Characterization of AlCrN and AlCrON Coatings Deposited on Plasma Nitrided AISI H13 Steels Using Ion-Source-Enhanced Arc Ion Plating

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

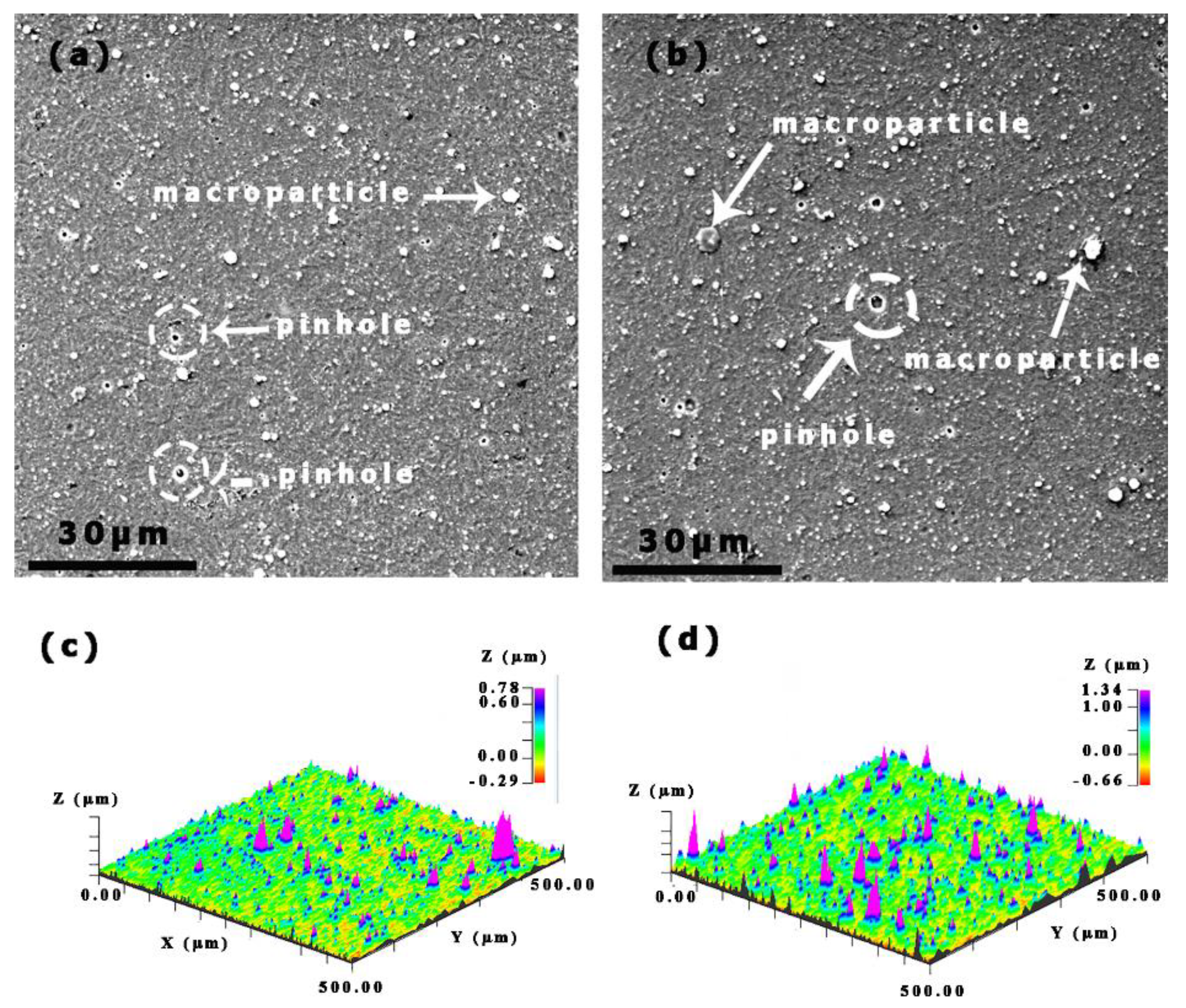

3.1. Coating Morphologies

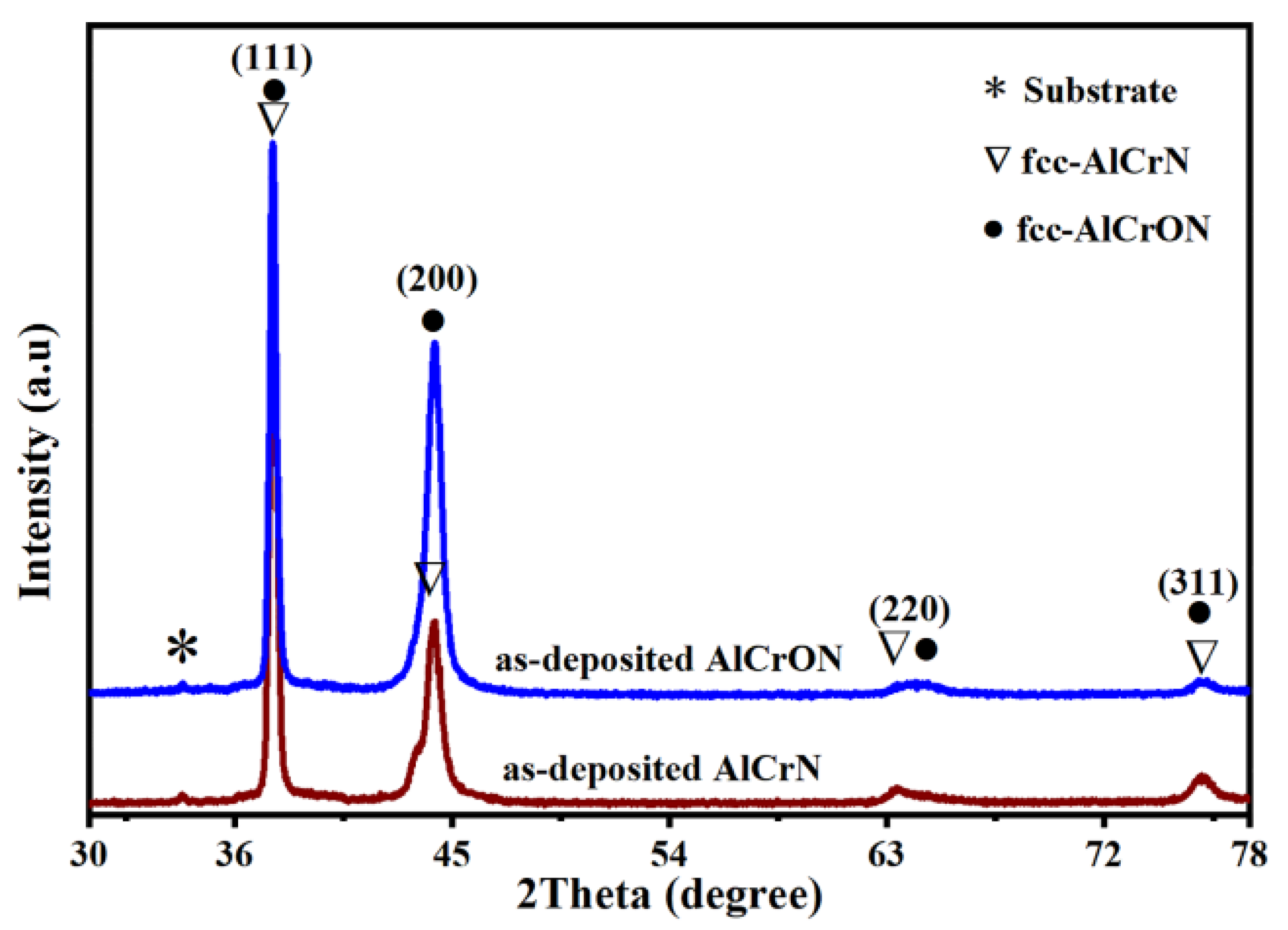

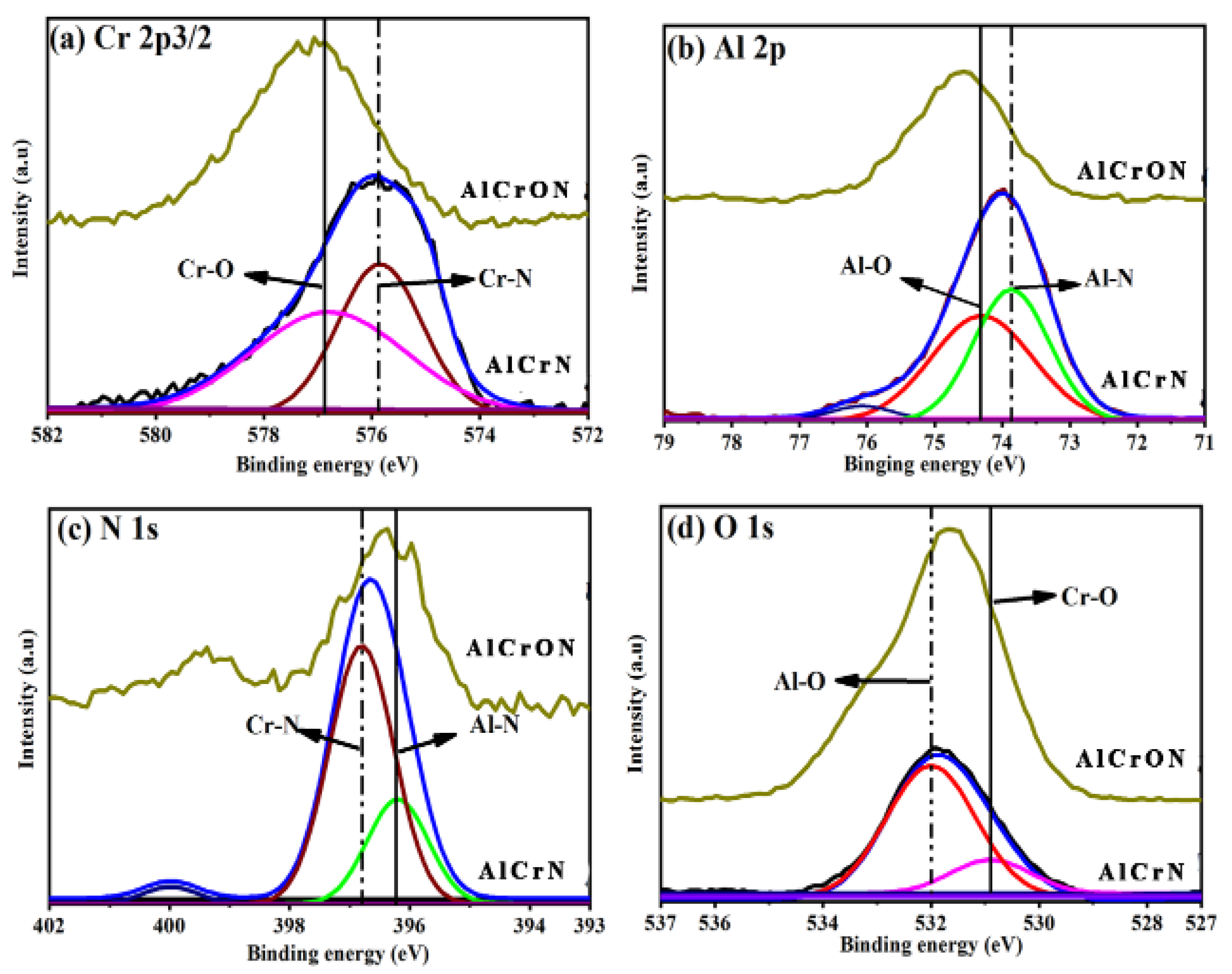

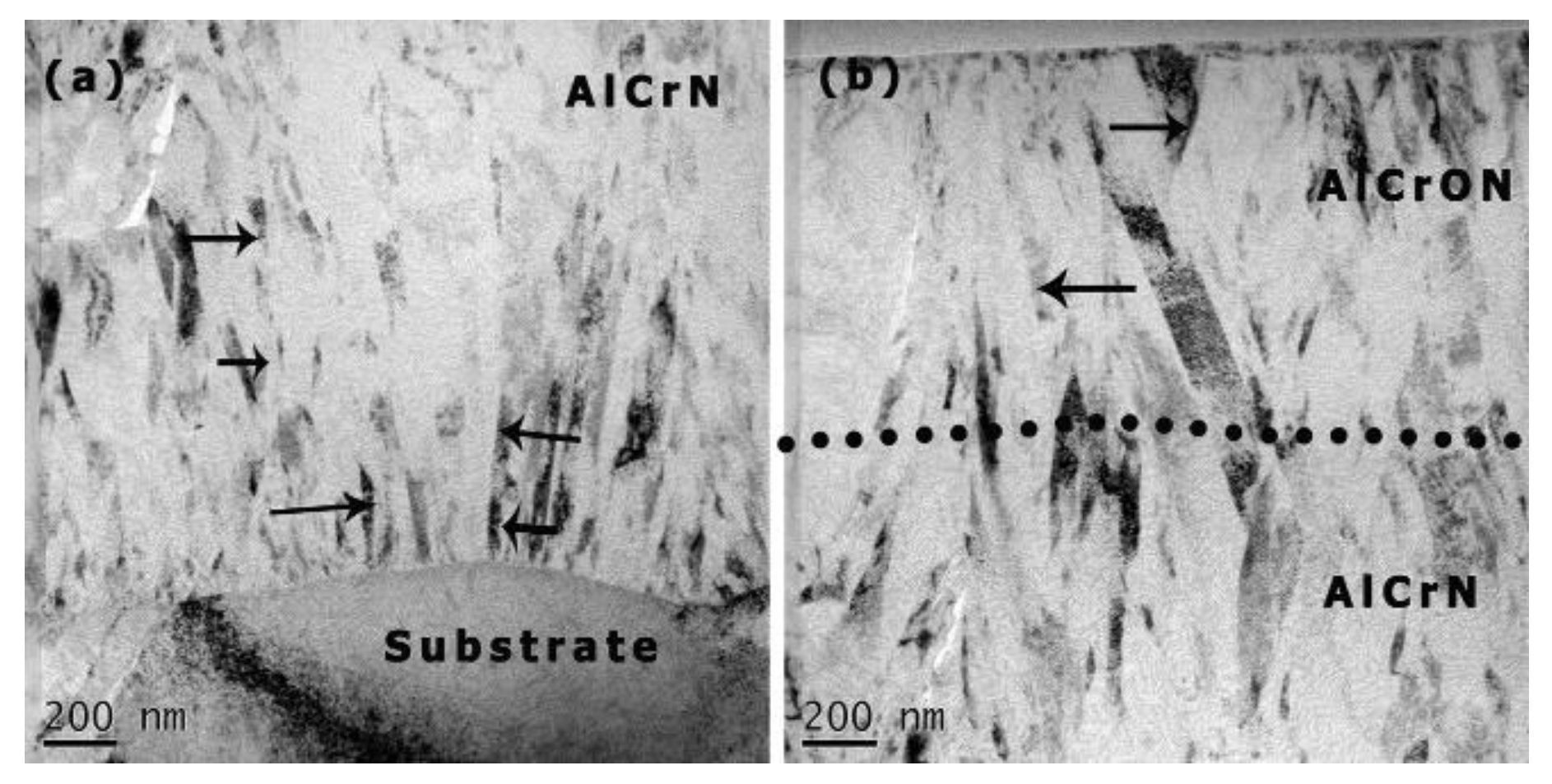

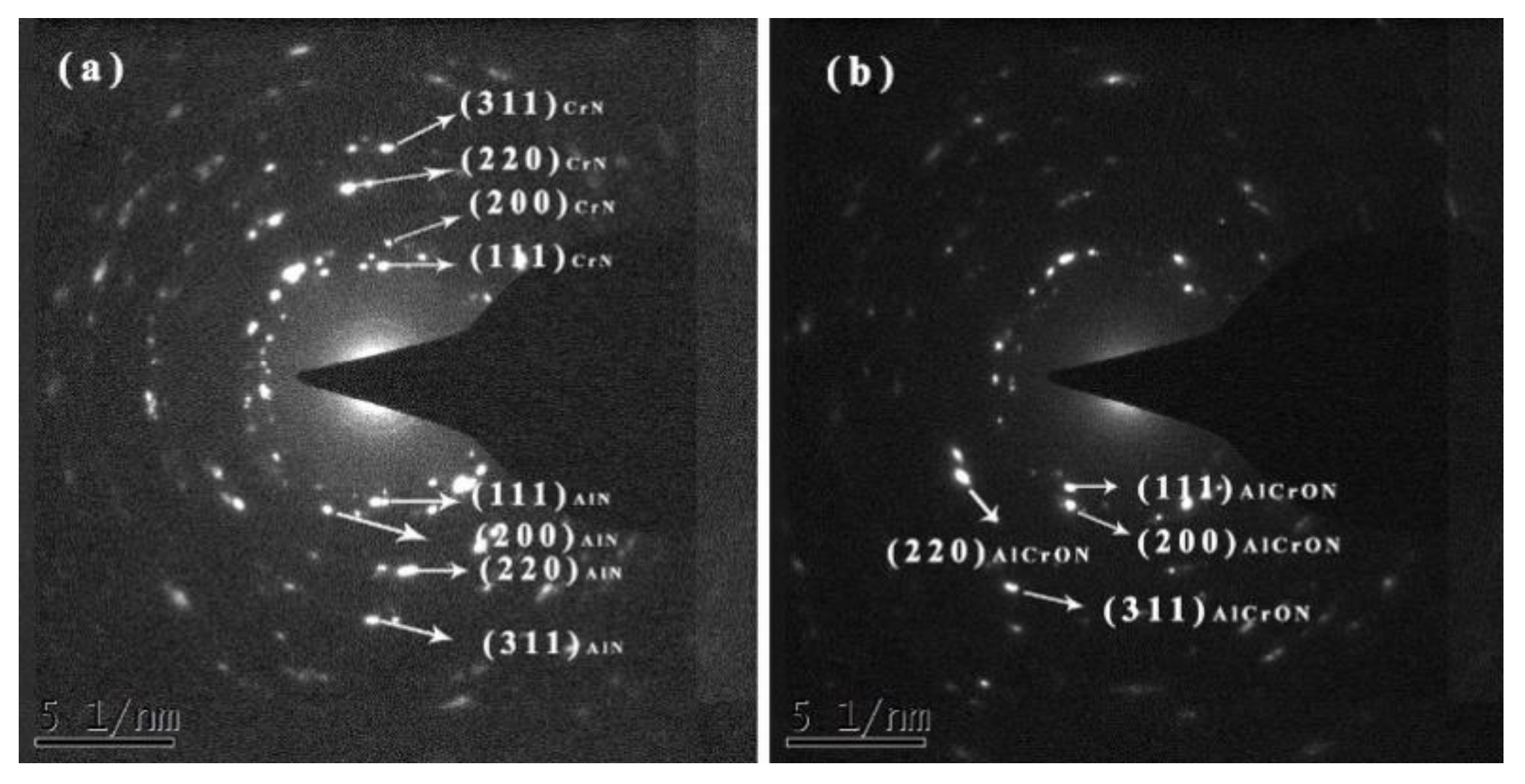

3.2. Microstructure Analysis

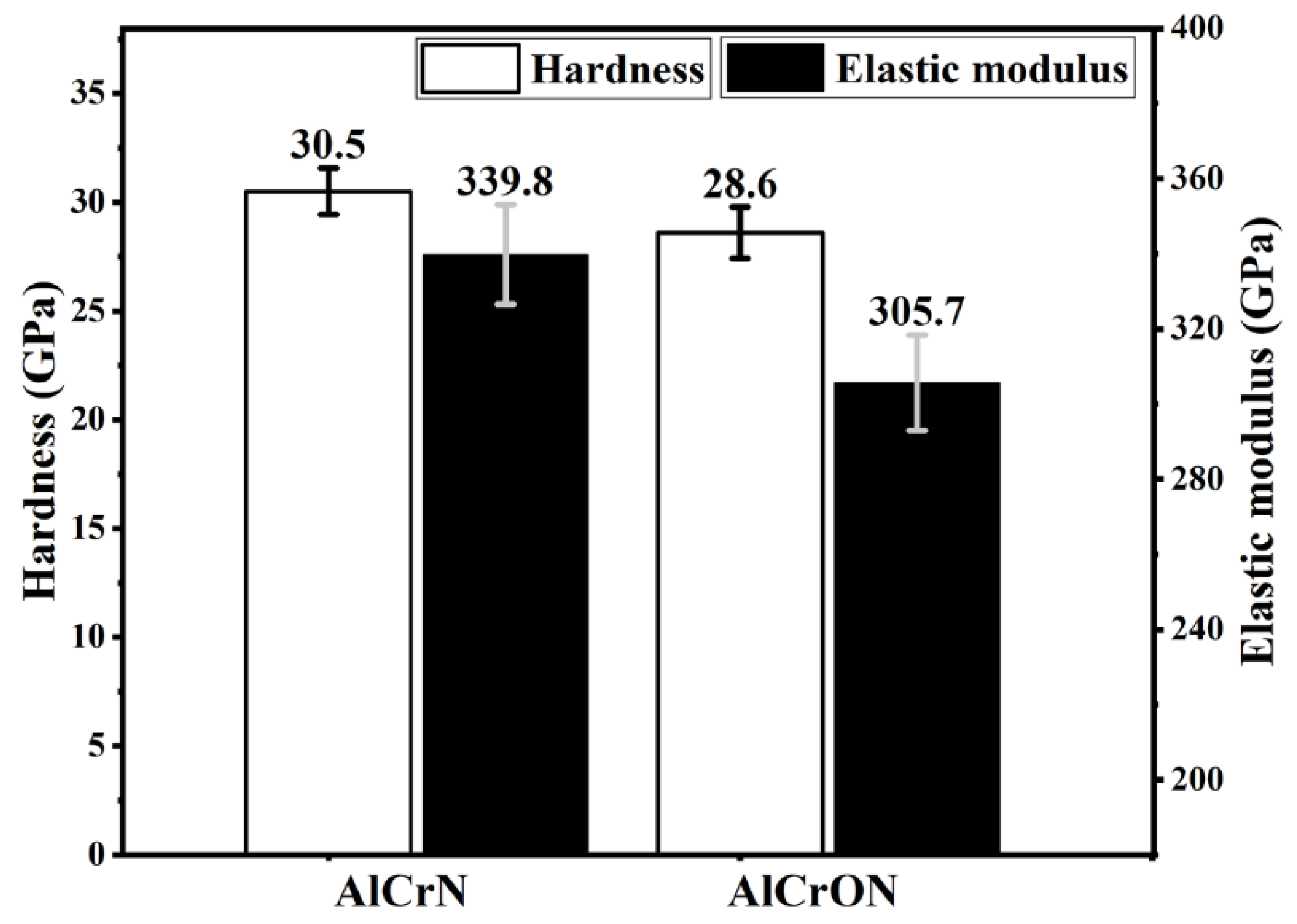

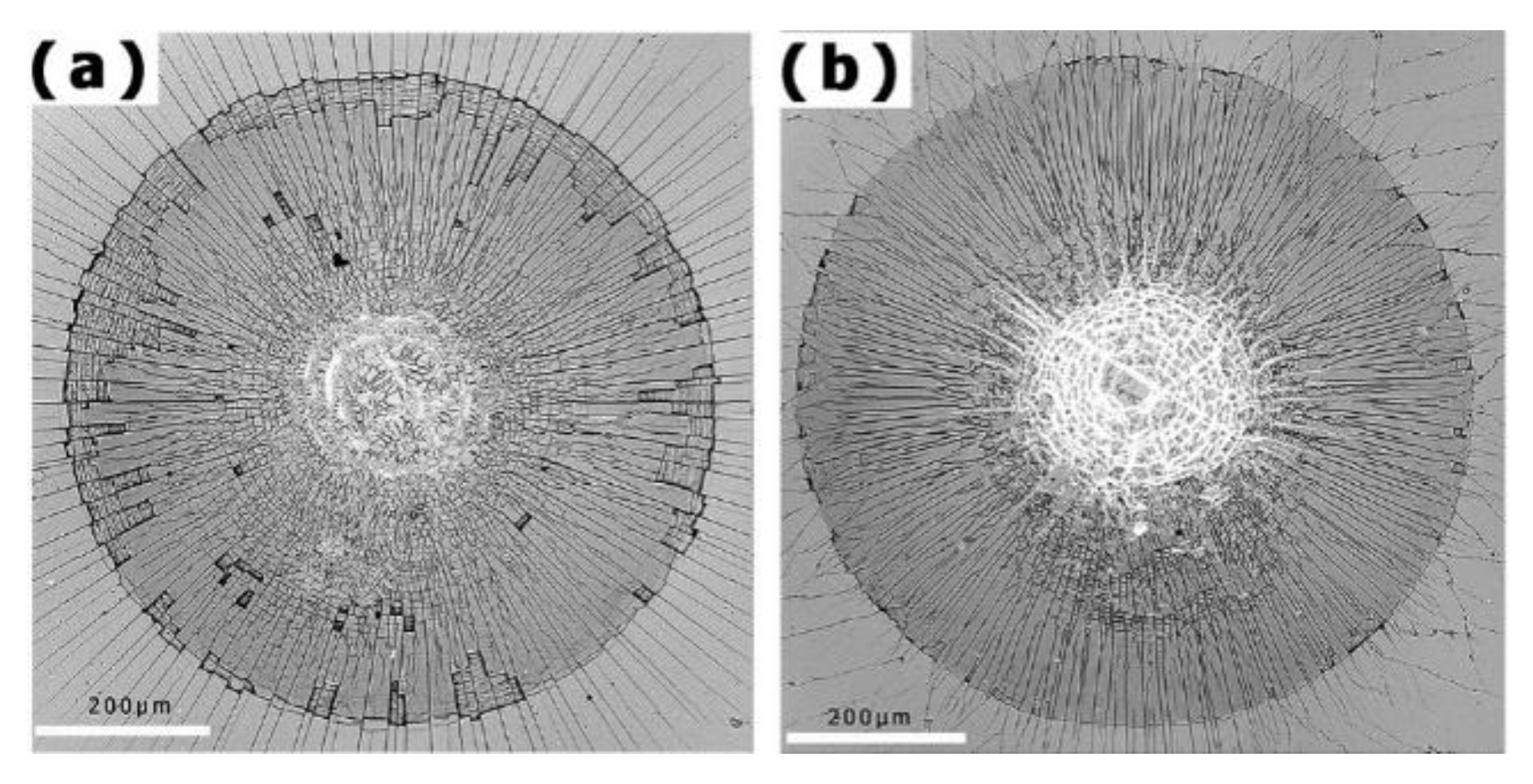

3.3. Mechanical Properties

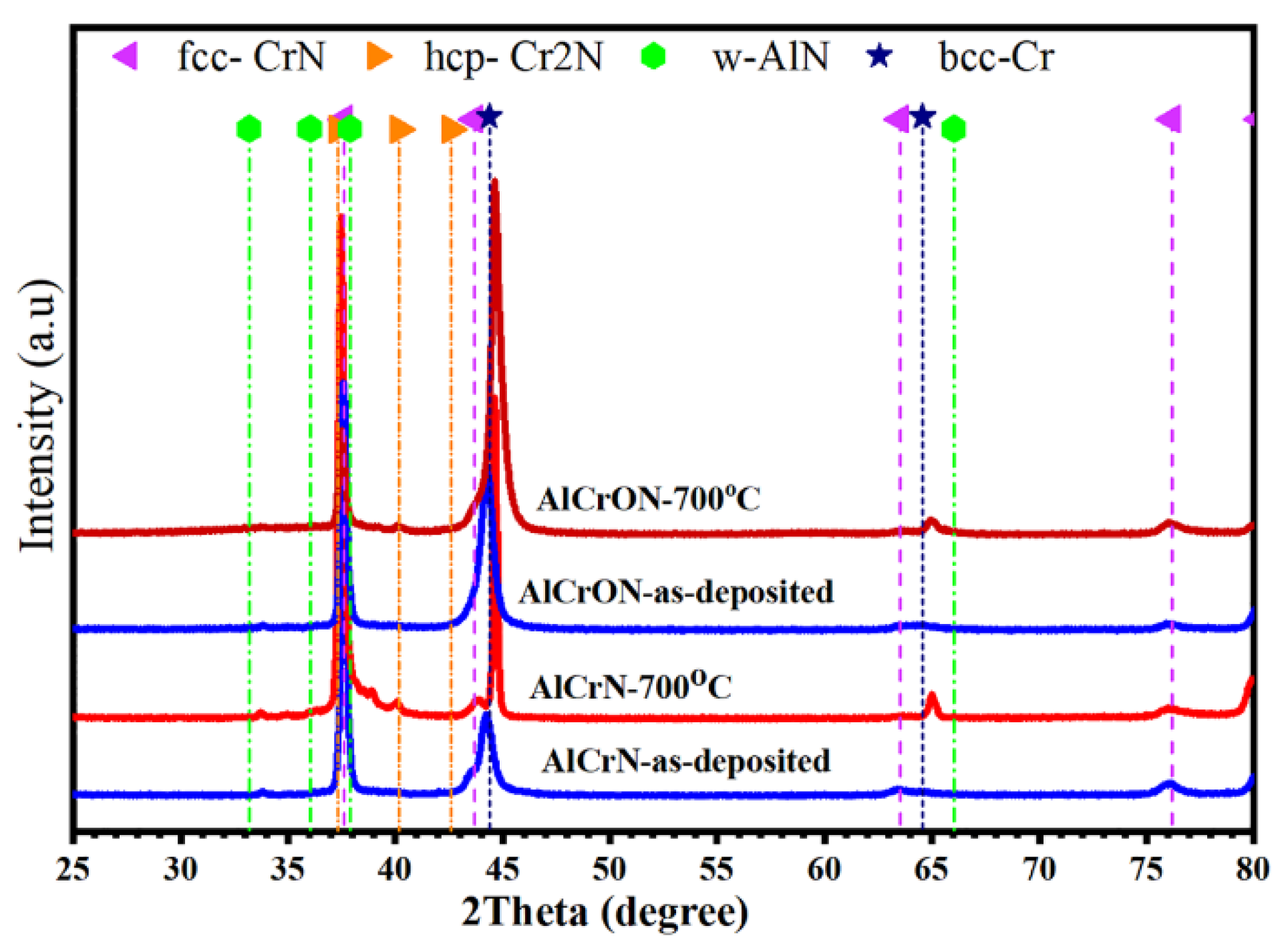

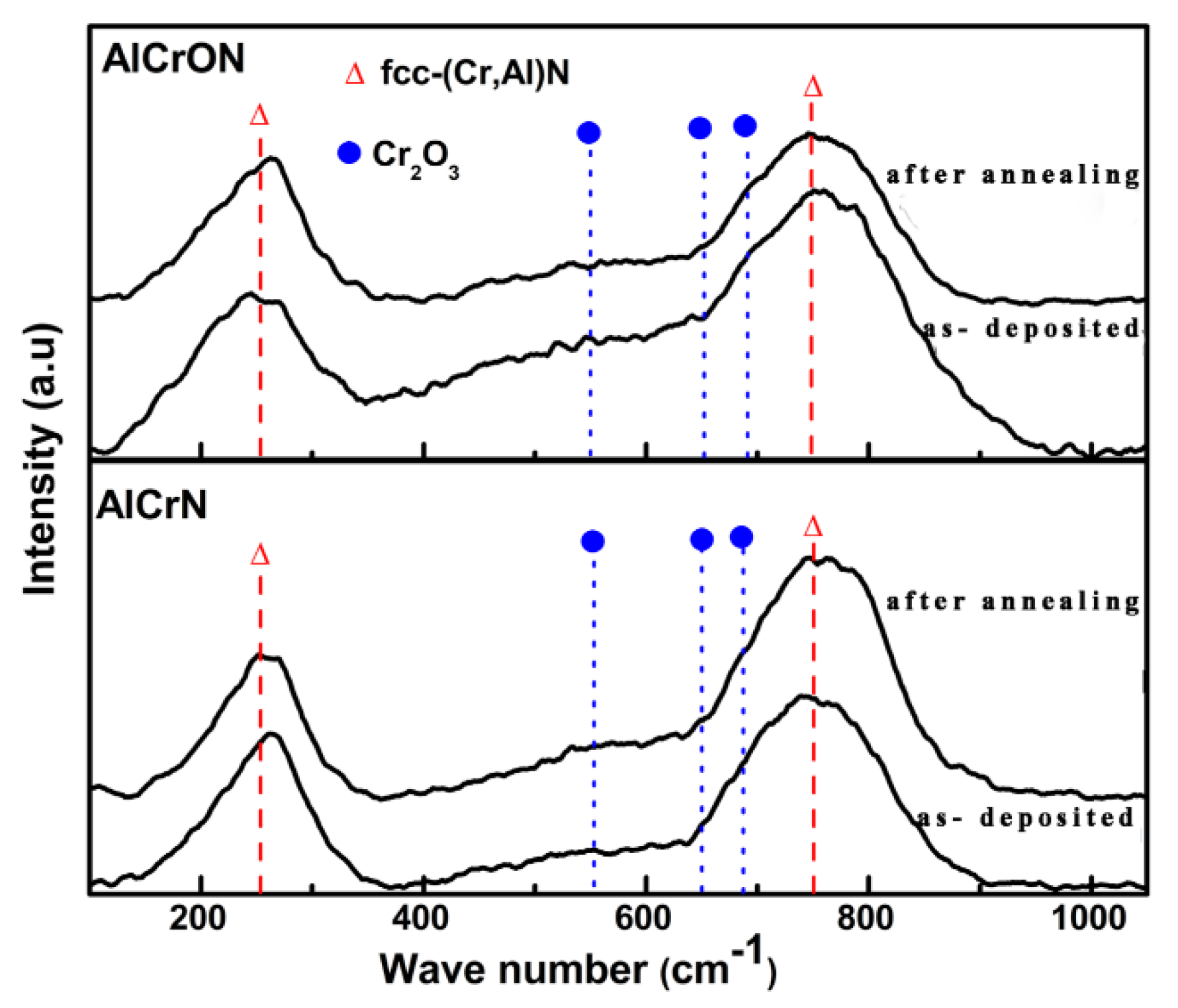

3.4. Thermal Stability

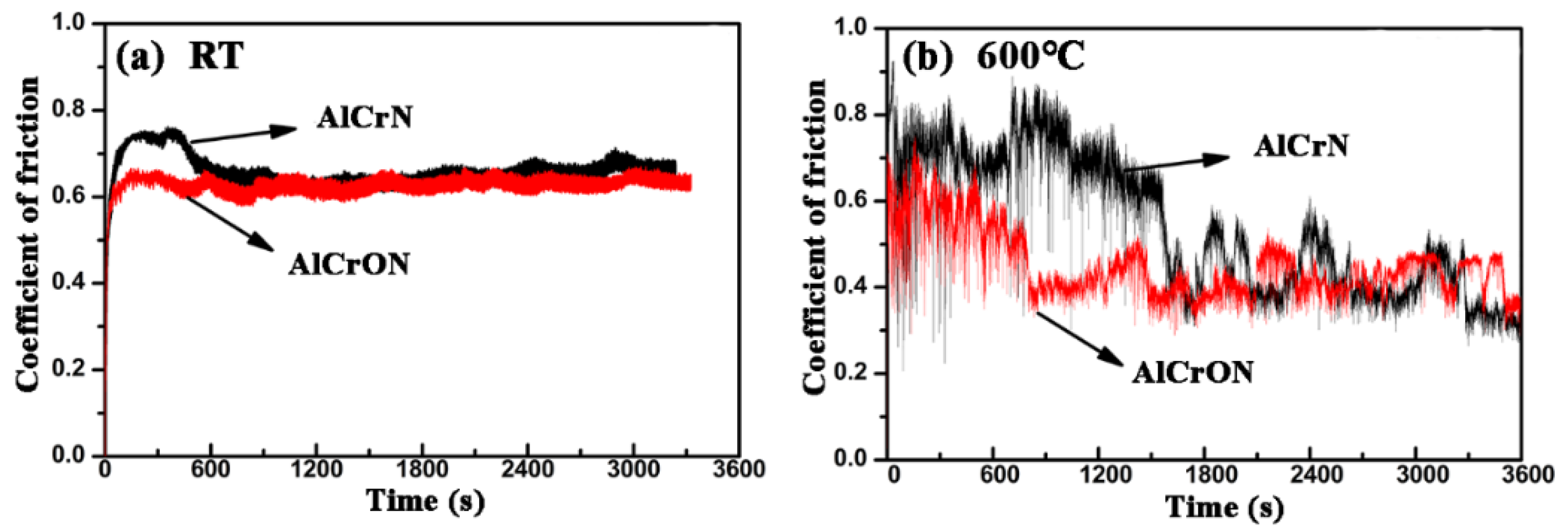

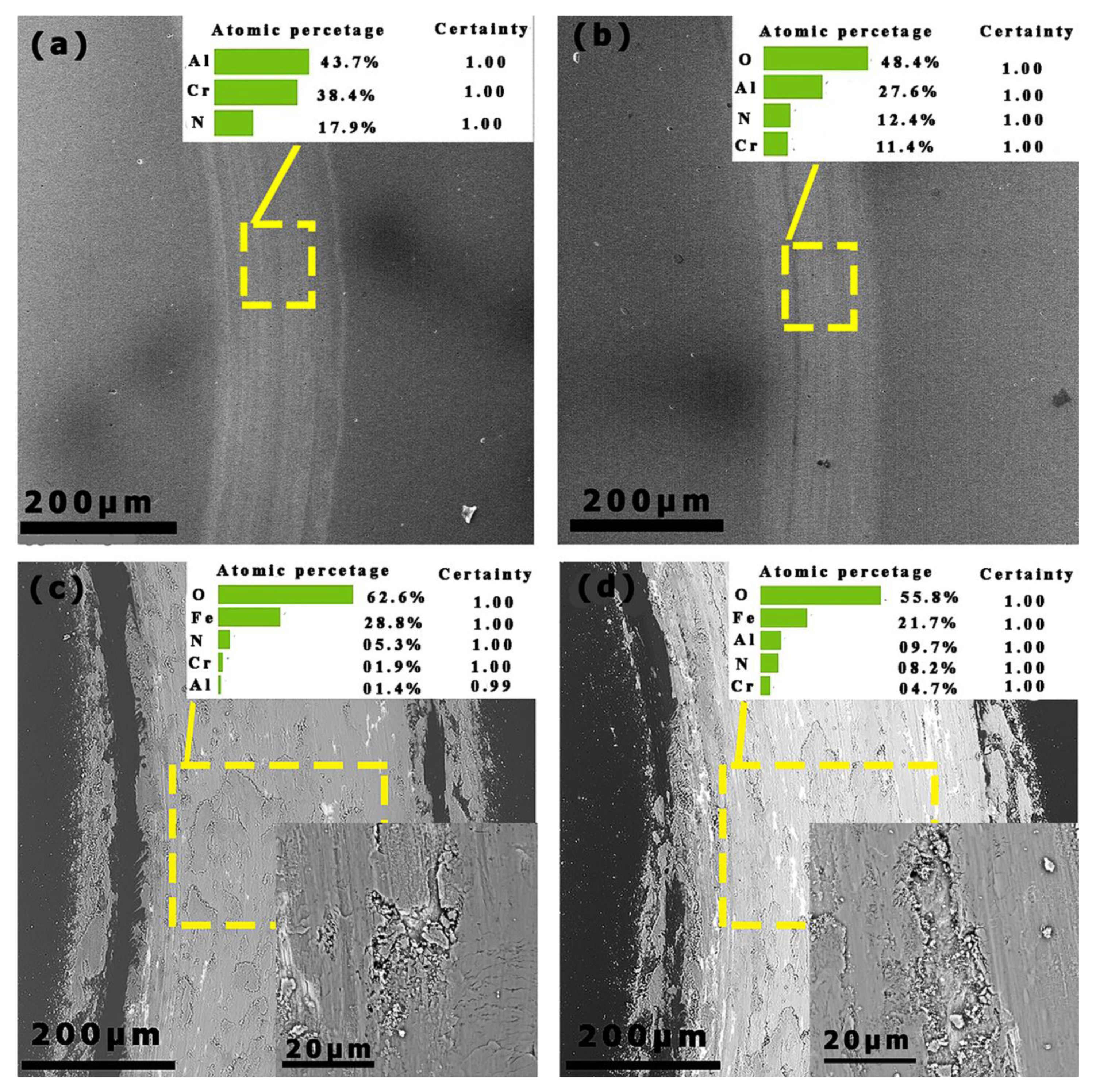

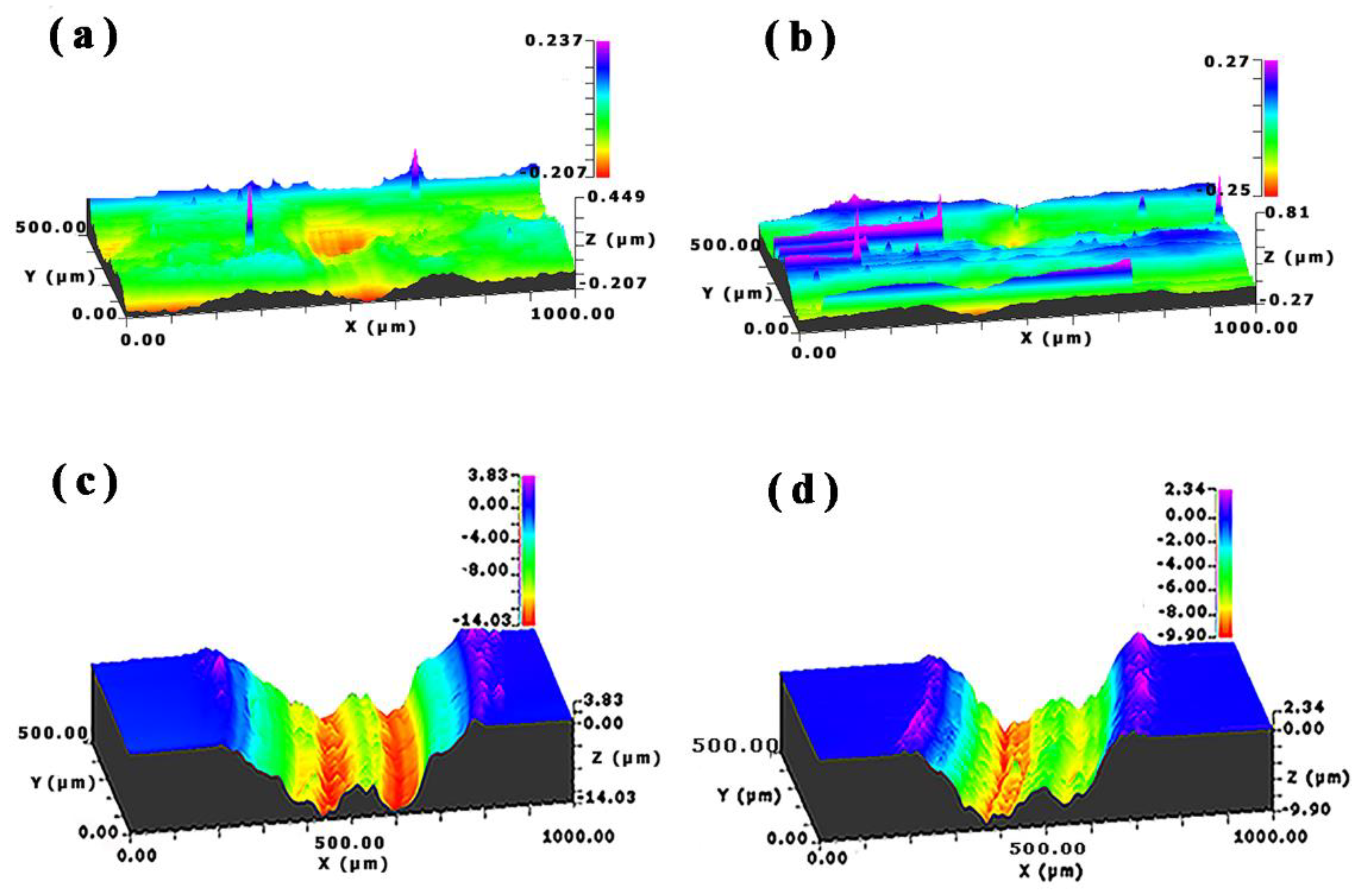

3.5. Tribological Properties

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Chen, Z.; Jahedi, M. Die erosion and its effect on soldering formation in high pressure die casting of aluminium alloys. Mater. Des. 1999, 20, 303–309. [Google Scholar] [CrossRef]

- Cundari, T. Experimental Study about Thermal Fatigue and Erosion Failures on HPDC Dies; Universita’ Degli Studi di Padova: Padova, Italy, 2016. [Google Scholar]

- Dasaratha Prabhu, B.; Ramesh Babu, K. Investigating the significance of parameters affecting the defects in HPDC component using design of experiment method. IOSR J. Environ. Sci. Toxicol. Food Technol. 2013, 4, 4–9. [Google Scholar] [CrossRef]

- Soković, M.; Panjan, P.; Kim, R. Possibilities of improvement of dies casting tools with duplex treatment. Proc. J. Mater. Process. Technol. 2004, 157–158, 613–616. [Google Scholar] [CrossRef]

- Navinšek, B.; Panjan, P.; Gorenjak, F. Improvement of hot forging manufacturing with PVD and DUPLEX coatings. Surf. Coat. Technol. 2001, 137, 255–264. [Google Scholar] [CrossRef]

- Jerina, J.; Kalin, M. Aluminium-alloy transfer to a CrN coating and a hot-work tool steel at room and elevated temperatures. Wear 2014, 340–341, 82–89. [Google Scholar] [CrossRef]

- Mitterer, C.; Holler, F.; Üstel, F.; Heim, D. Application of hard coatings in aluminium die casting—Soldering, erosion and thermal fatigue behaviour. Surf. Coat. Technol. 2000, 125, 233–239. [Google Scholar] [CrossRef]

- Birol, Y. Sliding wear of CrN, AlCrN and AlTiN coated AISI H13 hot work tool steels in aluminium extrusion. Tribol. Int. 2013, 57, 101–106. [Google Scholar] [CrossRef]

- Bobzin, K.; Brögelmann, T.; Hartmann, U.; Kruppe, N.C. Analysis of CrN/AlN/Al2O3 and two industrially used coatings deposited on die casting cores after application in an aluminum die casting machine. Surf. Coat. Technol. 2016, 308, 374–382. [Google Scholar] [CrossRef]

- Cha, S.C.; Erdemir, A. Coatings for Aluminum Die-Casting Dies. In Coating Technology for Vehicle Applications; Springer International Publishing: Basel, Switzerland, 2015; pp. 163–175. [Google Scholar]

- Xiao, B.; Li, H.; Mei, H.; Dai, W.; Zuo, F.; Wu, Z.; Wang, Q. A study of oxidation behavior of AlTiN-and AlCrN-based multilayer coatings. Surf. Coat. Technol. 2018, 333, 229–237. [Google Scholar] [CrossRef]

- Ho, W.Y.; Hsu, P.H.; Lin, C.L. Characteristics of aluminum chromium nitride, and aluminum chromium oxynitride coating through cathodic arc deposition. Key Eng. Mater. 2017, 735, 70–74. [Google Scholar] [CrossRef]

- Chen, W.; Zheng, J.; Meng, X.; Kwon, S.; Zhang, S. Investigation on microstructures and mechanical properties of AlCrN coatings deposited on the surface of plasma nitrocarburized cool-work tool steels. Vacuum 2015, 121, 194–201. [Google Scholar] [CrossRef]

- Stüber, M.; Albers, U.; Leiste, H.; Seemann, K.; Ziebert, C.; Ulrich, S. Magnetron sputtering of hard Cr-Al-N-O thin films. Surf. Coat. Technol. 2008, 203, 661–665. [Google Scholar] [CrossRef]

- Najafi, H.; Karimi, A.; Dessarzin, P.; Morstein, M. Correlation between anionic substitution and structural properties in AlCr(OxN1-x) coatings deposited by lateral rotating cathode arc PVD. Thin Solid Film. 2011, 520, 1597–1602. [Google Scholar] [CrossRef]

- Bobzin, K.; Brögelmann, T.; Kalscheuer, C.; Naderi, M. Hybrid dcMS/HPPMS PVD nitride and oxynitride hard coatings for adhesion and abrasion reduction in plastics processing. Surf. Coat. Technol. 2016, 308, 349–359. [Google Scholar] [CrossRef]

- Bobzin, K.; Brögelmann, T.; Kalscheuer, C.; Liang, T. High temperature oxidation protection of γ-titanium aluminide using (Cr, Al)ON coatings deposited by high-speed physical vapor deposition. Surf. Coat. Technol. 2017, 332, 2–11. [Google Scholar] [CrossRef]

- Bobzin, K.; Brögelmann, T.; Grundmeier, G.; de los Arcos, T.; Wiesing, M.; Kruppe, N.C. (Cr, Al)N/(Cr, Al)ON Oxy-nitride Coatings deposited by Hybrid dcMS/HPPMS for Plastics Processing Applications. Surf. Coat. Technol. 2016, 308, 394–403. [Google Scholar] [CrossRef]

- Pilkington, A.; Dowey, S.J.; Toton, J.T.; Doyle, E.D. Machining with AlCr-oxinitride PVD coated cutting tools. Tribol. Int. 2013, 65, 303–313. [Google Scholar] [CrossRef]

- Veprek, S.; Veprek-Heijman, M.J.G. Industrial applications of superhard nanocomposite coatings. Surf. Coat. Technol. 2008, 202, 5063–5073. [Google Scholar] [CrossRef]

- Veprek, S.; Zhang, R.F.; Veprek-Heijman, M.G.J.; Sheng, S.H.; Argon, A.S. Superhard nanocomposites: Origin of hardness enhancement, properties and applications. Surf. Coat. Technol. 2010, 204, 1898–1906. [Google Scholar] [CrossRef]

- Bagcivan, N.; Bobzin, K.; Brögelmann, T.; Kalscheuer, C. Development of (Cr, Al)ON coatings using middle frequency magnetron sputtering and investigations on tribological behavior against polymers. Surf. Coat. Technol. 2014, 260, 347–361. [Google Scholar] [CrossRef]

- Brögelmann, T.; Bobzin, K.; Kruppe, N.C.; Arghavani, M. Investigation on the influence of oxygen on the deformation and cracking behavior of (Cr, Al)ON hard coatings using combinatorial static and dynamic loadings. J. Vac. Sci. Technol. A 2019, 37, 061509. [Google Scholar] [CrossRef]

- Nohava, J.; Dessarzin, P.; Karvankova, P.; Morstein, M. Characterization of tribological behavior and wear mechanisms of novel oxynitride PVD coatings designed for applications at high temperatures. Tribol. Int. 2015, 81, 231–239. [Google Scholar] [CrossRef]

- Anders, A. A review comparing cathodic arcs and high power impulse magnetron sputtering (HiPIMS). Surf. Coat. Technol. 2014, 257, 308–325. [Google Scholar] [CrossRef]

- Cai, F.; Gao, Y.; Fang, W.; Mao, T.; Zhang, S.H.; Wang, Q.M. Improved adhesion and cutting performance of AlTiSiN coatings by tuning substrate bias voltage combined with Ar ion cleaning pre-treatment. Ceram. Int. 2018, 44, 18894–18902. [Google Scholar] [CrossRef]

- Qi, D.; Lei, H.; Wang, T.; Pei, Z.; Gong, J.; Sun, C. Mechanical, Microstructural and Tribological Properties of Reactive Magnetron Sputtered Cr-Mo-N Films. J. Mater. Sci. Technol. 2015, 31, 55–64. [Google Scholar] [CrossRef]

- Khatibi, A.; Sjölen, J.; Greczynski, G.; Jensen, J.; Eklund, P.; Hultman, L. Structural and mechanical properties of Cr-Al-O-N thin films grown by cathodic arc deposition. Acta Mater. 2012, 60, 6494–6507. [Google Scholar] [CrossRef]

- Castaldi, L.; Kurapov, D.; Reiter, A.; Shklover, V.; Schwaller, P.; Patscheider, J. Effect of the oxygen content on the structure, morphology and oxidation resistance of Cr-O-N coatings. Surf. Coat. Technol. 2008, 203, 545–549. [Google Scholar] [CrossRef]

- Bobzin, K.; Brögelmann, T.; Kruppe, N.C.; Arghavani, M.; Mayer, J.; Weirich, T.E. On the plastic deformation of chromium-based nitride hard coatings deposited by hybrid dcMS/HPPMS: A fundamental study using nanoscratch test. Surf. Coat. Technol. 2016, 308, 298–306. [Google Scholar] [CrossRef]

- Geng, D.; Li, H.; Zhang, Q.; Zhang, X.; Wang, C.; Wu, Z.; Wang, Q. Effect of incorporating oxygen on microstructure and mechanical properties of AlCrSiON coatings deposited by arc ion plating. Surf. Coat. Technol. 2017, 310, 223–230. [Google Scholar] [CrossRef]

- NIST Standard References Data (SRD). Available online: https://srdata.nist.gov/xps/selEnergyType.aspx (accessed on 11 January 2020).

- Barshilia, H.C.; Deepthi, B.; Selvakumar, N.; Jain, A.; Rajam, K.S. Nanolayered multilayer coatings of CrN/CrAlN prepared by reactive DC magnetron sputtering. Appl. Surf. Sci. 2007, 253, 5076–5083. [Google Scholar] [CrossRef]

- Najafi, H.; Karimi, A.; Oveisi, E.; Morstein, M. Structure and electronic properties of AlCrOxN1-X thin films deposited by reactive magnetron sputtering. Thin Solid Film. 2014, 572, 176–183. [Google Scholar] [CrossRef]

- Almandoz, E.; Fuentes, G.G.; Fernández, J.; de Bujanda, J.M.; Rodríguez, R.J.; Pérez-Trujillo, F.J.; Alcalá, G.; Lousa, A.; Qin, Y. Chemical and mechanical stability of air annealed cathodic arc evaporated CrAlON coatings. Surf. Coat. Technol. 2018, 351, 153–161. [Google Scholar] [CrossRef]

- Shaha, K.P.; Rueß, H.; Rotert, S.; To Baben, M.; Music, D.; Schneider, J.M. Nonmetal sublattice population induced defect structure in transition metal aluminum oxynitrides. Appl. Phys. Lett. 2013, 103, 1–6. [Google Scholar] [CrossRef]

- Soldán, J.; Neidhardt, J.; Sartory, B.; Kaindl, R.; Čerstvý, R.; Mayrhofer, P.H.; Tessadri, R.; Polcik, P.; Lechthaler, M.; Mitterer, C. Structure-property relations of arc-evaporated Al-Cr-Si-N coatings. Surf. Coat. Technol. 2008, 202, 3555–3562. [Google Scholar] [CrossRef]

- Haršáni, M.; Ghafoor, N.; Calamba, K.; Zacková, P.; Sahul, M.; Vopát, T.; Satrapinskyy, L.; Čaplovičová, M. Čaplovič Adhesive-deformation relationships and mechanical properties of nc-AlCrN/a-SiNx hard coatings deposited at different bias voltages. Thin Solid Film. 2018, 650, 11–19. [Google Scholar] [CrossRef]

- Panjan, P.; Drnovšek, A.; Kovač, J. Tribological aspects related to the morphology of PVD hard coatings. Surf. Coat. Technol. 2018, 343, 138–147. [Google Scholar] [CrossRef]

- Polcar, T.; Cavaleiro, A. High-temperature tribological properties of CrAlN, CrAlSiN and AlCrSiN coatings. Surf. Coat. Technol. 2011, 206, 1244–1251. [Google Scholar] [CrossRef]

- Polcar, T.; Cavaleiro, A. High temperature properties of CrAlN, CrAlSiN and AlCrSiN coatings—Structure and oxidation. Mater. Chem. Phys. 2011, 129, 195–201. [Google Scholar] [CrossRef]

- Polcar, T.; Parreira, N.M.G.; Novák, R. Friction and wear behaviour of CrN coating at temperatures up to 500 °C. Surf. Coat. Technol. 2007, 201, 5228–5235. [Google Scholar] [CrossRef]

- Adesina, A.Y.; Gasem, Z.M.; Mohammed, A.S. Comparative Investigation and Characterization of the Scratch and Wear Resistance Behavior of TiN, CrN, AlTiN and AlCrN Cathodic Arc PVD Coatings. Arab. J. Sci. Eng. 2019, 44, 10355–10371. [Google Scholar] [CrossRef]

- Souza, P.S.; Santos, A.J.; Cotrim, M.A.P.; Abrão, A.M.; Câmara, M.A. Analysis of the surface energy interactions in the tribological behavior of AlCrN and TiAlN coatings. Tribol. Int. 2020, 146, 106206. [Google Scholar] [CrossRef]

- Antonov, M.; Afshari, H.; Baronins, J.; Adoberg, E.; Raadik, T.; Hussainova, I. The effect of temperature and sliding speed on friction and wear of Si3N4, Al2O3, and ZrO2 balls tested against AlCrN PVD coating. Tribol. Int. 2018, 118, 500–514. [Google Scholar] [CrossRef]

| Coatings | Wear Rate-RT ×10−18 (m3/(N·m)) | Wear Rate-600 °C ×10−16 (m3/(N·m)) |

|---|---|---|

| AlCrN | 0.98 ± 0.02 | 4.5 ± 0.42 |

| AlCrN/AlCrON | 0.77 ± 0.01 | 2.7 ± 0.36 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmad, F.; Zhang, L.; Zheng, J.; Sidra, I.; Zhang, S. Characterization of AlCrN and AlCrON Coatings Deposited on Plasma Nitrided AISI H13 Steels Using Ion-Source-Enhanced Arc Ion Plating. Coatings 2020, 10, 306. https://doi.org/10.3390/coatings10040306

Ahmad F, Zhang L, Zheng J, Sidra I, Zhang S. Characterization of AlCrN and AlCrON Coatings Deposited on Plasma Nitrided AISI H13 Steels Using Ion-Source-Enhanced Arc Ion Plating. Coatings. 2020; 10(4):306. https://doi.org/10.3390/coatings10040306

Chicago/Turabian StyleAhmad, Farooq, Lin Zhang, Jun Zheng, Iram Sidra, and Shihong Zhang. 2020. "Characterization of AlCrN and AlCrON Coatings Deposited on Plasma Nitrided AISI H13 Steels Using Ion-Source-Enhanced Arc Ion Plating" Coatings 10, no. 4: 306. https://doi.org/10.3390/coatings10040306

APA StyleAhmad, F., Zhang, L., Zheng, J., Sidra, I., & Zhang, S. (2020). Characterization of AlCrN and AlCrON Coatings Deposited on Plasma Nitrided AISI H13 Steels Using Ion-Source-Enhanced Arc Ion Plating. Coatings, 10(4), 306. https://doi.org/10.3390/coatings10040306