3.1. Powder Characterization

In thermal spraying technology, it is accepted that the microstructure of the coatings depends considerably on the characteristics of the powder particles at the point of collision with the substrate. In the HVOF/HVAF processes, the residence time of the particles inside the equipment, although minimal due to the high velocities (which depend on the gases flow rate) of the outlet flow of the gases, controls the heat transfer between the hot gases and the feedstock material and consequently determines its temperature at the point of impact with the substrate. At this point, the microstructure of the coating is influenced by the processes of deformation and solidification, caused by the high velocities and temperatures of the particles. These two factors are highly dependent on the size distribution of the powder particles, which is typically polydisperse. As a result, the particles of different sizes experience different momentum and thermal inertias, affecting the physical states of the particles during flight time and impact with the substrate [

29,

30]. Therefore, it is important to study the size distribution of the feedstock and adjust the process parameters accordingly. Hence, the characteristics and size distribution of the powders played an important role in the coatings microstructure, especially in terms of porosity and roughness.

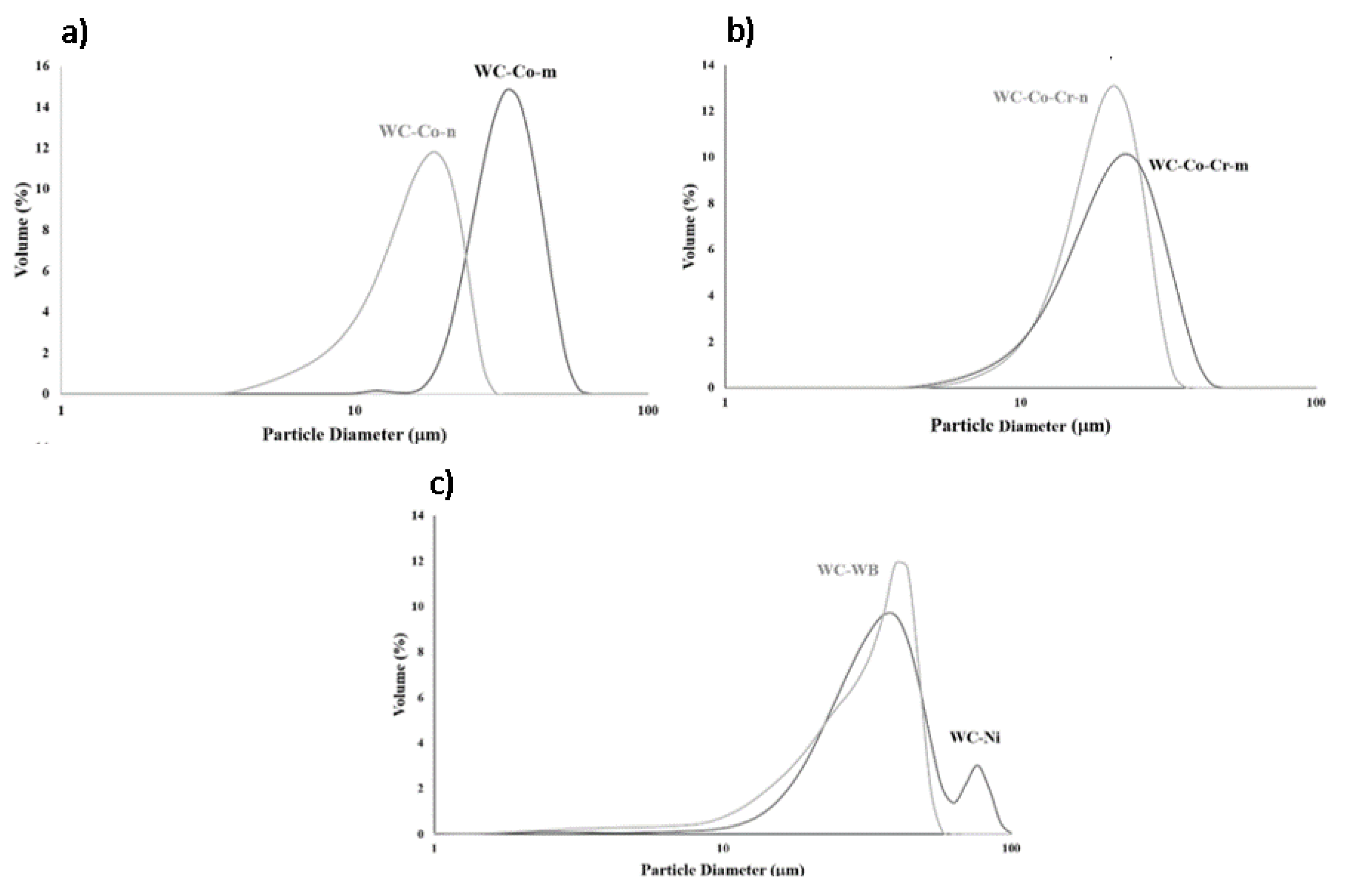

The statistical size distribution of the particles and the size distribution curves for all the powders under study in this work are reported in

Table 3 and

Figure 1, respectively. This comparison shows that the powders mainly resulted to have a homogeneous distribution, as expected for commercial feedstock materials. Nonetheless, some differences can be found regarding powder properties depending on the feedstock material composition. Thus, WC-Co (micro and nanometric) revealed a relevant difference in their mean particle size of these powders, which shows as the particles of the WC-Co-m powder are larger than that of the WC-Co-n material. In addition, the nanometric powder showed a narrower size distribution than the micrometric one. No relevant differences were observed between powders WC-Co–Cr-m and WC-Co–Cr-n, which resulted in almost equivalent distributions with similar mean particle size values, as it can be seen in

Figure 1b. On the contrary, the powders WC-WB and WC-Ni presented heterogeneous distributions, where the former one showed a distorted distribution with a bump, and the last one a distribution with two groups of particles with different sizes, resulting in the highest mean size distribution of all powders, with 80% of the particles with a diameter of between 20 and 61 µm.

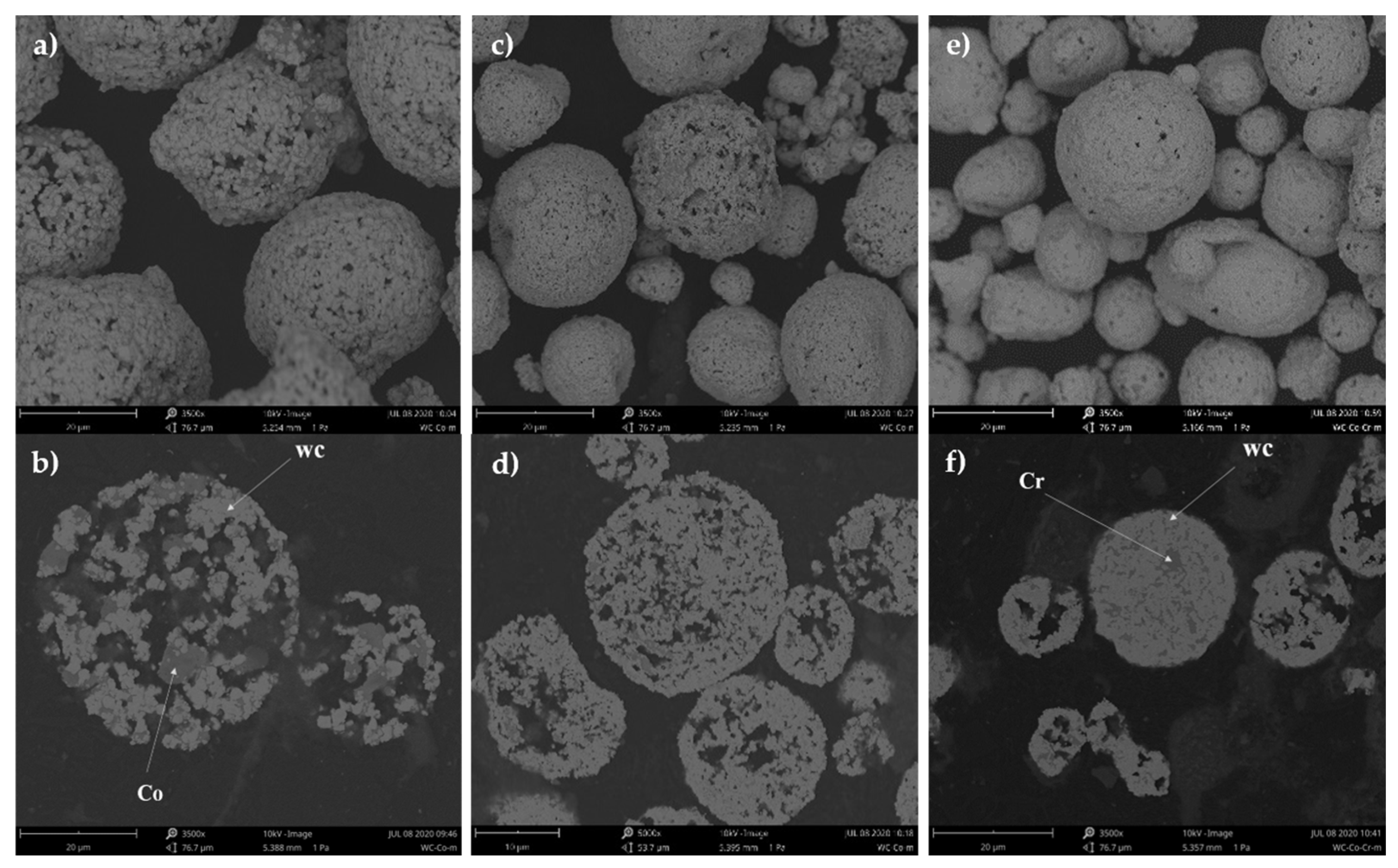

The spherical or irregular morphology of the powders and their microstructure was inspected by SEM.

Figure 2 shows only the images recorded for the most representative powders (WC-Co-m, WC-Co-n, and WC-Co–Cr-m) for the sake of brevity. SEM images confirmed that all powders were composed of agglomerated particles and had a spherical morphology and were composed of WC grains embedded in a metallic binder: Co, Co–Cr (for WC-Co–Cr and WC-WB-Co–Cr powders), or NiMoCrFeCo, depending on the composition of the powder. Consistent with the particle size distribution results (

Table 3), the free surface images showed the different sized particles of the powders. For instance, it is particularly interesting to observed the size diversity in the WC-Co-n powder (

Figure 2c).

In contrast to the free surface images, that show the size difference of the agglomerated particles between all powders, in the cross-sectional images, the microstructure of the WC-based particles can be observed and analyzed [

31]. Thus, the evaluation of the surface and core porosity level of the powders revealed that the WC-Co-m were slightly more porous than the WC-Co-n and WC-Co–Cr-n feedstock materials. Even though they are not shown, WC-Co–Cr-m powder presented similar porosity as WC-Co-m whilst powders WC-WB and WC-Ni were highly porous.

In order to identify the elements present in the powder composition, an EDS mapping analysis of the particles was performed and the images of this analysis are shown in

Supplementary Figures S1–S3 of the supplementary information file of this manuscript. The results allow conclude that the dark regions of the particles microstructure (shown in

Figure 2b,f) corresponded to the metallic binder of each powder, while the bright regions were ascribed to WC and/or WB grains. In this respect, in the powders with composition WC-Co, it was clearly identified that the metal matrix contained pure Co. Additionally, comparing their microstructure, in

Figure 2b,d is confirmed that the powders labelled as micrometric showed higher size of the WC grains compared to the ones labelled as nanometric. Finally, in the case of the powders WC-Co–Cr and WC-WB, Cr predominated in the composition of the dark regions. In the same way, powder WC-Ni was mainly composed of Cr, Ni, and Mo.

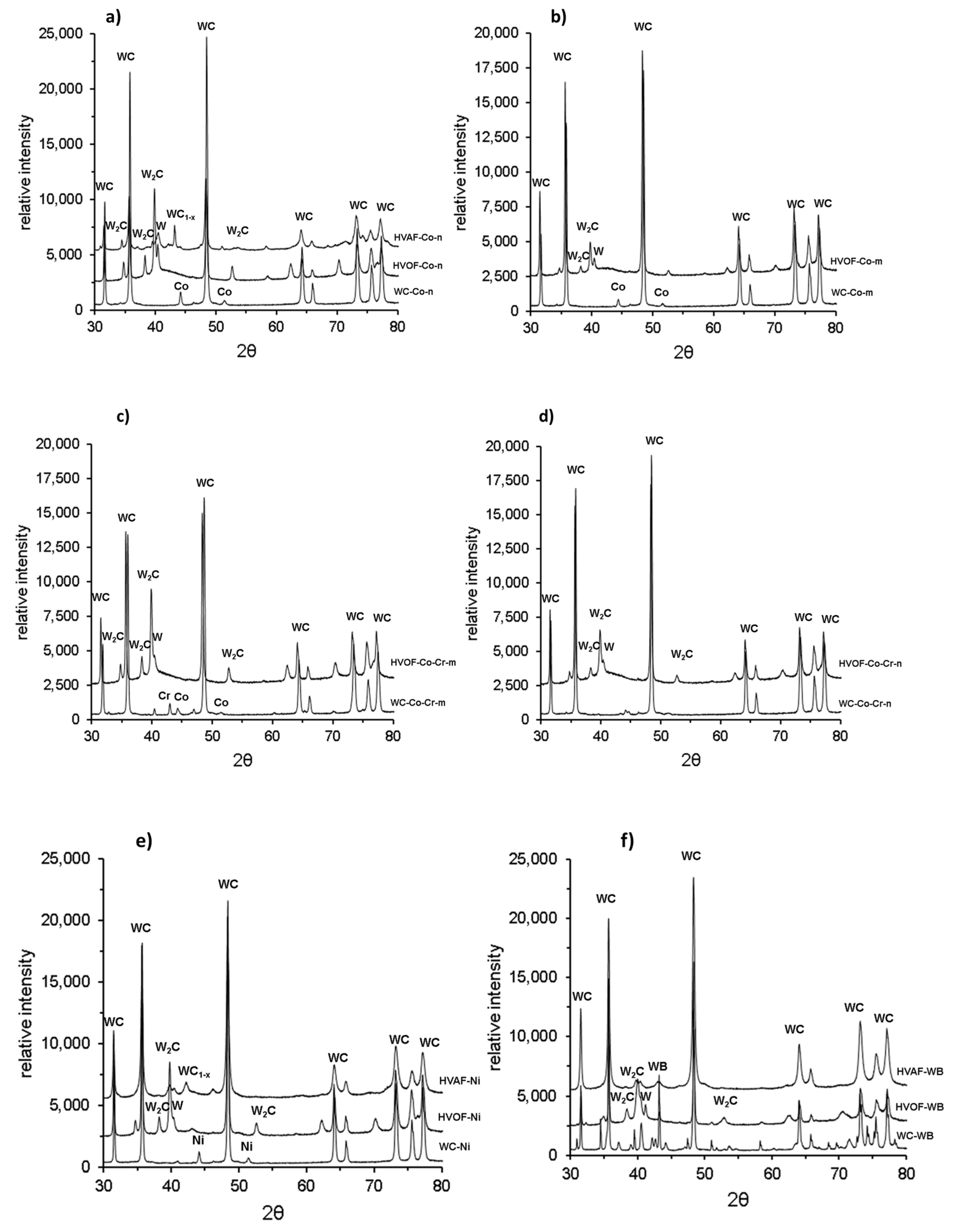

For corroborating the presence of these phases, the XRD diffractograms of the powders are shown in

Figure 3 According to the patterns, all the powders were found to contain only WC as a ceramic component and pure phases (Co, Cr, Ni, Mo) as the metallic binder.

In summary, the comparative analysis of the powders characteristics allowed concluding that all the powders are composed of WC grains embedded in a metallic matrix formed by metallic pure phases. WC-Co-m and WC-Co–Cr-m are composed of larger particles showing higher porosity than their respective nanometric powders. In addition, WC-Ni and WC-WB powders showed a broad size distribution, with two peaks in the WC-Ni case. These powders showed a highly porous microstructure.

3.2. Microstructure of the TS Coatings

It is worth remembering that the objective of this work was to compare the final coatings properties regarding the thermal spray process and composition and particle characteristics of feedstock materials. For this reason, the same spraying parameters were used in HVOF and HVAF processes respectively, for all the powders, except for powders WC-Ni and WC-WB, which were sprayed at a higher distance in order to minimize high porosity values.

As expected, the coatings exhibited different microstructures according to their grain size, composition and thermal spray process used.

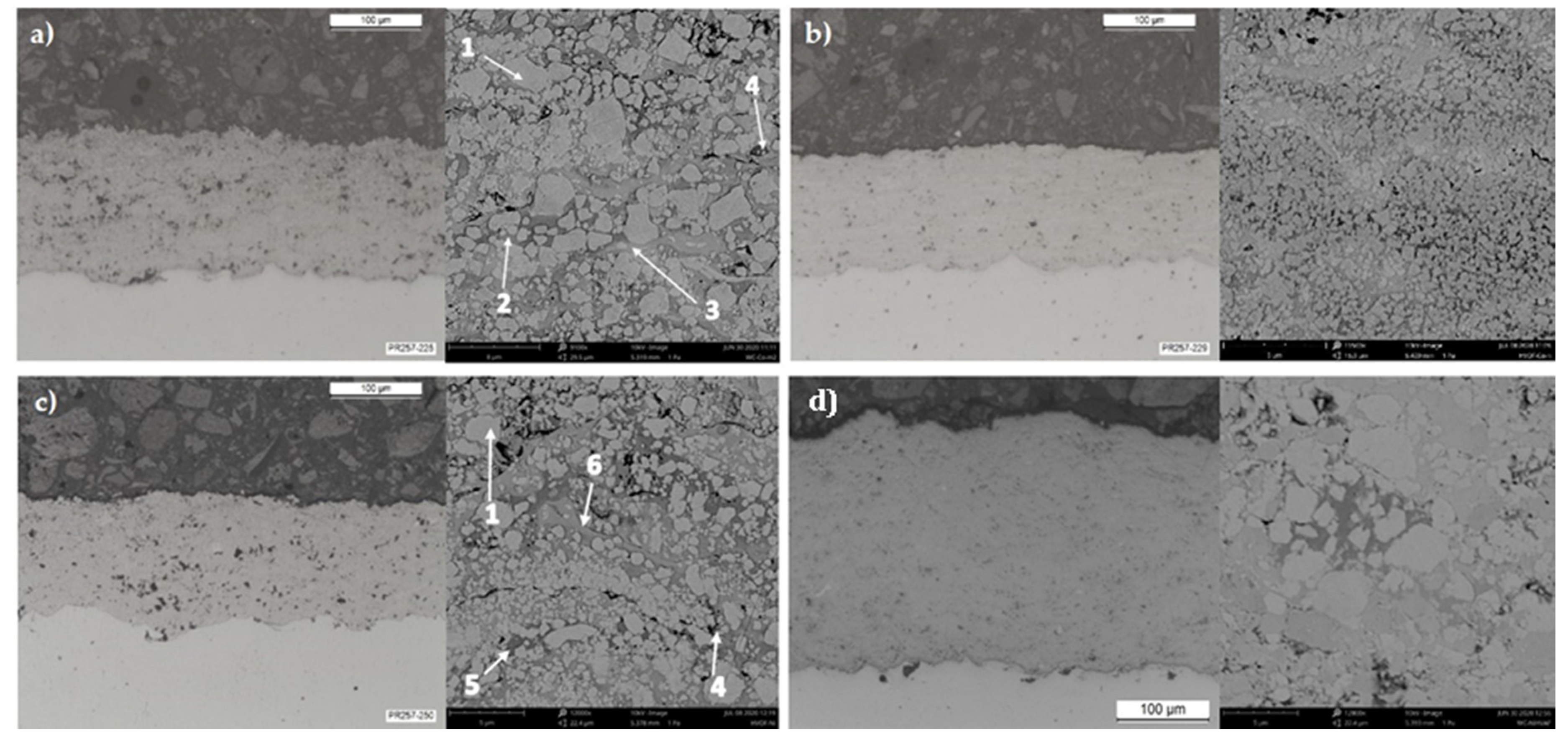

Figure 4 shows representative polished cross-sectional recorded by optical microscopy (OM) (left) and SEM (right) images of the coatings, while

Table 4 shows their thickness, porosity, roughness, and hardness values.

In general, from the results included in

Table 4, it can be concluded that the coatings sprayed by HVAF were thicker, less porous and more homogeneous than the HVOF ones. Thus, the coatings sprayed by HVAF showed thickness values between 230 and 150 µm, against values between 133 and 113 µm. With the exception of the coating HVAF-WB, with a porosity value higher than 9%, all coatings had low porosity with values between <1% and 2%. In the case of the roughness of the coatings, it may be suggested that this is influenced by the cermet composition. In this respect, WC-Co coatings showed a smother surface than WC-Ni and WC-WB coatings. No clear differences are observed in the roughness values measured for the same coating compositions but obtained by HVOF or HVAF, with the exception of the coating HVAF-WB which presented a mean roughness Ra of 8.2 ± 0.6 µm, while the other HVOF coating presented Ra value of 5.3 ± 0.4 µm.

These data were found to be consistent with the porosity observed in the free surface and cross-sectional SEM images of the powders, as the powder used for preparing this coating also showed a high porosity. However, the coating porosity is not only dependent on the powders characteristics, but also on the final particle temperature during spraying process. When particles are heated up to higher temperatures, it is easier for them to melt on-flight before colliding with the substrate, resulting in denser coatings. Thus, despite the fact that WC-Co-m, WC-Co–Cr-m, and WC-Ni powders were very porous materials, the high density shown by their respective coatings allow for the conclusion that the spraying parameters used were aggressive enough for melting the particles.

Cross section images show that the particles that build up the coatings are strongly bonded to each other, since no cracks nor delamination areas were observed. Furthermore, the SEM images at high magnifications made it possible to observe the different phases in the microstructure of the coatings. All of them showed a homogenous distribution of the WC grains embedded into a darker metallic matrix along with some pores that might have been formed between particle splats. In

Figure 4a,b the differences in the microstructure are clearly shown, especially regarding the WC grain size between micrometric and nanometric coatings. The WC grain size proved to be in the range of 1–4 µm for micrometric powders WC-Co-m and WC-Co–Cr-m, and 300–500 nm for nanometric powders WC-Co-n and WC-Co–Cr-n. Likewise powders WC-Ni and WC-WB had WC grains with sizes between <1–3 µm and <1–5 µm, respectively.

Looking at the coatings microstructure, it can be observed that those sprayed by HVOF showed some distinguished regions (darker than the WC grains), which might be attributed either to the metallic matrix or to the presence of undesired phases, difficultly distinguished in HVAF coatings. It is widely accepted that, in the thermal spraying methodology, the phase composition of a coating (WC-grains, metallic matrix and undesired phases) strongly depends on the flame temperature achieved. In this respect, the HVOF process leads to hotter and more oxidizing flame conditions than HVAF technique, which may explain these differences. In order to better identify these regions, the powders and coatings were further analyzed by EDS (

Supplementary Figures S4–S6). This analysis confirmed the regions ascribed to the WC grains, W

2C, and metallic matrix, as indicated in the labels of

Figure 4a,c. The identification of W

2C (lighter continuous regions surrounding WC grains with rounded shaped) allows concluding that certain processes of dissolution and decarburization of the WC grains occurred during spraying procedure. At high HVOF flame temperatures, the mechanism of decarburization starts with the melting of the metallic binder, since it has a lower melting point than the WC carbides. Afterwards, the WC grains begin to dissolve in the molten metal and, at the gas-liquid interface, carbon is released by its reaction with the oxygen of the gases. At the point of impact with the substrate, the particles are rapidly quenched and the dissolved WC grains become supersaturated, resulting in the formation of W

2C [

32]. In contrast, the W

2C phase was not clearly observed in the microstructure of the HVAF coatings.

A microstructure comparison between HVOF and HVAF coatings can be observed in

Figure 4c,d. In these images, it is shown that in the microstructure of the coating HVOF-Ni has a high presence of these lighter regions between different sized rounded grains, whereas coating HVAF-Ni only showed irregular grains embedded in the metallic matrix.

The XRD patterns of all the coatings were recorded for further support of the conclusion drawn from the visual inspection (

Figure 3). As expected, all the coatings were composed mainly of the phases also identified in their respective powders, that is, WC as ceramic phase and their correspondent metallic pure phases as matrix. In agreement with previous results, HVAF coatings showed little or none undesired phases, while some HVOF coatings suffered relevant decarburization. Thus, in the case of the HVOF coatings patterns, the presence of W

2C and W phases indicated that decarburization occurred. As above mentioned, since the HVOF process operates at higher temperatures, the coatings sprayed by this method were more likely to form undesired phases. This is clearly observed in coatings HVOF-Co-n and HVOF-Co–Cr-n, as they were the ones that showed more content of W

2C and W. Among all the HVOF coatings, the HVOF-Co-m was the one that underwent less decarburization, since the sprayed conditions (used for all coatings) were the optimal ones for the size distribution of this conventional powder. For this reason, the nanostructured coating HVOF-Co-n showed more W

2C phases in comparison to the HVOF-Co-m one, which can be understood regarding the smaller WC grain size for the nanometric powder that facilitates the dissolution of WC original grains and their final decarburization during fast solidification. Another factor that affected the presence of the undesired phases is the binder composition. As mentioned before, the addition of Cr to the matrix is known to prevent the WC grains decarburization. This explains that the XRD patterns of both coatings HVOF-Co–Cr-n and HVOF-Co–Cr-m feature few differences between them in terms of W

2C presence and, for hence, it points out that less decarburization occurs than for the coating HVOF-Co-n. Coatings HVOF-Ni and HVOF-WB showed little decarburization, attributed to their composition and elevated mean particle size, as these bigger particles lightly experienced the elevated temperatures of the process.

Compared to HVOF methodology, during HVAF processes the powders are subjected to lower temperatures, therefore, except for the coating HVAF-Co-n which presented some W2C, WC1−x and W phases, most HVAF sprayed coatings showed practically no decarburization, meaning that the peaks corresponded in great part only to WC.

Finally, it is worth noting that the coatings HVOF-Co-n, HVOF-Co–Cr-m and HVOF-Co–Cr-n revealed one bump between 40°–45° indicating the presence of amorphous/nanochrystalline phases that were formed during the dissolution of the WC grains [

15,

33].

Thus, comparing the general microstructure of the coatings, it can be concluded that the ones sprayed by HVAF were thicker, less porous, and more homogeneous than the HVOF ones as they presented less roughness and practically no undesired phases due to the conservation of the WC grains during the TS process.

3.3. Mechanical and Anti-Wear Properties of the Coatings

The mechanical properties of the coatings are defined by its microstructure and composition. For instance, hardness values depend on several factors based on the microstructure of the coatings: (i) it increases as a function of cohesion between particles and coating porosity [

34,

35]; (ii) decarburization degree has an important impact on hardness since the higher amount of W

2C, the higher the coating hardness [

36]; (iii) it depends on the WC grain size, as a small carbide size leads to a high hardness [

37]; and (iv) the presence of an amorphous/nanocrystalline phase results in an increased of cohesion between the carbide grain and the metallic matrix, that leads to an improvement of the hardness of the coating [

9].

Taking into account the previous discussion about the coatings microstructure, it would be expected that HVOF coatings showed higher hardness than the HVAF coatings because of the presence of W

2C in their composition. However, it becomes difficult to draw this conclusion looking at the Vickers hardness values (0.3 kgF) shown in

Table 4. In general, these data revealed that all the coatings featured very high hardness, above 1500 HV

0.3, independently of the TS process used for their preparation. This result suggests that the higher degree of amorphous/nanocrystalline phases identified in the HVAF coatings microstructure plays a key role and enhanced the cohesion between the carbide grains and the matrix, and as a result, increased the hardness of the coating.

Making a comparison based only on composition, both HVAF and HVOF coatings presented roughly the same trend in terms of hardness values. The coating with the WB in the ceramic phase resulted to have the greater hardness (this is not applicable for coating HVAF-WB since it showed very high porosity), which is followed, in order, by coatings with the binders Co–Cr, Co, and Ni-alloy. In the case of the micrometric and nanometric based coatings, the coating HVOF-Co-n resulted slightly harder than the conventional coating HVOF-Co-m, as the first one showed to have more W2C and phases than the former one. For this same reason, Co–Cr based coatings presented an inverse trend: the coating HVOF-Co–Cr-m resulted slighlty harder than the HVOF-Co–Cr-n.

Usually, high coating hardness is related to a decrease in its toughness, nonetheless hard metals have shown to maintain high toughness when having high hardness values [

38]. This unique combination of properties makes them excellent materials for applications that require high resistance to wear. Toughness fracture resistance mainly depends on two factors in this kind of coating, namely the amount and characteristics of the binder phase present and the grain size of the carbide phase [

39]. It is worth indicating that an attempt was made to measure the toughness of these coatings following the calculation method presented in the work of Lima et al. [

22]. Nevertheless, it was not possible to obtain the toughness values since the maximum indentation force of the equipment was not strong enough to produce the adequate length of the cracks needed in order to fulfill one of the restrictions of the method. Despite the fact that the toughness was not analytically calculated, it may be suggested that all coatings presented very high fracture toughness due to the heavy load necessary for crack formation and propagation. In addition, this observation would point out that, in these HVOF and HVAF coatings, there exists a high cohesion strength among the splats forming the coating microstructure.

Another important property of hard metals is their adhesion with the substrate surface, which determines the actual utility of the coating. Nowadays, it is considered that coatings prepared by conventional TS techniques are mechanically anchored to the substrate. Thus, a perfectly controlled cleaning and grit blasting process of the substrate has a strong influence on the adhesion strength at the interface. However, the degree of fusion of the particles but also the interfacial bonding within the lamellar microstructure, which integrates the pores size and distribution [

17] will be also crucial for a proper coating performance in terms of adhesion.

The adhesion strength of the coatings was measured by means of tensile tests and the results obtained are included in

Table 4. In the case of the HVAF coatings, HVAF-Ni, HVAF-Co, and HVAF-WB failed by adhesion of the coating–substrate interface at 60.5 ± 8.0 MPa, 50.3 ± 6.0 MPa, and 48.2 ± 7.0 MPa values, respectively. This kind of failure indicated that, at these tensile strength values, the coating was not strong enough to maintain its bond with the substrate. Moreover, from the analysis of these values, it can be concluded that the metallic binder has a relevant role in the adhesion resistance of the coatings, since the HVAF coating showing the highest adhesion strength is that with the highest metal/ceramic ratio and also with the lowest melting point, HVAF-Ni.

On the contrary, all the HVOF coating were able to withstand a higher tensile force than that withstand by the adhesive, exceeding the 65 MPa. In such a case, this is consistent with the difference in flame temperature of both processes, and the high flame temperature reached in the HVOF process allows the particles to fuse together and leads to stronger bonds within the microstructure.

It is important to highlight that the high adhesion strength values reported for all the coatings is in agreement with previous analysis, and supports the suggestion that there is high cohesion between the particles in coating.

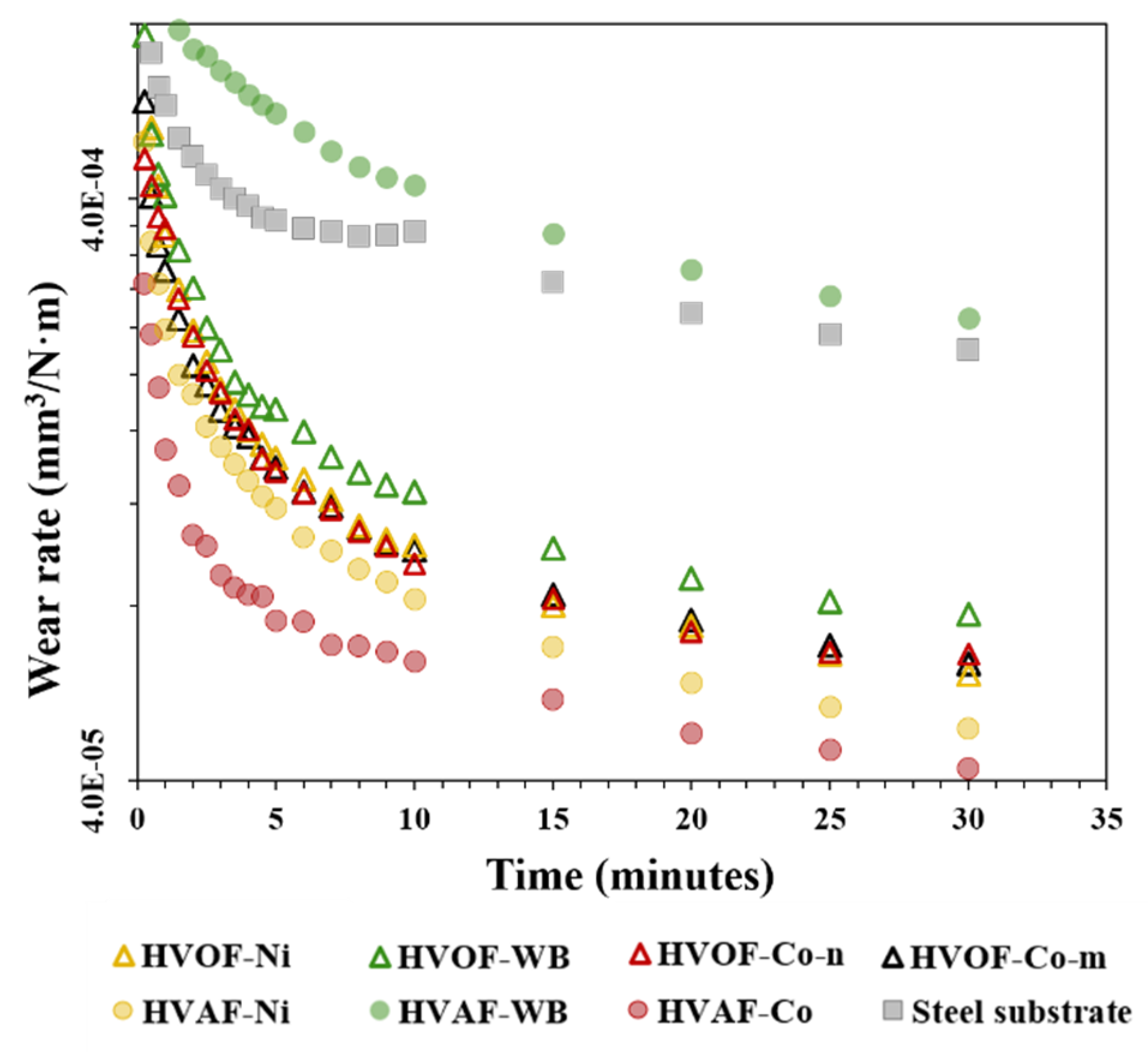

Rubber wheel experiments were performed for the HVAF sprayed coatings (HVAF-Co, HVAF-Ni, HVAF-WB), their respective HVOF coatings (HVOF-Co-n, HVOF-Ni, HVOF-WB), and the conventional coating (HVOF-Co-m) in order to evaluate their wear resistance to abrasive conditions. Wear behavior of the coatings during the experiments are shown in

Figure 5. In this plot, it is observed, within the first minutes of the test, that the wear rate significantly dropped due to the rapid decrease of the roughness of the coatings. The ones that presented higher roughness values (HVAF-Ni and HVAF-WB) showed a steeper drop in the wear rate curve in comparison to HVAF-Co and the steel substrate. In general, after the point where the surface evened out, the wear rate followed a flatter behavior for all the coatings, indicating the hardening of the coatings and the substrate.

Abrasive wear is the main mechanism of wear when the surface of two materials are facing each other with the presence of a third body in between. Abrasion then causes the removal of particles from the softest material. It has been shown that the wear resistance of the hard metals coatings is highly dependent on its composition, carbide grain size, porosity, toughness and hardness values [

39]. The degree of abrasive wear is defined by the hardness difference between the abrasive particles and the counter material, hence higher hardness values are desired to enhance the wear resistance of the coatings and ensure the protection of the coated surface. In the case of the cermets, both hardness and cohesion between the carbides are key properties to improve the abrasive wear resistance. It is clear that the WC particles contribute to the overall hardness, while the metallic matrix defines the cohesion of the WC grains. Therefore, it is important to consider the size of the carbide grains, the binder composition and the thermal sprayed conditions when analyzing the wear resistance of the coatings [

39].

In

Table 5 are shown the volume loss (measured at the end of the experiment) and the wear rate (final value in

Figure 5 for each coating) calculated for all the TS coatings. As can be observed from these data, the coatings HVAF-Co-n and HVAF-Ni resulted to have higher resistance to wear than the other TS coatings with a similar volume loss. This result can be understood if it is considered that these coatings showed low roughness, the absence of undesired phases, and one of the highest thickness and hardness values of the analyzed coatings. HVAF-WB coating experienced a high volume loss value of 37.0 mm

3, being even a greater value than the volume loss measured for the bare steel substrate, which can be explained because of its high porosity. For HVOF coatings, no clear differences in abrasive wear resistance were observed for the coatings HVOF-Co-m, HVOF-Co-n and HVOF-Ni as they showed practically identical wear rate values. In this case, HVOF-Co-n was expected to show the best performance (since nanostructured coatings are known to have enhanced mechanical properties), nevertheless this was not the case. As mentioned before, coating HVOF-Co-n suffered high decarburization, thus its abrasion resistance resulted degraded to slightly higher volume loss and wear rate values than coating HVOF-Co-m. In agreement with the results for HVAF technique, HVOF-WB coating also experienced a high volume loss, close to the value measure for the steel substrate (11.5 mm

3 and 11.7 mm

3, respectively). In this case, the HVOF-WB did not show a porosity that would explain the result, and for this reason, these volume loss and wear rates might be attributed to a poor cohesion between the WC/WB grains and the metallic matrix.

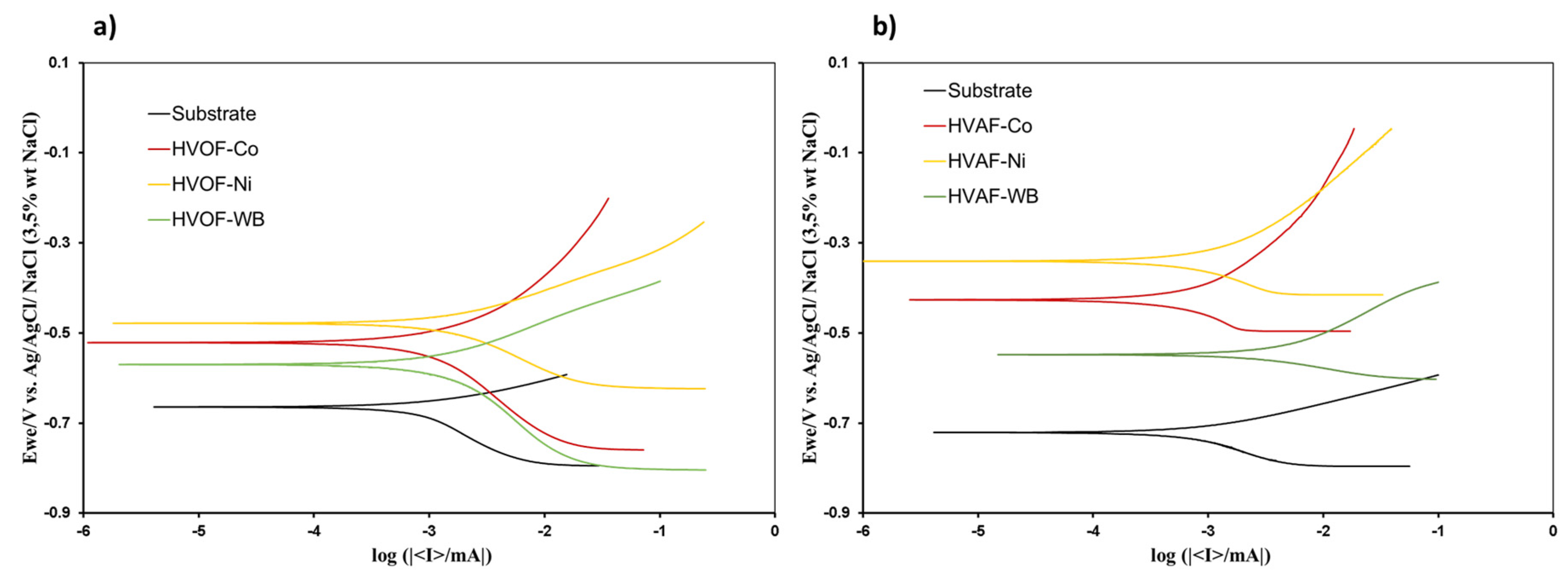

The corrosion behavior of the HVAF and HVOF coatings was evaluated and the resulting polarization curves are shown in

Figure 6a,b. The actual values of

Ecorr and

Icorr inferred from the polarization curves and calculated with Equation (1), respectively, are shown in

Table 5. According to this, a first differentiation can be made between coatings regarding the thermal spraying method used for its deposition, since, in general, the HVAF coatings show higher

Ecorr and lower

Icorr than the HVOF layers. This result can be clearly related to the differences found in the microstructure of coatings. It was demonstrated that HVAF coatings show higher compactness than HVOF coatings, that is a lower porosity and the presence of voids between splats, which is widely accepted in literature as a responsible of their better corrosion behavior [

40].

When subjecting a coated material to corrosive conditions, it is expected for the coating to prevent the effects of corrosion and to ensure the correct operation of the substrate. In hard metals the

Ecorr and

Icorr values are intrinsic of the metallic matrix material. Taking into account the results shown in

Figure 6, both HVOF and HVAF coatings can be classified as a function of their composition, from top to bottom, that is, from high to low

Ecorr, as follows: Ni-based (HVOF-Ni & HVAF-Ni), Co-based (HVOF-Co & HVAF-Co) and WB-based (HVOF-WB & HVAF-WB). These data can be justified since Ni is a more noble metal than Co or Co–Cr alloys.

On the other hand, the comparison of the Icorr values between HVOF-Co & HVOF-Ni and HVAF-Co and HVAF-Ni shows that these coatings present similar corrosion rates under open circuit potentials. Despite of this, when the potential is shifted to the anodic region, these coatings clearly show a different behavior since HVOF-Co and HVAF-Co coatings show a lower current intensity value than the Ni-based coatings over a potential region approximately of −340 and −185 mV, respectively. This data suggests that under polarization conditions, the Co-based coatings will corrode more slowly than the Ni-based coatings. Considering that this kind of coating is supposed to act as a protective barrier between the environment and the substrate, this allows for the conclusion that the HVOF-Co and HVAF-Co coatings will show higher corrosion protective performance than the rest of the coatings studied.

Finally, low coating porosity is mandatory for good corrosion protection. In the case of the HVAF-WB coating, which showed very high porosity, it still shows a certain protective ability since its Ecorr is higher than that of the steel substrate. However, the high Icorr value measured for this material reveals that there is a severe rate of corrosion in this system which might be ascribed to steel corrosion, and hence it indicates that this is not a good protective coating.