Foundation Research on Physicochemical Properties of Mine Insulation Materials

Abstract

1. Introduction

2. Experimental Research on Mine Insulation Materials

2.1. Preparation of Experimental Materials

2.1.1. Aggregate

2.1.2. Admixture

2.1.3. Additive

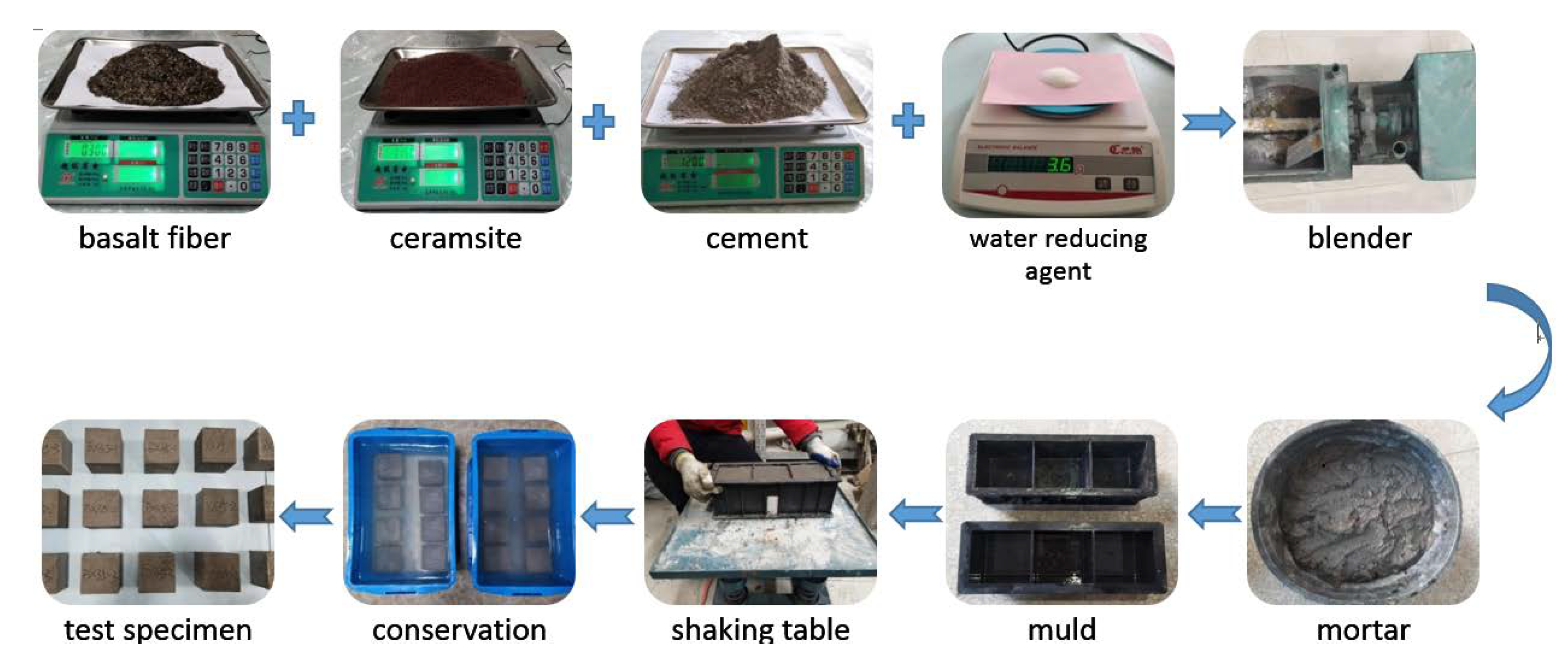

2.2. Preparation of Test Specimens

2.3. Measurement of Thermal Conductivity

2.4. Measurement of Compressive Strength

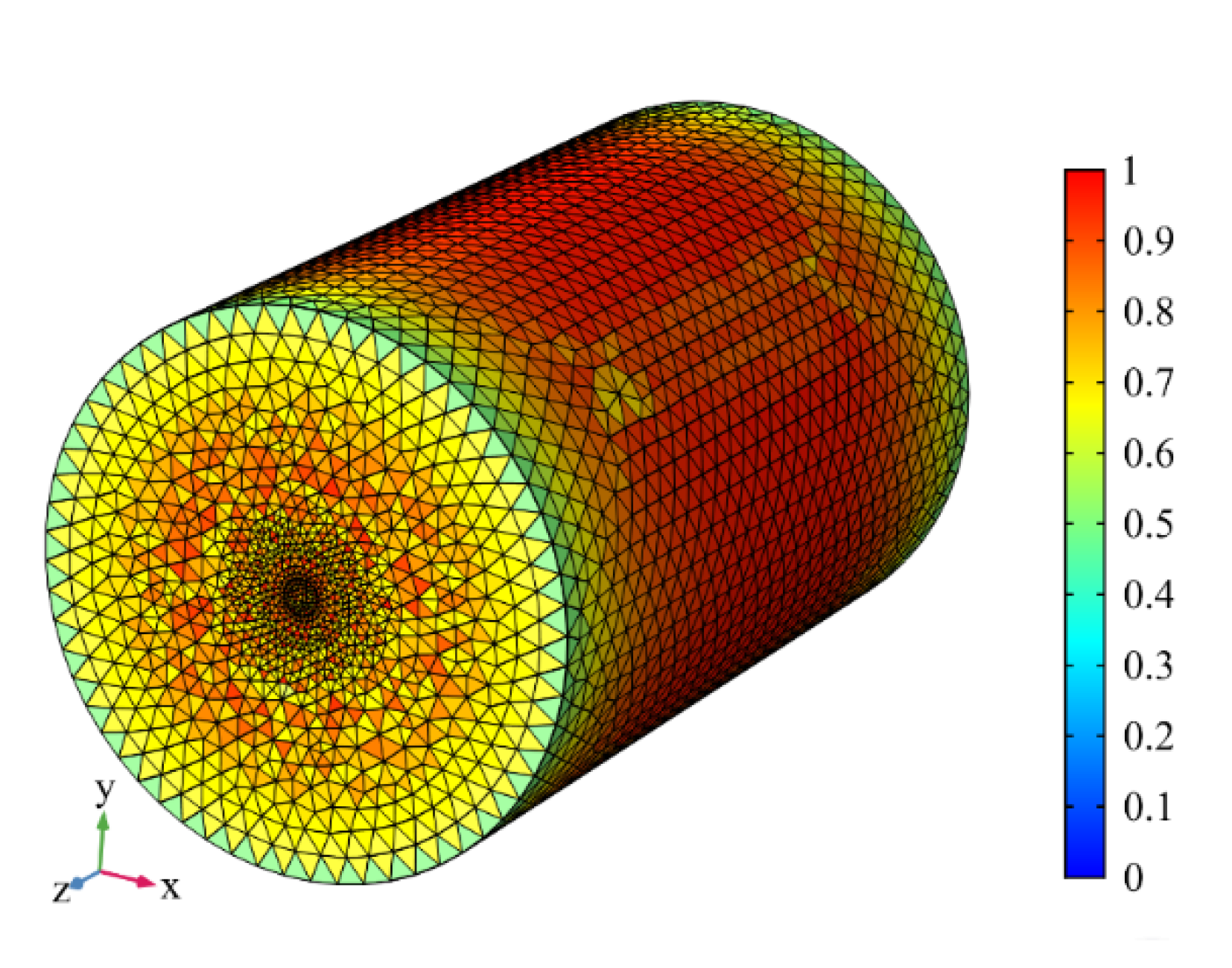

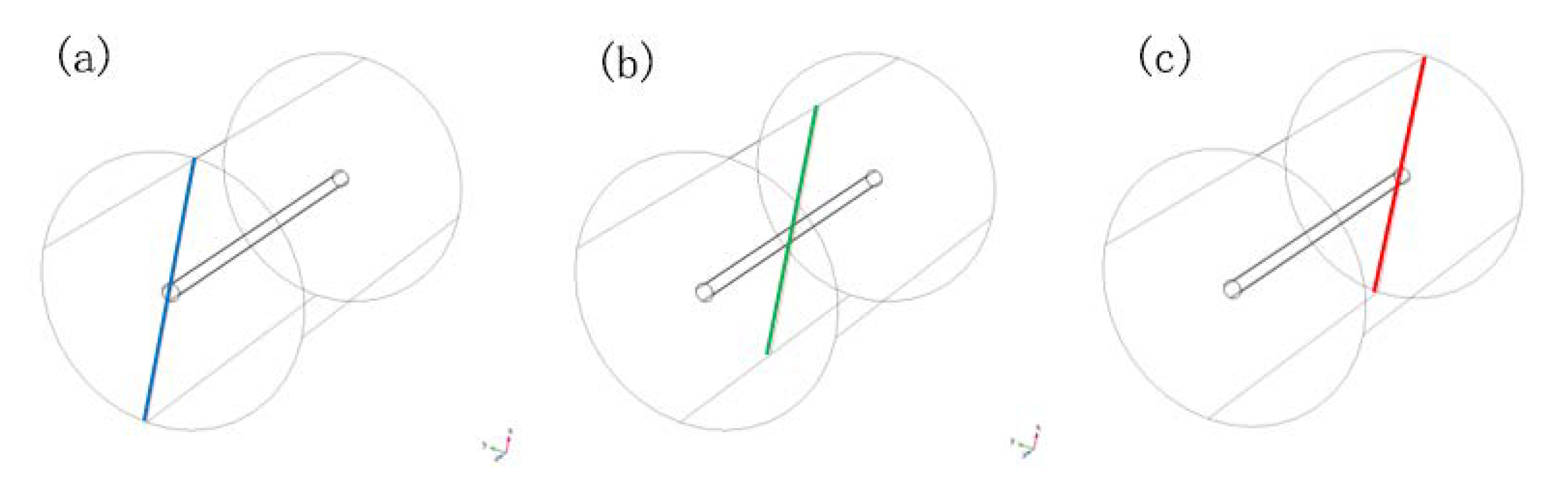

2.5. Numerical Simulation

3. Analysis of Test Results

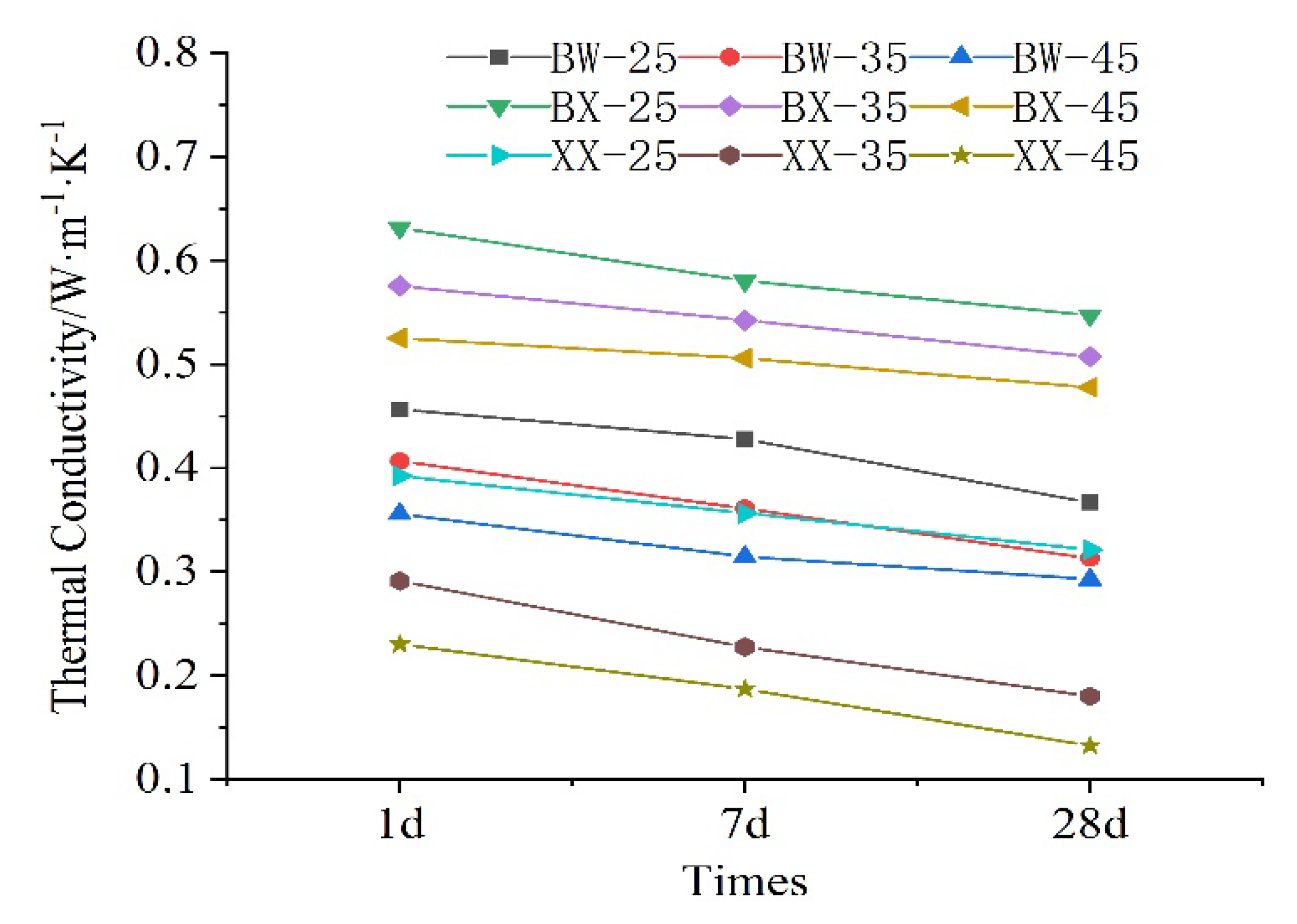

3.1. Measurement and Analysis of Thermal Conductivity

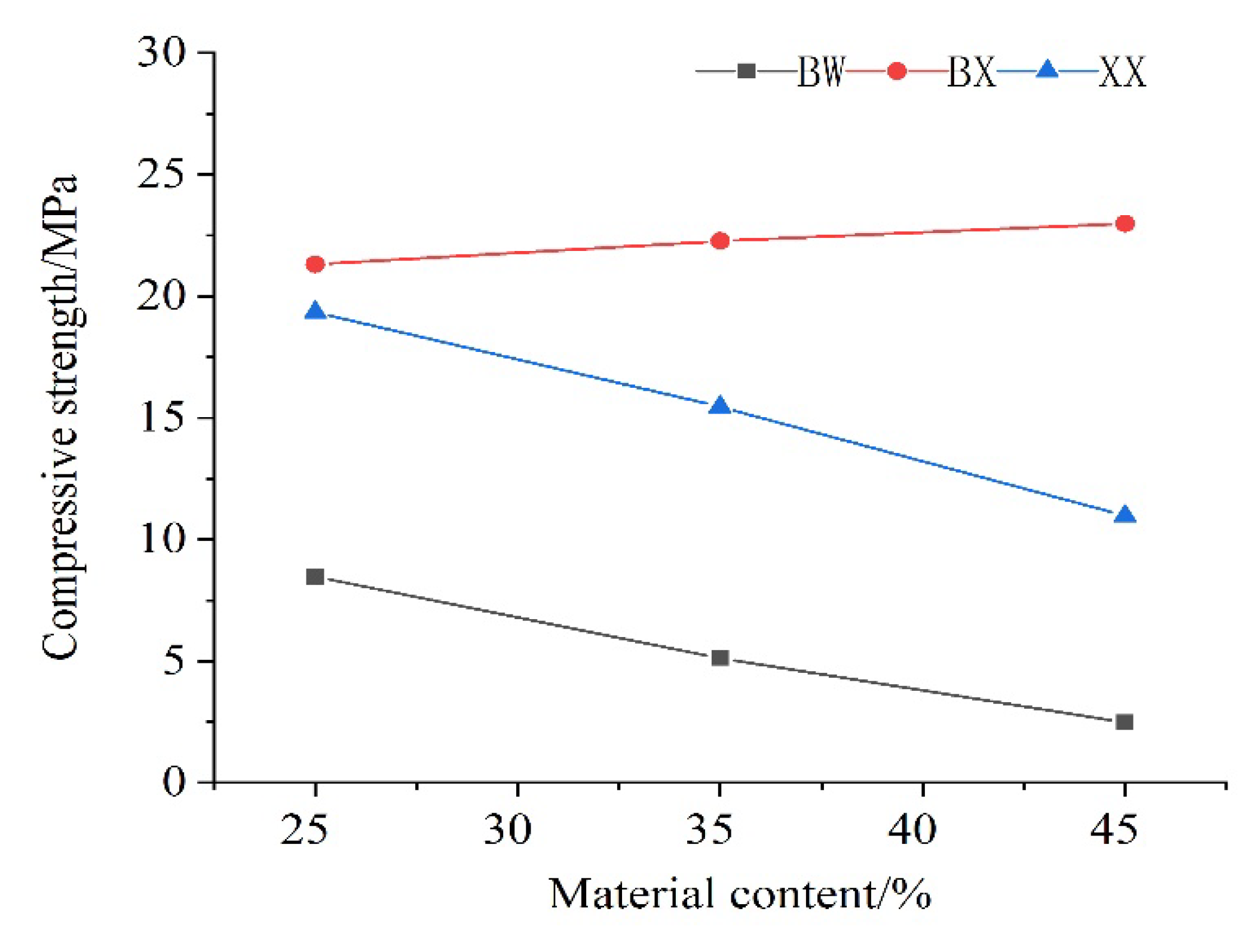

3.2. Measurement and Analysis of Compressive Strength

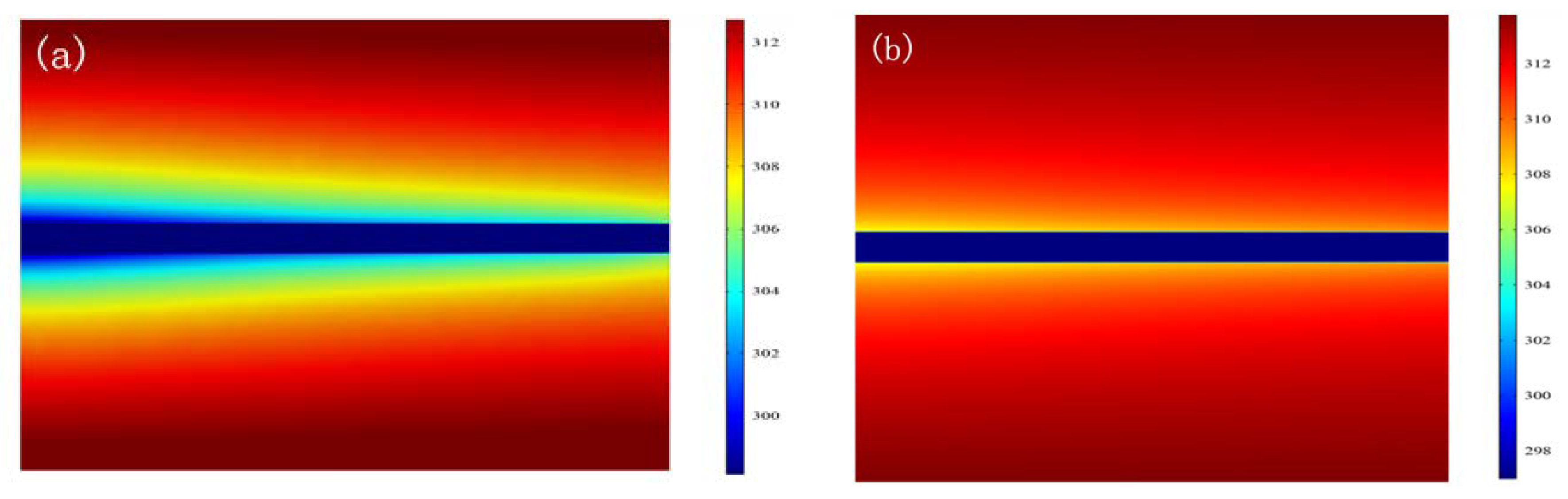

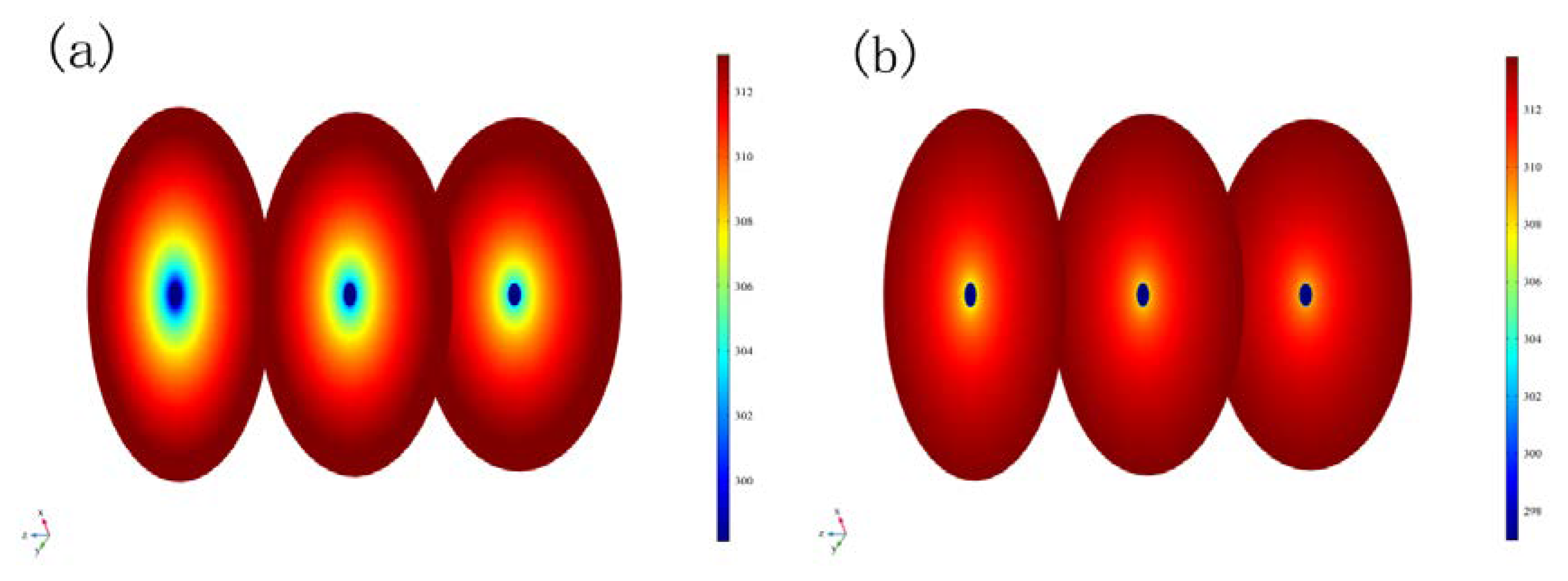

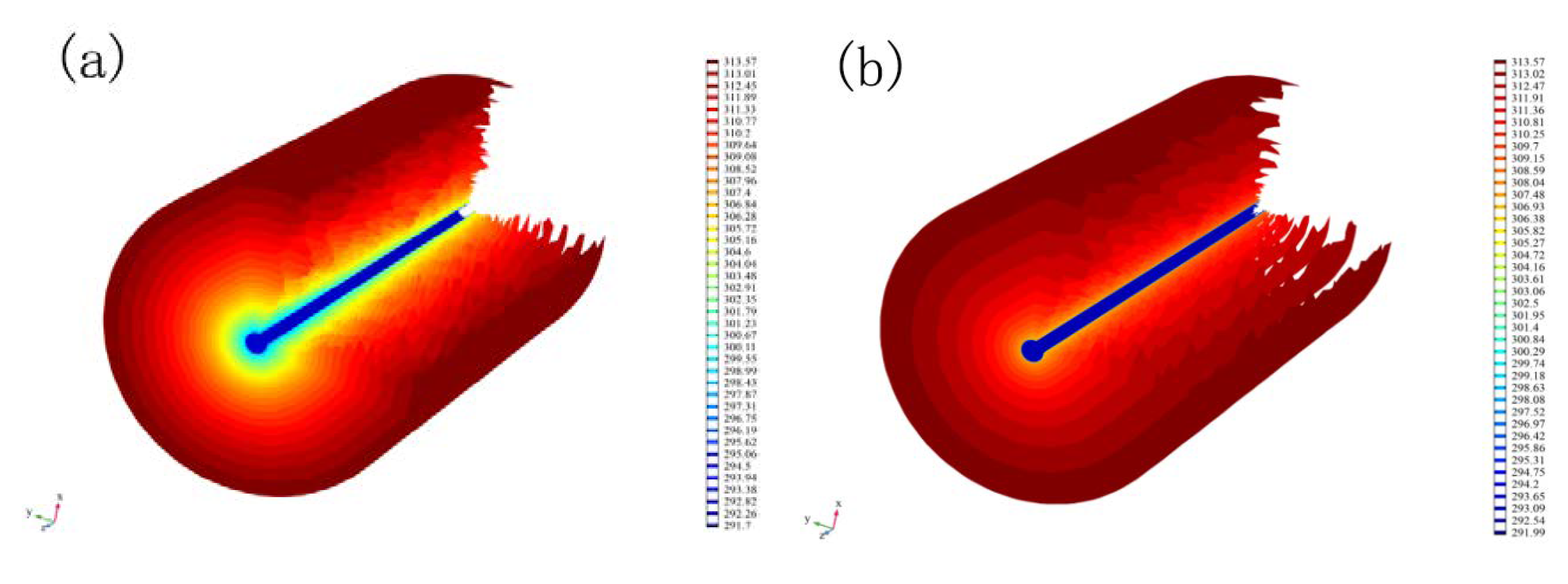

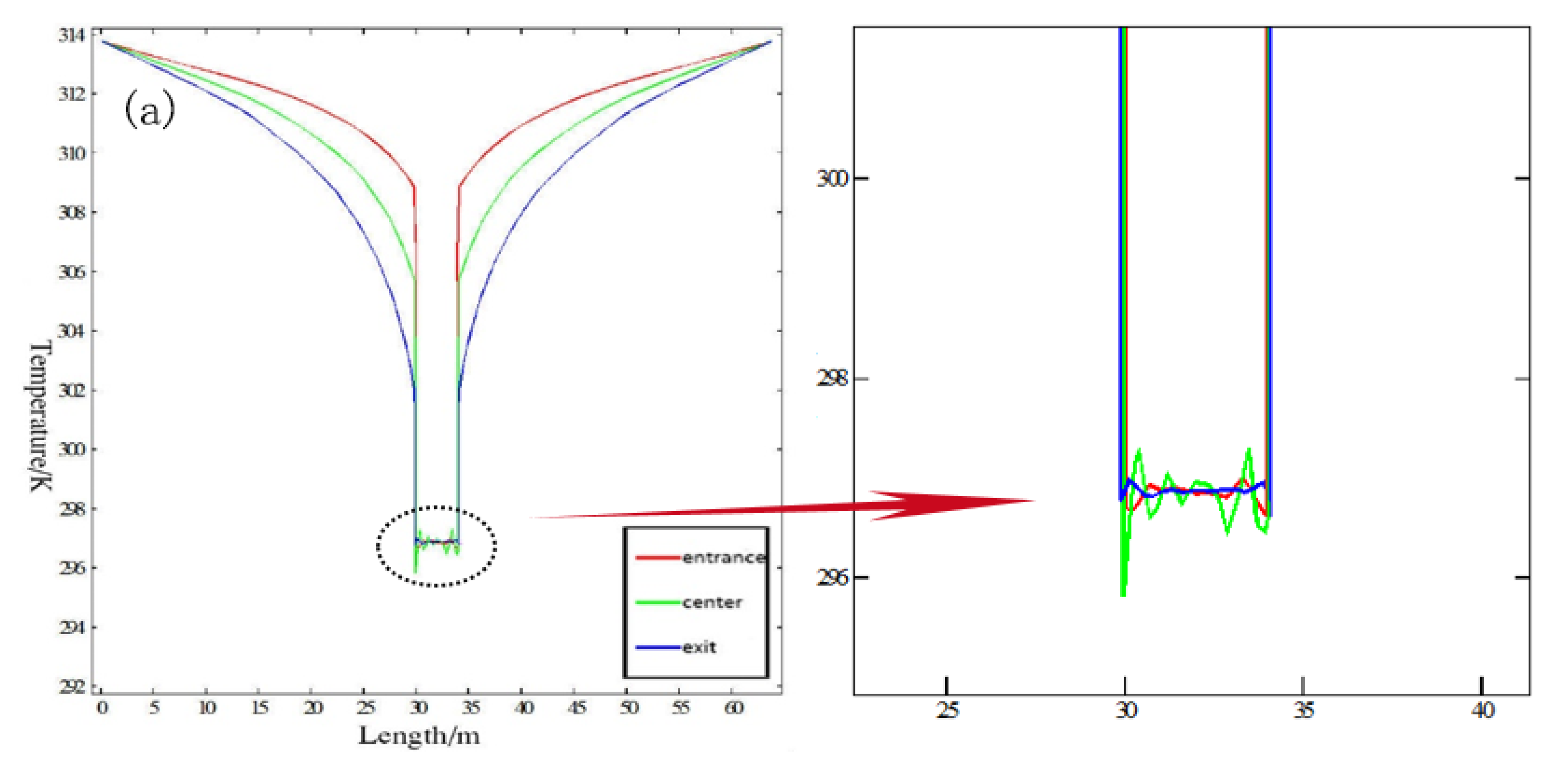

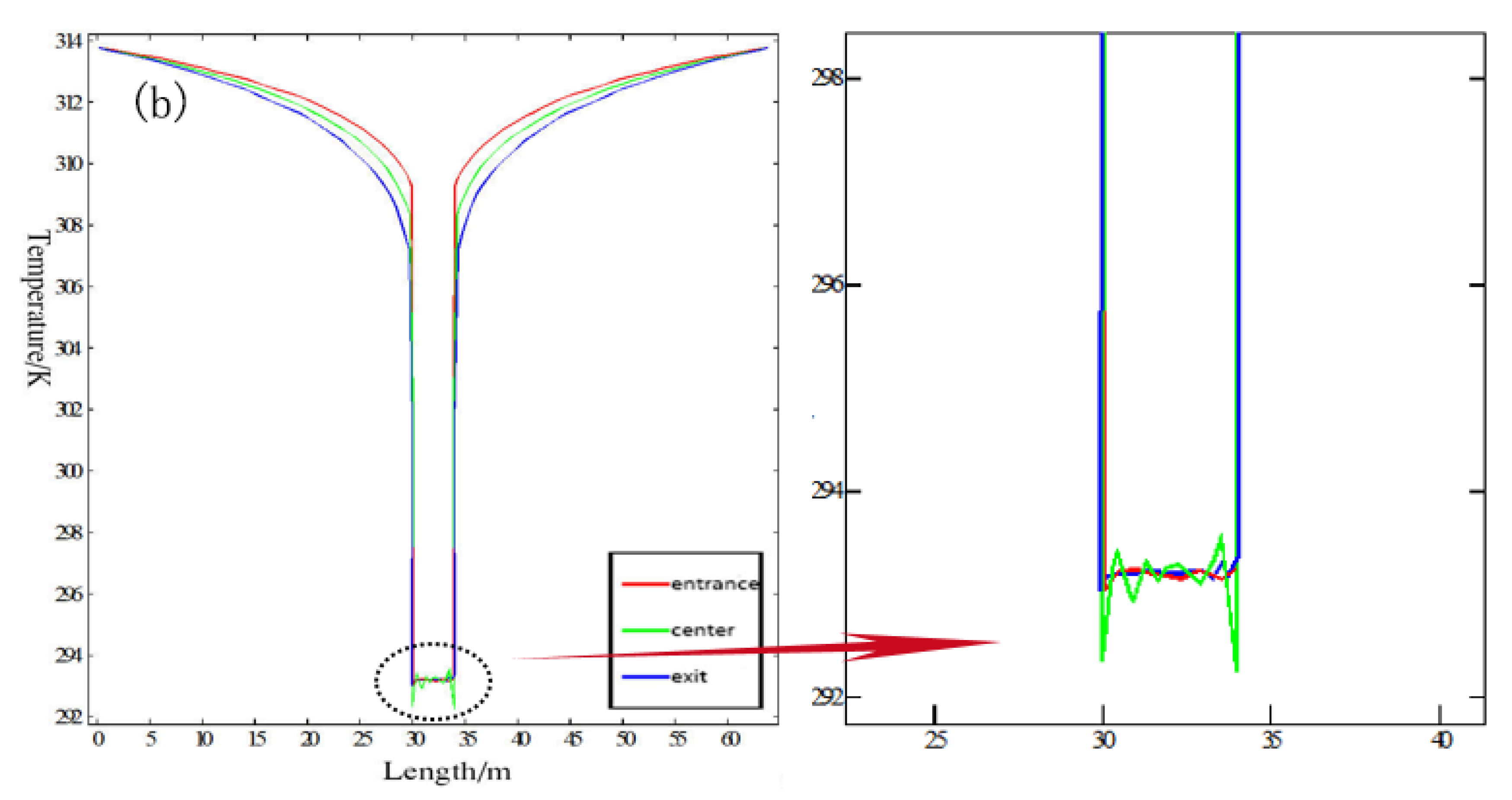

3.3. Comparative Analysis of Simulation Verification

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Yuan, L.; Zhang, N.; Yan, J. China Green Coal Resources Concept, Model and Forecast. J. China Univ. Min. Technol. 2018, 47, 1–8. [Google Scholar]

- Xie, H.; Zhou, H.; Xue, D. Research and Thinking of Deep Coal Mining and Extreme Mining Depth. J. China Coal. Soc. 2012, 37, 535–542. [Google Scholar]

- Xin, S. Mine Ventilation Technology and Air Conditioning; China Coal Industry Publishing House: Beijing, China, 2014; pp. 23–25. [Google Scholar]

- Zhang, Z.; Day, R.; Wang, K.; Wu, H.; Yuan, Y. Thermal performance analysis of an underground closed chamber with human body heat sources under natural convection. Appl. Therm. Eng. 2018, 145, 453–463. [Google Scholar] [CrossRef]

- Liu, D.; Zhang, Y.; Wang, L. Survey of high temperature mines in Chinese coal mines. Occup. Health 2012, 9, 1136–1138. [Google Scholar]

- Hou, Z.; Shen, B. Numerical calculation model of heating circle radius and its temperature field. J. Xiangtan Univ. Min. Technol. 1997, 1, 9–16. [Google Scholar]

- Song, D.; Zhou, X.; Bai, G. Study on temperature distribution of surrounding rock in active thermal insulation roadway of high temperature mine. Coal Sci. Technol. 2017, 45, 107–113. [Google Scholar]

- Sun, P. A new coumputation method for the unsteady heat transfer coefficient in a deep mine. J. China Coal Soc. 1999, 5, 57–61. [Google Scholar]

- Barrow, H.; Pope, C.W. A simple analysis of flow and heat transfer in railway tunnels. Int. J. Heat Fluid Flow 1987, 8, 119–123. [Google Scholar] [CrossRef]

- Li, G. Research on Support Technology of Active Cooling Support in High-Temperature Rock Strata. Ph.D. Thesis, Taiyuan University of Technology, Taiyuan, China, 2010. [Google Scholar]

- Wu, D. Experimental Study on Thermal Insulation Mechanism of Shotcrete in High Ground Temperature Roadway; China University of Mining: Beijing, China, 2019. [Google Scholar]

- Wang, C. Cooling Mechanism and Experimental Study of Injection Thermal Insulation Materials in Wells; China University of Mining: Xuzhou, China, 2011. [Google Scholar]

- Ji, G.; Yang, Y.; Li, T.; Pan, W. Numerical study of fluid-structure coupled heat transfer in deep mining roadway. Min. Res. Dev. 2019, 39, 68–72. [Google Scholar]

- Zhou, X.; Tang, X.; Song, D. Influence of Thermal Physical Properties of Thermal Insulation Layer of Active Insulation Roadway on Thermal Insulation Effect. Min. Saf. Environ. Prot. 2019, 46, 14–18. [Google Scholar]

- Ding, Y.; Wang, J.; Liu, D. Study on Preparation and Performance of Phosphate Tailings Thermal Insulation Blocks. Multipurp. Util. Min. Resour. 2019, 1, 96–101. [Google Scholar]

- Yao, R.; Zhang, Y. Development of thermal insulation material for deep mine coal mine roadway. Ordnance Mater. Sci. Eng. 2002, 20, 572–575. [Google Scholar]

- Yasir, M.; Amir, N.B.; Ahmad, F.; Rodzhan, N.S. Effect of basalt fibres reinforcement and aluminum trihydrate on the thermal properties of intumescent fire retardant coatings. IOP Conf. Ser. Mater. Sci. Eng. 2017, 226, 12185. [Google Scholar] [CrossRef]

- Pehlivanlı, Z.O.; Uzun, I.; Demir, İ. Mechanical and microstructural features of autoclaved aerated concrete reinforced with autoclaved polypropylene, carbon, basalt and glass fiber. Constr. Build Mater. 2015, 96, 428–433. [Google Scholar]

- Pehlivanlı, Z.O.; Uzun, I.; Demir, İ. Mechanical properties and fracture behavior of basalt and glass fiber reinforced concrete: An experimental study. Constr Build Mater. 2015, 100, 218–224. [Google Scholar]

- Chen, J.; Gu, Y.-Z.; Yang, Z.-J. Effects of elevated temperature treatment on compositions and tensile properties of several kinds of basale fibers. J. Mater. Eng. Perform. 2017, 45, 61–66. [Google Scholar]

- Li, F.; Li, G.; Wang, H.; Tong, Q. Study on high temperature re-sistance of basalt fiber yarn. J. Mater. Eng. Perform. 2015, 3, 3060–3063. [Google Scholar]

- Xuan, C.; Jun, J.; Liu, A. Study of the thermal insulation properties of the glass fiber board used for interior building envelope. Energ. Build. 2015, 107, 49–58. [Google Scholar]

- Jia, H.; Zhang, P. Measurement of Low Temperature Shrinkage of Glass Fiber Reinforced Plastics. J. Shanghai Jiaotong Univ. 2016, 50, 502–513. [Google Scholar]

- Yang, Y.; He, Y.; Chen, T. Study on Glass Fiber Modified Phenolic Foam. Eng. Plast. Appl. 2013, 41, 35–38. [Google Scholar]

- Yang, Y.; He, J. Mechanical characterization of phenolic foams modified by short glass fibers and polyurethane prepolymer. Polym. Compos. 2015, 36, 1584–1589. [Google Scholar] [CrossRef]

- Choe, J.; Kim, M.; Kim, J. A microwave foaming method for fabricating glass fiber reinforced phenolic foam. Compos. Struct. 2016, 23, 9–246. [Google Scholar] [CrossRef]

- Sayadi, A.; Neitzert, T.R.; Clifton, G.C. Influence of poly-lactic acid on the properties of perliteconcrete. Constr. Build. Mater. 2018, 189, 660–675. [Google Scholar] [CrossRef]

- Mahmoud, M.; Alireza, J. Effects of the mechanical milling method on transport properties of self-compacting concrete containing perlite powder as a supplementary cementitious material. Constr. Build. Mater. 2018, 172, 677–684. [Google Scholar]

- Study on Vitrified Microsphere Insulation System. Shanxi Archit. 2006, 24, 1–3.

- Li, Z.; Mu, Q. Performance analysis of vitrified microsphere thermal insulation mortar. Build. Mater. Technol. Appl. 2007, 3, 18–20. [Google Scholar]

- Li, Z. Study on Proportion and Mechanism Analysis of Vitrified Microsphere Thermal Insulation Mortar. New Build. Mater. 2011, 38, 46–48. [Google Scholar]

- Zhang, Z.; Wang, Y.; Li, Z.; Fan, L.; Dong, Y. Technical and economic analysis of vitrified microsphere thermal insulation mortar thermal insulation system. Build. Econ. 2007, 7, 57–60. [Google Scholar]

- Guo, Z.; Tu, Z.; Yao, R. Research on Roadway Thermal Insulation Materials in Shenjing Coal Mine. Coal Sci. Technol. 2009, 31, 23–26. [Google Scholar]

- Yao, R.; Wang, K. Effect of fly ash quality on properties of thermal insulation material in deep mine roadway. Henan Build. Mater. 2002, 2, 13–15. [Google Scholar]

- Shi, F.J. A Study on Structure and Properties of Basalt Fiber. Appl. Mech. Mater. 2012, 238, 17–21. [Google Scholar] [CrossRef]

- Schadeck, U.; Kyrgyzbaev, K.; Zettl, H.; Gerdes, T.; Moos, R. Flexible, Heat-Resistant, andFlame-RetardantGlass Fiber Nonwoven/Glass Platelet Composite Separator for Lithium-Ion Batteries. Energies 2018, 11, 999. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, Z.; Liu, Y. The importance of building energy efficiency and a new technology. Chin. J. Mech. Eng. 2006, 23, 146–148. [Google Scholar]

- Li, Y. Performance Research and Engineering Application of Concrete Mortar Master; Nanchang Institute of Technology: Nanchang, China, 2018. [Google Scholar]

- Xue, F. Application technology of polycarboxylate superplasticizer in concrete. Constr. Mach. 2019, 3, 50–53. [Google Scholar]

- Standard for Test Method of Performance on ordinary Fresh Concrete(GB/T 50080-2016); China Construction Industry Press: Beijing, China, 2016.

- Vejmelková, E.; Koňáková, D.; Scheinherrová, L.; Doleželová, M.; Keppert, M.; Černý, R. High temperature durability of fiber reinforced high alumina cement composites. Constr. Build Mater. 2018, 162, 881–891. [Google Scholar] [CrossRef]

- GB/T4272-2008 Inspection and Quarantine of the People’s Republic of China, China National Standardization Administration General Principles for Thermal Insulation Technique of Equipment and Pipes; General Administration of Quality Supervision: Beijing, China, 2008.

- GB/T35056-2018 China National Standardization Administration. Technical Specifications for Rock Bolting in Coal Mine Roadways; State Administration of Market Supervision and Administration: Beijing, China, 2018.

| Test Material Name | Parameter Introduction | Physical Map |

|---|---|---|

| ceramsite | colour: dark red; diameter: 3~5 mm; density: 980 kg/m3. |  |

| Test Material Name | Parameter Introduction | Physical Map |

|---|---|---|

| basalt fiber | form: chopped strands; basic performance: environmentally friendly and non-toxic; monofilament diameter: 7~17 μm; density: ≤3.0 g/cm3; fiber length: 0.3 or 0.6 cm; elongation: 3.1%; breaking strength: 3500~4300 MPa. |  |

| Test Material Name | Parameter Introduction | Physical Map |

|---|---|---|

| glass fiber | form: chopped strands; basic performance: white, environmentally friendly and non-toxic; alkali content: <0.8; monofilament diameter: 5~100 μm; density: ≤1.0 g/cm3; fiber length: 0.5~2 cm; elongation at break: ≤40%; water absorption: ≤2%; breaking strength: ≤450 MPa. |  |

| Test Material Name | Parameter Introduction | Physical Map |

|---|---|---|

| vitrified microspheres | morphology: spherical particles; basic requirements: fire resistance, high and low temperature resistance; colour: white; particle diameter: 0.15~1.5 mm; porous hollow particles; thermal conductivity: 0.036~0.054 W/(m·K); bulk density: 50~200 kg/m3; scoring rate: 80%~95%; water absorption: 20%~50%. |  |

| Test Material Name | Performance | Physical Map |

|---|---|---|

| polycarboxylic acid superplasticizer | appearance: white fluid powder; outer packing density: 350~500 kg/m3; moisture content: ≤3%; loss on ignition: ≥ 85%;PH value: 7~8; Fineness (0.315mm sieve): ≥90%; Cl− content: ≤0.1; mortar water reduction rate: ≥25%. |  |

| Inorganic Insulation Material (kg) | Cement (kg) | Sand (kg) | Ceramsite (kg) | Water (kg) | Water Reducing Agent (g) | |

|---|---|---|---|---|---|---|

| Material | Quantified Value | |||||

| basalt fiber | 0.30 (25%) | 1.2 | 2.54 | 1.21 | 1.08 | 3.6 |

| glass fiber | 0.42 (35%) | |||||

| vitrified beads | 0.54 (45%) | 1.32 | ||||

| Place Name | Boundary Type | Code | Place Name | Boundary Type | Code |

|---|---|---|---|---|---|

| laneway wall | Wall | Wi | pressure outlet | Pressure-outlet | Po |

| surrounding rock surface | Wall | Wo | fluid outlet | Outflow | F |

| speed entry | Velocity-inlet | Vi | coupling boundary | Wall-shadow | Ws |

| Part Name | Parameter Name | Model Parameters | |

|---|---|---|---|

| roadway | shape | cylinder | |

| length/m | 100 m | ||

| outer diameter/m+temperature/°C | 32 + 40.7 | ||

| inside diameter/m+temperature/°C | 2.15 + 34.06 | ||

| shotcrete | support thickness/m | 0.15 | |

| shotcrete-I | Concrete | density/(kg/m3) | 2400 |

| thermal conductivity/[W/(m·°C)] | 1.50 | ||

| merry | speed/(m/s) | 2.5 | |

| density/(kg/m3) | 1.2 | ||

| surrounding rock | thermal conductivity/[W/(m·°C)] | 2.10 | |

| temperature coefficient/(m2/s) | 0.843 × 10−5 | ||

| others | convection heat transfer coefficient/[W/(m2·°C)] | 24.35 | |

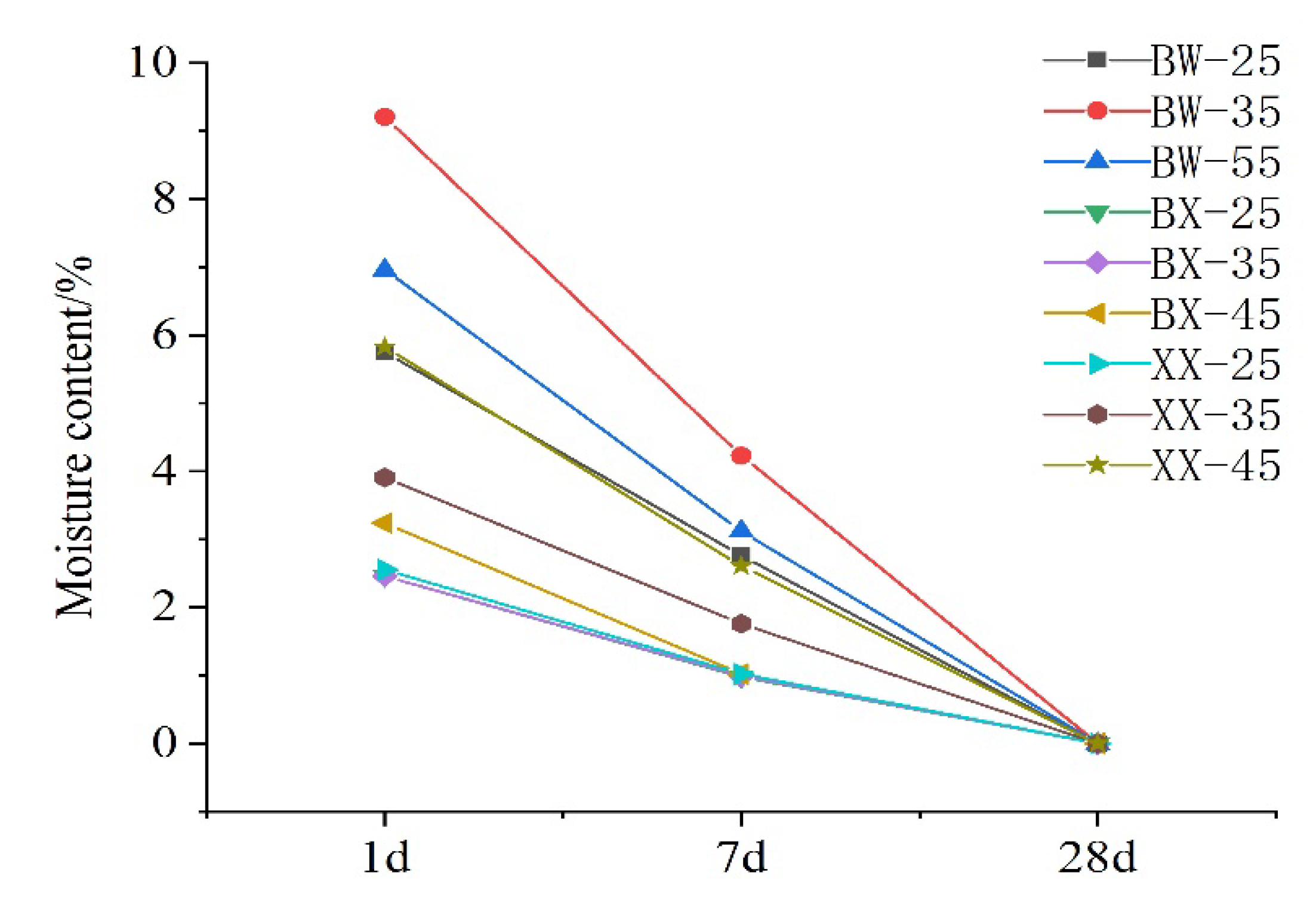

| Days | Average Moisture Content (%) | |||

|---|---|---|---|---|

| Specimen Number | 1 d | 7 d | 28 d | |

| BW | 25 | 5.75 | 2.76 | 0 |

| 35 | 9.21 | 4.23 | 0 | |

| 45 | 6.96 | 3.12 | 0 | |

| BX | 25 | 2.46 | 0.98 | 0 |

| 35 | 2.46 | 0.99 | 0 | |

| 45 | 3.24 | 1.02 | 0 | |

| XX | 25 | 2.55 | 1.02 | 0 |

| 35 | 3.91 | 1.76 | 0 | |

| 45 | 5.83 | 2.61 | 0 | |

| Days | Thermal Conductivity (Average Value) W/(K·m) | |||||||

|---|---|---|---|---|---|---|---|---|

| Specimen Number | 1d | 3d | 28d | |||||

| BW | 25 | 1 | 0.4578 | (0.4567) | 0.4201 | (0.4279) | 0.3895 | (0.3667) |

| 2 | 0.4622 | 0.4358 | 0.3306 | |||||

| 3 | 0.4501 | 0.4278 | 0.3799 | |||||

| 35 | 1 | 0.4101 | (0.4067) | 0.3632 | (0.3610) | 0.3174 | (0.3129) | |

| 2 | 0.4098 | 0.3541 | 0.3035 | |||||

| 3 | 0.4002 | 0.3658 | 0.3179 | |||||

| 45 | 1 | 0.3548 | (0.3560) | 0.3005 | (0.3146) | 0.2956 | (0.2928) | |

| 2 | 0.3571 | 0.3254 | 0.2998 | |||||

| 3 | 0.3562 | 0.3178 | 0.2831 | |||||

| BX | 25 | 1 | 0.6211 | (0.6315) | 0.5795 | (0.5804) | 0.5552 | (0.5470) |

| 2 | 0.6405 | 0.5788 | 0.5369 | |||||

| 3 | 0.6330 | 0.5829 | 0.5489 | |||||

| 35 | 1 | 0.5811 | (0.5753) | 0.5445 | (0.5424) | 0.5087 | (0.5073) | |

| 2 | 0.5744 | 0.5321 | 0.5002 | |||||

| 3 | 0.5705 | 0.5505 | 0.5130 | |||||

| 45 | 1 | 0.5341 | (0.5253) | 0.5056 | (0.5058) | 0.4852 | (0.4775) | |

| 2 | 0.5228 | 0.5000 | 0.4698 | |||||

| 3 | 0.5191 | 0.5118 | 0.4775 | |||||

| XX | 25 | 1 | 0.4012 | (0.3924) | 0.3606 | (0.3565) | 0.3101 | (0.3212) |

| 2 | 0.3956 | 0.3521 | 0.3183 | |||||

| 3 | 0.3804 | 0.3569 | 0.3351 | |||||

| 35 | 1 | 0.2951 | (0.2912) | 0.2216 | (0.2275) | 0.1779 | (0.1801) | |

| 2 | 0.2874 | 0.2347 | 0.1822 | |||||

| 3 | 0.2912 | 0.2261 | 0.1802 | |||||

| 45 | 1 | 0.2310 | (0.2302) | 0.1884 | (0.1870) | 0.1251 | (0.1323) | |

| 2 | 0.2254 | 0.1901 | 0.1319 | |||||

| 3 | 0.2343 | 0.1826 | 0.1399 | |||||

| Material Content/% | 25 | 35 | 45 | |

|---|---|---|---|---|

| Specimen Number | ||||

| BW | 0.213% | 0.00668% | 0.00754% | |

| BX | 0.229% | 0.00424% | 0.00593% | |

| XX | 0.016% | 0.00460% | 0.00548% | |

| Parameter | Compressive Strength (Average Value) MPa | |||

|---|---|---|---|---|

| Specimen Number | ||||

| BW | 25 | 1 | 8.442110 | (8.46) |

| 2 | 8.152187 | |||

| 3 | 8.790338 | |||

| 35 | 1 | 4.989604 | (5.13) | |

| 2 | 4.828739 | |||

| 3 | 5.561733 | |||

| 45 | 1 | 2.028973 | (2.48) | |

| 2 | 2.700337 | |||

| 3 | 2.701891 | |||

| BX | 25 | 1 | 21.39526 | (21.31) |

| 2 | 21.46985 | |||

| 3 | 21.05694 | |||

| 35 | 1 | 22.52147 | (22.27) | |

| 2 | 22.26835 | |||

| 3 | 22.01224 | |||

| 45 | 1 | 23.01549 | (22.99) | |

| 2 | 22.88358 | |||

| 3 | 23.08096 | |||

| XX | 25 | 1 | 18.96541 | (19.34) |

| 2 | 19.35963 | |||

| 3 | 19.68541 | |||

| 35 | 1 | 15.48659 | (15.46) | |

| 2 | 15.73184 | |||

| 3 | 15.15432 | |||

| 45 | 1 | 11.35646 | (10.98) | |

| 2 | 10.63288 | |||

| 3 | 10.94565 | |||

| Material Content/% | 25 | 35 | 45 | |

|---|---|---|---|---|

| Specimen Number | ||||

| BW | 10.2% | 14.8% | 15.0% | |

| BX | 4.80% | 6.4% | 10.0% | |

| XX | 13.0% | 8.3% | 13.1% | |

| Performance Parameter | Thermal Conductivity | Compressive Strength | |

|---|---|---|---|

| Parameter | |||

| Material | |||

| BW | moderate | softest | |

| XX | fastest | moderate | |

| BX | slowest | hardest | |

| Part Name | Parameter Name | Model Parameters | |

|---|---|---|---|

| shotcrete -II | XX45 | density/(kg/m3) | 2610 |

| thermal conductivity/[W/(m·℃)] | 0.1323 | ||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hou, C.; Xin, S.; Zhang, L.; Liu, S.; Zhang, X. Foundation Research on Physicochemical Properties of Mine Insulation Materials. Coatings 2020, 10, 355. https://doi.org/10.3390/coatings10040355

Hou C, Xin S, Zhang L, Liu S, Zhang X. Foundation Research on Physicochemical Properties of Mine Insulation Materials. Coatings. 2020; 10(4):355. https://doi.org/10.3390/coatings10040355

Chicago/Turabian StyleHou, Chuanbin, Song Xin, Long Zhang, Shangxiao Liu, and Xiao Zhang. 2020. "Foundation Research on Physicochemical Properties of Mine Insulation Materials" Coatings 10, no. 4: 355. https://doi.org/10.3390/coatings10040355

APA StyleHou, C., Xin, S., Zhang, L., Liu, S., & Zhang, X. (2020). Foundation Research on Physicochemical Properties of Mine Insulation Materials. Coatings, 10(4), 355. https://doi.org/10.3390/coatings10040355