Highly Hydrophobic and Self-Cleaning Heat-Treated Larix spp. Prepared by TiO2 and ZnO Particles onto Wood Surface

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Heat Treatment

2.3. Surface Modification of the TiO2 Particles

2.4. Surface Modification of the ZnO Particles

2.5. Wood Photography

2.6. Roughness

2.7. Colormeter

2.8. Scanning Electron Microscopy

2.9. Wood Contact Angles

2.10. FTIR

3. Results

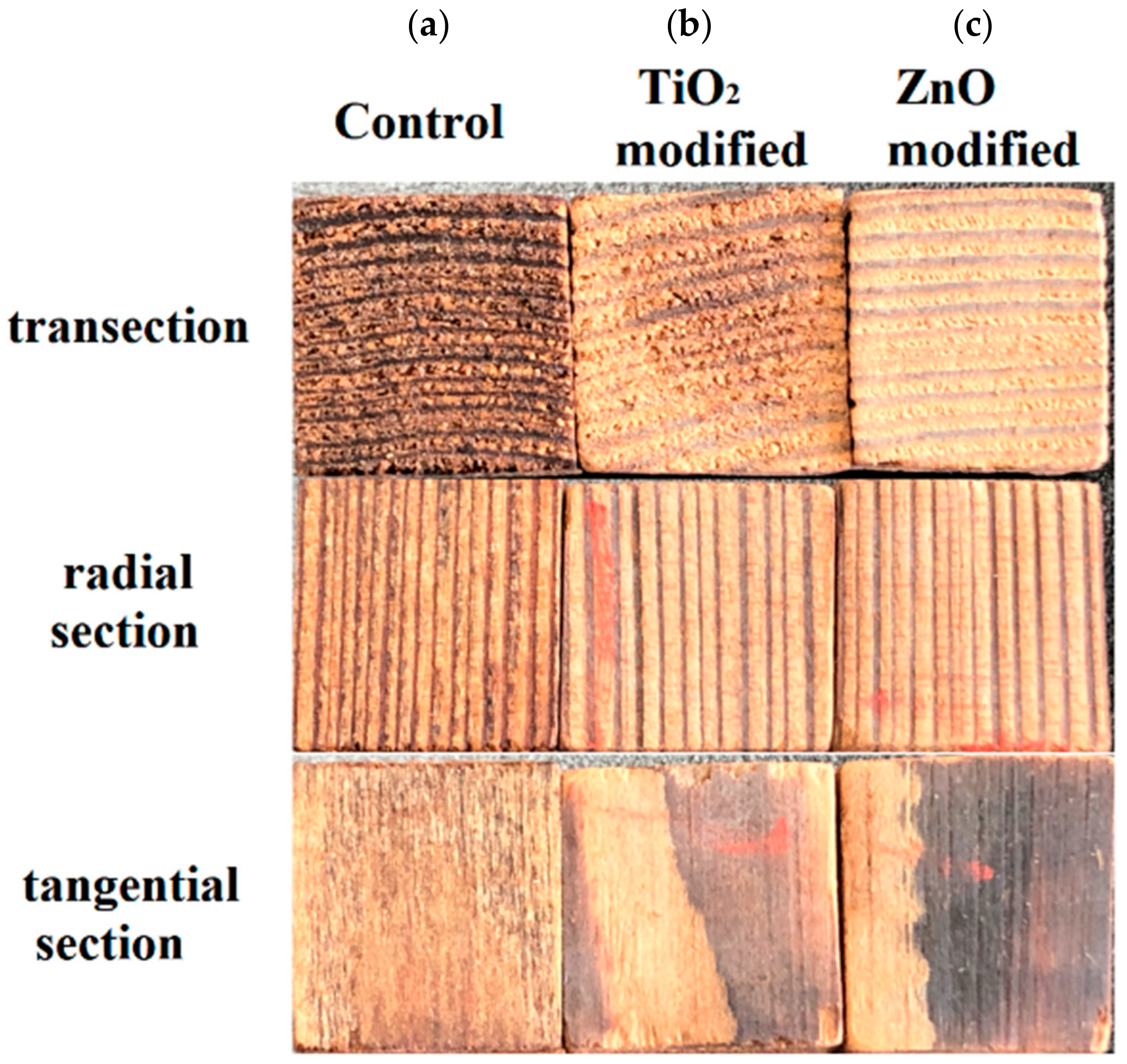

3.1. Visual Observation

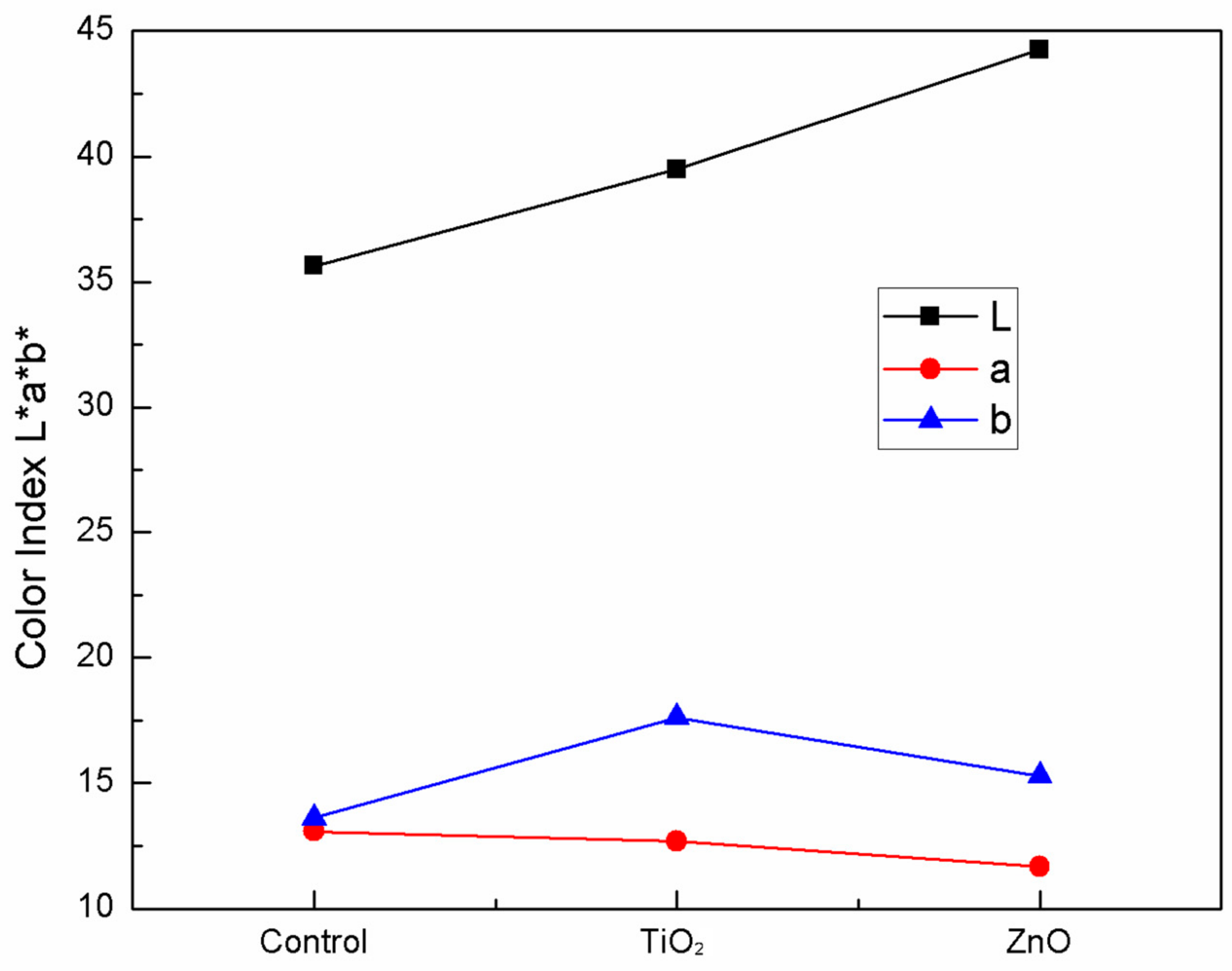

3.2. Color Changes

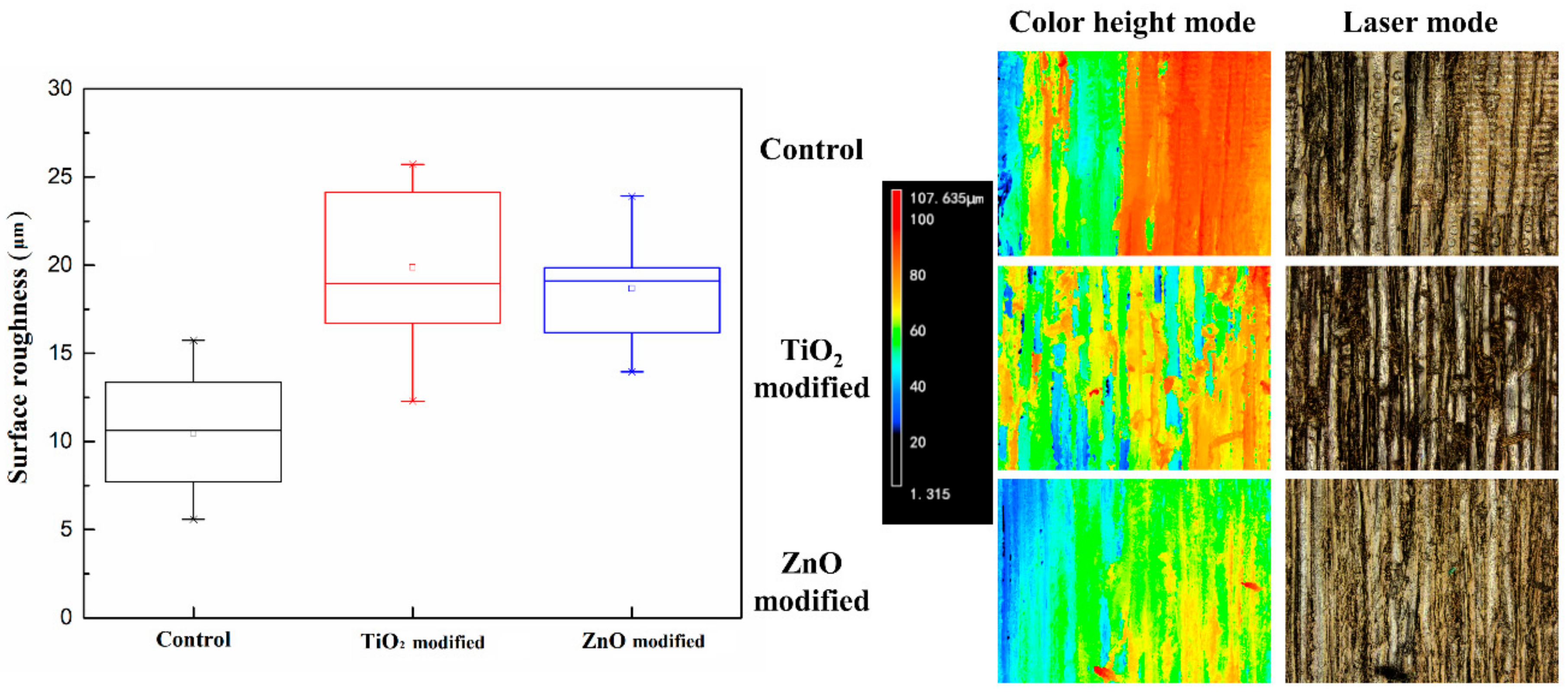

3.3. Roughness

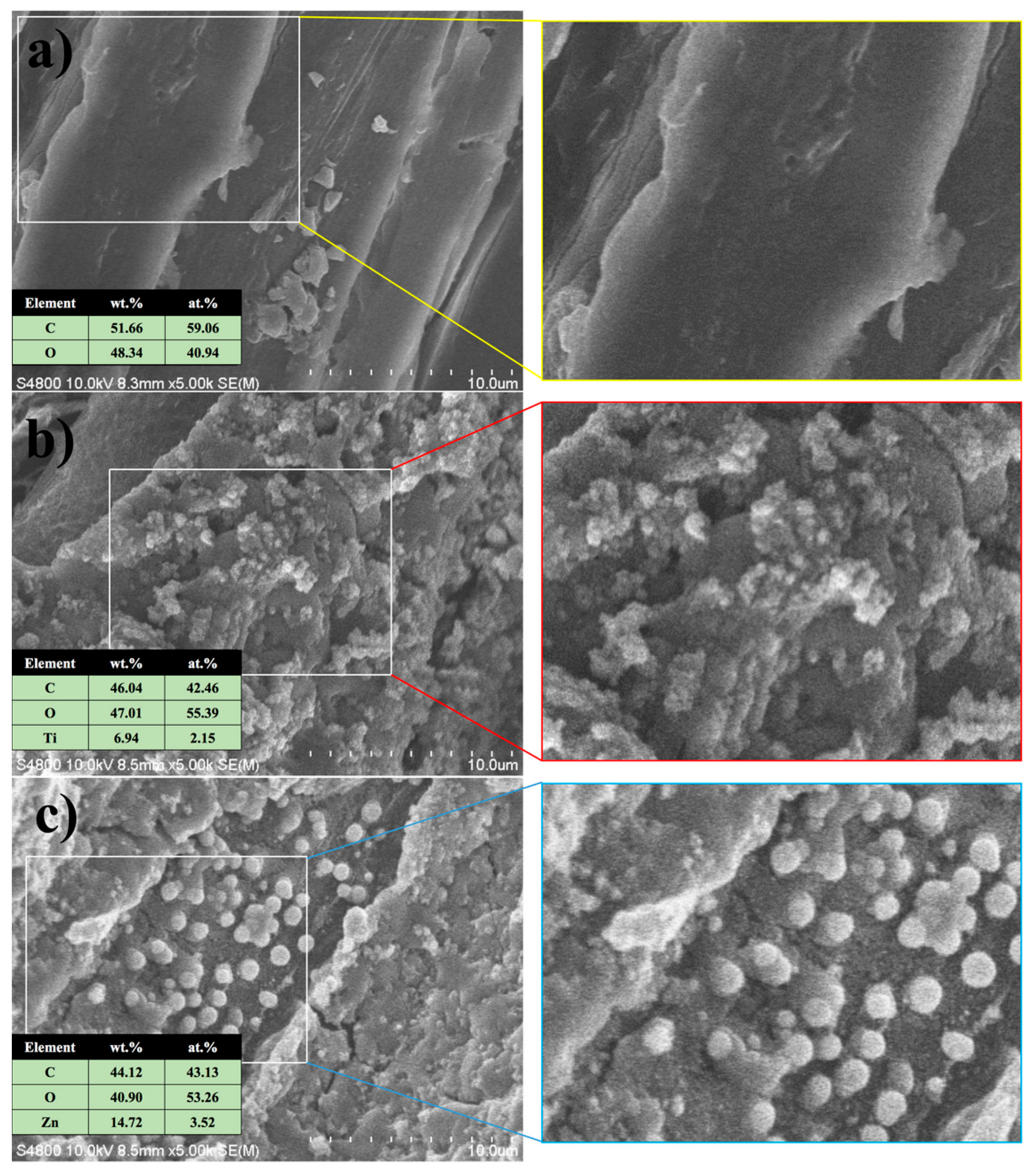

3.4. Microsturcture

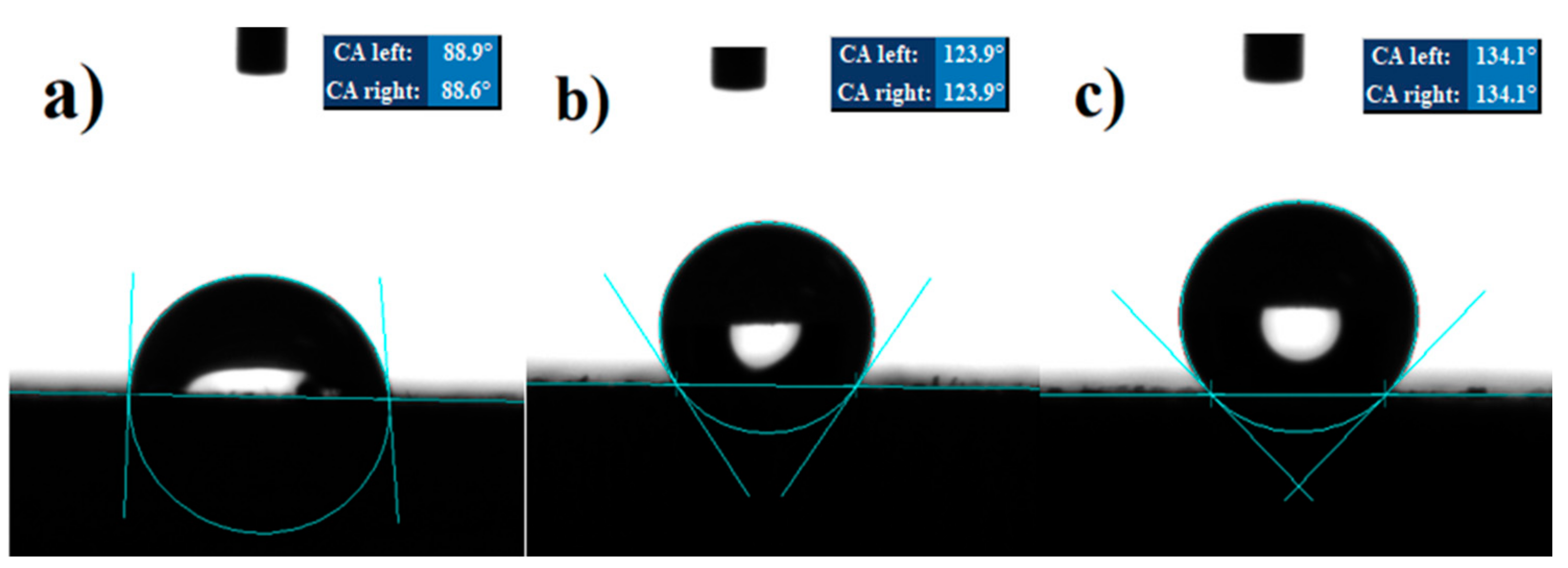

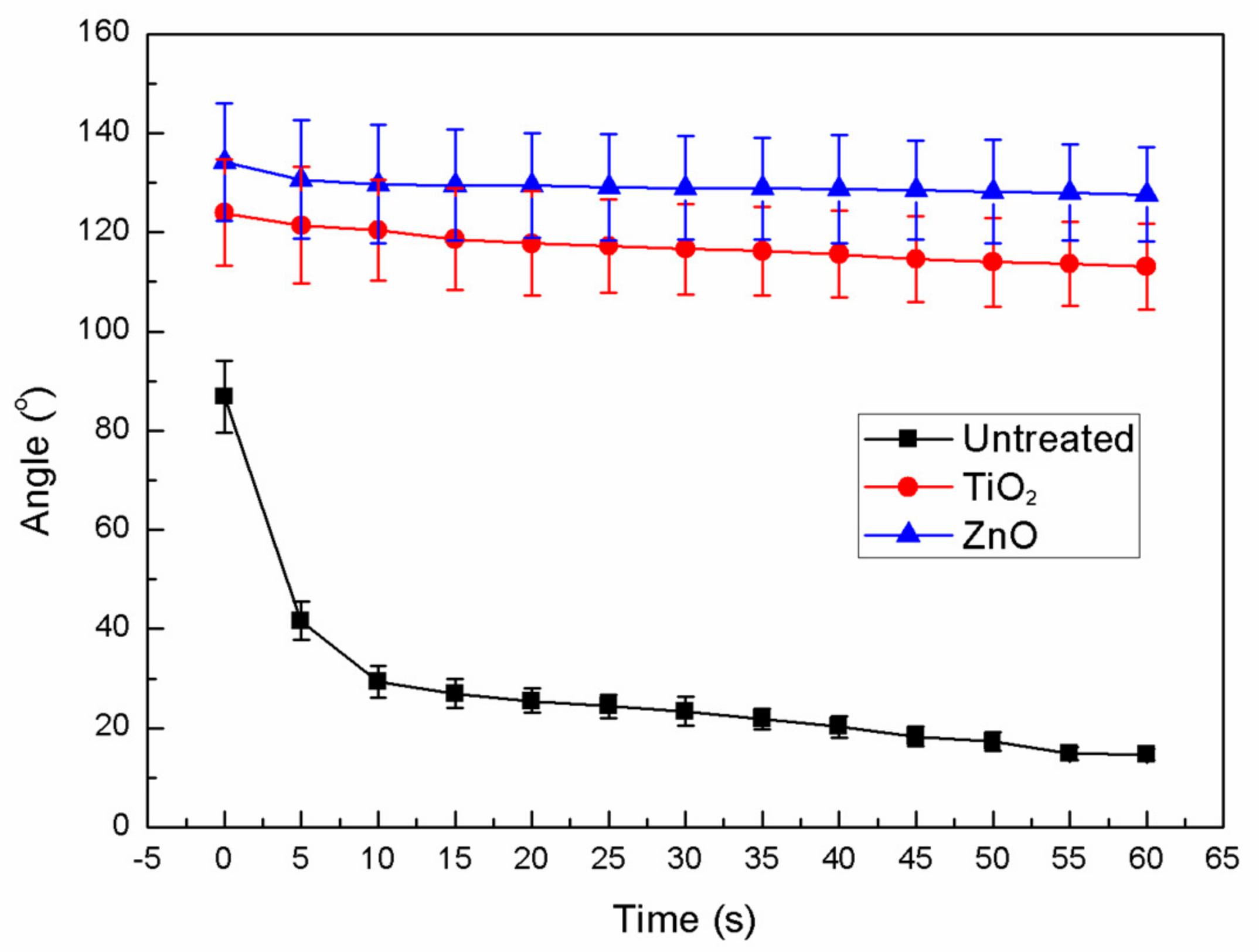

3.5. Contact Angle

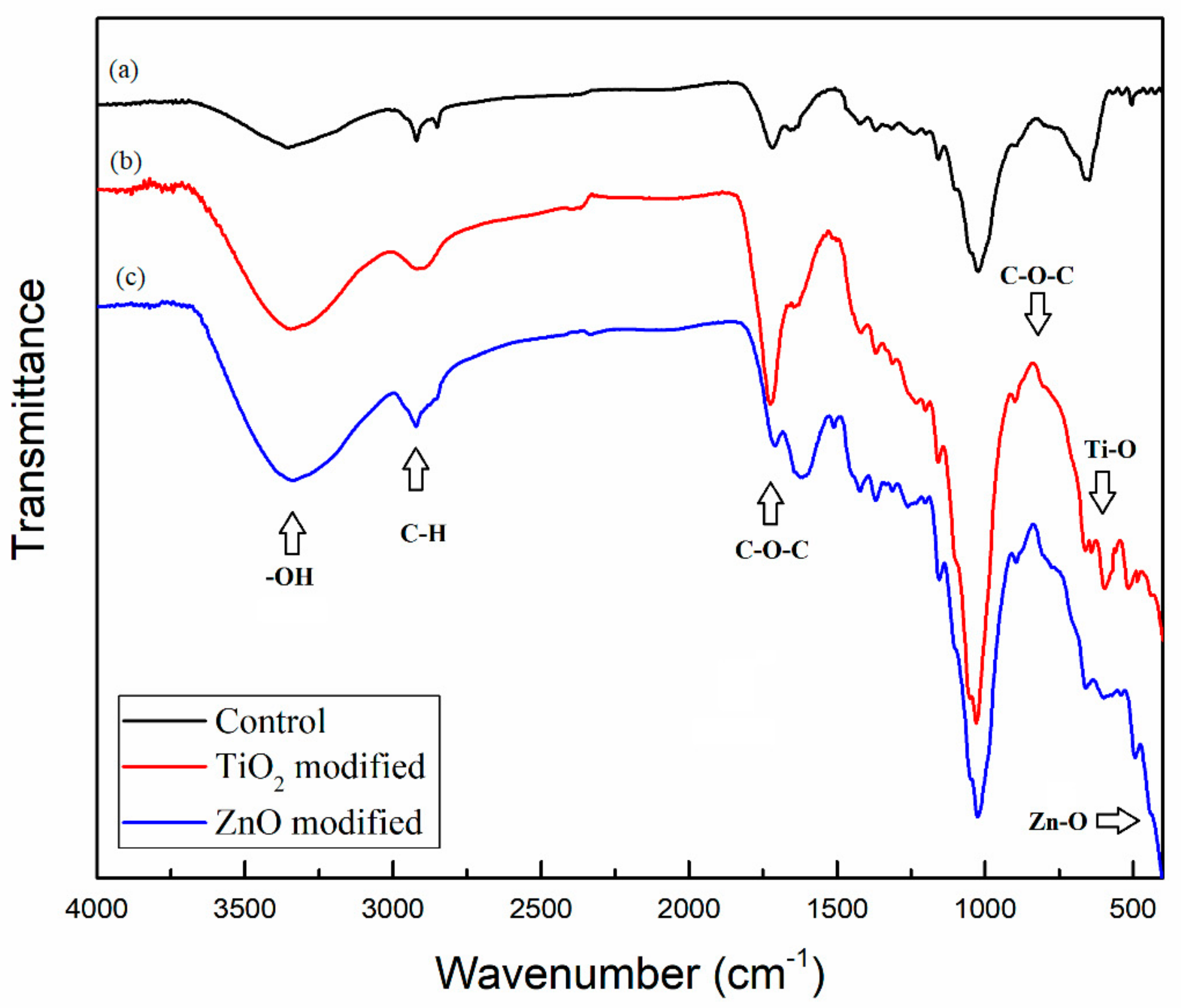

3.6. FTIR

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Chung, H.; Park, Y.; Yang, S.-Y.; Kim, H.; Han, Y.; Chang, Y.-S.; Yeo, H. Effect of heat treatment temperature and time on sound absorption coefficient of Larix kaempferi wood. J. Wood Sci. 2017, 63, 575–579. [Google Scholar] [CrossRef]

- Kamdem, D.P.; Pizzi, A.; Jermannaud, A. Durability of heat-treated wood. Holz Roh Werkst. 2002, 60, 1–6. [Google Scholar] [CrossRef]

- Tjeerdsma, B.F.; Militz, H. Chemical changes in hydrothermal treated wood: FTIR analysis of combined hydrothermal and dry heat-treated wood. Holz Roh Werkst. 2005, 63, 102–111. [Google Scholar] [CrossRef]

- Way, D.; Sinha, A.; Kamke, F.A. Laboratory and Outdoor Weathering of Wood-Composite I-Joists. J. Mater. Civ. Eng. 2018, 30, 04018148. [Google Scholar] [CrossRef]

- De Windt, I.; Bulcke, J.V.D.; Wuijtens, I.; Coppens, H.; Van Acker, J. Outdoor weathering performance parameters of exterior wood coating systems on tropical hardwood substrates. Holz Roh Werkst. 2014, 72, 261–272. [Google Scholar] [CrossRef]

- Forsthuber, B.; Schaller, C.; Gruell, G. Evaluation of the photo stabilising efficiency of clear coatings comprising organic UV absorbers and mineral UV screeners on wood surfaces. Wood. Sci. Technol. 2013, 47, 281–297. [Google Scholar] [CrossRef]

- Boris, N.K.; Svetlana, A.K.; Vladimir, G.D.; Olga, V.Y. Influence of UV pretreatment on the abies wood catalytic delignification in the medium acetic acid-hydrogen peroxide-TiO2. React. Kinet. Catal. Lett. 2009, 97, 295–300. [Google Scholar]

- Xu, J.F.; Wu, H.G.; Liu, R.; Long, L.; Lin, P. Preparation and properties of light-resistant printing UV ink modified with nano-TiO2 on wood substrate. Surf. Eng. 2019, 35, 557–564. [Google Scholar] [CrossRef]

- Sun, Q.F.; Lu, Y.; Zhang, H.M.; Zhao, H.J.; Yu, H.P.; Xu, J.S.; Fu, Y.C.; Yang, D.J.; Liu, Y.X. Hydrothermal fabrication of rutile TiO2 submicrospheres on wood surface: An efficient method to prepare UV-protective wood. Mater. Chem. Phys. 2012, 133, 253–258. [Google Scholar] [CrossRef]

- Tshabalala, M.A.; Libert, R.; Schaller, C.M. Photostability and moisture uptake properties of wood veneers coated with a combination of thin sol-gel films and light stabilizers. Holzforschung 2011, 65, 215–220. [Google Scholar] [CrossRef]

- Guo, H.Z.; Klose, D.; Hou, Y.H.; Jeschke, G.; Burgert, I. Highly Efficient UV Protection of the Biomaterial Wood by A Transparent TiO2/Ce Xerogel. ACS Appl. Mater. Interfaces 2017, 9, 39040–39047. [Google Scholar] [CrossRef]

- Baishya, P.; Saikia, D.; Mandal, M.; Maji, T.K. Biodegradability, flammability, dimensional stability, and UV resistance study of green wood starch gluten nanocomposites. Polym. Compos. 2017, 40, 46–55. [Google Scholar] [CrossRef]

- Jia, S.S.; Chen, H.B.; Luo, S.; Qing, Y.; Deng, S.L.; Yan, N.; Wu, Y.Q. One-step approach to prepare superhydrophobic wood with enhanced mechanical and chemical durability: Driving of alkali. Appl. Surf. Sci. 2018, 455, 115–122. [Google Scholar] [CrossRef]

- Saha, S.; Kocaefe, D.; Sarkar, D.K.; Boluk, Y.; Pichette, A. Effect of TiO2-containing nano-coatings on the color protection of heat-treated jack pine. J. Coat. Technol. Res. 2011, 8, 183–190. [Google Scholar] [CrossRef]

- Guo, H.; Fuchs, P.; Cabane, E.; Michen, B.; Hagendorfer, H.; Romanyuk, Y.E.; Burgert, I. UV-protection of wood surfaces by controlled morphology fine-tuning of ZnO nanostructures. Holzforschung 2016, 70, 699–708. [Google Scholar] [CrossRef]

- Salla, J.; Pandey, K.K.; Srinivas, K. Improvement of UV resistance of wood surfaces by using ZnO nanoparticles. Polym. Degrad. Stabil. 2012, 97, 592–596. [Google Scholar] [CrossRef]

- Xiong, J.; Sarkar, D.K.; Chen, X.G. Ultraviolet-Durable Superhydrophobic Nanocomposite Thin Films Based on Cobalt Stearate-Coated TiO2 Nanoparticles Combined with Polymethylhydrosiloxane. ACS Omega 2017, 2, 8198–8204. [Google Scholar] [CrossRef]

- Papa, N.D.; Tatjana, S.; Alain, C. Effects of thermo-hygro-mechanical densification on the surface characteristics of trembling aspen and hybrid poplar wood veneers. Appl. Surf. Sci. 2011, 257, 3558–3564. [Google Scholar]

- Croitoru, C.; Spirchez, C.; Lunguleasa, A.; Cristea, D. Surface properties of thermally treated composite wood panels. Appl. Surf. Sci. 2018, 438, 114–126. [Google Scholar] [CrossRef]

- Shen, H.; Zhang, S.; Cao, J.Z.; Jiang, J.; Wang, W. Improving anti-weathering performance of thermally modified wood by TiO2 sol or/and paraffin emulsion. Constr. Build. Mater. 2018, 169, 372–378. [Google Scholar] [CrossRef]

- Gao, X.; Dong, Y.; Wang, K.; Chen, Z.; Yan, Y.; Li, J.; Zhang, S. Improving Dimensional and Thermal Stability of Poplar Wood via Aluminum-based Sol-Gel and Furfurylation Combination Treatment. Bioresources 2017, 12, 3277–3288. [Google Scholar] [CrossRef]

- Weichelt, F.; Beyer, M.; Emmler, R.; Flyunt, R.; Beyer, E.; Buchmeiser, M. Zinc Oxide Based Coatings for the UV-Protection of Wood for Outdoor Applications. Macromol. Symp. 2011, 301, 23–30. [Google Scholar] [CrossRef]

- Shen, H.Y.; Cao, J.Z.; Jiang, J.; Xu, J.Q. Antiweathering properties of a thermally treated wood surface by two-step treatment with titanium dioxide nanoparticle growth and polydimethylsiloxane coating. Prog. Org. Coat. 2018, 125, 1–7. [Google Scholar] [CrossRef]

- Poubel, D.D.; Garcia, R.A.; Lelis, R.C.; Riedl, B. Effect of ZnO nanoparticles on UV resistance of the heat-treated pine wood. Sci. For. 2017, 45, 49–62. [Google Scholar]

- Xing, D.; Li, J.; Wang, S.Q. In situ measurement of heat-treated wood cell wall at elevated temperature by nanoindentation. Ind. Crop. Prod. 2016, 87, 142–149. [Google Scholar] [CrossRef]

- Rosu, L.; Varganici, C.-D.; Mustata, F.; Rosu, D.; Rosca, I.; Rusu, T. Epoxy Coatings Based on Modified Vegetable Oils for Wood Surface Protection against Fungal Degradation. ACS Appl. Mater. Interfaces 2020, 12, 14443–14458. [Google Scholar] [CrossRef]

- Ansari, M.A.; Mahadevamurthy, M.; Prasad, D.; Alzohairy, M.A.; Almatroudi, A.; Alomary, M.N.; Udayashankar, A.C.; Singh, S.B.; Asiri, S.M.M.; Ashwini, B.S. Cinnamomum verum Bark Extract Mediated Green Synthesis of ZnO Nanoparticles and Their Antibacterial Potentiality. Biomolecules 2020, 10, 336. [Google Scholar] [CrossRef]

- Rastogi, P.; Palazon, F.; Prato, M.; Stasio, F.D.; Krahne, R. Enhancing the Performance of CdSe/CdS Dot-in-Rod Light-Emitting Diodes via Surface Ligand Modification. ACS Applied. Mater. Interfaces 2018, 6, 5665–5672. [Google Scholar] [CrossRef]

- Gao, L.K.; Lu, Y.; Zhan, X.X.; Li, J.; Sun, Q.F. A robust, anti-acid, and high-temperature–humidity-resistant superhydrophobic surface of wood based on a modified TiO2 film by fluoroalkyl silane. Surf. Coat. Technol. 2015, 262, 33–39. [Google Scholar] [CrossRef]

- Zhan, C.; Li, Y.; Sharma, P.R.; He, H.R.; Sharma, S.K.; Wang, R.F.; Hsiao, B.S. A study of TiO2 nanocrystal growth and environmental remediation capability of TiO2/CNC nanocomposites. RSC Adv. 2019, 9, 40565–40576. [Google Scholar] [CrossRef]

- Srinivas, K.; Pandey, K.K. Photodegradation of thermally modified wood. J. Photochem. Photobiol. B Biol. 2012, 117, 140–145. [Google Scholar] [CrossRef] [PubMed]

- Guo, X.; Wu, Y.; Yan, N. In situ micro-FTIR observation of molecular association of adsorbed water with heat-treated wood. Wood Sci. Technol. 2018, 52, 971–985. [Google Scholar] [CrossRef]

- Xing, D.; Wang, S.; Li, J. Effect of Artificial Weathering on the Properties of Industrial-Scale Thermally Modified Wood. Bioresources 2015, 10, 8238–8252. [Google Scholar] [CrossRef]

- Lin, L.; Cao, J.; Zhang, J.; Cui, Q.L.; Liu, Y. Enhanced Anti-Mold Property and Mechanism Description of Ag/TiO2 Wood-Based Nanocomposites Formation by Ultrasound and Vacuum-Impregnation. Nanomaterials 2020, 10, 682. [Google Scholar] [CrossRef]

- Chandrasekhar, M.; Nagabhushana, H.; Sharma, S.C.; Kumar, K.H.; Sudheer, D.N.; Sunitha, D.V.; Shivakumara, C.; Nagabhushana, B.M. Particle size, morphology and colour tunable ZnO: Eu3+ nanophosphors via plant latex mediated green combustion synthesis. J. Alloys Compd. 2014, 584, 417–424. [Google Scholar] [CrossRef]

| Process | Heat Treatment | Surface Modification |

|---|---|---|

| Control | Heat-treated at 190 °C for 6 h | - |

| TiO2 modified | Heat-treated at 190 °C for 6 h | Surface modification of the TiO2 nanoparticles |

| ZnO modified | Heat-treated at 190 °C for 6 h | Surface modification of the ZnO nanoparticles |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xing, D.; Zhang, Y.; Hu, J.; Yao, L. Highly Hydrophobic and Self-Cleaning Heat-Treated Larix spp. Prepared by TiO2 and ZnO Particles onto Wood Surface. Coatings 2020, 10, 986. https://doi.org/10.3390/coatings10100986

Xing D, Zhang Y, Hu J, Yao L. Highly Hydrophobic and Self-Cleaning Heat-Treated Larix spp. Prepared by TiO2 and ZnO Particles onto Wood Surface. Coatings. 2020; 10(10):986. https://doi.org/10.3390/coatings10100986

Chicago/Turabian StyleXing, Dong, Yan Zhang, Jianpeng Hu, and Lihong Yao. 2020. "Highly Hydrophobic and Self-Cleaning Heat-Treated Larix spp. Prepared by TiO2 and ZnO Particles onto Wood Surface" Coatings 10, no. 10: 986. https://doi.org/10.3390/coatings10100986

APA StyleXing, D., Zhang, Y., Hu, J., & Yao, L. (2020). Highly Hydrophobic and Self-Cleaning Heat-Treated Larix spp. Prepared by TiO2 and ZnO Particles onto Wood Surface. Coatings, 10(10), 986. https://doi.org/10.3390/coatings10100986