Study on the Measurement of Stress in the Surface of Selective Laser Melting Forming Parts Based on the Critical Refraction Longitudinal Wave

Abstract

1. Introduction

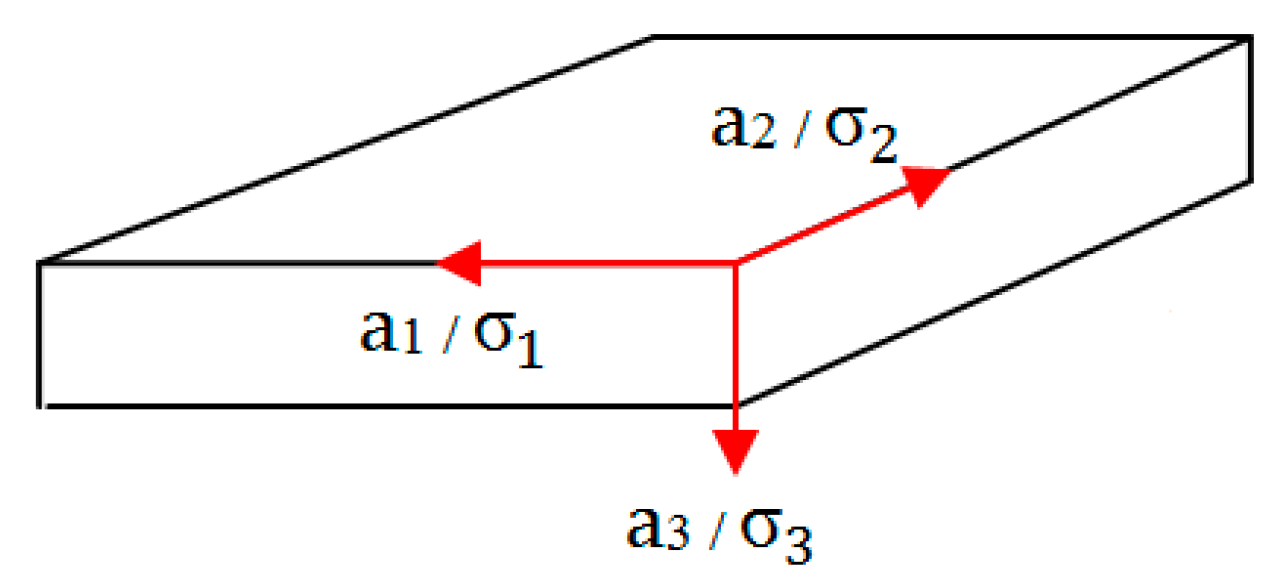

2. Acoustic-elastic Equation of LCR Wave Under Plane Stress

3. Experimental Procedure

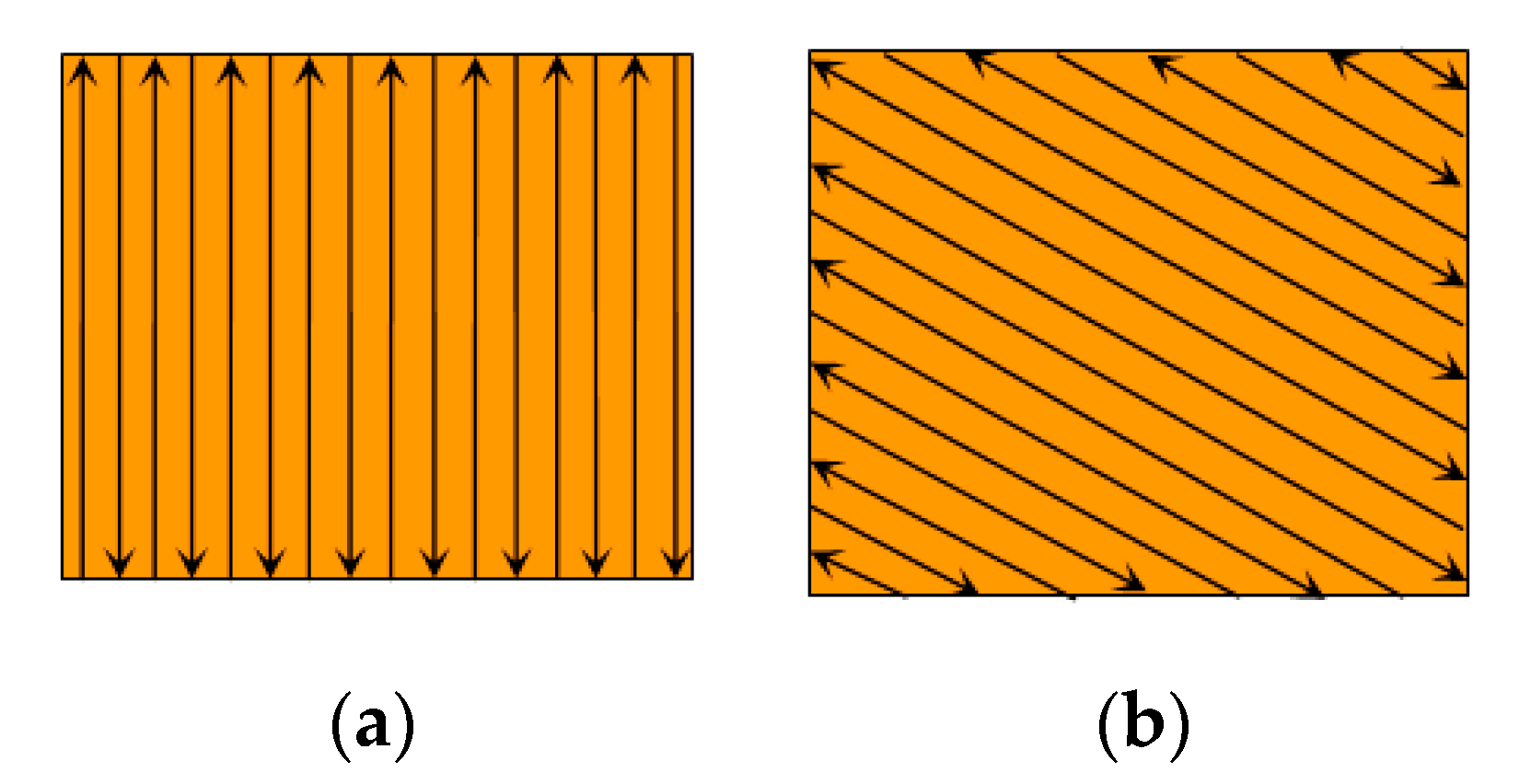

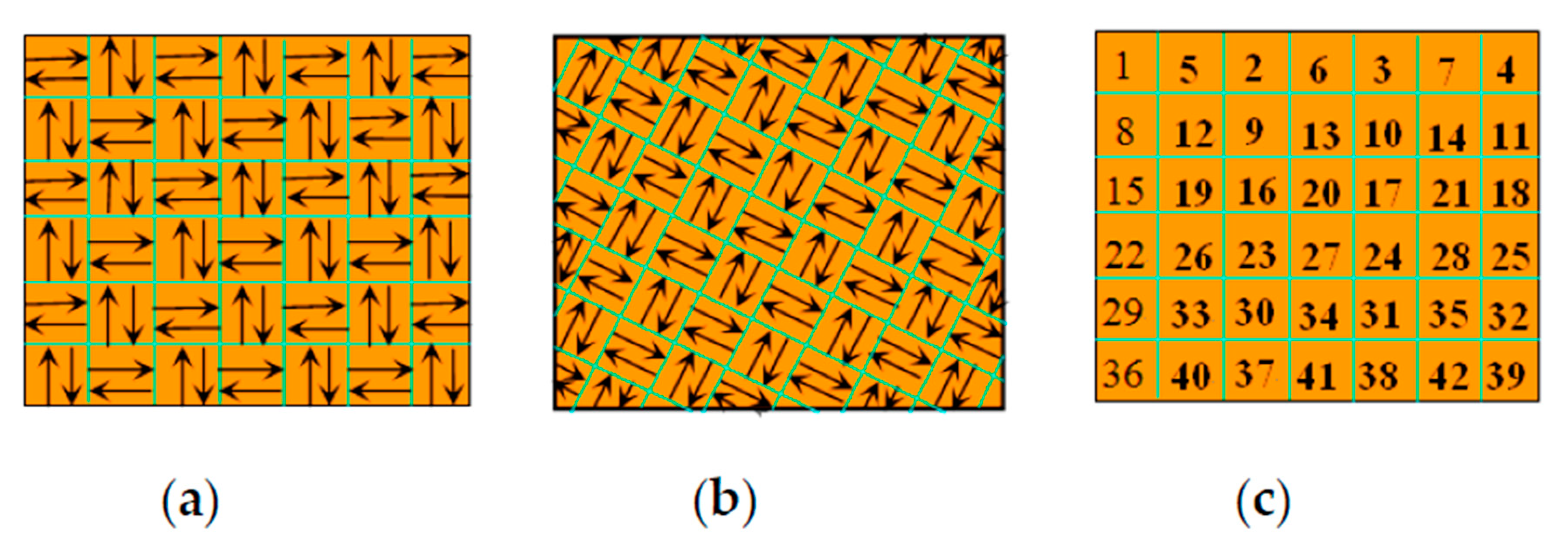

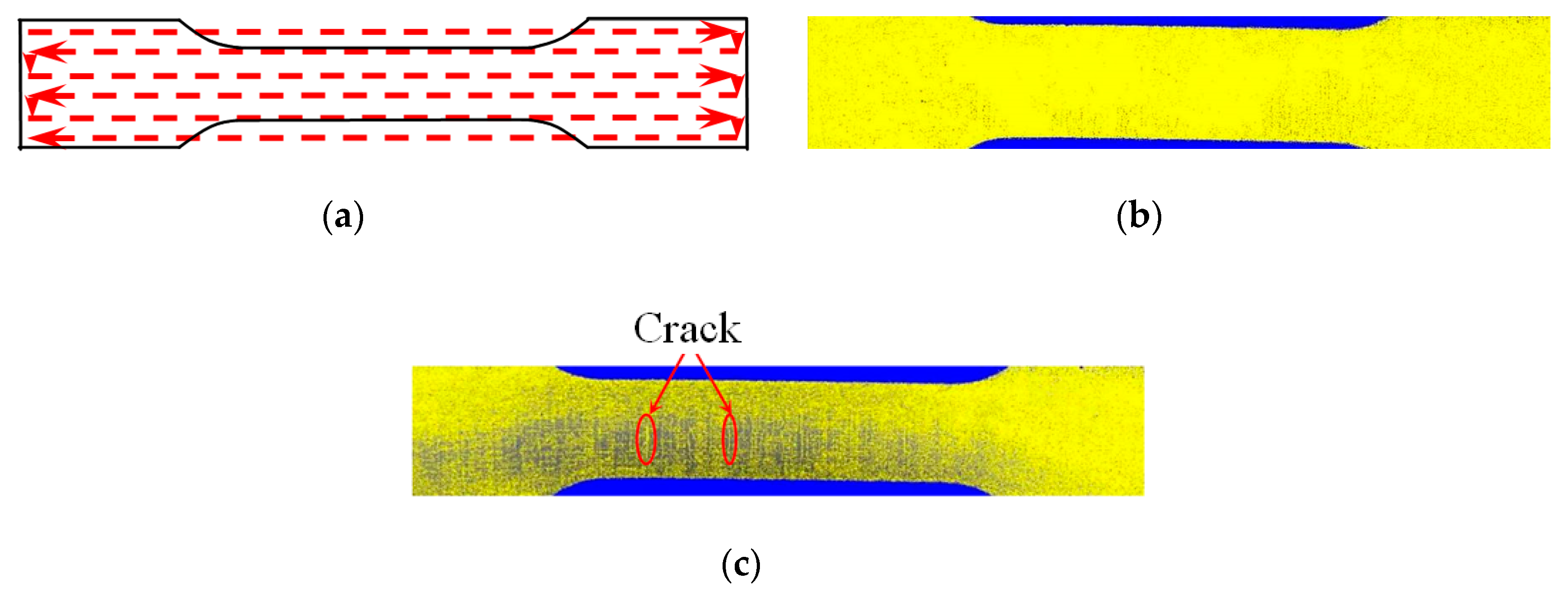

3.1. Specimen Preparation

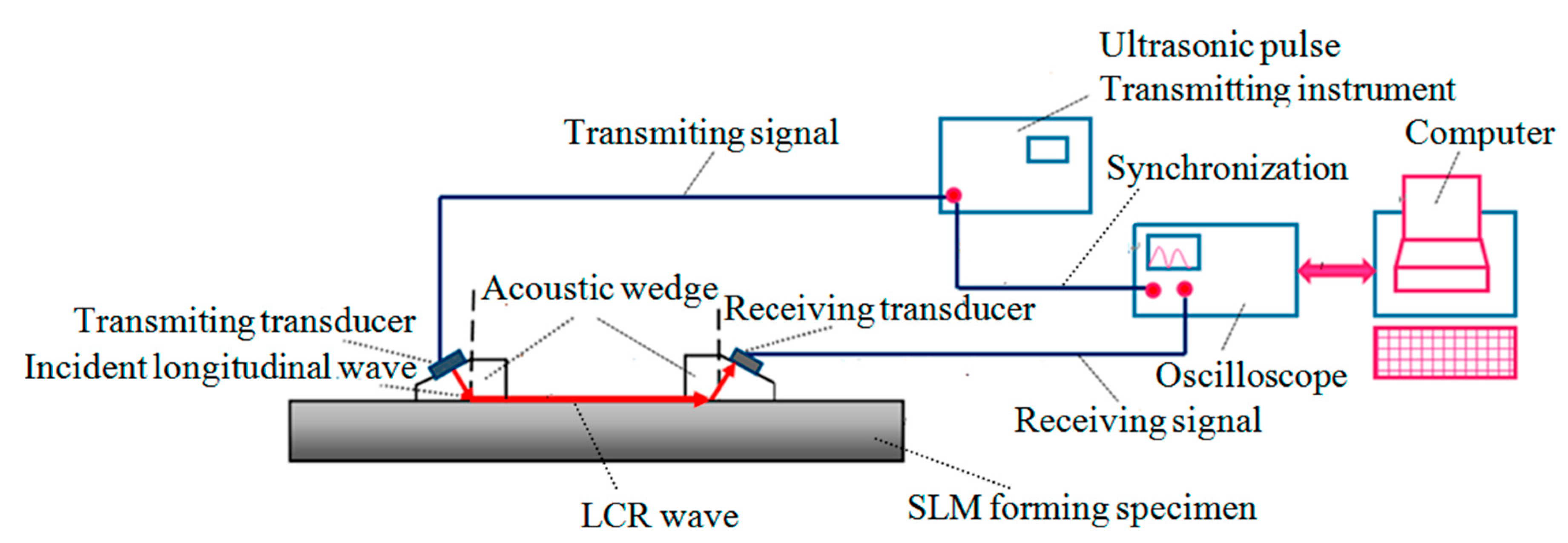

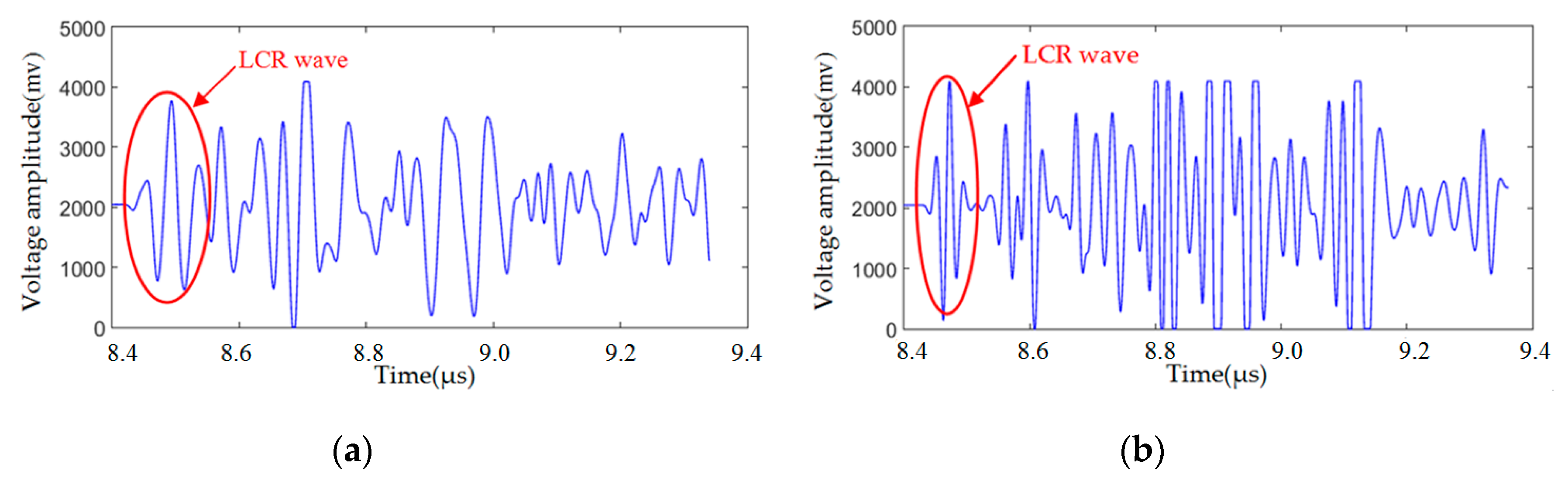

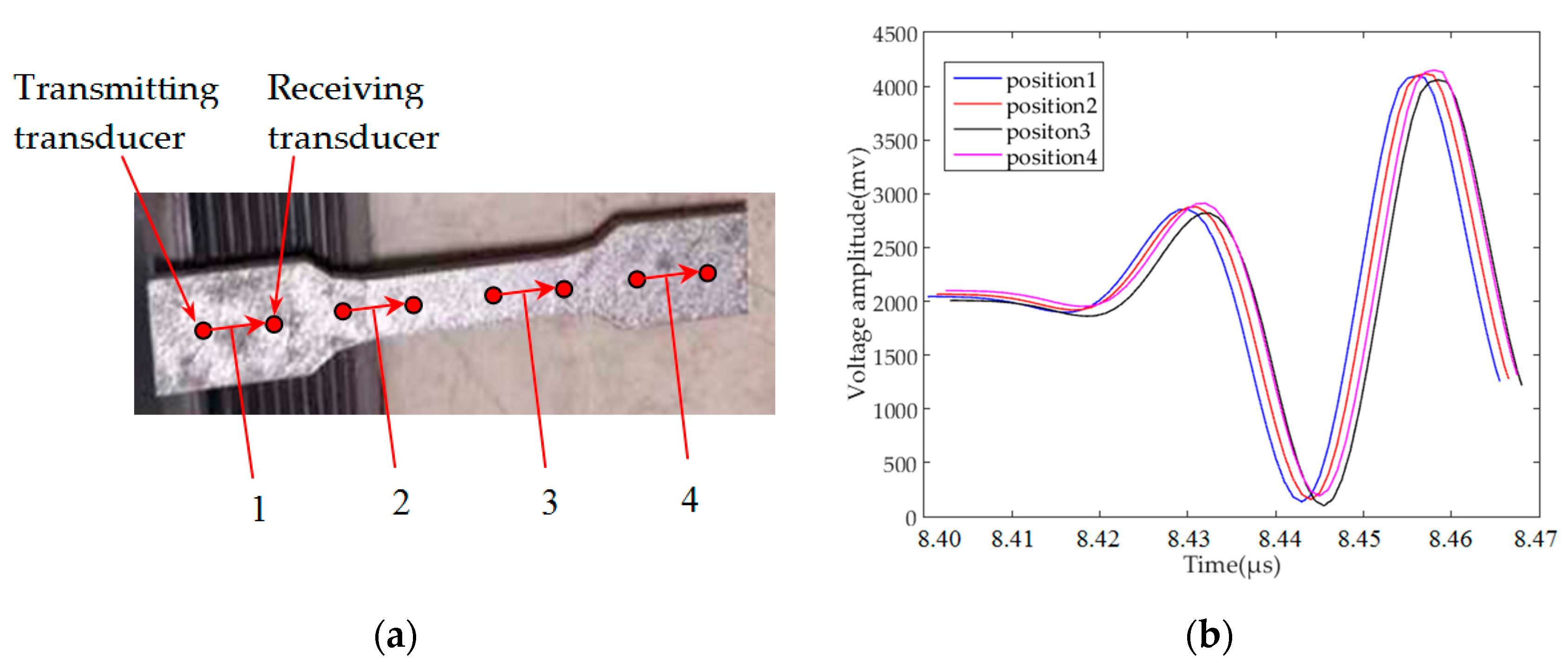

3.2. Experimental System

4. Experimental Results

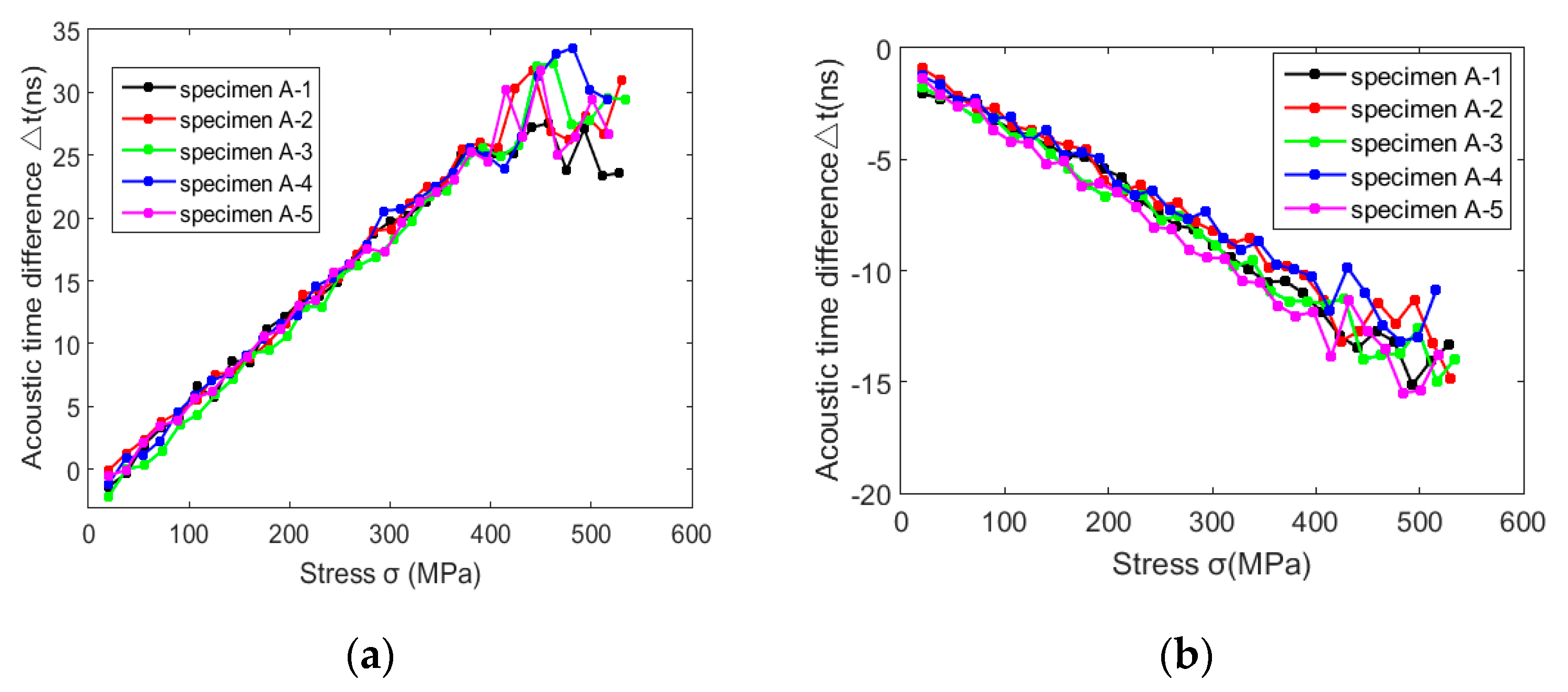

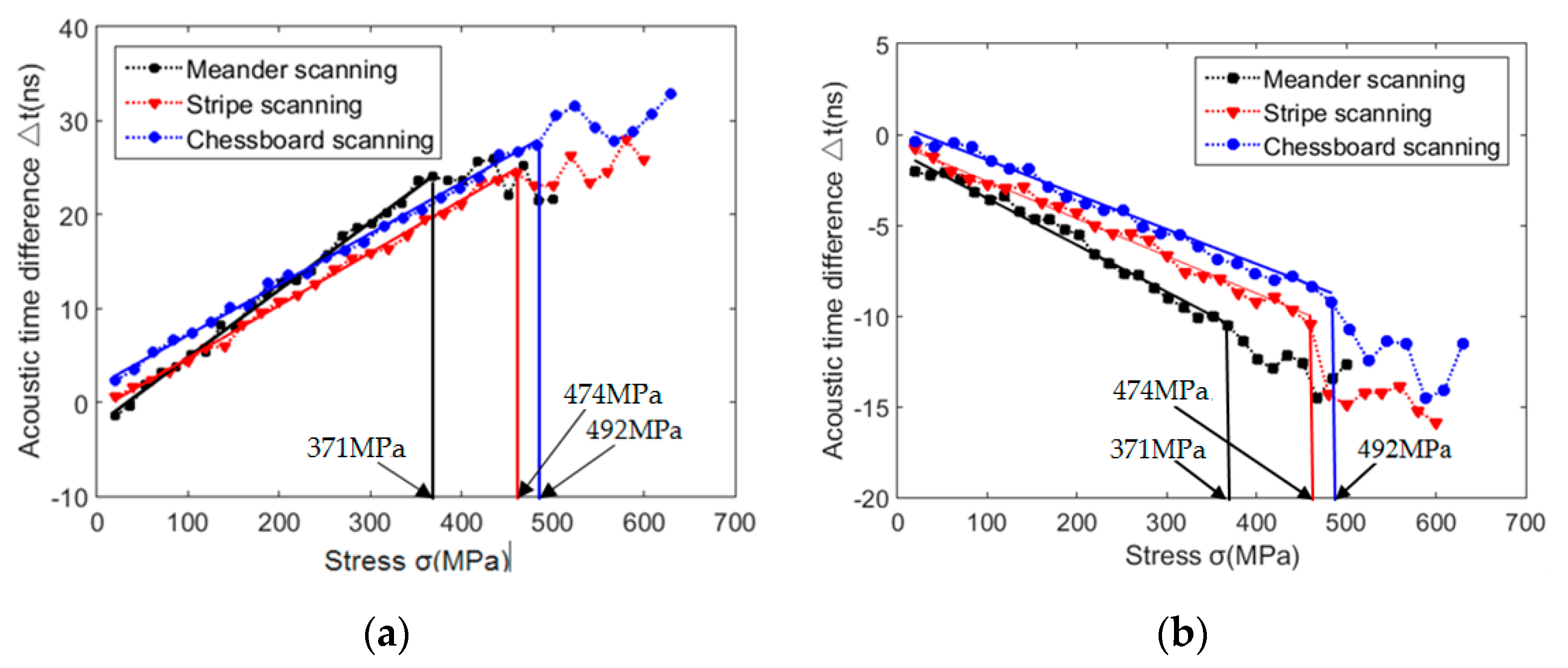

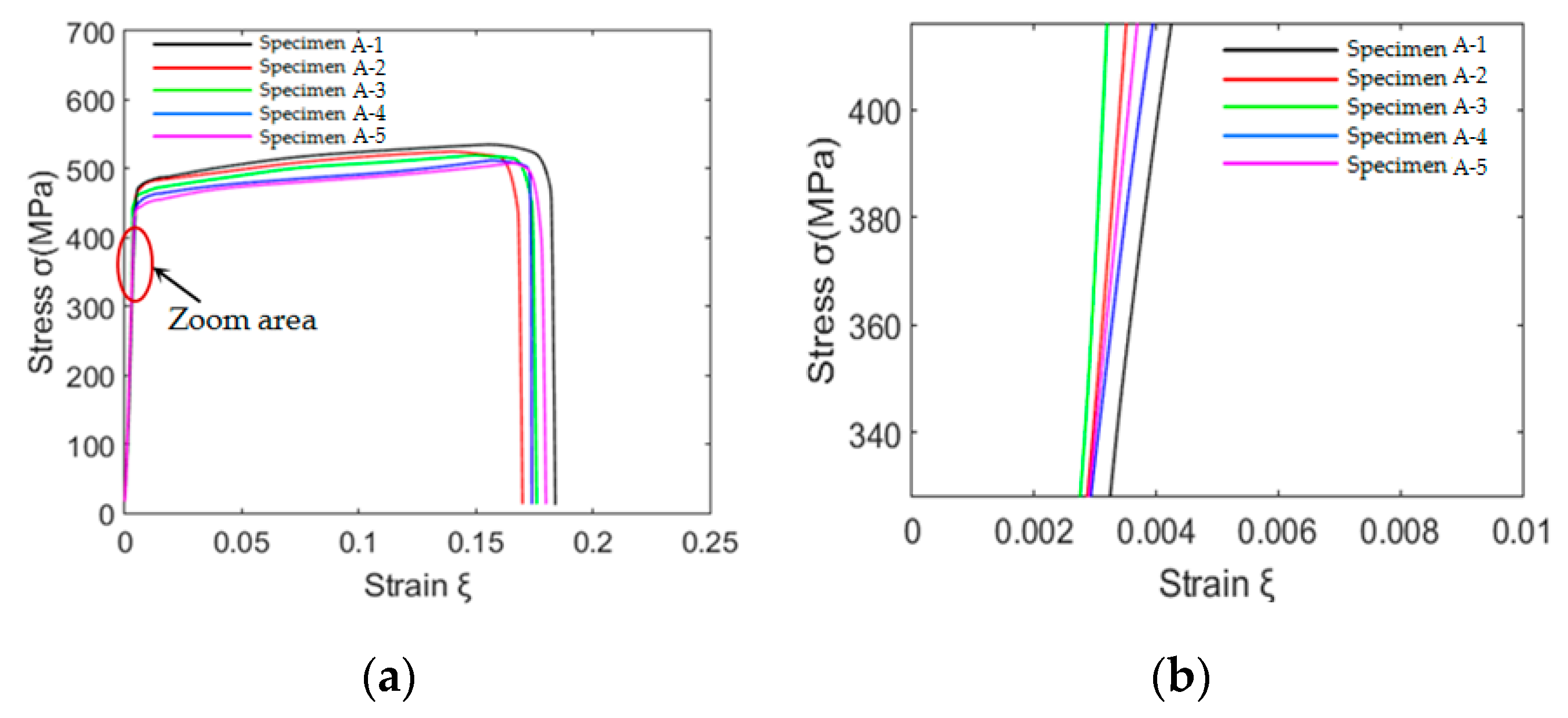

4.1. Calibration of the Acoustic–Elastic Coefficient

4.2. Analysis of Linear Part in Acoustic-Elastic Curves

4.3. Analysis of Non-Linear Parts in Acoustic-Elastic Curves

4.4. Acoustic-Elastic Equations for Testing Stress in 316 L Stainless Steel SLM Parts

5. Discussion

6. Conclusions

- It demonstrates that the absolute values of the acoustic–elastic coefficients show a significant dependence on the scanning strategies used in the SLM forming process, and the mechanical properties of the specimen vary with the scanning strategy [27,45]. For the specimen whose mechanical properties are better, the absolute values of the corresponding acoustic-elastic coefficients were less.

- The test results reveal that when the stress in an anisotropic SLM specimen is greater than critical stress and less than yield stress, many small cracks emerge inside the specimen. This indicates the specimen has entered the failure stage. This phenomenon reflects the sensibility of this method.

- As the 316 L stainless steel specimens manufactured by SLM technology present obvious anisotropic characteristics, the time of flight in ultrasonic distance measurement along the detection direction will be influenced by the anisotropic tissue. Generally, acoustic time difference in ultrasonic distance measurement keeps at nanosecond level, even if the influence of the anisotropic tissue on the acoustic time difference is very small, the influence on the reliability of stress detection results cannot be ignored. As shown in Equations (14)–(16), due to the acoustic-elastic coefficient being very small, the small fluctuation of acoustic time difference can lead to remarkable change in stress testing results. The test results indicate that the influence of anisotropic tissue on the test results can be characterized by the constant term in the linear acoustic-elastic formula, when other influencing factors in the experiment are excluded. Therefore when the LCR wave method is used to test stress, the influence of anisotropic tissue should be considered in characterizing stress in SLM forming parts.

- In any case, the sensibility of the LCR wave method to test stress has been widely proven and the robustness and stability will be particularity important in further research.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Fu, L.D.; Shi, Y.S.; Zhang, W.X.; Liu, J.H.; Lu, Z.L. The process research of 316 L stainless steel in selective laser melting. Appl. Laser 2008, 28, 108–111. [Google Scholar]

- AlMangour, B.; Grzesiak, D.; Yang, J.M. In-situ formation of novel TiC-particle-reinforced 316L stainless steel bulk-form composites by selective laser melting. J. Alloy. Compd. 2017, 706, 409–418. [Google Scholar] [CrossRef]

- Ali, H.; Ma, L.; Ghadbeigi, H.; Mumtaz, K. In-situ residual stress reduction, martensitic decomposition and mechanical properties enhancement through high temperature powder bed pre-heating of selective laser melted Ti6Al4V. Mater. Sci. Eng. 2017, 695, 211–220. [Google Scholar] [CrossRef]

- Lu, Y.J.; Wu, S.Q.; Gan, Y.L.; Huang, T.T.; Yang, C.G.; Lin, J.J.; Lin, J.X. Study on the microstructure, mechanical property and residual stress of SLM Inconel-718 alloy manufactured by differing island scanning strategy. Opt. Laser Technol. 2015, 75, 197–206. [Google Scholar] [CrossRef]

- Yan, X.L.; Pang, J.C.; Jing, Y.L. Ultrasonic measurement of stress in SLM 316 Lstainless steel forming parts manufactured using different scanning strategies. Materials 2019, 12, 2719. [Google Scholar] [CrossRef]

- Mugwawa, L.; Dimitrov, D.; Matope, S.; Yadroitsev, I. Evaluation of the impact of scanning strategies on residual stresses in selective laser melting. Int. J. Adv. Manuf. Technol. 2019, 102, 2441–2450. [Google Scholar] [CrossRef]

- Wang, D.; Wu, S.B.; Yang, Y.Q.; Dou, W.H.; Deng, S.S.; Wang, Z.; Li, S. The Effect of a scanning strategy on the residual stress of 316 L steel parts fabricated by selective laser melting (SLM). Materials 2018, 11, 1821. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Yadroitsava, I. Evaluation of residual stress in stainless steel 316L and Ti6Al4V samples produced by selective laser melting. Virtual Phys. Prototyp. 2015, 10, 67–76. [Google Scholar] [CrossRef]

- Yan, X.L.; Dong, S.Y.; Xu, B.S.; Cao, Y. Progress and challenges of ultrasonic testing for stress in remanufacturing laser cladding coating. Materials 2018, 11, 293. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, Y.M.; Zhou, Y.F.; Meng, S.H.; Chen, D.K.K. Plane stress measurement of orthotropic materials using critically refracted longitudinal waves. Ultrasonics 2019, 94, 430–437. [Google Scholar] [CrossRef]

- Liu, H.B.; Li, Y.P.; Li, T.; Zhang, X.; Liu, Y.K.; Liu, K.; Wang, Y.Q. Influence factors analysis and accuracy improvement for stress measurement using ultrasonic longitudinal critically refracted (LCR) wave. Appl. Acoust. 2018, 141, 178–187. [Google Scholar] [CrossRef]

- Zhu, Q.M.; Chen, J.; Gou, G.Q.; Chen, H.; Li, P. Ameliorated longitudinal critically refracted-attenuation velocity method for welding residual stress measurement. J. Mater. Process. Technol. 2017, 246, 267–275. [Google Scholar] [CrossRef]

- Kwaśniewki, J.; Dominik, I.; Lalik, K.; Holewa, K. Influence of acoustoelastic coefficient on wave time of flight in stress measurement in piezoelectric self-excited system. Mech. Syst. Signal Process. 2016, 78, 143–146. [Google Scholar] [CrossRef]

- El-Hadek, M.A. Dynamic equivalence of ultrasonic stress wave propagation in solids. Ultrasonics 2018, 83, 214–221. [Google Scholar] [CrossRef]

- Hughes, D.S.; Kelly, J.L. Second-order elastic deformation of solids. Phys. Rev. 1953, 92, 1145. [Google Scholar] [CrossRef]

- Johnson, G.C. Acoustoelastic theory for elastic-plastic materials. J. Acoust. Soc. Am. 1981, 70, 591–595. [Google Scholar] [CrossRef]

- Johson, G.C. The effect of plastic deformation on the acoustoelastic response of metals. J. Appl. Mech. 1983, 50, 689–691. [Google Scholar] [CrossRef]

- Rose, J.L. Ultrasonic Waves in Solid Media; Cambridge University Press: Cambridge, UK, 2004. [Google Scholar]

- King, R.B.; Fortunko, C.M. Determination of in-plane residual stress states in plates using horizontally polarized shear waves. J. Appl. Phys. 1983, 54, 3027–3035. [Google Scholar] [CrossRef]

- Allen, D.R.; Sayeres, C.M. The measurement of residual stress in textured steel using an ultrasonic velocity combinations technique. Ultrasonics 1984, 7, 179–188. [Google Scholar] [CrossRef]

- Iwashimizu, Y.; Kubomura, K. Stress-induced rotation of polarization directions of elastic waves in slightly anisotropic material. Solids Struct. 1973, 9, 99–114. [Google Scholar] [CrossRef]

- Thompson, R.B.; Smith, J.F.; Lee, S.S. Microstructure-independent acoustoelastic measurement of stress. Appl. Phys. Lett. 1984, 44, 296–298. [Google Scholar] [CrossRef]

- Walaszek, H.; Hoblos, J.; Bourse, G.; Robin, C. Effect of microstructure on ultrasonic measurement of residual stress in welded joints. Mater. Sci. Forum 2002, 404–407, 875–880. [Google Scholar] [CrossRef]

- Husson, D. A perturbation theory for the acoustoelastic effect of surface waves. Am. Inst. Phys. 1985, 57, 1562–1568. [Google Scholar] [CrossRef]

- Castellano, A.; Fraddosio, A.; Marzano, S.; Piccioni, M.D. Some advancements in the ultrasonic evaluation of initial stress states by the analysis of the acoustoelastic effect. Procedia Eng. 2017, 1999, 1519–1526. [Google Scholar] [CrossRef]

- The Standardization Administration of China. GB/T3075-2008 Control Method of Axial Force in Fatigue Test of Metallic Materials; The Standardization Administration of China: Beijing, China, 2008.

- Parry, L.; Ashcroft, I.A.; Wildman, R.D. Understanding the effect of laser scan strategy on residual stress in selective laser melting through thermo-mechanical simulation. Addit. Manuf. 2016, 12, 1–15. [Google Scholar] [CrossRef]

- Bo, C.; Shrestha, S.; Chou, K. Stress and deformation evaluations of scanning strategy effect in selective laser melting. Addit. Manuf. 2016, 12, 240–251. [Google Scholar]

- Yan, X.L.; Dong, S.Y.; Xu, B.S.; Liu, B.; Wang, W.L. Cepstrum analysis method in surface acoustic wave signals time delay estimation. Vib. Shock. 2013, 32, 159–162. [Google Scholar]

- Owen, M. Practical Signal Processing; Cambridge University Press: Cambridge, UK, 2007. [Google Scholar]

- Liu, C.; Zhang, Z.; Tang, X. Sign normalised spline adaptive filtering algorithms against impulsive noise. Signal Process. 2018, 148, 234–240. [Google Scholar] [CrossRef]

- AlMangour, B.; Grzesiak, D.; Yang, J. Scanning strategies for texture and anisotropy tailoring during selective laser melting of TiC/316 L stainless steel nanocomposites. J. Alloys Compd. 2017, 728, 424–435. [Google Scholar] [CrossRef]

- Dai, D.H.; Gu, D.D.; Zhang, H.; Xiong, J.P.; Ma, C.L.; Hong, C.; Poprawe, R. Influence of scan strategy and molten pool configuration on microstructures and tensile properties of selective laser melting additive manufactured aluminum based parts. Opt. Laser Technol. 2018, 99, 91–100. [Google Scholar] [CrossRef]

- Helwany, S. Elasticity and Plasticity; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2007. [Google Scholar]

- Hibbeler, R.C. Mechanics of Materials, 10th ed.; Pearson: London, UK, 2016. [Google Scholar]

- Zhang, H.H.; Li, L.X.; An, X.M.; Ma, G.W. Numerical analysis of 2-D crack propagation problems using the numerical manifold method. Eng. Anal. Bound. Elem. 2010, 34, 41–50. [Google Scholar] [CrossRef]

- Riemer, A.; Leuders, S.; Thöne, M.; Richard, H.A.; Tröster, T.; Niendorf, T. On the fatigue crack growth behavior in 316L stainless steel manufactured by selective laser melting. Eng. Fract. Mech. 2014, 120, 15–25. [Google Scholar] [CrossRef]

- Mishra, R.K. A review on fracture mechanics in piezoelectric structures. Mater. Today Proc. 2018, 5, 5407–5413. [Google Scholar] [CrossRef]

- Wu, S.H.; Chen, Y.; He, S.Q. Application of scanning acoustic microscope for coat testing. Aerosp. Mater. Technol. 2005, 35, 55–57. [Google Scholar]

- Shaw, A.; Liu, J.F.; Yoon, S.W.; Declercq, N.F. Characterization of the geometry of microscale periodic structures using acoustic microscopy. Ultrasonics 2016, 70, 258–265. [Google Scholar] [CrossRef] [PubMed]

- Burkov, S.I.; Zolotova, O.P.; Sorokin, B.P.; Turchin, P.P. The analysis of the effect of homogeneous mechanical stress on the acoustic wave propagation in the La3Ga5SiO14/fused silica piezoelectric layered structure. Ultrasonics 2015, 55, 104–112. [Google Scholar] [CrossRef]

- Qozam, H.; Chaki, S.; Bourse, G.; Robin, C.; Walaszek, H.; Bouteille, P. Microstructure effect on the Lcr elastic wave for welding residual stress measurement. Exp. Mech. 2010, 50, 179–185. [Google Scholar] [CrossRef]

- Mizukami, K.; Ikeda, T.; Ogi, K. Measurement of velocity and attenuation of ultrasonic guided wave for real-time estimation of cure-dependent anisotropic viscoelastic properties of carbon fiber-reinforced plastics. Ultrasonics 2019, 99, 105952. [Google Scholar] [CrossRef]

- Liu, X.C.; Wu, B.; Qin, F.; He, C.F.; Han, Q. Observation of ultrasonic guided wave propagation behaviors in pre-stressed multi-wire structures. Ultrasonics 2017, 73, 196–205. [Google Scholar] [CrossRef]

- He, X.; Kong, D.J.; Song, R.G. Microstructures and properties of laser cladding Al-TiC-CeO2 composite coatings. Materials 2018, 11, 198. [Google Scholar] [CrossRef]

| Element | C | Cr | Ni | Mo | Si | Mn | O | P | Fe |

|---|---|---|---|---|---|---|---|---|---|

| Content | 0.03 | 17.5 | 12.06 | 2.06 | 0.86 | 0.3 | 0.1 | 0.04 | Bal |

| Laser Power (W) | Scanning Speed (mm/s) | Layer Thickness (μm) | Scanning Interval (mm) | Spot Diameter (μm) | Volume Fraction of Oxygen (%) |

|---|---|---|---|---|---|

| 250 | 750 | 30 | 0.065 | 80 | 0.03 |

| Specimen Number | K1 (ns /MPa) | K2 (ns /MPa) | Critical Stress (MPa) |

|---|---|---|---|

| A-1 | 0.0801 | −0.0258 | 373 |

| A-2 | 0.0765 | −0.0246 | 381 |

| A-3 | 0.0776 | −0.0267 | 377 |

| A-4 | 0.0774 | −0.0236 | 366 |

| A-5 | 0.0789 | −0.0283 | 359 |

| Mean | 0.0781 | −0.0258 | 371 |

| Standard deviation | 0.0014 | 0.0018 | 8.78 |

| B-1 | 0.0574 | −0.0206 | 475 |

| B-2 | 0.0546 | −0.0220 | 479 |

| B-3 | 0.0558 | −0.0195 | 467 |

| B-4 | 0.0550 | −0.0194 | 486 |

| B-5 | 0.0566 | −0.0215 | 463 |

| Mean | 0.0566 | −0.0206 | 474 |

| Standard deviation | 0.0013 | 0.0012 | 9.22 |

| C-1 | 0.0543 | −0.0191 | 481 |

| C-2 | 0.0518 | −0.0177 | 496 |

| C-3 | 0.0542 | −0.0206 | 501 |

| C-4 | 0.0563 | −0.0199 | 486 |

| C-5 | 0.0560 | −0.0182 | 498 |

| Mean | 0.0544 | −0.0191 | 492 |

| Standard deviation | 0.0018 | 0.0012 | 8.50 |

| Specimen Number | Tensile Strength (MPa) | Yield Strength (MPa) | Elastic Modulus (N/mm2) | The Maximum Strain (%) |

|---|---|---|---|---|

| A-1 | 528 | 465 | 114,007 | 17.4 |

| A-2 | 530 | 470 | 115,092 | 18.4 |

| A-3 | 534 | 472 | 116,489 | 17.6 |

| A-4 | 516 | 450 | 114,023 | 18.0 |

| A-5 | 518 | 453 | 114,143 | 17.0 |

| Mean | 525.20 | 462.00 | 114,750 | 17.68 |

| Standard deviation | 7.82 | 9.98 | 1071.20 | 0.54 |

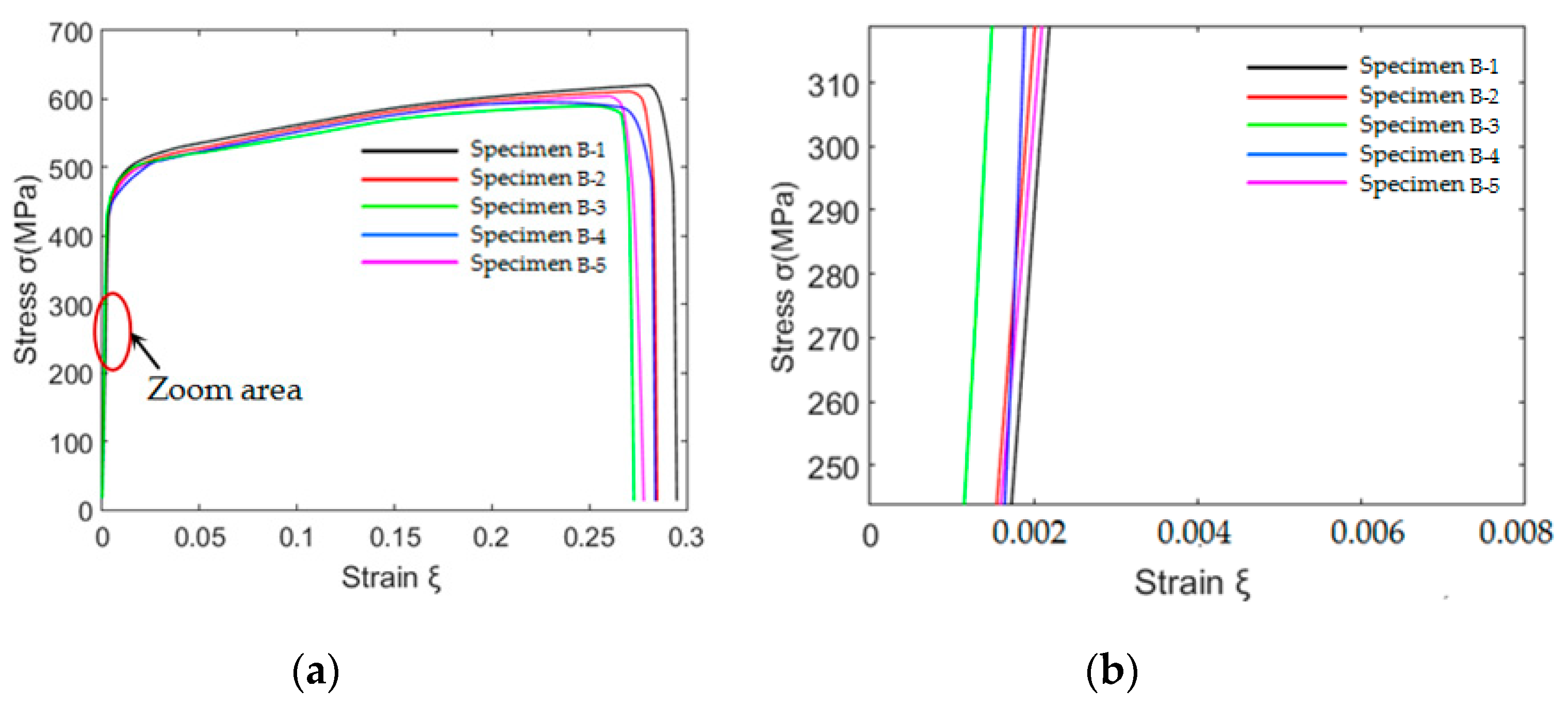

| B-1 | 620 | 532 | 151,064 | 29.5 |

| B-2 | 611 | 528 | 151,792 | 28.5 |

| B-3 | 590 | 522 | 154,266 | 27.3 |

| B-4 | 595 | 513 | 154,764 | 28.4 |

| B-5 | 604 | 520 | 151,357 | 27.8 |

| Mean | 604.00 | 520.80 | 152,650 | 28.30 |

| Standard deviation | 12.06 | 5.63 | 1732.30 | 0.82 |

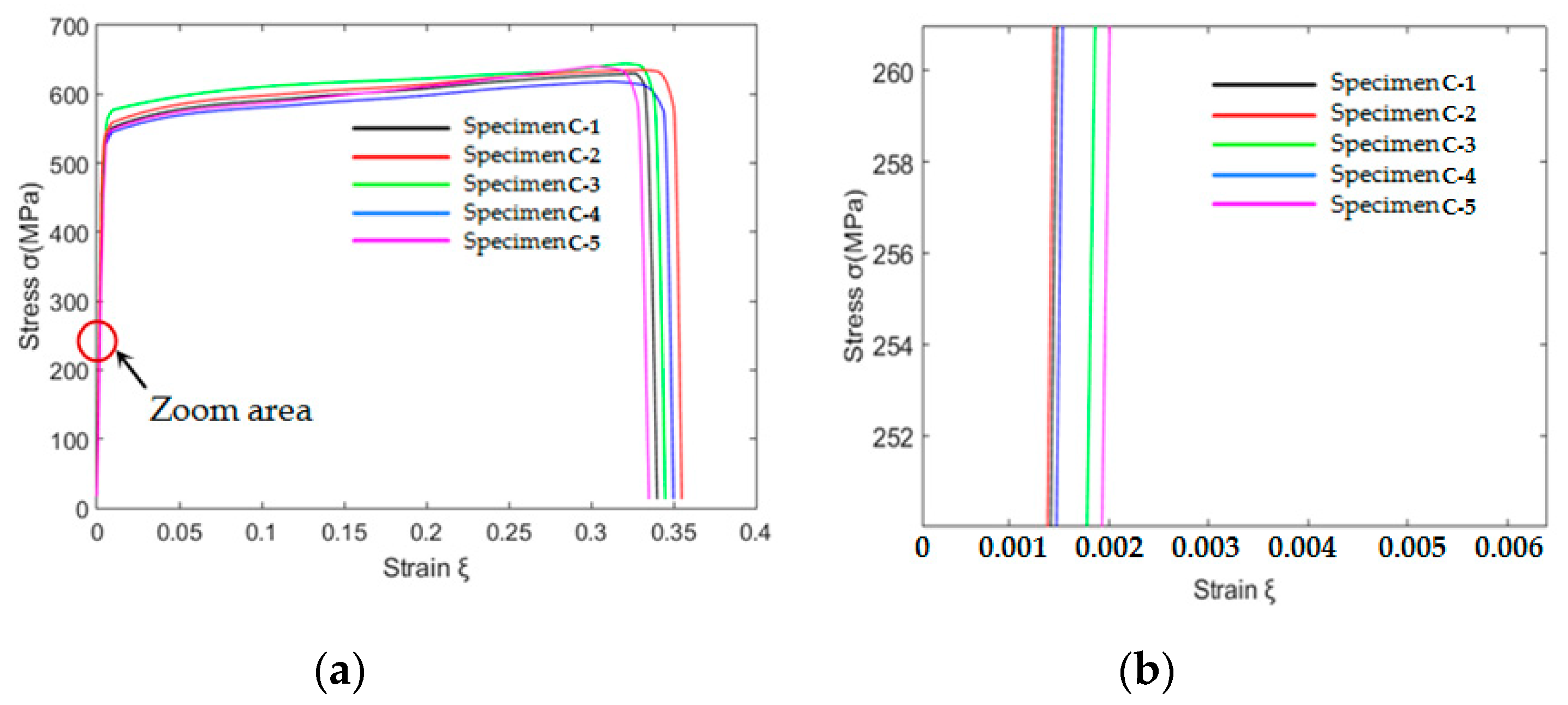

| C-1 | 629 | 532 | 177,896 | 33.2 |

| C-2 | 635 | 534 | 177,665 | 35.6 |

| C-3 | 646 | 550 | 176,953 | 34.6 |

| C-4 | 620 | 526 | 177,562 | 35.0 |

| C-5 | 640 | 528 | 176,356 | 32.8 |

| Mean | 634.00 | 534.00 | 177,290 | 34.24 |

| Standard deviation | 10.02 | 9.48 | 626.04 | 1.19 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, X.; Xu, X.; Pan, Q. Study on the Measurement of Stress in the Surface of Selective Laser Melting Forming Parts Based on the Critical Refraction Longitudinal Wave. Coatings 2020, 10, 5. https://doi.org/10.3390/coatings10010005

Yan X, Xu X, Pan Q. Study on the Measurement of Stress in the Surface of Selective Laser Melting Forming Parts Based on the Critical Refraction Longitudinal Wave. Coatings. 2020; 10(1):5. https://doi.org/10.3390/coatings10010005

Chicago/Turabian StyleYan, Xiaoling, Xiansheng Xu, and Qinxue Pan. 2020. "Study on the Measurement of Stress in the Surface of Selective Laser Melting Forming Parts Based on the Critical Refraction Longitudinal Wave" Coatings 10, no. 1: 5. https://doi.org/10.3390/coatings10010005

APA StyleYan, X., Xu, X., & Pan, Q. (2020). Study on the Measurement of Stress in the Surface of Selective Laser Melting Forming Parts Based on the Critical Refraction Longitudinal Wave. Coatings, 10(1), 5. https://doi.org/10.3390/coatings10010005