Room and High Temperature Tribological Behaviour of W-DLC Coatings Produced by DCMS and Hybrid DCMS-HiPIMS Configuration

Abstract

1. Introduction

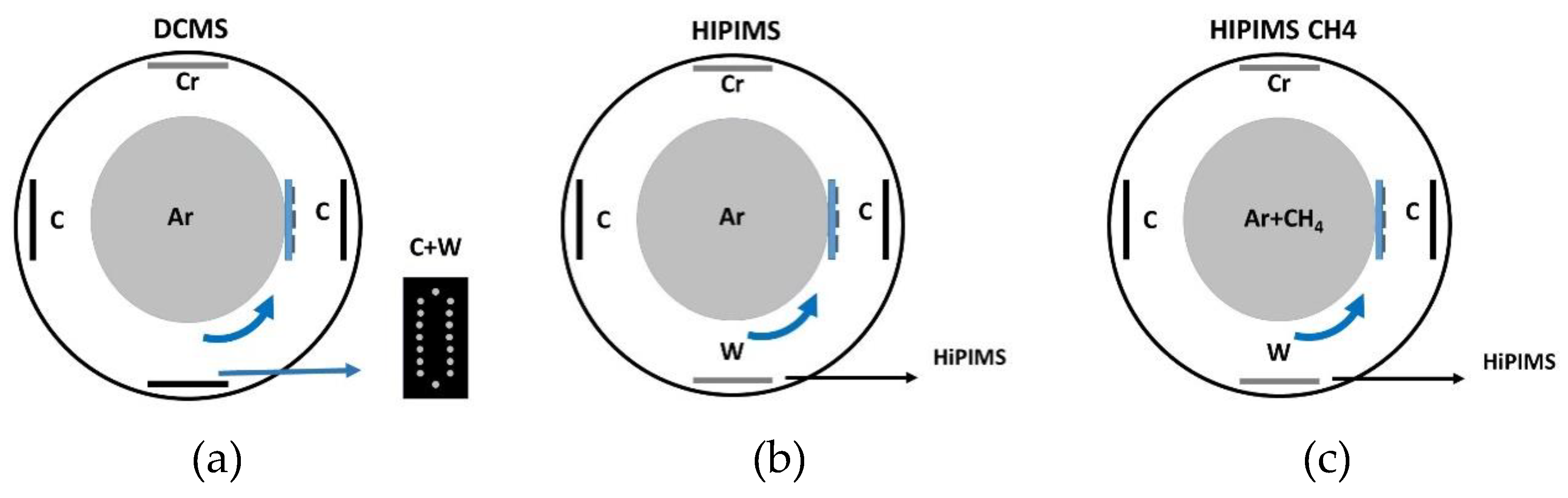

2. Experimental Details

3. Results

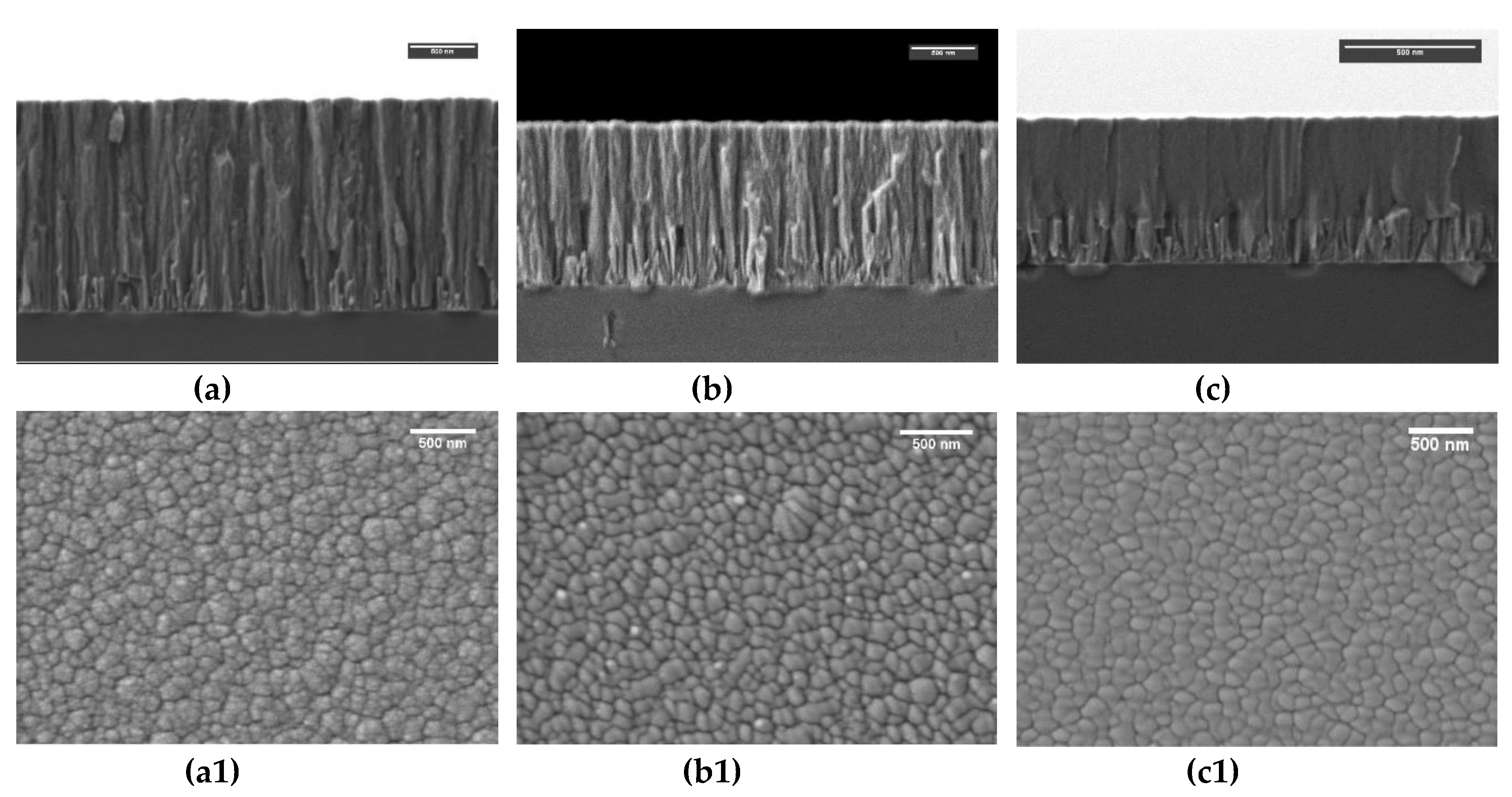

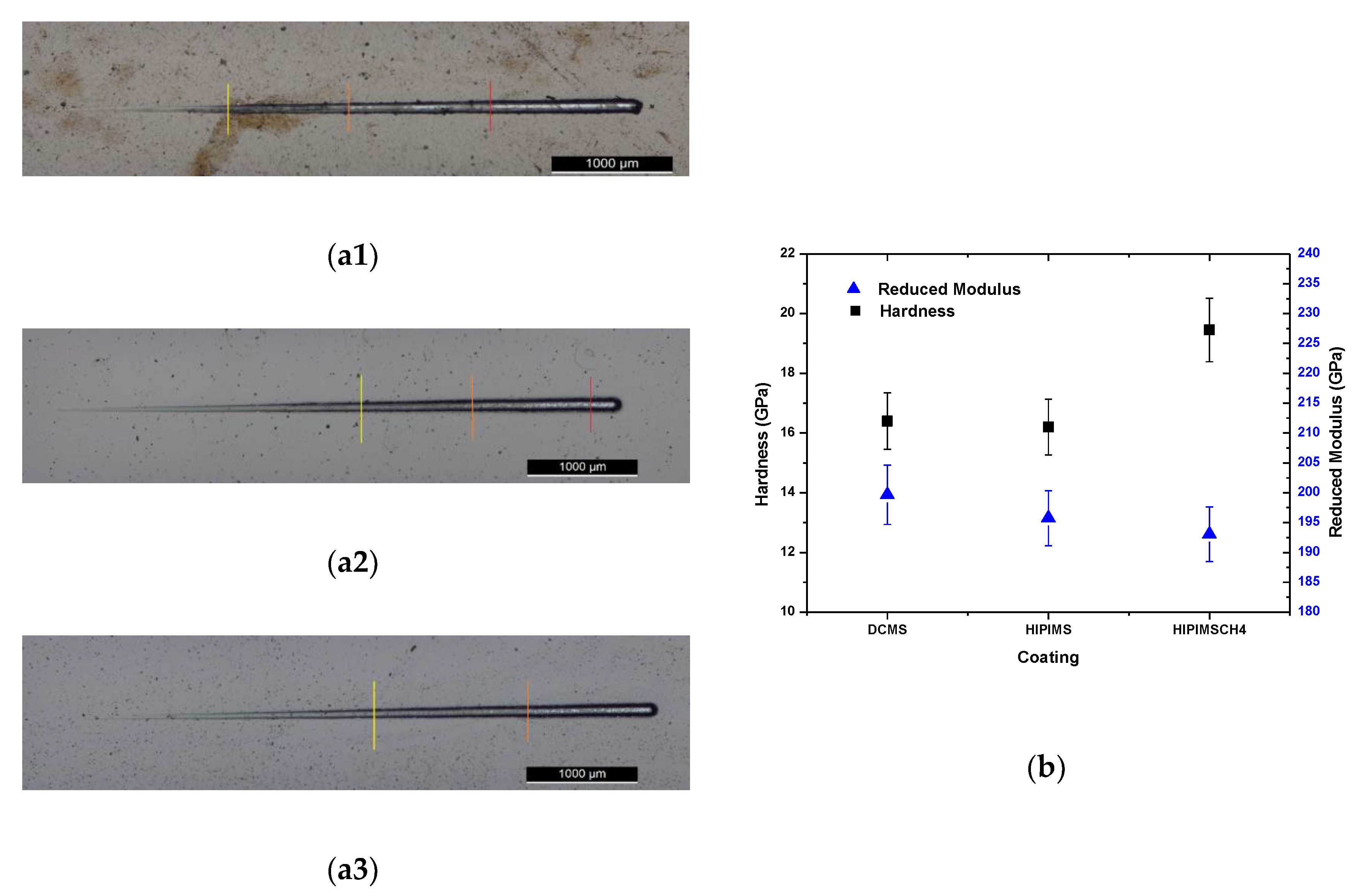

3.1. Coatings Charcterization

3.2. Tribological Behaviour

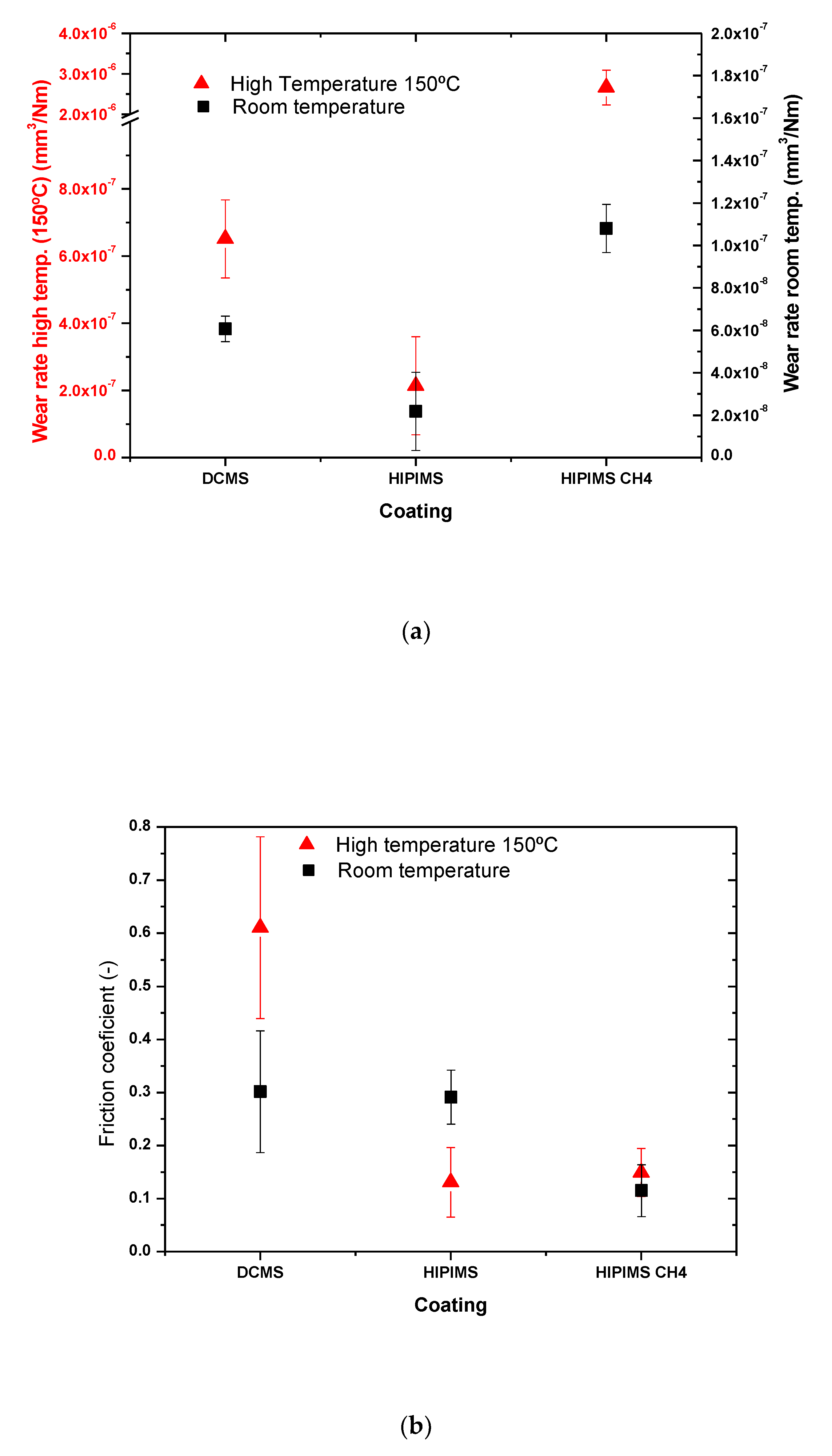

3.2.1. Wear Rate and Friction Coefficient at Room Temperature and 150 °C

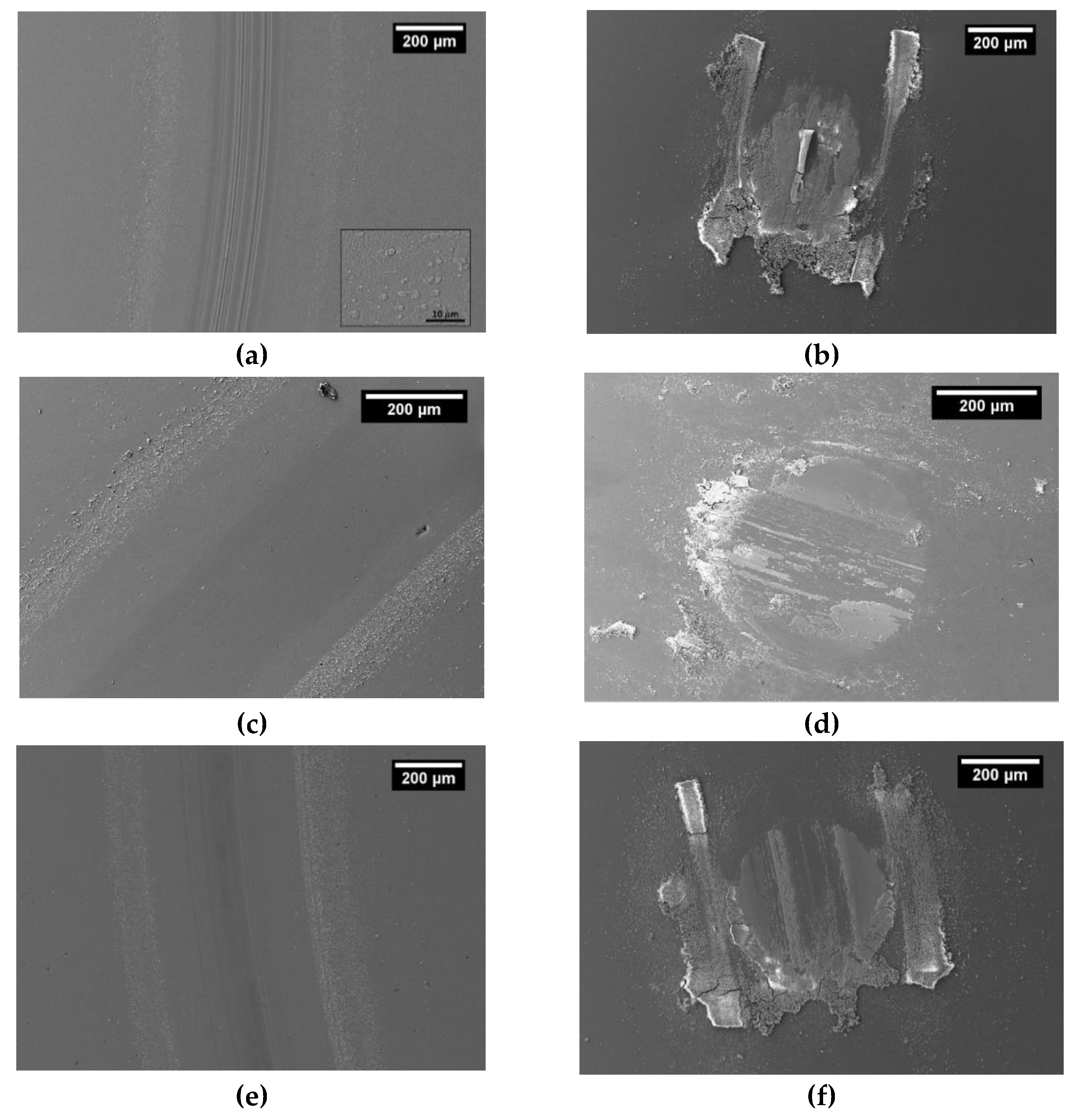

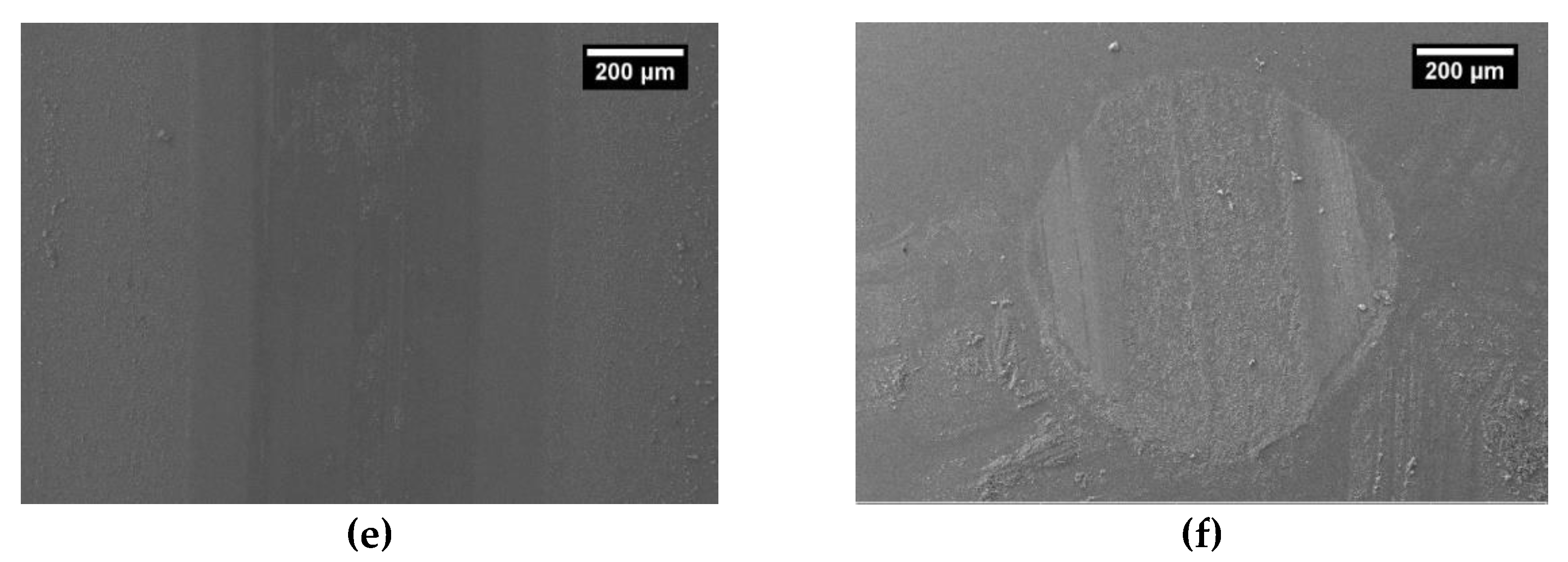

3.2.2. Wear Mechanisms and Surface Analysis of the Wear Track

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Erdemir, A.; Donnet, C. Tribology of diamond-like carbon films: Recent progress and future prospects. J. Phys. D Appl. Phys. 2006, 39, R311–R327. [Google Scholar] [CrossRef]

- Horiuchi, T.; Yoshida, K.; Kano, M.; Kumagai, M.; Suzuki, T. Evaluation of Adhesion and Wear Resistance of DLC Films Deposited by Various Methods. Plasma Process. Polym. 2009, 6, 410–416. [Google Scholar] [CrossRef]

- Wei, C.; Yen, J.Y. Effect of film thickness and interlayer on the adhesion strength of diamond like carbon films on different substrates. Diam. Relat. Mater. 2007, 16, 1325–1330. [Google Scholar] [CrossRef]

- Grill, A. Tribology of diamond like carbon and related materials: An updated review. Surf. Coat. Technol. 1997, 91–95, 507–513. [Google Scholar] [CrossRef]

- Abou Gharam, A.; Lukitsch, M.J.; Balogh, M.P.; Alpas, A.T. High temperature tribological behaviour of carbon based (B4C and DLC) coatings in sliding contact with aluminium. Thin Solid Films 2010, 519, 1611–1617. [Google Scholar] [CrossRef]

- Sánchez-López, J.C.; Fernández, A. Doping and Alloying Effects on DLC Coatings. In Tribology of Diamond-Like Carbon Films; Donnet, C., Erdemir, A., Eds.; Springer: Boston, MA, USA, 2008. [Google Scholar]

- Zhao, F.; Li, H.; Ji, L.; Wang, Y.; Zhou, H.; Chen, J. Ti-DLC films with superior friction performance. Diam. Relat. Mater. 2010, 19, 342–349. [Google Scholar] [CrossRef]

- Ming, M.Y.; Jiang, X.; Piliptsou, D.G.; Zhuang, Y.; Rogachev, A.V.; Rudenkov, A.S.; Balmakou, A. Chromium-modified a-C films with advanced structural, mechanical and corrosive-resistant characteristics. Appl. Surf. Sci. 2016, 379, 424–432. [Google Scholar] [CrossRef]

- Evaristo, M.; Polcar, T.; Cavaleiro, A. Tribological behaviour of W-alloyed carbon-based coatings in dry and lubricated sliding contact. Lubr. Sci. 2014, 26, 428–439. [Google Scholar] [CrossRef]

- Balestra, R.M.; Castro, A.M.G.; Evaristo, M.; Escudeiro, A.; Mutafov, P.; Polcar, T.; Cavaleiro, A. Carbon-based coatings doped by copper: Tribological and mechanical behavior in olive oil lubrication. Surf. Coat. Technol. 2011, 205, S79–S83. [Google Scholar] [CrossRef]

- Bociaga, D.; Komorowski, P.; Batory, D.; Szymanski, W.; Olejnik, A.; Jastrzebski, K.; Jakubowski, W. Silver-doped nanocomposite carbon coatings (Ag-DLC) for biomedical applications—Physiochemical and biological evaluation. Appl. Surf. Sci. 2015, 355, 388–397. [Google Scholar] [CrossRef]

- Voevodin, A.A.; O’Neill, J.P.; Zabinski, J.S. Tribological performance and tribochemistry of nanocrystalline WC/amorphous diamond-like carbon composites. Thin Solid Films 1999, 342, 194–200. [Google Scholar] [CrossRef]

- Abou Gharam, A.; Lukitsch, M.J.; Balogh, M.P.; Irish, N.; Alpas, A.T. High temperature tribological behavior of W-DLC against aluminium. Surf. Coat. Technol. 2011, 206, 1905–1912. [Google Scholar] [CrossRef]

- Pu, J.; He, D.; Wang, L. Effects of WC phase contents on the microstructure, mechanical properties and tribological behaviors of WC/a-C superlattice coatings. Appl. Surf. Sci. 2015, 357, 2039–2047. [Google Scholar] [CrossRef]

- Banerji, A.; Bhowmick, S.; Alpas, A.T. High temperature tribological behavior of W containing diamond-like carbon (DLC) coating against titanium alloys. Surf. Coat. Technol. 2014, 241, 93–104. [Google Scholar] [CrossRef]

- Bhowmick, S.; Lou, M.; Khan, M.Z.U.; Banerji, A.; Alpas, A.T. Role of an oxygen atmosphere in high temperature sliding behaviour of W containing diamond-like carbon (W-DLC). Surf. Coat. Technol. 2017, 332, 399–407. [Google Scholar] [CrossRef]

- Ferreira, F.; Serra, R.; Cavaleiro, A.; Oliveira, J. Diamond-like carbon coatings deposited by deep oscillation magnetron sputtering in Ar-Ne discharge. Diam. Relat. Mater. 2019, 98, 107521. [Google Scholar] [CrossRef]

- Aijaz, A.; Ferreira, F.; Oliveira, J.; Kubart, T. Mechanical Properties of Hydrogen Free Diamond-Like Carbon Thin Films Deposited by High Power Impulse Magnetron Sputtering with Ne. Coatings 2018, 8, 385. [Google Scholar] [CrossRef]

- Ferreira, F.; Serra, R.; Oliveira, J.C.; Cavaleiro, A. Effect of peak target power on the properties of Cr thin films sputtered by HiPIMS in deep oscillation magnetron sputtering (DOMS) mode. Surf. Coat. Technol. 2014, 258, 249–256. [Google Scholar] [CrossRef]

- Lin, J.; Zhang, X.; Lee, P.; Wei, R. Thick diamond like carbon coatings deposited by deep oscillation magnetron sputtering. Surf. Coat. Technol. 2017, 315, 294–302. [Google Scholar] [CrossRef]

- Sarakinos, K.; Alami, J.; Konstantinidis, S. High power pulsed magnetron sputtering: A review on scientific and engineering state of the art. Surf. Coat. Technol. 2010, 204, 1661–1684. [Google Scholar] [CrossRef]

- Robertson, J. Diamond-like amorphous carbon. Mater. Sci. Eng. 2002, 37, 129–281. [Google Scholar] [CrossRef]

- Lifshitz, Y.; Kasi, S.R.; Rabalais, J.W.; Eckstein, W. Subplantation model for film growth from hyperthermal species. Phys. Rev. 1990, 41, 10468–10480. [Google Scholar] [CrossRef] [PubMed]

- Robertson, J. Deposition mechanisms for promoting sp3 bonding in diamond-like carbon. Diam. Relat. Mater. 1993, 2, 984–989. [Google Scholar] [CrossRef]

- Radic, N.; Grzeta, B.; Milat, O.; Ivkov, J.; Stubicar, M. Tungsten–carbon films prepared by reactive sputtering from argon–benzene discharges. Thin Solid Films 1998, 320, 192–197. [Google Scholar] [CrossRef]

- Ronkainen, H.; Varjus, S.; Koskinen, J.; Holmberg, K. Differentiating the tribological performance of hydrogenated and hydrogen-free DLC coatings. Wear 2001, 249, 260–266. [Google Scholar] [CrossRef]

- Vitu, T.; Escudeiro, A.; Polcar, T.; Cavaleiro, A. Sliding properties of Zr-DLC coatings: The effect of tribolayer formation. Surf. Coat. Technol. 2014, 258, 734–745. [Google Scholar] [CrossRef]

- Sánchez-López, J.C.; Martínez-Martínez, D.; Abad, M.D.; Fernández, A. Metal carbide/amorphous C-based nanocomposite coatings for tribological applications. Surf. Coat. Technol. 2009, 204, 947–954. [Google Scholar] [CrossRef]

- Greenwood, O.D.; Moulzolf, S.C.; Blau, P.J.; Lad, R.J. The influence of microstructure on tribological properties of WO3 thin films. Wear 1999, 232, 84–90. [Google Scholar] [CrossRef]

- Semenov, A.P.; Khrushchov, M.M. Influence of Environment and Temperature on Tribological Behavior of Diamond and Diamond Like Coatings. J. Frict. Wear 2010, 31–32, 142–158. [Google Scholar] [CrossRef]

| Sample | Ar Flow (sccm) | CH4 Flow (sccm) | Pressure (Pa) | Power C. 1 (W) | Power C. 2 (W) | Power C–W Target (W) | |||

|---|---|---|---|---|---|---|---|---|---|

| DCMS | 46 | 0 | 0.45 | 1750 | 1750 | 1000 | |||

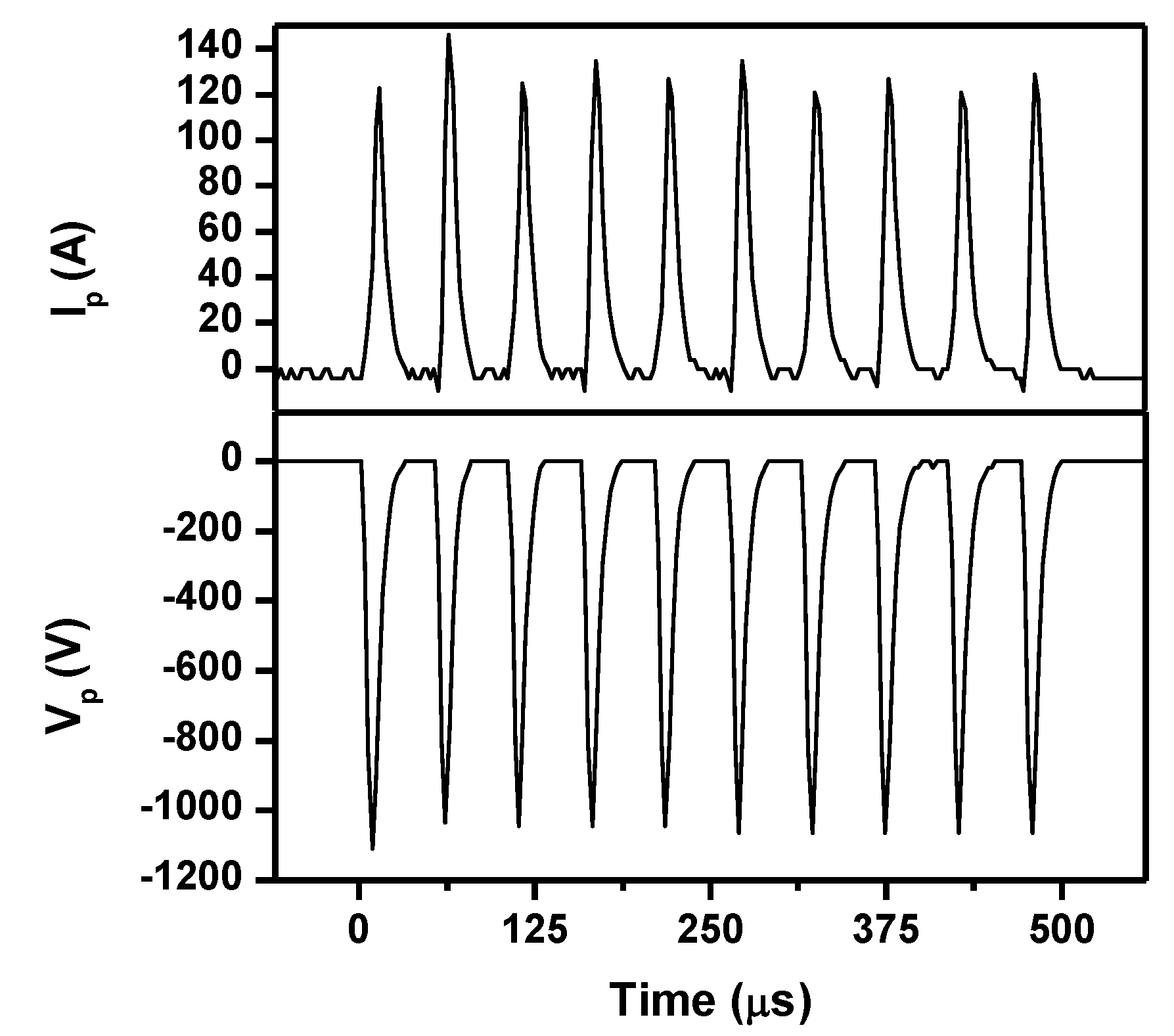

| Average Power (W) | DC int (V) | Vp (V) | Ip (A) | ||||||

| HiPIMS | 46 | 0 | 0.45 | 1750 | 1750 | 500 | 400 | 1112 | 130 |

| HiPIMS CH4 | 46 | 10 | 0.50 | 1750 | 1750 | 500 | 400 | 1156 | 109 |

| Sample | G Pos. cm−1 | ID/IG | G FWHM cm−1 |

|---|---|---|---|

| DCMS | 1561.6 | 5.1 | 146.2 |

| HIPIMS | 1557.4 | 5.3 | 141.4 |

| HIPIMS CH4 | 1557.4 | 3.4 | 130.6 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Evaristo, M.; Fernandes, F.; Cavaleiro, A. Room and High Temperature Tribological Behaviour of W-DLC Coatings Produced by DCMS and Hybrid DCMS-HiPIMS Configuration. Coatings 2020, 10, 319. https://doi.org/10.3390/coatings10040319

Evaristo M, Fernandes F, Cavaleiro A. Room and High Temperature Tribological Behaviour of W-DLC Coatings Produced by DCMS and Hybrid DCMS-HiPIMS Configuration. Coatings. 2020; 10(4):319. https://doi.org/10.3390/coatings10040319

Chicago/Turabian StyleEvaristo, Manuel, Filipe Fernandes, and Albano Cavaleiro. 2020. "Room and High Temperature Tribological Behaviour of W-DLC Coatings Produced by DCMS and Hybrid DCMS-HiPIMS Configuration" Coatings 10, no. 4: 319. https://doi.org/10.3390/coatings10040319

APA StyleEvaristo, M., Fernandes, F., & Cavaleiro, A. (2020). Room and High Temperature Tribological Behaviour of W-DLC Coatings Produced by DCMS and Hybrid DCMS-HiPIMS Configuration. Coatings, 10(4), 319. https://doi.org/10.3390/coatings10040319