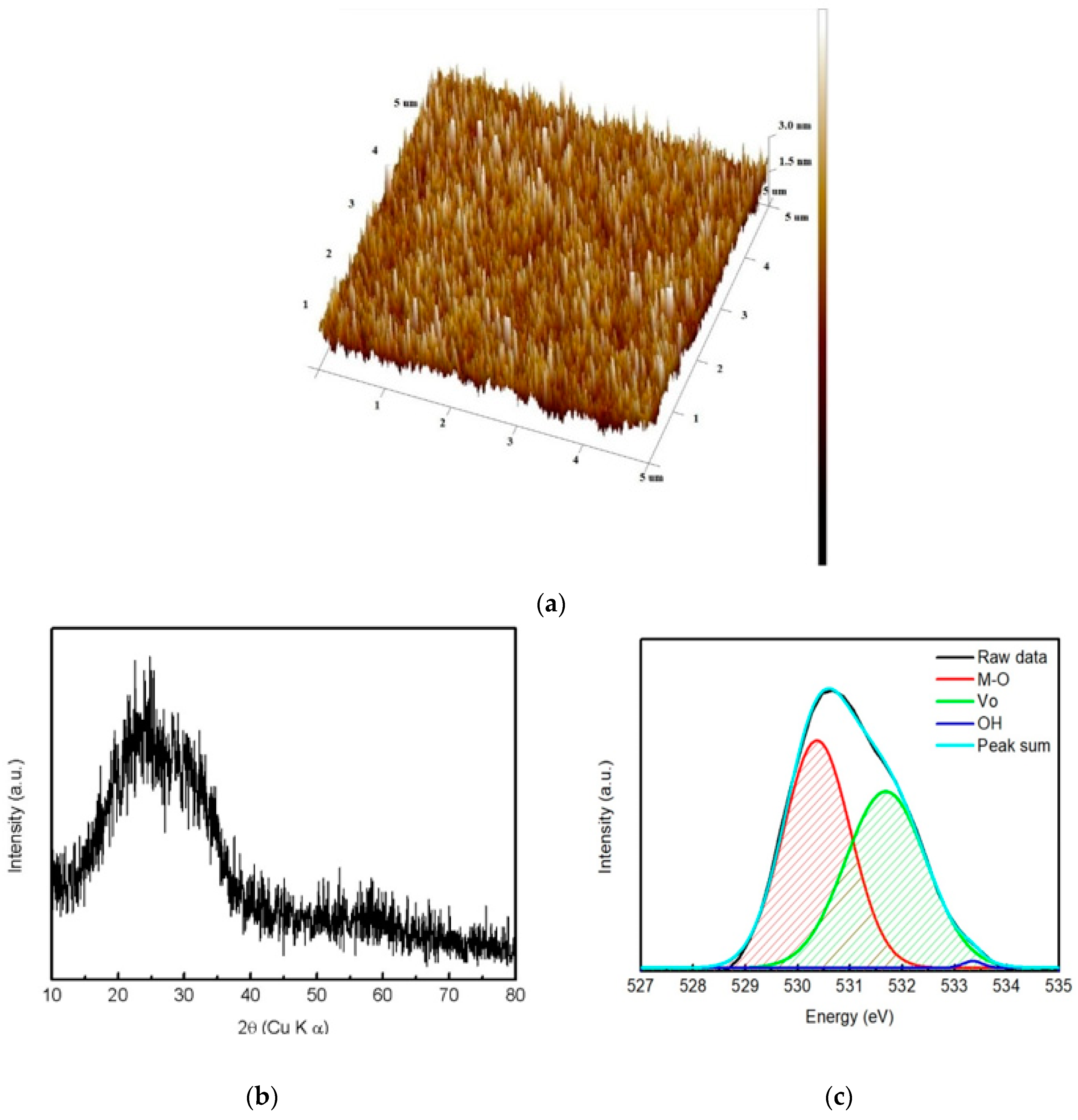

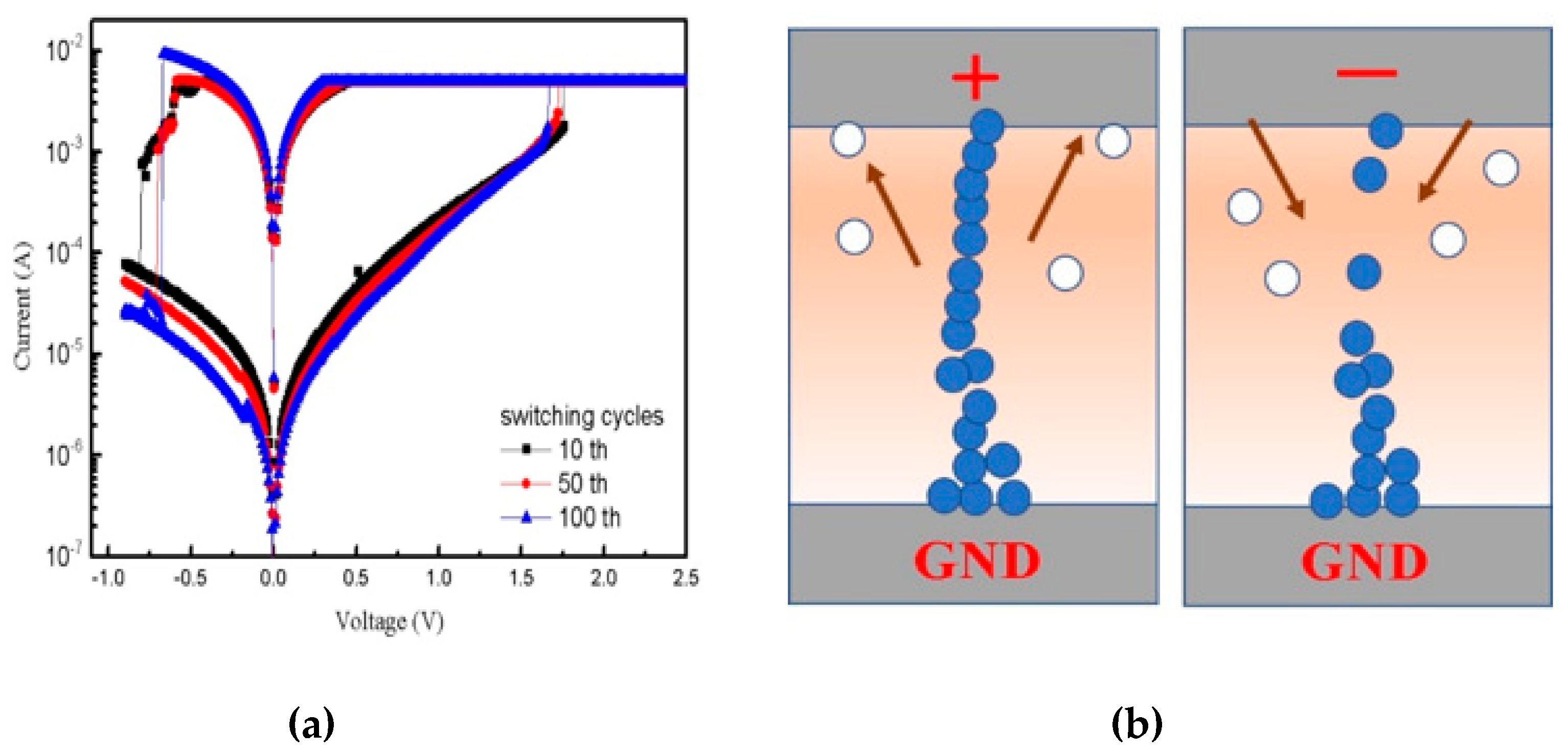

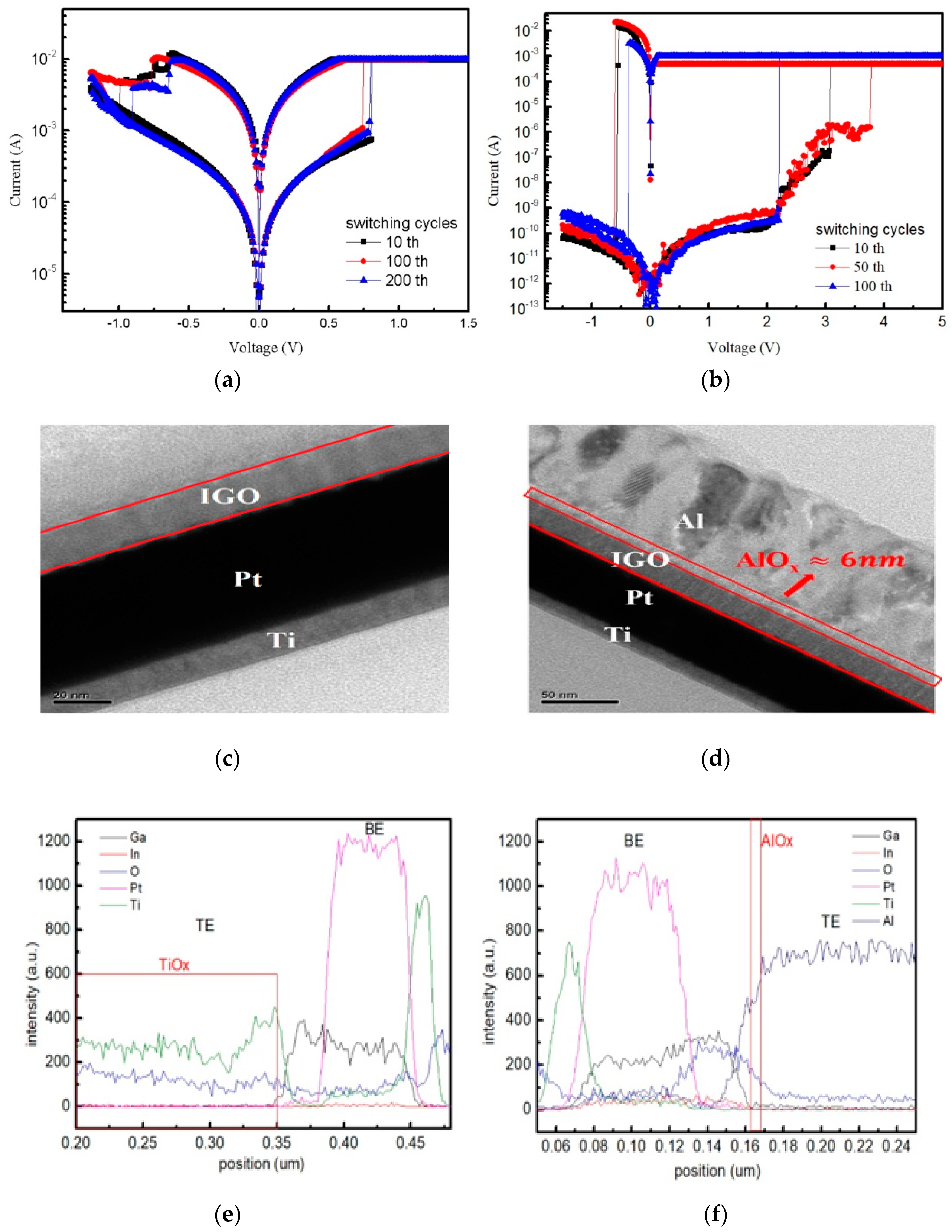

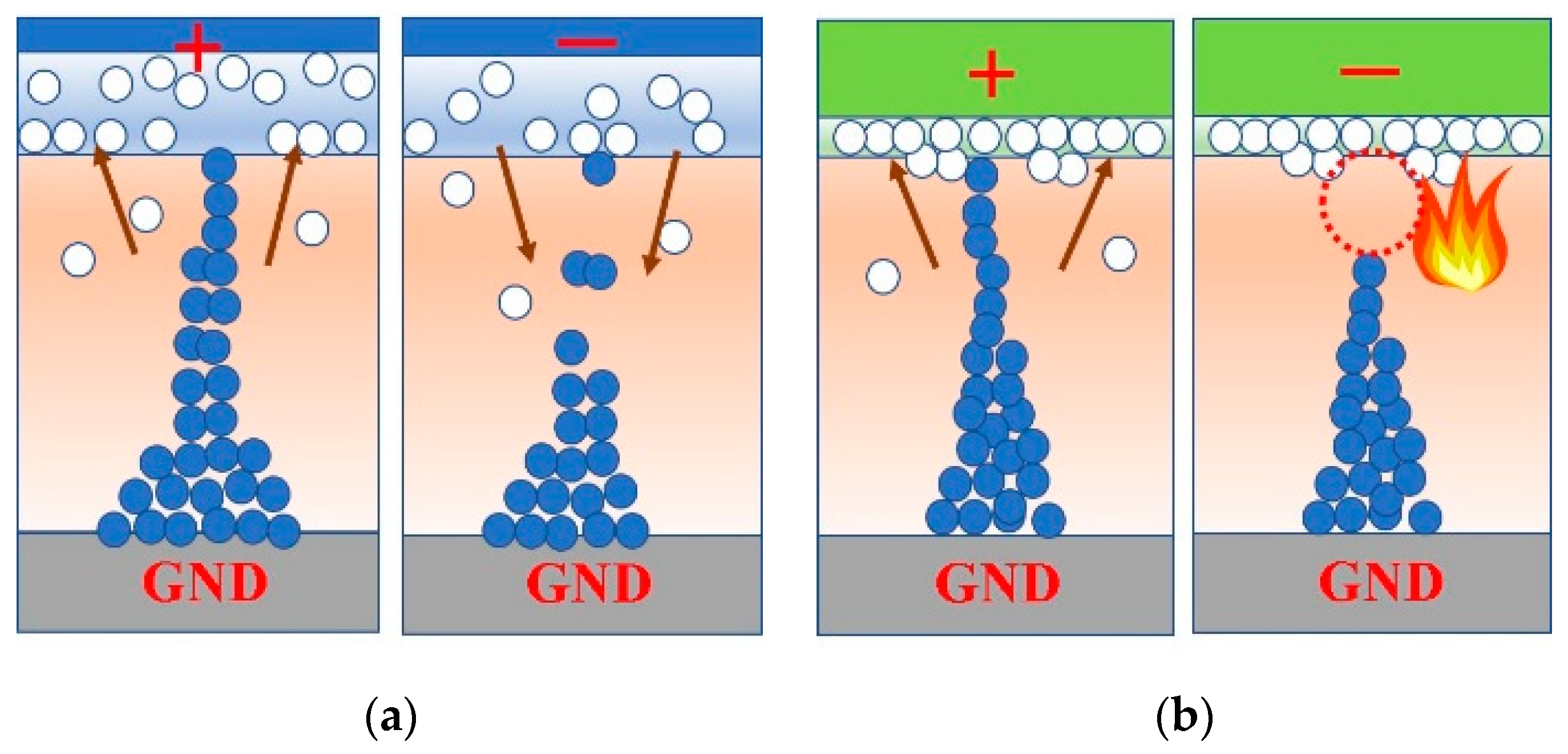

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Chen, A. A review of emerging non-volatile memory (NVM) technologies and applications. Solid-State Electron. 2016, 125, 25–38. [Google Scholar] [CrossRef]

- Hegedus, J.; Elliott, S.R. Microscopic origin of the fast crystallization ability of Ge-Sb-Te phase-change memory materials. Nat. Mater. 2008, 7, 399–405. [Google Scholar] [CrossRef] [PubMed]

- Hu, J.M.; Li, Z.; Chen, L.Q.; Nan, C.W. High-density magnetoresistive random access memory operating at ultralow voltage at room temperature. Nat. Commun. 2011, 2, 8. [Google Scholar] [CrossRef] [PubMed]

- Meena, J.S.; Sze, S.M.; Chand, U.; Tseng, T.Y. Overview of emerging nonvolatile memory technologies. Nanoscale Res. Lett. 2014, 9, 33. [Google Scholar] [CrossRef]

- Bez, R.; Pirovano, A. Non-volatile memory technologies: Emerging concepts and new materials. Mater. Sci. Semicond. Process. 2004, 7, 349–355. [Google Scholar] [CrossRef]

- Khvalkovskiy, A.V.; Apalkov, D.; Watts, S.; Chepulskii, R.; Beach, R.S.; Ong, A.; Tang, X.; Driskill-Smith, A.; Butler, W.H.; Visscher, P.B.; et al. Basic principles of STT-MRAM cell operation in memory arrays. J. Phys. D Appl. Phys. 2013, 46, 20. [Google Scholar]

- Engel, B.N.; Akerman, J.; Butcher, B.; Dave, R.W.; DeHerrera, M.; Durlam, M.; Grynkewich, G.; Janesky, J.; Pietambaram, S.V.; Rizzo, N.D.; et al. A 4-mb toggle MRAM based on a novel bit and switching method. IEEE Trans. Magn. 2005, 41, 132–136. [Google Scholar] [CrossRef]

- Dong, X.Y.; Xu, C.; Xie, Y.; Jouppi, N.P. NVSim: A Circuit-Level Performance, Energy, and Area Model for Emerging Nonvolatile Memory. IEEE Trans. Comput.-Aided Des. Integr. Circuits Syst. 2012, 31, 994–1007. [Google Scholar] [CrossRef]

- Raoux, S.; Burr, G.W.; Breitwisch, M.J.; Rettner, C.T.; Chen, Y.C.; Shelby, R.M.; Salinga, M.; Krebs, D.; Chen, S.H.; Lung, H.L.; et al. Phase-change random access memory: A scalable technology. IBM J. Res. Dev. 2008, 52, 465–479. [Google Scholar] [CrossRef]

- Wang, W.J.; Shi, L.P.; Zhao, R.; Lim, K.G.; Lee, H.K.; Chong, T.C.; Wu, Y.H. Fast phase transitions induced by picosecond electrical pulses on phase change memory cells. Appl. Phys. Lett. 2008, 93, 3. [Google Scholar] [CrossRef]

- Julliere, M. Tunneling between ferromagnetic-films. Phys. Lett. A 1975, 54, 225–226. [Google Scholar] [CrossRef]

- Hudgens, S.; Johnson, B. Overview of phase-change chalcogenide nonvolatile memory technology. MRS Bull. 2004, 29, 829–832. [Google Scholar] [CrossRef]

- Akbari, M.; Lee, J.S. Control of resistive switching behaviors of solution- processed HfOx-based resistive switching memory devices by n-type doping. RSC Adv. 2016, 6, 21917–21921. [Google Scholar] [CrossRef]

- Akbari, M.; Kim, M.-K.; Kim, D.; Lee, J.-S. Reproducible and reliable resistive switching behaviors of AlOx/HfOx bilayer structures with Al electrode by atomic layer deposition. RSC Adv. 2017, 7, 16704–16708. [Google Scholar] [CrossRef]

- Lai, C.-H.; Chen, H.-W.; Liu, C.-Y. The Resistive Switching Characteristics in ZrO2 and Its Filamentary Conduction Behavior. Materials 2016, 9, 551. [Google Scholar] [CrossRef] [PubMed]

- Ha, S.; Lee, H.; Lee, W.Y.; Jang, B.; Kwon, H.J.; Kim, K.; Jang, J. Effect of Annealing Environment on the Performance of Sol-Gel-Processed ZrO2 RRAM. Electronics 2019, 8, 947. [Google Scholar] [CrossRef]

- Park, K.; Lee, J.S. Reliable resistive switching memory based on oxygen-vacancy-controlled bilayer structures. RSC Adv. 2016, 6, 21736–21741. [Google Scholar] [CrossRef]

- Shen, Z.J.; Qi, Y.F.; Mitrovic, I.Z.; Zhao, C.Z.; Hall, S.; Yang, L.; Kuo, T.; Huang, Y.B.; Zhao, C. Effect of Annealing Temperature for Ni/AlOx/Pt RRAM Devices Fabricated with Solution-Based Dielectric. Micromachines 2019, 10, 446. [Google Scholar] [CrossRef]

- Jeong, H.Y.; Kim, S.K.; Lee, J.Y.; Choi, S.-Y. Role of interface reaction on resistive switching of metal/amorphous TiO2/Al RRAM devices. J. Electrochem. Soc. 2011, 158, H979–H982. [Google Scholar] [CrossRef]

- Lee, K.J.; Chang, Y.C.; Lee, C.J.; Wang, L.W.; Wang, Y.H. 1T1R Nonvolatile Memory with Al/TiO2/Au and Sol-Gel-Processed Insulator for Barium Zirconate Nickelate Gate in Pentacene Thin Film Transistor. Materials 2017, 10, 1408. [Google Scholar]

- Son, J.Y.; Shin, Y.-H.; Kim, H.; Jang, H.M. NiO resistive random access memory nanocapacitor array on graphene. ACS Nano 2010, 4, 2655–2658. [Google Scholar] [CrossRef] [PubMed]

- Guo, Z.; Sa, B.; Zhou, J.; Sun, Z. Role of oxygen vacancies in the resistive switching of SrZrO3 for resistance random access memory. J. Alloys Compd. 2013, 580, 148–151. [Google Scholar] [CrossRef]

- Wu, Z.; Zhu, J. Enhanced Unipolar Resistive Switching Characteristics of Hf0.5Zr0.5O2 Thin Films with High ON/OFF Ratio. Materials 2017, 10, 322. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Li, Y.H.; Gao, L.W.; Ma, F.; Song, Z.X.; Xu, K.W. Ru doping enhanced resistive switching behavior in InGaZnO thin films. RSC Adv. 2016, 6, 42347–42352. [Google Scholar] [CrossRef]

- Huang, Y.; Shen, Z.; Wu, Y.; Wang, X.; Zhang, S.; Shi, X.; Zeng, H. Amorphous ZnO based resistive random access memory. RSC Adv. 2016, 6, 17867–17872. [Google Scholar] [CrossRef]

- Rim, Y.S.; Choi, H.W.; Kim, K.H.; Kim, H.J. Effects of structural modification via high-pressure annealing on solution-processed InGaO films and thin-film transistors. J. Phys. D-Appl. Phys. 2016, 49, 6. [Google Scholar] [CrossRef]

- Huang, W.L.; Hsu, M.H.; Chang, S.P.; Chang, S.J.; Chiou, Y.Z. Indium Gallium Oxide Thin Film Transistor for Two-Stage UV Sensor Application. ECS J. Solid State Sci. Technol. 2019, 8, Q3140–Q3143. [Google Scholar] [CrossRef]

- Oshima, T.; Okuno, T.; Fujita, S. Ga2O3 thin film growth on c-plane sapphire substrates by molecular beam epitaxy for deep-ultraviolet photodetectors. Jpn. J. Appl. Phys. 2007, 46, 7217–7220. [Google Scholar] [CrossRef]

- Kokubun, Y.; Miura, K.; Endo, F.; Nakagomi, S. Sol-gel prepared beta-Ga2O3 thin films for ultraviolet photodetectors. Appl. Phys. Lett. 2007, 90, 3. [Google Scholar] [CrossRef]

- Kumar, S.; Soman, R.; Pratiyush, A.S.; Muralidharan, R.; Nath, D.N. A Performance Comparison Between beta-Ga2O3 and GaN HEMTs. IEEE Trans. Electron Devices 2019, 66, 3310–3317. [Google Scholar] [CrossRef]

- Yang, J.B.; Chang, T.C.; Huang, J.J.; Chen, Y.T.; Yang, P.C.; Tseng, H.C.; Chu, A.K.; Sze, S.M.; Tsai, M.J. Role of InGaOx resistive switching characteristics on the performances of resistance random access memory of Pt/IGO/TiN device. Thin Solid Film 2013, 528, 26–30. [Google Scholar] [CrossRef]

- Wang, X.T.; Qian, H.L.; Guan, L.; Wang, W.; Xing, B.R.; Yan, X.Y.; Zhang, S.C.; Sha, J.; Wang, Y.W. Influence of metal electrode on the performance of ZnO based resistance switching memories. J. Appl. Phys. 2017, 122, 5. [Google Scholar] [CrossRef]

- Hong, S.M.; Kim, H.D.; An, H.M.; Kim, T.G. Effect of Work Function Difference Between Top and Bottom Electrodes on the Resistive Switching Properties of SiN Films. IEEE Electron Device Lett. 2013, 34, 1181–1183. [Google Scholar] [CrossRef]

- Lee, C.B.; Kang, B.S.; Benayad, A.; Lee, M.J.; Ahn, S.E.; Kim, K.H.; Stefanovich, G.; Park, Y.; Yoo, I.K. Effects of metal electrodes on the resistive memory switching property of NiO thin films. Appl. Phys. Lett. 2008, 93, 3. [Google Scholar] [CrossRef]

- Lee, K.J.; Wang, L.W.; Chiang, T.K.; Wang, Y.H. Effects of Electrodes on the Switching Behavior of Strontium Titanate Nickelate Resistive Random Access Memory. Materials 2015, 8, 7191–7198. [Google Scholar] [CrossRef]

- Michaelson, H.B. The work function of the elements and its periodicity. J. Appl. Phys. 1977, 11, 4729–4733. [Google Scholar] [CrossRef]

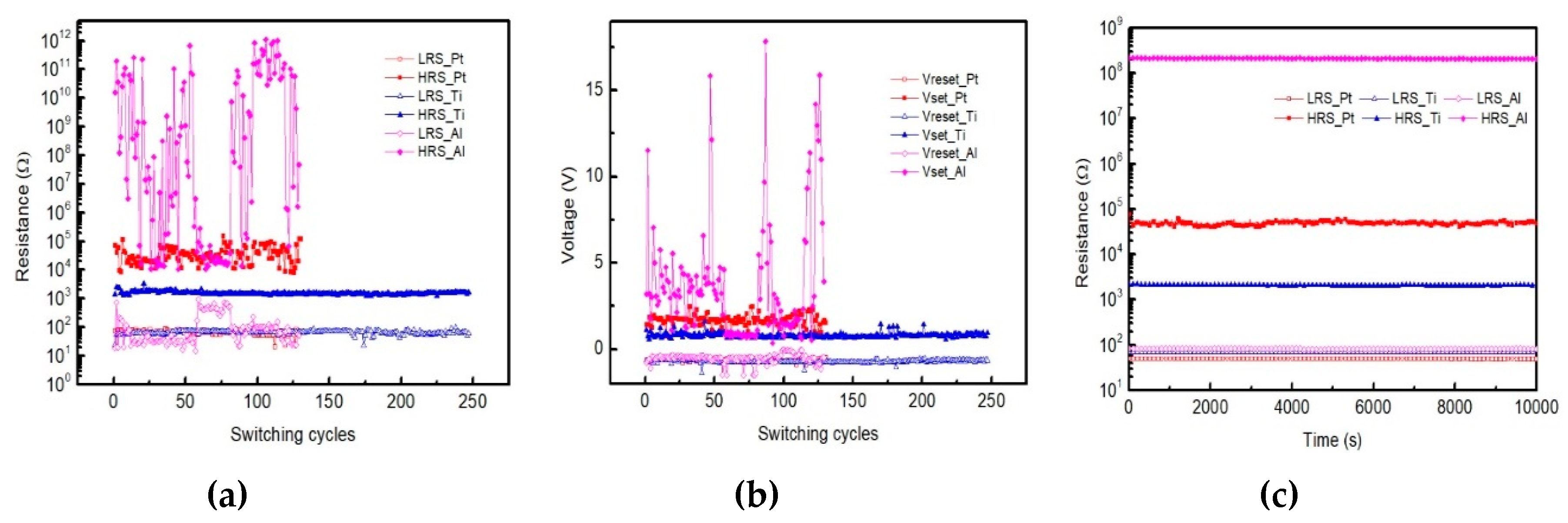

| TE | Switching Cycles | Average Vset (V) | SD of Vset (V) | Average Vreset (V) | SD of Vreset (V) | Average HRS (Ω) | SD of HRS (Ω) | Average LRS (Ω) | SD of LRS (Ω) |

|---|---|---|---|---|---|---|---|---|---|

| Pt | 130 | 1.727 | 0.299 | −0.596 | 0.077 | 54,954.09 | 31,622.78 | 64.97 | 9.99 |

| Ti | 247 | 0.811 | 0.139 | −0.7 | 0.084 | 1621.81 | 234.42 | 63.93 | 8.14 |

| Al | 129 | 3.749 | 3.543 | −0.523 | 0.289 | ~8 × 1010 | ~2 × 1011 | 145.3 | 191.27 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, W.-L.; Lin, Y.-Z.; Chang, S.-P.; Chang, S.-J. Investigation of Conductive Mechanism of Amorphous IGO Resistive Random-Access Memory with Different Top Electrode Metal. Coatings 2020, 10, 504. https://doi.org/10.3390/coatings10050504

Huang W-L, Lin Y-Z, Chang S-P, Chang S-J. Investigation of Conductive Mechanism of Amorphous IGO Resistive Random-Access Memory with Different Top Electrode Metal. Coatings. 2020; 10(5):504. https://doi.org/10.3390/coatings10050504

Chicago/Turabian StyleHuang, Wei-Lun, Yong-Zhe Lin, Sheng-Po Chang, and Shoou-Jinn Chang. 2020. "Investigation of Conductive Mechanism of Amorphous IGO Resistive Random-Access Memory with Different Top Electrode Metal" Coatings 10, no. 5: 504. https://doi.org/10.3390/coatings10050504

APA StyleHuang, W.-L., Lin, Y.-Z., Chang, S.-P., & Chang, S.-J. (2020). Investigation of Conductive Mechanism of Amorphous IGO Resistive Random-Access Memory with Different Top Electrode Metal. Coatings, 10(5), 504. https://doi.org/10.3390/coatings10050504