Service Behavior of Nitride Layers of Steels for Military Applications

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Chemical Composition

2.3. Specimen Preparation

2.4. Microstructure Evaluation

2.5. Hardness Measurement

2.6. Tribological Measurements

- Initiation of wear;

- Mutual adaptation of contact surfaces and creation of the layer;

- Stabilization of the COF;

- Rupture of the layer and its destruction to the base material [23].

- Influence of circle path radius on results of COF was not confirmed;

- In this case, a change in an angular velocity affects results solely after an increase near to the value 1000 rpm and above;

- By an increase in the indenter’s load, the higher COF was detected;

- The effect of different temperatures on the results of the measurements is significant.

2.7. Assessment of Wear

3. Results and Discussion

3.1. Chemical Composition

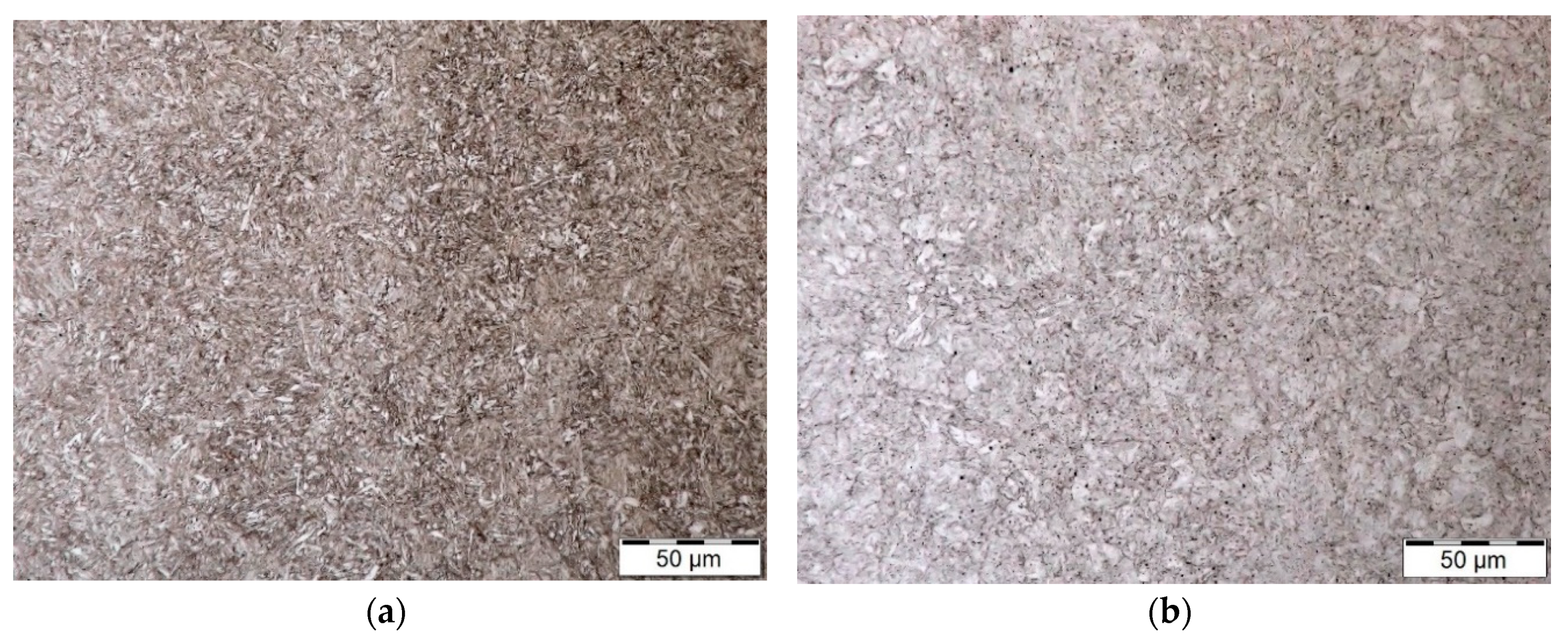

3.2. Microstructure Evaluation

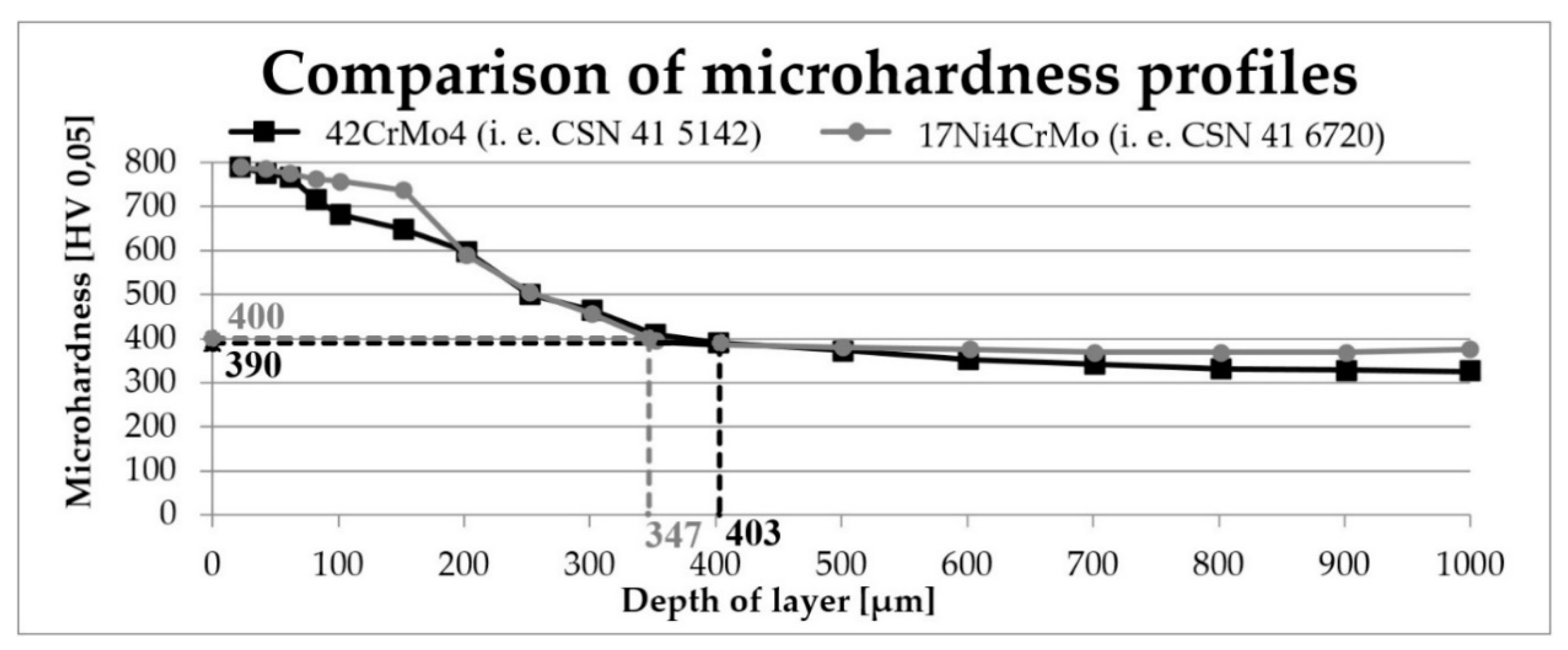

3.3. Hardness

- Limit value of microhardness of steel equivalent 42CrMo4 (i.e., CSN 41 5142) as NHD 390 HV 0.05 = 403 µm was assessed;

- In case of steel equivalent 17Ni4CrMo (i.e., CSN 41 6720) the value was evaluated as NHD 400 HV 0.05 = 347 µm.

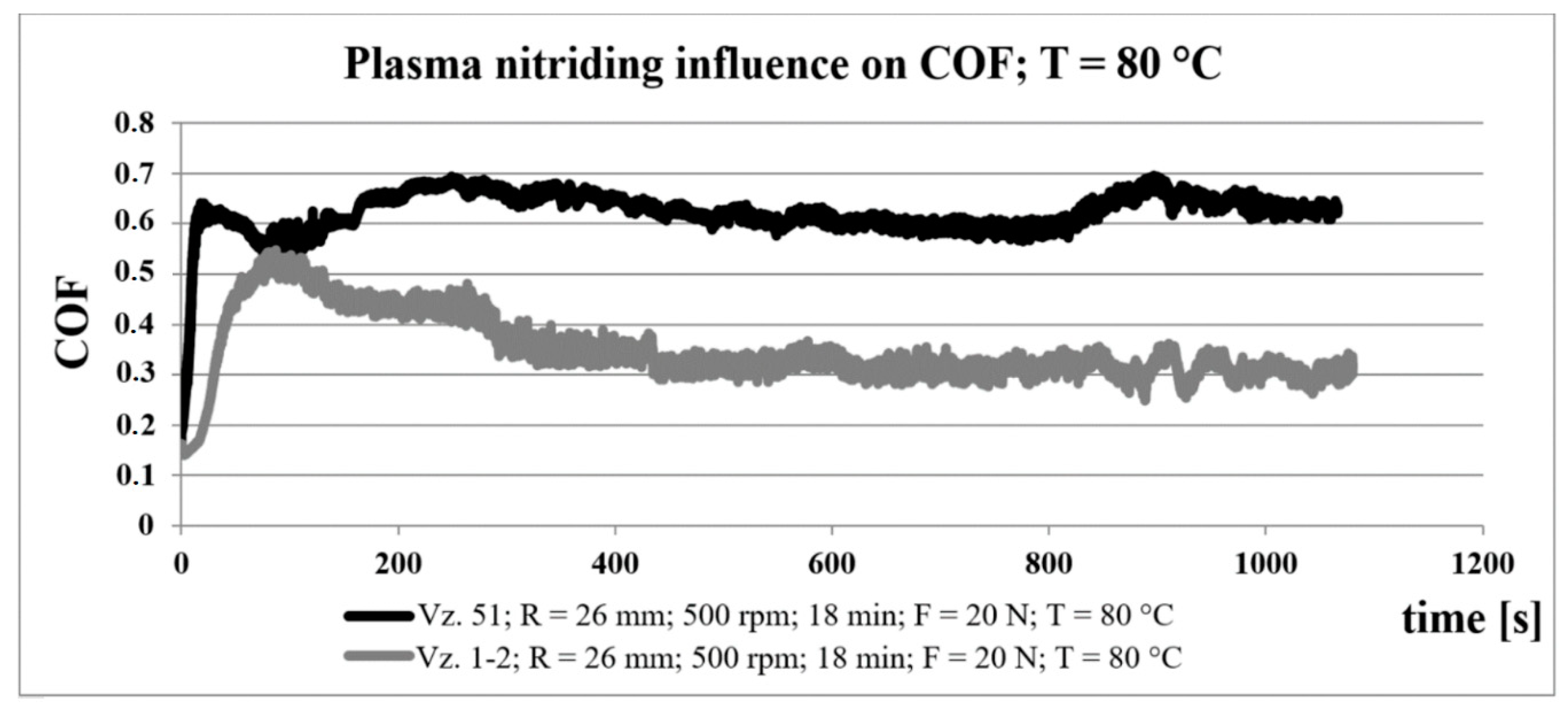

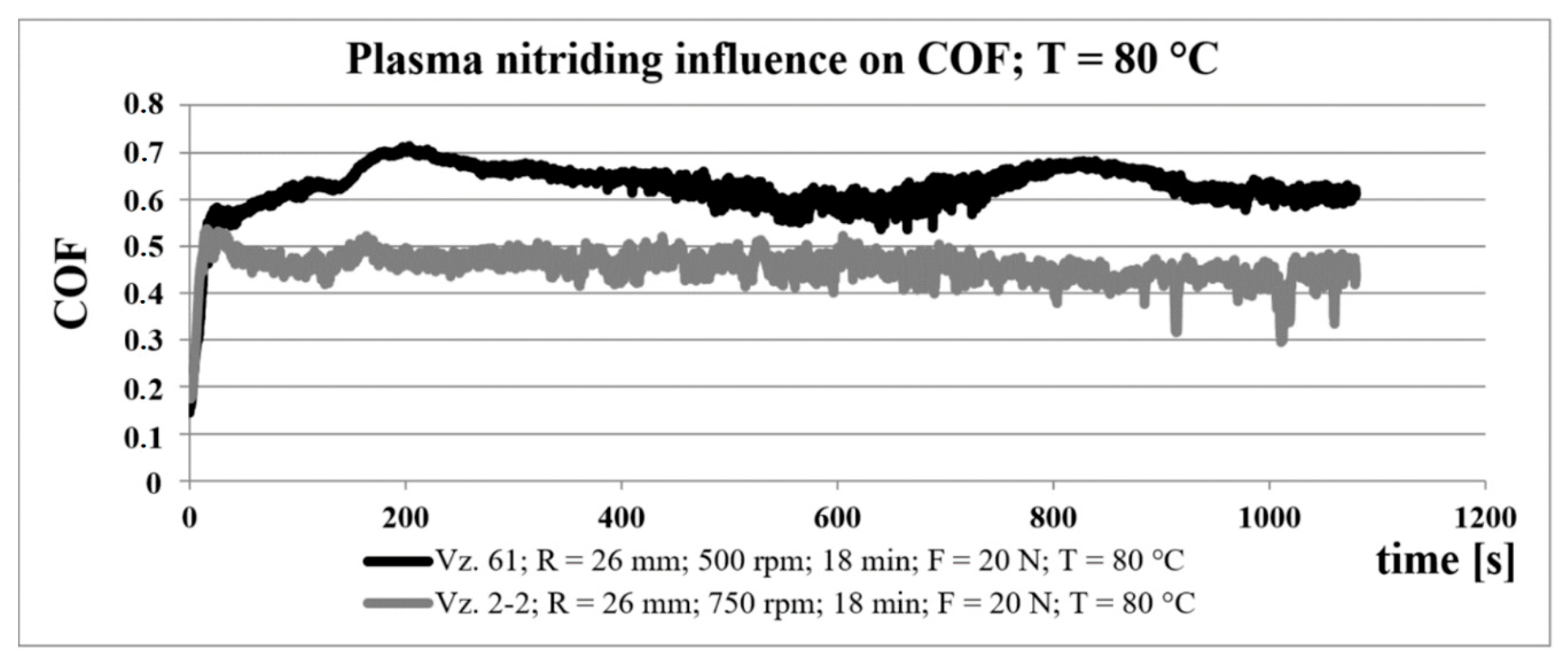

3.4. Coefficient of Friction

3.4.1. Influence of Plasma Nitriding on COF Measured at Room Temperature

3.4.2. Influence of Plasma Nitriding on COF Measured at Higher Temperatures

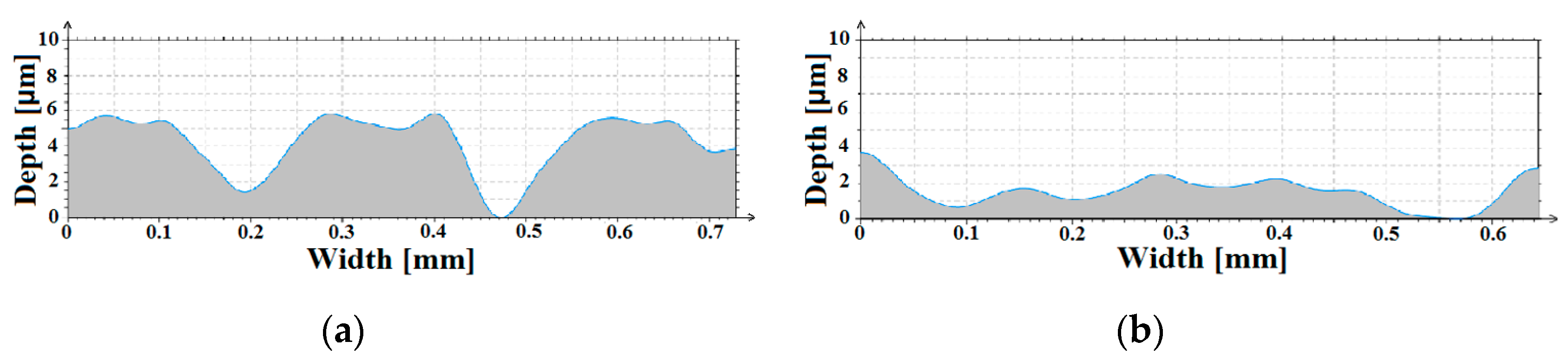

3.5. Assessment of Wear

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Barényi, I.; Majerík, J.; Pokorný, Z.; Sedlák, J.; Bezecný, J.; Dobrocký, D.; Jaroš, A.; Eckert, M.; Jambor, J.; Kusenda, R. Material and technological investigation of machined surfaces of the OCHN3MFA steel. Met. Mater. 2019, 57, 131–142. [Google Scholar] [CrossRef] [Green Version]

- Turo, T.; Neumann, V.; Krobot, Z. Aspects of Technical Requirements for the Future Autonomy of Military Vehicles. In Modelling and Simulation for Autonomous Systems; Mazal, J., Ed.; Lecture Notes in Computer Science; Springer International Publishing: Cham, Switzerland, 2018; pp. 374–380. ISBN 978-3-319-76071-1. [Google Scholar] [CrossRef]

- Hluchý, M.; Kolouch, J. Strojírenská Technologie 1; Scientia Publisher: Prague, Czech Republic, 2007. [Google Scholar]

- Macek, K. Strojírenské Materiály; ČVUT Publisher: Praha, Czech Republic, 2003. [Google Scholar]

- Klanica, O.; Svoboda, E.; Joska, Z. Changes of the surface texture after surface treatment HS6-5-2-5 steel. Manuf. Technol. 2015, 15, 47–53. [Google Scholar] [CrossRef]

- Hromádko, J. Spalovací Motory: Komplexní Přehled Problematiky Pro Všechny Typy Technických Automobilních Škol; Grada Publisher: Prague, Czech Republic, 2011. [Google Scholar]

- Fonte, M.; Freitas, M.; Reis, L. Failure analysis of a damaged diesel motor crankshaft. Eng. Fail. Anal. 2019, 102, 1–6. [Google Scholar] [CrossRef]

- Pišek, D. Chemicko-Tepelné Zpracování Ocelí. Bachelor’s Thesis, Vysoké učení technické v Brně, Brno, Czech Republic, 2015. [Google Scholar]

- Pokorny, Z.; Dobrocky, D.; Kadlec, J.; Studeny, Z. Influence of Alloying Elements on Gas Nitriding Process of High-Stressed Machine Parts of Weapons. Met. Mater. 2018, 56, 97–103. [Google Scholar] [CrossRef] [Green Version]

- Totten, G.E. Steel Heat Treatment: Metallurgy and Technologies, 2nd ed.; Taylor & Francis: Boca Raton, FL, USA, 2007. [Google Scholar]

- Dobrocky, D.; Pokorny, Z.; Studeny, Z.; Doan, T.V. Analyse of Tribological Properties of Layers Created by Plasma Nitriding + DLC. Manuf. Technol. 2018, 18, 379–386. [Google Scholar] [CrossRef]

- Pokorný, Z.; Hrubý, V.; Stránský, K.; Kadlec, J. Properties of plasma nitrided layers in deep cavities. In Proceedings of the METAL 2011, 20th Anniversary International Conference on Metallurgy and Materials, Brno, Czech Republic, 18–20 May 2011; TANGER Ltd.: Ostrava, Czech Republic, 2011; pp. 786–790. [Google Scholar]

- Jaros, A.; Sedlak, J.; Vondra, J. Investigation of the influence of PVD coatings for dry groove milling. Mm Sci. J. 2018, 2018, 2516–2520. [Google Scholar] [CrossRef]

- Arnošt, D. Tankové Spalovací Motory od Historie až po Současnost; Vysoké učení technické v Brně: Brno, Czech Republic, 2009. [Google Scholar]

- Bolek, A.; Kochman, J. Části Strojů: 2; SNTL Publisher: Prague, Czech Republic, 1990. [Google Scholar]

- Doan, T.V.; Dobrocky, D.; Pokorny, Z.; Kusmic, D.; Nguyen, V.T. Effect Of Plasma Nitriding On Mechanical And Tribological Properties Of 42CrMo4 Steel. In Proceedings of the ABAF 2016, 17th International Conference on Advanced Batteries, Accumulators and Fuel Cells, Brno, Czech Republic, 28–31 August 2016; ECS Transaction: Brno, Czech Republic, 2016; Volume 74, pp. 231–238. [Google Scholar]

- ISO 18203:2016. Steel–Determination of Thickness of Surface Hardened Layers; The International Organization for Standardization: Geneva, Switzerland, 2016. [Google Scholar]

- EN ISO 6507-1:2018. Metallic Materials-Vickers Hardness Test-Part 1: Test Method; The International Organization for Standardization: Geneva, Switzerland, 2018. [Google Scholar]

- EN ISO 14577-1:2015. Metallic Materials—Instrumented Indentation Test for Hardness and Materials Parameters–Part 1: Test Method; European Committee for Standardzation: Brussels, Belgium, 2015. [Google Scholar]

- Joska, Z.; Kadlec, J.; Hrubý, V.; Mrázková, T.; Maňas, K. Characteristics of Duplex Coating on Austenitic Stainless Steel. Key Eng. Mater. 2011, 465, 255–258. [Google Scholar] [CrossRef]

- Doan, T.V.; Kusmič, D.; Pospíchal, M.; Tran, Q.D.; Nguyen, V.T. Friction and Wear Behaviour of 42CrMo4 Steel Treated by Tenifer, Hard Chrome and Plasma Nitriding Technologies. Manuf. Technol. 2017, 17, 168–174. [Google Scholar] [CrossRef]

- ASTM. 99-95a Standard Test Method for Wear Testing with a Pin on Disc Apparatus; ASTM International: West Conshohocken, PA, USA, 2000. [Google Scholar]

- Kříž, A. Tribologická analýza PIN-ON-DISC. Metal 2004, pp. 1–8. Available online: https://opi.zcu.cz/TRIBOLOGICKA_ANALYZA_PIN-ON-DISC.pdf (accessed on 13 October 2020).

- Axén, N.; Hogmark, S.; Jacobson, S. Modern Tribology Handbook, Chapter 13: Friction and Wear Measurement Techniques; CRC Press: Boca Raton, FL, USA, 2001; pp. 493–510. [Google Scholar]

- Ptáček, L. Nauka o Materiálu II; CERM: Brno, Czech Republic, 1999; ISBN 80-7204-130-4. [Google Scholar]

- Peng, T.; Chen, Y.; Liu, X.; Wu, M.; Lu, Y.; Hu, J. Phase constitution control of plasma nitrided layer and its effect on wear behavior under different loads. Surf. Coat. Technol. 2020, 403. [Google Scholar] [CrossRef]

- Śnieżek, L.; Ślęzak, T.; Grzelak, K.; Hutsaylyuk, V. An experimental investigation of propagation the semi-elliptical surface cracks in an austenitic steel. Int. J. Press. Vessel. Pip. 2016, 144, 35–44. [Google Scholar] [CrossRef]

- Zhu, H.; Zhu, Q.; Tieu, A.K.; Kosasih, B.; Kong, C. A simulation of wear behaviour of high-speed steel hot rolls by means of high temperature pin-on-disc tests. Wear 2013, 302, 1310–1318. [Google Scholar] [CrossRef]

- Baccouch, Z.; Mnif, R.; Elleuch, R.; Richard, C. Analysis of friction, wear and oxidation behaviour of X40CrMoV5/Fe360B steel couple in an open-sliding contact. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2013, 228, 276–287. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

| Gasoline Engines | Gasoline and Diesel Engines | Diesel Engines (Alloyed Steels) | Diesel Engines (Upgraded Steel) | Diesel Engines (Hardened Steel) | Aircraft and Tank Engines |

|---|---|---|---|---|---|

| C35 | 34CrMo4 | 36Mn5 | C35 | 1.1191 | 30CrMoV9 |

| C45 | 34CrNiMo6 | 51CrV4 | 42CrMo4 | 35NiCr 6 | - |

| C55 | 17Ni4CrMo | 31NiCr 14 | 35NiCr 6 | - | - |

| 37MnSi5 | - | - | - | - | - |

| 36Mn5 | - | - | - | - | - |

| 1.7361 | - | - | - | - | - |

| 50CrV4 | - | - | - | - | - |

| 58CrV4 | - | - | - | - | - |

| 31NiCr14 | - | - | - | - | - |

| Steel | Applied Technology | |

|---|---|---|

| Heat Treatement (HT) | HT + Plasma Nitriding | |

| 42CrMo4 (i.e., CSN 41 5142) | Vz. 51 | Vz. 1-1, Vz. 1-2 |

| 17Ni4CrMo (i.e., CSN 41 6720) | Vz. 61 | Vz. 2-1, Vz. 2-2 |

| C | Mn | Si | P | S | Ni | Cr | Mo |

|---|---|---|---|---|---|---|---|

| OES/Bulk | |||||||

| 0.39 | 0.60 | 0.25 | 0.012 | 0.022 | 0.33 | 0.96 | 0.22 |

| Datasheet | |||||||

| 0.38–0.45 | 0.50–0.80 | 0.17–0.37 | <0.035 | <0.035 | <0.50 | 0.90–1.20 | 0.15–0.30 |

| C | Mn | Si | P | S | Ni | Cr | W |

|---|---|---|---|---|---|---|---|

| OES/Bulk | |||||||

| 0.15 | 0.398 | 0.25 | 0.013 | 0.025 | 4.118 | 1.542 | 0.82 |

| Datasheet | |||||||

| 0.14–0.21 | 0.25–0.55 | 0.17–0.37 | <0.035 | <0.035 | 4.00–4.50 | 1.35–1.65 | 0.80–1.20 |

| Specimen | Radius [mm] | Average Depth [μm] | Load [N] | Angular Velocity [rpm] | Initial Temperature [°C] |

|---|---|---|---|---|---|

| Vz.51 (CSN 41 5142) non-nitrided | 22 | 4.82 | 10 | 750 | 23 |

| 26 | 6.27 | 20 | 500 | 80 | |

| Vz.61 (CSN 41 6720) non-nitrided | 22 | 7.27 | 10 | 750 | 23 |

| 26 | 10.15 | 20 | 500 | 80 | |

| Vz.1-2 (CSN 41 5142) nitrided | 22 | 2.58 | 10 | 750 | 23 |

| 26 | 4.53 | 20 | 500 | 80 | |

| Vz.2-2 (CSN 41 6720) nitrided | 22 | 3.62 | 10 | 750 | 23 |

| 26 | 2.87 | 20 | 750 | 80 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Prochazka, J.; Pokorny, Z.; Dobrocky, D. Service Behavior of Nitride Layers of Steels for Military Applications. Coatings 2020, 10, 975. https://doi.org/10.3390/coatings10100975

Prochazka J, Pokorny Z, Dobrocky D. Service Behavior of Nitride Layers of Steels for Military Applications. Coatings. 2020; 10(10):975. https://doi.org/10.3390/coatings10100975

Chicago/Turabian StyleProchazka, Jiri, Zdenek Pokorny, and David Dobrocky. 2020. "Service Behavior of Nitride Layers of Steels for Military Applications" Coatings 10, no. 10: 975. https://doi.org/10.3390/coatings10100975

APA StyleProchazka, J., Pokorny, Z., & Dobrocky, D. (2020). Service Behavior of Nitride Layers of Steels for Military Applications. Coatings, 10(10), 975. https://doi.org/10.3390/coatings10100975