Research on the Chloride Ion Penetration Resistance of Magnesium Phosphate Cement (MPC) Material as Coating for Reinforced Concrete Structures

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Specimen Group and Material Mix Ratio

2.3. Test Methods

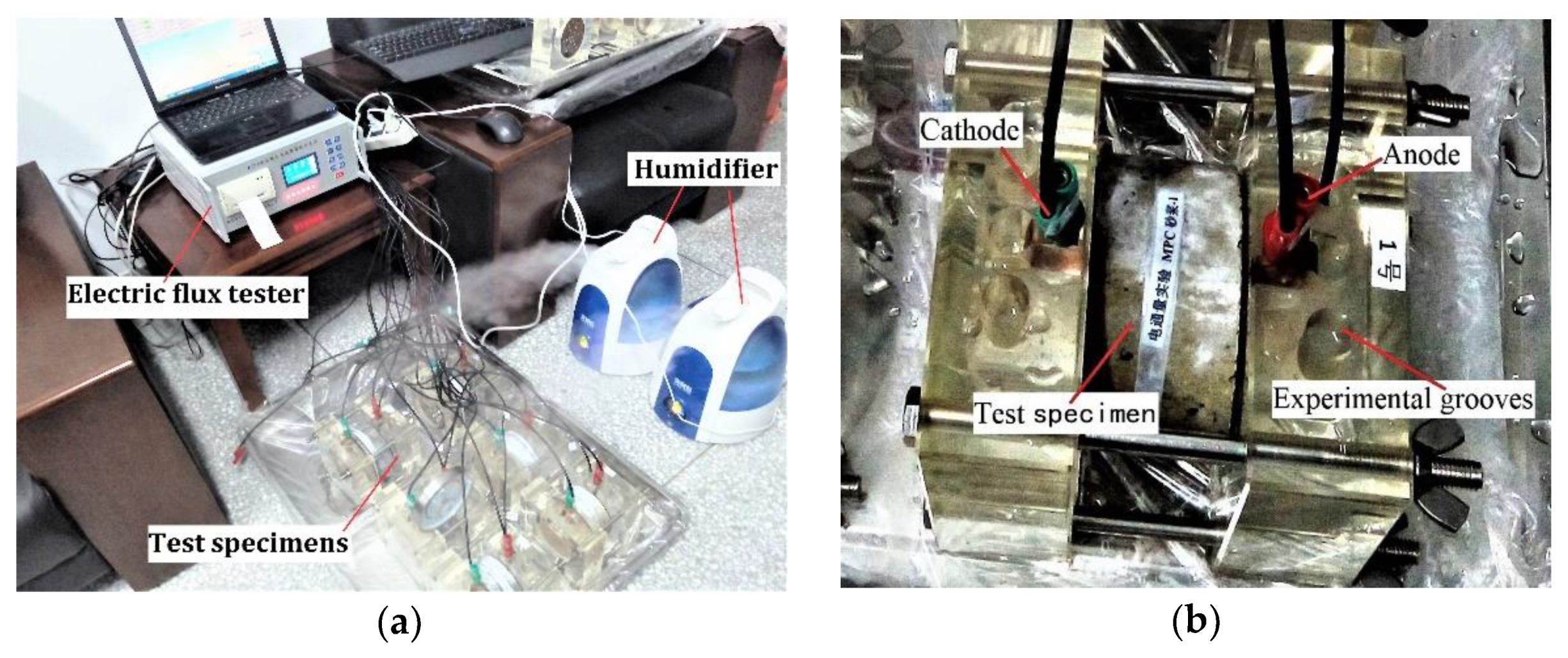

2.4. Test Equipment

2.5. Micromorphology Test

3. Test Results and Analysis

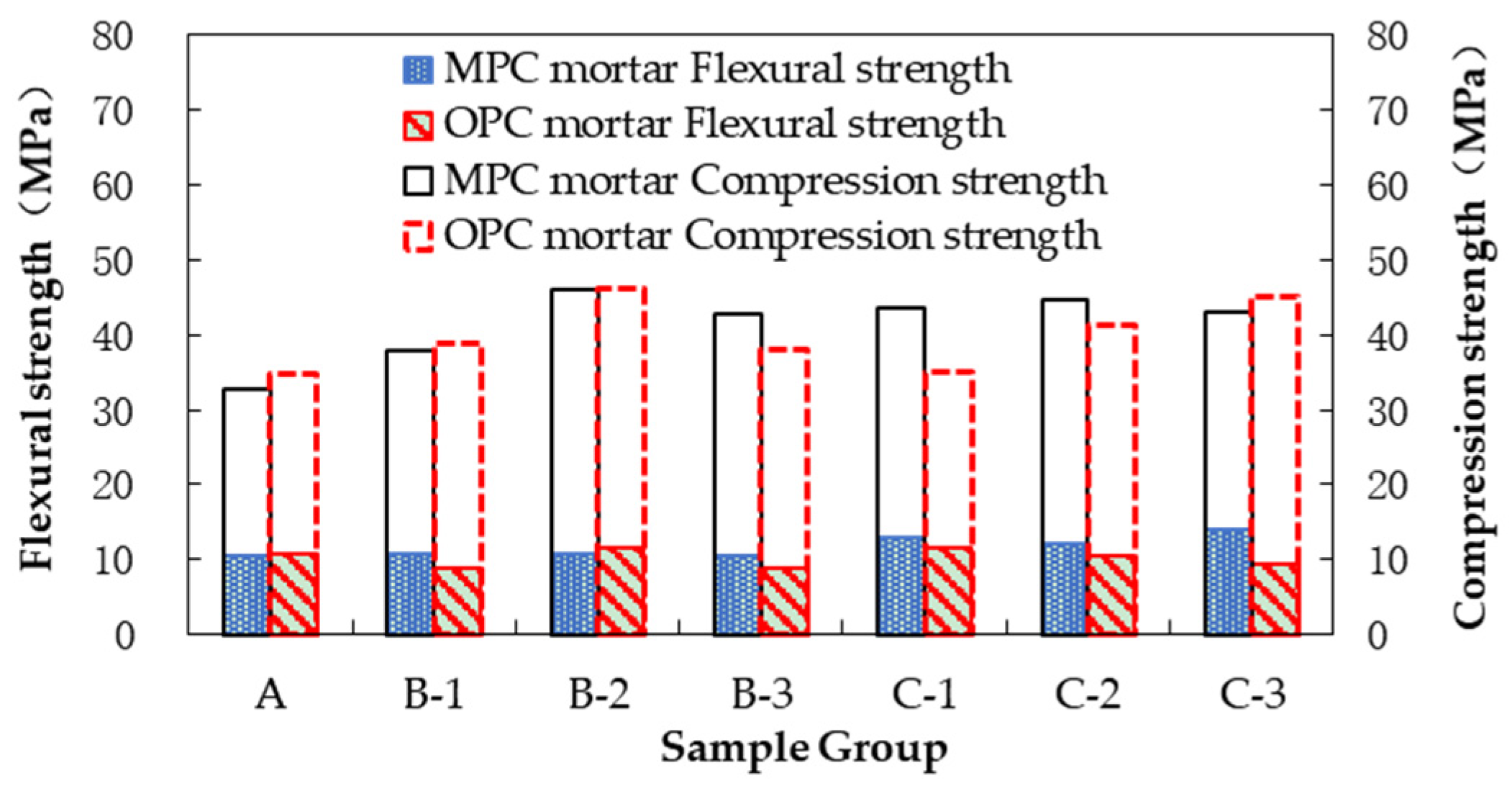

3.1. Single Material

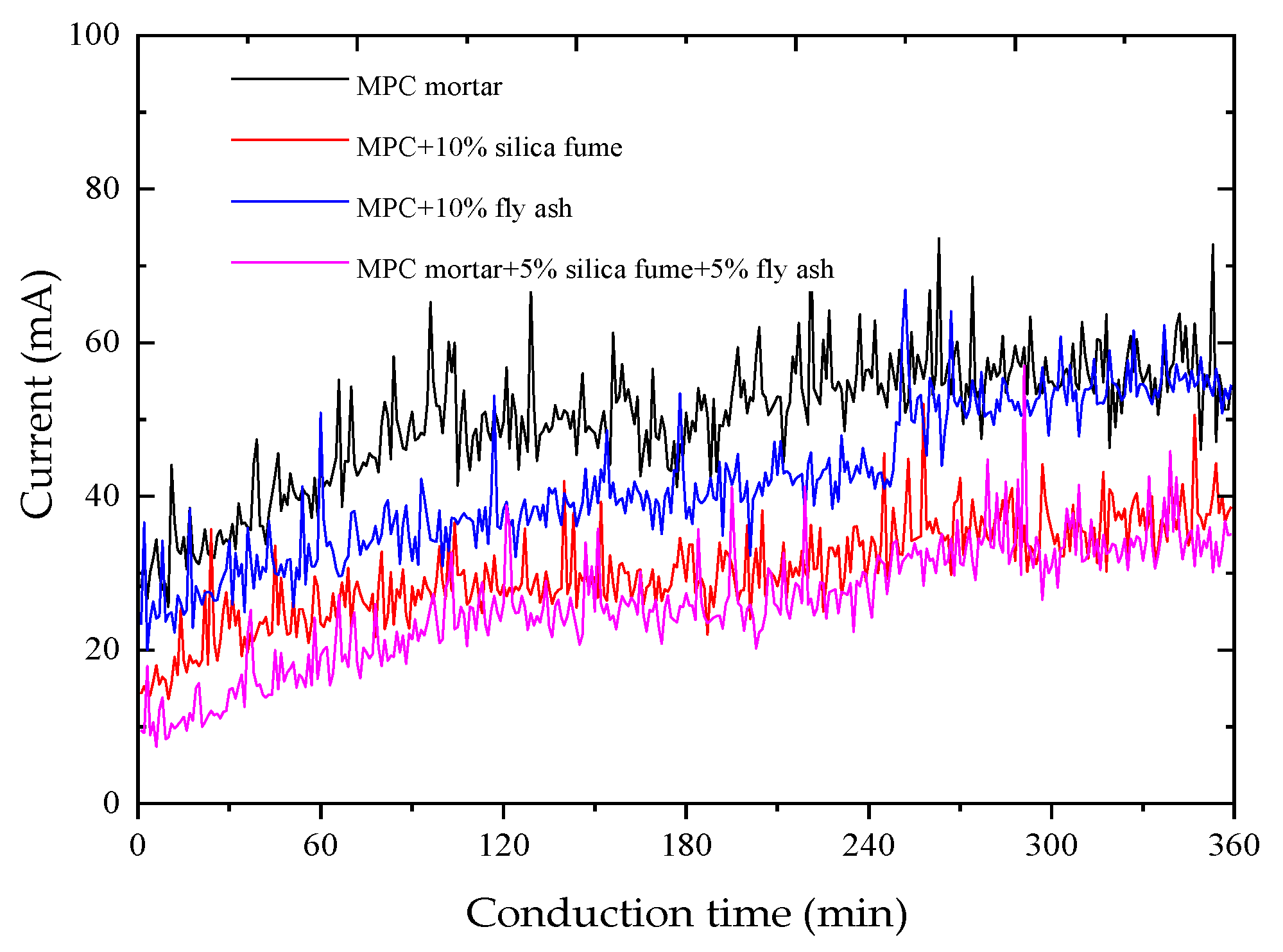

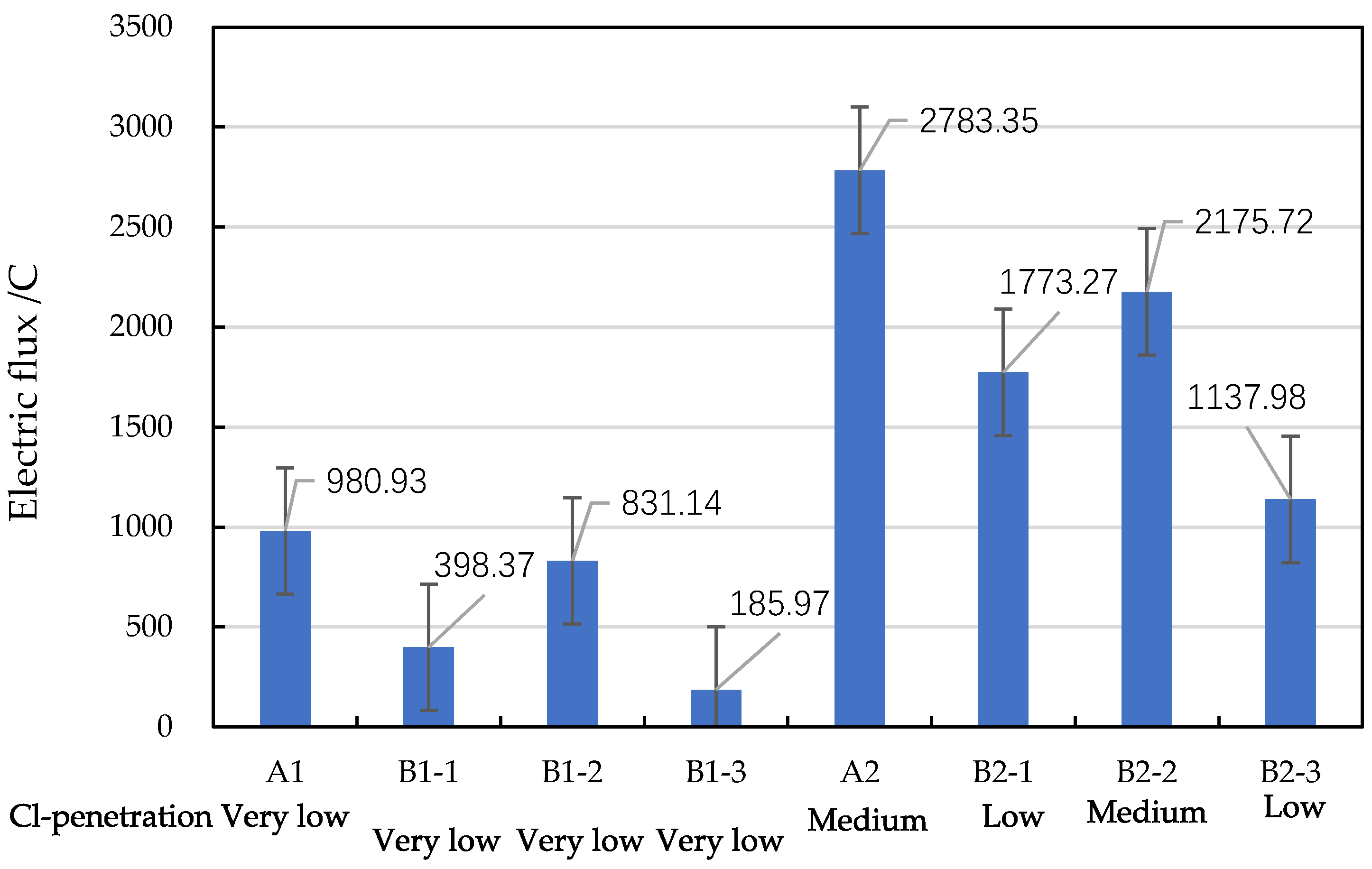

3.1.1. Influence of Admixture on Chloride Ion Penetration

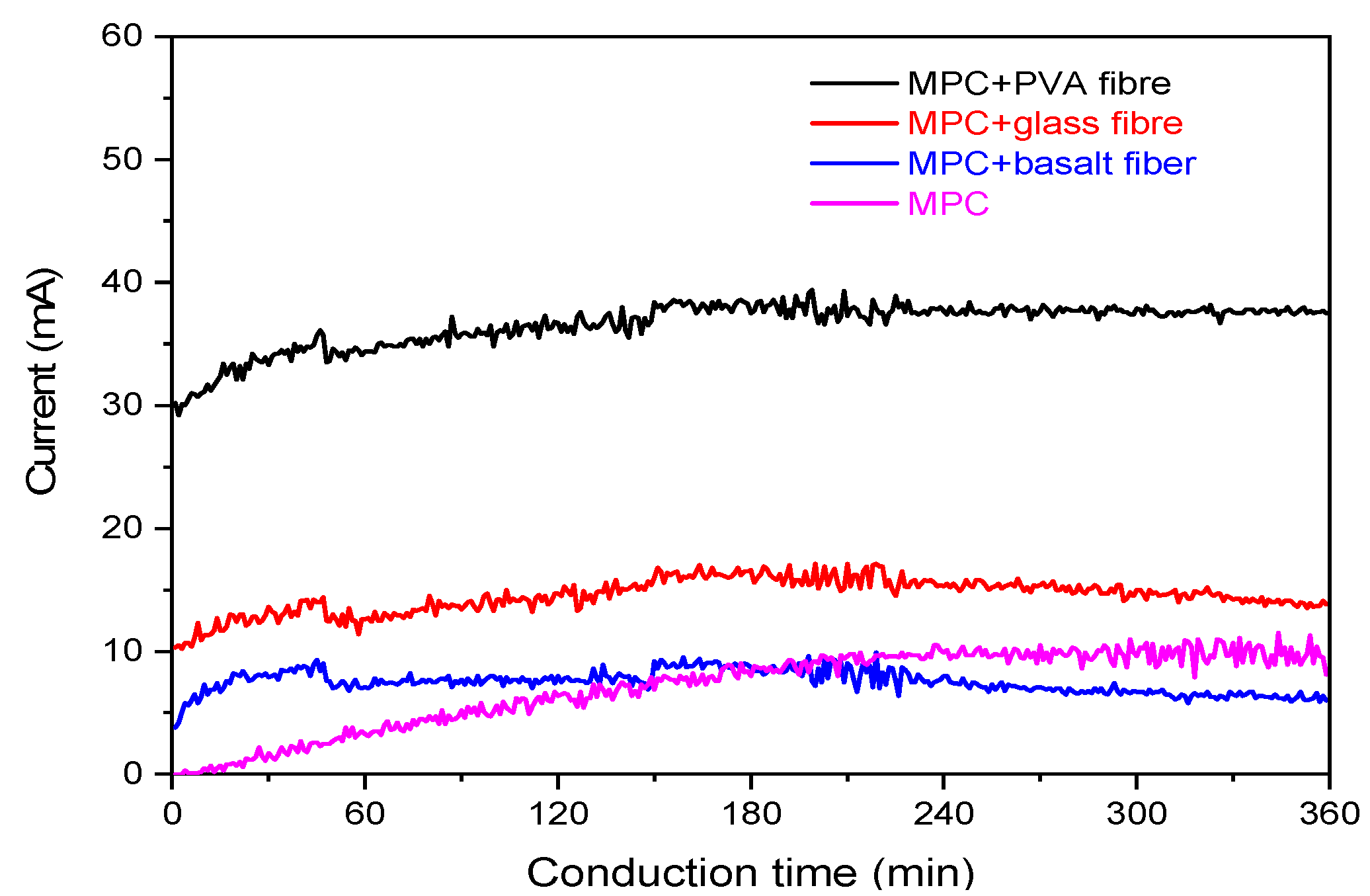

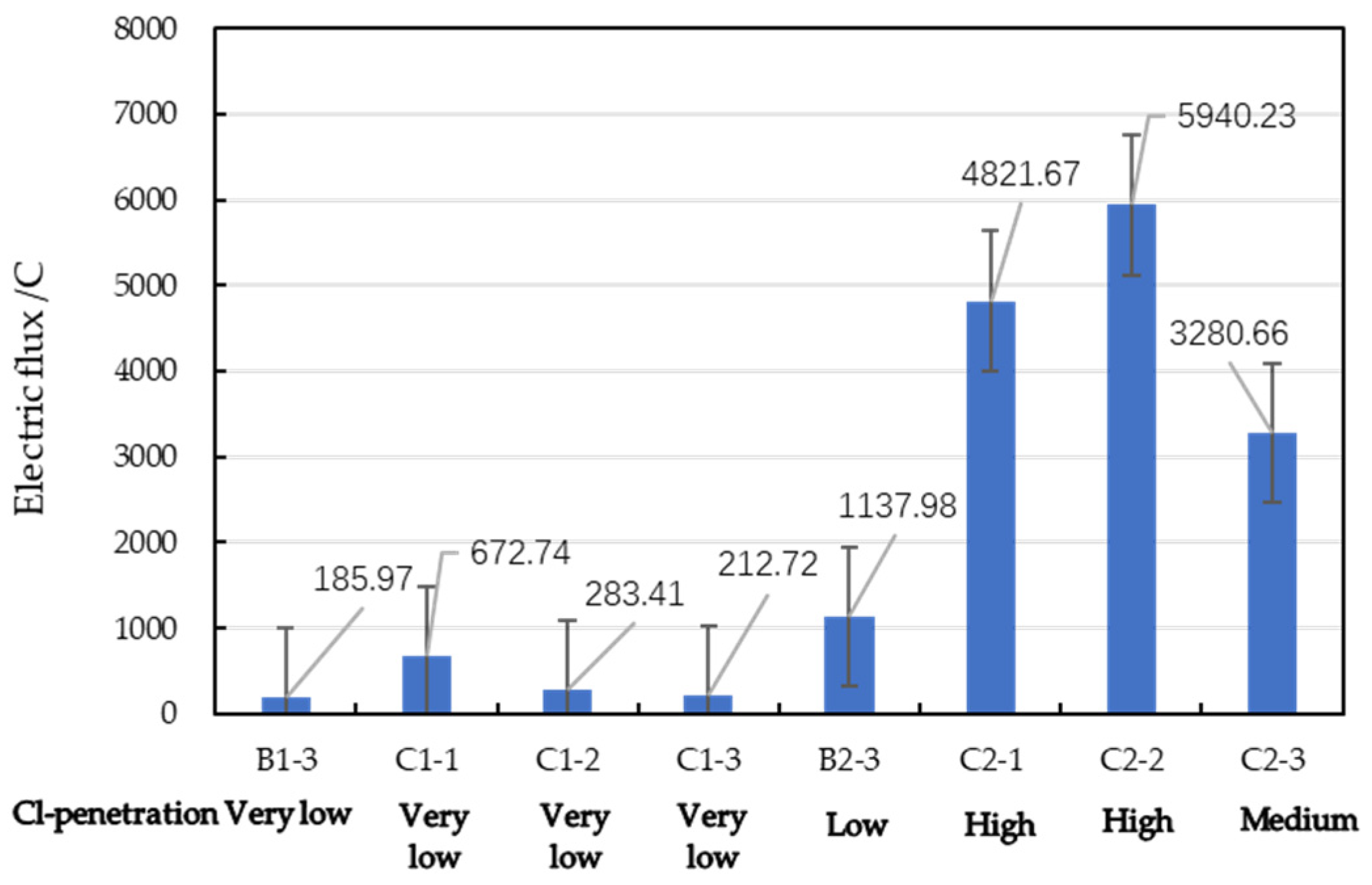

3.1.2. Influence of Fiber on Chloride Ion Penetration

3.2. Bilayer Material

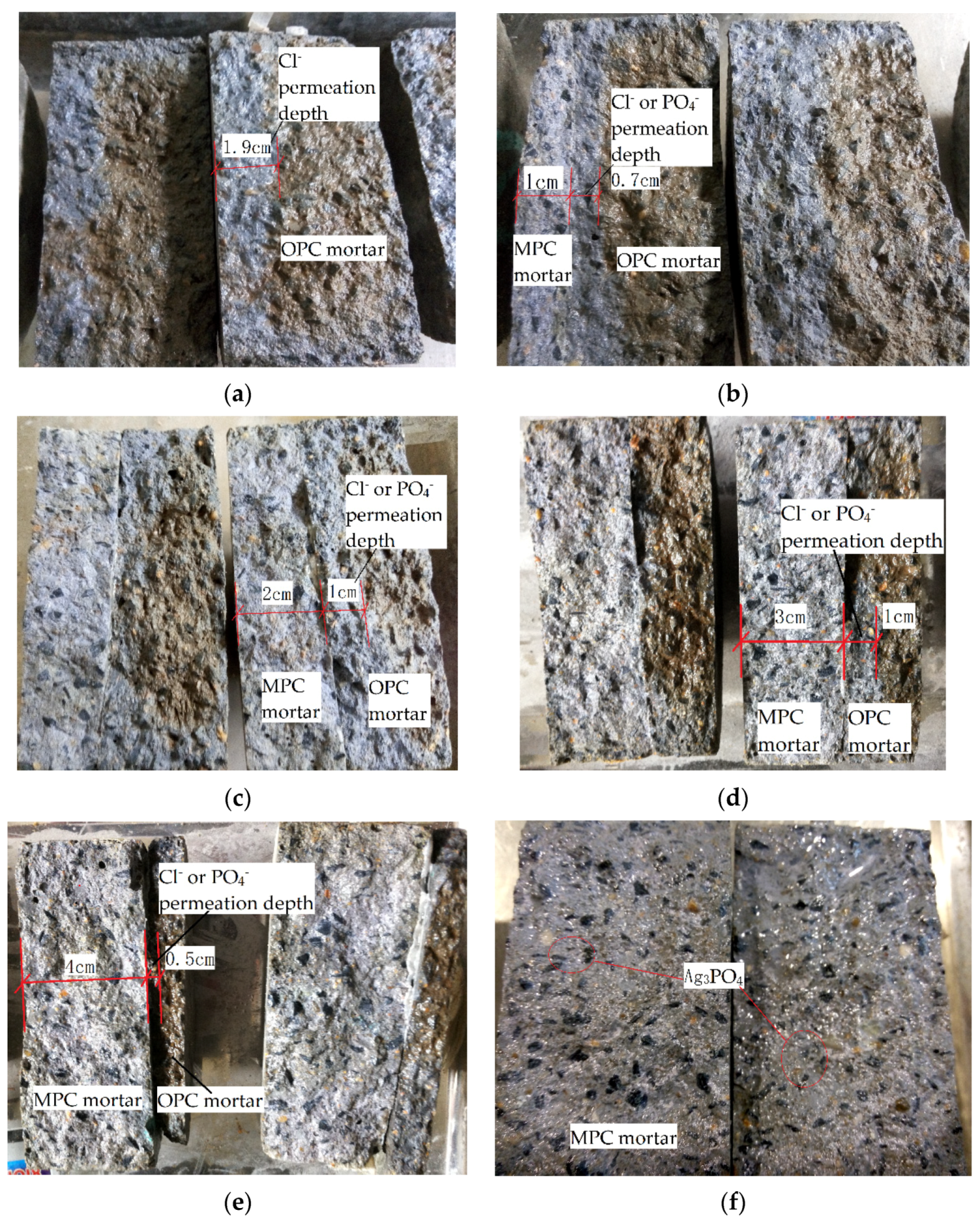

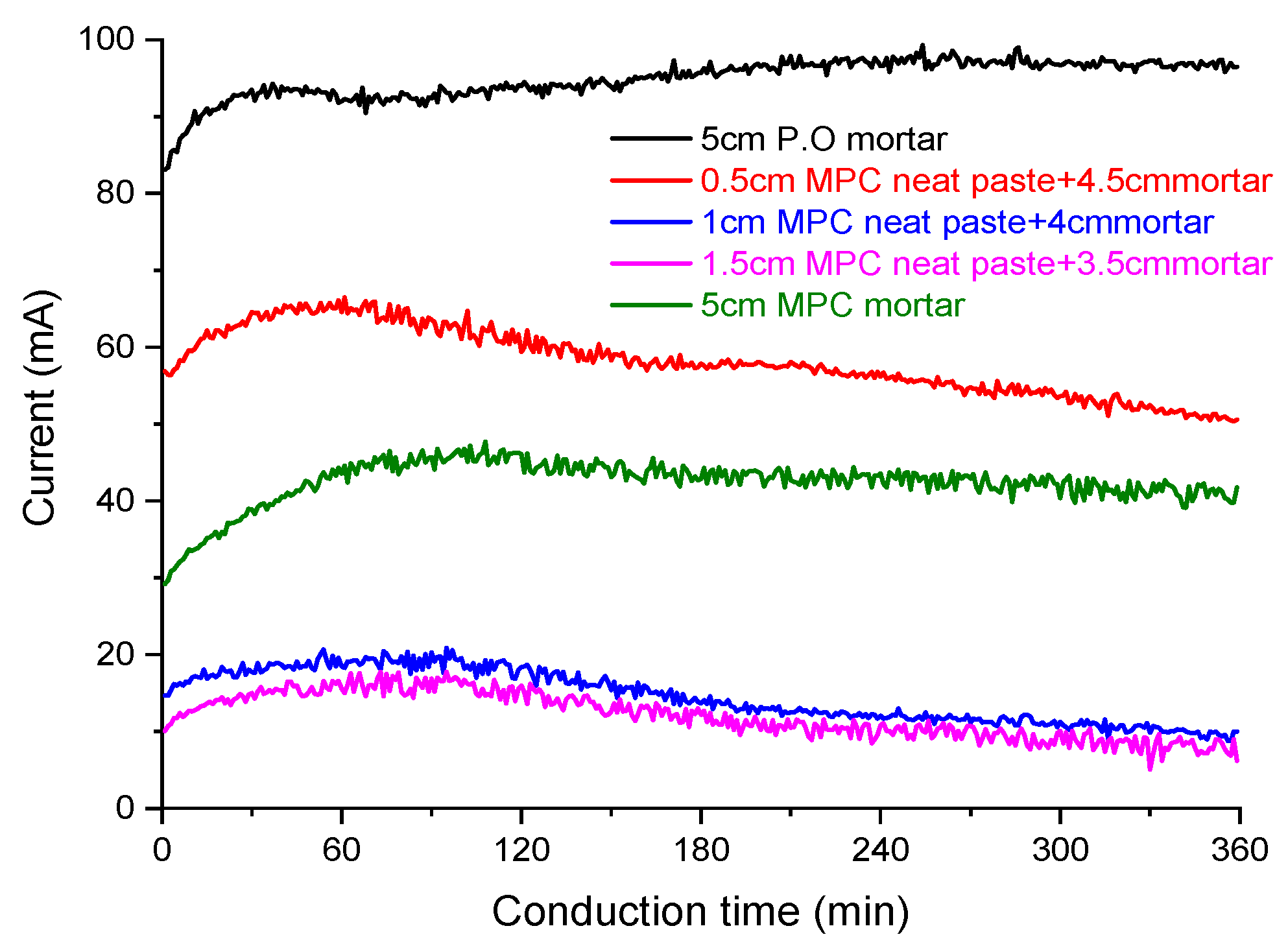

3.2.1. Influence of MPC Mortar Thickness on Chloride Icon Penetration

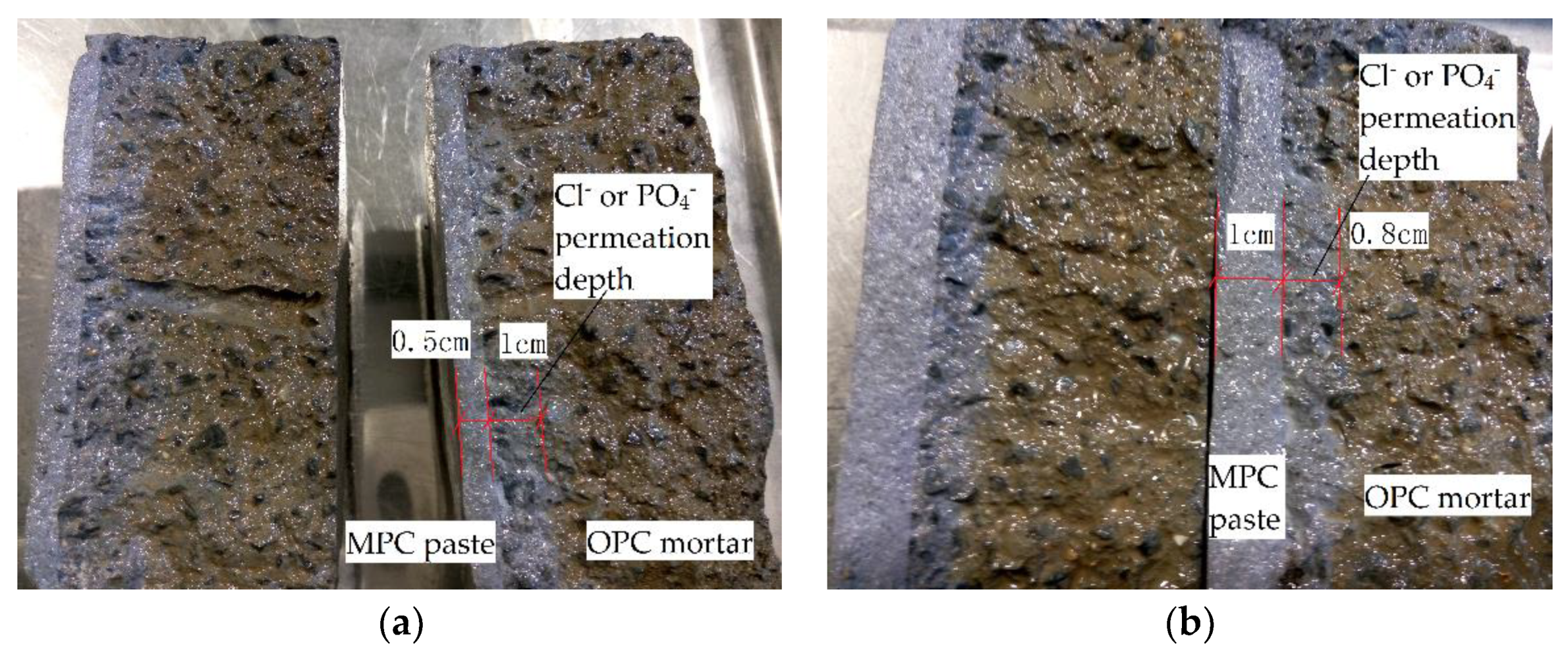

3.2.2. Influence of the MPC Paste Thickness on Chloride Icon Penetration

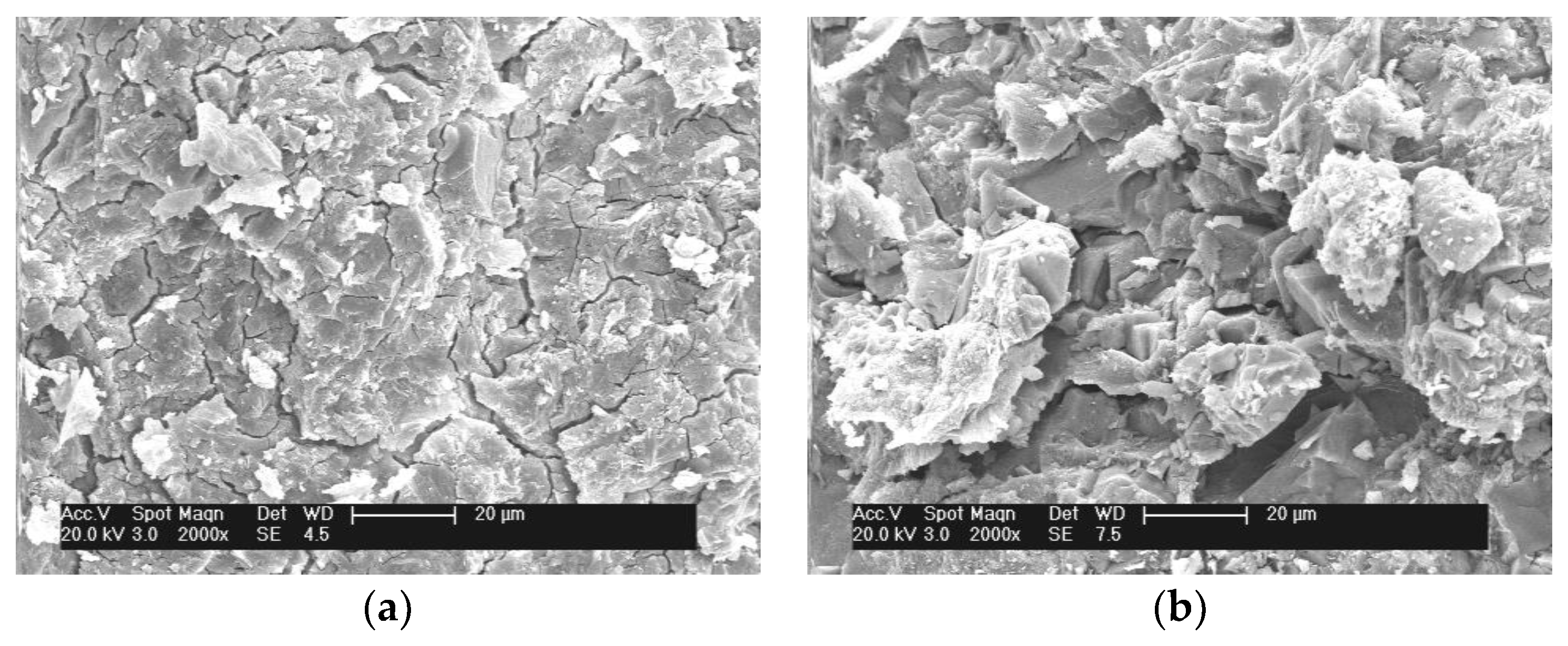

3.3. Microstructure Analysis

3.3.1. SEM

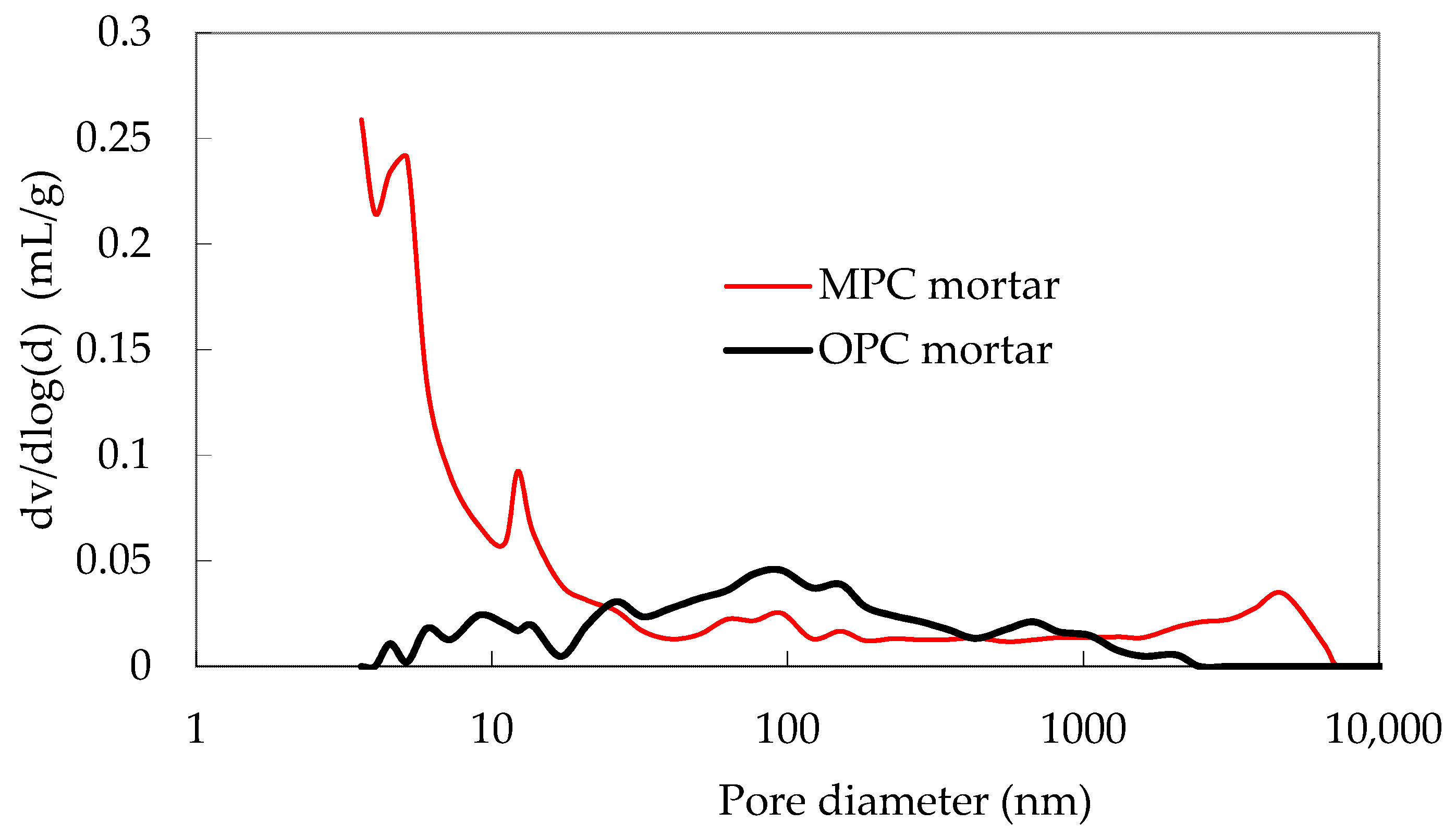

3.3.2. Mercury Intrusion Porosimetry (MIP)

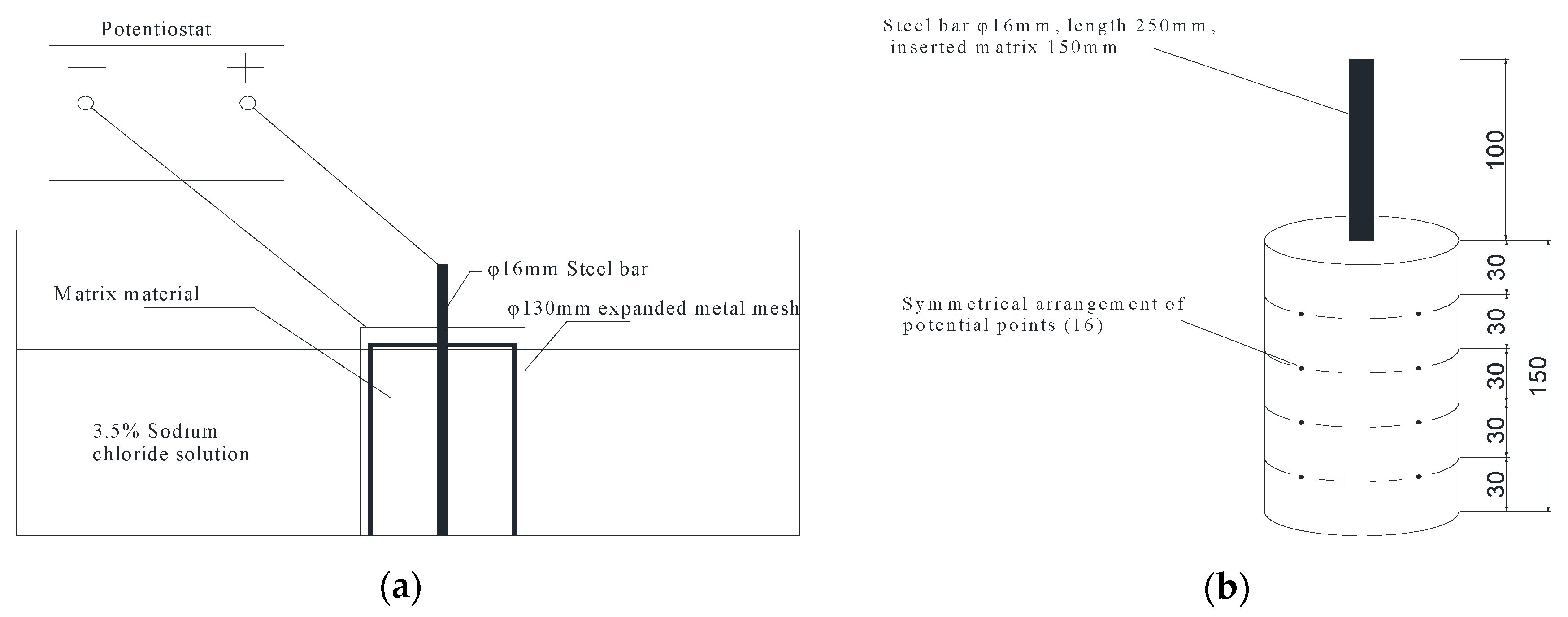

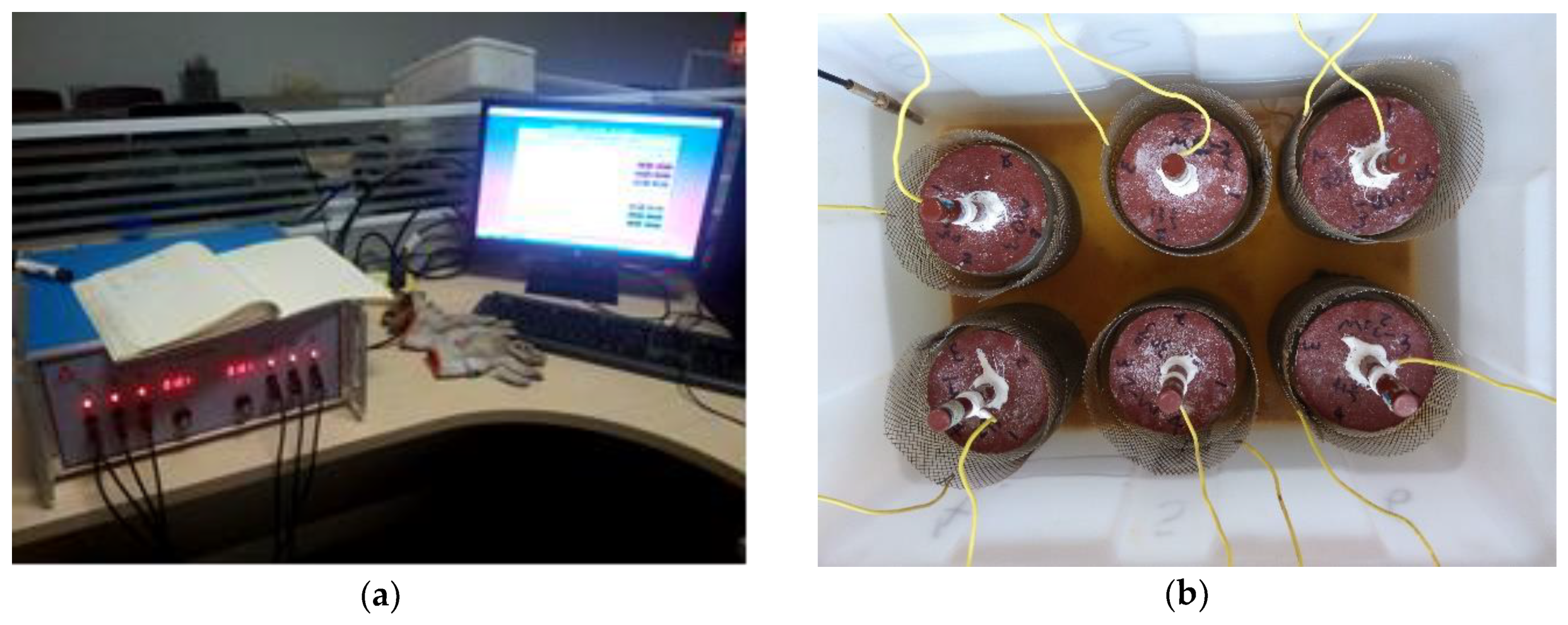

4. Accelerated Corrosion Test

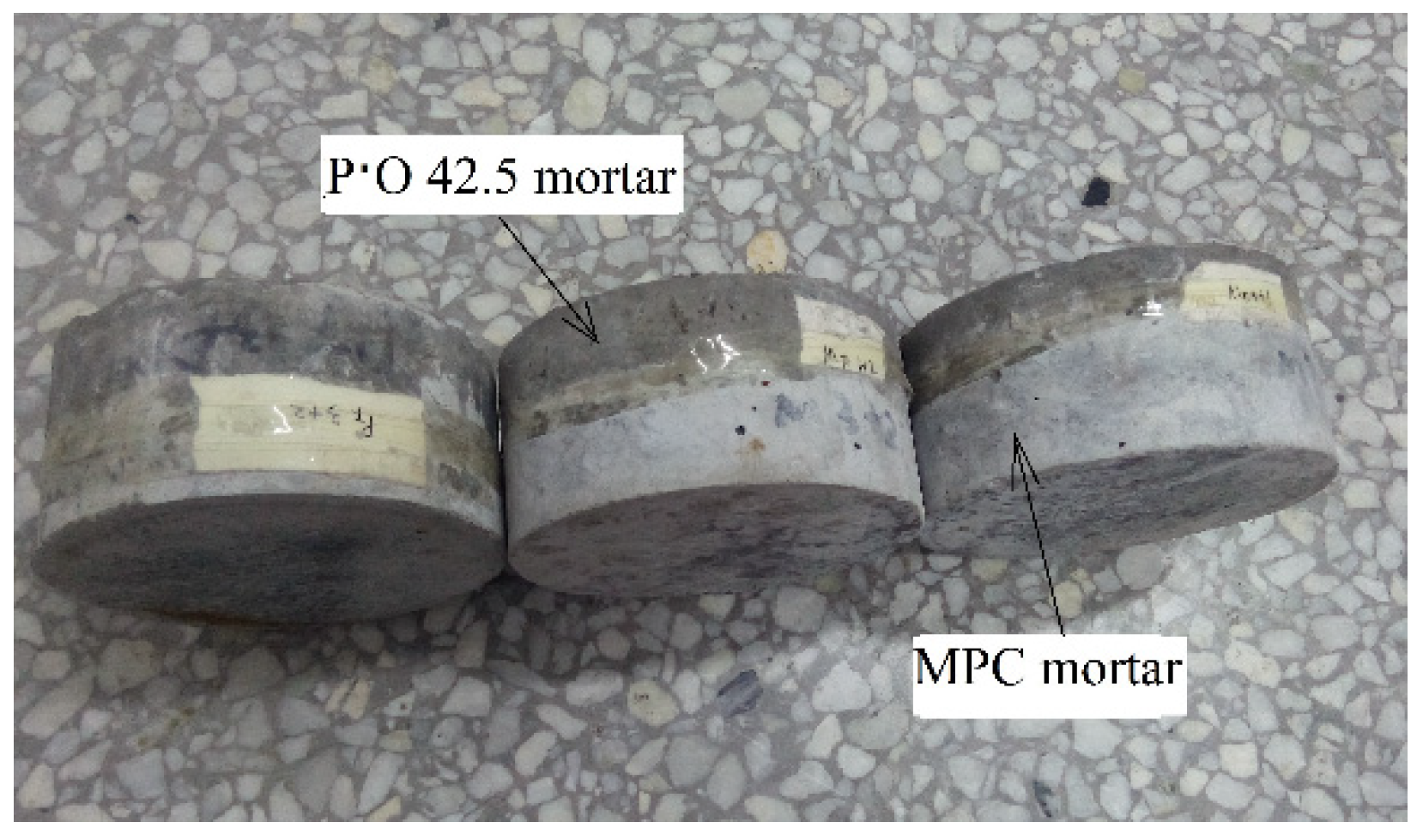

4.1. Sample Preparation

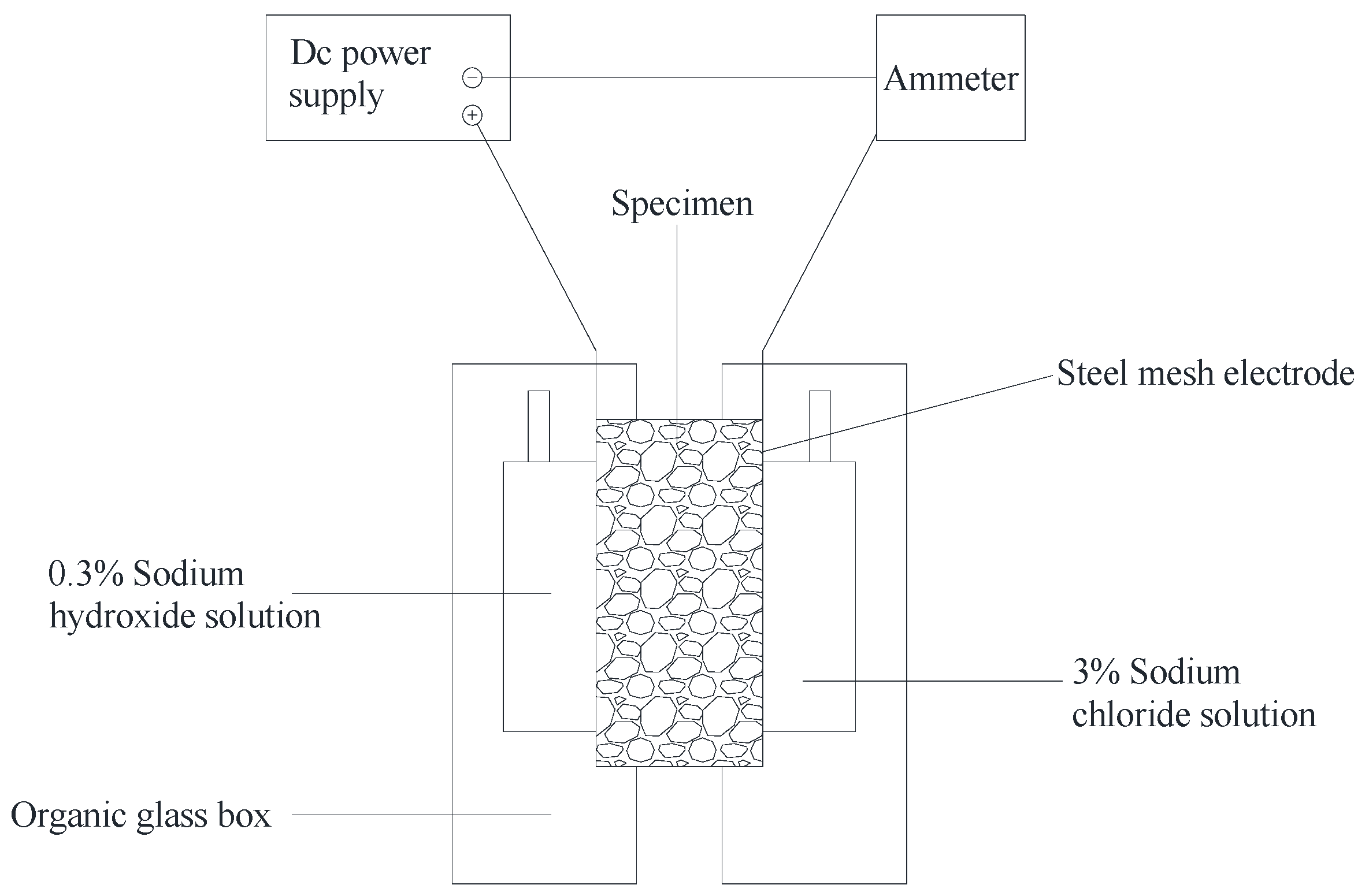

4.2. Experimental Method

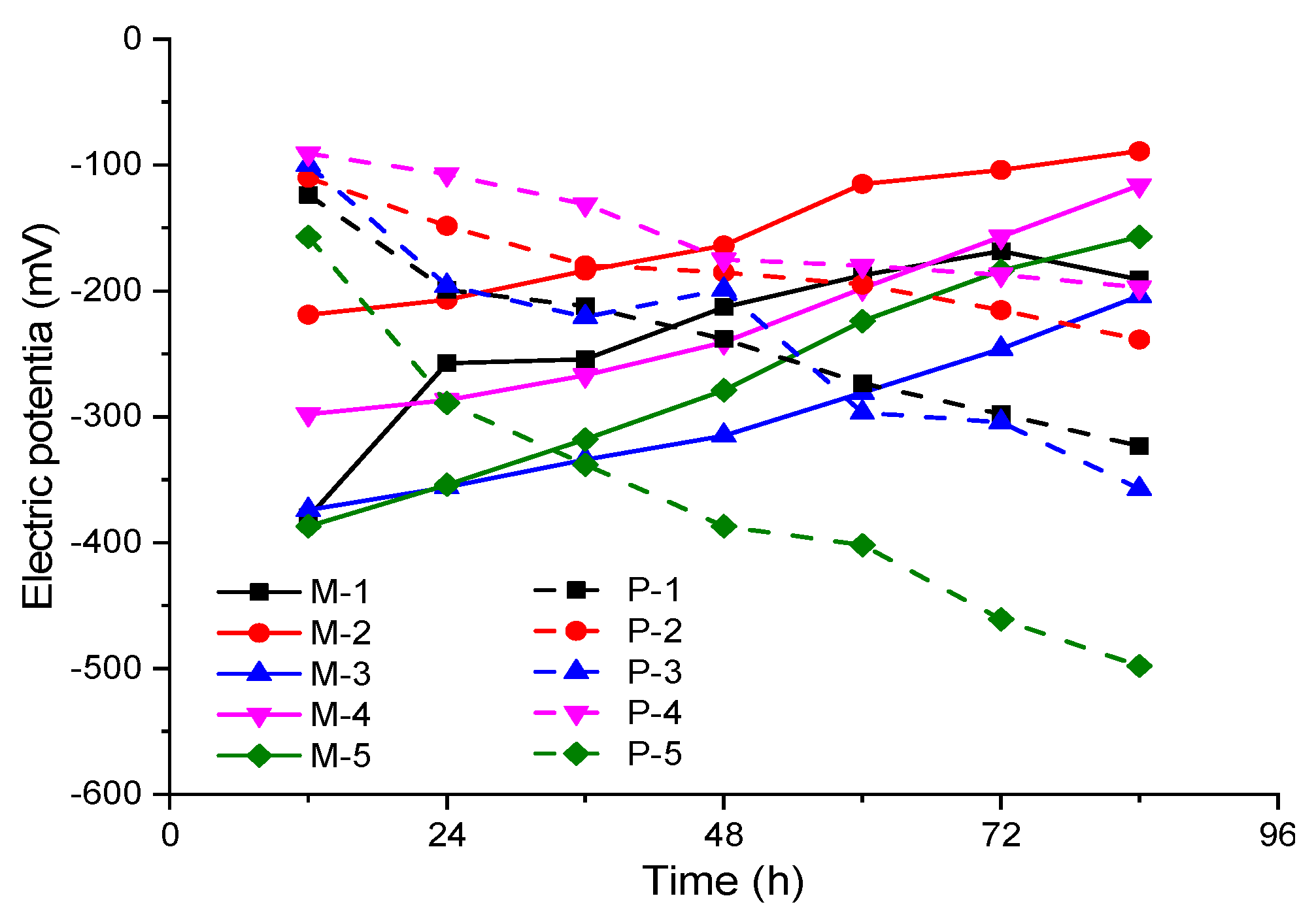

4.3. Test Results and Analysis

4.3.1. Specific Test

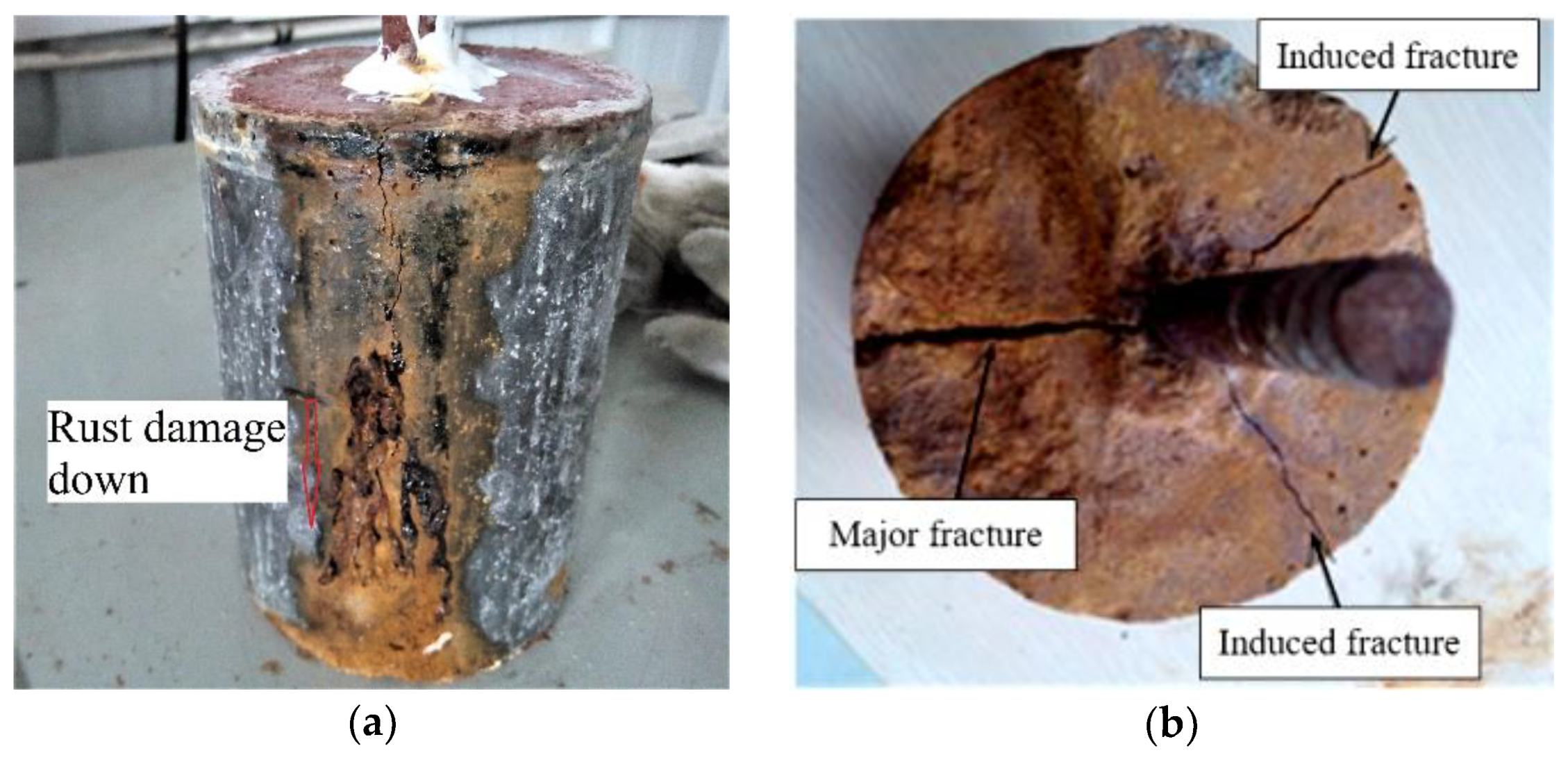

4.3.2. Corrosion Crack

5. Conclusions

- The electrical flux of the hardened body of MPC-based material is much lower than that of the Portland cement mortar, and the electrical flux of the hardened body of the MPC mortar can be obviously reduced by adding silica-fume and fly ash, which, when combined in a suitable proportion, will make the MPC hardened body more dense and impermeable.

- The addition of short cut fibers increases the number of pores, the pore size, and the electrical flux of the cement-mortar-hardened body. The adverse effects of the three fibers on the permeability of the MPC mortar against chlorine ions are as follows PVA fiber > glass fiber > basalt fiber.

- The electrical flux of the MPC mortar or MPC paste coated on the surface of the Portland cement mortar can be greatly reduced by using 1 cm MPC mortar or 1 cm mortar coatings of 36.0% and 84.2%, respectively.

- After nearly 100 h of accelerated corrosion, the steel bar in the Portland cement base material was seriously corroded, but the steel bar in the MPC material showed no signs of corrosion.

Author Contributions

Funding

Conflicts of Interest

References

- Neville, A. Chloride attack of reinforced concrete: An overview. Mater. Struct. 1995, 28, 63. [Google Scholar] [CrossRef]

- Chen, D.; Mahadevan, S. Chloride-induced reinforcement corrosion and concrete cracking simulation. Cem. Concr. Compos. 2008, 30, 227–238. [Google Scholar] [CrossRef]

- Wagh, A.S. Chemically Bonded Phosphate Ceramics: 21st Century Materials with Diverse Applications; Elsevier Science: London, UK, 2004. [Google Scholar]

- Andrade, A.; Schuiling, R.D. The chemistry of struvite crystallization. Min. J. 2001, 37–46, 5–6. [Google Scholar]

- Wagh, A.S.; Singh, D. Method for Stabilizing Low-Level Mixed Wastes at Room Temperature. U.S. Patent 5,645,518, 8 June 1997. [Google Scholar]

- Wagh, A.S.; Jeong, S.Y.; Sinhg, D. High strength phosphate cement using industrial by-product ashes. In Proceedings of the First International Conference on High Strength Concrete; ASCE: Reston, VA, USA, 2017; pp. 533–542. [Google Scholar]

- Ding, Z.; Dong, B.; Xing, F.; Han, N.; Li, Z. Cementing mechanism of potassium phosphate based magnesium phosphate cement. Ceram. Int. 2012, 38, 6281–6288. [Google Scholar] [CrossRef]

- Xu, B.; Ma, H.; Li, Z. Influence of magnesia-to-phosphate molar ratio on microstructures, mechanical properties and thermal conductivity of magnesium potassium phosphate cement paste with large water-to-solid ratio. Cem. Concr. Res. 2015, 68, 1–9. [Google Scholar] [CrossRef]

- Li, Y.; Sun, J.; Chen, B. Experimental study of magnesia and M/P ratio influencing properties of magnesium phosphate cement. Constr. Build. Mater. 2014, 65, 177–183. [Google Scholar] [CrossRef]

- Ma, H.; Xu, B.; Liu, J.; Pei, H.; Li, Z. Effects of water content, magnesia-to-phosphate molar ratio and age on pore structure, strength and permeability of magnesium potassium phosphate cement paste. Mater. Des. 2014, 64, 497–502. [Google Scholar] [CrossRef]

- Li, Y.; Chen, B. Factors that affect the properties of magnesium phosphate cement. Constr. Build. Mater. 2013, 47, 977–983. [Google Scholar] [CrossRef]

- Qiao, F.; Chau, C.K.; Li, Z. Property evaluation of magnesium phosphate cement mortar as patch repair material. Constr. Build. Mater. 2010, 24, 695–700. [Google Scholar] [CrossRef]

- Chau, C.K.; Fei, Q.; Li, Z. Microstructure of magnesium potassium phosphate cement. Constr. Build. Mater. 2011, 25, 2911–2917. [Google Scholar] [CrossRef]

- Yang, Q.; Zhu, B.; Wu, X. Characteristics and durability test of magnesium phosphate cement-based material for rapid repair of concrete. Mater. Struct. 2000, 33, 229–234. [Google Scholar] [CrossRef]

- Woo, P.J.; Hwan, K.K.; Yong, A.K. Fundamental Properties of Magnesium Phosphate Cement Mortar for Rapid Repair of Concrete. Adv. Mater. Sci. Eng. 2016, 2016, 7179403. [Google Scholar]

- Yang, J.; Wang, L.; Jin, C.; Sheng, D. Effect of fly ash on the corrosion resistance of magnesium potassium phosphate cement paste in sulfate solution. Constr. Build. Mater. 2020, 237, 117639. [Google Scholar]

- Ahmad, M.R.; Chen, B.; Yu, J. A comprehensive study of basalt fiber reinforced magnesium phosphate cement incorporating ultrafine fly ash. Compos. Part. B Eng. 2019, 168, 204–217. [Google Scholar] [CrossRef]

- Xu, X.; Lin, X.; Pan, X.; Ji, T.; Liang, Y.; Zhang, H. Influence of silica fume on the setting time and mechanical properties of a new magnesium phosphate cement. Constr. Build. Mater. 2019, 235, 117544. [Google Scholar] [CrossRef]

- Zheng, D.D.; Ji, T.; Wang, C.Q.; Sun, C.J.; Lin, X.J.; Hossain, K.M. Effect of the combination of fly ash and silica fume on water resistance of magnesium-potassium phosphate cement. Constr. Build. Mater. 2016, 106, 415–421. [Google Scholar] [CrossRef]

- Pera, J.; Ambroise, J. Fiber-reinforced Magnesia-phosphate Cement Composites for Rapid Repair. Cem. Concr. Compos. 1998, 20, 31–39. [Google Scholar] [CrossRef]

- Fang, Y.; Chen, B.; Oderji, S.Y. Experimental research on magnesium phosphate cement mortar reinforced by glass fiber. Constr. Build. Mater. 2018, 188, 729–736. [Google Scholar] [CrossRef]

- Qin, J.; Qian, J.; Li, Z.; You, C.; Dai, X.; Yue, Y.; Fan, Y. Mechanical properties of basalt fiber reinforced magnesium phosphate cement composites. Constr. Build. Mater. 2018, 188, 946–955. [Google Scholar] [CrossRef]

- Tang, H.; Qian, J.; Ji, Z.; Dai, X.; Li, Z. The protective effect of magnesium phosphate cement on steel corrosion. Constr. Build. Mater. 2020, 255, 119422. [Google Scholar] [CrossRef]

- Li, Y.; Shi, T.; Li, Y.; Bai, W.; Lin, H. Damage of magnesium potassium phosphate cement under dry and wet cycles and sulfate attack. Constr. Build. Mater. 2019, 210, 111–117. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, A.; Zhang, L.; Liu, J.; Han, Y.; Shu, H.; Wang, J. Study on the influence of compound rust inhibitor on corrosion of steel bars in chloride concrete by electrical parameters. Constr. Build. Mater. 2020, 262, 120763. [Google Scholar] [CrossRef]

- Wang, H.; Du, T.; Zhang, A.; Cao, P.; He, Z. Relationship between electrical resistance and rheological parameters of fresh cement slurry. Constr. Build. Mater. 2020, 256, 119479. [Google Scholar] [CrossRef]

- Yang, J.; Li, T.; Xu, X. Effect of Fine Aggregates on Properties of Magnesium Potassium Phosphate Cement Mortar. J. Mater. Civ. Eng. 2017, 29, 06017012. [Google Scholar]

- JGJ/T 98-2010. Specification for Mix Proportion Design of Masonry Mortar; Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijin, China, 2010.

- ASTM C1202-19. Standard Test Method for Electrical Indication of Concrete’s Ability to Resist Chloride Ion. Penetration; ASTM International: West Conshohocken, PA, USA, 2019. [Google Scholar]

- Gaitero, J.J.; Campillo, I.; Guerrero, A. Reduction of the calcium leaching rate of cement paste by addition of silica nanoparticles. Cem. Concr. Res. 2008, 38, 1112–1118. [Google Scholar] [CrossRef]

| Variety | SiO2 | Al2O3 | CaO | Fe2O3 | MgO | SO3 | K2O | Na2O | Others | Loss on Ignition |

|---|---|---|---|---|---|---|---|---|---|---|

| FA | 51.10 | 26.14 | 7.15 | 7.31 | 2.59 | 0.21 | 1.01 | 0.65 | 1.87 | 1.97 |

| SF | 91.67 | 1.16 | 0.54 | 0.31 | 1.10 | 0.12 | 0.20 | 0.47 | 1.90 | 2.53 |

| P·O 42.5 | 21.87 | 7.56 | 55.14 | 3.21 | 4.15 | 1.57 | 0.75 | 0.76 | 2.07 | 2.92 |

| Variety | Length /mm | Diameter /μm | Density /(g/cm3) | Tensile Strength /MPa | Elastic Modulus /GPa | Elongation at Break/% |

|---|---|---|---|---|---|---|

| PVA | 6 | 14 | 1.300 | 1200–1600 | 31.0–40.0 | 7.5 |

| Glass fiber | 6 | 16 | 2.667 | 3100–3800 | 72.5–75.5 | 4.7 |

| Basalt fiber | 6 | 5 | 2.771 | 3000–4840 | 79.3–93.1 | 3.1 |

| Aggregate Type | Pass Rate for Each Sieve (%) | Fineness Modulus | Apparent Density /(g/cm3) | Bulk Density /(g/cm3) | Void Ratio /% | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 4.75 | 2.36 | 1.18 | 0.6 | 0.3 | 0.15 | 0.075 | |||||

| NS | 98.4 | 90.2 | 74.4 | 45.9 | 5.6 | 0.5 | 0.3 | 2.8 | 2.611 | 1.508 | 41.5 |

| MS | 99.9 | 11.1 | 3.2 | 0.2 | 0 | 0 | 0 | 4.85 | 2.941 | 1.497 | 48.58 |

| One-half NS + one-half MS | 99.1 | 50.7 | 38.8 | 23 | 2.8 | 0.3 | 0.2 | 3.83 | 2.757 | 1.611 | 41.22 |

| Specimen Category 1 | Single Material Specimens | |||||

| Cement Type | MPC | OPC | ||||

| Material Characteristics | No. | Material Characteristics | No. | |||

| Base Specimen | No Admixture | A1 | No Admixture | A2 | ||

| Different Admixture | 10% SF | B1-1 | 10% SF | B2-1 | ||

| 10% FA | B1-2 | 20% FA | B2-2 | |||

| 5% SF + 5%FA | B1-3 | 10% SF + 10%FA | B2-3 | |||

| Different Fiber | 1% PVA fiber | C1-1 | 1% PVA fiber | C2-1 | ||

| 1% Glass fiber | C1-2 | 1% Glass fiber | C2-2 | |||

| 1% Basalt fiber | C1-3 | 1% Basalt fiber | C2-3 | |||

| Specimen Category 2 | Specimens Superimposed with Two Materials | |||||

| Combination Mode | Mode One | Mode Two | ||||

| Layer Material and Thickness | MPC Mortar | OPC Mortar | No. | MPC Paste | OPC Mortar | No. |

| 1.0 cm | 4.0 cm | D-1 | 0.5 cm | 4.5 cm | E-1 | |

| 2.0 cm | 3.0 cm | D-2 | 1.0 cm | 4.0 cm | E-2 | |

| 3.0 cm | 2.0 cm | D-3 | 1.5 cm | 3.5 cm | E-3 | |

| 4.0 cm | 1.0 cm | D-4 | - | - | - | |

| No. | Fiber/V% | |||||||

|---|---|---|---|---|---|---|---|---|

| A1 | 1:2.00 | 7.33% | 1:1 | 1:1 | 0% | 0% | 0 | 0.18 |

| B1-1 | 1:2.00 | 7.33% | 1:1 | 1:1 | 0% | 10% | 0 | 0.18 |

| B1-2 | 1:2.00 | 7.33% | 1:1 | 1:1 | 10% | 0% | 0 | 0.18 |

| B1-3 | 1:2.00 | 7.33% | 1:1 | 1:1 | 5% | 5% | 0 | 0.18 |

| C1-1–C1-3 | 1:2.00 | 7.33% | 1:1 | 1:1 | 5% | 5% | 1 | 0.18 |

| D-1–D-4 | 1:2.00 | 7.33% | 1:1 | 1:1 | 0% | 0% | 0 | 0.18 |

| E-1–E-3 | 1:3.00 | 7.33% | 0:1 | - | 0% | 0% | 0 | 0.12 |

| No. | Proportion (kg/m3) | W/C | |||||

|---|---|---|---|---|---|---|---|

| Cement | Si | FA | Natural Sand | Manufactured Sand | Water | ||

| A2 | 500 | - | - | 805.2 | 805.2 | 225 | 0.45 |

| B2-1 | 450 | 50 | - | 805.2 | 805.2 | 250 | 0.50 |

| B2-2 | 400 | - | 100 | 805.2 | 805.2 | 235 | 0.47 |

| B2-3 | 400 | 50 | 50 | 805.2 | 805.2 | 240 | 0.48 |

| 6 h Electrical Flux/C | Chloride Ion Penetration | Concrete Type |

|---|---|---|

| >4000 | High | W/C ratio > 0.6 |

| 2000–4000 | Moderate | W/C ratio 0.5–0.6 |

| 1000–2000 | Low | Low W/C ratio |

| 100–1000 | Very low | Low W/C ratio with 5–10% SF |

| <100 | Negligible | Polymer concrete with 5–10% SF |

| Specimens | Total Porosity/mL/g | Pore Volume Distribution/% | |||

|---|---|---|---|---|---|

| <50 nm | 50–100 nm | 100–1000 nm | >1000 nm | ||

| MPC Mortar | 1.9733 | 48.04 | 17.68 | 26.03 | 8.25 |

| OPC Mortar | 0.6577 | 1.98 | 11.48 | 83.78 | 2.76 |

| Cement Material | MPC Material | Portland Cement Material | ||

|---|---|---|---|---|

| Group | No. | Type | No. | Type |

| M-1 | MPC slurry | P-1 | OPC slurry | |

| M-2 | MPC + 10% Si | P-2 | OPC + 10% Si | |

| M-3 | MPC + 10% FA | P-3 | OPC + 20% FA | |

| M-4 | MPC + 5%FA + 5% Si | P-4 | OPC + 10% Si + 10% FA | |

| MPC Material | Portland Cement Material | ||||

|---|---|---|---|---|---|

| No. | Type | Crack Time/h | No. | Type | Crack Time/h |

| M-1 | MPC mortar | - | P-1 | OPC mortar | 68.5 |

| M-2 | MPC + 10%Si | - | P-2 | OPC + 10% Si | 95.5 |

| M-3 | MPC + 10%FA | - | P-3 | OPC + 20% FA | 72.5 |

| M-4 | MPC + 5% FA + 5% Si | - | P-4 | OPC + 10% Si + 10% FA | 87.5 |

| M-5 | MPC + 1% PVA | - | P-5 | OPC + 1% PVA | 28.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, Y.; Gao, P.; Yang, J.; Shi, F. Research on the Chloride Ion Penetration Resistance of Magnesium Phosphate Cement (MPC) Material as Coating for Reinforced Concrete Structures. Coatings 2020, 10, 1145. https://doi.org/10.3390/coatings10121145

Du Y, Gao P, Yang J, Shi F. Research on the Chloride Ion Penetration Resistance of Magnesium Phosphate Cement (MPC) Material as Coating for Reinforced Concrete Structures. Coatings. 2020; 10(12):1145. https://doi.org/10.3390/coatings10121145

Chicago/Turabian StyleDu, Yubing, Peiwei Gao, Jianming Yang, and Feiting Shi. 2020. "Research on the Chloride Ion Penetration Resistance of Magnesium Phosphate Cement (MPC) Material as Coating for Reinforced Concrete Structures" Coatings 10, no. 12: 1145. https://doi.org/10.3390/coatings10121145

APA StyleDu, Y., Gao, P., Yang, J., & Shi, F. (2020). Research on the Chloride Ion Penetration Resistance of Magnesium Phosphate Cement (MPC) Material as Coating for Reinforced Concrete Structures. Coatings, 10(12), 1145. https://doi.org/10.3390/coatings10121145