Abstract

Hydroxyapatite (HA) delivery with resin adhesives has potential for re-mineralization of resin–dentin interface. The study prepared an adhesive containing HA and confirmed its presence in adhesive and interaction with the dentin using scanning electron microscopy (SEM), Fourier transform infrared spectroscopy (FTIR), and Micro-Raman spectroscopy. The aim was to assess the influence of HA incorporation in dentin adhesive on its microtensile bond strength (μ-tbs) and Knoop microhardness (KHN). Thirty teeth each were bonded with CA and HA adhesive using a 10-s smear and photo-polymerized. The specimens in each adhesive group (CA and HA) were divided into sub-groups of 24 h, 8 weeks, and 16 weeks (n = 10) aging durations. μ-tbs was assessed at a crosshead speed of 0.5 mm/minute and bonded interface was analyzed using SEM (n = 20) and Raman spectroscopy (n = 10). Softening of HA adhesive and CA was assessed using KHN. HA adhesive presented higher μ-tbs compared to CA. With an increase in storage time, HA adhesive presented with 100% adhesive failure. Softening was less and KHN was higher for HA adhesive compared to CA (p < 0.05). KHN reduction was higher in CA [19.6 (5.1)%] compared to the HA adhesives [9.7 (4.5)%]. HA adhesive showed superior μTBS and microhardness compared to CA. In the absence of nanoleakage, HA modified adhesive exhibited enhanced bond integrity and better durability of resin dentin bond compared to control adhesive.

1. Introduction

In recent times, the incorporation of nanofillers has led to a change in the paradigm of restorative dentistry. The addition of organic and inorganic fillers has shown distinct alteration in the mechanical and adhesive properties of the material, such as microhardness, wear resistance, water sorption, and solubility [1]. Traditionally, dentin adhesives are resin-based, formulated with monomers including, 2-hydroxyethyl methacrylate (HEMA), bisphenol A glycol dimethacrylate (BisGMA) and triethylene glycol dimethacrylate (TEGDMA) without additional fillers [2]. However, with an improved understanding of dentin bonding, incorporation of fillers in the adhesive systems is recommended to reduce water sensitivity, solubility and enhance the mechanical properties of the adhesive and hybrid layer [3]. Despite the developments, the bond strength of the adhesive to dentin is weaker compared to enamel due to lower organic content in the dentin.

Tooth adhesion critically depends on the dentin substrate and the quality of adhesive polymer [4]. Thus, to improve the adhesives interaction with the hybrid layer, nanofillers are incorporated into the polymeric adhesive. Studies have suggested that incorporation of nanoparticles in restorative resin-based composites has enhanced their mechanical strength, therefore, a similar concept is being used in formulating the adhesives [4,5]. In addition, it was observed that particle size plays an important role in governing the properties of the material, hence, the nano-scale filler size has modified the mechanical, physical, and chemical properties of the adhesives [1,2]. However, this inclusion of dense fillers can limit the wettability of adhesives, and with restricted light transmission and differential refractive index, the degree of monomer to polymer of the adhesive is compromised [6]. Thus, a low degree of conversion affects the bond strength of the material and integrity of hybrid layer formation.

With evolving techniques, researchers have adopted a strategy of Biomimetic mineralization, based on the use of nanotechnology to mimic the biological mineralization [7]. Within tooth dentin, hydroxyapatite (HA) crystals play a significant role in the mineralization processes, and it is artificially incorporated to induce re-mineralization of the dentin and enamel [8]. HA is a non-toxic and biocompatible agent that has shown chemical stability in the physiological environment with specific biological actions [8]. HA has the ability to interact and form the inorganic structure of dental hard tissues in order to regain its structural integrity. As a filler, HA is reported to be added to many products including resin composites, in a dentifrice, mouth rinses, and energy drinks [7]. Thus, its bioactivity and re-mineralization capacity have enabled its use as a filler in adhesives to enhance the material properties.

In the treatment of dentin with conditioning acid during dentin bonding, the partially demineralized dentin holds hydroxyapatite crystals that possess undamaged nuclei, this induces re-mineralization with calcium interaction [9,10]. Providing HA in the form of the bioactive material triggers the epitaxial growth of the available HA in dentin, leading to re-mineralization of areas within the hybrid layer [9]. Initial studies on the incorporation of HA micro-fillers in adhesives presented improved bond strength and reduced degradation of the hybrid layer due to hydrophilic absorption property and enzymatic action [10]. However, as filler particles have evolved, nano-structured HA nanospheres have been introduced for incorporation of dental materials. However, there are limited reports available on the characterization and interaction of HA nanospheres in adhesives and their adhesive bond integrity to dentin within adhesive resins. Therefore, the present study aimed to prepare an experimental adhesive containing HA nanospheres and confirm HA presence and its interaction with the dentin using scanning electron microscopy, Micro-Raman spectroscopy and Fourier transform infrared spectroscopy (FTIR). The aim was also to assess the influence of HA incorporation in dentin adhesive on its microtensile bond strength (μ-tbs) and Knoop microhardness (KHN).

2. Materials and Methods

2.1. Synthesis of Experimental and HA Resin Adhesives

The experimental adhesive was synthesized using methods from the study by Ye et al. [11]. The adhesive was prepared using monomers, 2-hydroxyethyl methacrylate (HEMA), bisphenol A glycol dimethacrylate (BisGMA), triethylene glycol dimethacrylate (TEGDMA), ethyl 4-dimethylamino benzoate and camphorquinone (Esstech Inc., Essington, PA, USA). A precise weighing balance (Precisa 1600C, Mineapolis, MN, USA) was used to identify ingredient portions with accuracy. The adhesive was formulated by mixing 25% HEMA, 25% TEGDMA and 50% Bis-GMA by weight with ethanol as a solvent (30%). Ethyl 4-(dimethylamino)beanzoate (0.5% n/n) and camphorquinone (0.5% n/n) were added as photo-initiators, whereas diphenyliodonium hexafluorophosphate (1.0% n/n) was employed as the electron initiator [12]. Using a three-necked flask and a magnetic stirrer with condenser, the mixture was prepared (SUS304 REXIM; MonotaRO, Tokyo, Japan). The adhesive was mixed in a dark chamber (red light) and stored in isolation covered with foil, to prevent photo-polymerization.

The produced adhesive was considered the control adhesive (CA). Nanoparticles of Hydroxyapatite (HA) [Hydroxyapatitie, Sigma Aldrich, Armada, MI, USA) were obtained commercially and were silanized. Silanization was performed to improve adhesion of HA spheres to the matrix by adding 5% silane (Methyltrimethoxysilane, MTS, ABCR GmbH & Co. Karlsruhe, Frankfurt, Germany) to the solvent (95% acetone) [13]. Five percent silanized HA particles were added to the adhesive to produce HA experimental adhesive (HAA). The weight of the HA nanoparticles was calculated in milligrams (100 mg) and the volume of resin in milliliters (2 mL). In order to calculate 5 wt./vol.%, the following calculations were used.

Weight/volume% (5%) = mass of solute (100 mg)/volume of solution (2 mL) × 100

The HA particles were dispersed using sonication in solvent for dispersion in an ultrasonic bath (VWR USC-TH sonicator bath, Tokyo, Japan) for 10 min. To ensure homogenous dispersion after storage, re-homogenization in ultrasonic bath was performed prior to use in testing. The solvent was allowed to evaporate as the mixture was stored at 37 °C for 24 h. Due to limited shelf life, the adhesives were used within two weeks and were stored at 4 °C.

2.2. Characterization of HA and Synthesized Adhesive

Using Scanning Electron microscopy (SEM, FEI Quanta 250, Salem, OR, USA), the morphology of the HA nanospheres was assessed. In addition, the presence of HA nanospheres within the experimental adhesive was evaluated with SEM, Fourier transform infrared spectroscopy (FTIR) and Micro-Raman spectroscopy. For analysis of FTIR spectrum, the HAA adhesive was placed in contact with the sensors (Potassium bromide disc, Shimadzu, Kyoto, Japan) and FTIR (Thermo Scientific Nicolet iS20 FTIR spectrometer, Salem, MA USA) absorbance peaks were recorded. The elements and chemical groups were identified using Energy Dispersive X-Ray spectroscopy (EDX, FEI Quanta 250), Micro-Raman spectroscopy (JASCO, Easton, MD, USA) and FTIR. HAA was polymerized with a dental light-curing unit (Eliphar S10; 600 mW·cm−2 output; 3M ESPE, St. Paul, MN, USA) at 10 mm distance for 20 s. The specimens were mounted on aluminum stubs with the help of conductive tape and coated with gold thin layer for 100 s (Baltec sputter, Scotia, NY, USA). Specimens were evaluated at multiple magnifications with SEM), operating at 10 kV accelerating voltage.

2.3. Tooth Preparation and Bonding Procedure

Ninety premolar teeth were disinfected with chloramine trihydrate solution (Merck, Frankfurt, Germany) for 48 h at a temperature of 10 °C. Specimens were embedded in acrylic resin (Opti-Cryl, South Carolina, Columbia) up to the cemento-enamel junction in sections of polyvinyl pipes (4 mm) and stored in distilled water. Teeth were used within four weeks of the storage period. Twenty specimen teeth were utilized for SEM analysis of bonded interface for CA and HAA, ten specimens were used for Micro-Raman spectroscopy analysis, and microtensile bond strength (μTBS) testing for CA and HAA was performed on sixty teeth further subdivided based on storage durations (24 h, 8 weeks, and 16 weeks (n = 10).

Dentin on the teeth was exposed by removing occlusal enamel with a low-speed diamond saw (Buehler Isomet 2000 Precision saw, Rockford, IL, USA), 1 mm below the detino-enamel junction. Dentin was etched with 35% phosphoric acid gel (Ultra etch Econo Kit, Optident, Yorkshire, UK) for 10 s followed by washing with distilled water and drying with cotton pellets. Half of the teeth (n = 30) were bonded with CA and half with HAA. Application to dentin included two applications with a micro-brush (10 s smear), and air thinning (4 s) for dentin penetration. Photopolymerization was performed with a blue light (Eliphar S10; 600 mW·cm−2 output; 3M ESPE, St. Paul, MN, USA) for 20 s. A dental resin composite was bonded to adhesive surface on dentin in 1.5 mm increments (Filtek Universal; 3M ESPE, St. Paul, MN, USA) using a resin jig and dental condenser. Composite resin was light-cured for polymerization for 80 s total. The specimens in each adhesive group (CA and HAA) were subdivided into three sub-groups based on the duration of specimen aging of 24 h, 8 weeks, and 16 weeks (n = 10). Microstructural analysis of bonded adhesive–dentin interface was performed using SEM (n = 20) and Micro-Raman spectroscopy (n = 10).

2.4. Microtensile Bond Test (μTBS)

The bonded specimens were sectioned (Slow speed diamond saw, Buehler Isomet 2000 Precision saw) to produce composite-adhesive-dentin bonded beams (1 × 1 mm2). Fractured or failed beams were excluded from testing. Fifty beams were assessed for μTBS in each adhesive subgroup (CA-24, CA-8, CA-16; HAA-24, HAA-8, HAA-16) after completion of specific storage durations. Bonded beams were attached with cyanoacrylate (Superglue, Plymouth, MN, USA) to the microtensile tester jaws. The microtensile tester (Bisco Inc., Virginia, VA, USA) evaluated the specimen under tension at a crosshead speed of 0.5 mm/min until failure. Failure modes were divided into adhesive, cohesive, and mixed types, and fractured specimens were assessed under a digital microscope (Hirox KH 7700, Tokyo, Japan). The means and standard deviations of μTBS were analyzed using ANOVA and post hoc Tukey multiple comparisons test.

2.5. Micro-Raman Spectroscopy of Dentin-Adhesive Bonded Specimen

Micro-Raman spectroscopy analysis of bonded beam specimens was performed. A Raman spectrometer (ProRaman-L Analyzer; TSI, Shoreview, MN, USA) and Raman microscopic software (Ramanreader) was utilized to identify Raman spectra. The specimens were positioned to target HAA, to obtain targeted signals. In addition, the background was corrected for dark counts having normal intensity. Laser beams were focused on the dentin-HAA interface (600 mW) with a 0.9 objective lens. Using a computer-guided stage, Raman scatters of different locations of interest in the specimens were obtained. With an excitation laser beam wavelength of 785 nm, details of the spectra were acquired between 800 and 1800 cm −1 along with noise filtration. Three scans were performed for each zone of interest, with a 60 s scan over 1 mm area of the specimen.

2.6. SEM Observation of Bonded Adhesive/Dentin Interface

The bonded beam specimens for HAA and CA groups were wet-polished (Beuhler Polisher, Lake Bluff, IL, USA) and cleaned in distilled water ultrasonic bath (Bandelin Digital, Sigma-Aldrich, Darmstadt, Germany) for 5 min. The specimens were etched (35% phosphoric acid gel, Ultra etch Econo Kit, Optident, Yorkshire, UK) for 10 s, washed with distilled water (15 s), immersed in sodium hypochlorite (2.5%) solution (10 min), and washed. Prior to mounting, the specimens were dried and desiccated using ethanol at 80%, 90%, and 100% concentration. Specimens were assessed under FE-SEM at 10 kV using different magnifications.

2.7. Assessment of Softening

Softening of HAA and CA in ethanol was assessed using Knoop microhardness. Ten specimens of adhesives per group in the form of discs of 5 mm (±0.5) diameter and 1.0 mm thickness (±0.1) were fabricated. The discs were mounted in acrylic resin and polished (Beuhler Polisher, Lake Bluff, IL, USA) with alumina suspension (Alumina, 10 mm, Arotec, Cotia, SP, Brazil). Specimens were stored in dry conditions for 24 h at 37 °C. All specimens were exposed to three Knoop micro-indentations at 25 g force and 15 s duration, 100 microns apart, using a micro indentation tester (Innovatest-Maastricht, Tiburg, The Netherlands). Knoop microhardness was assessed using the following formula.

f is load in grams and d is the length of diagonal (large) in micro meters.

Knoop microhardness = 14.229 (f/d2)

The Knoop hardness number was determined (KHN1), following which, specimens were placed in absolute ethanol for 5 h at 37 °C for softening effect. Post softening Knoop hardness indentation was performed to identify KHN2, and a difference in percentage between KHN1 and KHN2 was evaluated.

3. Results

3.1. SEM of the Synthesized HAA Adhesive

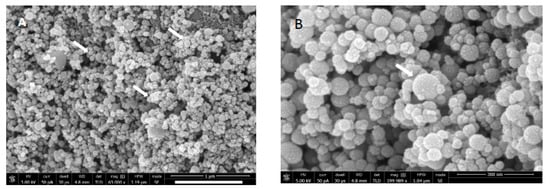

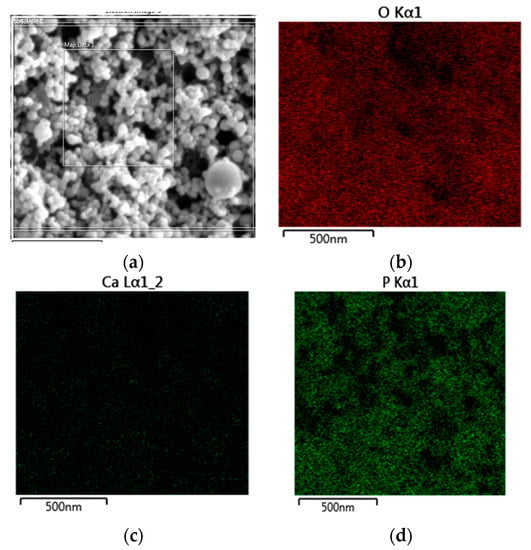

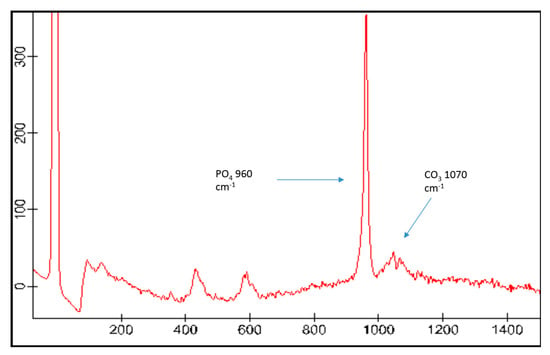

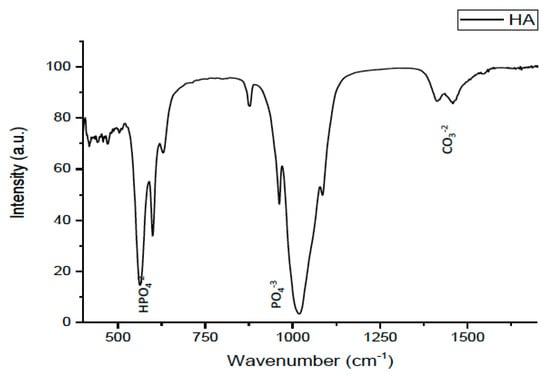

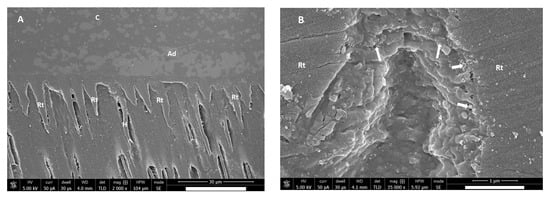

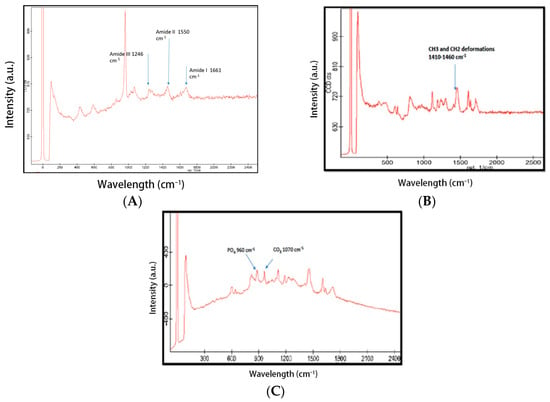

The morphology of the HA nanoparticles is presented in Figure 1A,B. The microscopic imagery exhibited the presence of rounded nanoparticles of HA, in isolated and agglomerated forms. Based on the observation, the HA particles can be regarded as nanospheres with crystal size ranging well below 50 nm. The EDX analysis showed evidence of phosphorus, oxygen, and calcium in the hydroxyapatite samples (Figure 2). In addition to EDX, Micro-Raman spectra of the hydroxyapatite nanospheres showed typical chemical groups, identified as phosphate (υ1 PO4 ~960 cm−1) and carbonate (CO3 ~1070 cm−1) (Figure 3). FTIR Spectrum of HA nanoparticles showed strong peaks at 560 cm−1 and 1017 cm−1, representing hydrogen phosphate (HPO4) and phosphate (PO4), respectively. The smaller peak at 1460 cm−1 indicated carbonate (CO3) (Figure 4).

Figure 1.

Field emission scanning electron microscopic (FESEM) micrograph under (A) low and (B) high magnification showing hydroxyapatite nanoparticle agglomerates with round morphology. The white arrowhead in Figure 1B, clearly showing the spherical HA nanoparticle.

Figure 2.

EDX elemental mapping of the HA nanoparticles (a) showing evidence of oxygen (b), calcium (c), and phosphorus (d) in the hydroxyapatite samples.

Figure 3.

Typical Raman spectra of the HA showing chemical groups identified by Micro-Raman analysis that could be identified as phosphate (υ1 PO4 ~960 cm−1) and carbonate (CO3 ~1070 cm−1).

Figure 4.

FTIR (Fourier transform infrared spectroscopy) Spectrum of HA nanoparticles, the two strong peaks at 56 and 1017 cm−1 representing hydrogen phosphate (HPO4) and phosphate (PO4), respectively. The smaller peak at 1460 cm−1 indicated carbonate (CO3).

3.2. SEM and Micro-Raman of Adhesive Dentin Interface

Figure 5A,B, presents SEM images of the resin dentin bonded specimen showing HA modified experimental dentin adhesive. The imagery presents the interfacial cross-section containing HA adhesive, dentin hybrid layer, and resin tags within dentin/hybrid layer. The HA adhesive shows considerable penetration within the dentinal tubules in the form of resin tags, forming a relatively uniform and dense hybrid layer. Moreover, a heavy layer of the HA adhesive is detected, reflecting probably increased viscosity and durable existence of the experimental adhesive. A high magnification image (Figure 5B, 35,000×) of the hybrid layer presents a homogenous distribution of hydroxyapatite nanoparticles in the space between two resin tags.

Figure 5.

(A) Field emission scanning electron microscopic (FESEM) micrograph showing resin–dentin interface using HA-modified experimental dentin adhesive. (B) High magnification of hybrid layer showing space between two resin tags. White arrowheads point to homogenous distribution of hydroxyapatite nanoparticles. C: Composite, Ad: Adhesive, H: Hybrid layer, Rt: Resin tags.

Figure 6 presents Micro-Raman spectra of control adhesive in dentin between 600 cm−1 to 1800 cm−1. The peaks at 1246 cm−1, 1550 cm−1, and 1661 cm−1 are associated with organic components, such as Amide III, Amid II, and Amide 1 for dentin collagen, respectively (Figure 6A) [14]. The peaks between 1410 and 1460 cm−1 are due to the –CH3 and –CH2 deformations within the adhesive (Figure 6B) [15]. HAA showed a characteristic peak of Micro-Raman scattering between 900 and 1800 cm−1. The inclusion of HA nanoparticles in the adhesive is evidenced by strong peaks indicative of phosphate at (υ1 PO4) 960 cm−1 and for carbonate (CO3) at 1070 cm−1 (Figure 3 and Figure 6C).

Figure 6.

Raman spectra (A) The peaks at 1246 cm−1, 1550 cm−1, and 1661 cm−1 are associated with organic components, such as Amide III, Amide II, and Amide I for dentin collagen, respectively, representing dentin at the interface. (B) Control Adhesive. The peaks between 1410 and 1460 cm−1 are due to the “–CH3 and –CH2” deformations within the adhesive. (C) HA-modified adhesive. The inclusion of HA nanoparticles in the adhesive is evidenced by the spectrum at 960 cm−1 for phosphate and 1070 cm−1 for carbonate.

3.3. Microtensile Bond Strength (μTBS-MPa)

The results of the μTBS test between study groups are presented in Table 1. The study compared the μTBS between the two adhesive groups, hydroxyapatite adhesive (HAA) and control adhesive (CA), each categorized according to the storage time: 24 h, 8 weeks, and 16 weeks. Analysis of variance presented significant differences among the study groups (p < 0.01). The maximum mean value of μTBS (MPa) observed was at 24 h storage [36.81 (3.47) MPa] in HAA treated specimens, whereas the minimum mean value obtained was at 16-week storage in CA [25.95 (3.90) MPa]. Regardless of storage period, the incorporation of HAA presented with a significantly higher μTBS value compared to the control.

Table 1.

Microtensile bond strength (Mean and SD) and failure modes distribution among the investigated groups.

Both adhesives showed a negative influence of the storage period on bond strength. However, an earlier impact on the μTBS was observed in CA at eight weeks [26.42 (3.71) MPa] compared to HAA in 16 weeks [28.50 (4.41) MPa] of storage. The change in bond strength values was minimal from 8 [26.42 (3.71) MPa] to 16 weeks [25.95 (3.90) MPa] in CA specimens compared to HAA specimens. HAA specimens demonstrated reduction in μTBS between 24 h [36.81 (3.47) MPa] to eight weeks [34.42 (3.73) MPa].

The results of the failure mode analysis are presented in Table 1. Comparing the adhesives, HAA presented higher adhesive type failures compared to control specimens. At 24 h, HAA specimens showed 80% adhesive failure compared to 60% in the control group. At eight weeks, HAA specimens exhibited 100% adhesive failures. On the other hand, for control group specimens, at 8 weeks and 16 weeks, 70%–100% of adhesive failures and 30% of mixed failures, respectively, were observed.

3.4. Softening of Experimental Adhesive (Knoop Hardness-KHN)

The Knoop microhardness (KHN) values before and after solvent immersions are shown in Table 2. The study compares the influence of the incorporation of HA on the microhardness of the experimental adhesive. The results of the study demonstrated a significant difference between the two adhesives HAA and CA, before and after the immersion in the solvent. Both adhesives presented a significant decrease in microhardness after the immersion. However, the percentage of the reduction was higher in CA [19.6 (5.1)%] compared to the HA adhesives [9.7 (4.5)%].

Table 2.

Comparison of Knoop Microhardness for CA and HAA before and after solvent immersion.

The initial KHN measurements were higher in HAA [25.4 (0.4)] compared to the control [22.0 (0.6)] samples. However, the reduction in the microhardness was twice greater in control [17.5 (1.0)] compared to HAA [22.7 (0.6)] samples. This indicated a positive influence of HAA on enhancing the microhardness of dentin adhesive.

4. Discussion

The present study prepared an experimental adhesive containing HA nanospheres and confirmed its interaction within dentin using SEM, Micro-Raman spectroscopy and FTIR with further assessment of its hardness and dentin bond integrity. In the present study, SEM analysis showed HA fillers at nano-scale with a consistent homogenous distribution of hydroxyapatite nanospheres with round morphology and size ranging well below 60 nm. The amalgamation of the nanospheres with the adhesive showed a significant positive influence on the microtensile bond strength and microhardness of the material, as HA adhesive showed increased μTBS and decreased softening compared to control. Therefore, the null hypothesis can be rejected. A cascade of events is implicated for the present study findings, including the interaction of experimental adhesive (HAA) with the hybrid layer, resistance of HA to degradation, size of HA nanospheres, and affinity of HA molecules and re-mineralization potential.

The longevity of dental restorations is characterized on the groups of resin adhesives and well-defined dentin interaction [16]. Studies investigating the modification of adhesive systems to reduce susceptibility to degradation have proposed incorporation of nanofillers to reduce hydrophilicity, minimize enzymatic collagen degradation, and lower stress contraction relatively due to a decrease in a polymeric matrix [1,16]. In the present study, the HA-filled adhesive resin demonstrated greater resistance to surface degradation in absolute ethanol and distilled water, by showing lower softening of specimens using microhardness testing. It is suggested that ethanol solvent in immersed adhesives samples diffuse through the polymer chains, elute the groups, and plasticize them [7,17]. This partly supports our findings, as control samples without HA filler showed higher KHN% reduction compare to HAA specimens. In addition, it is suggested that the nanosphere agglomerates possibly provide resistance against the diffusion and degradation of the material [7]. The surface microhardness of the HAA samples may also be enhanced due to the presence of functionalized silane groups on HA nanospheres, which are suggested to lower the capacity of water sorption and prolong bond durability [17]. Leitune et al., investigating the influence of HA in dentin adhesive, showed a decrease in microhardness percentage reduction after solvent immersion as the HA concentration increased [9]. In a similar study by Sadat-Shojai et al., HA-incorporated adhesives showed improved tensile strength, flexural strength, and micro-shear bond strength compared to controls [10]. This complements the findings of the present study. By contrast, their study showed a drop in depth of cure in HA adhesive samples [10], attributed to the HA rod structure, which interfered with the light penetration for polymerization due to HA opacity. It is pertinent to mention that HA nanospheres used in the present study may have resulted in the enhanced surface hardness and low softening effect as compared to earlier studies [10].

One of the major observations of the study was the enhanced bond strength of HA-incorporated adhesive compared to control. This is in line with previous studies, assessing bond integrity of HA containing adhesive to dentin in in vitro condition [9,10]. The precise structure of the nanoparticles has been shown to alter the mechanical properties through interaction with a dense collagen network. This complex interaction is supported by the hydrogen bonding between –COOH, –OH, and –NH2 of the collagen network with the –OH group of the hydroxyapatite particles, triggering re-mineralization at the interface of adhesive dentin [18,19,20]. On the other hand, silane also acts as a strengthening agent that chemically bonds to matrix and nanosphere particles, requiring a high amount of energy to break these linkages [21]. Hence, the conceived agglomerate structure occupies lesser space and assimilates effectively within the hybrid layer and forms deeper resin tags that stimulate the durable existence of the experimental adhesive with the high tensile bond strength and microhardness. These are possible explanations for the improved μTBS of HAA group specimens compared to controls in the present study.

A high frequency of adhesive failures among the study specimens was possibly due to HA nanoparticle aggregation over the dentin. Long-term analysis has shown superior properties of HA agents that allow epitaxial deposition of CaP on their external surfaces to reinforce the bond with dentin in the hybrid layer [17,22]. The concern, however, rises for the increase in viscosity of the material due to dense filler incorporation. It has been reported that the low hydrophilic nature, concentration, and size of the filler produce a viscous material, which fails to penetrate deep into the conditioned dentin [23]. Previous SEM studies have suggested dentinal tubular openings up to 500 nm in size, however, the size of the collagen inter-fibrillar spaces are around 20–30 nm [23]. Thus, for penetration of HA nanoparticle incorporated dentin adhesive to demineralized dentin, particle size should be comparable to the inter-fibrillar space.

In the present study, an experimental adhesive was prepared containing, HEMA, TEGDMA, and Bis-GMA with other components. The universal adhesives consist of two major groups, HEMA and Bis GMA, that balance the flow ability of the resins and influence dentin penetration. However, added fillers are bound to increase the viscosity of the adhesives [22]. Unlike metallic oxides, HAA varies in its physical, chemical, and biological actions [23]. In contrast to the metallic oxides, amphophilic nature and amorphous/sheet structure, HA nanospheres enable development of the adhesive mechanical properties producing a thicker and supportive hybrid layer with optimum penetration of the material. In addition, a complex interaction observed within dentin for HAA, is deposition of HA nanoparticles around the denuded collagen in the conditioned dentin [24,25]. In the present study, the EDX and SEM analysis validated this interaction through the presence of carbon, phosphorus, oxygen, and calcium at the hydroxyapatite–dentin interface. Thus, it is hypothesized that HA in the form of nanosphere establishes a stable release to achieve improved dentin resin interaction and possible re-mineralization. However, further studies are recommended in this regard.

The Micro-Raman analysis defines and characterizes the interaction of HAA with dentin, to observe the complex bonding of the groups in the experimental adhesives within the hybrid layer. According to Ryu et al. [26], the Micro-Raman spectra underlined the bond characteristics through representing chemical groups, phosphate and carbonate at peak values 960 and 1070 cm−1, respectively. In the present study, peaks at 960 and 1070 cm−1 due to the presence of HA were observed, whereas the peak observed at 1610 cm−1 highlights the adhesive monomer [27,28]. Therefore, signifying the interaction of the HA within groups of adhesive in dentin. Furthermore, the peaks recorded at 1410–1460 cm−1 were due to the –CH3 and –CH2 deformations within the adhesive (Figure 6B), representing characteristic polymerization activity within universal adhesives [29]. Moreover, the characteristic collagen peaks at 1661 cm−1 (typical of amide I due to carbonyl stretching, C–H), 1550 cm−1 (corresponding to amide II due to C–N stretching and N–H bond vibrations), and 1246 cm−1 (for amide III due to C–N stretching and N–H deformation) for dentin presence shows an overall complex hybrid layer formation comprised of HA nanospheres, tooth dentin, and resin adhesive [8,30].

In the present study, the presence of HA nanospheres was confirmed with SEM, EDX, Micro-Raman Spectroscopy, and FTIR. X-ray powder diffraction (XRD) is a technique for phase identification of crystalline materials and is performed for unit cell dimensions of particles, however, it was not performed in the present study [31]. Therefore, further investigations to assess the HA nanosphere within adhesives using XRD are recommended. In addition, to comprehend the adhesive interface interaction, a detailed understanding of the adhesive groups is essential. A possible concern is leaching of HA particles, with possible cytotoxic effects, such as free radical generation, inducing apoptosis [9]. However, previous evidence suggests that the proposed silanization of HA particles neutralizes this effect through reduced solubility [32]. Regardless, cytotoxic potential of HA still poses a risk over a period of time. Therefore, in vivo and in vitro studies are recommended to assess the extent of clinical application of HA nanospheres incorporated dentin adhesives under the dynamic loading in oral conditions with respect to variations of the adhesives.

5. Conclusions

HA nanospheres incorporated experimental dentin adhesive presented with enhanced interaction with dentin compared to control adhesives. HA adhesive showed formation of resin tags and thick hybrid layer, indicating standard formation of dentin bond integrity. HA adhesive showed superior μTBS compared to control adhesive. With an increase in storage time, HA adhesive presented with 100% adhesive failures. Softening was less and KHN was higher for HA adhesive compared to control adhesive and KHN reduction was higher in control adhesive compared to the HA adhesives. In the absence of nanoleakage, HA modified adhesive exhibited enhanced bond strength and showed better durability of resin dentin bond compared to control adhesive. There is potential in HA adhesives for re-mineralization of carious dentin, therefore, further in vitro and in vivo studies are recommended.

Author Contributions

R.SA.-H. and H.FK.: Data collection, study design, data assessment, and manuscript writing, final manuscript approval, Investigation and methodology (FTIR, EDX, MTBS). B.A., S.A.: Data inference, experiments performance (SEM and RS), study design, manuscript drafting, data analysis, and manuscript approval. F.V. and T.A.: Experiment (KHN), Data collection, data interpretation, writing, revise, and editing and final manuscript approval. All authors have read and agreed to the published version of the manuscript.

Funding

The authors are grateful to the Deanship of Scientific Research, King Saud University for funding through Vice Deanship of Scientific Research Chairs, Research Chair for Biological Research in Dental Health.

Conflicts of Interest

The authors declare that they have no conflict of interest and all authors have read and approved the final draft.

References

- Maman, P.; Nagpal, M.; Gilhotra, R.M.; Aggarwal, G. Nano Era of Dentistry-An Update. Curr. Drug Deliv. 2018, 15, 186–204. [Google Scholar] [CrossRef] [PubMed]

- Foong, L.K.; Foroughi, M.M.; Mirhosseini, A.F.; Safaei, M.; Jahani, S.; Mostafavi, M.; Ebrahimpoor, N.; Sharifi, M.; Varma, R.S.; Khatami, M. Applications of nano-materials in diverse dentistry regimes. RSC Adv. 2020, 10, 15430–15460. [Google Scholar] [CrossRef]

- Toledano Pérez, M.; Osorio Ruiz, R. New Advanced Materials for High Performance at the Resin-Dentin Interface; Karger Publishers: Berlin, Germany, 2015. [Google Scholar]

- Jojibabu, P.; Jagannatham, M.; Haridoss, P.; Ram, G.J.; Deshpande, A.P.; Bakshi, S.R. Effect of different carbon nano-fillers on rheological properties and lap shear strength of epoxy adhesive joints. Compos. Part A Appl. Sci. Manuf. 2016, 82, 53–64. [Google Scholar] [CrossRef]

- Korkmaz, Y.; Gurgan, S.; Firat, E.; Nathanson, D. Effect of adhesives and thermocycling on the shear bond strength of a nano-composite to coronal and root dentin. Oper. Dent. 2010, 35, 522–529. [Google Scholar] [CrossRef]

- Abdelaziz, E.M.; Al-Wakeel, E.; El-Morsy, F.; Sheha, R.R.; Enan, E.T. Viscosity and micro-tensile bond strength of total-etch adhesive system reinforced with hydroxyapatite nano-particles. Mansoura J. Dent. 2014, 1, 115–118. [Google Scholar]

- Wagner, A.; Belli, R.; Stotzel, C.; Hilpert, A.; Muller, F.; Lohbauer, U. Biomimetically-and hydrothermally-grown HAp nanoparticles as reinforcing fillers for dental adhesives. J. Adhes. Dent. 2013, 15, 413–422. [Google Scholar]

- Carvalho, E.; de Paula, D.; Neto, D.A.; Costa, L.; Dias, D.; Feitosa, V.; Fechine, P.B.A. Radiopacity and mechanical properties of dental adhesives with strontium hydroxyapatite nanofillers. J. Mech. Behav. Biomed. Mater. 2020, 101, 103447. [Google Scholar] [CrossRef] [PubMed]

- Leitune, V.C.B.; Collares, F.M.; Trommer, R.M.; Andrioli, D.G.; Bergmann, C.P.; Samuel, S.M.W. The addition of nanostructured hydroxyapatite to an experimental adhesive resin. J. Dent. 2013, 41, 321–327. [Google Scholar] [CrossRef] [PubMed]

- Sadat-Shojai, M.; Atai, M.; Nodehi, A.; Khanlar, L.N. Hydroxyapatite nanorods as novel fillers for improving the properties of dental adhesives: Synthesis and application. Dent. Mater. 2010, 26, 471–482. [Google Scholar] [CrossRef] [PubMed]

- Ye, Q.; Spencer, P.; Wang, Y.; Misra, A. Relationship of solvent to the photopolymerization process, properties, and structure in model dentin adhesives. J. Biomed. Mater. Res. Part A 2007, 80, 342–350. [Google Scholar] [CrossRef]

- Park, J.; Ye, Q.; Topp, E.M.; Misra, A.; Kieweg, S.L.; Spencer, P. Effect of photoinitiator system and water content on dynamic mechanical properties of a light-cured bisGMA/HEMA dental resin. J. Biomed. Mater. Res. Part A 2010, 93, 1245–1251. [Google Scholar] [CrossRef] [PubMed]

- Sideridou, I.D.; Karabela, M.M. Effect of the amount of 3-methacyloxypropyltrimethoxysilane coupling agent on physical properties of dental resin nanocomposites. Dent. Mater. 2009, 25, 1315–1324. [Google Scholar] [CrossRef] [PubMed]

- Xu, C.; Wang, Y. Collagen cross-linking increases its biodegradation resistance in wet dentin bonding. J. Adhes. Dent. 2012, 14, 11. [Google Scholar] [PubMed]

- Ozaki, M.; Suzuki, M.; Itoh, K.; Wakumoto, S.; Hisamitsu, H. Laser-Raman Spectroscopic Study of the Adhesive Interface. Dent. Mater. J. 1992, 11, 70–76,114. [Google Scholar] [CrossRef] [PubMed]

- Makvandi, P.; Gu, J.T.; Zare, E.N.; Ashtari, B.; Moeini, A.; Tay, F.R.; Niu, L.N. Polymeric and inorganic nanoscopical antimicrobial fillers in dentistry. Acta Biomater. 2020, 101, 69–101. [Google Scholar] [CrossRef] [PubMed]

- Dorozhkin, S.V. Chapter 7: Nanodimensional and Nanocrystalline Calcium Orthophosphates. In Tissue Regeneration: Where Nano-Structure Meets Biology; World Scientific: Singapore, 2014; pp. 219–341. [Google Scholar]

- Prakasam, M.; Locs, J.; Salma-Ancane, K.; Loca, D.; Largeteau, A.; Berzina-Cimdina, L. Fabrication, properties and applications of dense hydroxyapatite: A review. J. Funct. Biomater. 2015, 6, 1099–1140. [Google Scholar] [CrossRef]

- Bonaparte, N. Dedicated to: McGill University; Canada. 2019. [Google Scholar]

- Erol-Taygun, M.; Unalan, I.; Idris, M.I.B.; Mano, J.F.; Boccaccini, A.R. Bioactıve Glass-Polymer Nanocomposites for Bone Tıssue Regeneration Applicatıons: A Revıew. Adv. Eng. Mater. 2019, 21, 1900287. [Google Scholar] [CrossRef]

- Sezinando, A.; Serrano, M.L.; Pérez, V.M.; Muñoz, R.; Ceballos, L.; Perdigao, J. Chemical adhesion of polyalkenoate-based adhesives to hydroxyapatite. J. Adhes. Dent. 2016, 18, 257–265. [Google Scholar]

- Dorozhkin, S.V. Nanometric calcium orthophosphates (capo4): Preparation, properties and biomedical applications. Adv. Nano Bio. M&D 2019, 3, 422–513. [Google Scholar]

- Liu, Y.; Dang, Z.; Wang, Y.; Huang, J.; Li, H. Hydroxyapatite/graphene-nanosheet composite coatings deposited by vacuum cold spraying for biomedical applications: Inherited nanostructures and enhanced properties. Carbon 2014, 67, 250–259. [Google Scholar] [CrossRef]

- Marghalani, H.Y. Sorption and solubility characteristics of self-adhesive resin cements. Dent. Mater. 2012, 28, e187–e198. [Google Scholar] [CrossRef] [PubMed]

- Provenzi, C.; Leitune, V.C.; Collares, F.M.; Trommer, R.; Bergmann, C.P.; Samuel, S.M. Interface evaluation of experimental dental adhesives with nanostructured hydroxyapatite incorporation. Appl. Adhes. Sci. 2014, 2, 1–5. [Google Scholar] [CrossRef]

- Ryu, J.; Ku, S.H.; Lee, M.; Park, C.B. Bone-like peptide/hydroxyapatite nanocomposites assembled with multi-level hierarchical structures. Soft Matter 2011, 7, 7201–7206. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, Y. The effect of hydroxyapatite presence on the degree of conversion and polymerization rate in a model self-etching adhesive. Dent. Mater. 2012, 28, 237–244. [Google Scholar] [CrossRef]

- Ishimaru, Y.; Oshima, Y.; Imai, Y.; Iimura, T.; Takanezawa, S.; Hino, K.; Miura, H. Raman spectroscopic analysis to detect reduced bone quality after sciatic neurectomy in mice. Molecules 2018, 23, 3081. [Google Scholar] [CrossRef]

- Esmonde-White, K.A.; Le Clair, S.V.; Roessler, B.J.; Morris, M.D. Effect of conformation and drop properties on surface-enhanced Raman spectroscopy of dried biopolymer drops. Appl. Spectrosc. 2008, 62, 503–511. [Google Scholar] [CrossRef]

- Ubaldini, A.L.; Baesso, M.L.; Sehn, E.; Sato, F.; Benetti, A.R.; Pascotto, R.C. Fourier transform infrared photoacoustic spectroscopy study of physicochemical interaction between human dentin and etch-&-rinse adhesives in a simulated moist bond technique. J. Biomed. Opt. 2012, 17, 065002. [Google Scholar]

- Predoi, D.; Iconaru, S.L.; Predoi, M.V. Bioceramic layers with antifungal properties. Coatings 2018, 8, 276. [Google Scholar] [CrossRef]

- Dupraz, A.M.; De Wijn, J.R.; vd Meer, S.A.; De Groot, K. Characterization of silane-treated hydroxyapatite powders for use as filler in biodegradable composites. J. Biomed. Mat. Res. 1996, 30, 231–238. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).