1. Introduction

The production rates of existing oil fields are declining and the frequency of new explorations has become scarce. Therefore, the significance of enhanced oil recovery (EOR) techniques is highly understood by oil companies [

1,

2]. In this regard, nanoparticles (NPs) have been researched as additives to improve water flooding oil recovery. The small size (1–100 nm) of the nanoparticles and large surface area-to-volume ratio increase the particle mobility and surface activity, particularly at elevated temperature, which contribute to alter the fluid–rock interface properties [

2,

3,

4]. This makes the NPs appropriate for oil production. Moreover, NPs can travel long distances and reach untouched zones of a reservoir with no severe impact to permeability [

3,

5,

6]. The expected outcome is the mobilization of capillary trapped-oil or by-passed oil during the early stages of oil production, thus improving the microscopic sweep efficiency of water flooding. Thus far, silica NPs are the most studied nano-materials for EOR-applications [

7,

8,

9,

10], as they are the most abundant compounds on Earth and are of natural occurrence in sandstone formations. More importantly, silica NPs can be easily produced and surface modified to target specific applications [

3,

11].

Previous studies have reported promising oil recovery results due to silica NPs injection [

5,

6,

12,

13,

14,

15,

16,

17,

18,

19,

20] under a variety of laboratory conditions. The flooding experiments varied from the use of silica NPs with different size, composition, surface modification, etc., and the NPs suspended in aqueous solutions with diverse ionic strength [

5,

6,

12,

13,

14,

15,

16,

17,

18,

20,

21,

22] or in non-aqueous solutions [

12]. The concentration of silica NPs in the suspension is also varied. Despite the potential of the nanoparticles, there is a lack of experimental repeatability. This poses many challenges in assessing the effectiveness of silica NPs for EOR applications and an adequate understanding of the oil recovery mechnisms. The EOR application of NPs is also hampered by poor dispersibility or stability in the injection fluid (e.g., water). Nanoparticles have an immense surface free energy triggered by their ultra-small size and large surface area, which increases the tendency of the NPs to aggregate/agglomerate in solution in an attempt to gain the low energy state [

23]. As the NPs approach each other, their surface functionalities at the fluid–rock interfaces are reduced. Additionally, the binding of the primary NPs to form large nano-structures can block reservoir pore channels [

24] from start of the injection, and increase the pressure and costs of oil production. To overcome the stability issues, the surface of the nanoparticles can be modified by attaching or coating macro-molecules (e.g., polymers) on NPs surface on it, or new functionalities (silane coupling agents) may be given to the surface of the NPs to prevent them from attracting each other or with the surrounding molecules.

Nanoparticles with polymer chains coating on the particle surface were recently proposed for EOR applications. These nanomaterials are often referred to as polymer-coated NPs, and they can offer significant advantages such as improved solubility and stability, greater stabilization of emulsions, and easier transport through porous media [

25,

26] over bare nanoparticles. There are still very few experimental studies concerning their EOR applications. Accordingly, the oil recovery mechanisms of the NPs need to be well understood. Recently, Choi et al. [

27] demonstrated that polymer-coated silica NPs could enhance oil recovery by 5% volume while lowering the injection pressure. They attributed the EOR mechanisms to the reduced oil and water IFT and the formation of wedge film between the oil and the rock surface that readily altered the wettability. The effect of surface-modified silica NPs to decrease the water injection pressure for EOR purposes was studied by Dai et al. [

23] and Zhao et al. [

28]. The authors observed that, during the injection of nanofluid, NPs adsorbed and formed layers on the rock surface, thereby crowding the water out on it and increasing the water flowing channels, thus decreasing the injection pressure. The formed layer of NPs also altered the surface wettability. Behzadi and Mohammadi [

29] evaluated the EOR potential of polymer-coated silica NPs as secondary EOR-agents using glass micromodels. They reported about 59% oil recovery at breakthrough point compared to 39% OOIP achieved by water flood. This study highlighted the change in wettability of an oil-wet glass towards water-wet as the governing EOR mechanism over oil–water IFT reduction (from 28.2 mN/m to 14.1 mN/m). Azarshin et al. [

30] found that contact angle of an oil-wet surface decreased more in the presence of modified-silica NPs than bare silica NPs. This effect contributed for 18% increase in total oil recovery compared to bare NPs in their work. Again, the adhesion of NPs and subsequent formation of nanotexture coating on the rock surface and the reduction of oil–water IFT were invoked as the main oil recovery mechanisms, although the reported reduction of IFT was from 37 mN/m to 12 mN/m. Other experimental studies focusing on the evaluation of modified silica NPs to improve oil recovery have found that the NPs are more efficient in displacing light oils than heavy oils [

7,

31]. In these studies, the reduction of oil and water IFT from 26.5 to 1.9 mN/m and the change in wettability from water- to oil-wet condition are also identified as the key parameters for oil production.

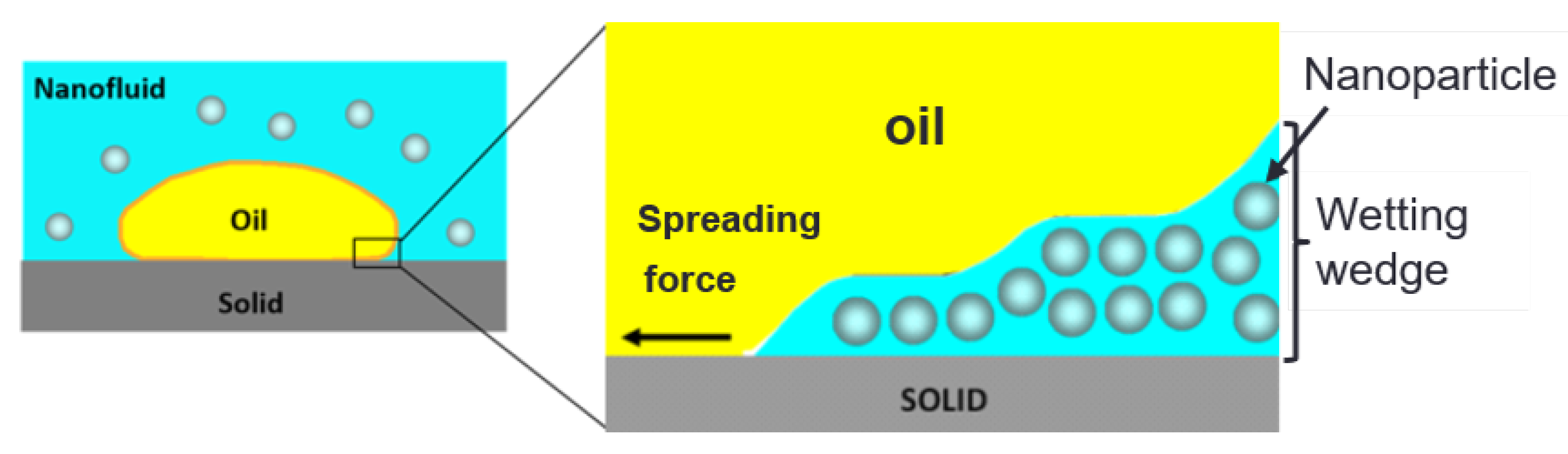

The formation of such NP layers or nanotextures on the rock surface was experimentally observed by Wasan and Nikolov [

32], and the authors proposed the concept of structural disjoining pressure to explain the influence of NPs on rock wettability and oil recovery. The authors asserted that the well-ordered layers formed in the confined space of the wetting wedge, as shown in

Figure 1, result in: (i) increased NP concentration in the wedge than in the bulk suspension, which creates an osmotic pressure that attempts to separate the oil from the rock surface, thus increasing oil recovery; and (ii) as the film tension increases toward the vertex of the wedge, an extra force is also developed that promotes the spreading of NPs on the rock surface and wetting effect. Dai et al. [

33] added that the spreading of NPs on the rock surface may develop new surface roughness that can change the wettability. It is worth noting that for the structural disjoining pressure mechanism to be effective for EOR, it requires a long-range force or high NP concentration [

32,

34]. Additionally, there should be no tendency for the NPs to adsorb on the rock surface [

35], so that NPs can confine themselves in a pre-existing wetting-wedge [

36]. Thus, it seems that the concept of structural disjoining pressure mechanism cannot be generalized to explain the wetting and oil recovery by virtue of nanofluids. For instance, in oil-wet reservoirs, oil films coat on the rock surface, which is unfavorable to the existence of a wetting-wedge.

Thus far, the wettability alteration and the reduction of oil–water IFT are put forth as the main EOR mechanisms of surface-modified silica NPs. It should, however, be noted that the reported IFT reduction in the literature is still modest and cannot prove a surfactant-like behavior of the NPs, since properly chosen surfactants would lower the IFT values down to <10 mN/m and contribute significantly to the recovery of oil. This may be the reason the oil recovery due to NPs was attributed to a joint contribution of wettability alteration and reduction of the interfacial tension. The objective of this work was to evaluate the effect of polymer-coated silica NPs for enhancing oil recovery on neutral-wet Berea sandstone rocks and propose possible EOR mechanisms. The NPs were prepared in seawater at a concentration of 0.1 wt %. Two-phase flow experiments were performed directly and after water flood at room temperature. Fluid–rock interface interactions and migration behavior of the NPs through the rock were studied to understand the effect of NPs on oil recovery.

2. Experimental Materials and Methods

2.1. Polymer-Coated Silica Nanoparticles and Synthetic Seawater

Five types of hydrophilic silica nanoparticles (NPs) were used in this work. These nanomaterials are special research and development laboratory products from Evonik Industries. The particles are spherical and amorphous silica products marketed under AEROSIL

® trade name. The original nanoparticles are commercially available from Evonik Industries, and are unstable in synthetic seawater containing divalent cations such as Ca

and Mg

[

37]. Therefore, the surface of the particles was modified by attaching polymer chains on it to provide a long-term stability and supplied to us as AERODISP

®, which is AEROSIL

® particles in liquid solution as shown in

Figure 2. The concentration of the particles in distilled water varied from 21.6 wt % to 36.8 wt %. The main component of the particles was silicon dioxide, other components comprised of aluminum oxide, mixed oxides (MOX), etc. These types of nanomaterials are referred to as polymer-coated silica nanoparticle (PSiNP) hereafter. The specific surface area of PSiNPs varied from 140 to 220 m

/g. The selected properties of the NPs are summarized in

Table 1. The primary size of the NPs was measured with dynamic light scattering technique. The NF stands for nanofluid and the number is used to identify the NP type.

The concentrated solutions of PSiNPs were diluted at a concentration of 0.1 wt % in SSW. The prepared nanofluid (NF) solution was stirred for approximately 30 min using a magnetic stirrer to ensure a homogeneous solution before use. The SSW was prepared by adding salt components found in North Sea water. The total dissolved salts was 38,318 ppm. The properties of the prepared solutions of SSW and NF are reported in

Table 2. The density was measured with Anton Paar density meter DMA

TM 4100 M series. A rotating viscometer (Brook-field, model LVDV-II+P) was used to obtain viscosity. The pH of the solutions was measured using a pH Meter (model pH 1000 L, phenomenal

®).

2.2. Oleic Phase

Two types of crude oils were used in this work and were obtained from North Sea fields, here referred to as A and B. The crude oils were filtered twice through a 5

m Millipore filter. The density and viscosity were measured using the same instruments as in

Section 2.1. The measured values are presented in

Table 3, including the saturates, aromates, resins, and asphaltenes (SARA) analysis. Crude oil A was used for aging the cores and crude oil B used for additional tests.

Normal decane (dyed red) with density of 0.73 g/cm and a viscosity of 0.9 cP was used for wettability experiments.

2.3. Interfacial Tension and Amott–Harvey Wettability Tests

Interfacial tension was measured between crude oil B and SSW or nanofluid using pendant drop method at ambient conditions. The Krüss drop shape analyzer (100) was assembled with a J-shape syringe needle with an inner diameter of 1.0047 mm to dose crude oil drops in the bulk phase. The dosing rate was 2.67 L/s. With the oil drop hanging from the needle in the designated fluid or bulk phase, the measurements were taken every 20 s until the equilibrium was reached (i.e., for ≈2 h). Then, the static IFT value was reported.

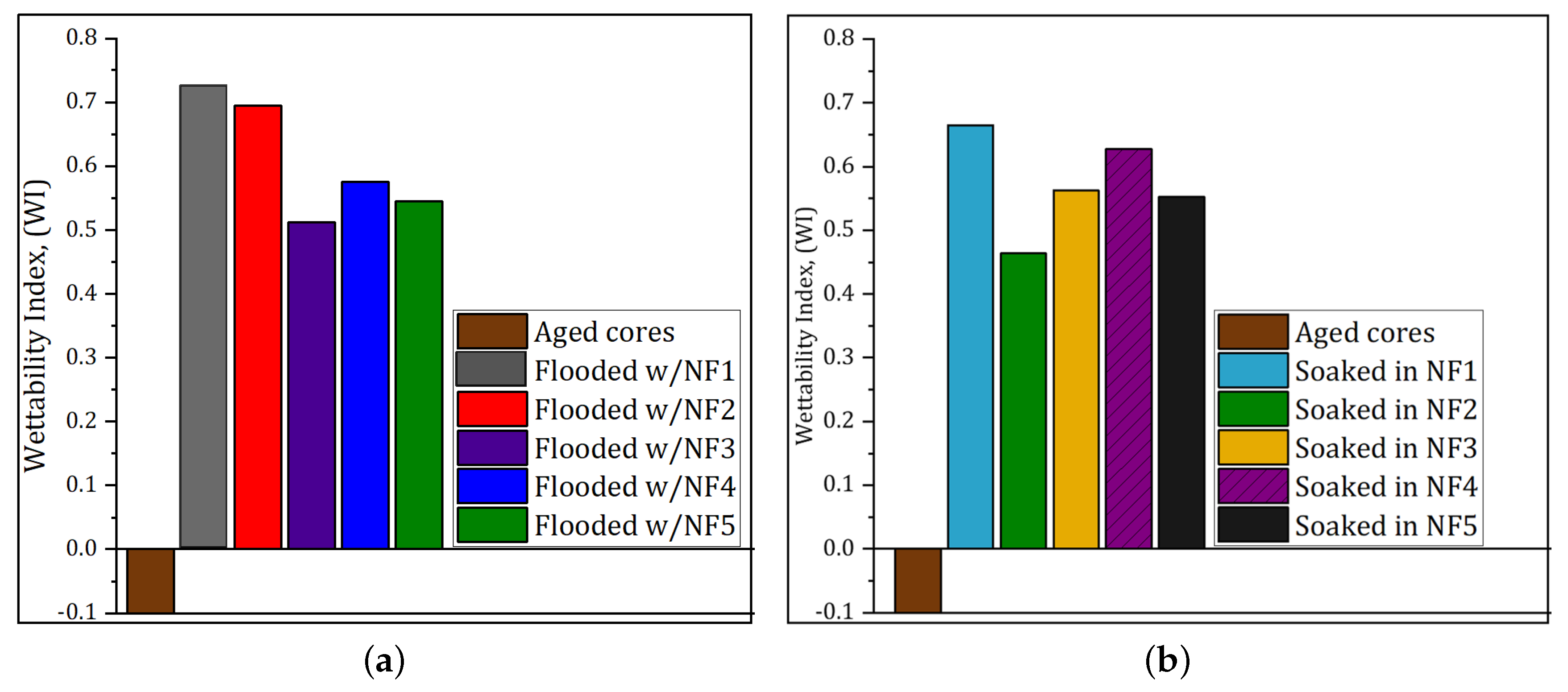

The rock wettability was evaluated before and after nanofluid flooding using Amott-Harvey method. This method is one of the most used for the characterization of the wettability of reservoir cores in petroleum engineering. More importantly, it combines spontaneous and forced displacements of the fluids to obtain the average wettability of a core [

38]. The main problem with Amott–Harvey method is its insensitivity near neutral-wettability [

38]. In this work, we used the following Amott–Harvey evaluation procedure:

The core set at irreducible water saturation (S) was submerged in an Amott–Harvey cell filled with SSW. The SSW was allowed to imbibe spontaneously into the core displacing oil until equilibrium was reached. The amount of oil produced overtime was step-wise recorded, and the total denoted as V.

The remaining mobile oil in the core was forcibly produced using a centrifuge down to residual oil saturation (S). The oil produced at this stage was recorded as V.

The core at S was placed in an Amott–Harvey cell filled with oil. Then, the oil was allowed to imbibe into the core to displace the SSW until the equilibrium was achieved. The total volume of SSW produced was recorded as V.

The remaining mobile SSW in the core was force produced using a centrifuge and the production recorded as V.

Each cycle of spontaneous water and oil imbibition tests were conducted for 15 days, while forced displacement tests were performed using a centrifuge at 5000 rpm and 25 °C for 2 h. Normal decane was used as the oil phase. All experiments were carried out at ambient conditions. The Amott–Harvey wettability index (WI) is the difference between the displacement-by-water ratio (water index, I

= V

/(V

) and the displacement-by-oil ratio (oil index, I

= V

/(V

). A categorization of the rock wettability based on WI was given by Anderson [

38].

2.4. Porous Medium and Preparation Procedure

Twenty-four Berea sandstone core plugs initially at water-wet conditions were used throughout this work. The cores were drilled from the same block of Berea sandstone; the bulk mineral composition was measured by X-ray diffraction. The cores were nearly homogeneous and composed of 93.7 vol % quartz, 5.0 vol % of microcline (alkali feldspar), and diopside (1.3 vol %). The cores were prepared to have similar dimensions in length: ≈4.5 cm, and diameter: ≈3.8 cm. The average porosity of the cores was 18% and permeability ranged from 228–391 mD.

Cleaning: The core plugs were rinsed with methanol through Soxhlet apparatus for approximately 8 h. Then, they were dried at 60 C for 2–3 days in the oven.

Porosity and Permeability: Porosity and permeability were measured on cleaned and dried cores using saturation and helium porosimeter methods and gas permeameter, respectively.

Core saturation: The cores were vacuumed for 2 h under 100 mbar pressure before allowing SSW to enter the cores. The system was left under vacuum for additional 2–3 h to ensure 100% SSW saturation. Then, they were left submerged in SSW for at least 10 days to establish ionic equilibrium with the rock system.

Irreducible water saturation: Centrifuge was used to establish S. The cores saturated with SSW were centrifuged in crude oil B at 5000 rpm for 2 h at 25 C. This procedure also established OOIP;

Core Aging: To rupture the water films to allow the polar components of crude oil to adsorb onto rock surface, the original water-wet cores at S were submerged in crude oil A inside metallic containers (aging cells) and placed in an oven set at 80 C for 4–6 weeks.

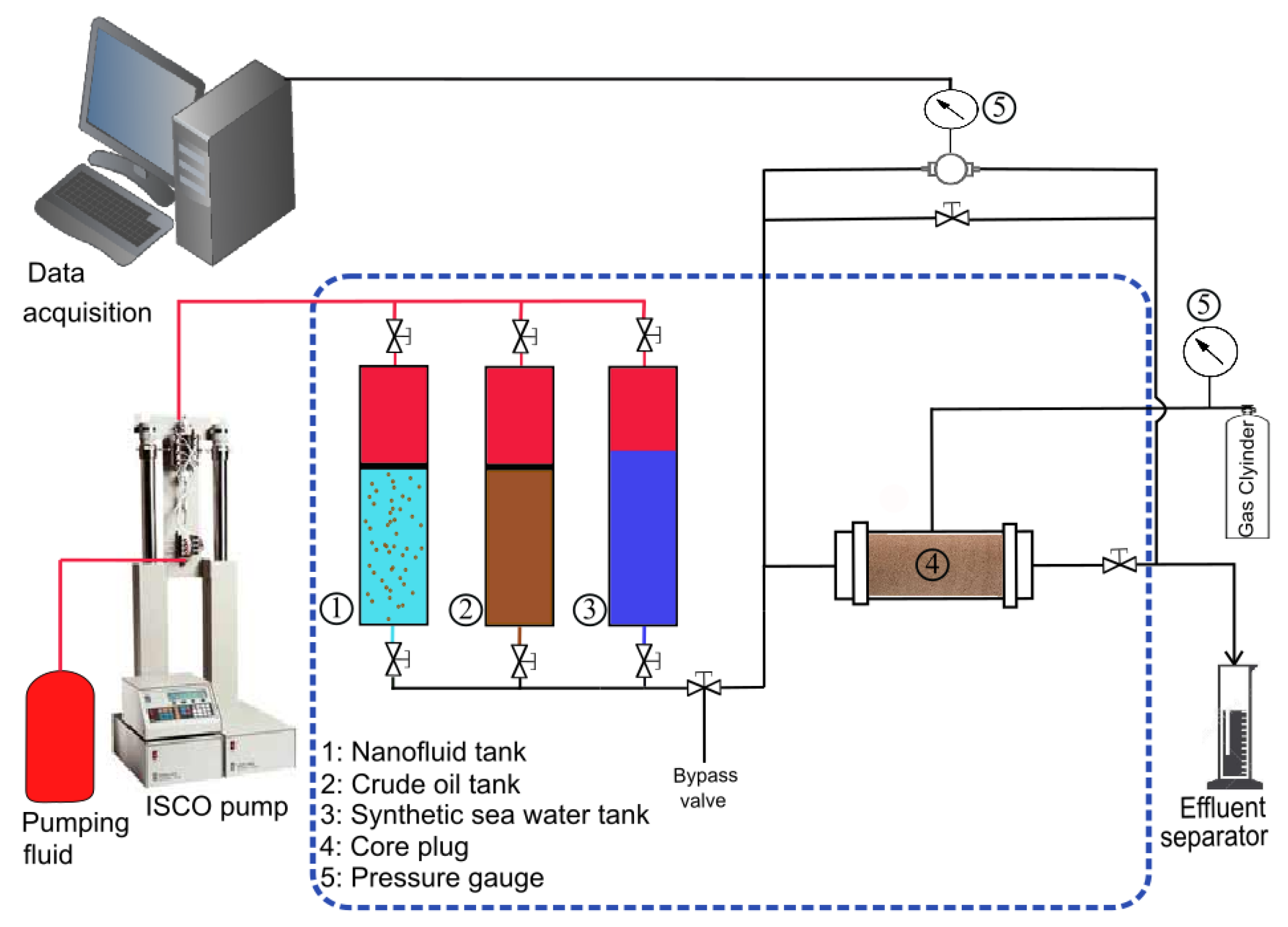

2.5. Rock Core Flooding

The effect of the PSiNP based nanofluids on oil recovery was evaluated using unsteady-state core flooding procedure in secondary and tertiary oil recovery modes under nearly atmospheric conditions. The flooding tests were performed on induced neutral-wet cores (aged cores). Twin core plugs were used for each nanofluid test. This procedure aimed at reducing the experimental errors and reproduce the results. Prior to the flooding experiments, the aged cores were cooled to room temperature followed by injection of 1–2 pore volumes (PVs) of fresh crude oil B. This was to eliminate air bubbles and/or re-establish oil connectivity within the cores. Secondary nanofluid flooding was then performed at 0.2 mL/min until no oil production was occurring for 2–4 PVs. Afterwards, the injection was switched to water flooding (WF) at 0.5 mL/min to measure if additional oil could be recovered with the increased flow-rate.

In the case of tertiary flooding scheme, WF was conducted before nanofluid flooding under the same flow-rate of 0.2 mL/min. However, the injection was switched from water to nanofluid flooding after no oil was produced for 1–2 PVs. This procedure was to ensure that any oil produced afterwards was a result of nanofluid effect. During the experiments, the amount of oil produced was collected every PV and corrected for the flooding system dead volume. When the oil production was produced at low pace, a camera with automated capturing was set to record the oil production in a graded line overtime while the total production was being collected in a larger graded effluent collector. The pictures were then analyzed to determine the amount of oil production overtime. This oil was compared to the total oil production volume read off in the large graded effluent collector. Meanwhile, the oil recovery factor (RF) and differential pressure (dP) across the core were recorded versus PVs, and the residual oil saturation was calculated.

Figure 3 presents a schematic of core flooding experimental setup with its main components labeled. It utilizes an injection pump, three tanks containing crude oil, SSW and nanofluid each. All tanks were assembled vertically inside a temperature controlled oven. The core was loaded in the Hassler core-holder and oriented horizontally under confining pressure held within 18–22 bar. Two pressure sensors were connected at the inlet and outlet of the core-holder to monitor the fluid differential pressure (dP) across the core. The differential pressure was recorded every 15 s. The outlet of the core was at atmospheric pressure as no back pressure was used.