Investigation of the Performance of Fumed Silica as Flow Additive in Polyester Powder Coatings

Abstract

:1. Introduction

2. Experimental

2.1. Preparation of the Samples

2.1.1. Preparation of Powder Samples

2.1.2. Preparation of Finished Film

2.2. Characterization of the Coating Samples

2.2.1. Characterization of Powder Paints

2.2.2. Characterization of Properties Related to Coating Process

2.2.3. Characterization of Finished Films

3. Results and Discussion

3.1. Powder Properties

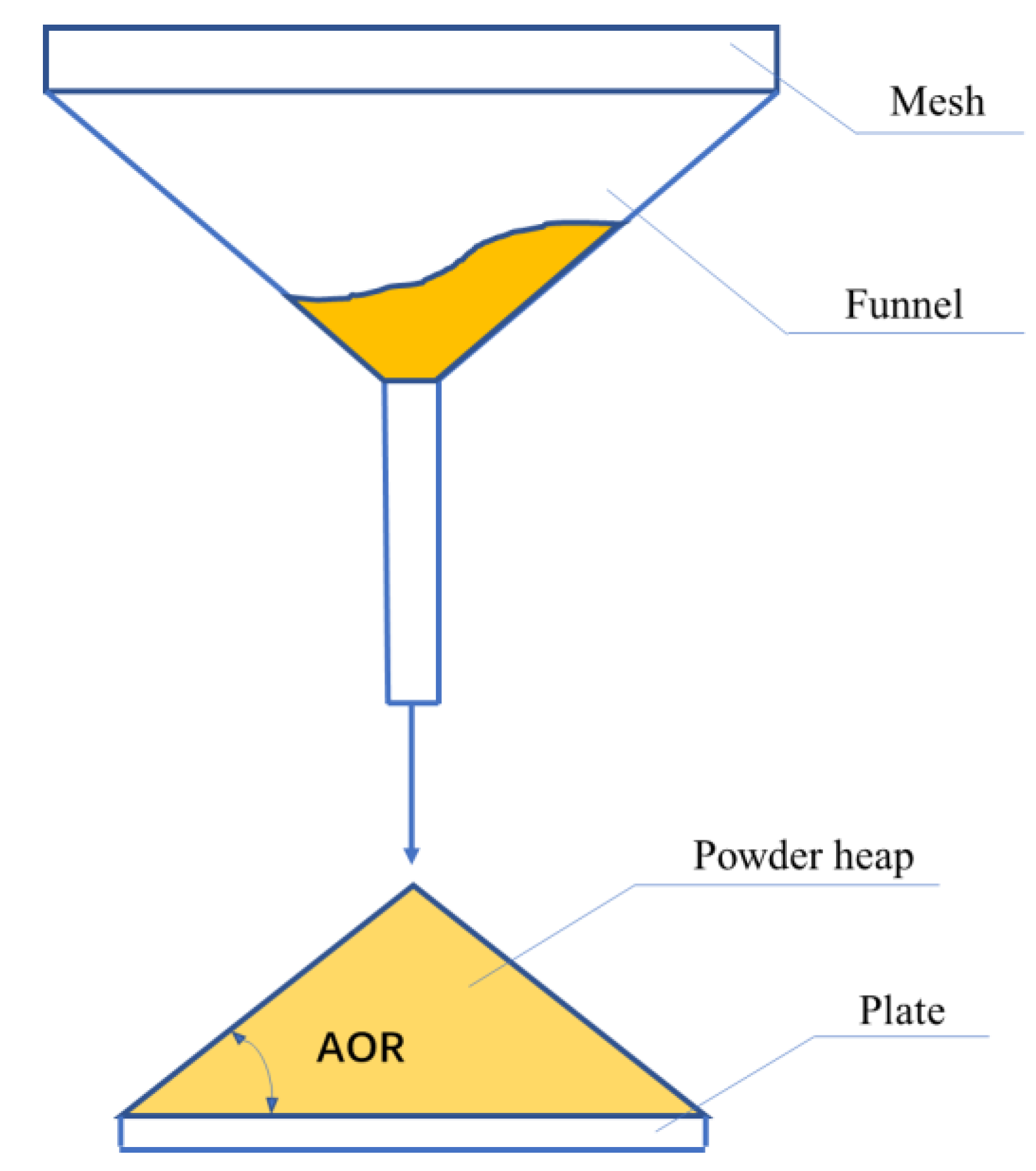

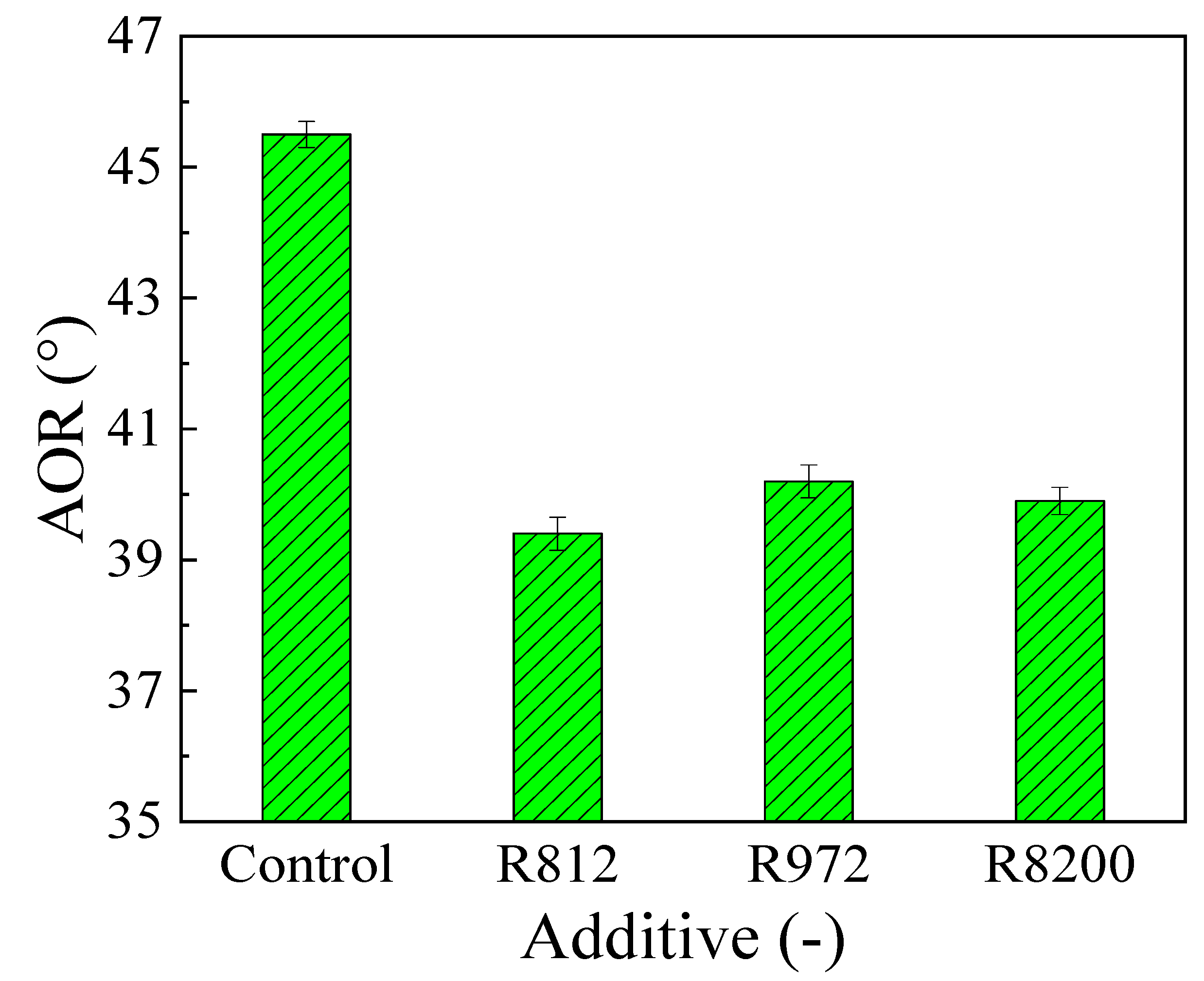

3.1.1. Semi-Dynamic Flowability-AOR

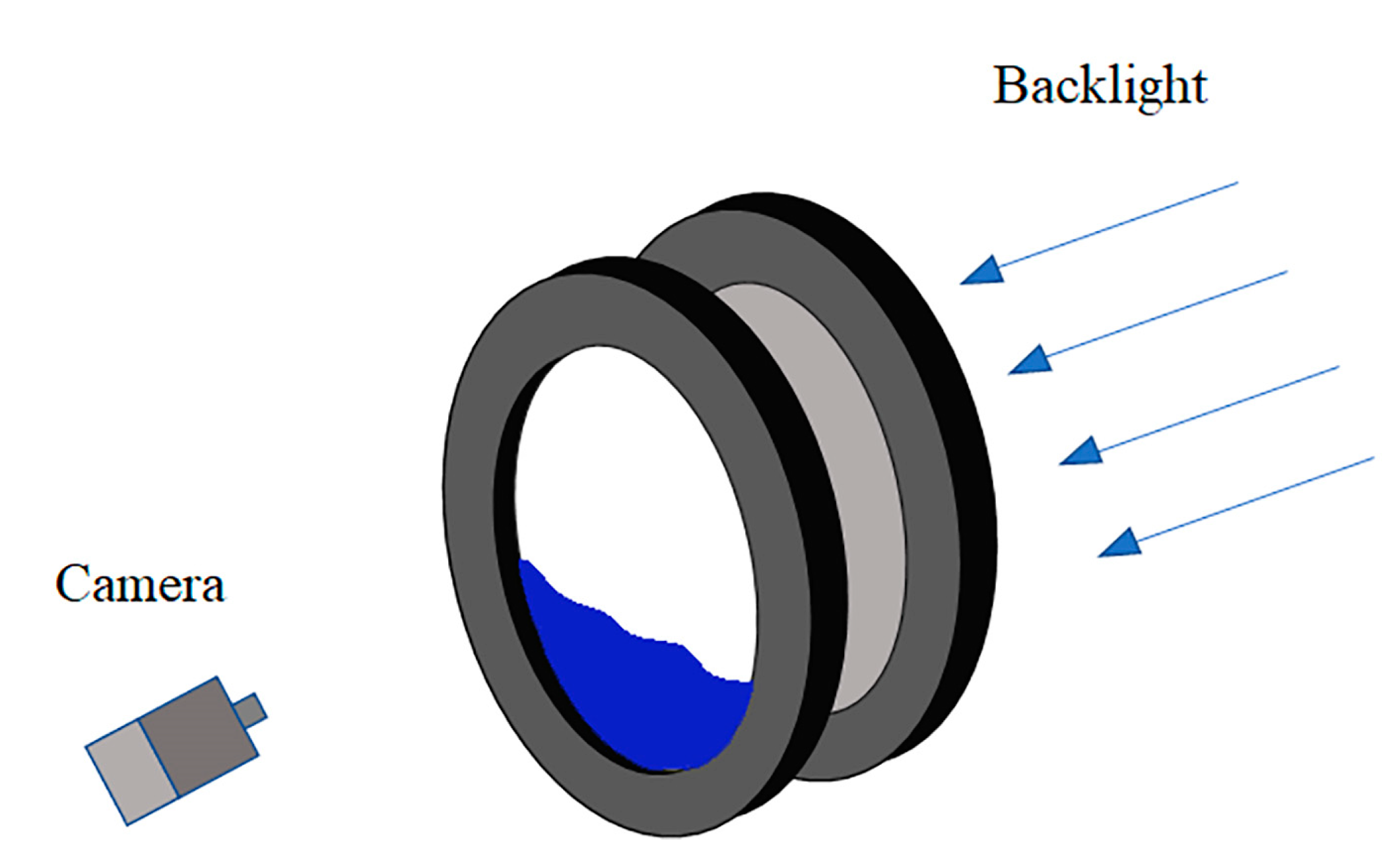

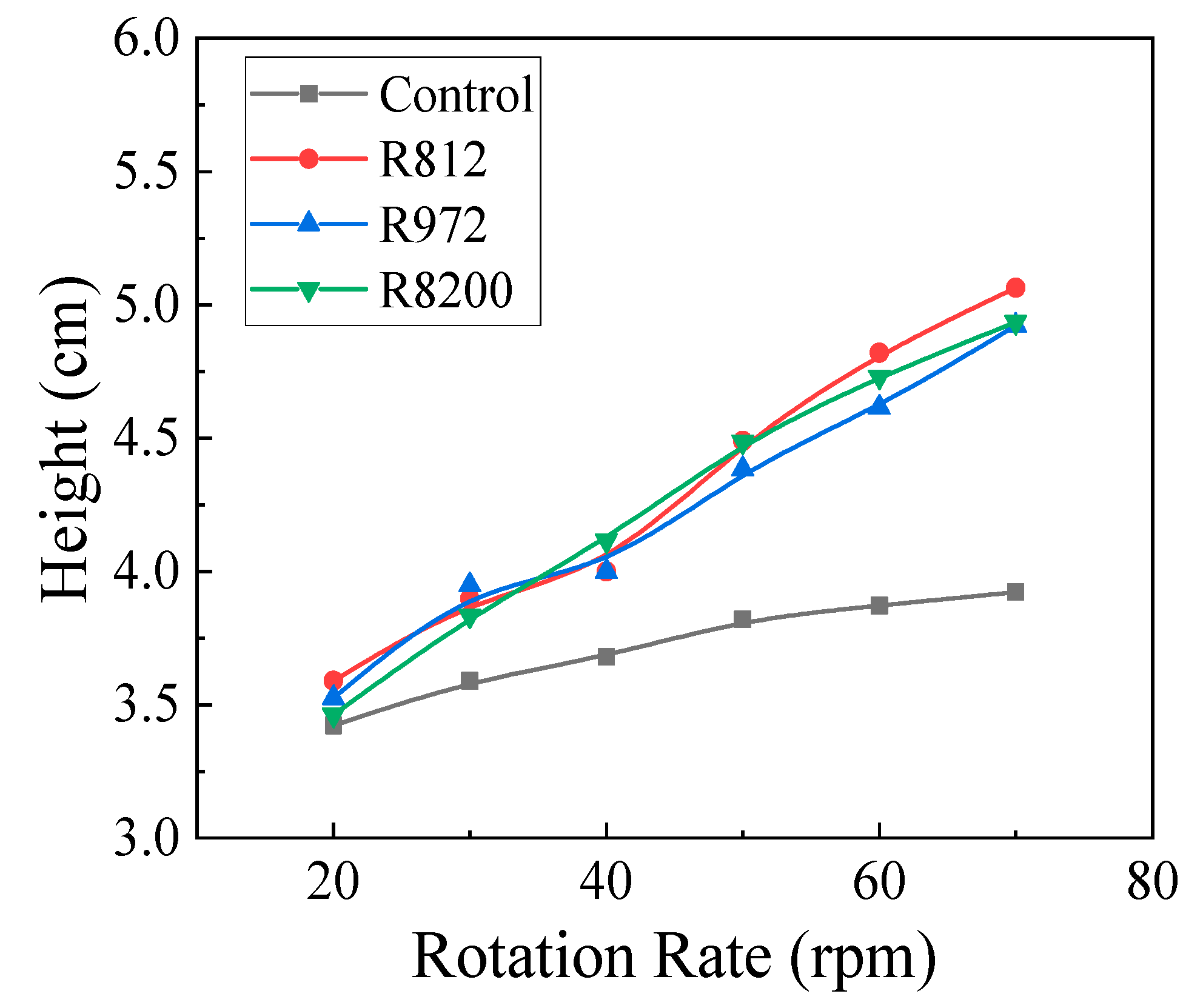

3.1.2. Dynamic Flowability-BE

3.2. Coating Process Related Properties

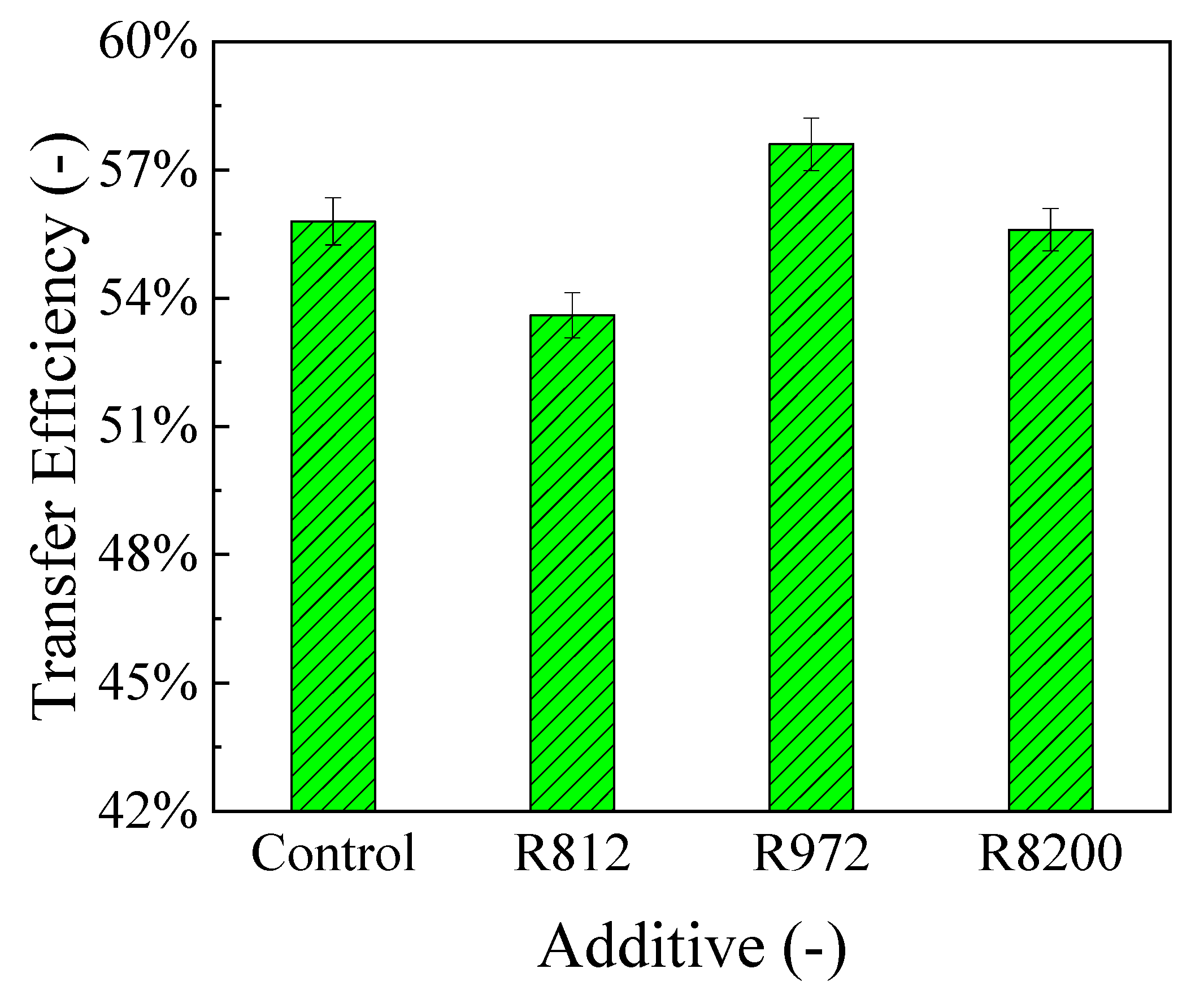

3.2.1. Transfer Efficiency

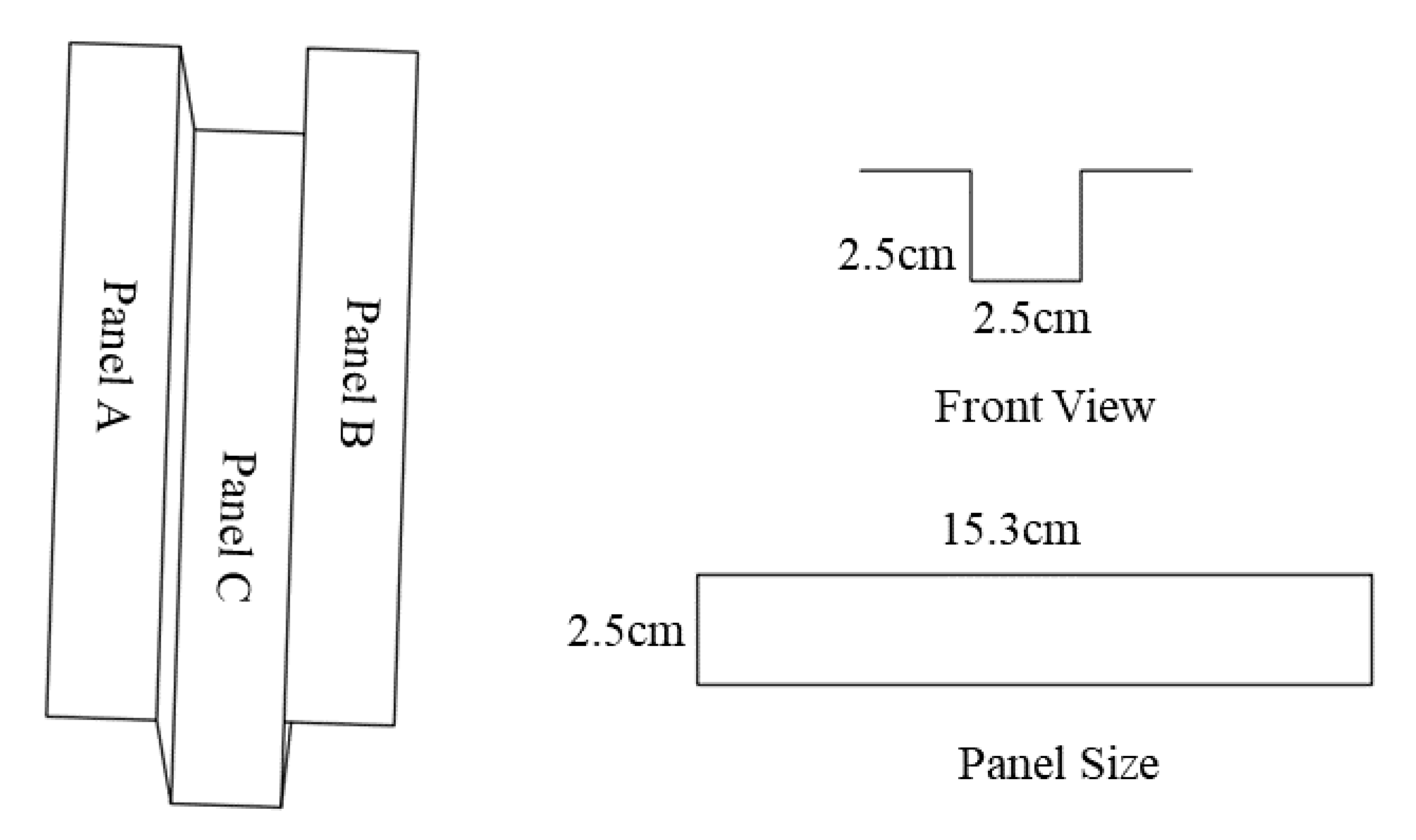

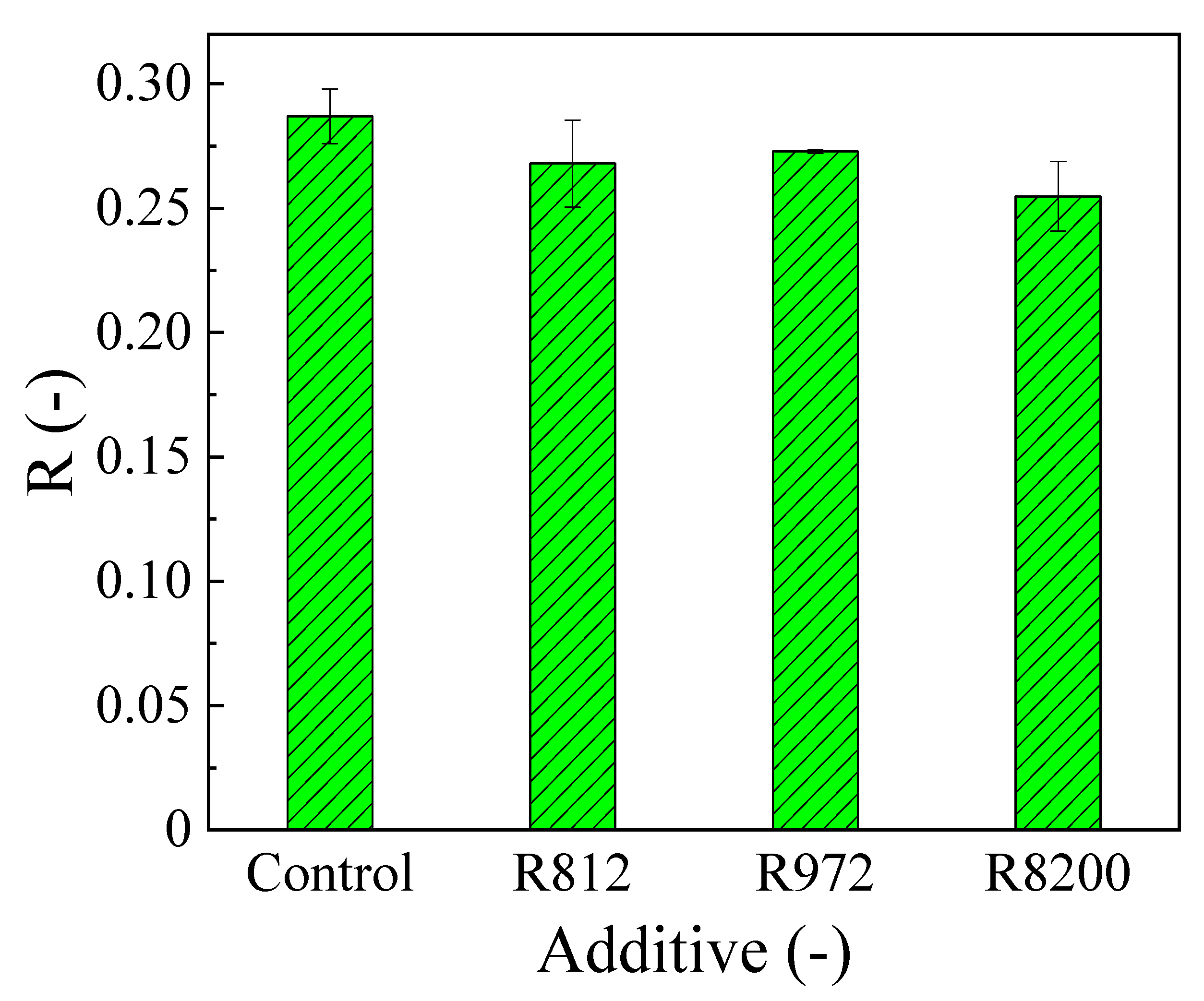

3.2.2. Anti-Faraday Cage Effect

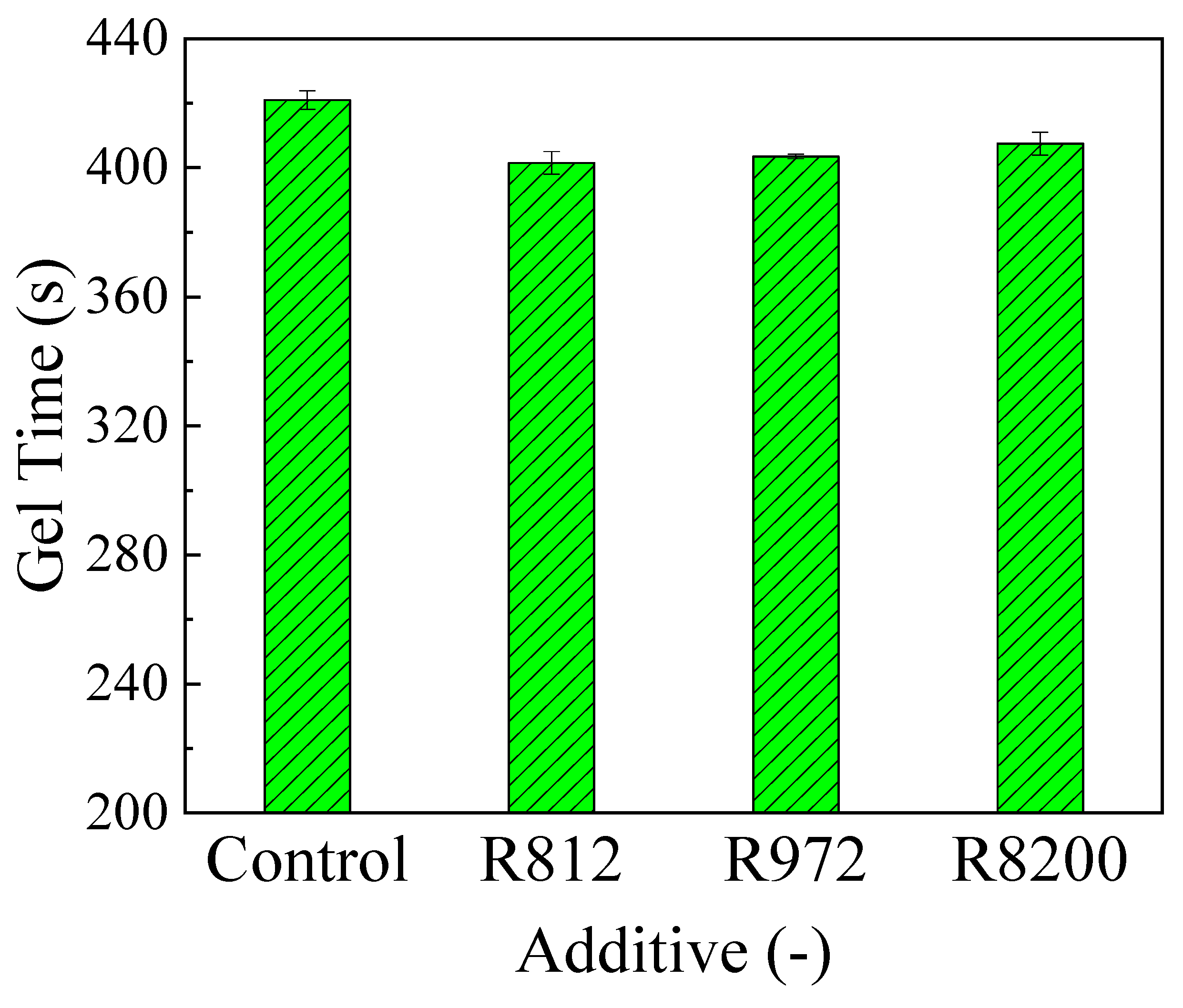

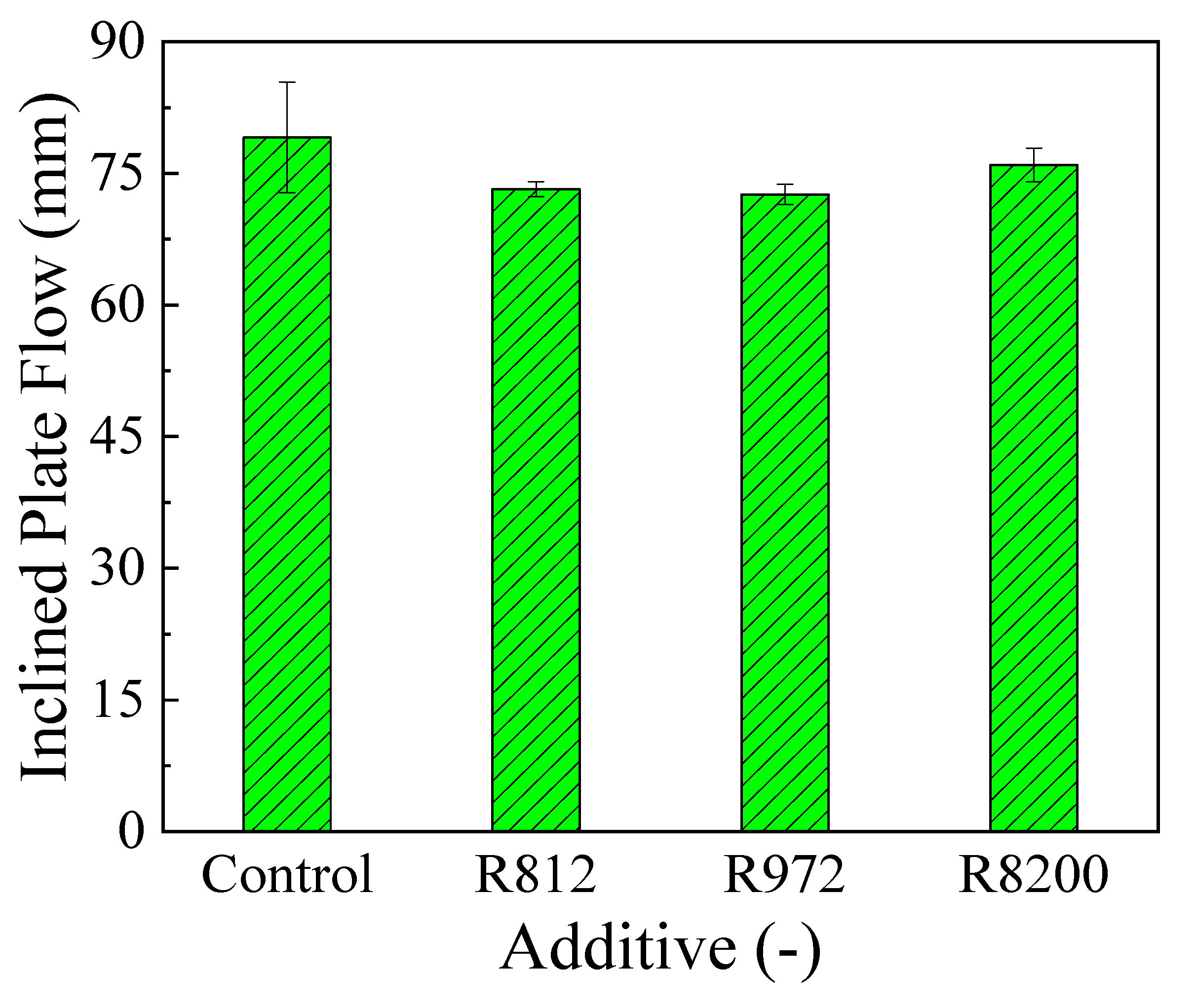

3.2.3. Gel Time and Inclined Plate Flow

3.3. Film Properties

3.3.1. Thickness

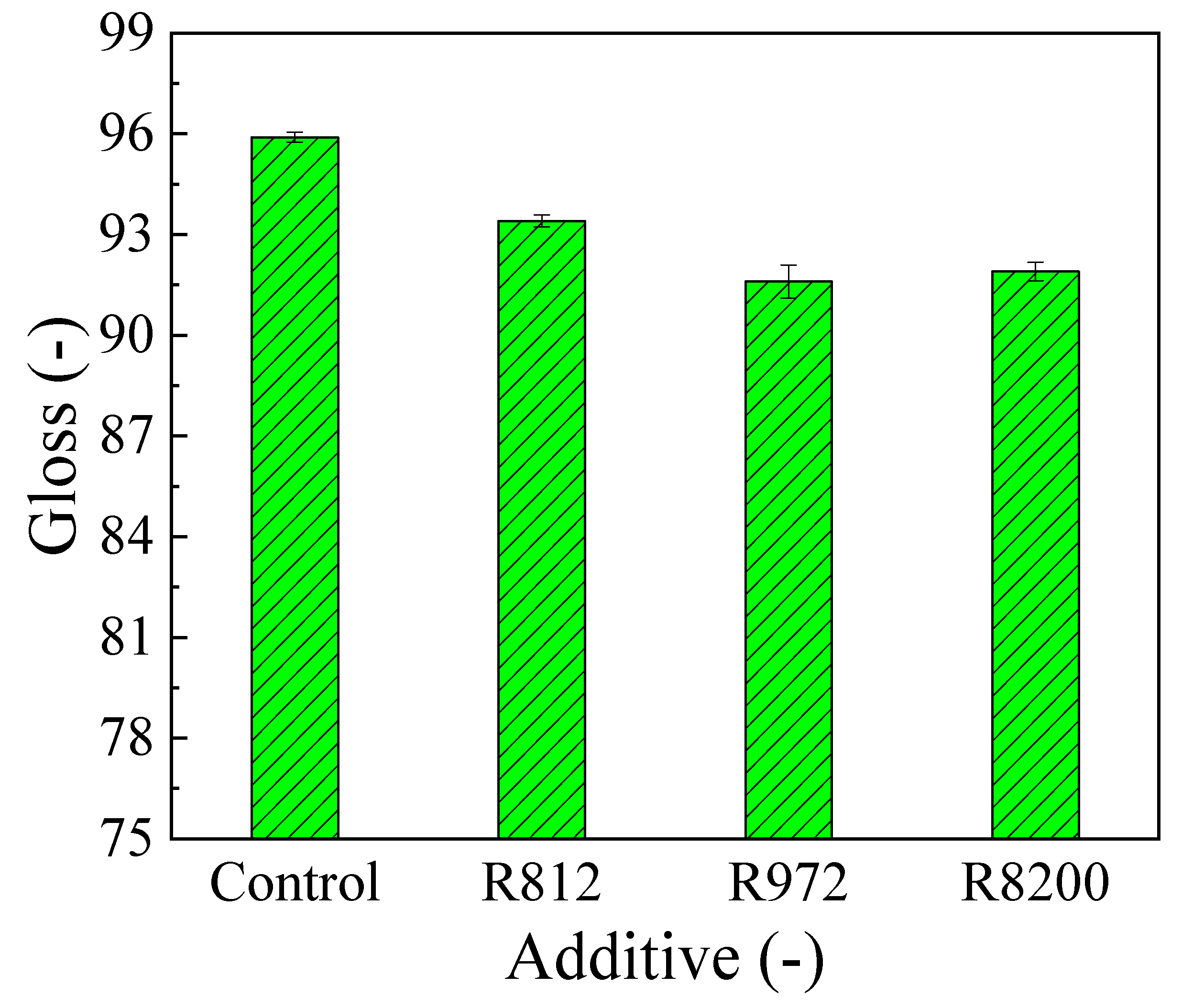

3.3.2. Gloss

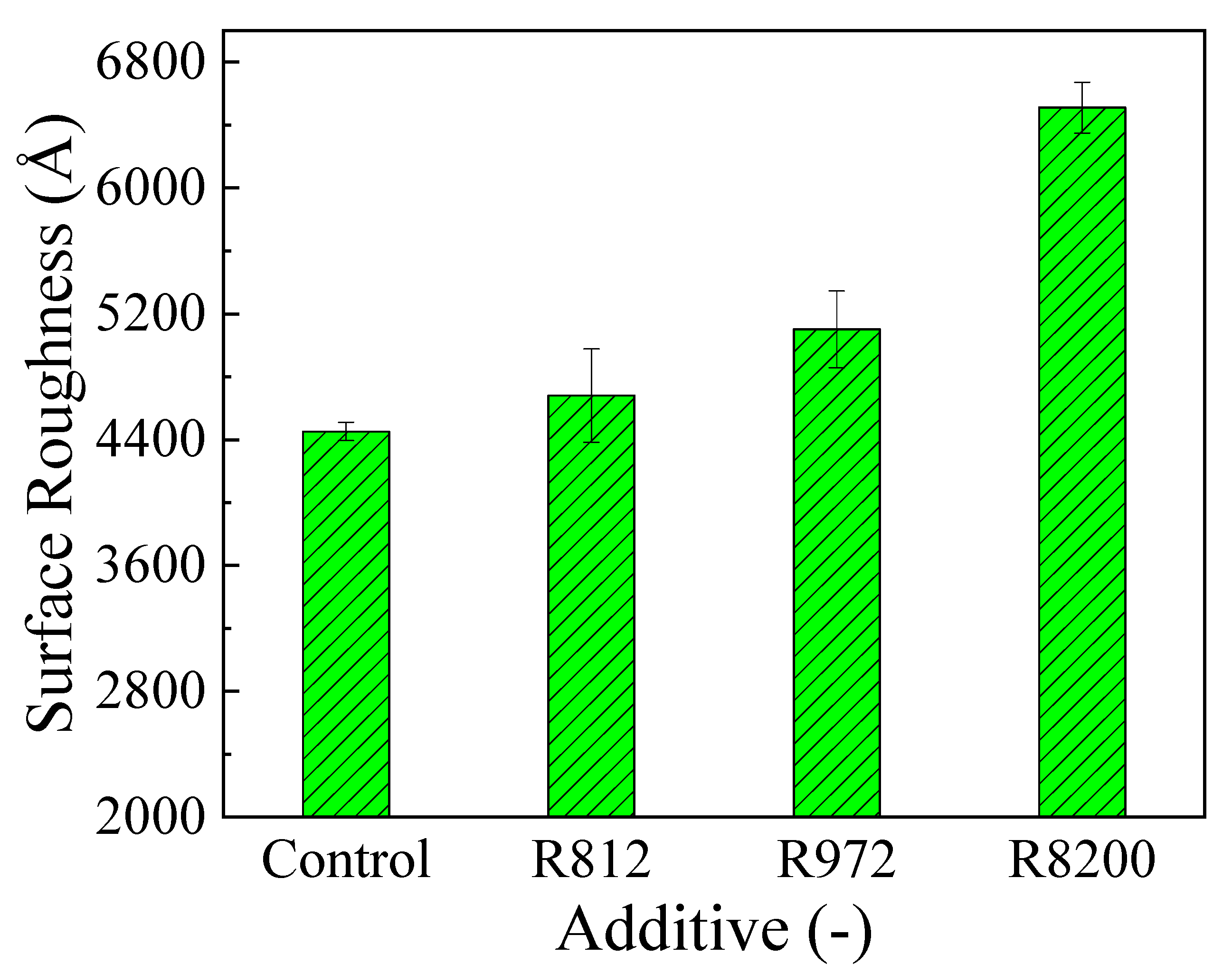

3.3.3. Surface Profile

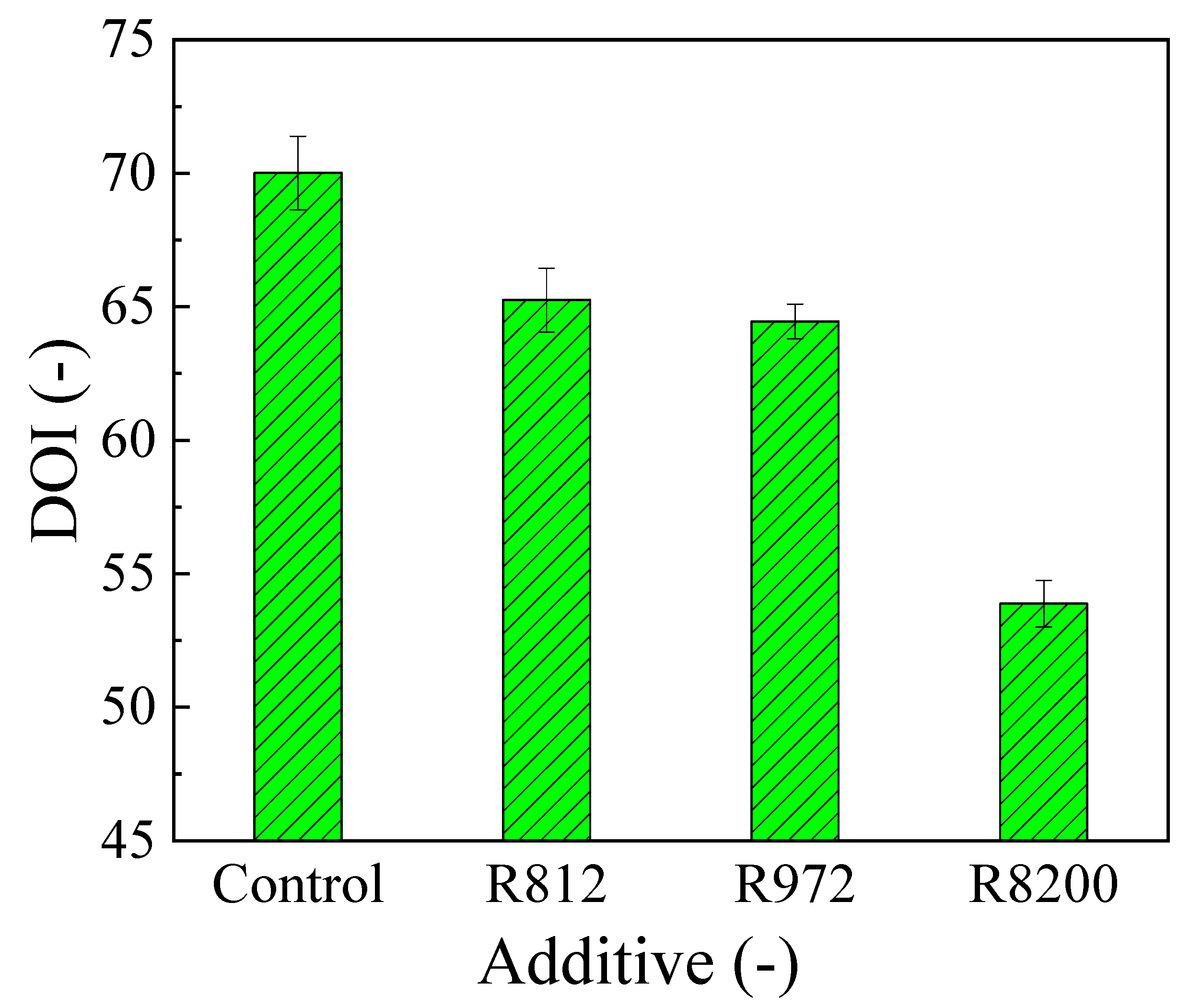

3.3.4. DOI

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Okadaa, K.; Yamaguchi, K.; Takeda, H. Acrylic/polyester hybrid powder coating system having excellent weather durability. Prog. Org. Coat. 1997, 34, 169–174. [Google Scholar] [CrossRef]

- Verlaak, J. A powder coating progress review. Focus Powder Coat. 2010, 1, 1–3. [Google Scholar]

- Flosbach, C.; Matten, S.; Donnermeyer, J. Process for the preparation of a powder coating composition. US Patent 074576, 26 June 2014. [Google Scholar]

- Grendahl, H. Clariant revolutionizes powder coating aesthetics and performance with new additives. Focus Powder Coat. 2011, 40, 98–113. [Google Scholar]

- Zeren, S.; Renoux, D. Powder coatings additives. Paint. Coat. Ind. 2002, 18, 116. [Google Scholar]

- Grundke, K.; Uhlmann, P. Influence of additives on interfacial phenomena during film formation of powder coatings. J. Coat. Technol. 2001, 73, 59–65. [Google Scholar]

- Kendall, K.; Stainton, C. Adhesion and aggregation of fine particles. Powder Technol. 2001, 121, 223–229. [Google Scholar] [CrossRef]

- Visser, J. An invited review: Van der waals and other cohesive forces affecting power fluidization. Powder Technol. 1989, 58, 1–10. [Google Scholar] [CrossRef]

- Huang, Q.; Zhang, H.; Zhu, J. Flow properties of fine powders in powder coating. Particuology 2010, 8, 19–27. [Google Scholar] [CrossRef]

- Castellanos, A. The relationship between attractive interparticle forces and bulk behaviour in dry and uncharged fine powders. Adv. Phys. 2005, 54, 263–376. [Google Scholar] [CrossRef]

- Jing, F.; Krantz, M.; Hui, Z.; Zhu, J.; Lis, K. Investigation of the recyclability of powder coatings. Powder Technol. 2011, 211, 38–45. [Google Scholar]

- Geldart, D. Types of gas fluidization. Powder Technol. 1973, 7, 285–292. [Google Scholar] [CrossRef]

- Todorova, Z.; Wünsche, S.; Hintz, W. Improved Flowability of Ultrafine, Cohesive Glass Particles by Surface Modification Using Hydrophobic Silanes. In Particles in Contact; Antonyuk, S., Ed.; Springer: Cham, Switzerland, 2019; pp. 631–662. [Google Scholar]

- Zhou, Y.; Liang, H.Q.; Shi, Y.F. Study on fluidization mechanism and agglomerating behavior of ultrafine powders. Chem. React. Eng. Technol. 2003, 19, 289–294. [Google Scholar]

- Barthel, H.; Dreyer, M.; Gottschalk-Gaudig, T.; Litvinov, V.; Nikitina, E. Fumed silica–rheological additive for adhesives, resins, and paints. Macromol. Symposia 2002, 187, 573–584. [Google Scholar] [CrossRef]

- Xu, C.; Zhu, J. Parametric study of fine particle fluidization under mechanical vibration. Powder Technol. 2006, 161, 135–144. [Google Scholar] [CrossRef]

- Barletta, D.; Donsì, G.; Ferrari, G.; Poletto, M.; Russo, P. The effect of mechanical vibration on gas fluidization of a fine aeratable powder. Chem. Eng. Res. Design 2008, 86, 359–369. [Google Scholar] [CrossRef]

- Qian, G.H.; Bágyi, I.; Burdick, I.W.; Pfeffer, R.; Stevens, J.G. Gas–solid fluidization in a centrifugal field. AIChE J. 2001, 47, 1022–1034. [Google Scholar] [CrossRef]

- Zhu, Q.S.; Li, H.Z. Magnetic fluidization of Group C powder (I)—Mechanism. J. Chem. Industry Eng. 1996, 47, 53–58. [Google Scholar]

- Zhu, Q.; Li, H. Study on magnetic fluidization of group C powders. Powder Technol. 1996, 86, 179–185. [Google Scholar]

- Yu, Q.; Dave, R.N.; Zhu, C.; Quevedo, J.A.; Pfeffer, R. Enhanced fluidization of nanoparticles in an oscillating magnetic field. AIChE J. 2005, 51, 1971–1979. [Google Scholar] [CrossRef]

- Xu, C.B.; Cheng, Y.; Zhu, J. Fluidization of fine particles in a sound field and identification of group C/A particles using acoustic waves. Powder Technol. 2006, 161, 227–234. [Google Scholar] [CrossRef]

- Ajbar, A.; Alhumazi, K.; Asif, M. Improvement of the fluidizability of cohesive powders through mixing with small proportions of group A particles. Can. J. Chem. Eng. 2005, 83, 930–943. [Google Scholar] [CrossRef]

- Duan, H.; Liang, X.; Zhou, T.; Wang, J.; Tang, W. Fluidization of mixed SiO2 and ZnO nanoparticles by adding coarse particles. Powder Technol. 2014, 267, 315–321. [Google Scholar] [CrossRef]

- Hirotaka, N.; Masakatsu, U. Powder-coated aluminum building material for outdoor use. CN103154415 A, 12 June 2013. [Google Scholar]

- Craven, J.M. Powder coating composition for automotive topcoat. US Patent 4402983, 6 September 1983. [Google Scholar]

- Gao, S.; Zhu, X.P.; Zhang, H.; Zhu, J. Powder coating of plastic components. In Proceedings of the SPE Automotive Composites Conference & Exhibition, Novi, MI, USA, 7–9 September 2016. [Google Scholar]

- Xu, C.B.; Zhang, H.; Zhu, J. Improving flowability of cohesive particles by partial coating on thesurfaces. Can. J. Chem. Eng. 2009, 87, 403–414. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhu, J. Group C+ particles: Enhanced flow and fluidization of fine powders with nano-modulation. Chem. Eng. Sci. 2019, 207, 653–662. [Google Scholar] [CrossRef]

- Krantz, M.; Zhang, H.; Zhu, J. Characterization of powder flow: Static and dynamic testing. Powder Technol. 2009, 194, 239–245. [Google Scholar] [CrossRef]

- Li, W.; Franco, D.C.; Yang, M.S.; Zhu, X.; Zhang, H.; Shao, Y.; Zhang, H.; Zhu, J. Comparative study of the performances of Al(OH)3 and BaSO4 in ultrafine powder coatings. Processes 2019, 7, 316. [Google Scholar] [CrossRef] [Green Version]

- Bao, D. Effects of Additive Modification on Flow Properties of Fine Coating Particles. Master’s Thesis, UWO, London, ON, Canada, 2013. [Google Scholar]

- Geldart, D.; Wong, A.C.Y. Fluidization of powders showing degrees of cohesiveness—I. Bed expansion. Chem. Eng. Sci. 1984, 39, 1481–1488. [Google Scholar] [CrossRef]

- Xue, D. Study on Fine Powder Coating with Modified Additive. Master’s Thesis, UWO, London, ON, Canada, 2013. [Google Scholar]

- ASTM D4217-07 (2013). Standard Test Method for Gel Time of Thermosetting Coating Powder; ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- ASTM D4242-07 (2017). Standard Test Method for Inclined Plate Flow for Thermosetting Coating Powder; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- Gruber, D.P.; Buder-Stroisznigg, M.; Wallner, G.; Strauss, B.; Jandel, L.; Lang, R.W. A novel methodology for the evaluation of distinctness of image of glossy surfaces. Prog. Org. Coat. 2008, 63, 377–381. [Google Scholar] [CrossRef]

- Dutta, A.; Dullea, L.V. Comparative evaluation of negatively and positively charged submicron particles as flow conditioners for a cohesive powder. AIChE Symposium Series 1990, 86, 26–40. [Google Scholar]

- Xie, H.Y. The role of interparticle forces in the fluidization of fine particles. Powder Technol. 1997, 94, 99–108. [Google Scholar] [CrossRef]

- Kojima, T.; Elliott, J.A. Effect of silica nanoparticles on the bulk flow properties of fine cohesive powders. Chem. Eng. Sci. 2013, 101, 315–328. [Google Scholar] [CrossRef]

- Garle, A.L.; White, F.; Budhlall, B.M. Improving the antifouling properties of polypropylene surfaces by melt blending with polyethylene glycol diblock copolymers. J. Appl. Polym. Sci. 2017, 135, 1–12. [Google Scholar] [CrossRef]

- Qing, Y.; Yang, C.; Hu, C.; Zheng, Y.; Liu, C. A facile method to prepare superhydrophobic fluorinated polysiloxane/ZnO nanocomposite coatings with corrosion resistance. Appl. Surf. Sci. 2015, 326, 48–54. [Google Scholar] [CrossRef]

- Sharma, R.; Trigwell, S.; Biris, A.S.; Sims, R.A.; Mazumder, M.K. Effect of ambient relative humidity and surface modification on the charge decay properties of polymer powders in powder coating. IEEE Trans. Ind. Appl. 2003, 39, 87–95. [Google Scholar] [CrossRef]

- Messaoudi, R.; Younsi, A.; Massines, F.; Despax, B.; Mayoux, C. Influence of humidity on current waveform and light emission of a low-frequency discharge controlled by a dielectric barrier. IEEE Trans. Dielectr. Electr. Insul. 1996, 3, 537–543. [Google Scholar] [CrossRef]

- Kline, S.R., Jr. Breaking through the faraday cage. Prod. Finish. 1999, 63, 64–67. [Google Scholar]

- Biris, A.S.; De, S.; Yurteri, C.U.; Mazumder, M.K.; Sims, R.A. Parametric study of the Faraday cage effect of charged particles and its implications in the powder coating process. In Proceedings of the 2002 IEEE Industry Applications Conference. 37th IAS Annual Meeting (Cat. No. 02CH37344), Pittsburgh, PA, USA, 13–18 October 2002. [Google Scholar]

- Adamiak, K. Numerical investigation of powder trajectories and deposition in tribocharge powder coating. IEEE Trans. Ind. Appl. 2011, 37, 1603–1609. [Google Scholar] [CrossRef]

- Meng, X.; Zhu, J.; Zhang, H. The characteristics of particle charging and deposition during powder coating processes with ultrafine powder. J. Phys. D-Appl. Phys. 2009, 42, 065201. [Google Scholar] [CrossRef]

- Shi, Q.; Huang, W.; Zhang, Y.; Zhang, Y.; Xu, Y.; Guo, G. Curing of polyester powder coating modified with rutile nano-sized titanium dioxide studied by DSC and real-time FT-IR. J. Therm. Anal. Calorim. 2011, 108, 1243–1249. [Google Scholar] [CrossRef]

- Ramis, X.; Cadenato, A.; Morancho, J.M.; Salla, J.M.J.P. Curing of a thermosetting powder coating by means of DMTA, TMA and DSC. Polymer 2003, 44, 2067–2079. [Google Scholar] [CrossRef]

- Halász, L.; Belina, K. An investigation into the curing of epoxy powder coating systems. J. Therm. Anal. Calorim. 2015, 119, 1971–1980. [Google Scholar] [CrossRef]

- Lee, S.S.; Koo, J.H.; Lee, S.S.; Chai, S.G.; Lim, J.C. Gloss reduction in low temperature curable hybrid powder coatings. Prog. Org. Coat. 2003, 46, 266–272. [Google Scholar] [CrossRef]

- Biris, A.S.; Mazumder, M.K.; Yurteri, C.U.; Sims, R.A.; Snodgrass, J.; De, S. Gloss and texture control of powder coated films. Part. Sci. Technol. 2001, 19, 199–217. [Google Scholar] [CrossRef]

- Gooch, J.W. Distinctness-of-Image. In Encyclopedic Dictionary of Polymers; Springer: New York, NY, USA, 2011. [Google Scholar] [CrossRef]

- Billmeyer Jr, F.W.; O’Donnell, F.X. Visual gloss scaling and multidimensional scaling analysis of painted specimens. Color Res. Appl. 1987, 12, 315–326. [Google Scholar] [CrossRef]

- Delaney, J.K.; de la Rie, E.R.; Elias, M.; Sung, L.-P.; Morales, K.M. The Role of Varnishes in Modifying Light Reflection from Rough Surfaces—A Study of Changes in Light Scattering Caused by Variations in Varnish Topography and Development of a Drying Model. Stud. Conserv. 2008, 53, 170–186. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

| Class | Sub Class | Specification |

|---|---|---|

| Binder | polymer resin | Polyester |

| curing agent | TGIC | |

| Pigment | pigment | Carbon black |

| additive | Degassing agent, Flow agent | |

| filler | BaSO4 | |

| Density | - | 1250 kg/m3 |

| Gloss | - | Ultra-high-gloss |

| Surface appearance | - | Smooth |

| Cure parameters | - | 200 °C/10 min |

| Properties | R812 | R972 | R8200 |

|---|---|---|---|

| Behavior in water | Hydrophobic | ||

| Degree of hydrophobicity 2 | 60% | 40% | 50% |

| Mean size/nm | 7 | 16 | 12 |

| Specific surface area m2/g | 260 ± 30 | 110 ± 20 | 190 ± 25 |

| Tamped density g/L | 60 | 50 | 140 |

| Drying loss (2 h at 105 °C) % | <0.5% | ≤2.0 | ≤0.5 |

| pH-value (4% suspension) | 5.5–8.0 | 3.6–4.4 | ≥5.0 |

| Carbon content % | 2.0–3.0% | 0.6–1.2 | 2.0–4.0 |

| SiO2 % | >99.8% | ≥99.8 | ≥99.8 |

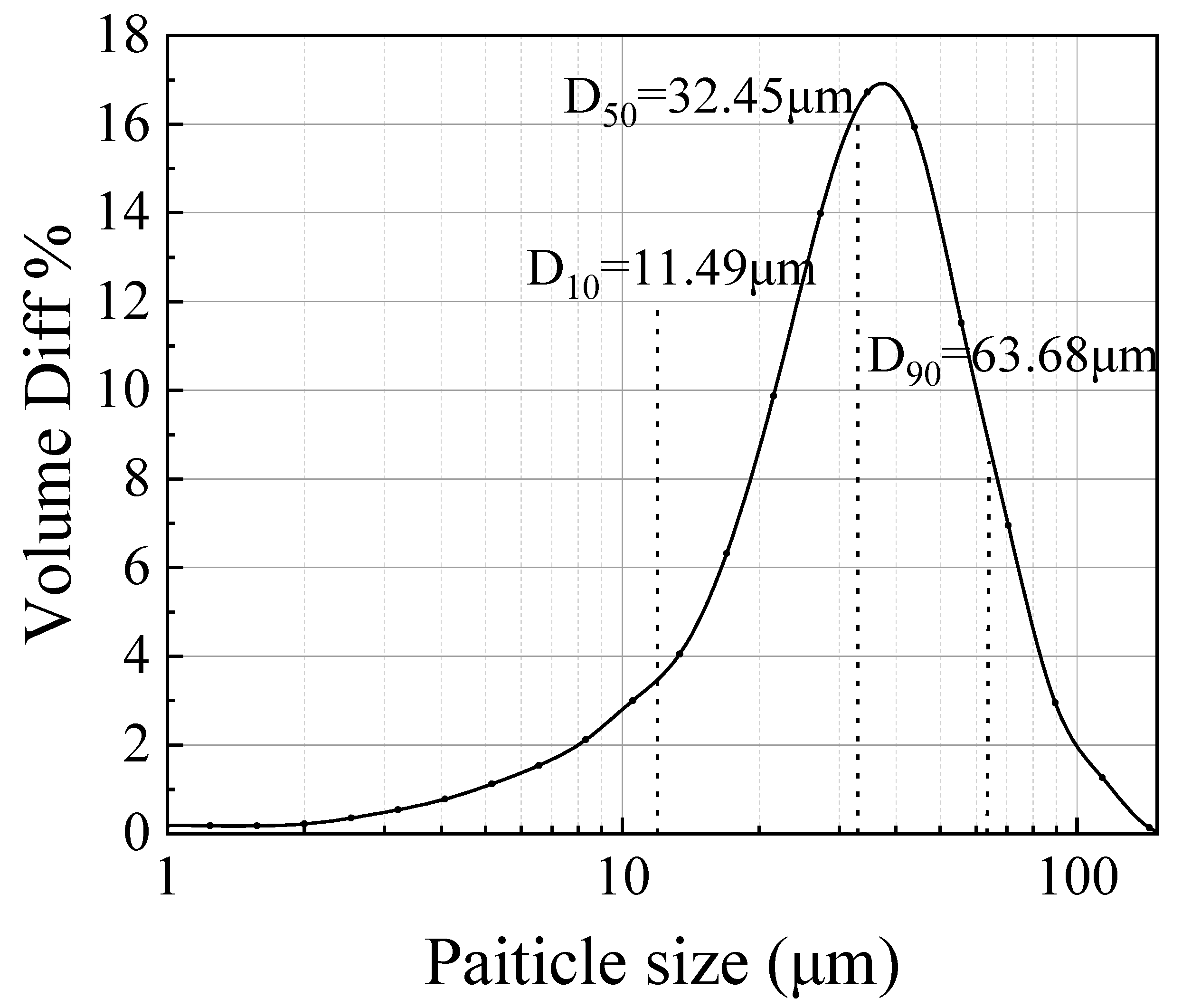

| Additive Used | Particle Size of Polyester Paint/μm | |||

|---|---|---|---|---|

| D10 3 | D50 3 | D90 3 | Span 4 | |

| Control (No additive) | 11.49 | 32.45 | 63.68 | 1.608 |

| R812 | 10.65 | 31.14 | 62.34 | 1.660 |

| R972 | 11.64 | 32.48 | 63.43 | 1.595 |

| R8200 | 11.36 | 32.32 | 63.88 | 1.625 |

| Angle of Repose (AOR) | Flowability |

|---|---|

| 25° < θ < 30° | Very free-flowing |

| 30° < θ < 38° | Free-flowing |

| 38° < θ < 45° | Fair to passable flow |

| 45° < θ < 55° | Cohesive |

| 45° < θ < 70° | Very cohesive |

| Additive Used | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Average (μm) |

|---|---|---|---|---|---|---|---|---|---|---|

| - | 58.0 | 55.0 | 61.0 | 58.5 | 59.0 | 60.0 | 56.0 | 65.0 | 59.5 | 59.1 |

| R812 | 60.5 | 61 | 55.5 | 61.0 | 59.0 | 54.0 | 63.5 | 59 | 52.5 | 58.4 |

| R972 | 55.5 | 67.5 | 63.5 | 57.0 | 66.5 | 64.0 | 56.5 | 61.5 | 65.0 | 61.8 |

| R8200 | 63.5 | 64.5 | 59.0 | 60.5 | 61.0 | 59.5 | 58.0 | 63.0 | 61.0 | 61.1 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, J.; Zhang, H.; Shao, Y.; Bao, D.; Zhang, H.; Zhu, J. Investigation of the Performance of Fumed Silica as Flow Additive in Polyester Powder Coatings. Coatings 2020, 10, 977. https://doi.org/10.3390/coatings10100977

Xie J, Zhang H, Shao Y, Bao D, Zhang H, Zhu J. Investigation of the Performance of Fumed Silica as Flow Additive in Polyester Powder Coatings. Coatings. 2020; 10(10):977. https://doi.org/10.3390/coatings10100977

Chicago/Turabian StyleXie, Junqing, Haiping Zhang, Yuanyuan Shao, Danni Bao, Hui Zhang, and Jesse Zhu. 2020. "Investigation of the Performance of Fumed Silica as Flow Additive in Polyester Powder Coatings" Coatings 10, no. 10: 977. https://doi.org/10.3390/coatings10100977

APA StyleXie, J., Zhang, H., Shao, Y., Bao, D., Zhang, H., & Zhu, J. (2020). Investigation of the Performance of Fumed Silica as Flow Additive in Polyester Powder Coatings. Coatings, 10(10), 977. https://doi.org/10.3390/coatings10100977