Reducing Static and Impact Ice Adhesion with a Self-Lubricating Icephobic Coating (SLIC)

Abstract

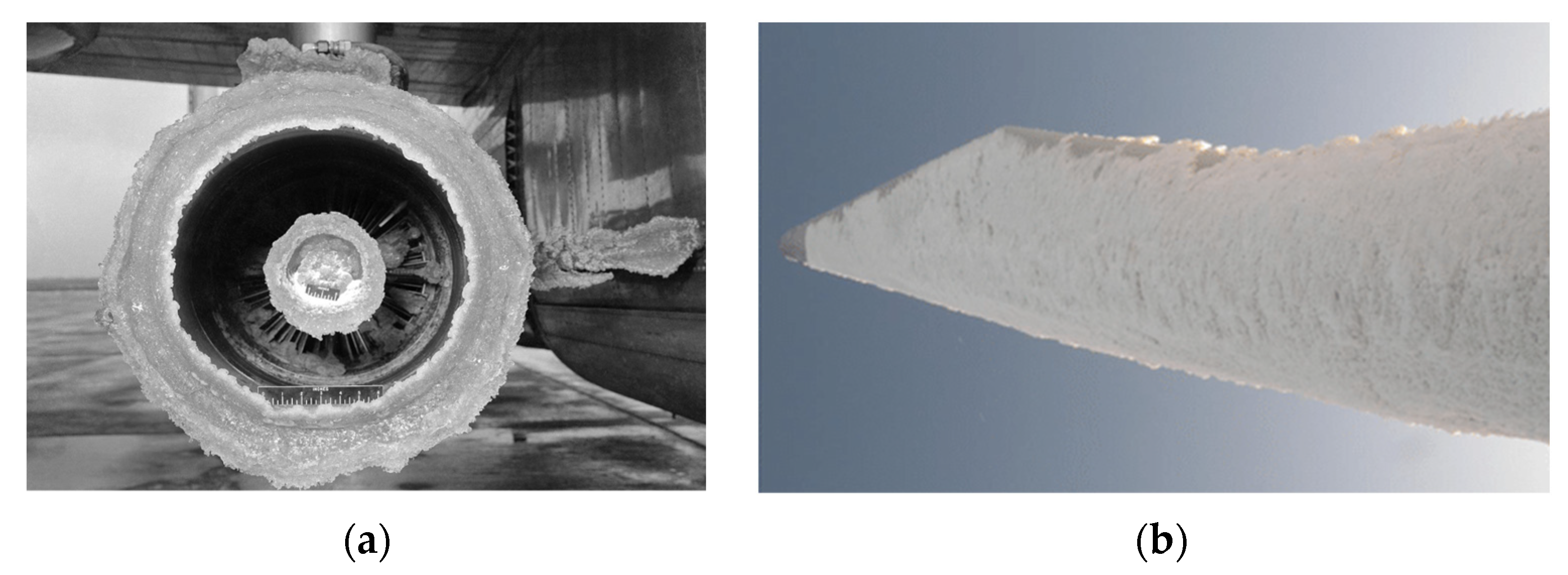

1. Introduction

2. Materials and Methods

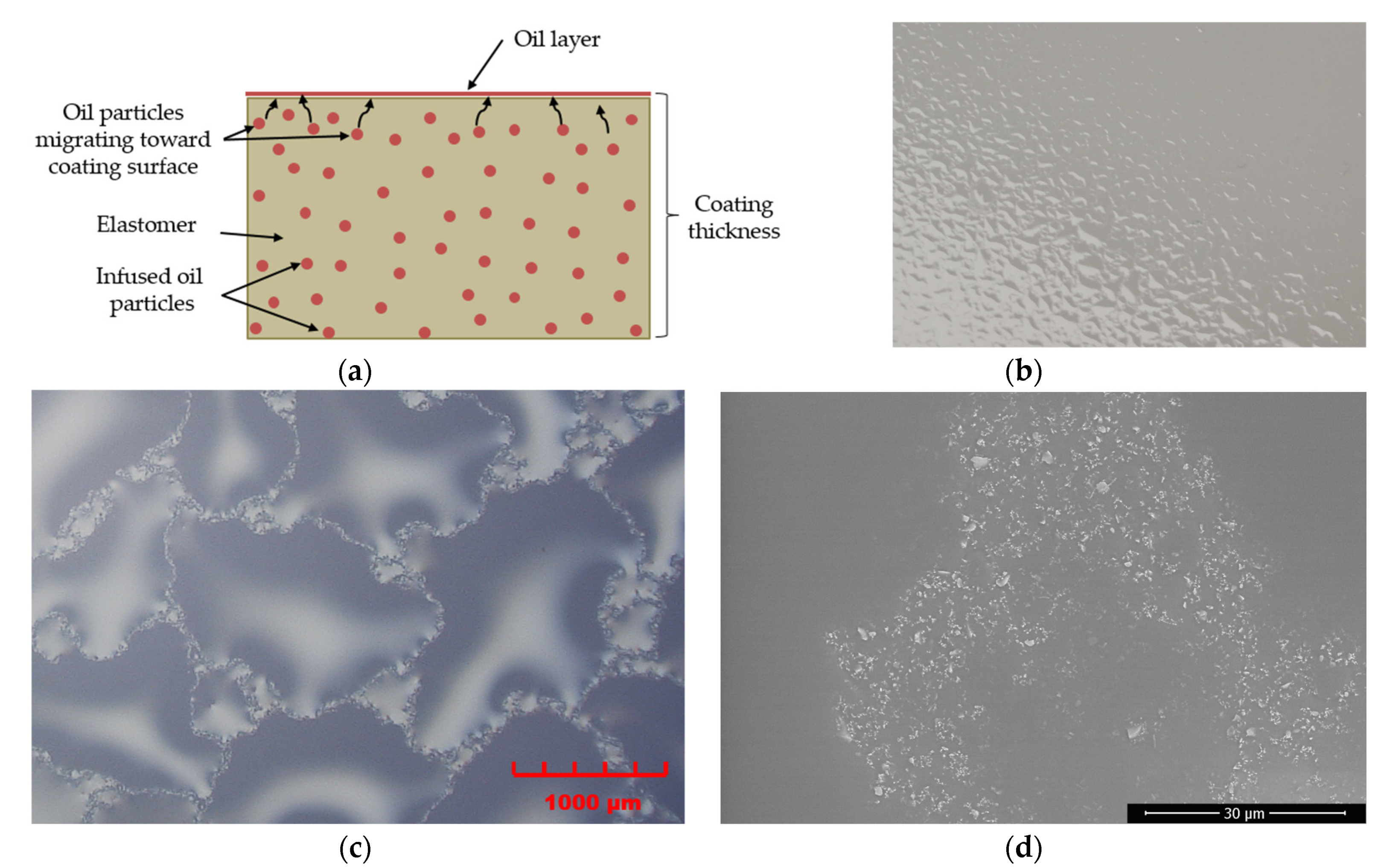

2.1. Tested Surfaces

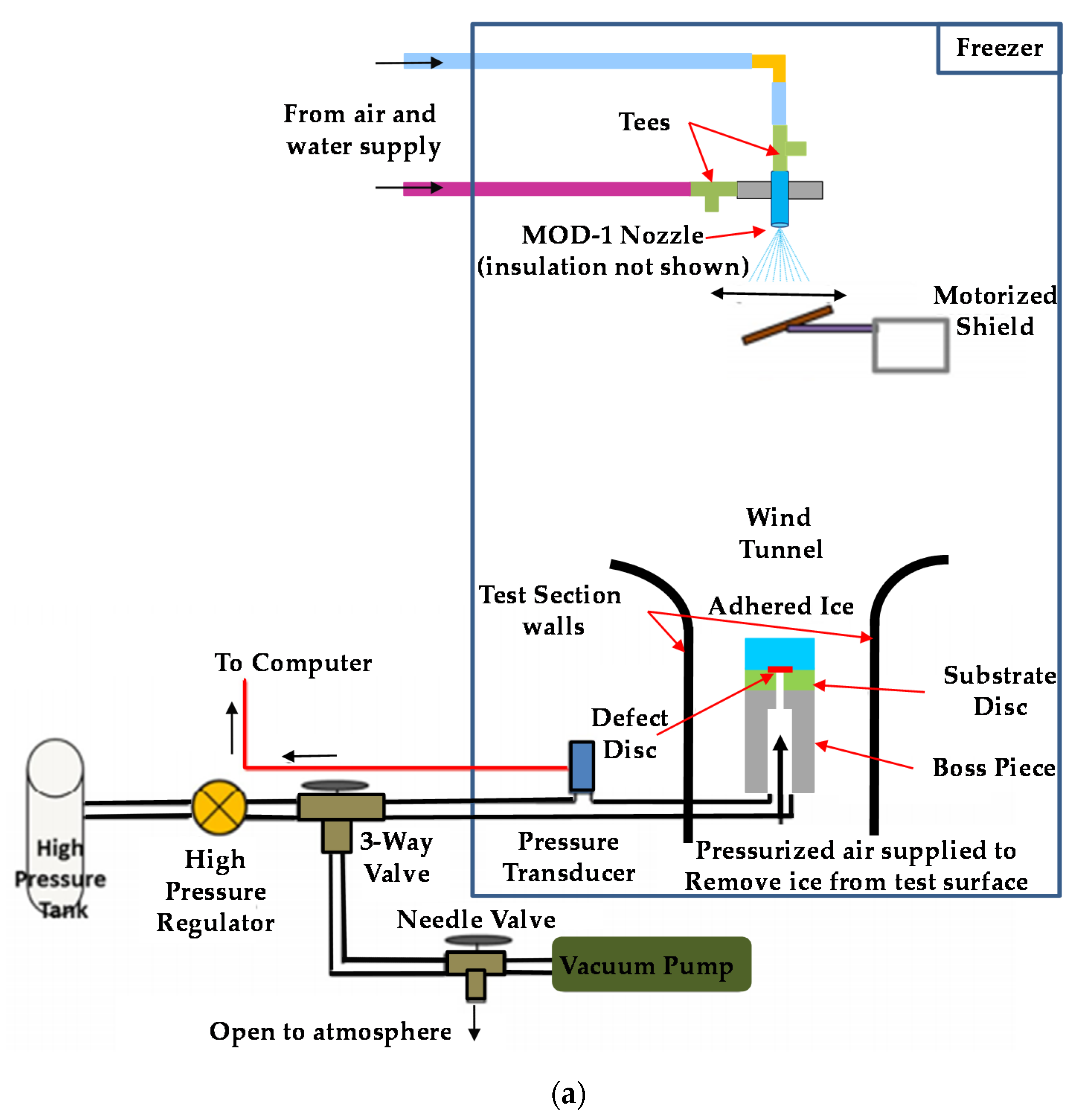

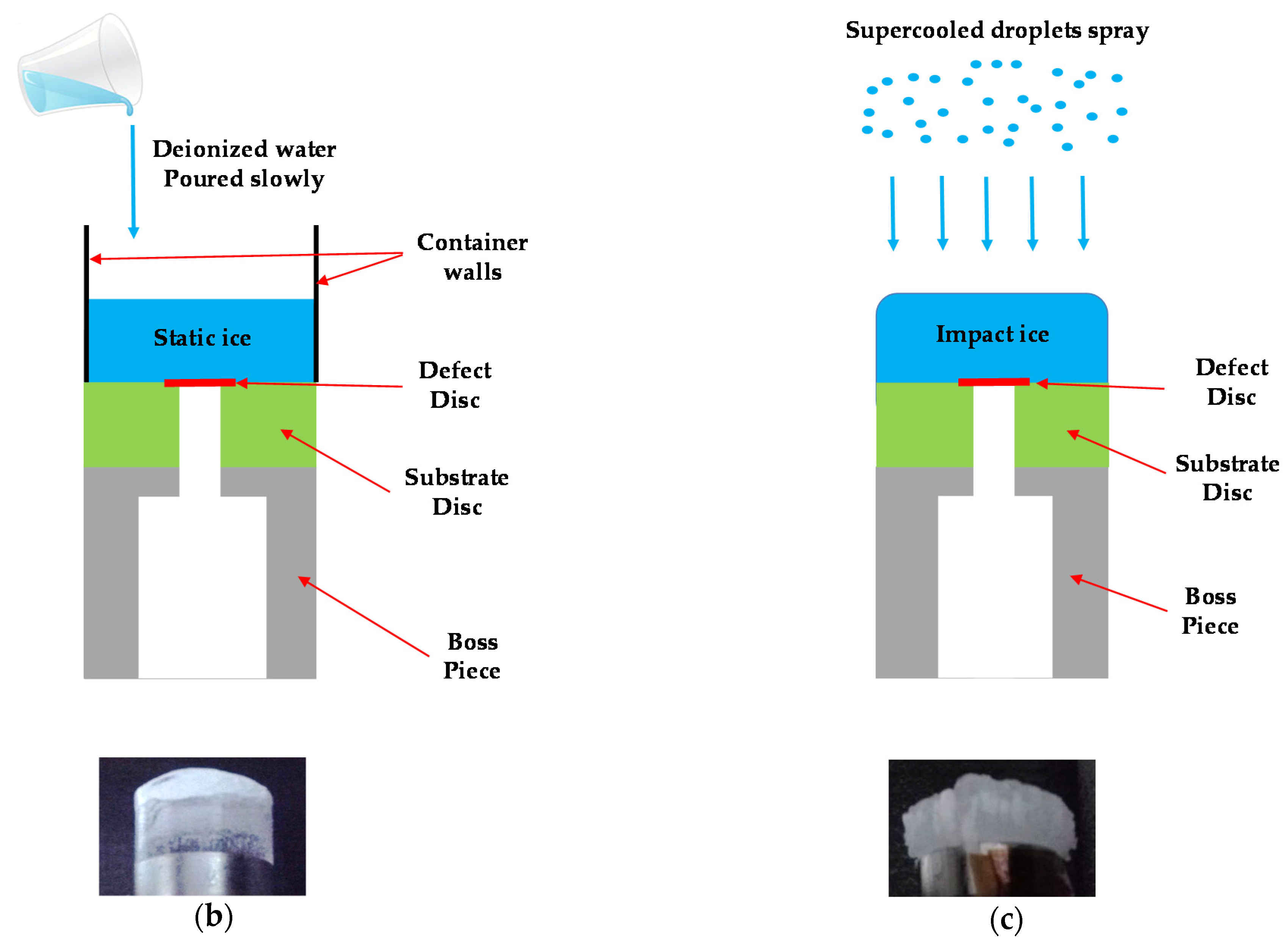

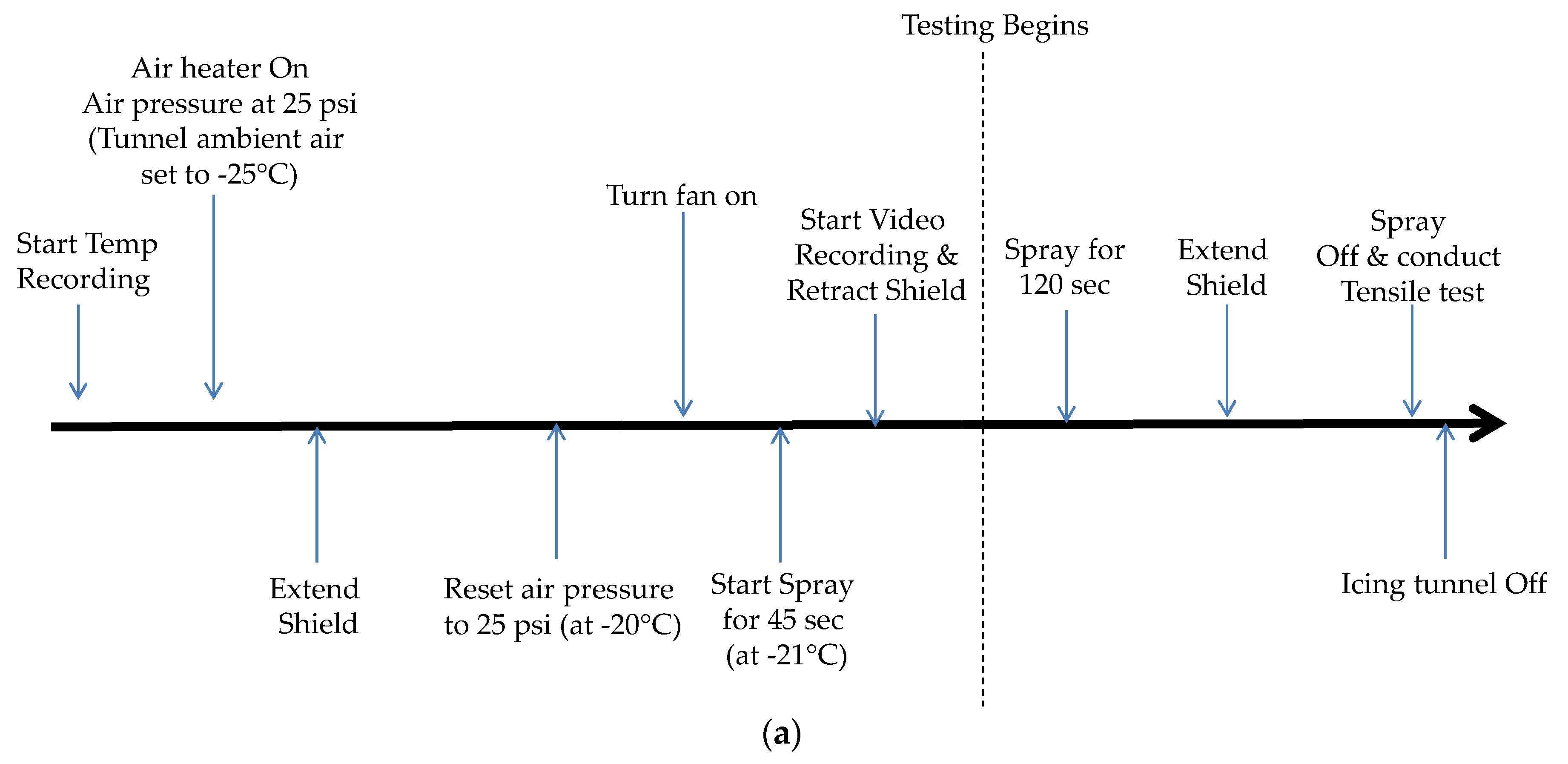

2.2. Ice Tensile Facility

2.3. Ice Tensile Test Procedures

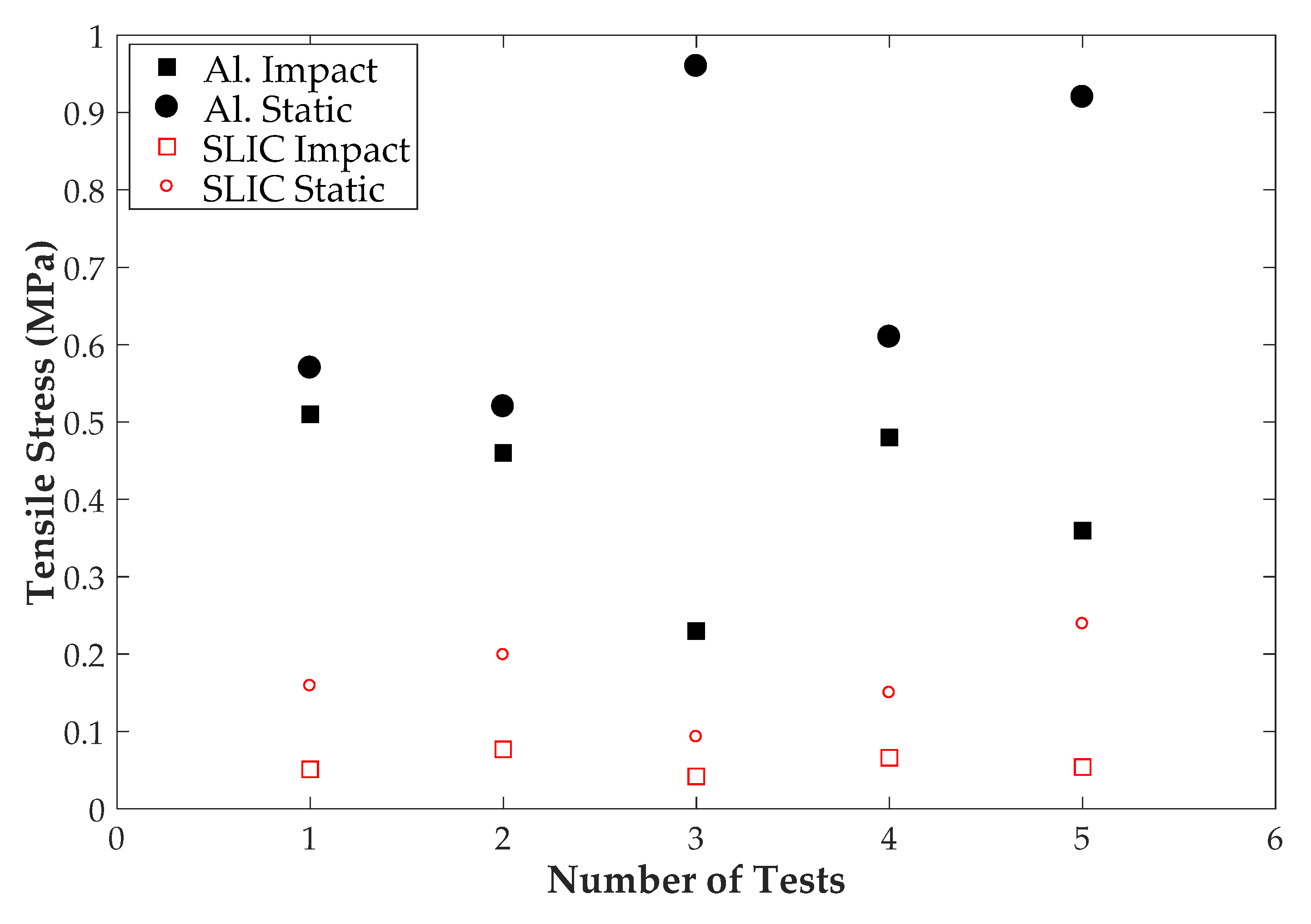

3. Results and Discussion

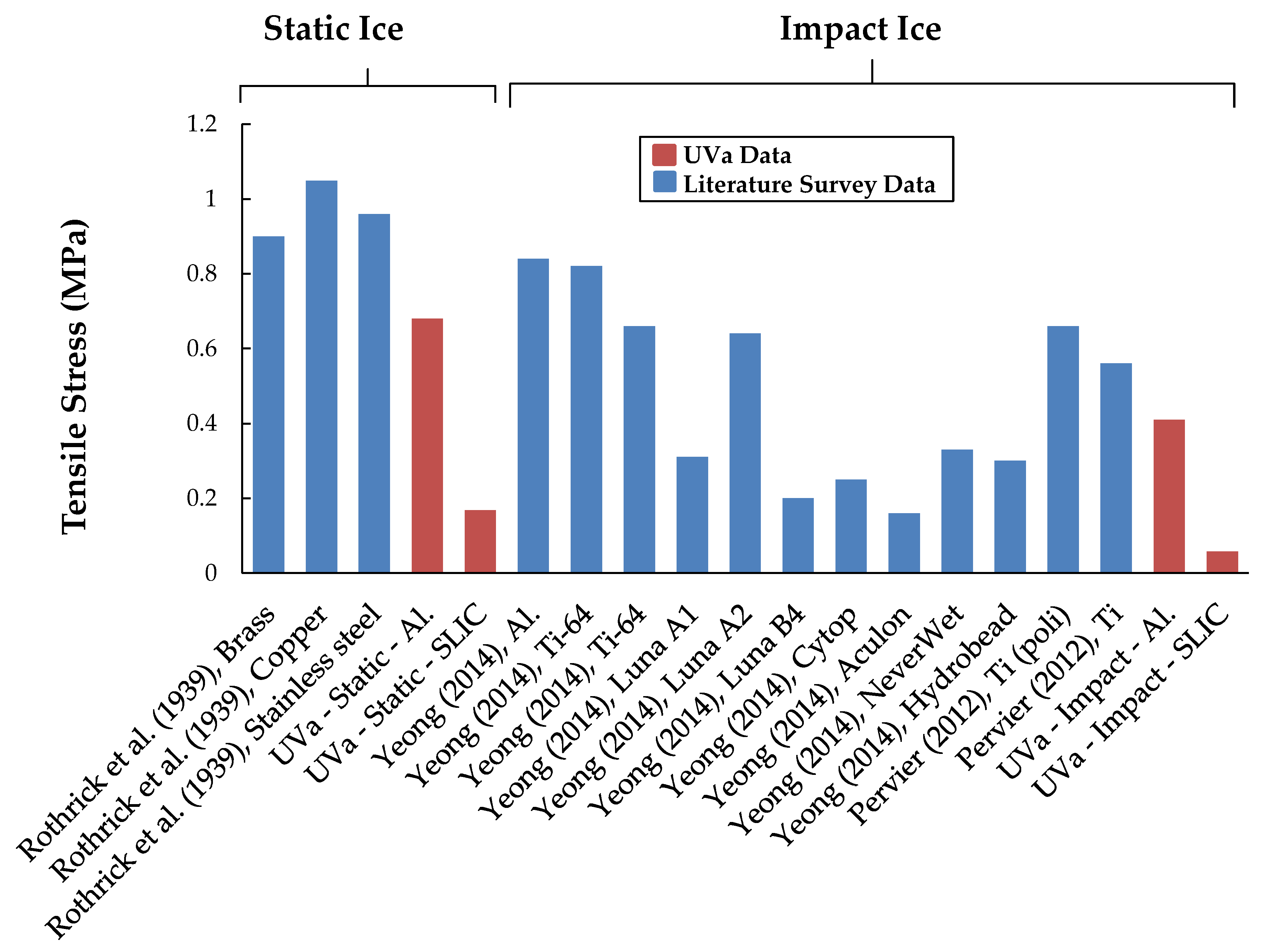

3.1. Tensile Adhesion Test Results

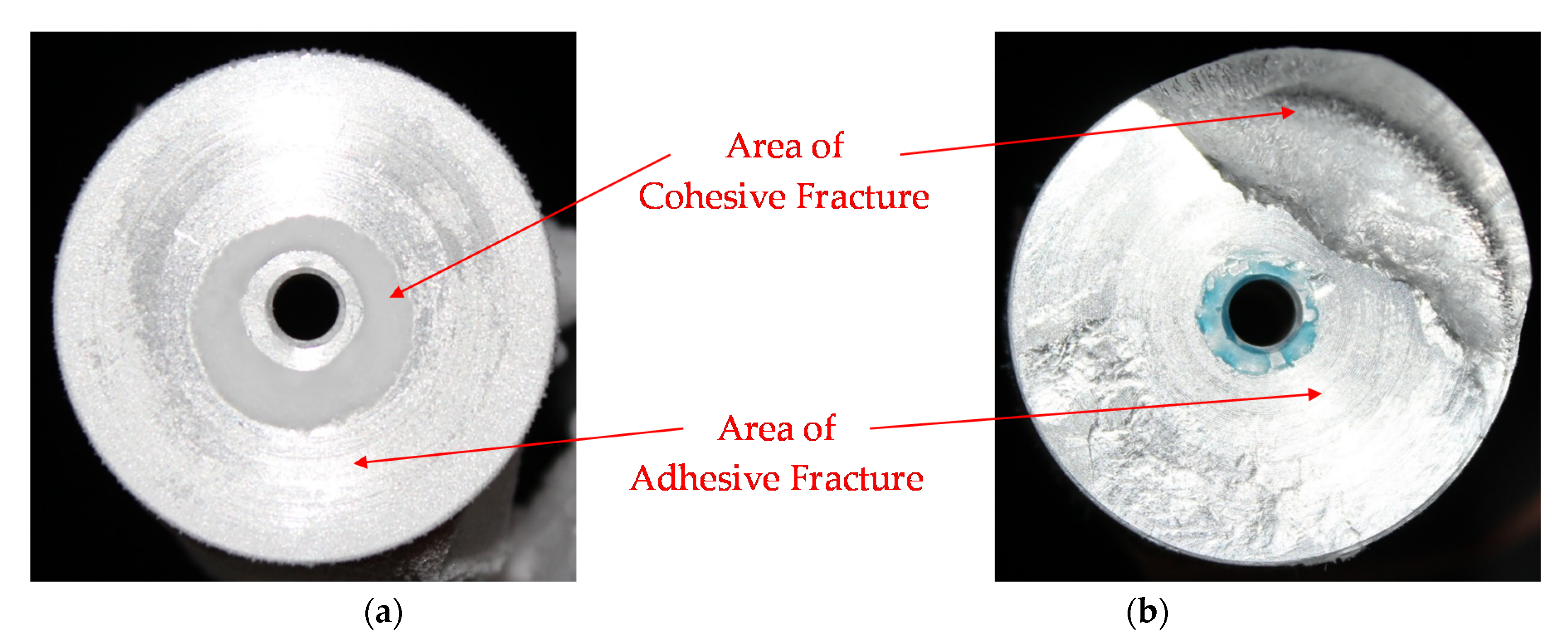

- A full cohesive fracture (leaving a complete layer of ice residue on the surface)

- A full adhesive fracture (leaving no ice residue on the surface)

- A mixed-mode fracture (leaving ice residue on only part of the surface)

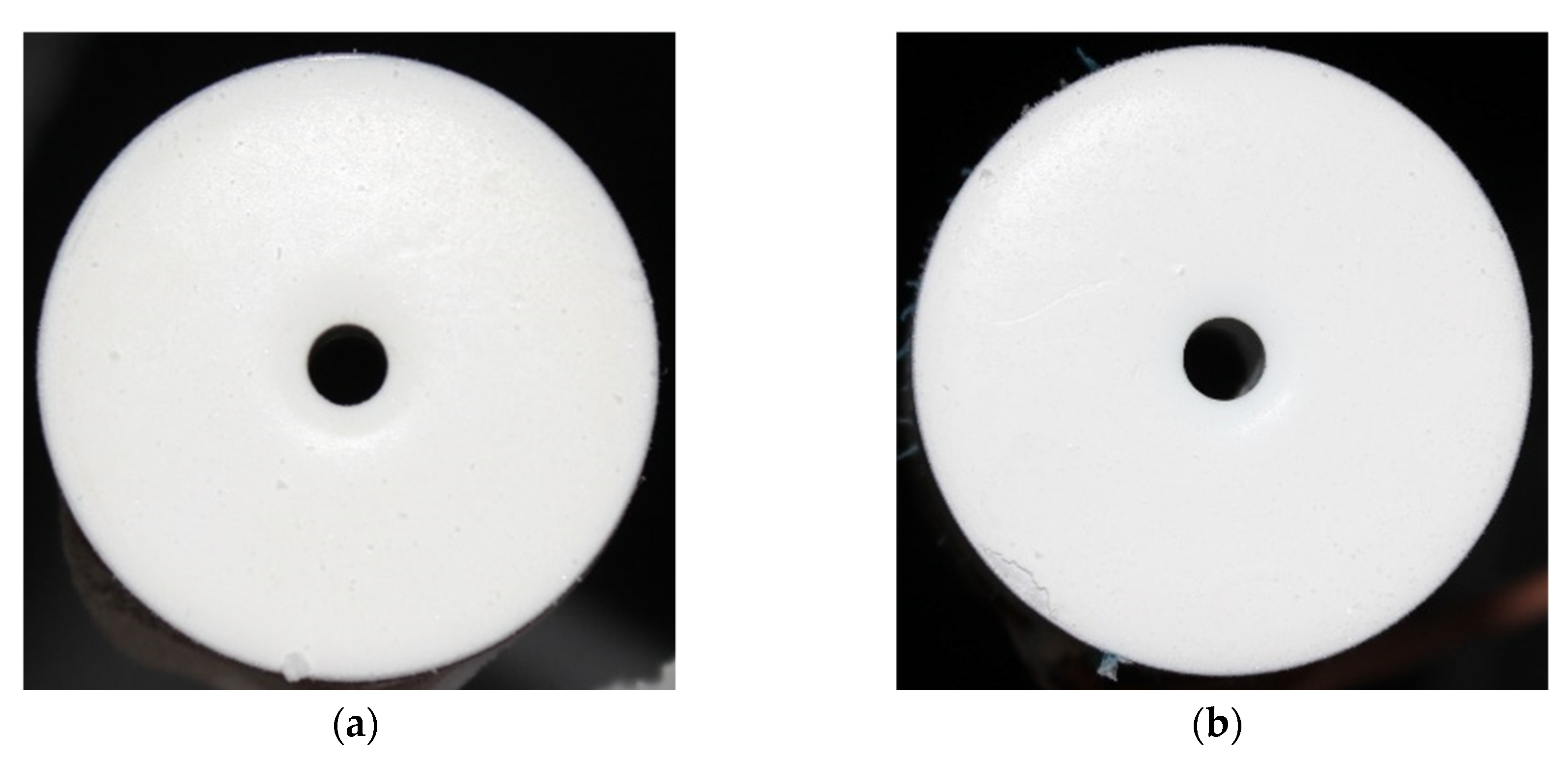

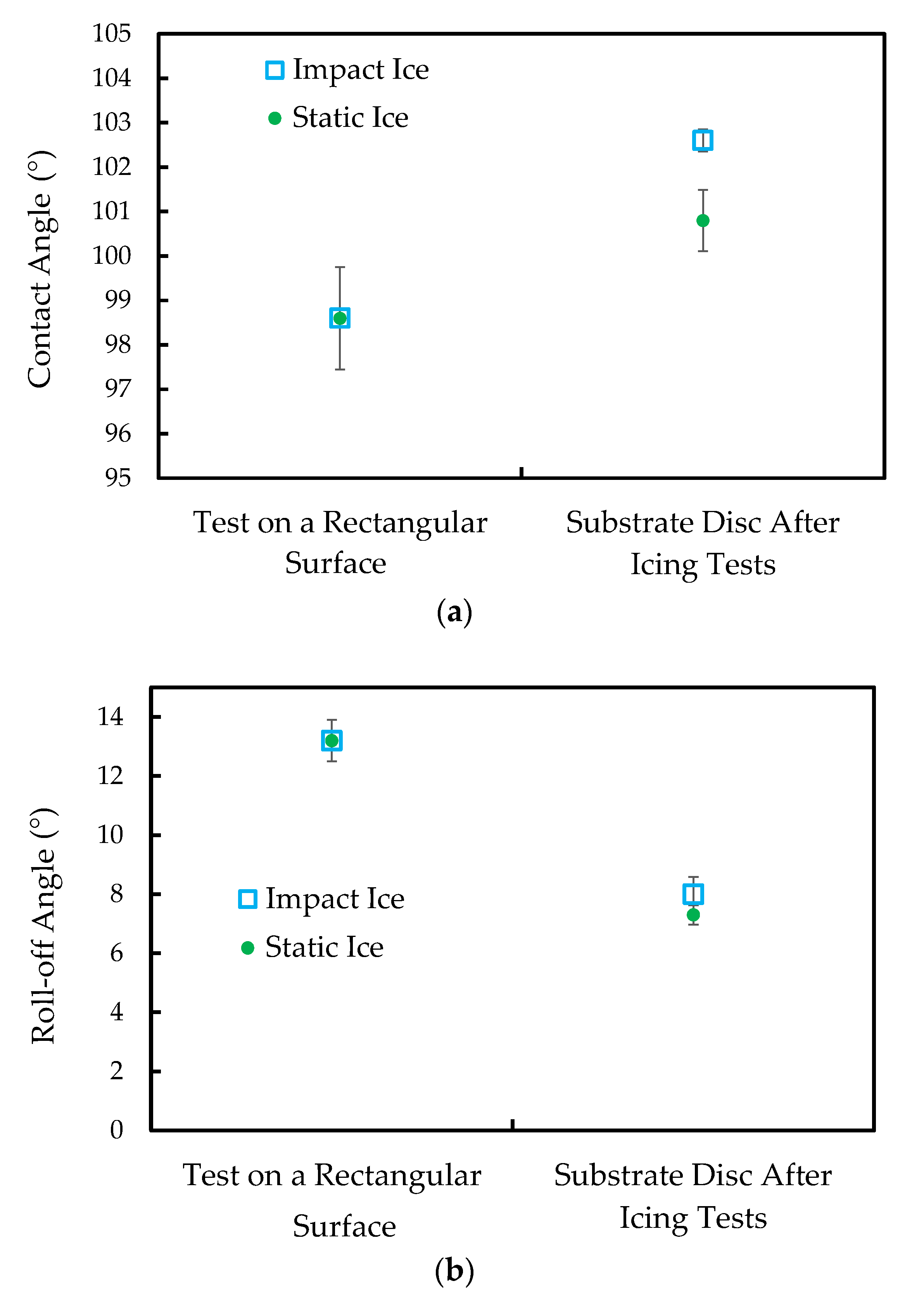

3.2. Durability of Wetting Properties

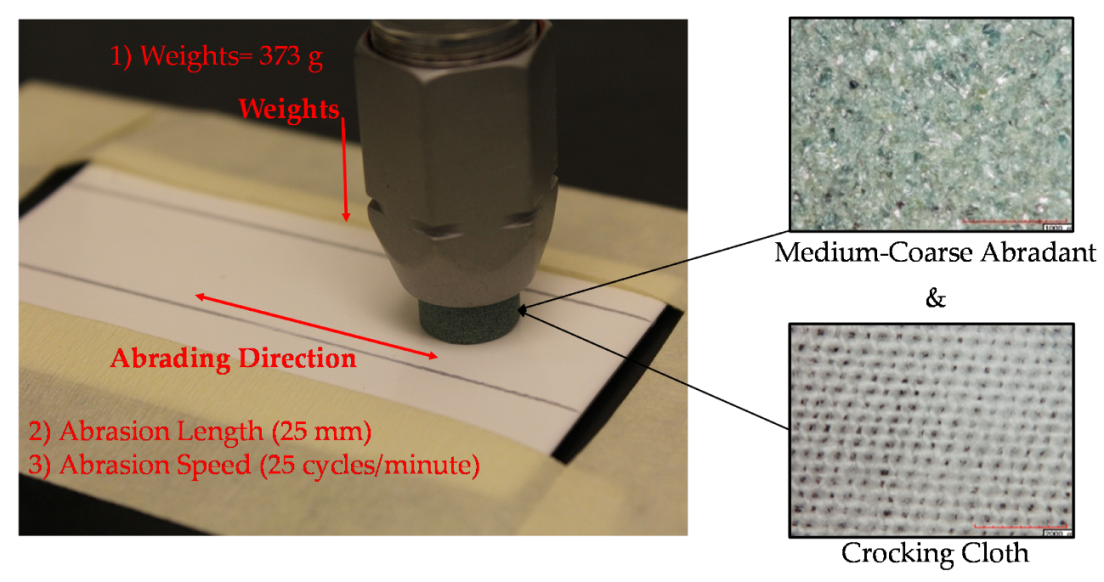

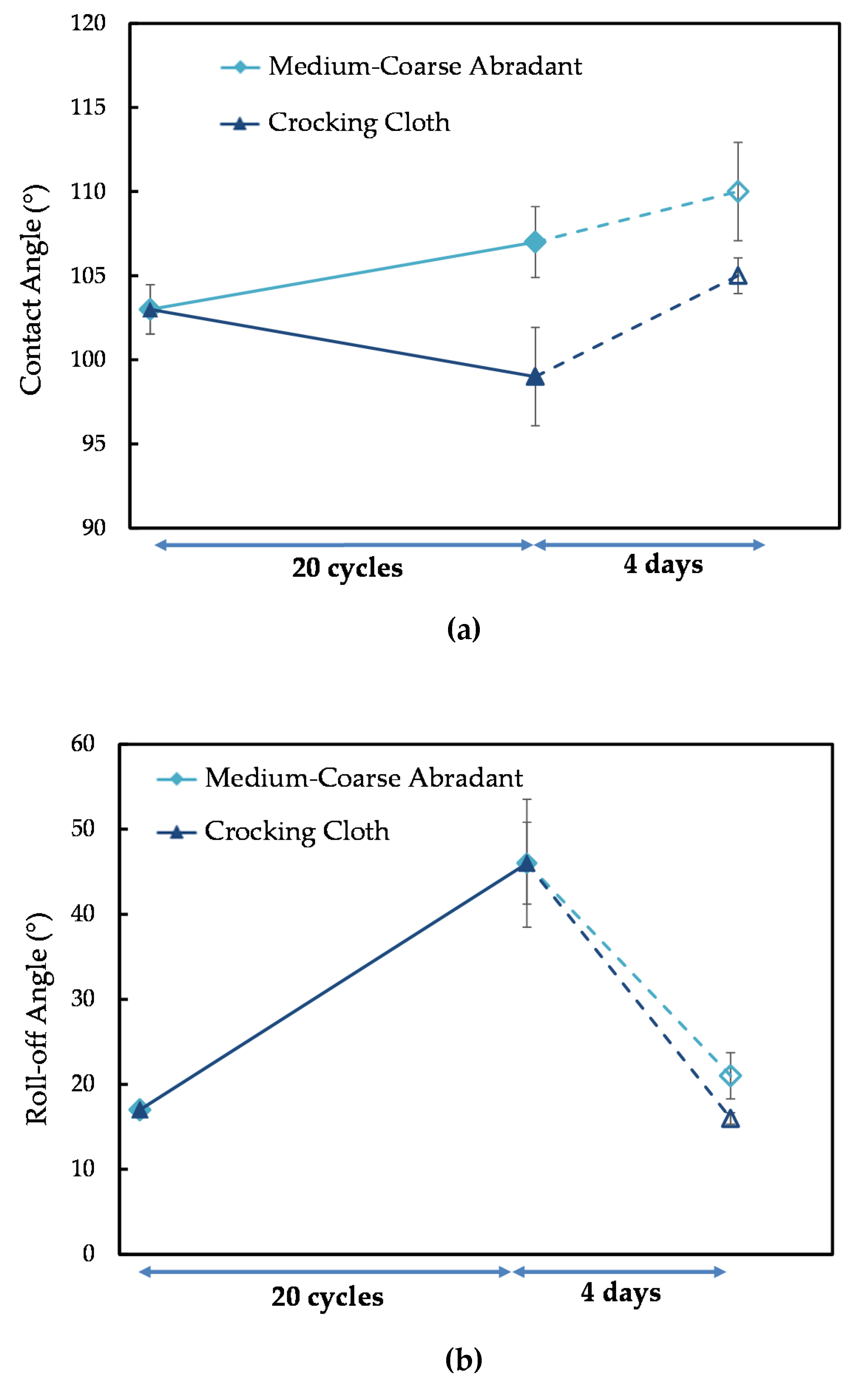

3.3. Investigation of Mechanical Durability

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gent, R.W.; Dart, N.P.; Cansdale, J.T. Aircraft icing. Philos. Trans. R. Soc. London Ser. A Math. Phys. Eng. Sci. 2000, 358, 2873–2911. [Google Scholar] [CrossRef]

- Jin, Z.; Hu, H. Icing process of small water droplets impinging onto a frozen cold plate. J. Thermophys. Heat Transf. 2010, 24, 841–844. [Google Scholar] [CrossRef]

- Yeong, Y.H.; Milionis, A.; Loth, E.; Sokhey, J. Self-lubricating icephobic elastomer coating (SLIC) for ultralow ice adhesion with enhanced durability. Cold Reg. Sci. Technol. 2018, 148, 29–37. [Google Scholar] [CrossRef]

- Yirtici, O.; Tuncer, I.H.; Ozgen, S. Ice accretion prediction on wind turbines and consequent power losses. J. Phys. Conf. Ser. 2016, 753, 022022. [Google Scholar] [CrossRef]

- Jasinski, W.J.; Noe, S.C.; Selig, M.S.; Bragg, M.B. Wind turbine performance under icing conditions. J. Sol. Energy Eng. 1998, 120, 60–65. [Google Scholar] [CrossRef]

- Dalili, N.; Edrisy, A.; Carriveau, R. A review of surface engineering issues critical to wind turbine performance. Renew. Sustain. Energy Rev. 2009, 13, 428–438. [Google Scholar] [CrossRef]

- Antonini, C.; Innocenti, M.; Horn, T.; Marengo, M.; Amirfazli, A. Understanding the effect of superhydrophobic coatings on energy reduction in anti-icing systems. Cold Reg. Sci. Technol. 2011, 67, 58–67. [Google Scholar] [CrossRef]

- Boinovich, L.B.; Emelyanenko, A.M. Anti-icing potential of superhydrophobic coatings. Mendeleev Commun. 2013, 23, 3–10. [Google Scholar] [CrossRef]

- Schutzius, T.M.; Jung, S.; Maitra, T.; Eberle, P.; Antonini, C.; Stamatopoulos, C.; Poulikakos, D. Physics of icing and rational design of surfaces with extraordinary icephobicity. Langmuir 2015, 31, 4807–4821. [Google Scholar] [CrossRef]

- Zheng, S.; Li, C.; Fu, Q.; Hu, W.; Xiang, T.; Wang, Q.; Du, M.; Liu, X.; Chen, Z. Development of stable superhydrophobic coatings on aluminum surface for corrosion-resistant, self-cleaning, and anti-icing applications. Mater. Des. 2016, 93, 261–270. [Google Scholar] [CrossRef]

- Susoff, M.; Siegmann, K.; Pfaffenroth, C.; Hirayama, M. Evaluation of icephobic coatings—Screening of different coatings and influence of roughness. Appl. Surf. Sci. 2013, 282, 870–879. [Google Scholar] [CrossRef]

- Cao, L.; Jones, A.K.; Sikka, V.K.; Wu, J.; Gao, D. Anti-Icing superhydrophobic coatings. Langmuir 2009, 25, 12444–12448. [Google Scholar] [CrossRef]

- Chavan, S.; Carpenter, J.; Nallapaneni, M.; Chen, J.Y.; Miljkovic, N. Bulk water freezing dynamics on superhydrophobic surfaces. Appl. Phys. Lett. 2017, 110, 041604. [Google Scholar] [CrossRef]

- Chavan, S.; Park, D.; Singla, N.; Sokalski, P.; Boyina, K.; Miljkovic, N. Effect of latent heat released by freezing droplets during frost wave propagation. Langmuir 2018, 34, 6636–6644. [Google Scholar] [CrossRef] [PubMed]

- De Koninck, L.H.; Ahmadi, S.F.; Boreyko, J.B. Passive anti-frosting cables. Int. J. Heat Mass Transf. 2020, 146, 118808. [Google Scholar] [CrossRef]

- Esmeryan, K.D.; Bressler, A.H.; Castano, C.E.; Fergusson, C.P.; Mohammadi, R. Rational strategy for the atmospheric icing prevention based on chemically functionalized carbon soot coatings. Appl. Surf. Sci. 2016, 390, 452–460. [Google Scholar] [CrossRef]

- Esmeryan, K.D.; Castano, C.E.; Mohammadi, R.; Lazarov, Y.; Radeva, E.I. Delayed condensation and frost formation on superhydrophobic carbon soot coatings by controlling the presence of hydrophilic active sites. J. Phys. D Appl. Phys. 2018, 51, 055302. [Google Scholar] [CrossRef]

- Farhadi, S.; Farzaneh, M.; Kulinich, S.A. Anti-icing performance of superhydrophobic surfaces. Appl. Surf. Sci. 2011, 257, 6264–6269. [Google Scholar] [CrossRef]

- Liu, Y.; Li, L.; Li, H.; Hu, H. An experimental study of surface wettability effects on dynamic ice accretion process over an UAS propeller model. Aerosp. Sci. Technol. 2018, 73, 164–172. [Google Scholar] [CrossRef]

- Wang, N.; Xiong, D.; Deng, Y.; Shi, Y.; Wang, K. Mechanically robust superhydrophobic steel surface with anti-icing, UV-durability, and corrosion resistance properties. ACS Appl. Mater. Interfaces 2015, 7, 6260–6272. [Google Scholar] [CrossRef]

- Verho, T.; Bower, C.; Andrew, P.; Franssila, S.; Ikkala, O.; Ras, R.H.A. Mechanically durable superhydrophobic surfaces. Adv. Mater. 2011, 23, 673–678. [Google Scholar] [CrossRef]

- Ellinas, K.; Tserepi, A.; Gogolides, E. Durable superhydrophobic and superamphiphobic polymeric surfaces and their applications: A review. Adv. Colloid Interface Sci. 2017, 250, 132–157. [Google Scholar] [CrossRef]

- Balordi, M.; Cammi, A.; Santucci de Magistris, G.; Chemelli, C. Role of micrometric roughness on anti-ice properties and durability of hierarchical super-hydrophobic aluminum surfaces. Surf. Coat. Technol. 2019, 374, 549–556. [Google Scholar] [CrossRef]

- Boinovich, L.B.; Emelyanenko, A.M.; Ivanov, V.K.; Pashinin, A.S. Durable icephobic coating for stainless steel. ACS Appl. Mater. Interfaces 2013, 5, 2549–2554. [Google Scholar] [CrossRef]

- Song, J.; Zhao, D.; Han, Z.; Xu, W.; Lu, Y.; Liu, X.; Liu, B.; Carmalt, C.J.; Deng, X.; Parkin, I.P. Super-robust superhydrophobic concrete. J. Mater. Chem. A 2017, 5, 14542–14550. [Google Scholar] [CrossRef]

- Kulinich, S.A.; Farhadi, S.; Nose, K.; Du, X.W. Superhydrophobic surfaces: Are they really ice-repellent? Langmuir 2011, 27, 25–29. [Google Scholar] [CrossRef]

- Kim, P.; Wong, T.S.; Alvarenga, J.; Kreder, M.J.; Adorno-Martinez, W.E.; Aizenberg, J. Liquid-infused nanostructured surfaces with extreme anti-ice and anti-frost performance. ACS Nano 2012, 6, 6569–6577. [Google Scholar] [CrossRef]

- Esmeryan, K.D. From extremely water-repellent coatings to passive icing protection—principles, limitations and innovative application aspects. Coatings 2020, 10, 66. [Google Scholar] [CrossRef]

- Yeong, Y.H.; Loth, E.; Sokhey, J. Ice adhesion on superhydrophobic coatings in a icing wind tunnel. In Advances in Polymer Science; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Maitra, T.; Jung, S.; Giger, M.E.; Kandrical, V.; Ruesch, T.; Poulikakos, D. Superhydrophobicity vs. ice adhesion: The quandary of robust icephobic surface design. Adv. Mater. Interfaces 2015, 2, 1500330. [Google Scholar] [CrossRef]

- Yeong, Y.H.; Milionis, A.; Loth, E.; Sokhey, J.; Lambourne, A. Atmospheric ice adhesion on water-repellent coatings: Wetting and surface topology effects. Langmuir 2015, 31, 13107–13116. [Google Scholar] [CrossRef]

- Kreder, M.J.; Alvarenga, J.; Kim, P.; Aizenberg, J. Design of anti-icing surfaces: Smooth, textured or slippery? Nat. Rev. Mater. 2016, 1, 1–15. [Google Scholar] [CrossRef]

- Jung, S.; Dorrestijn, M.; Raps, D.; Das, A.; Megaridis, C.M.; Poulikakos, D. Are superhydrophobic surfaces best for icephobicity? Langmuir 2011, 27, 3059–3066. [Google Scholar] [CrossRef] [PubMed]

- Wier, K.A.; McCarthy, T.J. Condensation on ultrahydrophobic surfaces and its effect on droplet mobility: Ultrahydrophobic surfaces are not always water repellant. Langmuir 2006, 22, 2433–2436. [Google Scholar] [CrossRef]

- Wilson, P.W.; Lu, W.; Xu, H.; Kim, P.; Kreder, M.J.; Alvarenga, J.; Aizenberg, J. Inhibition of ice nucleation by slippery liquid-infused porous surfaces (SLIPS). Phys. Chem. Chem. Phys. 2013, 15, 581–585. [Google Scholar] [CrossRef]

- Smith, J.D.; Dhiman, R.; Anand, S.; Reza-Garduno, E.; Cohen, R.E.; McKinley, G.H.; Varanasi, K.K. Droplet mobility on lubricant-impregnated surfaces. Soft Matter 2013, 9, 1772–1780. [Google Scholar] [CrossRef]

- Subramanyam, S.B.; Rykaczewski, K.; Varanasi, K.K. Ice adhesion on lubricant-impregnated textured surfaces. Langmuir 2013, 29, 13414–13418. [Google Scholar] [CrossRef]

- Ozbay, S.; Yuceel, C.; Erbil, H.Y. Improved icephobic properties on surfaces with a hydrophilic lubricating liquid. ACS Appl. Mater. Interfaces 2015, 7, 22067–22077. [Google Scholar] [CrossRef]

- Rykaczewski, K.; Anand, S.; Subramanyam, S.B.; Varanasi, K.K. Mechanism of frost formation on lubricant-impregnated surfaces. Langmuir 2013, 29, 5230–5238. [Google Scholar] [CrossRef]

- Wong, T.S.; Kang, S.H.; Tang, S.K.Y.; Smythe, E.J.; Hatton, B.D.; Grinthal, A.; Aizenberg, J. Bioinspired self-repairing slippery surfaces with pressure-stable omniphobicity. Nature 2011, 477, 443–447. [Google Scholar] [CrossRef]

- Wang, G.; Guo, Z. Liquid infused surfaces with anti-icing properties. Nanoscale 2019, 11, 22615–22635. [Google Scholar] [CrossRef]

- Erbil, H.Y. Improvement of lubricant-infused surfaces for anti-icing applications. Surf. Innov. 2016, 4, 214–217. [Google Scholar] [CrossRef]

- Zhang, M.; Yu, J.; Chen, R.; Liu, Q.; Liu, J.; Song, D.; Liu, P.; Gao, L.; Wang, J. Highly transparent and robust slippery lubricant-infused porous surfaces with anti-icing and anti-fouling performances. J. Alloy. Compd. 2019, 803, 51–60. [Google Scholar] [CrossRef]

- Zhu, L.; Xue, J.; Wang, Y.; Chen, Q.; Ding, J.; Wang, Q. Ice-phobic coatings based on silicon-oil-infused polydimethylsiloxane. ACS Appl. Mater. Interfaces 2013, 5, 4053–4062. [Google Scholar] [CrossRef]

- Wang, Y.; Yao, X.; Chen, J.; He, Z.; Liu, J.; Li, Q.; Wang, J.; Jiang, L. Organogel as durable anti-icing coatings. Sci. China Mater. 2015, 58, 559–565. [Google Scholar] [CrossRef]

- Urata, C.; Dunderdale, G.J.; England, M.W.; Hozumi, A. Self-lubricating organogels (SLUGs) with exceptional syneresis-induced anti-sticking properties against viscous emulsions and ices. J. Mater. Chem. A 2015, 3, 12626–12630. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, P.; Liu, M.; Wang, S.; Jiang, L. Organogel-based thin films for self-cleaning on various surfaces. Adv. Mater. 2013, 25, 4477–4481. [Google Scholar] [CrossRef]

- Eifert, A.; Paulssen, D.; Varanakkottu, S.N.; Baier, T.; Hardt, S. Simple fabrication of robust water-repellent surfaces with low contact-angle hysteresis based on impregnation. Adv. Mater. Interfaces 2014, 1, 1300138. [Google Scholar] [CrossRef]

- Damle, V.G.; Uppal, A.; Sun, X.; Burgin, T.P.; Rykaczewski, K. Rapid and scalable lubrication and replenishment of liquidinfused materials. Surf. Innov. 2015, 4, 102–108. [Google Scholar] [CrossRef]

- Zhuo, Y.; Håkonsen, V.; He, Z.; Xiao, S.; He, J.; Zhang, Z. Enhancing the mechanical durability of icephobic surfaces by introducing autonomous self-healing function. ACS Appl. Mater. Interfaces 2018, 10, 11972–11978. [Google Scholar] [CrossRef]

- Golovin, K.; Kobaku, S.P.R.; Lee, D.H.; DiLoreto, E.T.; Mabry, J.M.; Tuteja, A. Designing durable icephobic surfaces. Sci. Adv. 2016, 2, 1501496. [Google Scholar] [CrossRef]

- Potapczuk, M.G. Aircraft icing research at NASA glenn research center. J. Aerosp. Eng. 2013, 26, 260–276. [Google Scholar] [CrossRef]

- Acker, L.W. Preliminary Results of Natural Icing of an Axial-Flow Turbojet Engine; NACA Research Memorandum: Washington, DC, USA, 1948. [Google Scholar]

- Tetteh, E.Y.; Loth, E.; Loebig, J.; Cummings, J.; Lilly, N. The compact icing research tunnel (CIRT). In Proceedings of the AIAA Propulsion and Energy 2019 Forum, Indianapolis, IN, USA, 19–22 August 2019. [Google Scholar]

- Yeong, Y.H. Impinging Drops on Superhydrophobic Surfaces at Icing Conditions. Ph.D. Thesis, University of Virginia, Charlottesville, VA, USA, April 2014. [Google Scholar]

- Andrews, E.H.; Lockington, N.A. The cohesive and adhesive strength of ice. J. Mater. Sci. 1983, 18, 1455–1465. [Google Scholar] [CrossRef]

- Andrews, E.H.; Majid, H.A.; Lockington, N.A. Adhesion of ice to a flexible substrate. J. Mater. Sci. 1984, 19, 73–81. [Google Scholar] [CrossRef]

- Andrews, E.H.; Stevenson, A. Fracture energy of epoxy resin under plane strain conditions. J. Mater. Sci. 1978, 13, 1680–1688. [Google Scholar] [CrossRef]

- Pervier, M.-L. Mechanics of Ice Detachment Applied To Turbomachinery. Ph.D. Thesis, Cranfield University, Bedford, UK, 2012. [Google Scholar]

- Meuler, A.J.; Smith, J.D.; Varanasi, K.K.; Mabry, J.M.; McKinley, G.H.; Cohen, R.E. Relationships between water wettability and ice adhesion. ACS Appl. Mater. Interfaces 2010, 2, 3100–3110. [Google Scholar] [CrossRef]

- Chu, M.; Scavuzzo, R.; Kellackey, C. Tensile properties of impact ices. In Proceedings of the 30th Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 6–9 January 1992. [Google Scholar]

- Rothrock, A.M.; Selden, R.F. Adhesion of Ice in its Relation to the De-Icing of Airplanes; National Advisory Committee for Aeronautics: Washington, DC, USA, 1939. [Google Scholar]

- Milionis, A.; Loth, E.; Bayer, I.S. Recent advances in the mechanical durability of superhydrophobic materials. Adv. Colloid Interface Sci. 2016, 229, 57–79. [Google Scholar] [CrossRef]

- Cho, S.H.; White, S.R.; Braun, P.V. Self-healing polymer coatings. Adv. Mater. 2009, 21, 645–649. [Google Scholar] [CrossRef]

- Zhuo, Y.; Xiao, S.; Håkonsen, V.; Li, T.; Wang, F.; He, J.; Zhang, Z. Ultrafast self-healing and highly transparent coating with mechanically durable icephobicity. Appl. Mater. Today 2020, 19, 100542. [Google Scholar] [CrossRef]

| Wettability Properties | Aluminum | SLIC |

|---|---|---|

| Contact Angle (°) | 82.4 | 99 |

| Roll-off Angle (°) | 27 | 13 |

| Surfaces | Avg. % Cohesive Residue Area Fraction | |

|---|---|---|

| Impact | Static | |

| Al. Surface | 20 | 44 |

| SLIC Surface | 0 | 0 |

| Impact Ice | Static Ice | |||

|---|---|---|---|---|

| Contact Angle (°) | Roll-off Angle (°) | Contact Angle (°) | Roll-off Angle (°) | |

| Test on a Rectangular Coupon | 99 | 13 | 99 | 13 |

| Substrate Disc After Icing Tests (SLIC) | 102 | 8 | 101 | 7 |

| Abradants | Contact Angle (°) | Roll-off Angle (°) | ||||

|---|---|---|---|---|---|---|

| Zero Cycle | After 20 Cycles | After 4 Days | Zero Cycle | After 20 Cycles | After 4 Days | |

| Medium-Coarse Abradant | 103 | 107 | 110 | 17 | 46 | 21 |

| Crocking Cloth | 103 | 99 | 105 | 17 | 46 | 16 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tetteh, E.; Loth, E. Reducing Static and Impact Ice Adhesion with a Self-Lubricating Icephobic Coating (SLIC). Coatings 2020, 10, 262. https://doi.org/10.3390/coatings10030262

Tetteh E, Loth E. Reducing Static and Impact Ice Adhesion with a Self-Lubricating Icephobic Coating (SLIC). Coatings. 2020; 10(3):262. https://doi.org/10.3390/coatings10030262

Chicago/Turabian StyleTetteh, Edem, and Eric Loth. 2020. "Reducing Static and Impact Ice Adhesion with a Self-Lubricating Icephobic Coating (SLIC)" Coatings 10, no. 3: 262. https://doi.org/10.3390/coatings10030262

APA StyleTetteh, E., & Loth, E. (2020). Reducing Static and Impact Ice Adhesion with a Self-Lubricating Icephobic Coating (SLIC). Coatings, 10(3), 262. https://doi.org/10.3390/coatings10030262