Investigation on the Selenization Treatment of Kesterite Cu2Mg0.2Zn0.8Sn(S,Se)4 Films for Solar Cell

Abstract

:1. Introduction

2. Experimental Methods

2.1. Synthesis of Cu2Mg0.2Zn0.8Sn(S,Se)4 Precursor Films

2.2. Selenization of Cu2Mg0.2Zn0.8Sn(S,Se)4 Films

2.3. Materials Characterization

3. Results and Discussion

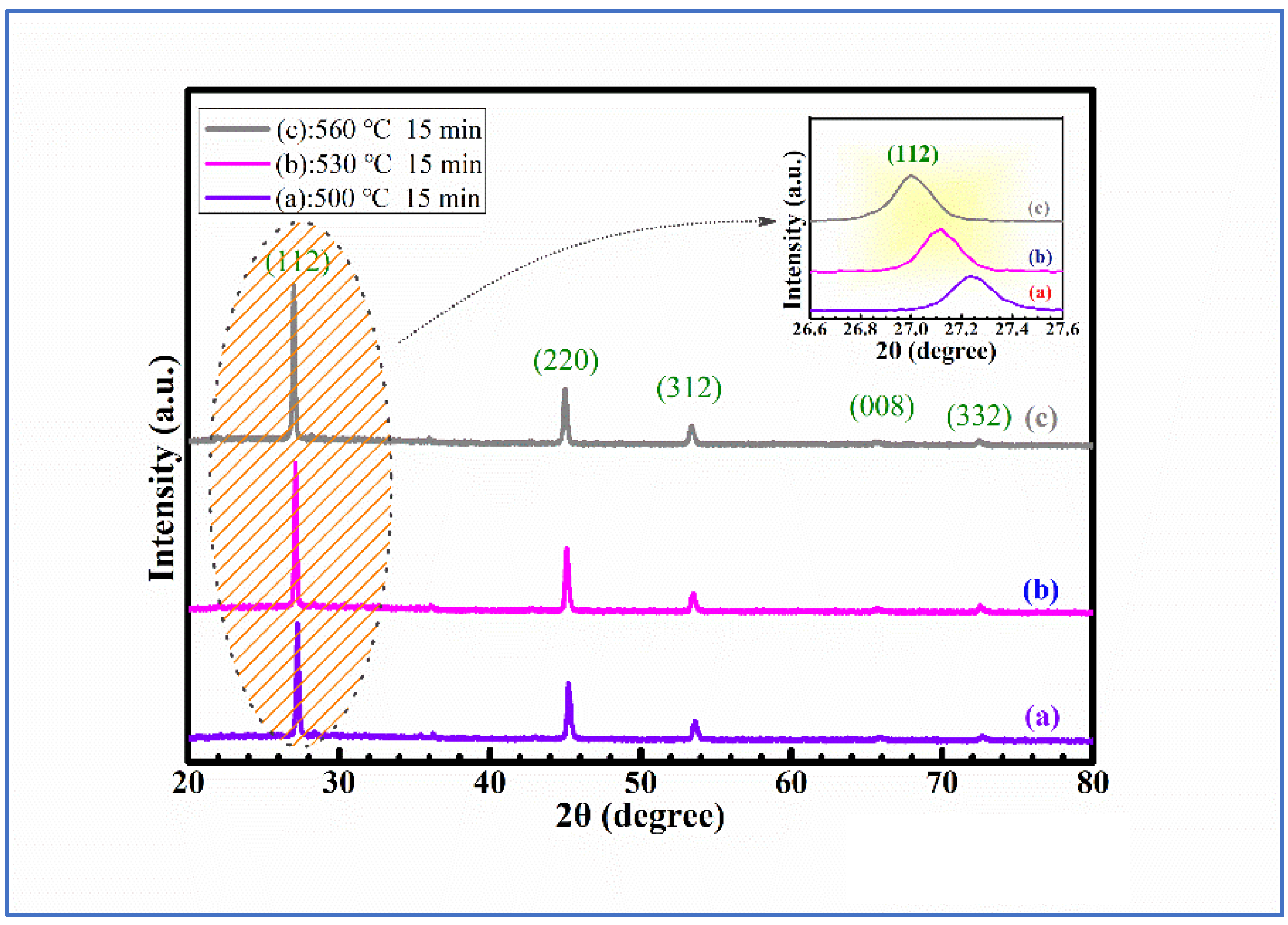

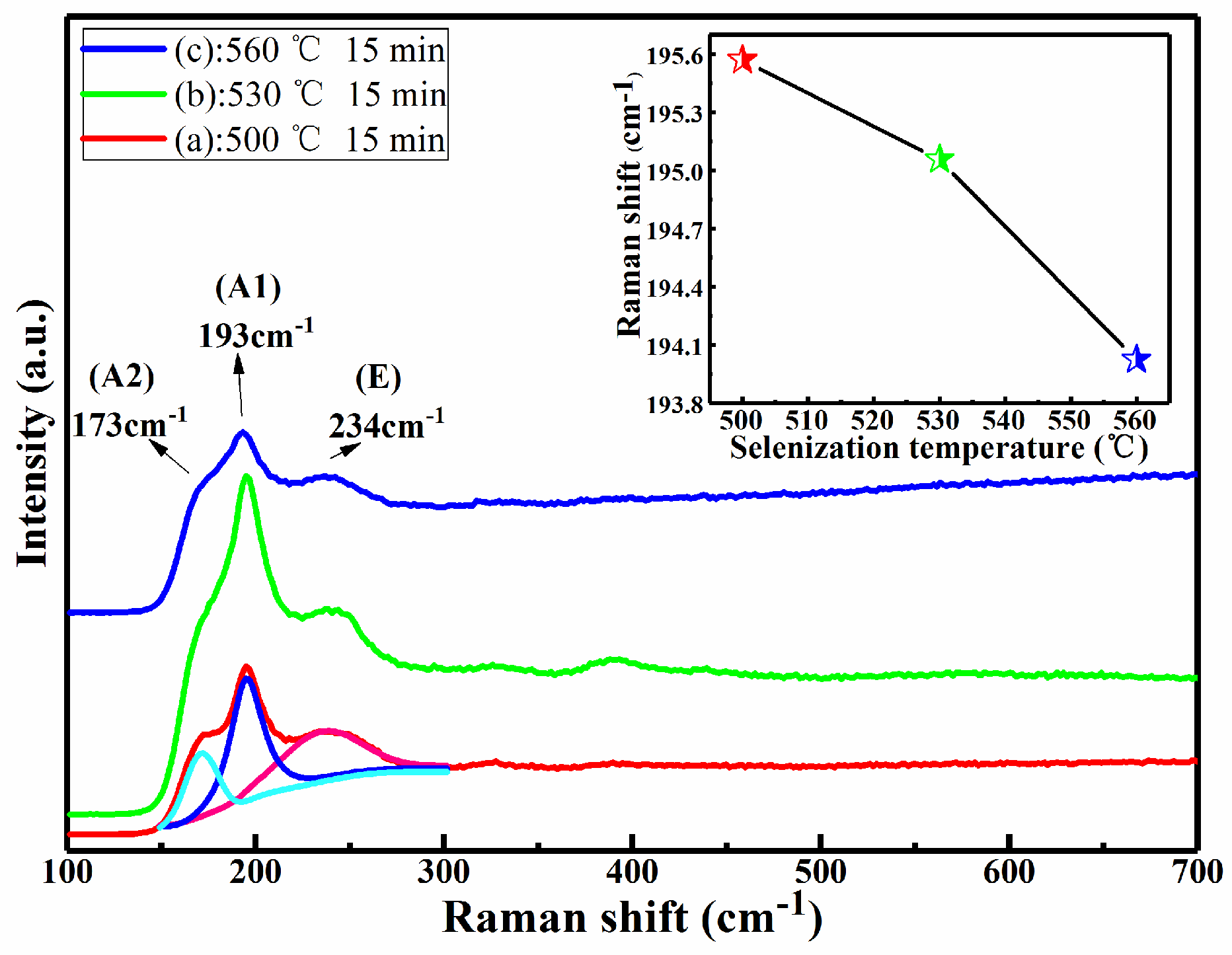

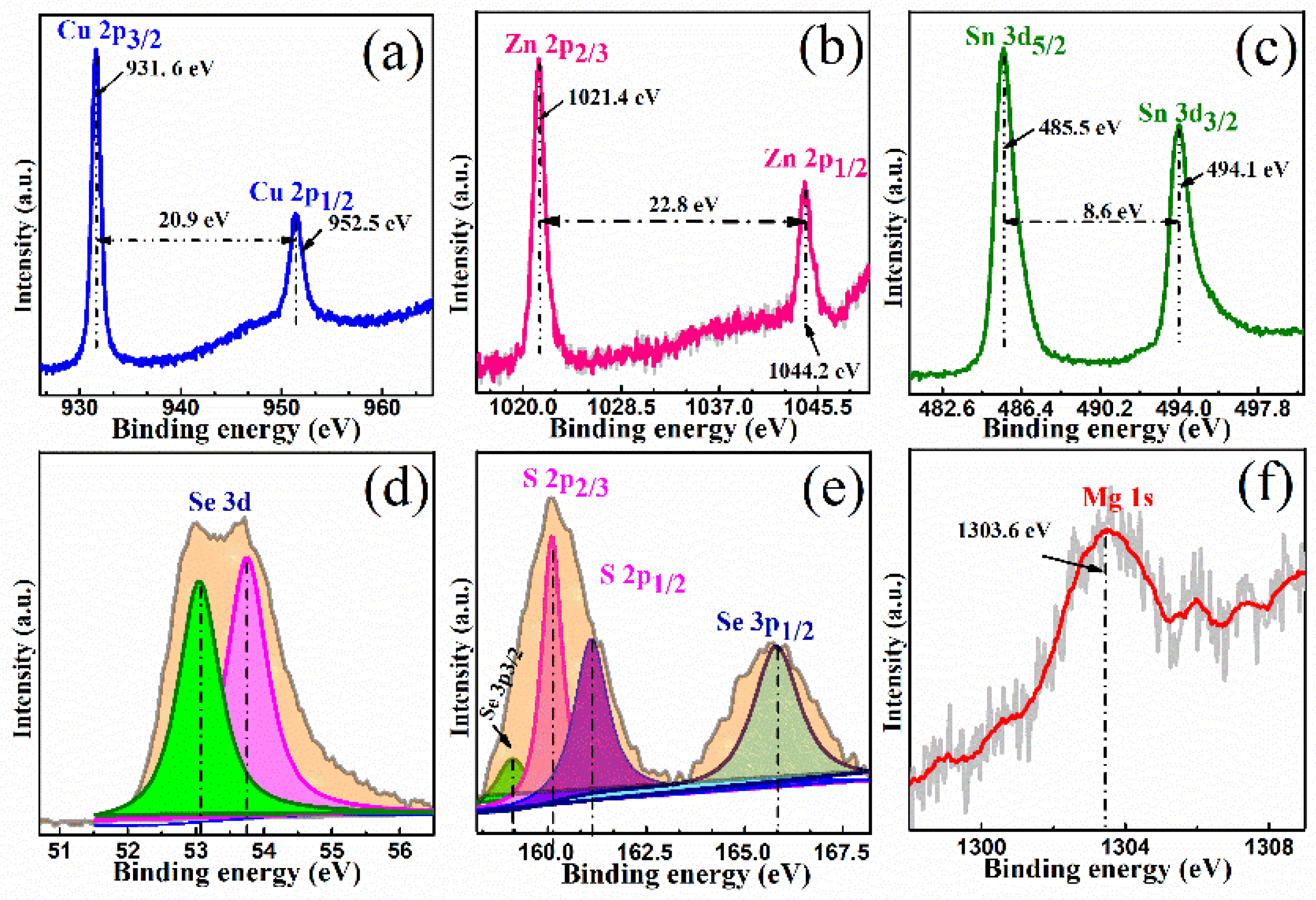

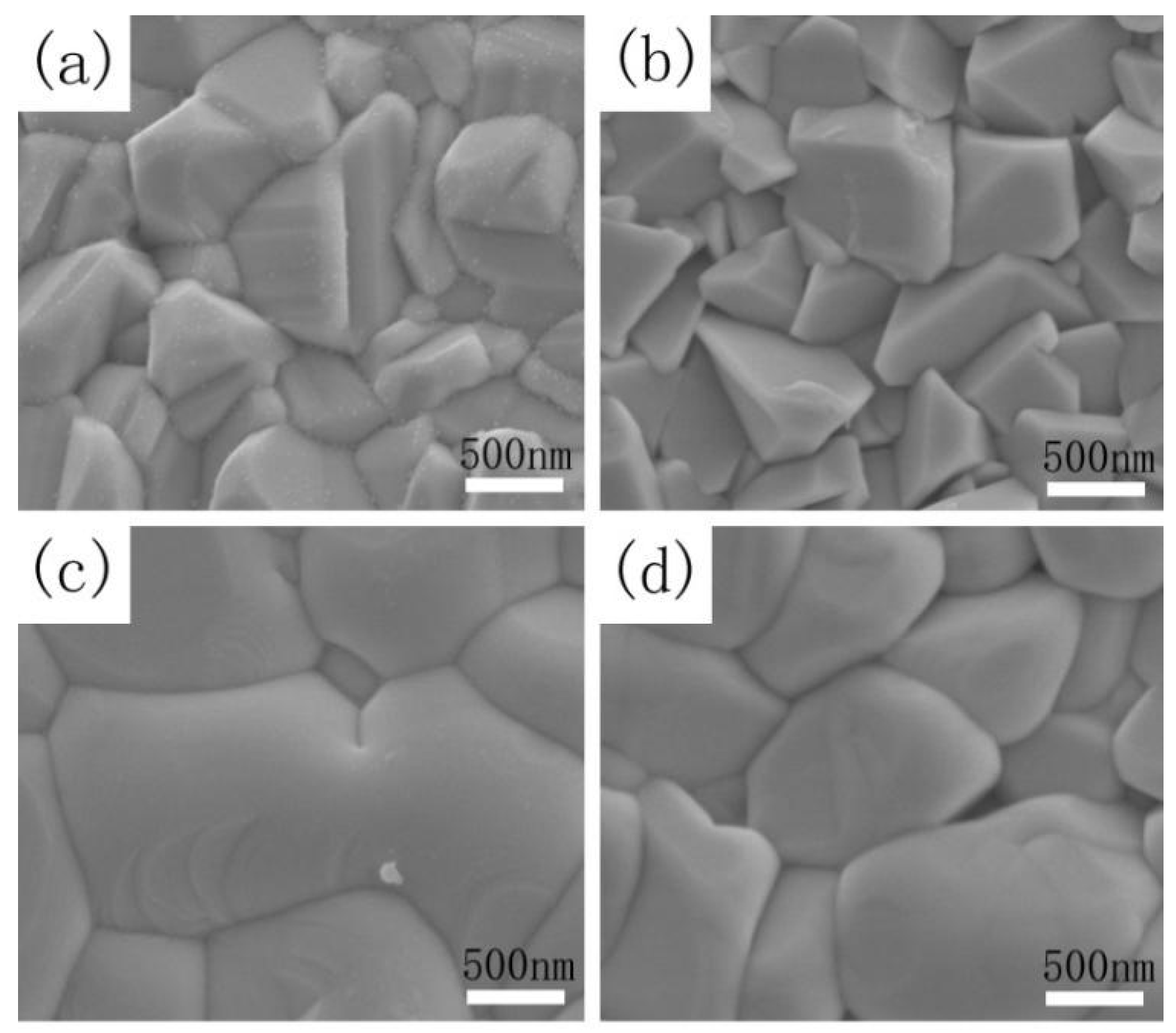

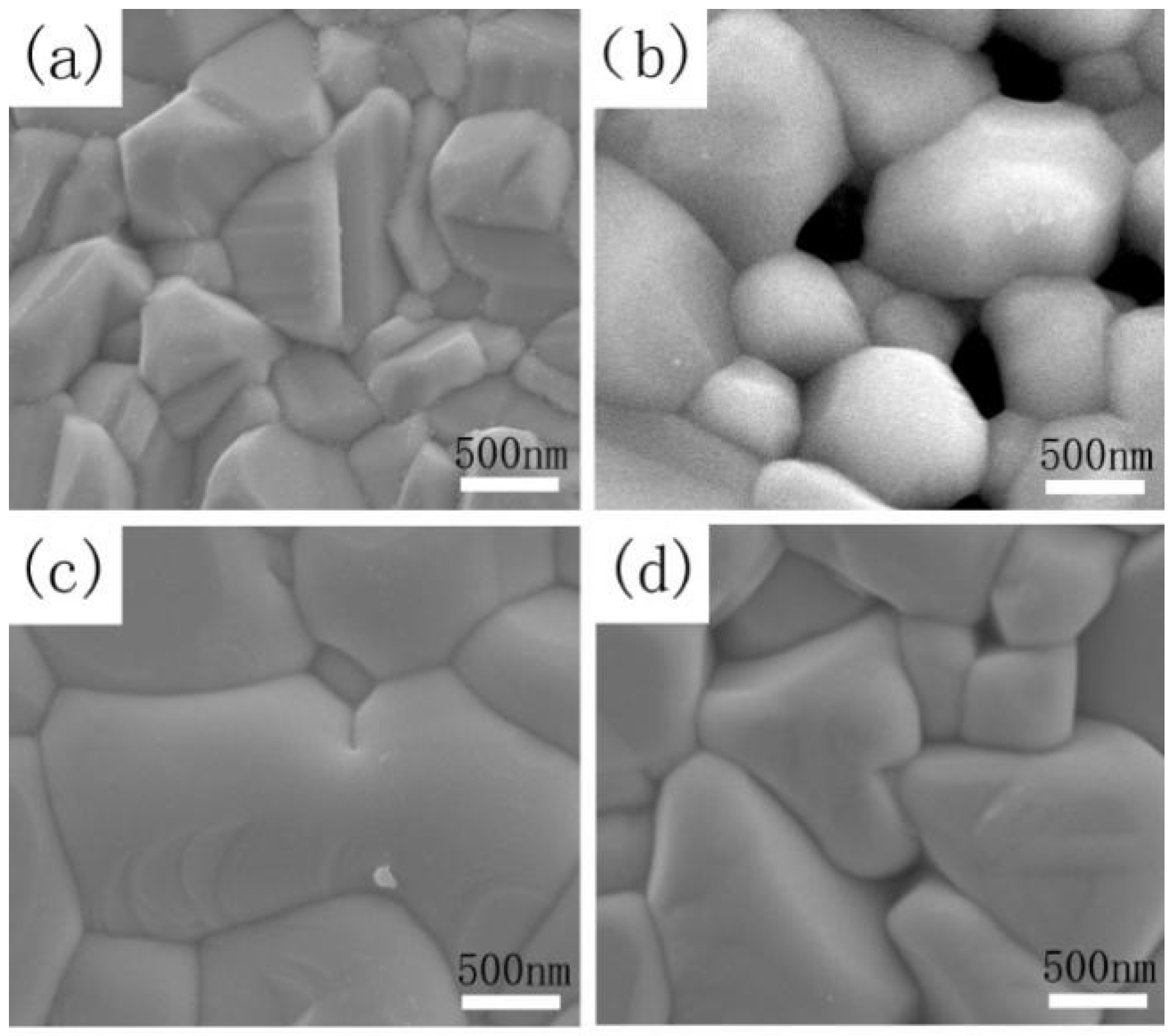

3.1. Influence of Annealing Temperature on the Properties of Cu2Mg0.2Zn0.8Sn(S,Se)4 Films

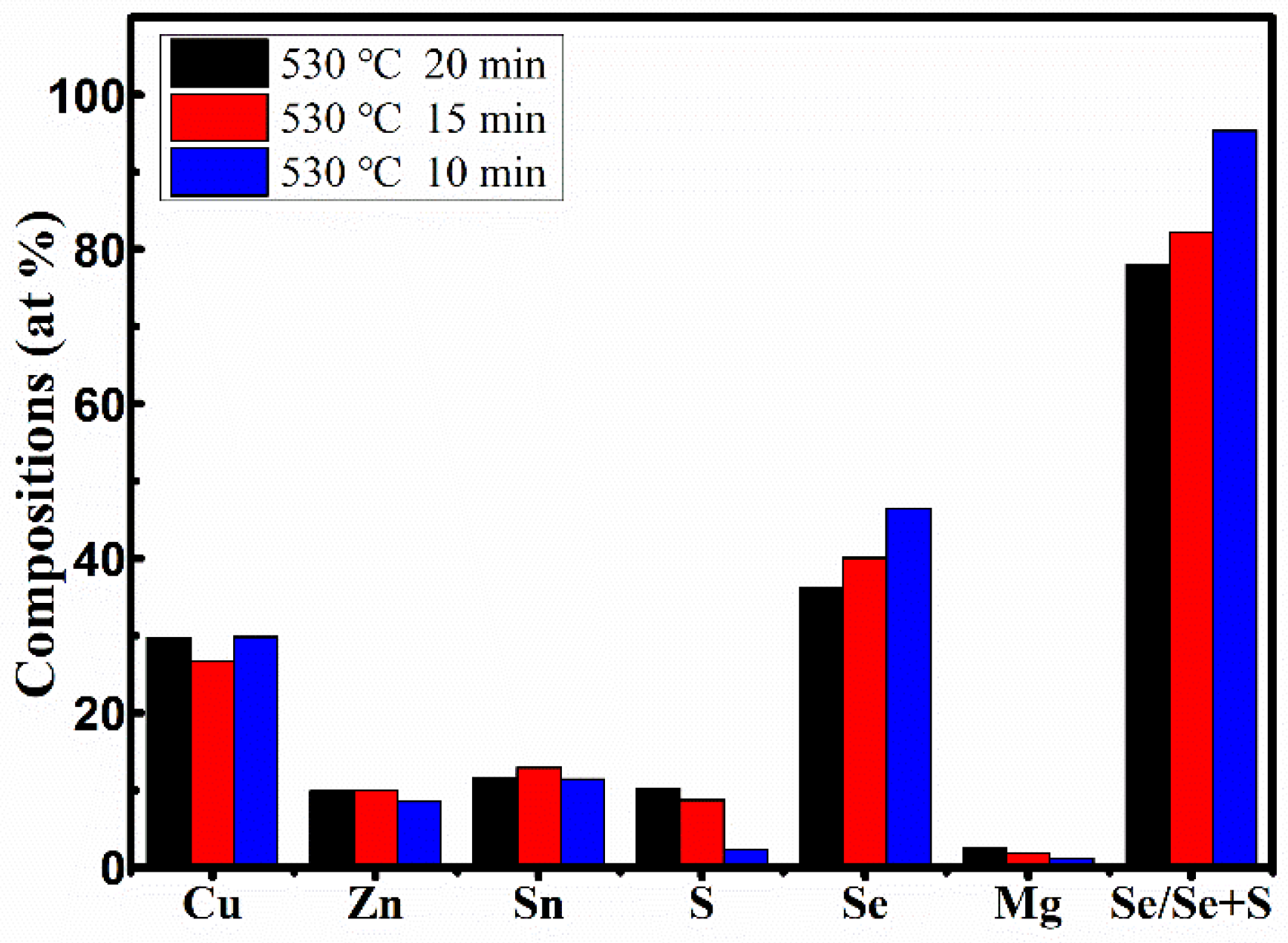

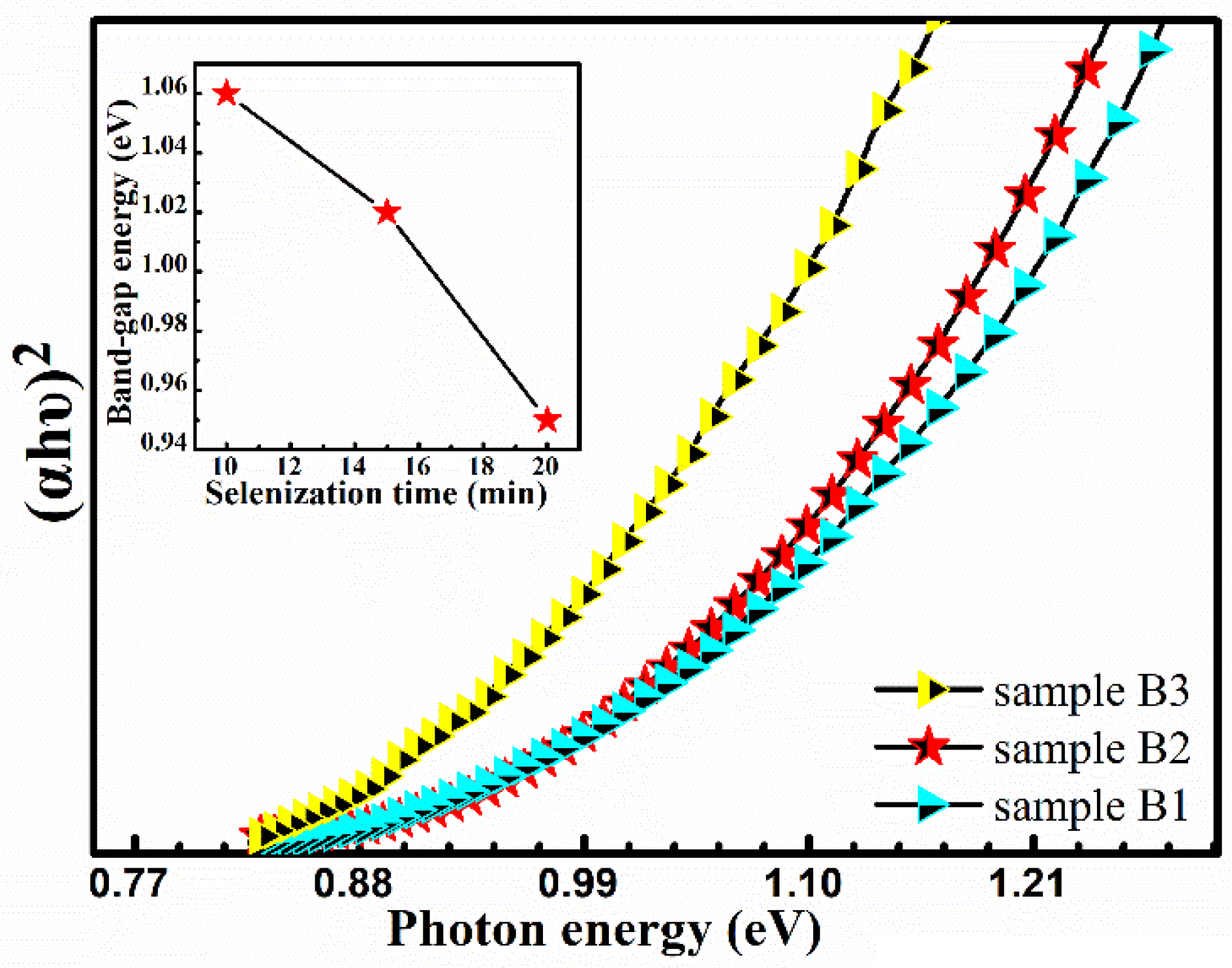

3.2. Effect of Selenization Time on Properties of CMZTSSe Films

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Lokhande, A.C.; Chalapathy, R.B.V.; He, M.; Jo, E.; Gang, M.; Pawar, S.A.; Lokhande, C.D.; Kim, J.H. Development of Cu2SnS3 (CTS) thin film solar cells by physical techniques: A status review. Sol. Energy Mater. Sol. Cells 2016, 153, 84–107. [Google Scholar] [CrossRef]

- Jackson, P.; Hariskos, D.; Wuerz, R.; Kiowski, O.; Bauer, A.; Friedlmeier, T.M.; Powalla, M. Properties of Cu(In,Ga)Se2 solar cells with new record efficiencies up to 21.7%. Phys. Status Solidi 2015, 9, 28–31. [Google Scholar]

- Park, J.Y.; Chalapathy, R.B.V.; Lokhande, A.C.; Hong, C.W.; Kim, J.H. Fabrication of earth abundant Cu2ZnSnSSe4 (CZTSSe) thin film solar cells with cadmium free zinc sulfide (ZnS) buffffer layers. J. Alloy. Compd. 2017, 695, 2652–2660. [Google Scholar] [CrossRef]

- Nguyen, M.; Ernits, K.; Tai, K.F.; Ng, C.F.; Pramana, S.S.; Sasangka, W.A.; Batabyal, S.K.; Holopainen, T.; Meissner, D.; Neisser, A.; et al. ZnS buffffer layer for Cu2ZnSn(SSe)4 monograin layer solar cell. Sol. Energy. 2015, 111, 344–349. [Google Scholar] [CrossRef]

- Ito, K.; Nakazawa, T. Electrical and Optical Properties of Stannite-Type Quaternary Semiconductor Thin Films. Jpn. J. Appl. Phys. 1998, 27, 2094–2097. [Google Scholar] [CrossRef]

- Ramasamy, K.; Malik, M.A.; O′Brien, P. Routes to Copper Zinc Tin Sulfide Cu2ZnSnS4 a Potential Material for Solar Cells. Chem. Commun. 2012, 48, 5703–5714. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Winkler, M.T.; Gunawan, O.; Gokmen, T.; Todorov, T.K.; Zhu, Y.; Mitzi, D.B. Device characteristics of CZTSSe thin-Film solar cells with 12.6% efficiency. Adv. Energy Mater. 2014, 4, 1301465. [Google Scholar] [CrossRef]

- Kato, T.; Wu, J.L.; Hirai, Y.; Sugimoto, H.; Bermudez, V. Record Efficiency for Thin Film Polycrystalline Solar Cells Up to 22.9% Achieved by Cs-Treated Cu(In,Ga)(Se,S)2. IEEE J. Photovolt. 2018, 9, 325–330. [Google Scholar] [CrossRef]

- Sui, Y.R.; Wu, Y.J.; Zhang, Y.; Wang, F.Y.; Gao, Y.B.; Lv, S.Q.; Wang, Z.W.; Sun, Y.F.; Wei, M.B.; Yao, B.; et al. Synthesis of simple, low cost and benign sol–gel Cu2InxZn1-xSnS4 alloy thin films: Influence of different rapid thermal annealing conditions and their photovoltaic solar cells. RSC Adv. 2018, 8, 9038–9048. [Google Scholar] [CrossRef]

- Jiang, Y.H.; Yao, B.; Li, Y.F.; Ding, Z.H.; Xiao, Z.Y.; Yang, G.; Liu, R.J.; Liu, K.S.; Sun, Y.M. Effect of Cd content and sulfurization on structures and properties of Cd doped Cu2SnS3 thin films. J. Alloy. Compd. 2017, 721, 92–99. [Google Scholar] [CrossRef]

- Kaur, K.; Kumar, N.; Kumar, M. Strategic review of interface carrier recombination in earth abundant Cu–Zn–Sn–S–Se solar cells: Current challenges and future prospects. J. Mater. Chem. A 2017, 5, 3069–3090. [Google Scholar] [CrossRef]

- Rey, G.; Redinger, A.; Sendler, J.; Weiss, T.P.; Thevenin, M.; Guennou, M.; El Adib, B.; Siebentritt, S. The bandgap of Cu2ZnSnSe4: Effect of order-disorder. Appl. Phys. Lett. 2014, 105, 112106. [Google Scholar] [CrossRef]

- Johnson, M.; Baryshev, S.V.; Thimsen, E.; Manno, M.; Zhang, X.; Veryovkin, I.V.; Leighton, C.; Aydil, E.S. AlkaliMetal-Enhanced Grain Growth in Cu2ZnSnS4 Thin Films. Energy Environ. Sci. 2014, 7, 1931–1938. [Google Scholar] [CrossRef]

- Yuan, M.; Mitzi, D.B.; Gunawan, O.; Kellock, A.J.; Chey, S.J.; Deline, V.R. Antimony Assisted Low-Temperature Processing of CuIn1-xGaxSe2-ySy Solar Cells. Thin Solid Films 2010, 519, 852–856. [Google Scholar] [CrossRef]

- Hsieh, Y.T.; Han, Y.T.; Jiang, C.; Song, T.B.; Chen, H.; Meng, L.; Zhou, H.; Yang, Y. Efficiency Enhancement of Cu2ZnSn(S,Se)4 Solar Cells via Alkali Metals Doping. Adv. Energy Mater. 2016, 6, 1502386. [Google Scholar] [CrossRef]

- Tai, K.F.; Fu, D.C.; Chiam, S.Y.; Huan, C.H.A.; Batabyal, S.K.; Wong, L.H. Antimony Doping in Solution-processed Cu2ZnSn(S,Se)4 Solar Cells. Chemsus Chem. 2015, 8, 3504–3511. [Google Scholar] [CrossRef] [PubMed]

- Khadka, D.B.; Kim, J.H. Structural Transition and Bandgap Tuning of Cu2(Zn,Fe)SnS4 Chalcogenide for Photovoltaic Application. J. Phys. Chem. C 2014, 118, 14227–14237. [Google Scholar] [CrossRef]

- Khadka, D.B.; Kim, J.H. Structural optical and electrical properties of Cu2FeSnX4 (X=S, Se) thin films prepared by chemical spray pyrolysis. J. Alloy. Compd. 2015, 638, 103–108. [Google Scholar] [CrossRef]

- Zhang, Y.; Sui, Y.R.; Wu, Y.J.; Jiang, D.Y.; Wang, Z.W.; Wang, F.Y.; Lv, S.Q.; Yao, B.; Yang, L.L. Synthesis and Investigation of environmental protection and Earth-abundant Kesterite Cu2MgxZn1-xSn(S,Se)4 thin films for Solar Cells. Ceram. Int. 2018, 44, 15249–15255. [Google Scholar] [CrossRef]

- Wei, M.; Du, Q.; Wang, R.; Jiang, G.; Liu, W.; Zhu, C. Synthesis of New Earth-abundant Kesterite Cu2MgSnS4 Nanoparticles by Hot-injection Method. Chem. Lett. 2014, 43, 1149–1151. [Google Scholar] [CrossRef]

- Xiao, Z.Y.; Yao, B.; Li, Y.F.; Ding, Z.H.; Gao, Z.M.; Zhao, H.F.; Zhang, L.G.; Zhang, Z.Z.; Sui, Y.R.; Wang, G. Influencing Mechanism of the Selenization Temperature and Time on the Power Conversion Efficiency of Cu2ZnSn(S,Se)4-based Solar Cells. ACS Appl. Mater. Interfaces 2016, 8, 17334–17342. [Google Scholar] [CrossRef] [PubMed]

- Scragg, J.J.; Ericson, T.; Kubart, T.; Edoff, M.; Platzer-Björkman, C. Chemical Insights into the Instability of Cu2ZnSnS4 Films during Annealing. Chem. Mater. 2011, 23, 4625–4633. [Google Scholar] [CrossRef]

- Hsu, C.J.; Duan, H.S.; Yang, W.; Zhou, H.; Yang, Y. Benign Solutions and Innovative Sequential Annealing Processes for High Performance Cu2ZnSn(S,Se)4 Photovoltaics. Adv. Energy Mater. 2014, 4, 1301287. [Google Scholar] [CrossRef]

- Nguyen, D.C.; Ito, S.; Dung, D.V.A. Effects of Annealing Conditions on Crystallization of the CZTS Absorber and Photovoltaic Properties of Cu(Zn,Sn)(S,Se)2 Solar Cells. J. Alloy. Compd. 2015, 632, 676–680. [Google Scholar] [CrossRef]

- Ranjbar, S.; Rajesh Menon, M.R.; Fernandes, P.A. Effect of Selenization Conditions on the Growth and Properties of Cu2ZnSn(S,Se)4 Thin Films. Thin Solid Films 2015, 582, 188–192. [Google Scholar] [CrossRef]

- Wu, Y.J.; Zhang, Y.; Sui, Y.R.; Wang, Z.W.; Lv, S.Q.; Wei, M.B.; Sun, Y.F.; Yao, B.; Liu, X.Y.; Yang, L.L. Bandgap engineering of Cu2InxZn1−xSn(S,Se)4 alloy films for photovoltaic applications. Ceram. Int. 2018, 44, 1942–1950. [Google Scholar] [CrossRef]

- Kishor Kumar, Y.B.; Suresh Babu, G.; Uday Bhaskar, P.; Sundar Raja, V. Preparation and characterization of spray-deposited Cu2ZnSnS4 thin films. Sol. Energy Mater. Sol. Cells 2009, 93, 1230–1237. [Google Scholar] [CrossRef]

- Walsh, A.; Chen, S.; Wei, S.H.; Gong, X.G. Kesterite Thin-Film Solar Cells: Advances in Materials Modelling of Cu2ZnSnS4. Adv. Energy Mater. 2012, 2, 400–409. [Google Scholar] [CrossRef]

- Khadka, D.B.; Kim, J.H. Bandgap Engineering of Alloyed Cu2ZnGexSn1-xQ4 (Q=S,Se) Films for Solar Cell. J. Phys. Chem. C 2015, 119, 1706–1713. [Google Scholar] [CrossRef]

- Rondiya, S.; Wadnerkar, N.; Jadhav, Y.; Jadkar, S.; Haram, S.; Kabir, M. Structural, Electronic, and Optical Properties of Cu2NiSnS4: A Combined Experimental and Theoretical Study toward Photovoltaic Applications. Chem. Mater. 2017, 29, 3133–3142. [Google Scholar] [CrossRef]

- Calderón, C.; Gordillo, G.; Becerra, R.; Bartolo-Pérez, P. XPS analysis and characterization of thin films Cu2ZnSnS4 grown using a novel solution based route. Mater. Sci. Semicond. Process. 2015, 39, 492–498. [Google Scholar] [CrossRef]

- Tsega, M.; Dejene, F.B.; Kuo, D.H. Morphological evolution and structural properties of Cu2ZnSn(S,Se)4 thin films deposited from single ceramic target by a one-step sputtering process and selenization without H2Se. J. Alloy. Compd. 2015, 642, 140–147. [Google Scholar] [CrossRef]

- Liu, W.C.; Guo, B.L.; Wu, X.S.; Zhang, F.M.; Mak, C.L.; Wong, K.H. Facile hydrothermal synthesis of hydrotropic Cu2ZnSnS4 nanocrystal quantum dots: Band-gap engineering and phonon confinement effect. J. Mater. Chem. A 2013, 1, 3182–3186. [Google Scholar] [CrossRef]

- Xiao, Z.Y.; Li, Y.F.; Yao, B.; Ding, Z.H.; Deng, R.; Zhao, H.F.; Zhang, L.G.; Zhang, Z.Z. Significantly Enhancing the Stability of a Cu2ZnSnS4 Aqueous/Ethanol-based Precursor Solution and Its Application In Cu2ZnSn(S,Se)4 Solar Cells. RSC Adv. 2015, 5, 103451–103457. [Google Scholar] [CrossRef]

- Shannon, R.; Parkinson, B.A.; Prieto, A.L. Compositionally Tunable Cu2ZnSn(S1-xSex)4 Nanocrystals: Probing the Effect of Se-Inclusion in Mixed Chalcogenide Thin Films. J. Am. Chem. Soc. 2011, 133, 15272–15275. [Google Scholar]

- Pankove, I.V. Optical Processes in Semiconductors; Dover Inc.: New York, NY, USA, 1975; pp. 34–95. [Google Scholar]

- Chen, S.; Walsh, A.; Yang, J.H.; Gong, X.G.; Sun, L.; Yang, P.X.; Chu, J.H.; Wei, S.H. Compositional dependence of structural and electronic properties of Cu2ZnSn(S,Se)4 alloys for thin film solar cells. Phys. Rev. B 2011, 83, 1252011–1252015. [Google Scholar]

- Fernandes, P.A.; Salomé, P.M.P.; Cunha, A.F.D. A Study of Ternary Cu2SnS3 and Cu3SnS4 Thin Films Prepared by Sulfurizing Stacked Metal Precursors. J. Phys. D Appl. Phys. 2010, 43, 215403. [Google Scholar] [CrossRef]

- Riha, S.C.; Parkinson, B.A.; Prieto, B.A. Solution-Based Synthesis and Characterization of Cu2ZnSnS4 Nanocrystals. J. Am. Chem. Soc. 2009, 131, 12054–12055. [Google Scholar] [CrossRef]

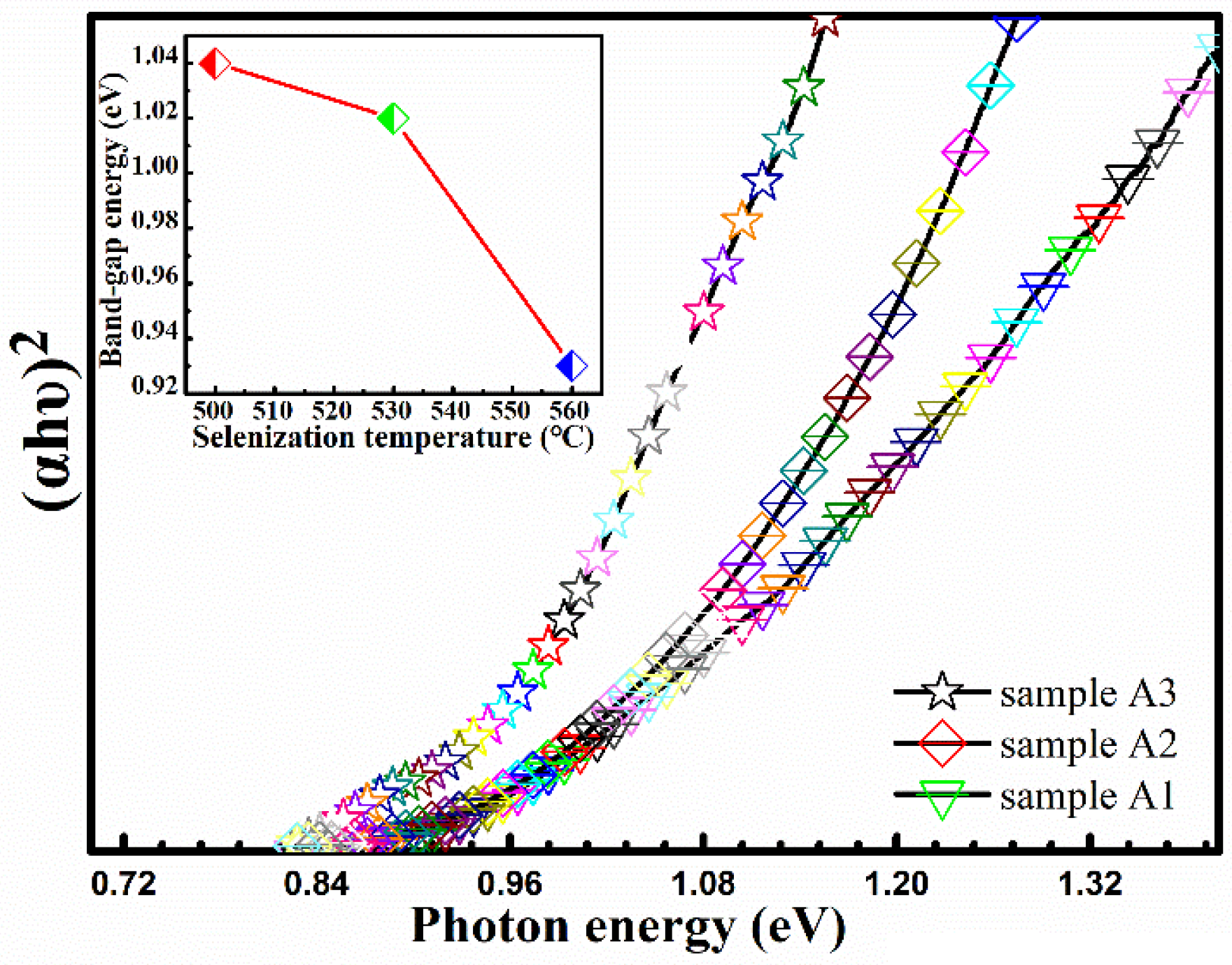

| Sample | Temperature (°C) | Time (min) | a (Å) | c (Å) | Crystalline Size (nm) | FWHM |

|---|---|---|---|---|---|---|

| A1 | 500 | 15 | 5.669 | 11.305 | 58.2 | 0.172 |

| A2 | 530 | 15 | 5.681 | 11.415 | 71.1 | 0.156 |

| A3 | 560 | 15 | 5.691 | 11.635 | 67.1 | 0.163 |

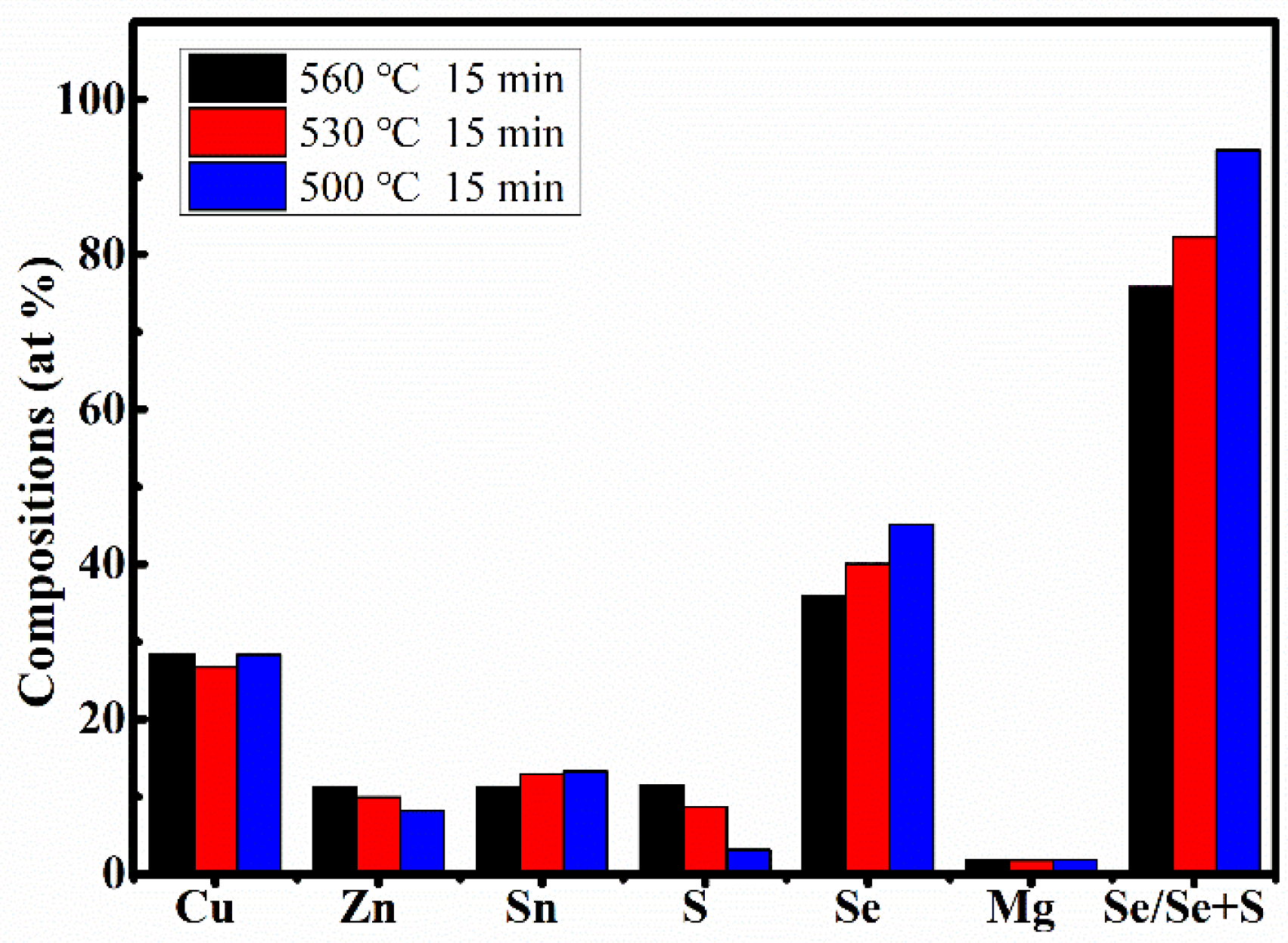

| Sample | Temperature (°C) | Cu (at%) | Zn (at%) | Sn (at%) | Mg (at%) | S (at%) | Se (at%) | Se/(S + Se) | Cu/(Zn + Mg + Sn) | Mg/(Mg + Zn) |

|---|---|---|---|---|---|---|---|---|---|---|

| A1 | 500 | 28.46 | 11.30 | 11.14 | 1.78 | 11.46 | 35.87 | 75.79 | 1.18 | 0.14 |

| A2 | 530 | 26.71 | 9.91 | 12.88 | 1.76 | 8.67 | 40.08 | 82.22 | 1.09 | 0.15 |

| A3 | 560 | 28.32 | 8.16 | 13.28 | 1.88 | 3.16 | 45.20 | 93.47 | 1.22 | 0.19 |

| Sample | Temperature (°C) | Time (min) | ρ (Ω·cm) | n (cm−3) | μ (cm−2V−1s−1) | Conduction Type |

|---|---|---|---|---|---|---|

| A1 | 500 | 15 | 6.18 × 100 | 9.22 × 1017 | 1.09 × 100 | p |

| A2 | 530 | 15 | 2.85 × 10−1 | 6.47 × 1018 | 3.31 × 10−1 | p |

| A3 | 560 | 15 | 1.10 × 102 | 5.54 × 1017 | 1.04 × 10−1 | p |

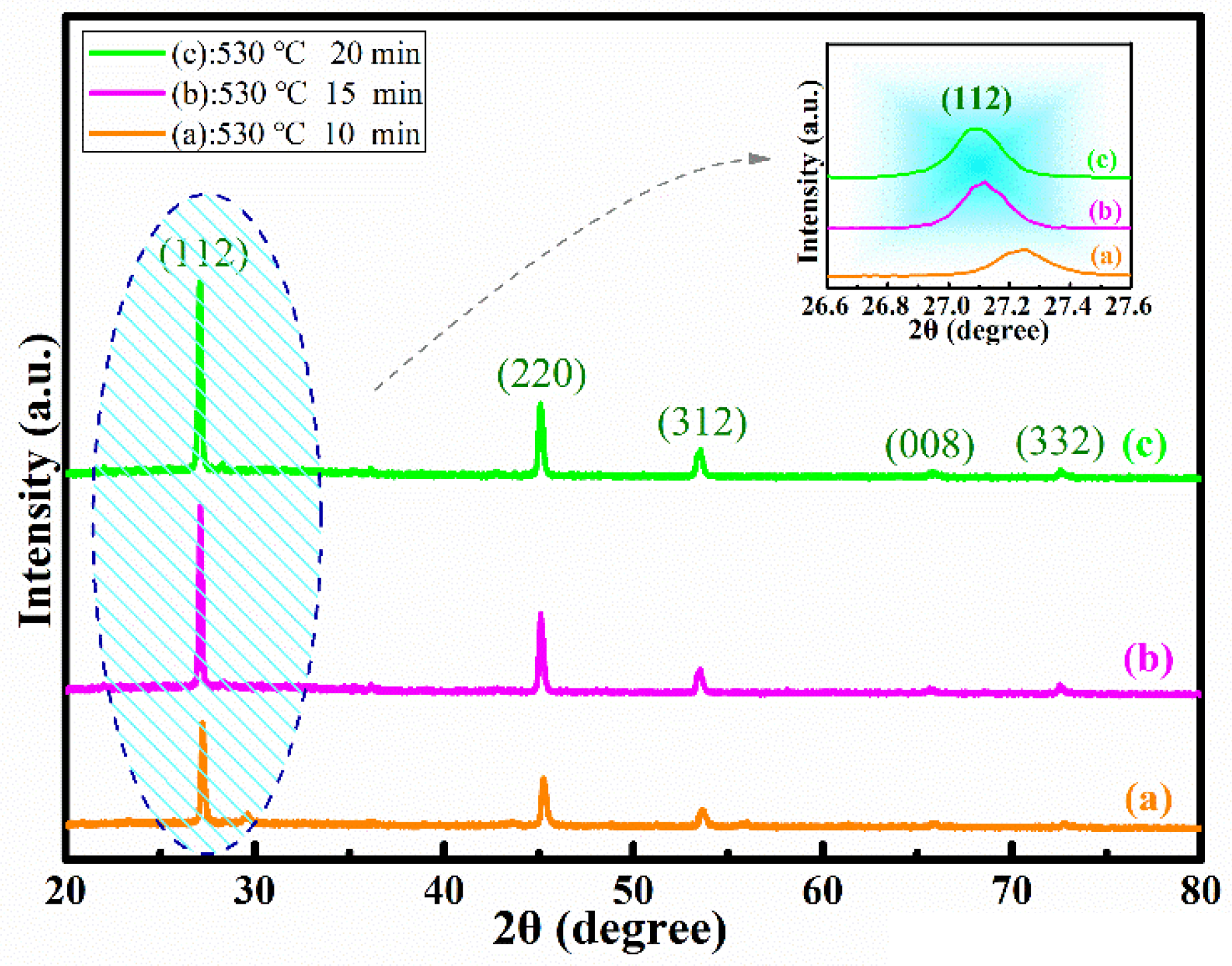

| Sample | Temperature (°C) | Time (min) | a (Å) | c (Å) | Crystalline Size (nm) | FWHM |

|---|---|---|---|---|---|---|

| B1 | 530 | 10 | 5.665 | 11.334 | 52.8 | 0.190 |

| B2 | 530 | 15 | 5.681 | 11.415 | 71.1 | 0.156 |

| B3 | 530 | 20 | 5.684 | 11.453 | 61.8 | 0.171 |

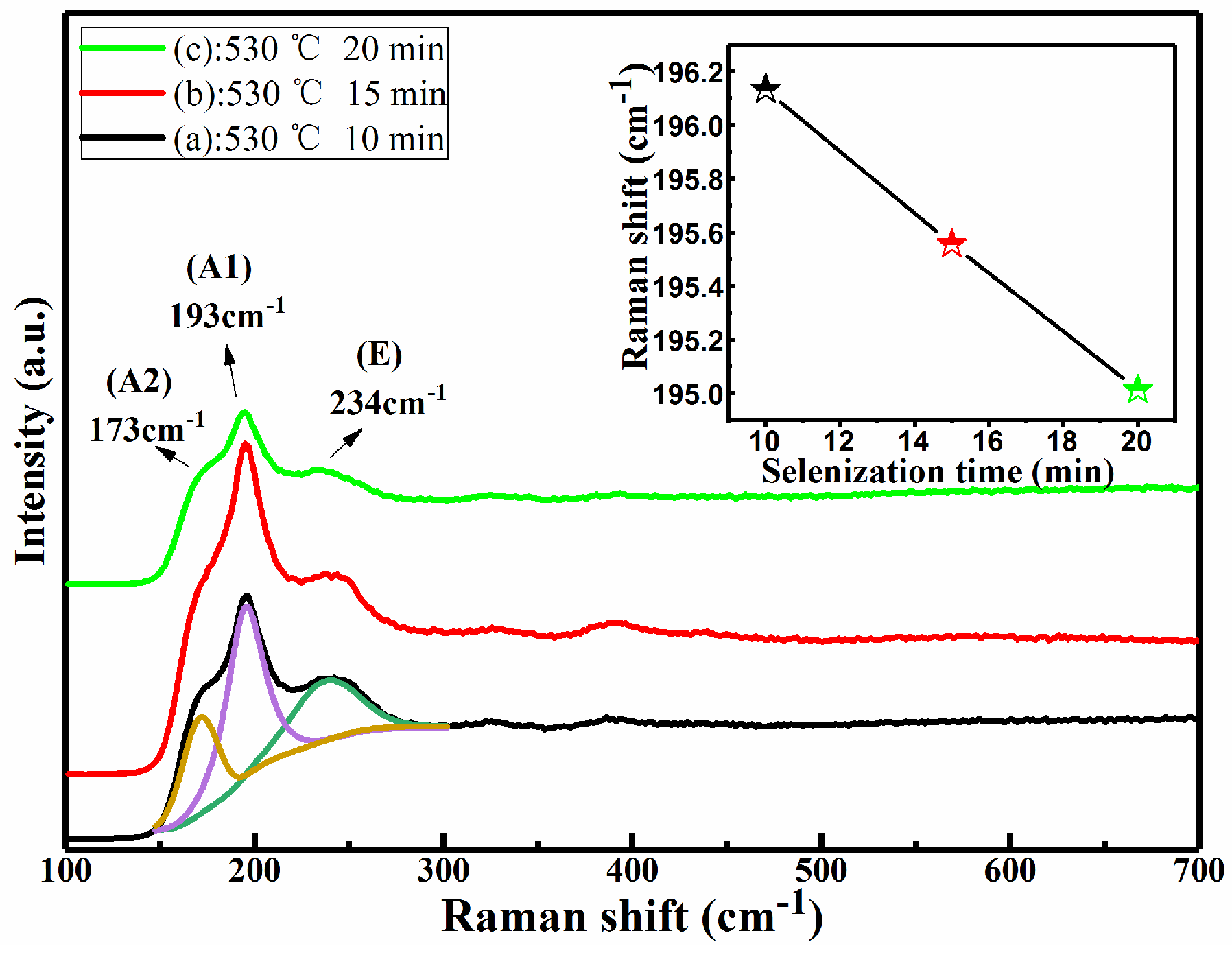

| Sample | Time (min) | Cu (at%) | Zn (at%) | Sn (at%) | Mg (at%) | S (at%) | Se (at%) | Se/(S + Se) | Cu/(Zn + Mg + Sn) | Mg/(Mg + Zn) |

|---|---|---|---|---|---|---|---|---|---|---|

| B1 | 10 | 29.66 | 9.88 | 11.60 | 2.39 | 10.23 | 36.24 | 77.99 | 1.24 | 0.19 |

| B2 | 15 | 26.71 | 9.91 | 12.88 | 1.76 | 8.67 | 40.08 | 82.22 | 1.09 | 0.18 |

| B3 | 20 | 29.81 | 8.49 | 11.43 | 1.18 | 2.26 | 46.44 | 95.36 | 1.41 | 0.12 |

| Sample | Temperature (°C) | Time (min) | ρ (Ω·cm) | n (cm−3) | μ (cm−2V−1s−1) | Conduction Type |

|---|---|---|---|---|---|---|

| B1 | 530 | 10 | 6.18 × 100 | 9.22 × 1017 | 1.09 × 100 | p |

| B2 | 530 | 15 | 2.85 × 10−1 | 6.47 × 1018 | 3.31 × 10−1 | p |

| B3 | 530 | 20 | 1.10 × 102 | 5.54 × 1017 | 1.04 × 10−1 | p |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, D.; Zhang, Y.; Sui, Y.; He, W.; Wang, Z.; Yang, L.; Wang, F.; Yao, B. Investigation on the Selenization Treatment of Kesterite Cu2Mg0.2Zn0.8Sn(S,Se)4 Films for Solar Cell. Nanomaterials 2019, 9, 946. https://doi.org/10.3390/nano9070946

Jiang D, Zhang Y, Sui Y, He W, Wang Z, Yang L, Wang F, Yao B. Investigation on the Selenization Treatment of Kesterite Cu2Mg0.2Zn0.8Sn(S,Se)4 Films for Solar Cell. Nanomaterials. 2019; 9(7):946. https://doi.org/10.3390/nano9070946

Chicago/Turabian StyleJiang, Dongyue, Yu Zhang, Yingrui Sui, Wenjie He, Zhanwu Wang, Lili Yang, Fengyou Wang, and Bin Yao. 2019. "Investigation on the Selenization Treatment of Kesterite Cu2Mg0.2Zn0.8Sn(S,Se)4 Films for Solar Cell" Nanomaterials 9, no. 7: 946. https://doi.org/10.3390/nano9070946

APA StyleJiang, D., Zhang, Y., Sui, Y., He, W., Wang, Z., Yang, L., Wang, F., & Yao, B. (2019). Investigation on the Selenization Treatment of Kesterite Cu2Mg0.2Zn0.8Sn(S,Se)4 Films for Solar Cell. Nanomaterials, 9(7), 946. https://doi.org/10.3390/nano9070946