Anticorrosion Properties of the Low-Temperature Glow Plasma Nitriding Layer on AISI 904L Austenitic Stainless Steel in Hydrofluoric Acid Obtained at Various NH3 Pressures

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Nitriding

2.3. Morphological Characterization

2.4. Microhardness

2.5. X-ray Diffraction

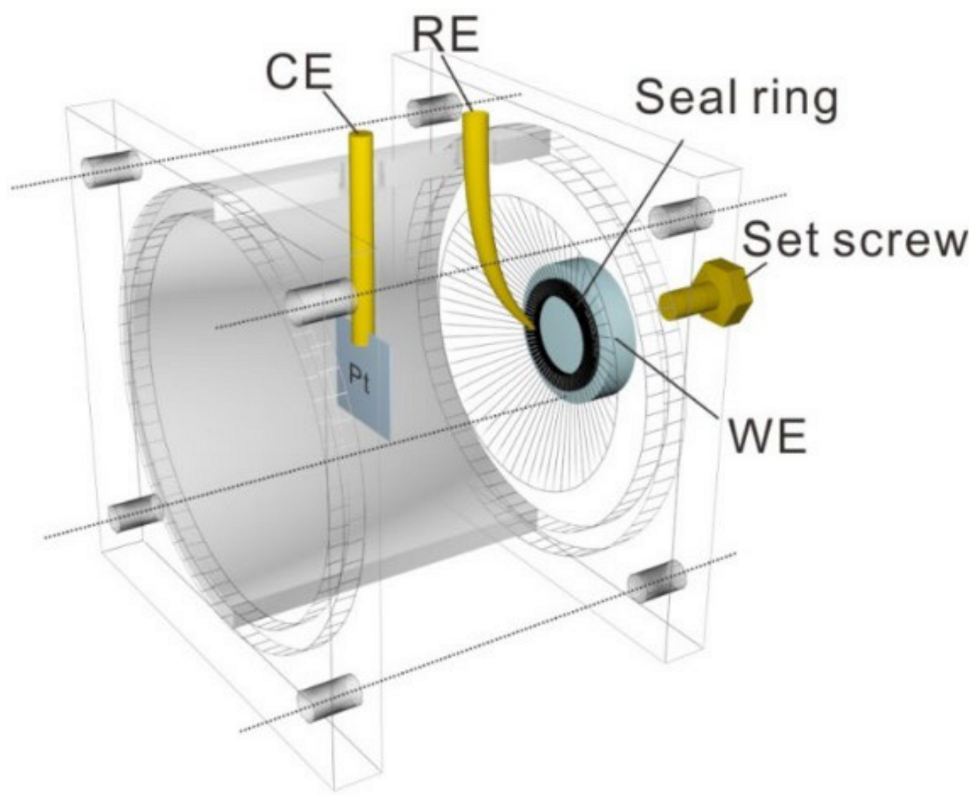

2.6. Electrochemical Tests

2.7. Immersed Corrosion Test

2.8. Scanning Kelvin Probe (SKP)

3. Results

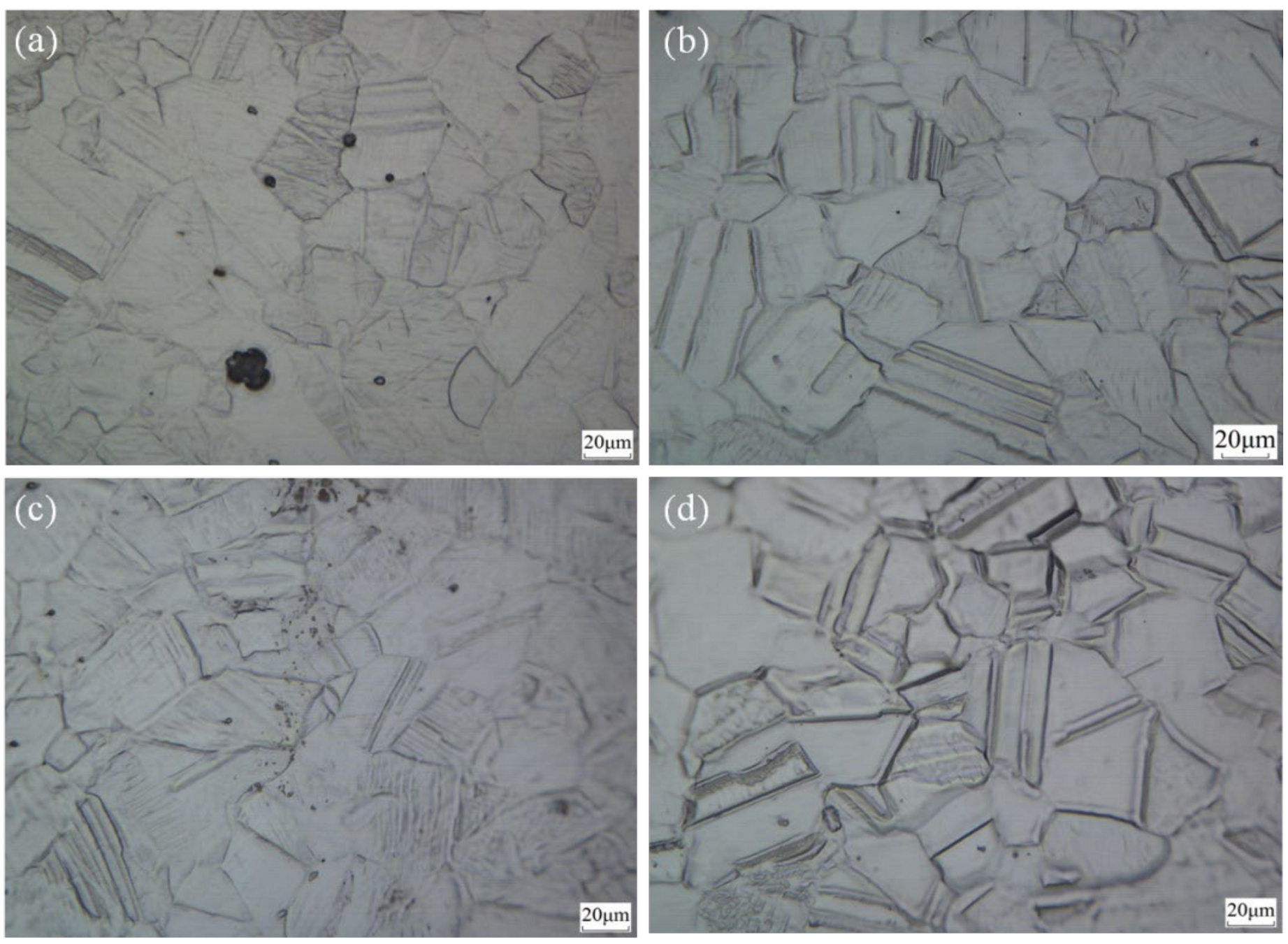

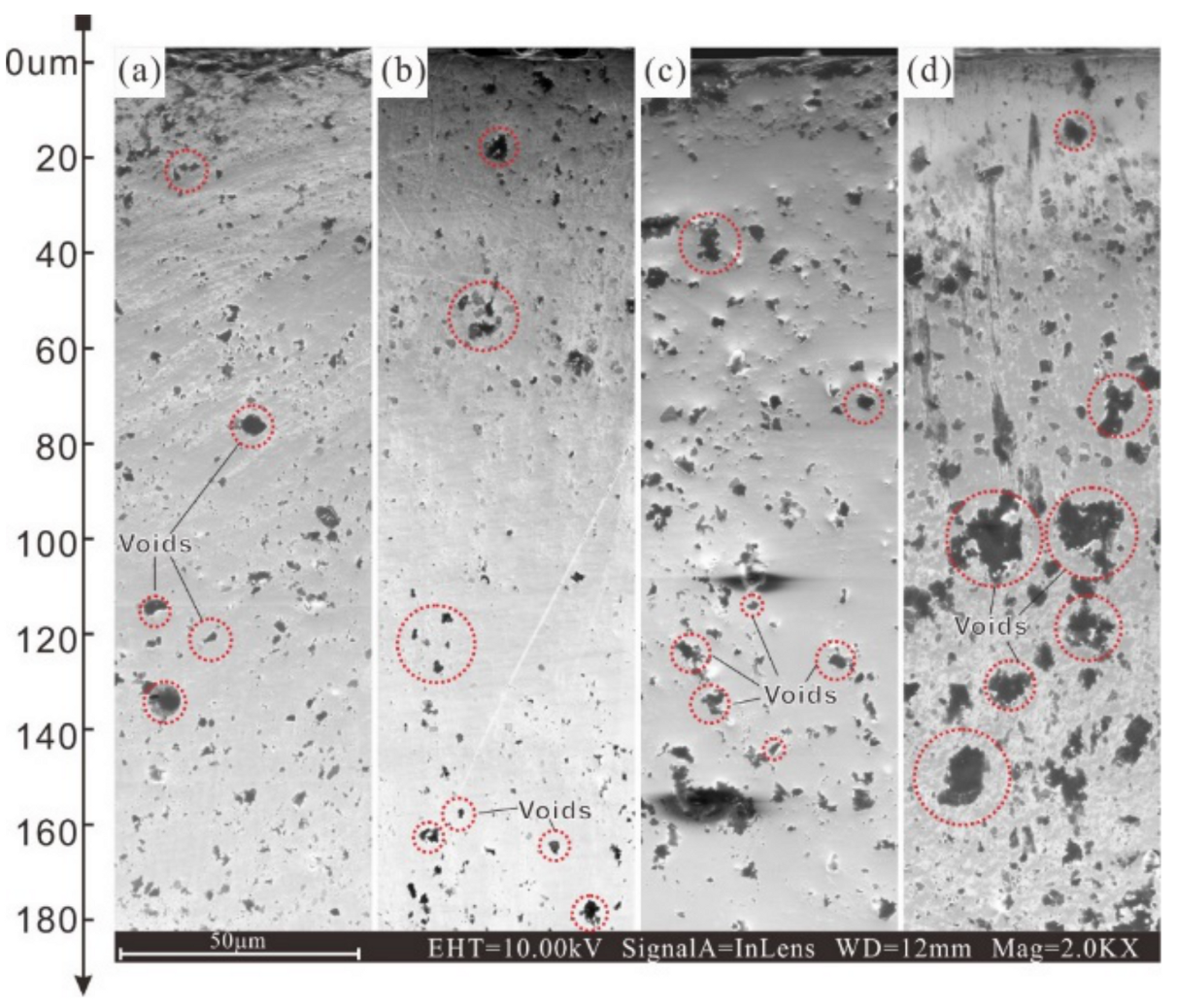

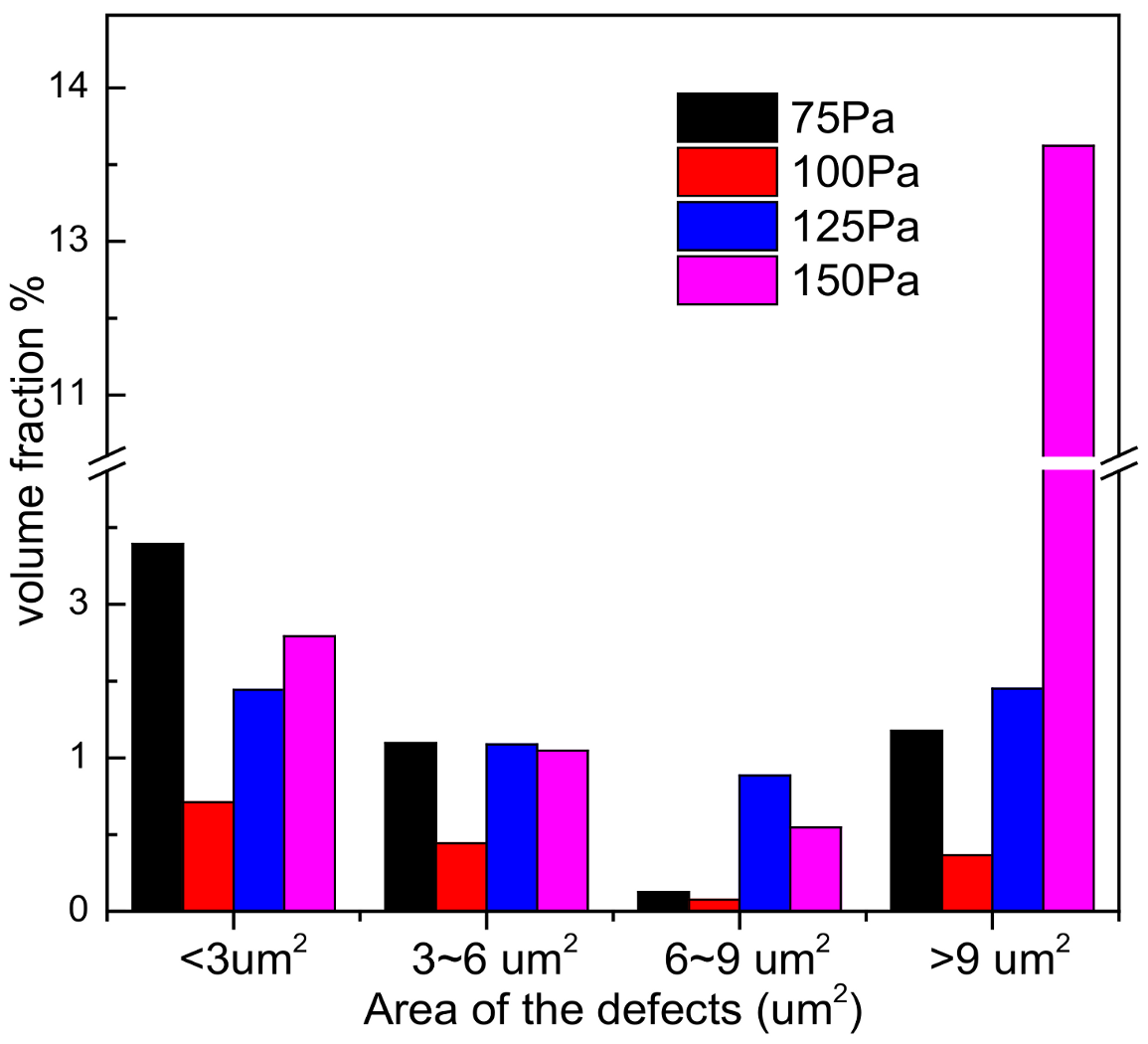

3.1. Optical Micrograph and Microhardness

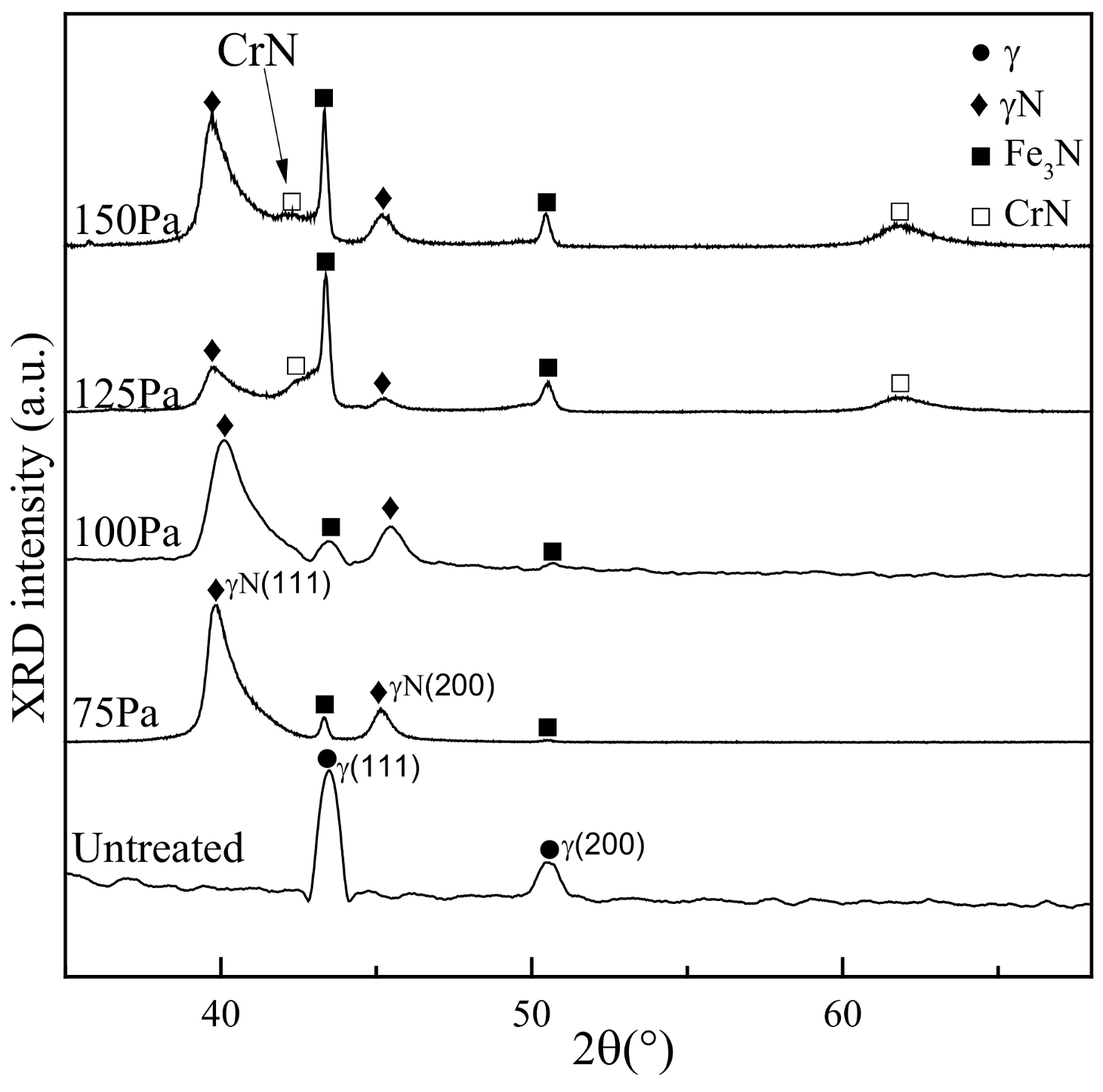

3.2. X-ray Diffractometer (XRD) Spectrum Analysis

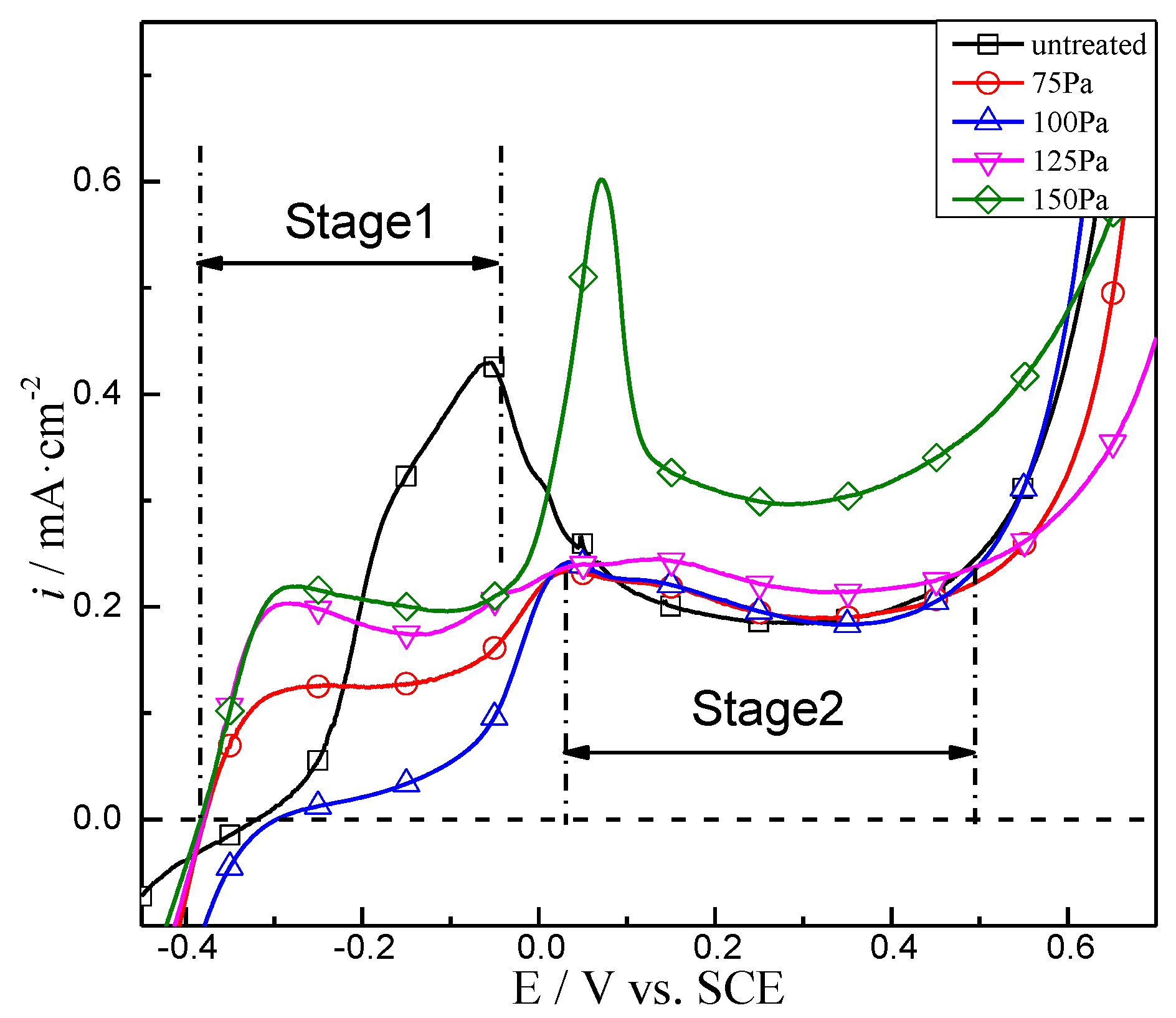

3.3. Electrochemical Behavior

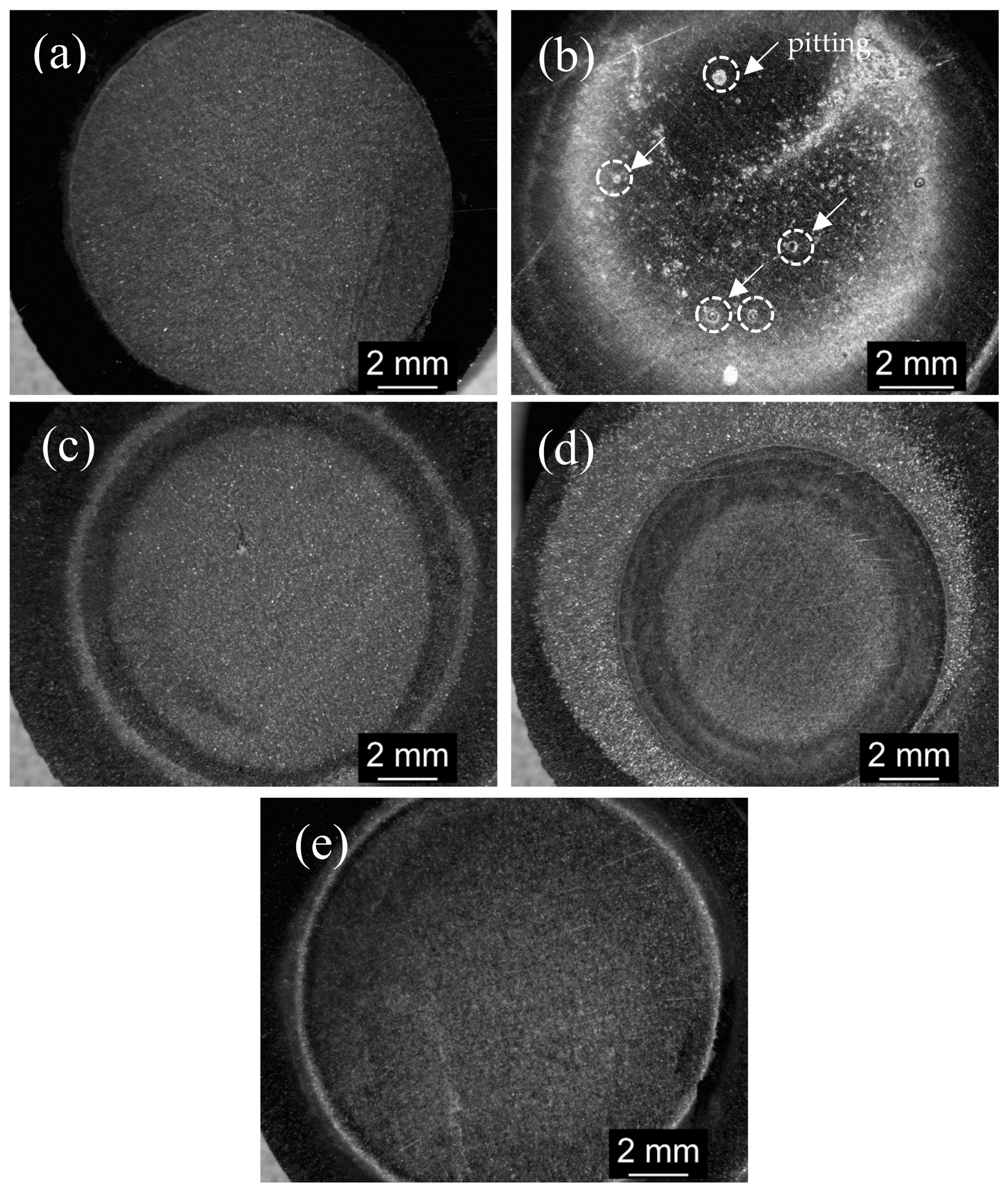

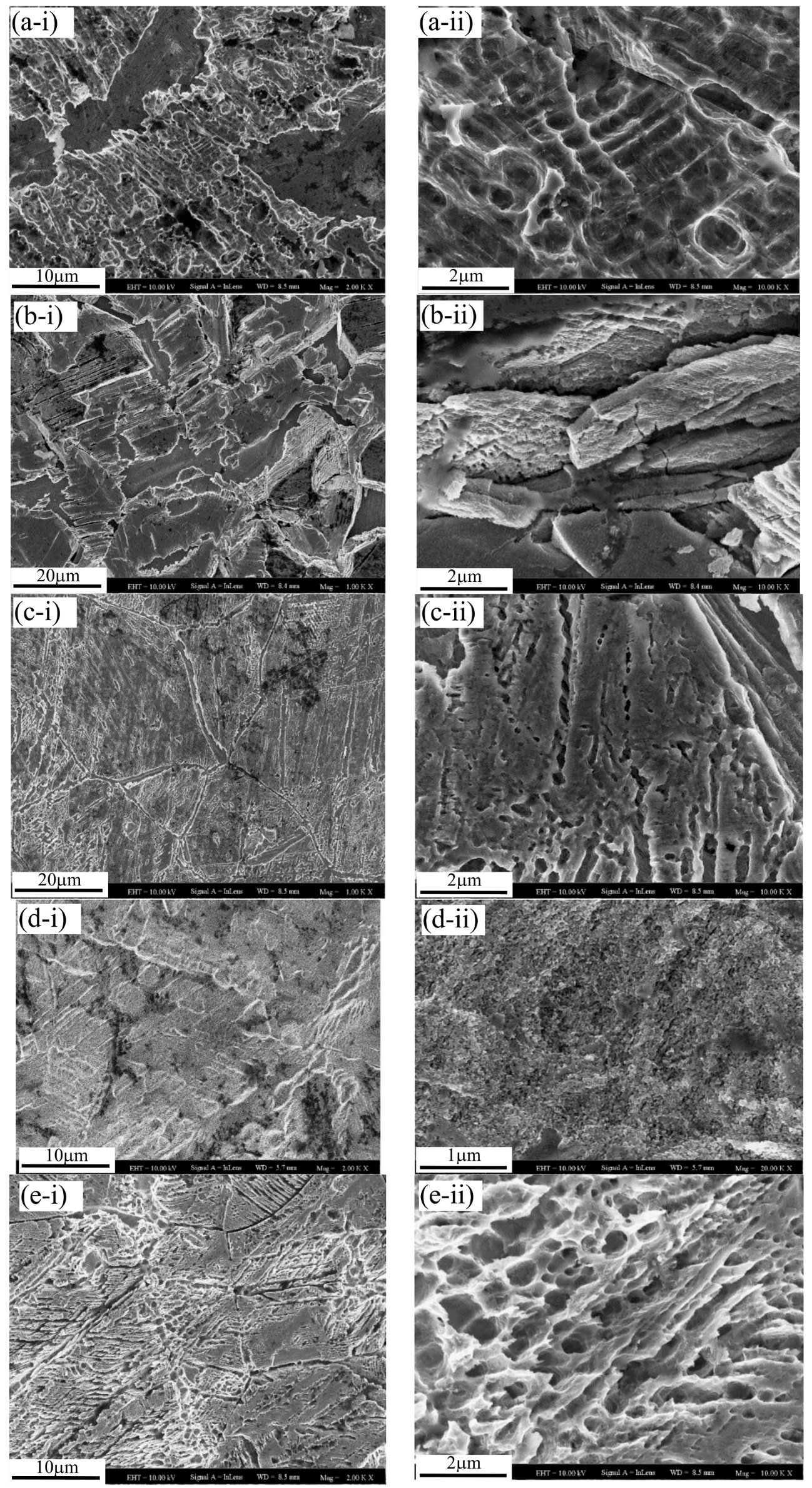

3.4. Corrosion Morphology Analysis

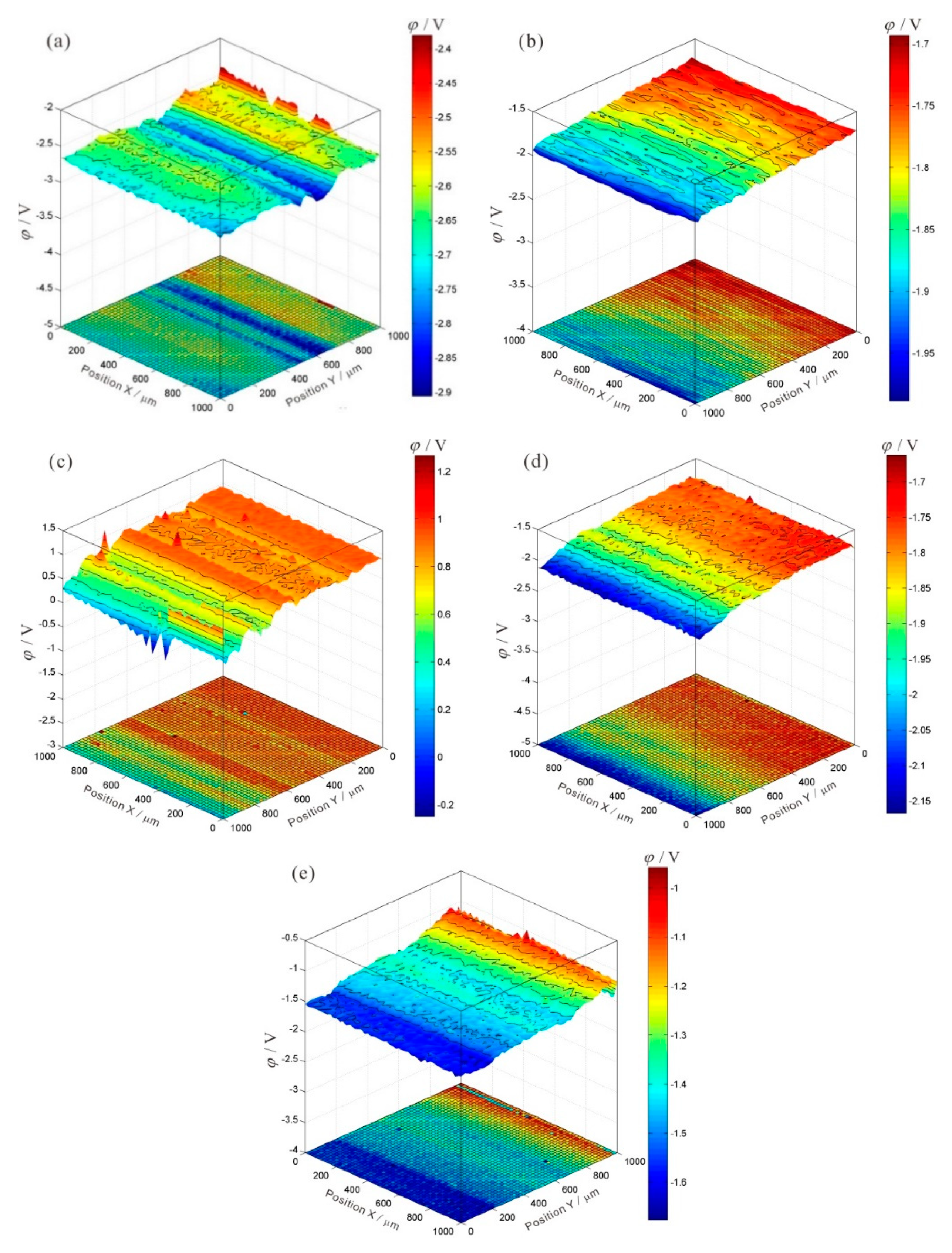

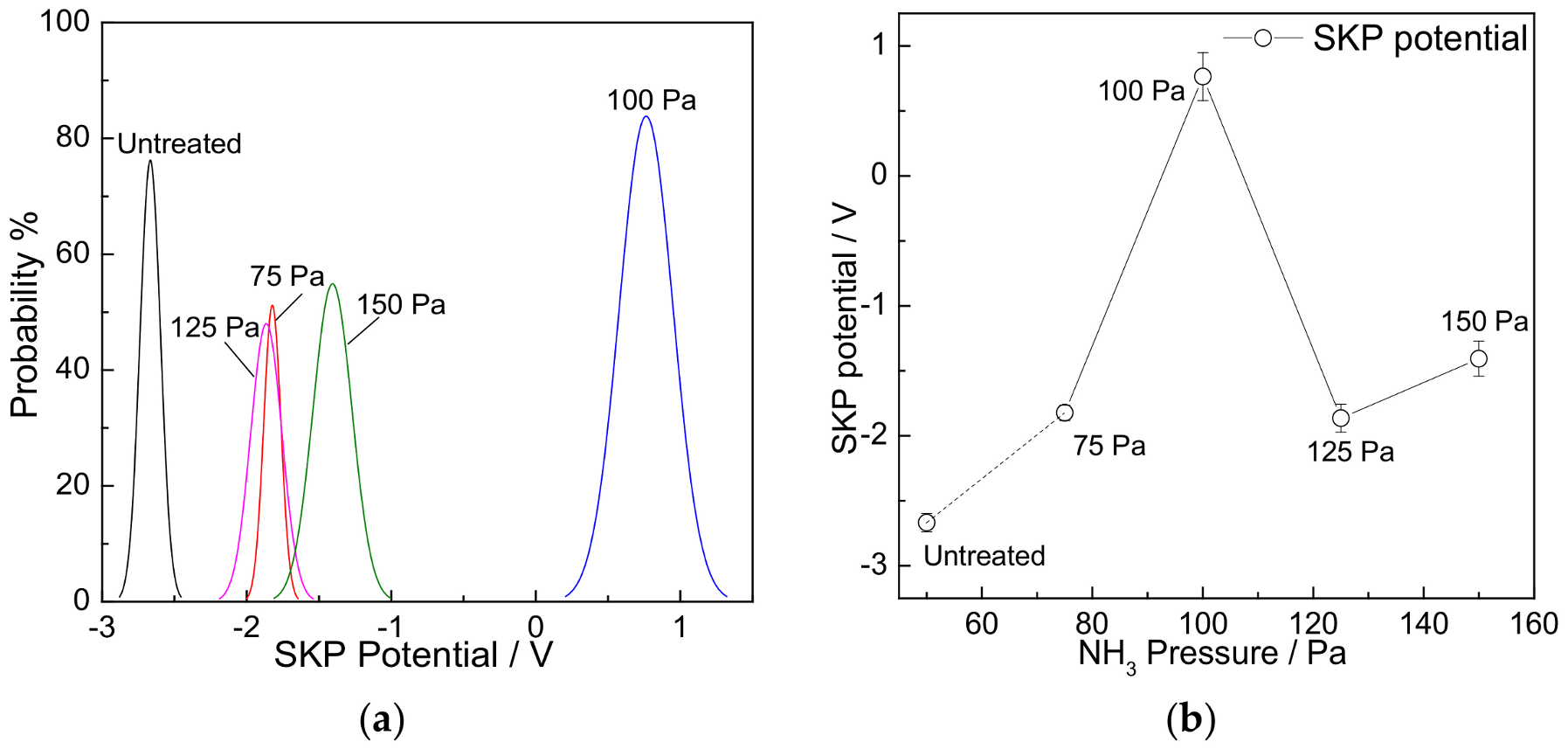

3.5. SKP

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Jones, R.; Randle, V.; Owen, G. Carbide precipitation and grain boundary plane selection in overaged type 316 austenitic stainless steel. Mater. Sci. Eng. A 2008, 496, 256–261. [Google Scholar] [CrossRef]

- Schwind, M.; Källqvist, J.; Nilsson, J.O. σ-phase precipitation in stabilized austenitic stainless steels. J. Acta Mater. 2000, 48, 2473–2481. [Google Scholar] [CrossRef]

- Zou, G.; Shi, W.; Xiang, S.; Ji, X.; Ma, G.; Ballinger, R.G. Corrosion behavior of 904L austenitic stainless steel in hydrofluoric acid. RSC Adv. 2018, 8, 2811–2817. [Google Scholar] [CrossRef]

- Fernandes, F.A.P.; Heck, S.; Pereira, R.; Picon, C.; Nascente, P.; Casteletti, L.C. Ion nitriding of a superaustenitic stainless steel: Wear and corrosion characterization. Surf. Coat. Technol. 2010, 204, 3087–3090. [Google Scholar] [CrossRef]

- Fossati, A.; Galvanetto, E.; Bacci, T.; Borgioli, F. Improvement of corrosion resistance of austenitic stainless steels by means of glow-discharge nitriding. Corros. Rev. 2011, 29, 209–221. [Google Scholar] [CrossRef]

- Li, X.; Thaiwatthana, S.; Dong, H.; Bell, T. Thermal stability of carbon S phase in 316 stainless steel. Surf. Eng. 2002, 18, 448–451. [Google Scholar] [CrossRef]

- Zhang, Z.L.; Bell, T. Structure and corrosion resistance of plasma nitrided stainless steel. Surf. Eng. 1985, 1, 131–136. [Google Scholar] [CrossRef]

- D’Avico, L.; Beltrami, R.; Pargoletti, E.; Trasatti, S.P.; Cappelletti, G. Insight into the release agents/PVD coatings interaction for plastic mold technology. Coatings 2020, 10, 281. [Google Scholar] [CrossRef]

- Gaona-Tiburcio, C.; Montoya-Rangel, M.; Cabral-Miramontes, J.A.; Estupiñan-López, F.; Zambrano-Robledo, P.; Orozco-Cruz, R.; Chacon-Nava, J.; Baltazar-Zamora, M.A.; Almeraya-Calderón, F. Corrosion resistance of multilayer coatings deposited by PVD on inconel 718 using electrochemical impedance spectroscopy technique. Coatings 2020, 10, 521. [Google Scholar] [CrossRef]

- Dinu, M.; Mouele, E.S.; Parau, A.C.; Vladescu, A.; Petrik, L.F.; Braic, M. Enhancement of the corrosion resistance of 304 stainless steel by Cr–N and Cr(N,O) coatings. Coatings 2018, 8, 132. [Google Scholar]

- Lo, K.; Shek, C.; Lai, J. Recent developments in stainless steels. Mater. Sci. Eng. R Rep. 2009, 65, 39–104. [Google Scholar] [CrossRef]

- Borgioli, F.; Galvanetto, E.; Bacci, T. Low temperature nitriding of AISI 300 and 200 series austenitic stainless steels. Vacuum 2016, 127, 51–60. [Google Scholar] [CrossRef]

- Collins, G.A.; Hutchings, R.; Short, K.T.; Tendys, J.; Li, X.; Samandi, M. Nitriding of austenitic stainless steel by plasma immersion ion implantation. Surf. Coat. Technol. 1995, 74, 417–424. [Google Scholar] [CrossRef]

- Christiansen, T.; Somers, M.A.J. On the crystallographic structure of S-phase. Scr. Mater. 2004, 50, 35–37. [Google Scholar] [CrossRef]

- Maistro, G. Microstructural Characterization of Expanded Austenite in 304L and 904L Austenitic Stainless Steels; Chalmers University of Technology: Gothenburg, Sweden, 2015. [Google Scholar]

- Ramkumar, K.D.; Chandrasekhar, A.; Srivastava, A.; Preyas, H.; Chandra, S.; Dev, S.; Arivazhagan, N. Effects of filler metals on the segregation, mechanical properties and hot corrosion behaviour of pulsed current gas tungsten arc welded super-austenitic stainless steel. J. Manuf. Process. 2016, 24, 46–61. [Google Scholar] [CrossRef]

- Bellezze, T.; Giuliani, G.; Viceré, A.; Roventi, G. Study of stainless steels corrosion in a strong acid mixture. Part 2: Anodic selective dissolution, weight loss and electrochemical impedance spectroscopy tests. Corros. Sci. 2018, 130, 12–21. [Google Scholar] [CrossRef]

- Bellezze, T.; Giuliani, G.; Roventi, G. Study of stainless steels corrosion in a strong acid mixture. Part 1: Cyclic potentiodynamic polarization curves examined by means of an analytical method. Corros. Sci. 2018, 130, 113–125. [Google Scholar] [CrossRef]

- Haruman, E.; Sun, Y.; Adenan, M.S. A comparative study of the tribocorrosion behaviour of low temperature nitrided austenitic and duplex stainless steels in NaCl solution. Tribol. Int. 2020, 151, 106412. [Google Scholar] [CrossRef]

- Dearnley, P.A.; Aldrich-Smith, G. Corrosion—wear mechanisms of hard coated austenitic 316L stainless steels. Wear 2004, 256, 491–499. [Google Scholar] [CrossRef]

- Nakanishi, T.; Tsuchiyama, T.; Mitsuyasu, H.; Iwamoto, Y.; Takaki, S. Effect of partial solution nitriding on mechanical properties and corrosion resistance in a type 316L austenitic stainless steel plate. Mater. Sci. Eng. A 2007, 460, 186–194. [Google Scholar] [CrossRef]

- Yasumaru, N. Low-temperature ion nitriding of austenitic stainless steels. Mater. Trans. JIM 1998, 39, 1046–1052. [Google Scholar] [CrossRef][Green Version]

- Yang, W.; Zhang, M.; Zhao, Y.; Shen, M.; Lei, H.; Xu, L.; Xiao, J.; Gong, J.; Yu, B.; Sun, C. Enhancement of mechanical property and corrosion resistance of 316L stainless steels by low temperature arc plasma nitriding. Surf. Coat. Technol. 2016, 298, 64–72. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, W.; Wang, J.; Jiang, R.; Xiang, S. Anticorrosion Properties of the Low-Temperature Glow Plasma Nitriding Layer on AISI 904L Austenitic Stainless Steel in Hydrofluoric Acid Obtained at Various NH3 Pressures. Coatings 2020, 10, 1156. https://doi.org/10.3390/coatings10121156

Shi W, Wang J, Jiang R, Xiang S. Anticorrosion Properties of the Low-Temperature Glow Plasma Nitriding Layer on AISI 904L Austenitic Stainless Steel in Hydrofluoric Acid Obtained at Various NH3 Pressures. Coatings. 2020; 10(12):1156. https://doi.org/10.3390/coatings10121156

Chicago/Turabian StyleShi, Wei, Jiaxu Wang, Ruyi Jiang, and Song Xiang. 2020. "Anticorrosion Properties of the Low-Temperature Glow Plasma Nitriding Layer on AISI 904L Austenitic Stainless Steel in Hydrofluoric Acid Obtained at Various NH3 Pressures" Coatings 10, no. 12: 1156. https://doi.org/10.3390/coatings10121156

APA StyleShi, W., Wang, J., Jiang, R., & Xiang, S. (2020). Anticorrosion Properties of the Low-Temperature Glow Plasma Nitriding Layer on AISI 904L Austenitic Stainless Steel in Hydrofluoric Acid Obtained at Various NH3 Pressures. Coatings, 10(12), 1156. https://doi.org/10.3390/coatings10121156