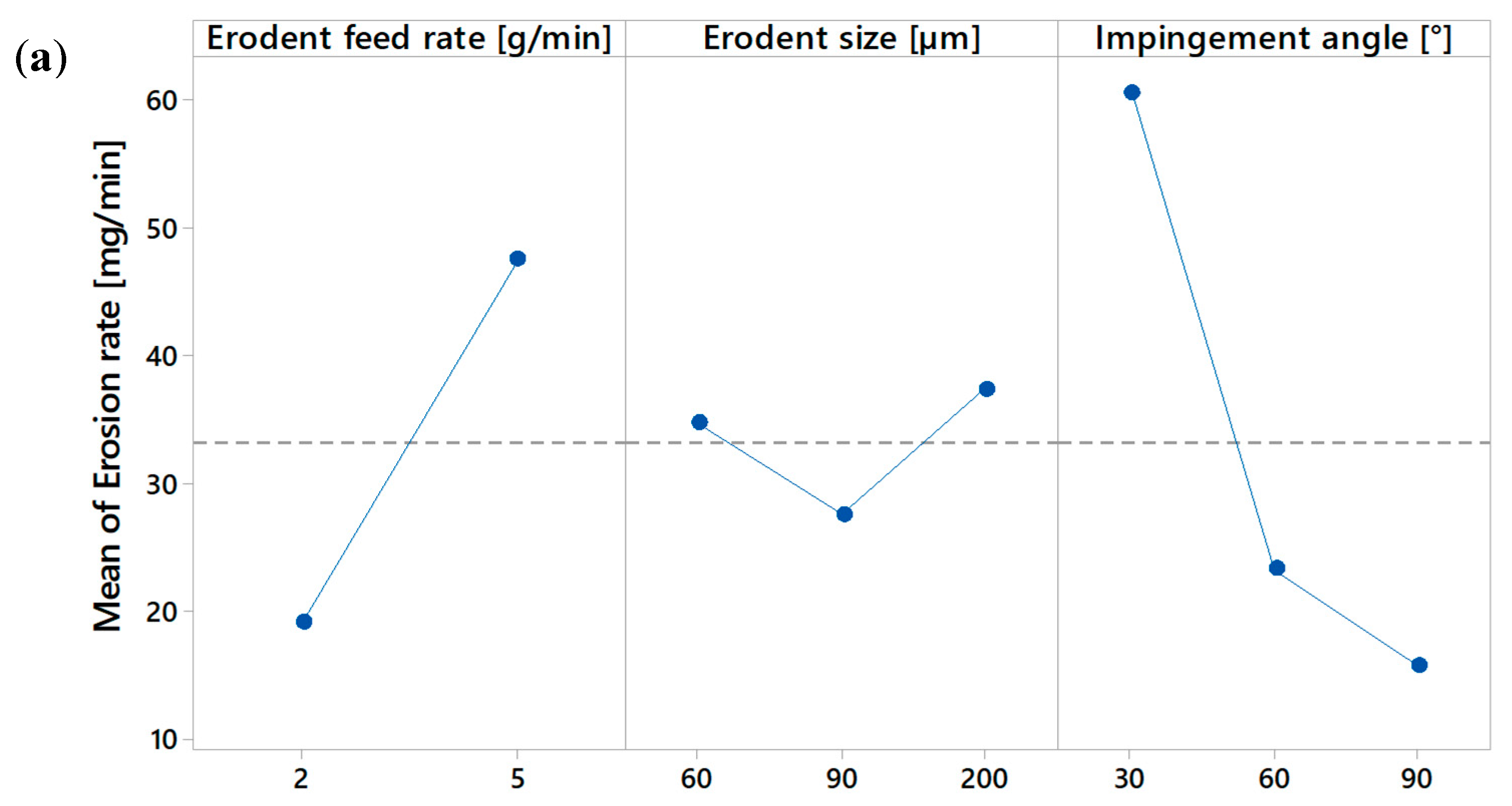

3.2.1. Erosion Rates Analysis

The results of the 18 erosion tests, which are given in

Table 6, are statistically analyzed using the software MINITAB

®.

Table 7 shows the ANOVA for the Erosion rate. In addition, the main effect and the interaction plots are reported in

Figure 5. A first qualitative analysis may be performed by analyzing the main effect plot of

Figure 5, in which the higher the slope of the line that connects the levels of the process variables, the greater the influence of each variable [

25]. It is evident from

Figure 5 that the impingement angle has the highest effect on the Erosion rate, followed by the Erodent feed rate, while the lowest effect is due to the Erodent size. Specifically, an angle of 90° produces an erosion rate of about 16 mg/min; conversely, using an angle of 30°, the erosion rate is slightly above 60 mg/min. Using the intermediate angle, 60°, the erosion rate is reduced to about 23 mg/min. Moreover, an erodent feed rate of 2 g/min causes an erosion rate of about 19 mg/min, while with its increase to 5 g/min, the corresponding erosion rate reaches 47.5 mg/min. It should be noted that this linear trend, as shown in

Figure 5a, represents a first approximation of the dependence between the

Erosion rate and the Erodent feed rate. In order to define this dependence with more accuracy, further erosion tests would be necessary, e.g., by including a third level within the erodent feed rate range of 2–5 g/min. As far as the erodent size is concerned, it produces the weakest effect on the erosion rate (60 μm, 90 μm, and 200 μm corresponds to 34.6 mg/min, 27.6 mg/min, and 37.5 mg/min, respectively) with respect to the other two process variables. It should be highlighted that the trend of the impingement angle on the response is of indirect proportionality, whereas that of the erodent feed rate is of direct proportionality. A case apart is that of the erodent size, because from 60° to 90° the erosion rate decreases, while between 60° and 90°, a growing positive trend is exhibited. These results are in accordance with other previous studies [

24,

37,

38,

39,

40]. However, they strongly depend on the impacting particle properties (density, hardness, size, and shape), target materials, temperature, and velocity of abrasive particles. In agreement with the main effect plot of

Figure 5a, in the ANOVA, see

Table 7, it emerges that the erodent feed rate and the impingement angle are significant, i.e., their

p-values are less than 5%.

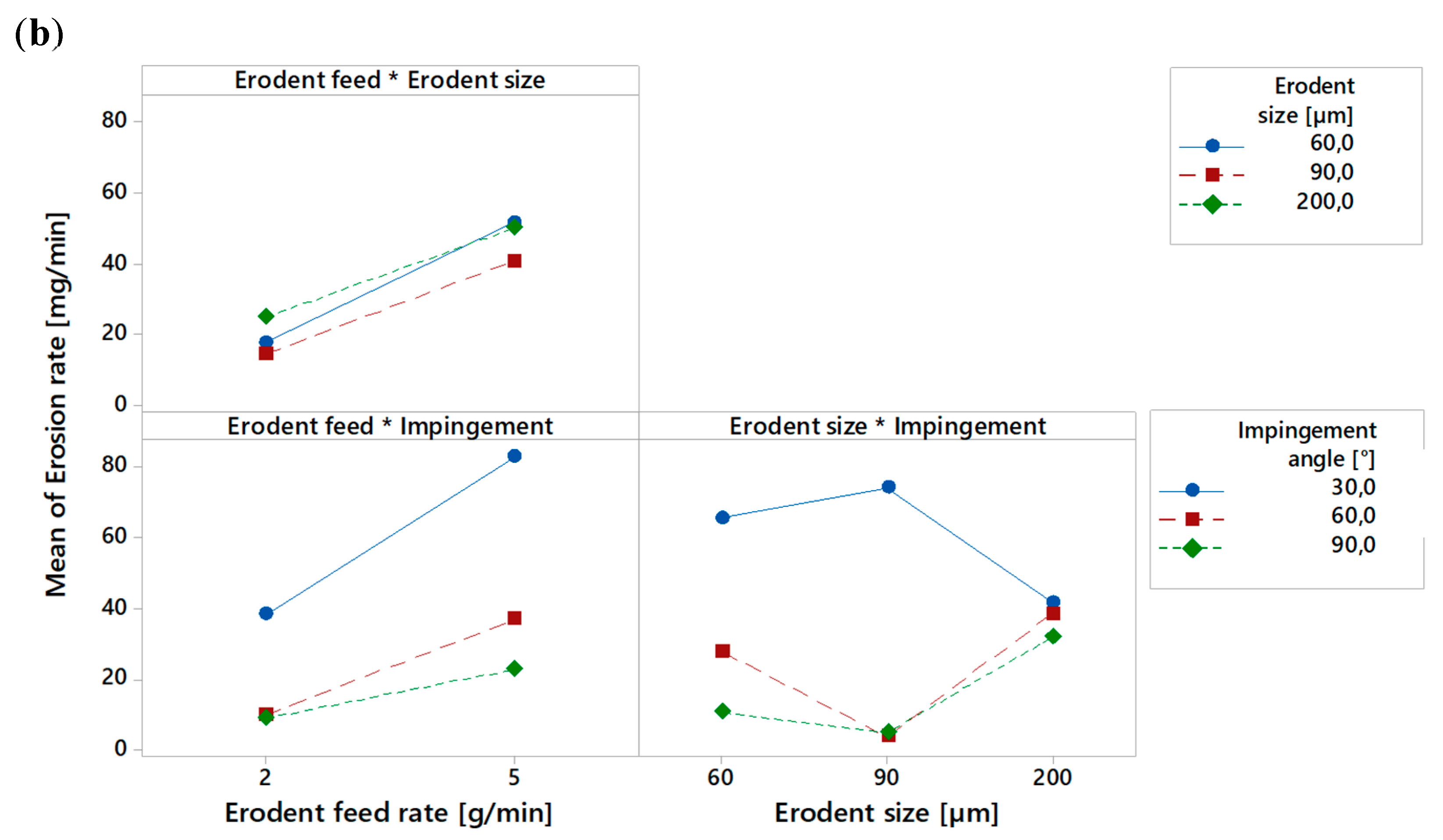

The interactions between the process variables may be evidenced by using the interaction plot (see

Figure 5). Parallel lines in an interaction plot indicate no interaction, while the greater the deviation of the lines from the parallel state, the higher the degree of interaction [

25]. In the plot, interactions between the erodent feed rate and size are shown, as well as between the erodent feed rate and impingement angle. However, the most evident interaction is the one between the erodent size and impingement angle. With a particle size of 200 μm, the erosion rate is almost the same when using the three different impact angles. When, on the other hand, the particle size ranges from 60 to 200 μm, the mass loss is greater at 30° than at the other two impact angles. In this range of erodent size, at 90°, the erosion rate is always lower than using an angle of 30°, except for particles of 90 μm, where no significant difference between the two angles is found. In the ANOVA, although the

p-value of the interaction between erodent size and impingement angle is greater than the other two interactions, neither is nevertheless statistically significant at a level of significance of 5%. As explained hereafter, excluding from the analysis some non-significant factors, the significance of the last interaction of

Table 7 will be highlighted.

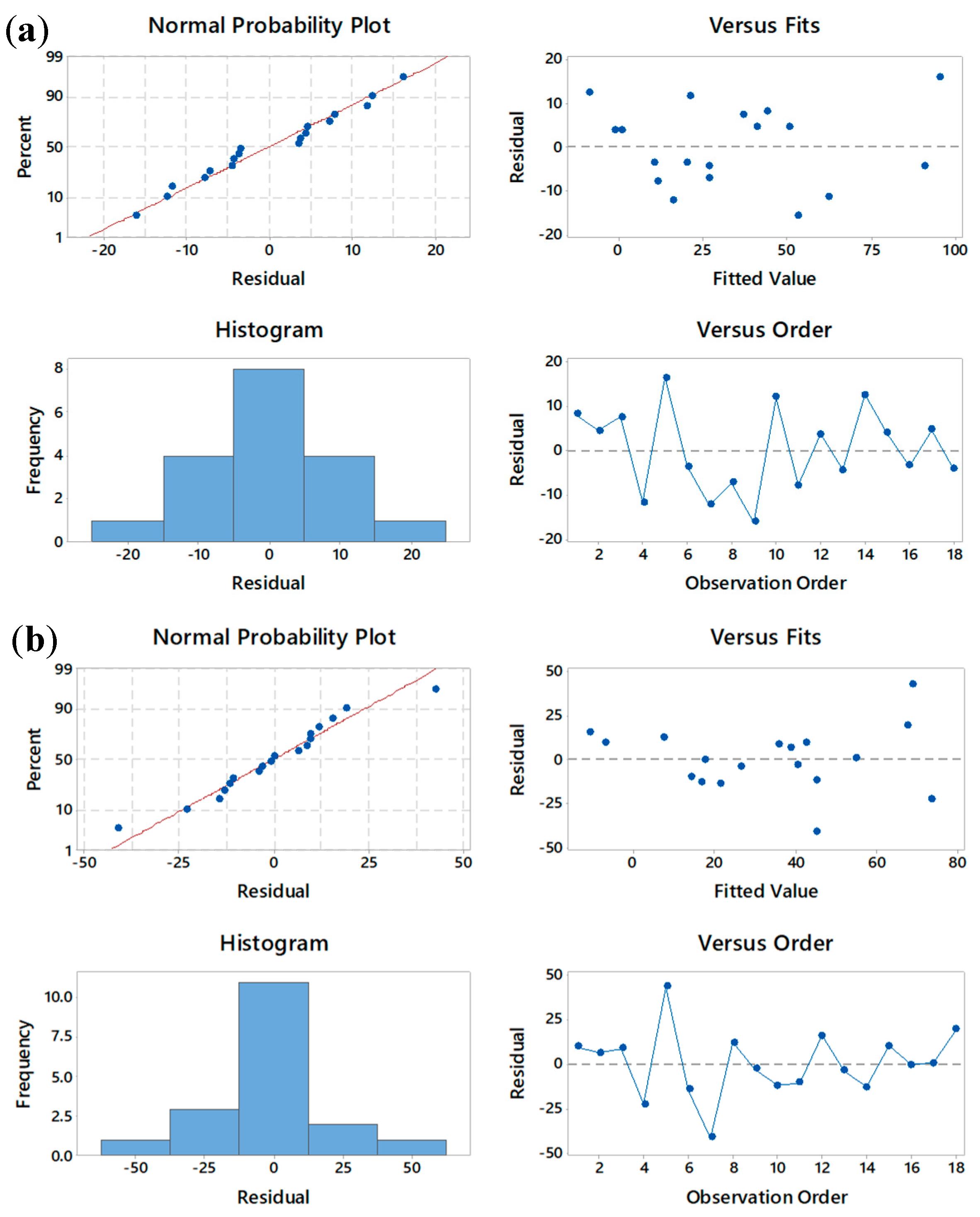

In

Figure 6a, the residual plots for the response Erosion rate are reported. As evidenced in

Figure 6a, the normality of the residuals, which are defined as the differences between the observed and the corresponding fitted, i.e., predicted, values, is graphically confirmed by the Normal Probability Plot (NPP), in which the experimental values are placed approximately along a straight line, and by the histogram. The normality of residuals is also statistically confirmed by performing the Anderson–Darling test, in which the null hypothesis, i.e., that the residuals follow a normal distribution, cannot be rejected with a

p-value of 0.59 [

41]. The residuals versus fitted values plot shows a horizontal band around the residual line (value 0), and no recognizable patterns are evidenced. The residuals versus order plot also does not reveal non-random errors, especially concerning time-related effects. The coefficient of determination,

R2, which is a goodness of fit measure of the model, reveals that the observed variation in the Erosion rate explained by the model is 90.95%.

In order to obtain a model that contains exclusively significant predictors, the factorial design was analyzed using the stepwise method. The stepwise method both adds and removes predictors at each step, according to selected α to enter and α to remove values [

41]. In line with the literature, the α to enter and α to remove values were set to 0.15 in this study [

42]. The new ANOVA table obtained from the stepwise method is shown in

Table 8. As expected, only significant terms are present in

Table 8. Specifically, the Erodent feed rate and the Impingement angle are highly significant (

p-value ≤ 0.01), while the interaction between the Erodent size and Impingement angle is significant at an α level of 0.10. The

R2 value decreases to 84.27%. However, the

R2 adjusted increases from 61.54% (model containing all predictors) to 73.27% (model containing only significant predictors). Indeed, the

R2 value always increases when adding additional predictors to a model, whereas the

R2 adjusted shows as a percentage how much the model explains the variance of the response considering the numbers of predictors [

35].

The analysis of residuals obtained with the stepwise method is shown in

Figure 6b and suggests, again, that the model fits the data well. However, examining the residuals versus the fitted values plot, slight heteroscedasticity is highlighted, i.e., the residuals in correspondence to the higher fitted values have a greater variance than the lower fitted values. In order to overcome this problem, a weighted regression is implemented. Indeed, when the least squares assumption of constant variance in the residuals is violated, a weighted regression can be adopted to produce residuals with constant variance (homoscedasticity) [

41]. Consequently, in order to estimate the coefficients of the model containing the significant process variables exclusively (see

Table 8), the weighted regression reported in Equation (2) was implemented:

Therefore, the predicted response, the

Erosion rate, was related to the set of regression coefficients (

c): the intercept (

c0), linear (

c1 and

c2), and interaction (

c3). The regression weights used are the reciprocal of the variance of each

Erosion rate value and then normalized. The regression implemented provided the coefficients of the regression model, which are reported in

Table 9.

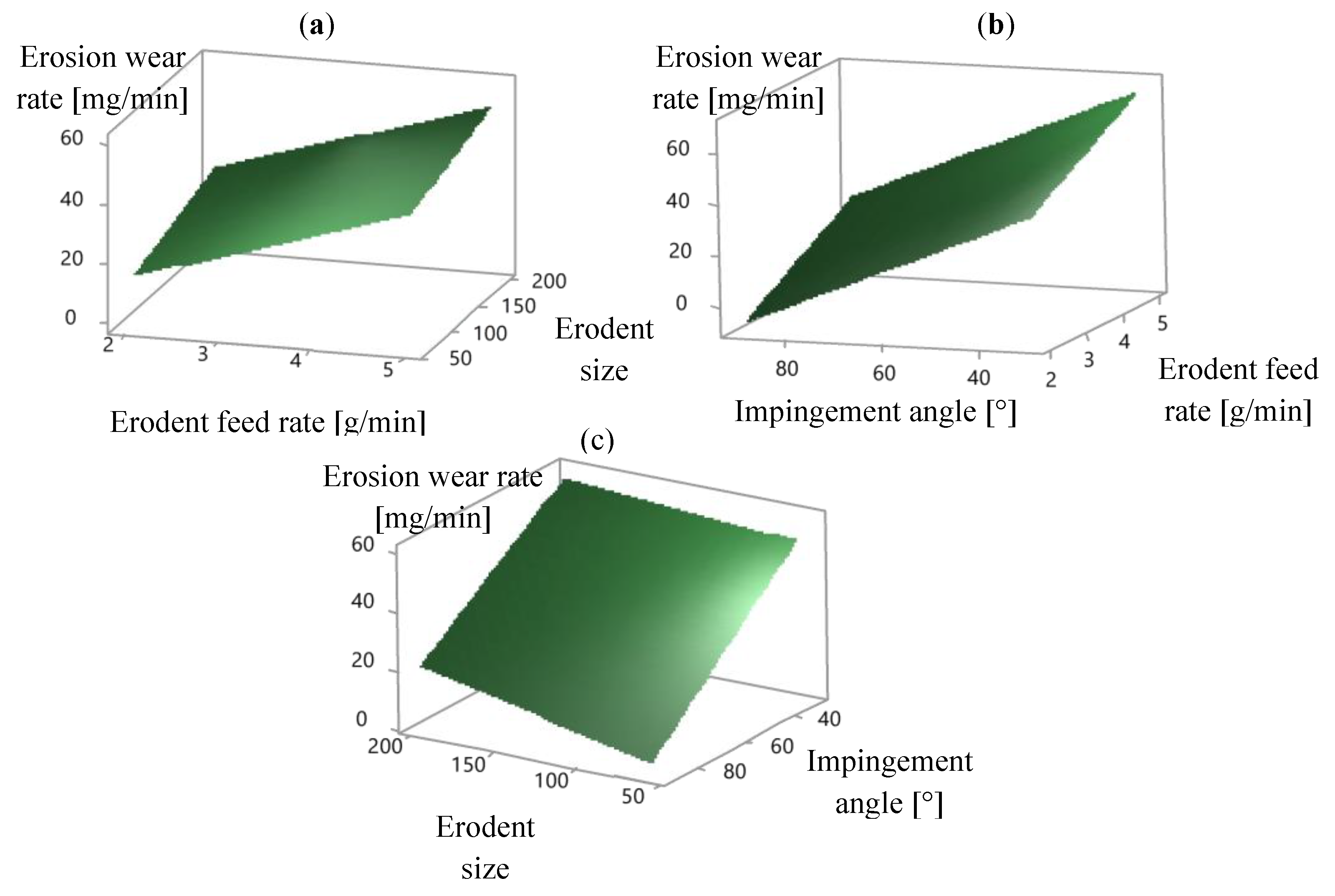

In order to visualize the trend of the response as a function of the variations of the process variables,

Figure 7 is provided. In

Figure 7, the surface plots relating the fitted response to the three pairs of independent variables are reported. A surface plot displays the three-dimensional relationship with the independent variables on the

x-axis and

y-axis, and the response (

z) variable represented by a smooth surface. The graphs are generated by calculating the fitted responses using the independent variables and keeping the third control variable constant at a specified value.

3.2.2. Optimization

From the analysis and optimization of the model reported in Equation (2) and the related surface plots illustrated in

Figure 7, the combination of process variables optimizing the response for the cold-sprayed IN718-Ni composite coating was obtained. Indeed, the model identified (see Equation (2) and

Table 9) has the dual purpose of (i) predicting the erosion performance of the real component deposited with IN718-Ni coating under the working conditions, and of (ii) properly designing the in-service conditions of the new cold-sprayed component. Specifically, the objective function was the minimization of the response, i.e., the Erosion rate. Such a process variables setup is summarized in

Table 10, together with the predicted value of the Erosion rate. To validate the optimized parameter settings, four erosion tests were performed using the optimal set of process variables, and the average value of the Erosion rate obtained in such tests is reported in

Table 10. The result shows that the average value for the Erosion rate falls within the prediction interval, with a deviation from the model prediction of 7.47%.

It should be highlighted that the optimal set of process variables reported in

Table 10 is the same used in Run 12 of

Table 6, but the erosion rates obtained are slightly different. Indeed, the experimental and predicted values (reported in

Table 10) and the erosion rate of Run 12 (shown in

Table 6) are respectively 3.31 mg/min, 3.08 mg/min, and 3.49 mg/min. Such differences in the erosion rate are to be attributed to the intrinsic variability of the erosion process (random effects). Besides, the minimum value of the

Erosion rate obtained in the experiments (see

Table 6) was achieved in test no. 15, by setting the Erodent feed rate and the Impingement angle at the same value reported in

Table 10, using however an Erodent size of 90 μm instead of 60 μm. This result should not be surprising, because the predicted value of the response using the same parameters set of the test no. 15 is 3.12 mg/min, which is slightly higher than the minimum value reached by the prediction model. These conclusions are in accordance with what has been discussed in relation to

Figure 7.

3.2.3. Worn Surface Analysis

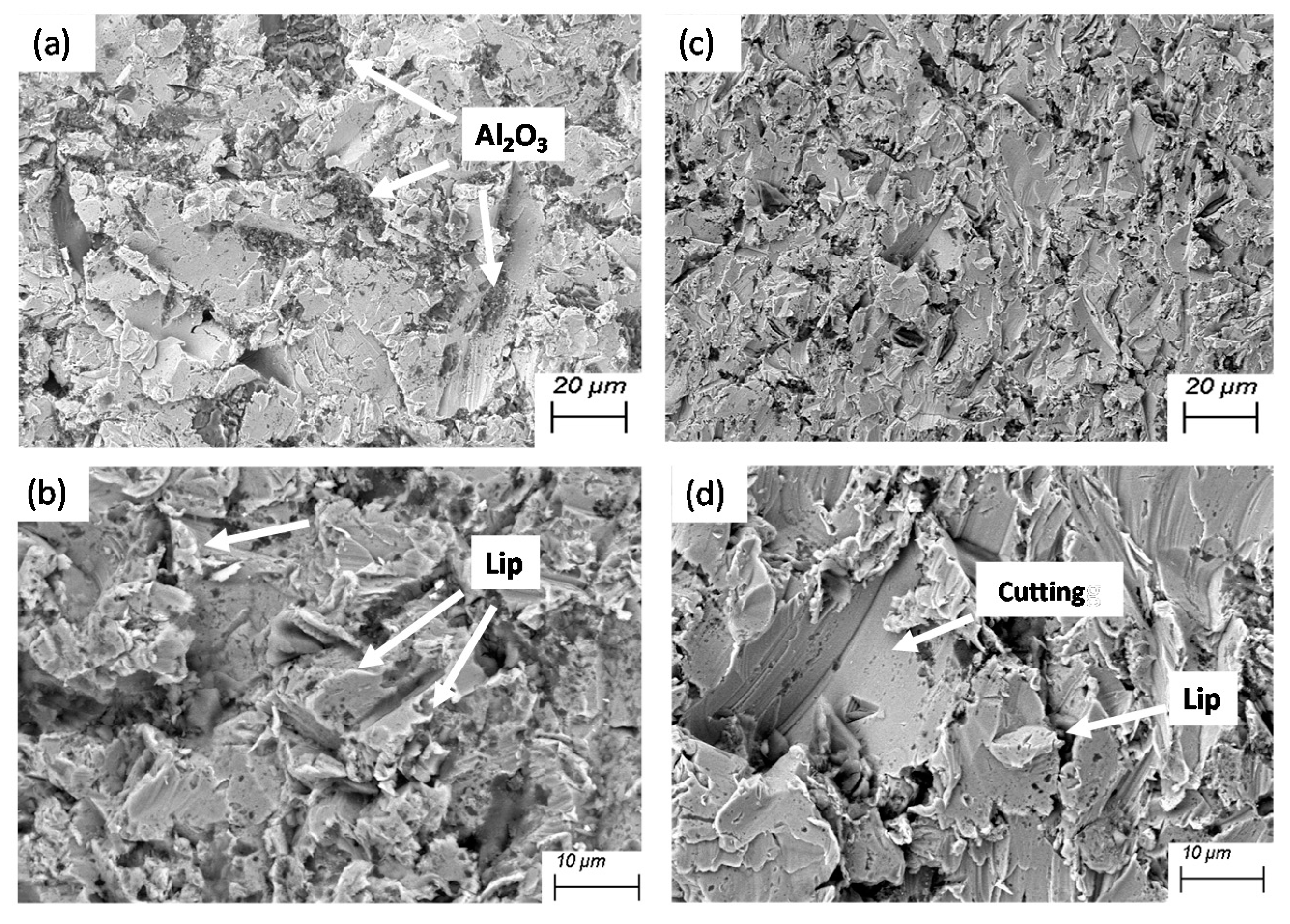

To investigate the erosion mechanism caused by the erodent particles on the surfaces of the Ni-INC718 coating, the worn surfaces were analyzed by SEM. The worn surfaces of the coatings tested using the optimal set of parameters reported in

Table 10 were analyzed and then compared with the worst-case scenario obtained in the planned experimentation, i.e., the test performed using an impingement angle of 30°, erodent size of 90 μm, and erodent feed rate of 5 g/min. The analysis performed on the two cases show a significant difference in mass loss, and both were consistent with the characteristics of particle erosion of ductile materials [

43]. In the case of low impact angles, when erosion resistance increases with increase in hardness and the mechanism of micro-cutting is dominant, the structure with a high hard phase content, as in the case of IN718 particles in the Ni matrix, is preferable. In the case of 90° impact, the structure with medium-hard phase content but higher hardness shows better erosion resistance. Particle velocity also has a key role in the erosion process. When the velocities are high, the eroded material may be plastically deformed, but if the particles are sharp, then other erosion mechanisms such as cutting and brittle fragmentation are more likely to occur [

44]. The eroded surface under the optimal condition of erosion rate is illustrated in

Figure 8a,b. The surface was not cut, but it was deeply perforated, and the coating underwent a surface extrusion forming erosion lips.

Figure 8a shows how the erodent particles that hit the coating surface at high velocities split into small fragments. Alumina fragments embedded in the coating, which have been detected more frequently at 90° than at 30°, can provide a surface shielding effect against further material loss and thus decrease the erosion rate [

26]. Erodent particle fragmentation becomes more probable at high velocities and at a 90° impact angle. The dissipation of kinetic energy at impact did not result in any evident surface crack. In the case in which the erodent particles impacted on the coating surface at 30°, it is evident from

Figure 8c,d that the cutting mechanism and chip removal are dominant. In such a case, it was observed that the alumina erodent particles generated plastic scratches because, according to Hutchings [

40], the ratio

Ha/

Hs >1.2 (where

Ha is the hardness of abrasive particles and

Hs is the harness of the surface) and therefore abrasive erosion mechanism occurred.

Figure 8c shows the erosion track caused by the erodent particle. At a 30° impact angle, the size of the craters is larger than at a 90° angle, suggesting higher erosion rates. Such erosion morphologies produced by erodent particles at oblique angles have also been observed in other studies, see e.g., [

26,

45].