Design and Fabrication of Wafer-Level Microlens Array with Moth-Eye Antireflective Nanostructures

Abstract

1. Introduction

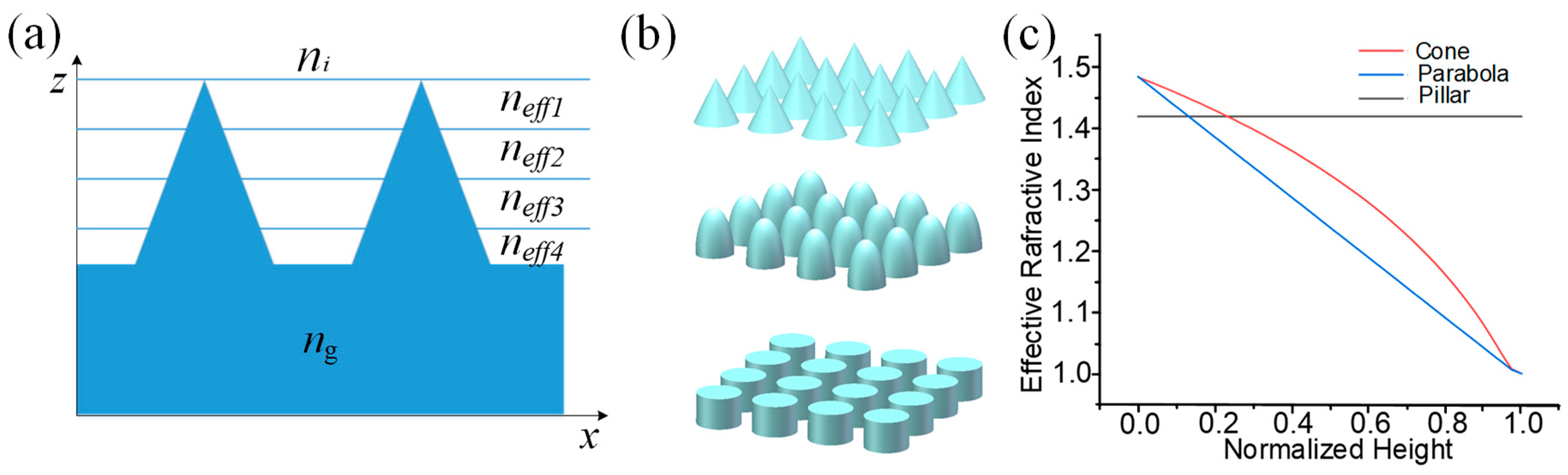

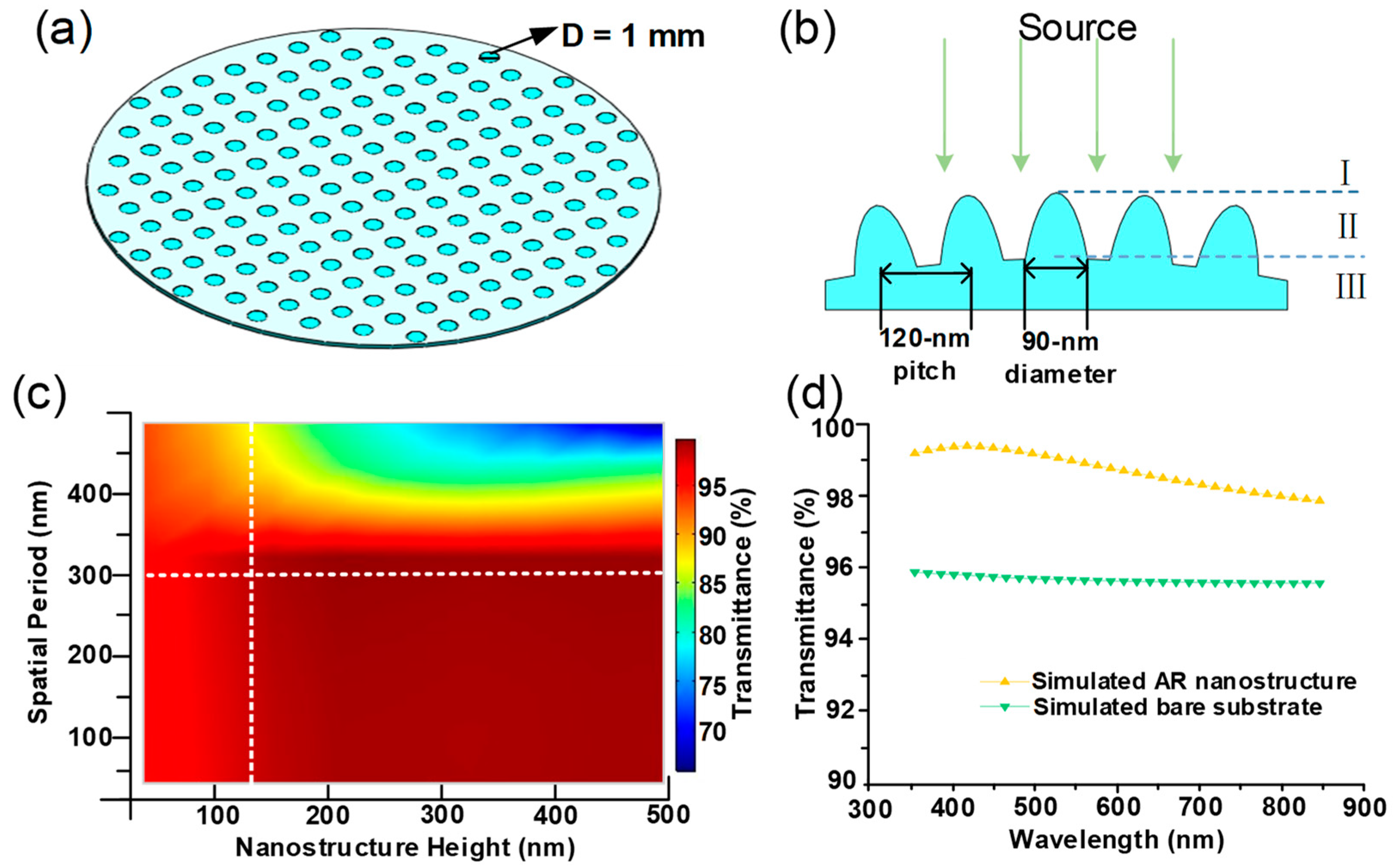

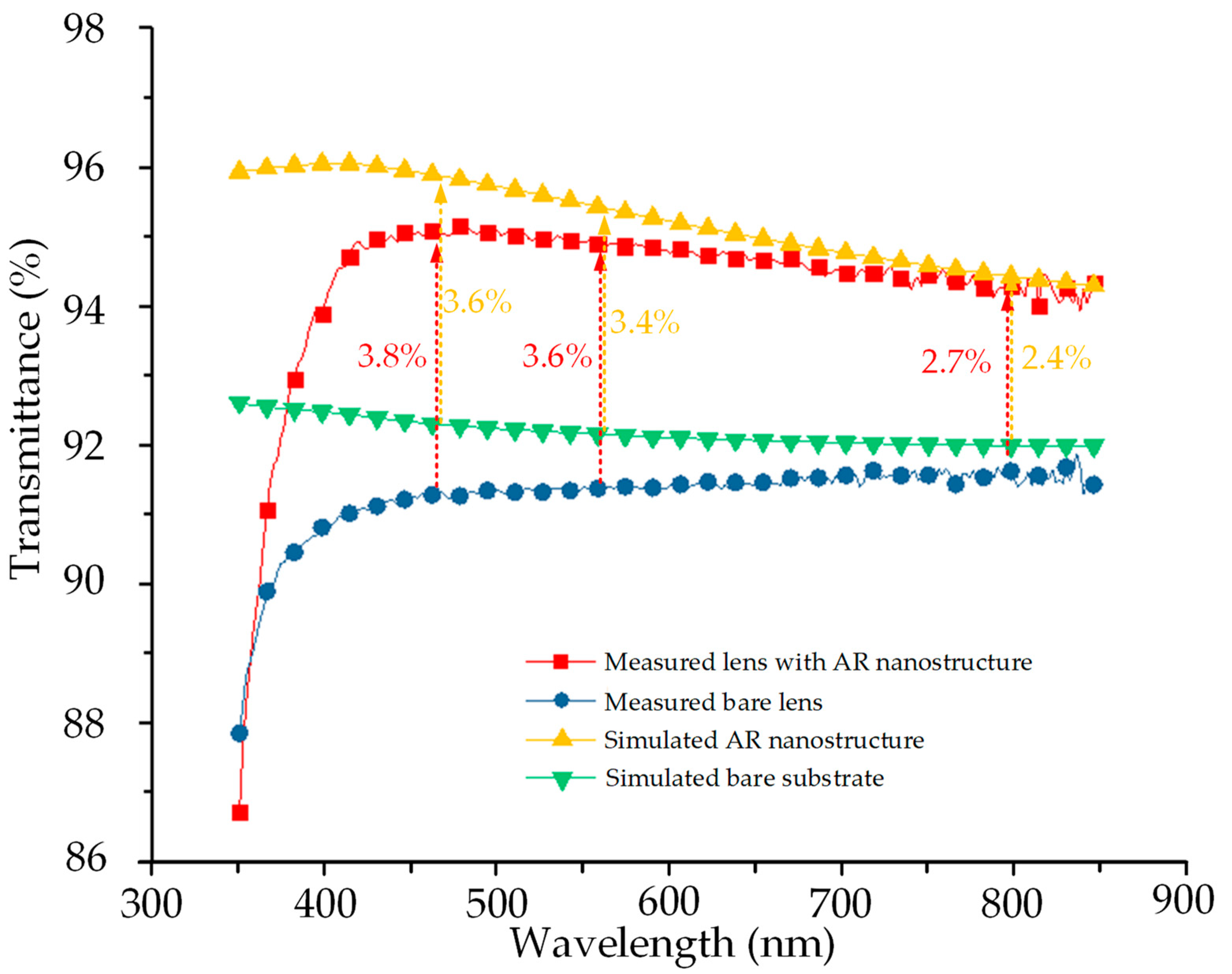

2. Moth-Eye AR Theory and Simulation

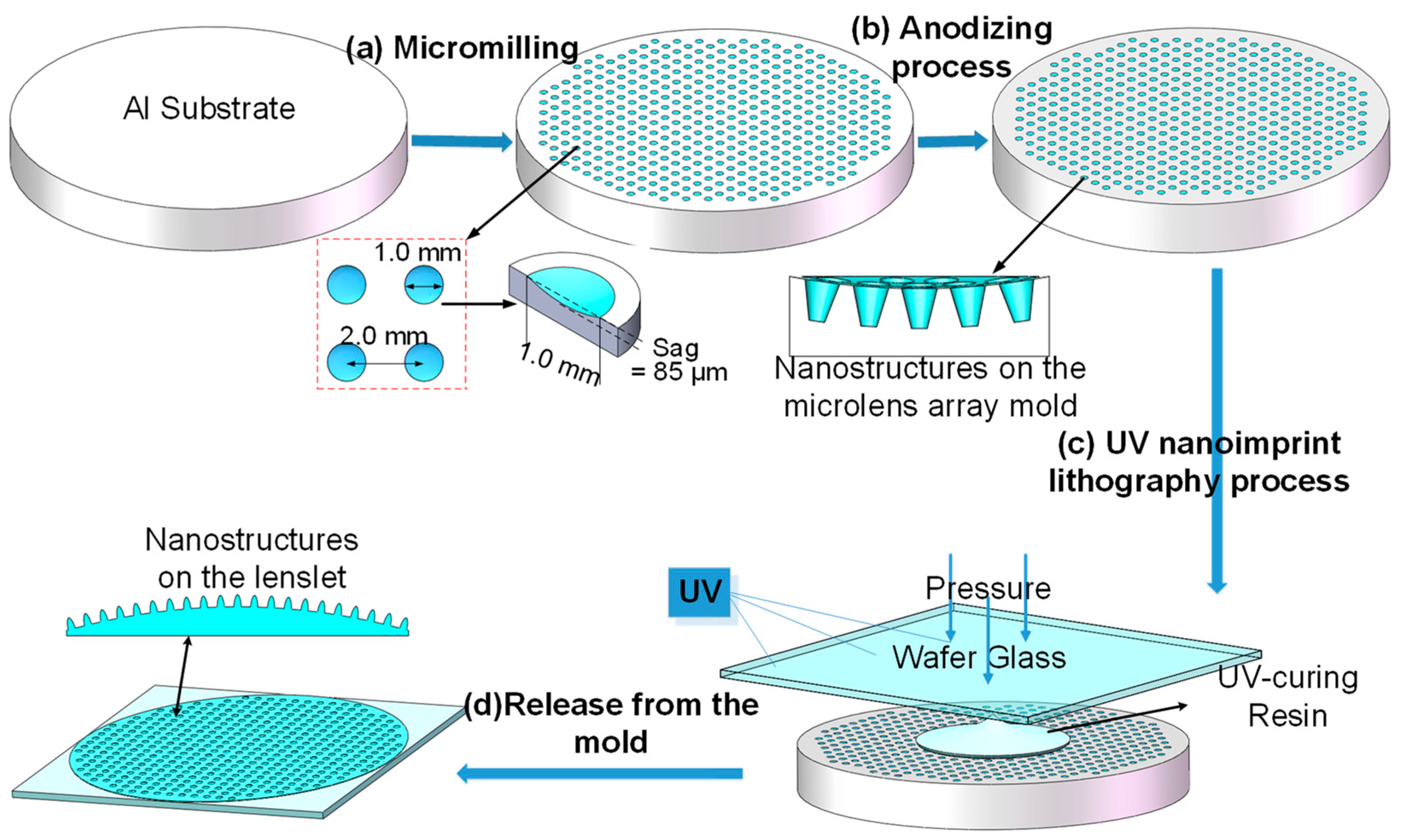

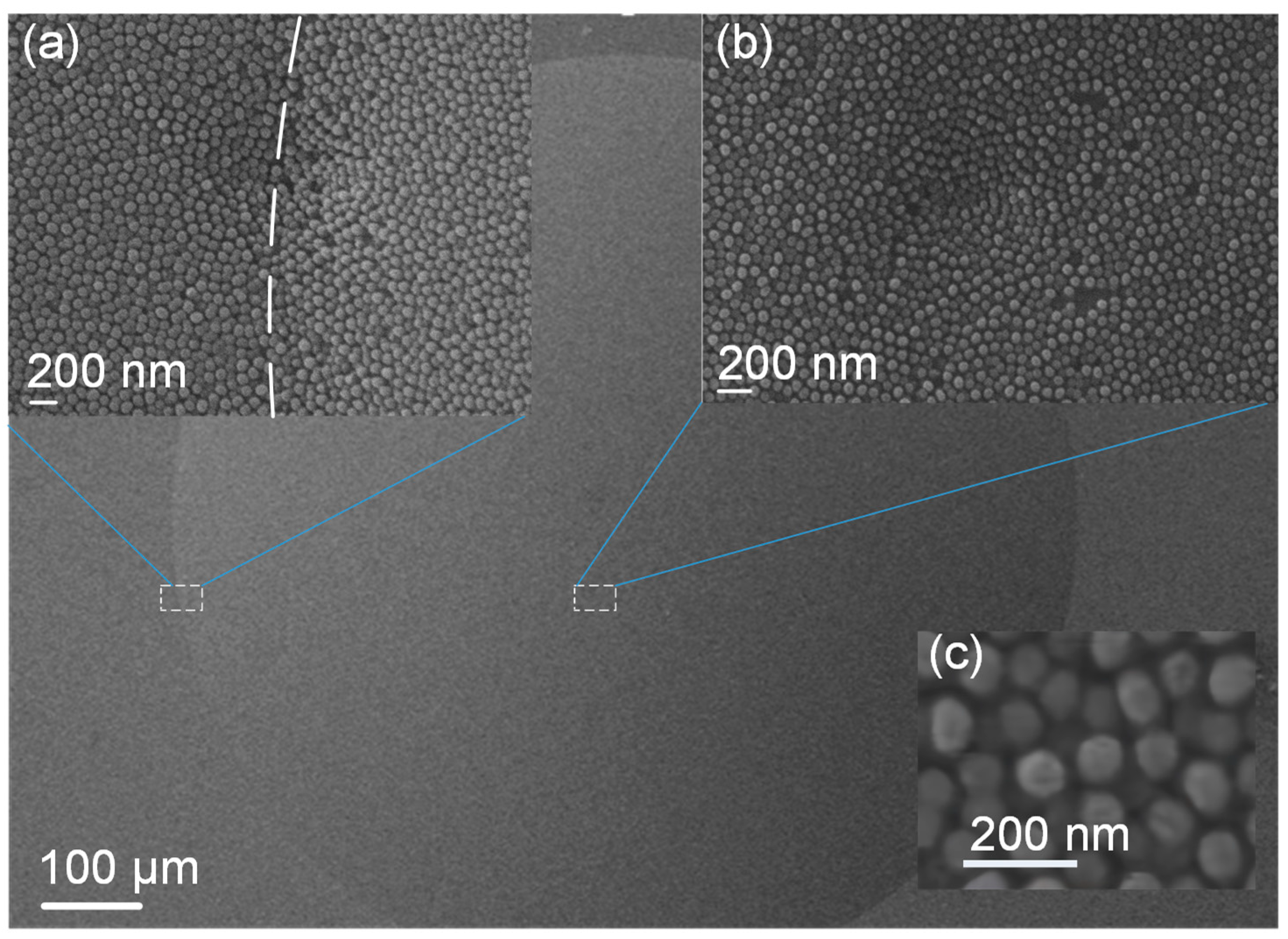

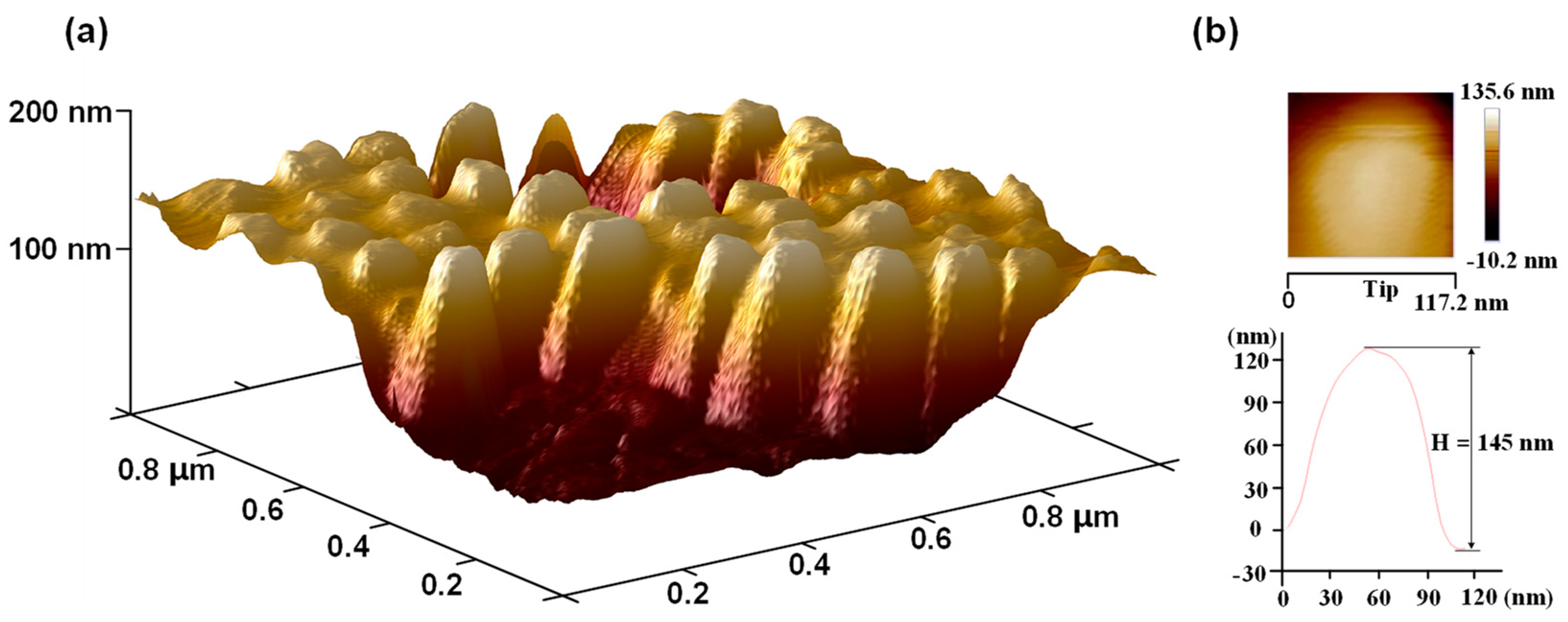

3. Fabrication Process

3.1. General Process Flow

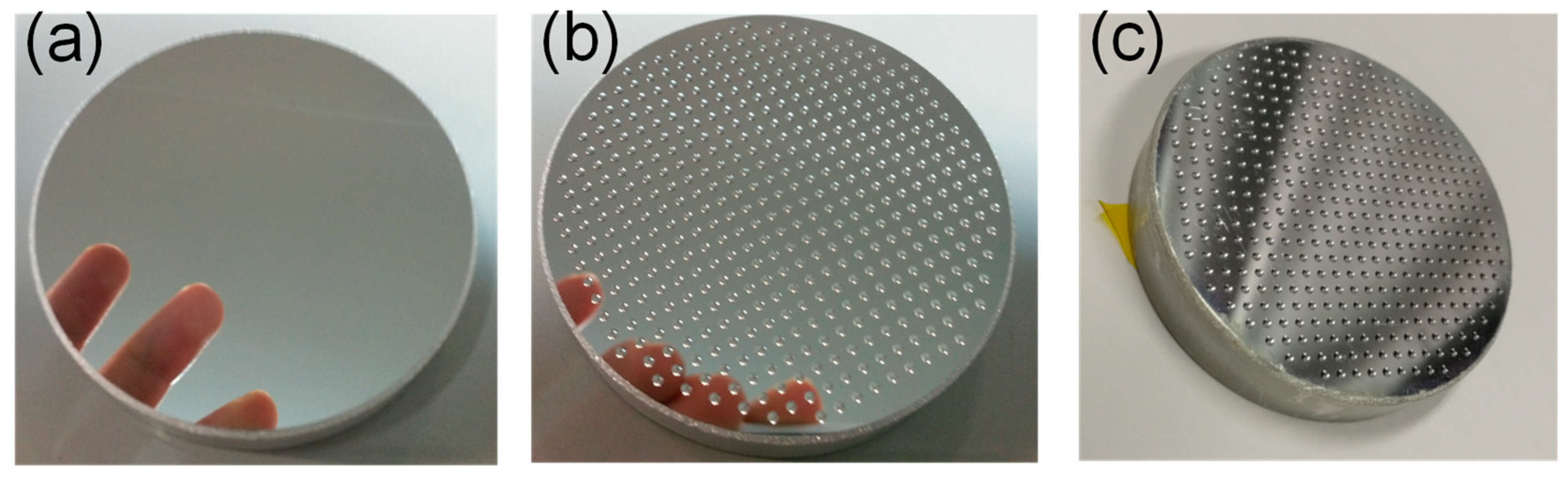

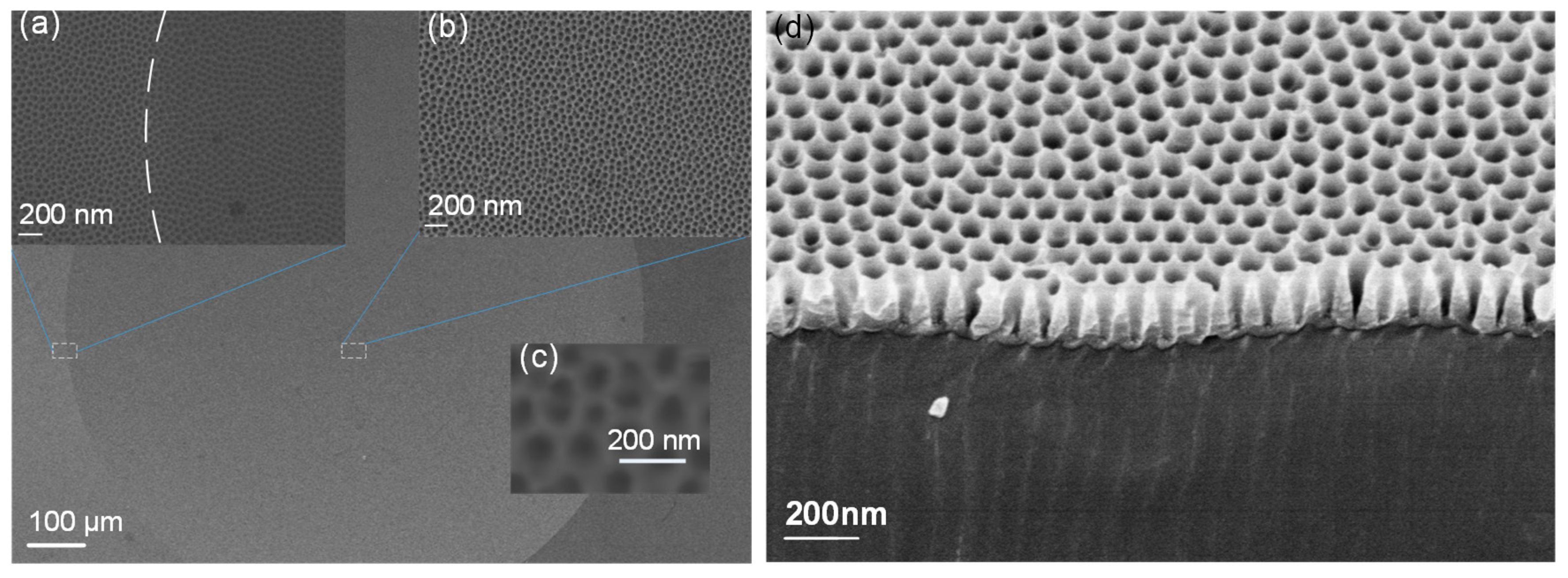

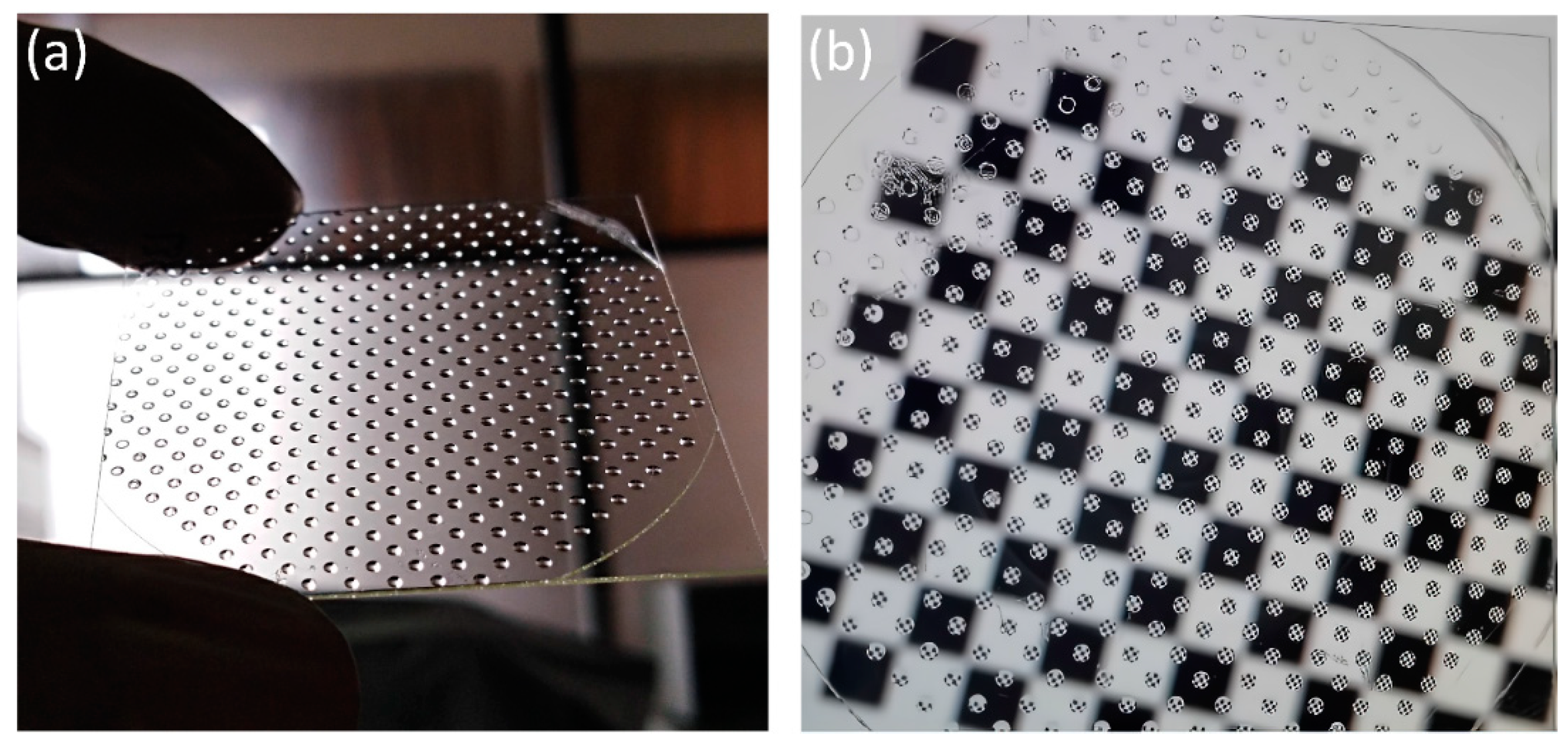

3.2. Fabrication of the Precision Hybrid-Structured Metal Wafer Mold

3.3. UV Resin-Based Nanoimprint Lithography Process

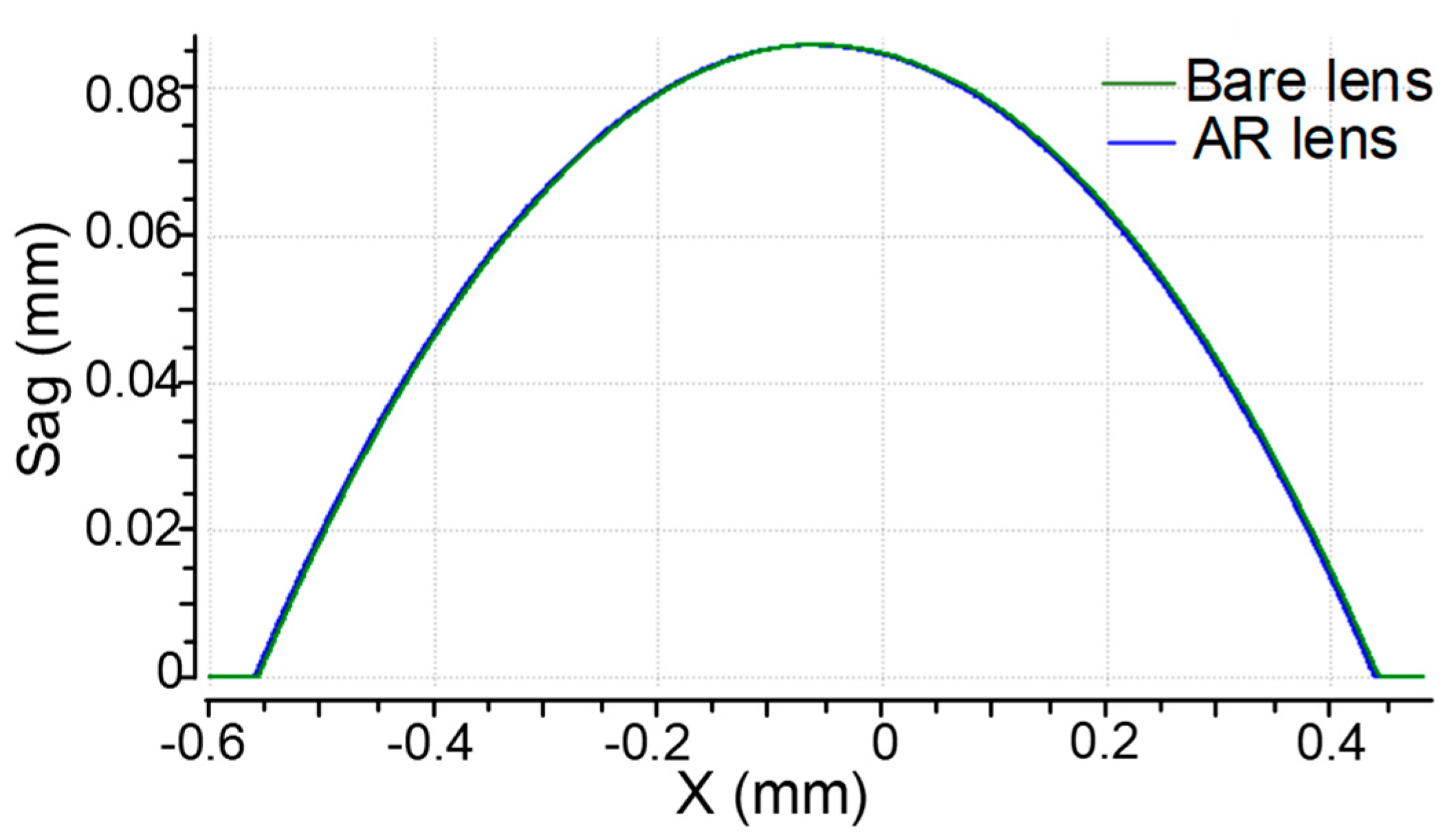

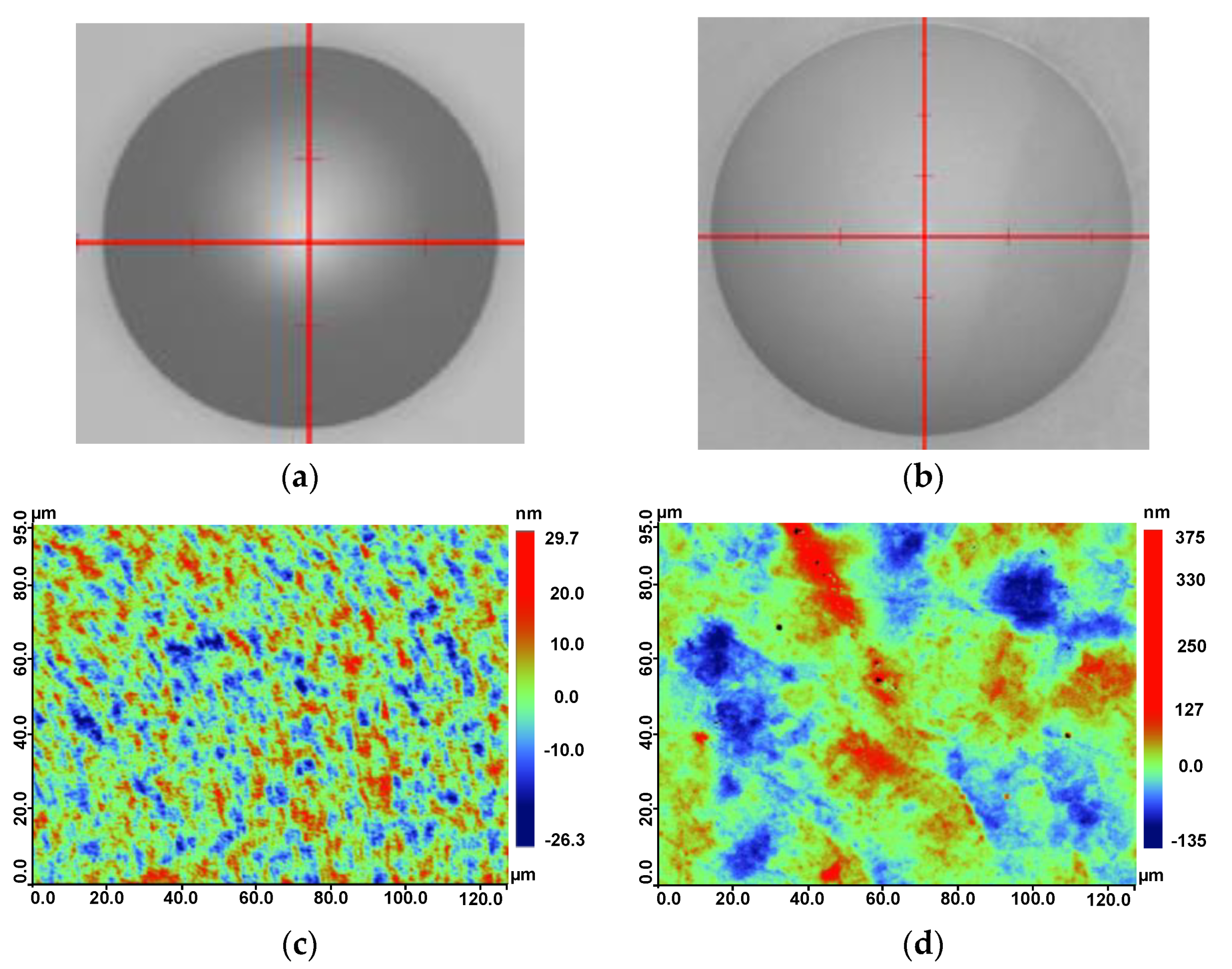

4. Sample Analysis and Discussion

5. Summary

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Dannberg, P.; Wippermann, F.; Brückner, A.; Matthes, A.; Schreiber, P.; Bräuer, A. Wafer-level hybrid integration of complex micro-optical modules. Micromachines 2014, 5, 325–340. [Google Scholar] [CrossRef]

- Raut, H.K.; Ganesh, V.A.; Nair, A.S.; Ramakrishna, S. Anti-reflective coatings: A critical, in-depth review. Energ. Environ. Sci. 2011, 4, 3779–3804. [Google Scholar] [CrossRef]

- Spinelli, P.; Verschuuren, M.A.; Polman, A. Broadband omnidirectional antireflection coating based on subwavelength surface Mie resonators. Nat. Commun. 2012, 3, 692. [Google Scholar] [CrossRef] [PubMed]

- Walheim, S.; Schaffer, E.; Mlynek, J.; Steiner, U. Nanophase-separated polymer films as high-performance antireflection coatings. Science 1999, 283, 520–522. [Google Scholar] [CrossRef] [PubMed]

- Yamada, N.; Ijiro, T.; Okamoto, E.; Hayashi, K.; Masuda, H. Characterization of antireflection moth-eye film on crystalline silicon photovoltaic module. Opt. Express 2011, 19 (Suppl. 2), A118. [Google Scholar] [CrossRef] [PubMed]

- Raut, H.K.; Dinachali, S.S.; Loke, Y.C.; Ganesan, R.; Ansah-Antwi, K.K.; Góra, A.; Khoo, E.H.; Ganesh, V.A.; Saifullah, M.S.M.; Ramakrishna, S. Multiscale ommatidial arrays with broadband and omnidirectional antireflection and antifogging properties by sacrificial layer mediated nanoimprinting. ACS Nano 2015, 9, 1305–1314. [Google Scholar]

- Jang, S.J.; Song, Y.M.; Chan, I.Y.; Chang, Y.P.; Yu, J.S.; Yong, T.L. Antireflective property of thin film a-Si solar cell structures with graded refractive index structure. Opt. Express 2011, 19 (Suppl. 2), A108. [Google Scholar] [CrossRef]

- Munday, J.N.; Atwater, H.A. Large integrated absorption enhancement in plasmonic solar cells by combining metallic gratings and antireflection coatings. Nano. Lett. 2011, 11, 2195–2201. [Google Scholar] [CrossRef]

- Perl, E.E.; Mcmahon, W.E.; Bowers, J.E.; Friedman, D.J. Design of antireflective nanostructures and optical coatings for next-generation multijunction photovoltaic devices. Opt. Express 2014, 22 (Suppl. 5), A1243. [Google Scholar] [CrossRef] [PubMed]

- Bernhard, C.G.; Miller, W.H. A corneal nipple pattern in insect compound eyes. Acta Physiol. Scand. 2010, 56, 385–386. [Google Scholar] [CrossRef] [PubMed]

- Kaless, A.; Schulz, U.; Munzert, P.; Kaiser, N. NANO-motheye antireflection pattern by plasma treatment of polymers. Surf. Coat. Tech. 2005, 200, 58–61. [Google Scholar] [CrossRef]

- Yang, L.; Feng, Q.; Ng, B.; Luo, X.; Hong, M. Hybrid moth-eye structures for enhanced broadband antireflection characteristics. Appl. Phys. Express 2010, 3, 2602. [Google Scholar] [CrossRef]

- Ji, S.; Song, K.; Nguyen, T.B.; Kim, N.; Lim, H. Optimal moth eye nanostructure array on transparent glass towards broadband antireflection. Acs Appl. Mater. Interfaces 2013, 5, 10731–10737. [Google Scholar] [CrossRef] [PubMed]

- Chidambaram, N.; Kirchner, R.; Altana, M.; Schift, H. High fidelity 3D thermal nanoimprint with UV curable polydimethyl siloxane stamps. J. Vac. Sci. Technol. B 2016, 34, 6K401. [Google Scholar] [CrossRef]

- Tan, G.; Cheng, I.; Lee, J.H.; Peng, L.H.; Wei, M.K.; Wu, S.T.; Lan, Y.H. Broadband antireflection film with moth-eye-like structure for flexible display applications. Optica 2017, 4, 678. [Google Scholar] [CrossRef]

- Leem, J.W.; Guan, X.Y.; Choi, M.; Yu, J.S. Broadband and omnidirectional highly-transparent coverglasses coated with biomimetic moth-eye nanopatterned polymer films for solar photovoltaic system applications. Sol. Energy Mat. Sol. C 2015, 134, 45–53. [Google Scholar] [CrossRef]

- Spinelli, P.; Hebbink, M.; De, W.R.; Black, L.; Lenzmann, F.; Polman, A. Optical impedance matching using coupled plasmonic nanoparticle arrays. Nano Lett. 2011, 11, 1760–1765. [Google Scholar] [CrossRef] [PubMed]

- Buencuerpo, J.; Llorens, J.M.; Dotor, M.L.; Ripalda, J.M. Broadband antireflective nano-cones for tandem solar cells. Opt. Express 2015, 23, A322. [Google Scholar] [CrossRef]

- Yongjin, W.; Fangren, H.; Yoshiaki, K.; Tong, W.; Kazuhiro, H. Large area, freestanding GaN nanocolumn membrane with bottom subwavelength nanostructure. Opt. Express 2010, 18, 5504–5511. [Google Scholar]

- Yongjin, W.; Yoshiaki, K.; Jiasheng, Y.; Hidehisa, S.; Kazuhiro, H. Fabrication and characterization of nanoscale resonant gratings on thin silicon membrane. Opt. Express 2009, 17, 4938–4943. [Google Scholar]

- Lee, Y.; Park, S.; Kim, K.; Lee, J. Fabrication of hierarchical structures on a polymer surface to mimic natural superhydrophobic surfaces. Adv. Mater. 2010, 19, 2330–2335. [Google Scholar] [CrossRef]

- Vukusic, A.P.; Sambles, J.R. Photonic structures in biology. Nature 2003, 424, 852–855. [Google Scholar] [CrossRef] [PubMed]

- Dewan, R.; Fischer, S.; Meyer-Rochow, V.B.; Özdemir, Y.; Hamraz, S.; Knipp, D. Studying nanostructured nipple arrays of moth eye facets helps to design better thin film solar cells. Bioinspir. Biomim. 2011, 7, 016003. [Google Scholar] [CrossRef]

- Ji, S.; Park, J.; Lim, H. Improved antireflection properties of moth eye mimicking nanopillars on transparent glass: Flat antireflection and color tuning. Nanoscale 2012, 4, 4603–4610. [Google Scholar] [CrossRef] [PubMed]

- Jacobsen, K.W.; Norskov, J.K.; Puska, M.J. Interatomic interactions in the effective-medium theory. Phys. Rev. B Condens. Matter. 1987, 35, 7423–7442. [Google Scholar] [CrossRef] [PubMed]

- Wu, F.; Shi, G.; Xu, H.; Liu, L.; Wang, Y.; Qi, D.; Lu, N. Fabrication of antireflective compound eyes by imprinting. Acs Appl. Mater. Interfaces 2013, 5, 12799–12803. [Google Scholar] [CrossRef]

- Solano, M.E.; Faryad, M.; Monk, P.B.; Mallouk, T.E.; Lakhtakia, A. Periodically multilayered planar optical concentrator for photovoltaic solar cells. Appl. Phys. Lett. 2013, 103, 191115. [Google Scholar] [CrossRef]

- Mousa, H.M. Antireflection coating at metamaterial waveguide structure by using superlattices (LANS). J. Mod. Phys. 2014, 5, 633–642. [Google Scholar] [CrossRef]

- Jia, Z.; Zongfu, Y.; Burkhard, G.F.; Ching-Mei, H.; Connor, S.T.; Yueqin, X.; Qi, W.; Michael, M.G.; Shanhui, F.; Yi, C. Optical absorption enhancement in amorphous silicon nanowire and nanocone arrays. Nano Lett. 2009, 9, 279–282. [Google Scholar]

- Zhu, J.; Hsu, C.M.; Yu, Z.; Fan, S.; Cui, Y. Nanodome solar cells with efficient light management and self-cleaning. Nano Lett. 2010, 10, 1979–1984. [Google Scholar] [CrossRef]

- Zhong, J.; Chen, H.; Saraf, G.; Lu, Y.; Choi, C.K.; Song, J.J.; Mackie, D.M.; Shen, H. Integrated ZnO nanotips on GaN light emitting diodes for enhanced emission efficiency. Appl. Phys. Lett. 2007, 90, 855. [Google Scholar] [CrossRef]

- Sergey, G.; Guzenko, V.A.; Joan, V.C.; Christian, D. Direct e-beam writing of dense and high aspect ratio nanostructures in thick layers of PMMA for electroplating. Nanotechnology 2010, 21, 295303. [Google Scholar]

- Colburn, M.; Johnson, S.C.; Stewart, M.D.; Damle, S.; Bailey, T.C.; Choi, B.; Wedlake, M.; Michaelson, T.B.; Sreenivasan, S.V.; Ekerdt, J.G. Step and flash imprint lithography: A new approach to high-resolution patterning. Proc. SPIE 1999, 3676, 379–389. [Google Scholar]

- Yang, S.; Liu, T.; Jiang, Z. Electromagnetic exploration of far-field super-focusing nanostructured metasurfaces. Opt. Express 2016, 24, 16297. [Google Scholar]

- Divliansky, I.; Mayera, T.S.; Holliday, K.S.; Crespi, V.H. Fabrication of three-dimensional polymer photonic crystal structures using single diffraction element interference lithography. Appl. Phys. Lett. 2003, 82, 1667–1669. [Google Scholar] [CrossRef]

- Mukaida, M.; Yan, J. Fabrication of hexagonal microlens arrays on single-crystal silicon using the tool-servo driven segment turning method. Micromachines 2017, 8, 323. [Google Scholar] [CrossRef] [PubMed]

- Chang, X.; Xu, K.; Xie, D.; Luo, S.; Shu, X.; Ding, H.; Zheng, K.; Li, B. Microforging technique for fabrication of spherical lens array mold. Int. J. Adv. Manuf. Technol. 2018, 96, 3843–3850. [Google Scholar] [CrossRef]

- Gao, P.; Liang, Z.; Wang, X.; Zhou, T.; Xie, J.; Li, S.; Shen, W. Fabrication of a micro-lens array mold by micro ball end-milling and its hot embossing. Micromachines 2018, 9, 96. [Google Scholar] [CrossRef] [PubMed]

- Xie, S.; Wan, X.; Wei, X. Fabrication of multiscale-structure wafer-level microlens array mold. Appl. Sci. 2019, 9, 487. [Google Scholar] [CrossRef]

- Keller, F.; Hunter, M.S.; Robinson, D.L. Structural features of oxide coatings on aluminum. J. Electrochem. Soc. 1953, 100, 411–419. [Google Scholar] [CrossRef]

- Huangfu, Y.; Zhan, W.; Hong, X.; Fang, X.; Ding, G.; Ye, H. Heteroepitaxy of Ge on Si(001) with pits and windows transferred from free-standing porous alumina mask. Nanotechnology 2013, 24, 185302. [Google Scholar] [CrossRef] [PubMed]

- Ding, J.; Yun, Z.; Yuan, N.; Ding, G. Reduction of nanoparticle deposition during fabrication of porous anodic alumina. Thin Solid Films 2012, 520, 4321–4325. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, S.; Wan, X.; Yang, B.; Zhang, W.; Wei, X.; Zhuang, S. Design and Fabrication of Wafer-Level Microlens Array with Moth-Eye Antireflective Nanostructures. Nanomaterials 2019, 9, 747. https://doi.org/10.3390/nano9050747

Xie S, Wan X, Yang B, Zhang W, Wei X, Zhuang S. Design and Fabrication of Wafer-Level Microlens Array with Moth-Eye Antireflective Nanostructures. Nanomaterials. 2019; 9(5):747. https://doi.org/10.3390/nano9050747

Chicago/Turabian StyleXie, Shuping, Xinjun Wan, Bo Yang, Wei Zhang, Xiaoxiao Wei, and Songlin Zhuang. 2019. "Design and Fabrication of Wafer-Level Microlens Array with Moth-Eye Antireflective Nanostructures" Nanomaterials 9, no. 5: 747. https://doi.org/10.3390/nano9050747

APA StyleXie, S., Wan, X., Yang, B., Zhang, W., Wei, X., & Zhuang, S. (2019). Design and Fabrication of Wafer-Level Microlens Array with Moth-Eye Antireflective Nanostructures. Nanomaterials, 9(5), 747. https://doi.org/10.3390/nano9050747