Self-Organized In-Depth Gradients in Highly Ti-Doped ZnO Films: Thermal Versus MW Plasma Annealing

Abstract

1. Introduction

2. Materials and Methods

2.1. Sol Gel Processing of Ti-Doped ZnO Thin Films

2.2. Annealing of Ti-Doped ZnO Thin Films

2.3. Microstructural Characterization

2.4. Optical, Electrical and Wetting Characterization

3. Results and Discussion

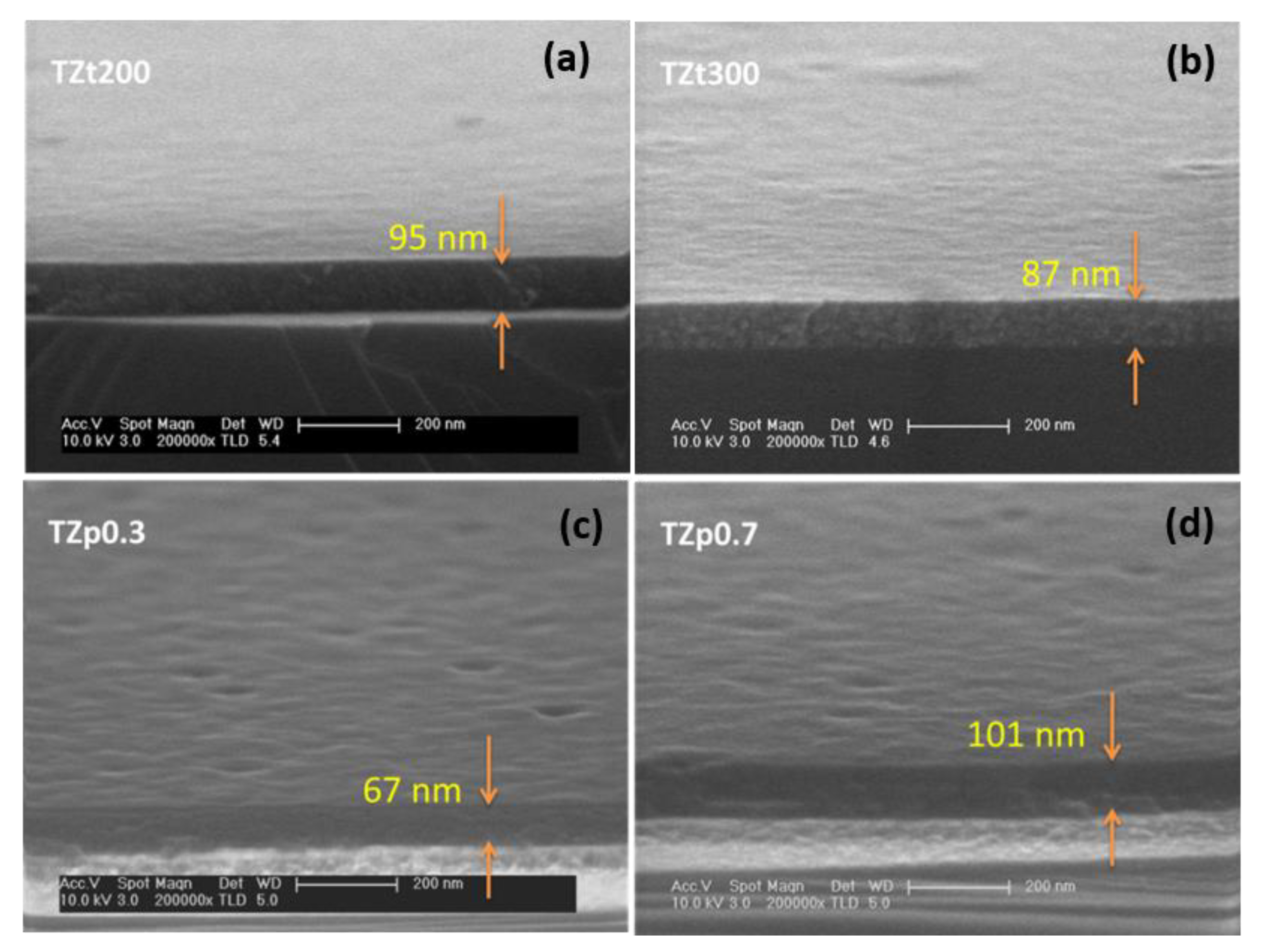

3.1. Thin Film Morphology

3.2. Structural Properties

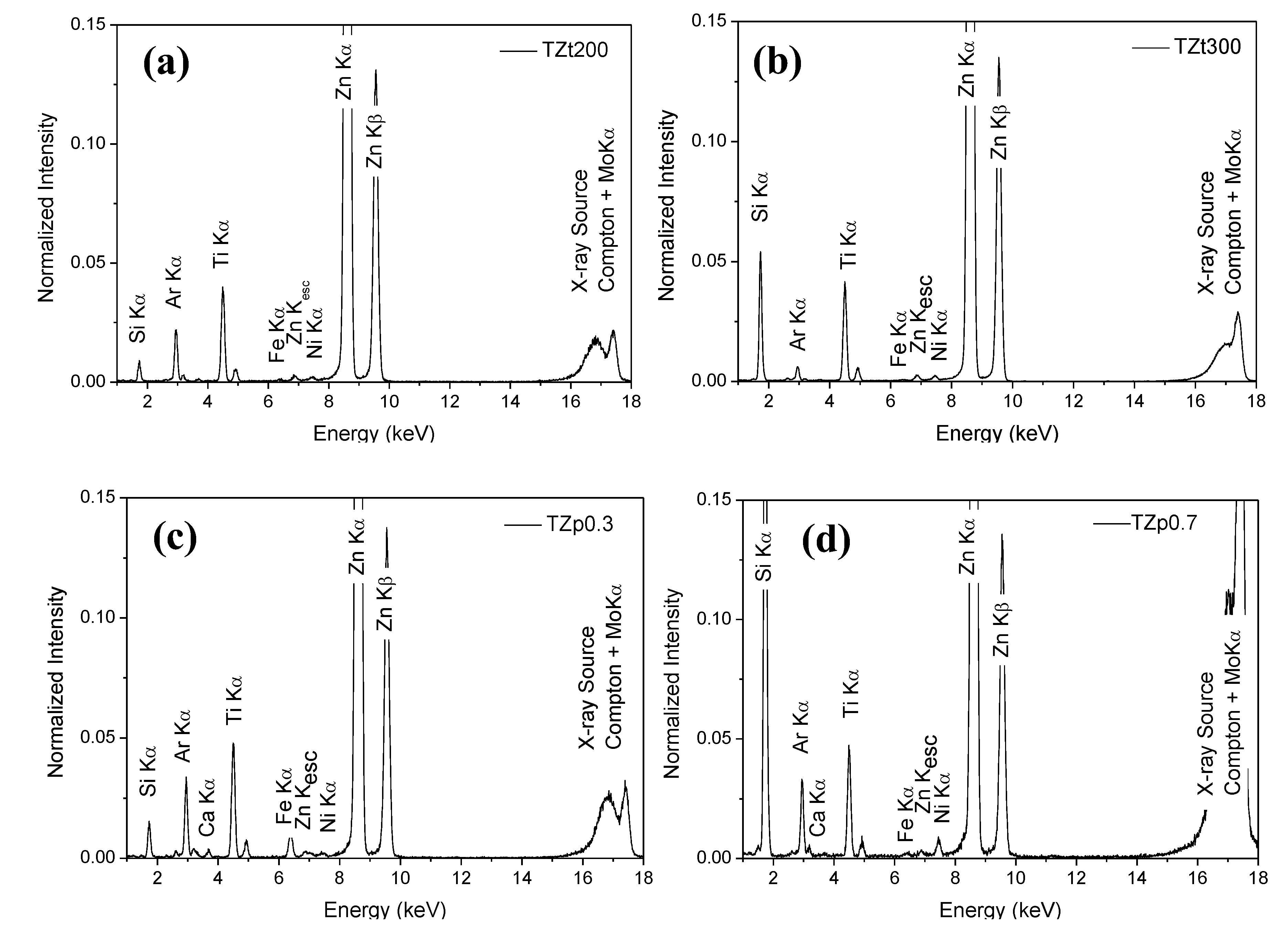

3.2.1. Total-Reflection X-Ray Fluorescence Spectrometry

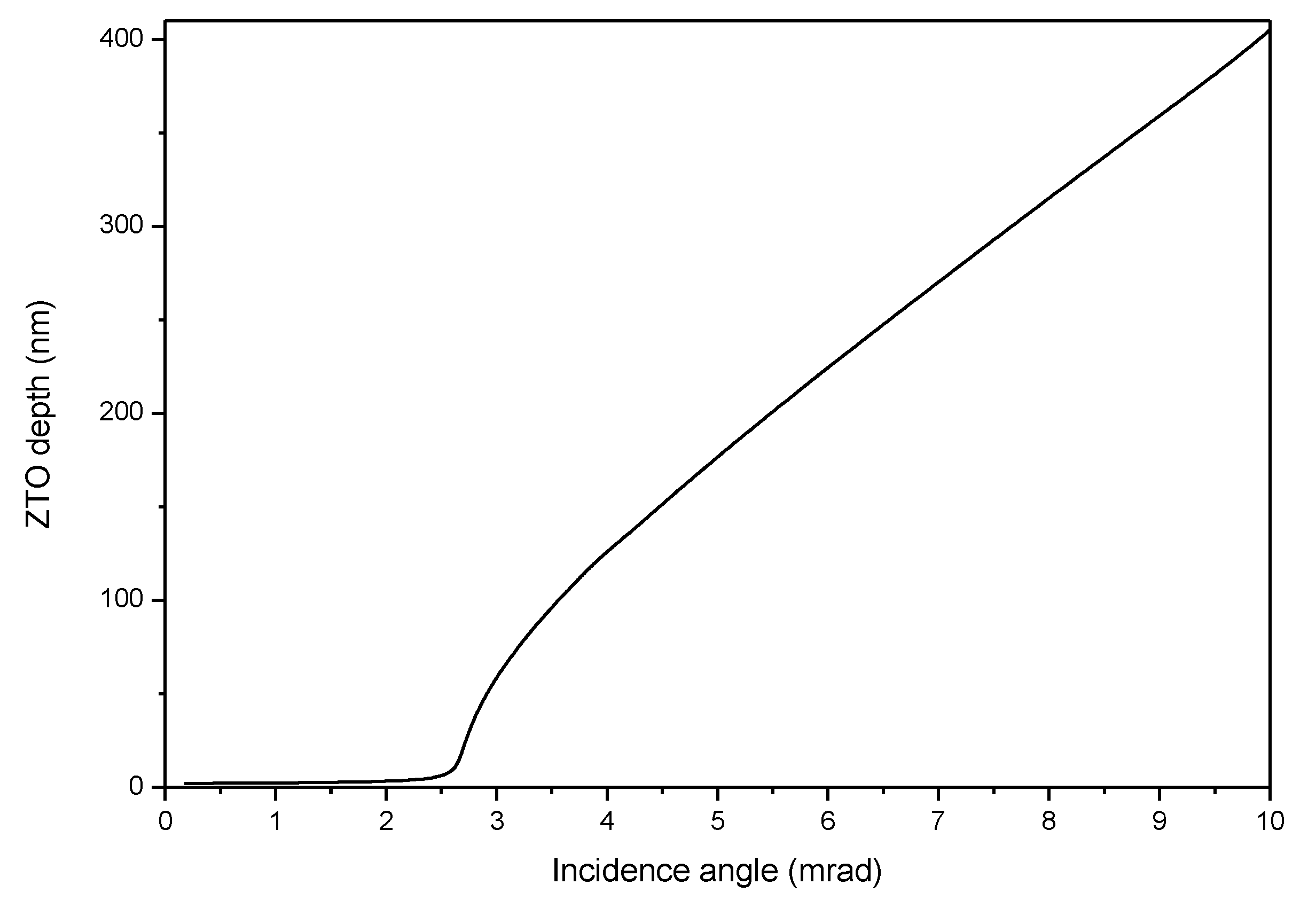

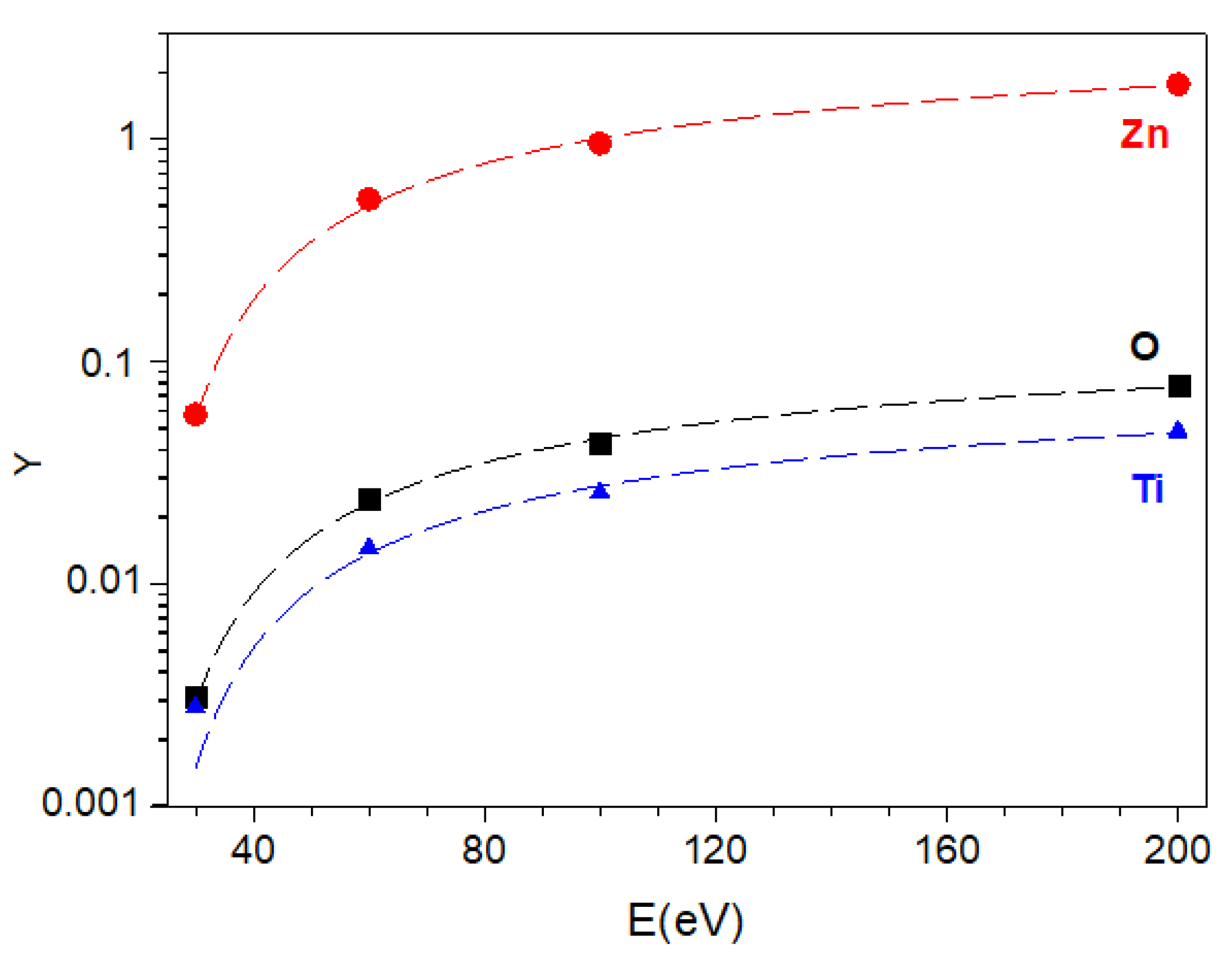

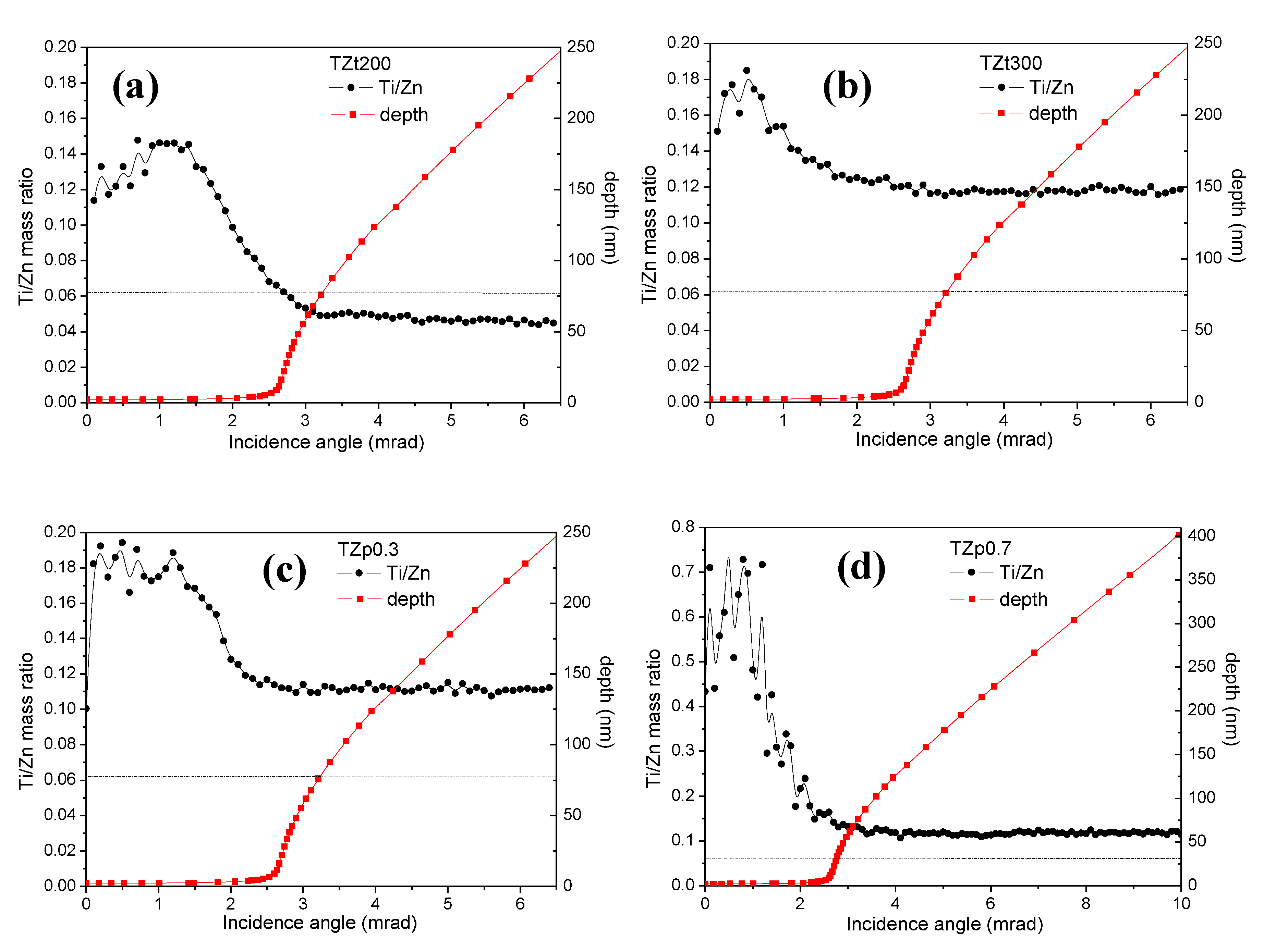

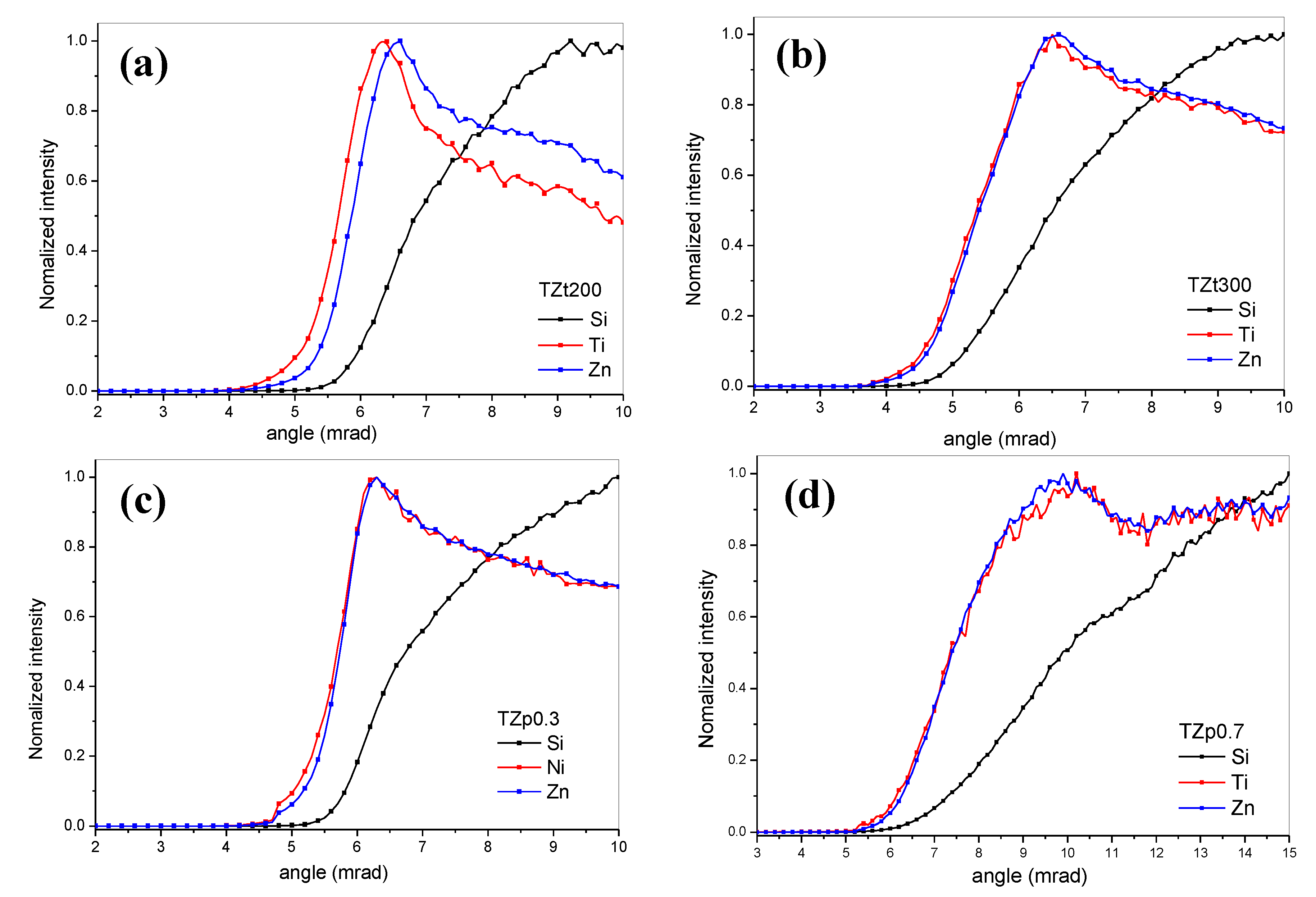

3.2.2. Grazing Incidence X-Ray Fluorescence Spectrometry

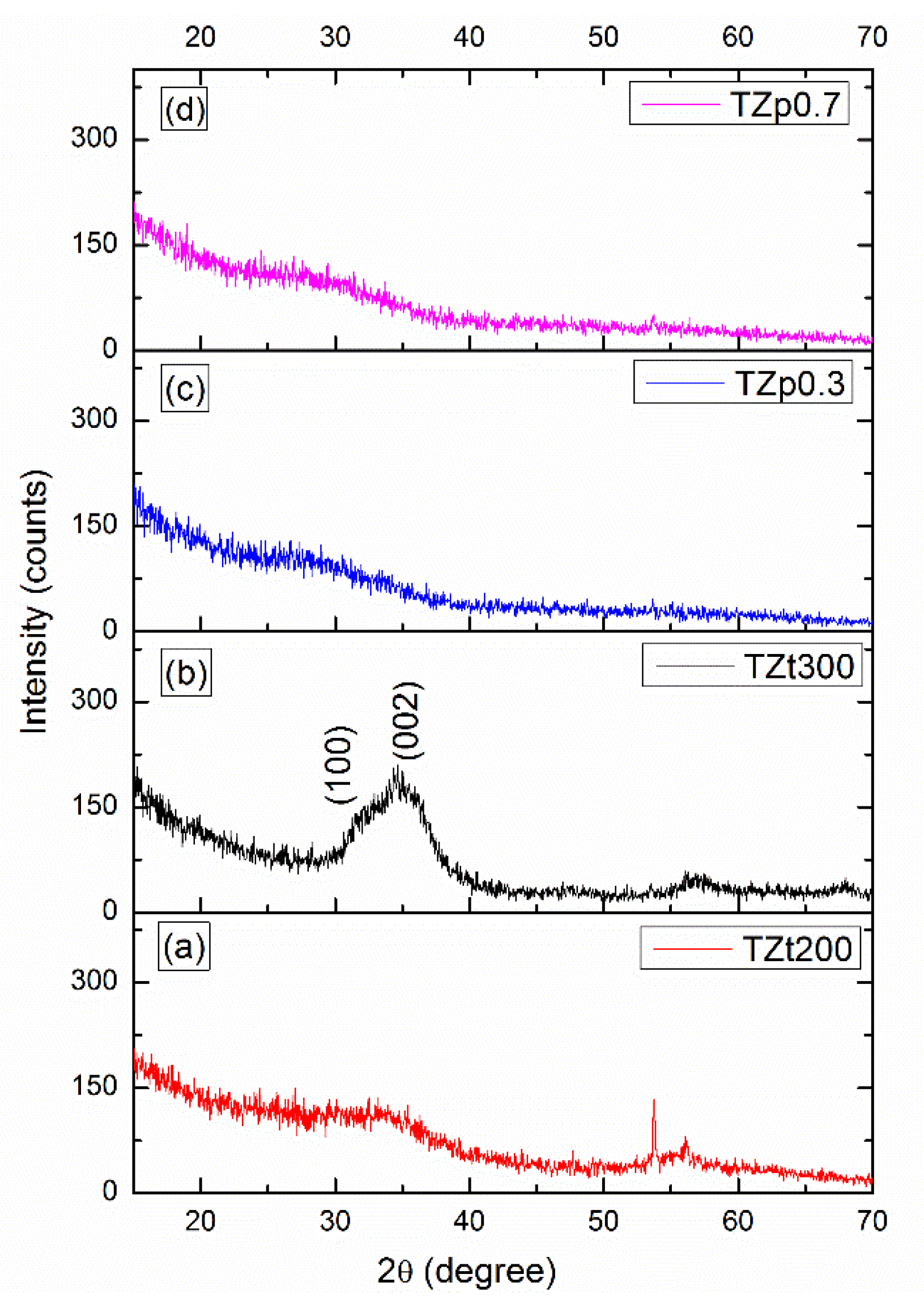

3.2.3. X-Ray Diffraction

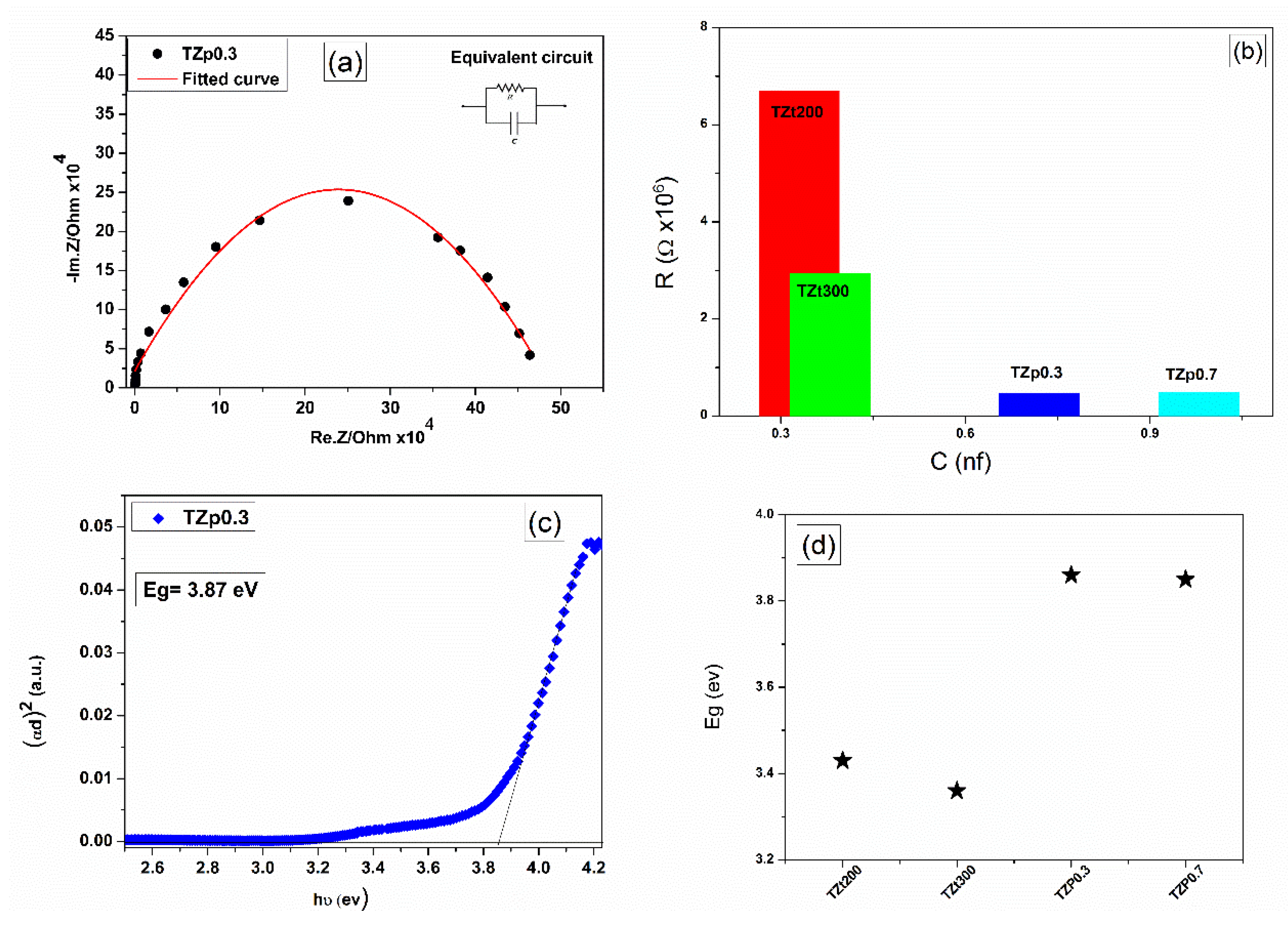

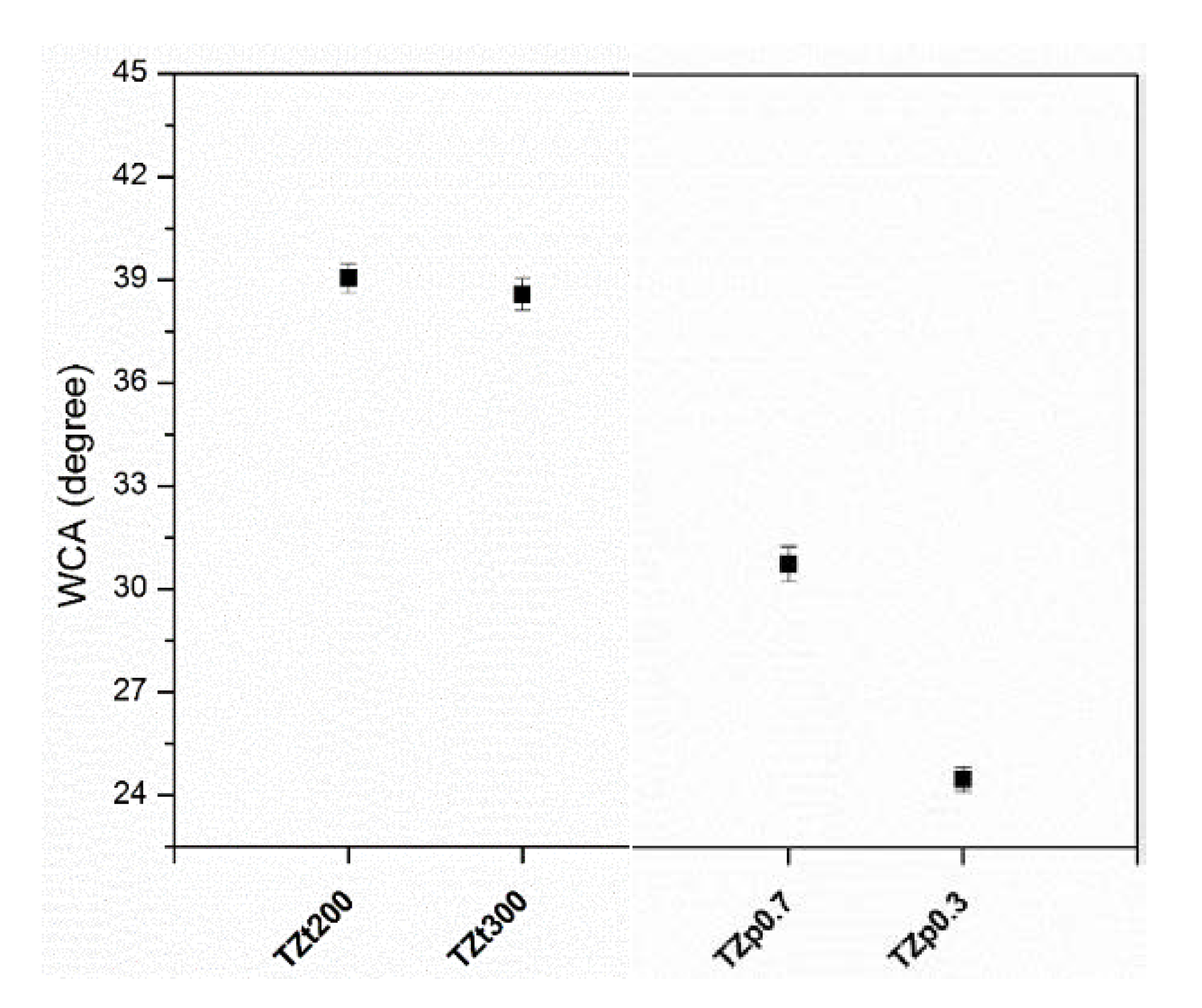

3.3. Electrical, Optical and Wetting Properties

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

Appendix B

References

- Jeong, J.A.; Park, Y.S.; Kim, H.K. Comparison of electrical, optical, structural, and interface properties of IZO-Ag-IZO and IZO-Au-IZO multilayer electrodes for organic photovoltaics. J. Appl. Phys. 2010, 107. [Google Scholar] [CrossRef]

- Gallach, D.; Munoz-Noval, A.; Torres-Costa, V.; Manso-Silvan, M. Luminescence and fine structure correlation in ZnO permeated porous silicon nanocomposites. Phys. Chem. Chem. Phys. 2015, 17, 20597–20604. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Li, W.B.; Pan, L.J.; Zhai, D.Y.; Wang, Y.; Li, L.L.; Cheng, W.; Yin, W.; Wang, X.R.; Xu, J.B.; et al. ZnO-nanorods/graphene heterostructure: A direct electron transfer glucose biosensor. Sci. Rep. 2016, 6. [Google Scholar] [CrossRef] [PubMed]

- Makila, E.; Bimbo, L.M.; Kaasalainen, M.; Herranz, B.; Airaksinen, A.J.; Heinonen, M.; Kukk, E.; Hirvonen, J.; Santos, H.A.; Salonen, J. Amine Modification of Thermally Carbonized Porous Silicon with Silane Coupling Chemistry. Langmuir 2012, 28, 14045–14054. [Google Scholar] [CrossRef] [PubMed]

- Ghosh, S.; Sarkar, A.; Chaudhuri, S.; Pal, A.K. Optical-properties of zno—All films prepared by reactive dc magnetron sputtering. Vacuum 1991, 42, 645–648. [Google Scholar] [CrossRef]

- Zhang, X.T.; Liu, Y.C.; Ma, J.G.; Lu, Y.M.; Shen, D.Z.; Xu, W.; Zhong, G.Z.; Fan, X.W. Room-temperature blue luminescence from ZnO: Er thin films. Thin Solid Film 2002, 413, 257–261. [Google Scholar] [CrossRef]

- Kim, J.H.; Kim, H.; Kim, D.; Ihm, Y.E.; Choo, W.K. Magnetic properties of epitaxially grown semiconducting Zn1-xCoxO thin films by pulsed laser deposition. J. Appl. Phys. 2002, 92, 6066–6071. [Google Scholar] [CrossRef]

- Fujihara, S.; Sasaki, C.; Kimura, T. Crystallization behavior and origin of c-axis orientation in sol-gel-derived ZnO: Li thin films on glass substrates. Appl. Surf. Sci. 2001, 180, 341–350. [Google Scholar] [CrossRef]

- Fathollahi, V.; Amini, M.M. Sol-gel preparation of highly oriented gallium-doped zinc oxide thin films. Mater. Lett. 2001, 50, 235–239. [Google Scholar] [CrossRef]

- Chen, X.L.; Lin, Q.; Ni, J.; Zhang, D.K.; Sun, J.; Zhao, Y.; Geng, X.H. Textured surface boron-doped ZnO transparent conductive oxides on polyethylene terephthalate substrates for Si-based thin film solar cells. Thin Solid Film. 2011, 520, 1263–1267. [Google Scholar] [CrossRef]

- Lin, M.C.; Chang, Y.J.; Chen, M.J.; Chu, C.J. Characteristics of Zr-Doped ZnO Thin Films Grown by Atomic Layer Deposition. J. Electrochem. Soc. 2011, 158, D395–D398. [Google Scholar] [CrossRef]

- Lee, Y.L.; Chen, S.F.; Ho, C.L.; Wu, M.C. Effects of Oxygen Plasma Post-Treatment on Ga-Doped ZnO Films Grown by Thermal-Mode ALD. ECS J. Solid State Sci. Technol. 2013, 2, P316–P320. [Google Scholar] [CrossRef]

- Park, Y.S.; Seo, M.; Yi, J.; Lim, D.; Lee, J. Characteristics of aluminum-doped zinc oxide films with oxygen plasma treatment for solar cell applications. Thin Solid Film. 2013, 547, 47–51. [Google Scholar] [CrossRef]

- Uprety, P.; Macco, B.; Junda, M.M.; Grice, C.R.; Kessels, W.M.M.; Podraza, N.J. Optical and electrical properties of H-2 plasma-treated ZnO films prepared by atomic layer deposition using supercycles. Mater. Sci. Semicond. Process. 2018, 84, 91–100. [Google Scholar] [CrossRef]

- Krajangsang, T.; Hiza, S.; Hayashi, T.; Yunaz, I.A.; Hongsingthong, A.; Miyajima, S.; Konagai, M. Quantitative Analysis of Surface Morphology of Boron-Doped Zinc Oxide for Microcrystalline Silicon Solar Cells. Jpn. J. Appl. Phys. 2012, 51. [Google Scholar] [CrossRef]

- Wang, F.H.; Chao, J.C.; Liu, H.W.; Liu, F.J. Physical properties of TiO2-doped zinc oxide thin films: Influence of plasma treatment in H-2 and/or Ar gas ambient. Vacuum 2017, 140, 155–160. [Google Scholar] [CrossRef]

- Chung, J.L.; Chen, J.C.; Tseng, C.J. The influence of titanium on the properties of zinc oxide films deposited by radio frequency magnetron sputtering. Appl. Surf. Sci. 2008, 254, 2615–2620. [Google Scholar] [CrossRef]

- Yuste, M.; Escobar-Galindo, R.; Benito, N.; Palacio, C.; Martinez, O.; Albella, J.M.; Sanchez, O. Effect of the Incorporation of Titanium on the Optical Properties of ZnO Thin Films: From Doping to Mixed Oxide Formation. Coatings 2019, 180. [Google Scholar] [CrossRef]

- Ramadan, R.; Romera, D.; Carrascón, R.D.; Cantero, M.; Aguilera-Correa, J.-J.; García Ruiz, J.P.; Esteban, J.; Silván, M.M. Sol–Gel-Deposited Ti-Doped ZnO: Toward Cell Fouling Transparent Conductive Oxides. ACS Omega 2019, 4, 11354–11363. [Google Scholar] [CrossRef]

- Noma, T.; Miyata, H.; Ino, S. Grazing exit x-ray-fluorescence spectroscopy for thin-film analysis. Jpn. J. Appl. Phys. Part 2-Lett. 1992, 31, L900–L903. [Google Scholar] [CrossRef]

- Pagels, M.; Reinhardt, F.; Pollakowski, B.; Roczen, M.; Becker, C.; Lips, K.; Rech, B.; Kanngiesser, B.; Beckhoff, B. GIXRF-NEXAFS investigations on buried ZnO/Si interfaces. Nucl. Instrum. Methods Phys. Res. Sect. B 2010, 268, 370–373. [Google Scholar] [CrossRef]

- Jiang, H.; Chou, K.W.; Petrash, S.; Williams, G.; Thieme, J.; Nykypanchuk, D.; Li, L.; Muto, A.; Chen-Wiegart, Y.C.K. Environmentally induced chemical and morphological heterogeneity of zinc oxide thin films. Appl. Phys. Lett. 2016, 109. [Google Scholar] [CrossRef]

- Rodriguez, K.L.S.; Hoffmann, M.; Golmar, F.; Pasquevich, G.; Werner, P.; Hergert, W.; Torres, C.E.R. Producing ZnFe2O4 thin films from ZnO/FeO multilayers. Appl. Surf. Sci. 2017, 393, 256–261. [Google Scholar] [CrossRef]

- RoteIla, H.; Caby, B.; Menesguen, Y.; Mazel, Y.; Valla, A. Elemental depth profiling in transparent conducting oxide thin film by X-ray reflectivity and grazing incidence X-ray fluorescence combined analysis. Spectrochimica Acta Part B: Atomic Spectroscopy 2017, 135, 22–28. [Google Scholar] [CrossRef]

- Sampson, M.D.; Emery, J.D.; Pellin, M.J.; Martinson, A.B.F. Inhibiting Metal Oxide Atomic Layer Deposition: Beyond Zinc Oxide. ACS Appl. Mater. Interfaces 2017, 9, 33429–33436. [Google Scholar] [CrossRef]

- Ramadan, R.; Simiz, J.G.; Ynsa, M.D.; Silván, M.M. Microwave plasma annealing of sol-gel deposited tantalum oxide and zinc oxide films. Vacuum 2018, 149, 336–342. [Google Scholar] [CrossRef]

- Ramadan, R.; Abdelhady, K.; Manso-Silván, M.; Torres-Costa, V.; Martín-Palma, R.J. Microwave plasma and rapid thermal processing of indium-tin oxide thin films for enhancing their performance as transparent electrodes. J. Photonics Energy 2019, 9, 034001. [Google Scholar] [CrossRef]

- Veldhuis, S.A.; Brinks, P.; Stawski, T.M.; Gobel, O.F.; ten Elshof, J.E. A facile method for the density determination of ceramic thin films using X-ray reflectivity. J. Sol-Gel Sci. Technol. 2014, 71, 118–128. [Google Scholar] [CrossRef]

- Simon, A.H. Sputter processing. In Handbook of Thin Film Deposition, 4th ed.; Elsevier: Amsterdam, The Netherlands, 2018; pp. 195–230. [Google Scholar] [CrossRef]

- Deshmukh, H.; Shinde, P.; Patil, P. Structural, optical and electrical characterization of spray-deposited TiO2 thin films. Mater. Sci. Eng. B 2006, 130, 220–227. [Google Scholar] [CrossRef]

- Castanedo-Perez, R.; Jimenez-Sandoval, O.; Jimenez-Sandoval, S.; Marquez-Marin, J.; Mendoza-Galvan, A. Influence of annealing temperature on the formation and characteristics of sol-gel prepared ZnO films. J. Vac. Sci. Technol. A 1999, 17, 1811–1816. [Google Scholar] [CrossRef]

- Viezbicke, B.D.; Patel, S.; Davis, B.E.; Birnie III, D.P. Evaluation of the Tauc method for optical absorption edge determination: ZnO thin films as a model system. Physica Status Solidi (B) 2015, 252, 1700–1710. [Google Scholar] [CrossRef]

- Singh, J.; Kumar, P.; Hui, K.S.; Hui, K.N.; Ramam, K.; Tiwari, R.S.; Srivastava, O.N. Synthesis, band-gap tuning, structural and optical investigations of Mg doped ZnO nanowires. Crystengcomm 2012, 14, 5898–5904. [Google Scholar] [CrossRef]

- Kawakami, R.; Tominaga, K.; Okada, K.; Nouda, T.; Inaoka, T.; Takeichi, A.; Fukudome, T.; Murao, K. Etch damage characteristics of TiO2 thin films by capacitively coupled RF Ar plasmas. Vacuum 2010, 84, 1393–1397. [Google Scholar] [CrossRef]

- Ziegler, J.F.; Ziegler, M.D.; Biersack, J.P. SRIM—The stopping and range of ions in matter (2010). Nucl. Instrum. Methods Phys. Res. Sect. B-Beam Interact. Mater. Atoms 2010, 268, 1818–1823. [Google Scholar] [CrossRef]

| Sample | Ti (rmu) | Zn (rmu) | Ti/Zn |

|---|---|---|---|

| TZt200 | 14.48 | 100 | 0.14 |

| TZt300 | 14.84 | 100 | 0.15 |

| TZp0.3 | 17.52 | 100 | 0.18 |

| TZp0.7 | 17.00 | 100 | 0.17 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramadan, R.; Fernández-Ruiz, R.; Manso Silván, M. Self-Organized In-Depth Gradients in Highly Ti-Doped ZnO Films: Thermal Versus MW Plasma Annealing. Coatings 2020, 10, 418. https://doi.org/10.3390/coatings10040418

Ramadan R, Fernández-Ruiz R, Manso Silván M. Self-Organized In-Depth Gradients in Highly Ti-Doped ZnO Films: Thermal Versus MW Plasma Annealing. Coatings. 2020; 10(4):418. https://doi.org/10.3390/coatings10040418

Chicago/Turabian StyleRamadan, Rehab, Ramón Fernández-Ruiz, and Miguel Manso Silván. 2020. "Self-Organized In-Depth Gradients in Highly Ti-Doped ZnO Films: Thermal Versus MW Plasma Annealing" Coatings 10, no. 4: 418. https://doi.org/10.3390/coatings10040418

APA StyleRamadan, R., Fernández-Ruiz, R., & Manso Silván, M. (2020). Self-Organized In-Depth Gradients in Highly Ti-Doped ZnO Films: Thermal Versus MW Plasma Annealing. Coatings, 10(4), 418. https://doi.org/10.3390/coatings10040418