Ge-Sb-Te Chalcogenide Thin Films Deposited by Nanosecond, Picosecond, and Femtosecond Laser Ablation

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

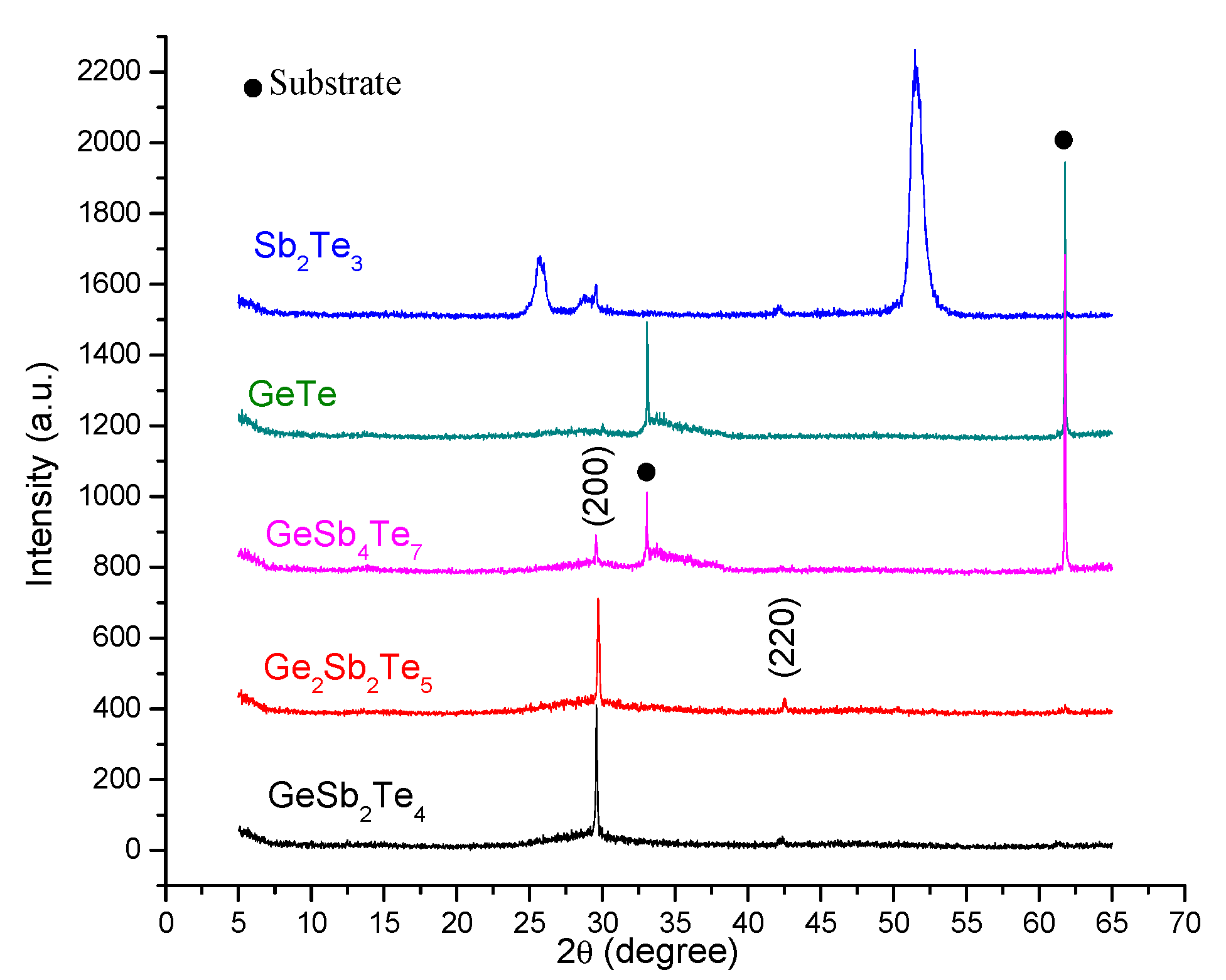

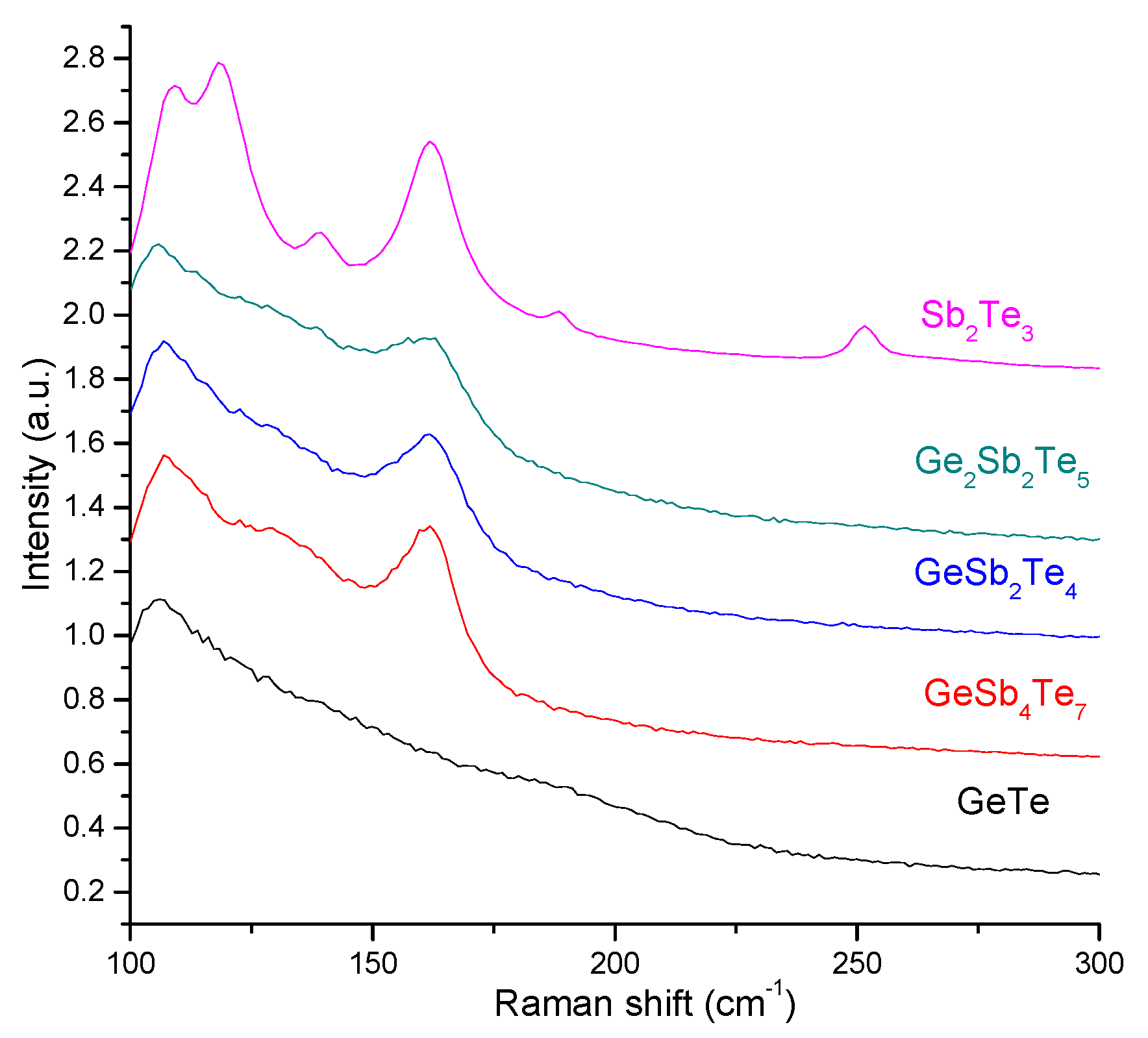

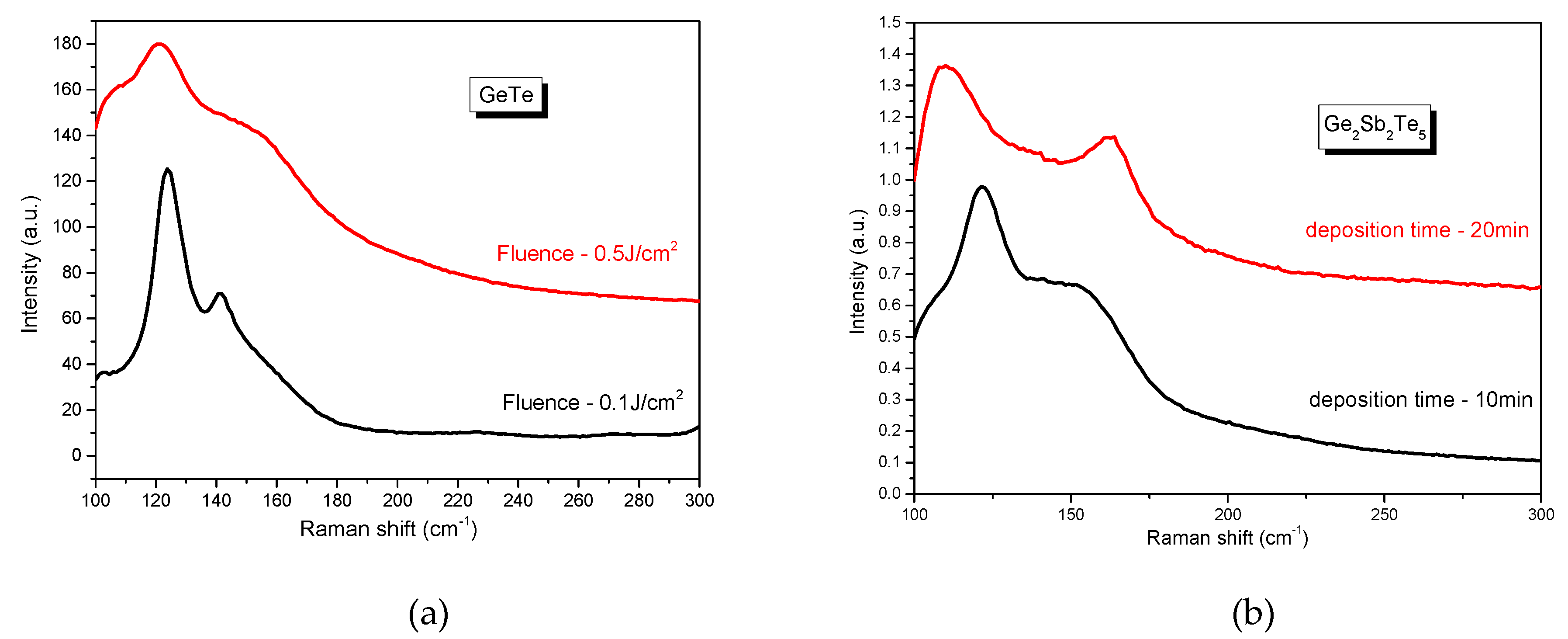

3.1. Topography, Chemical Composition, and Structural Properties

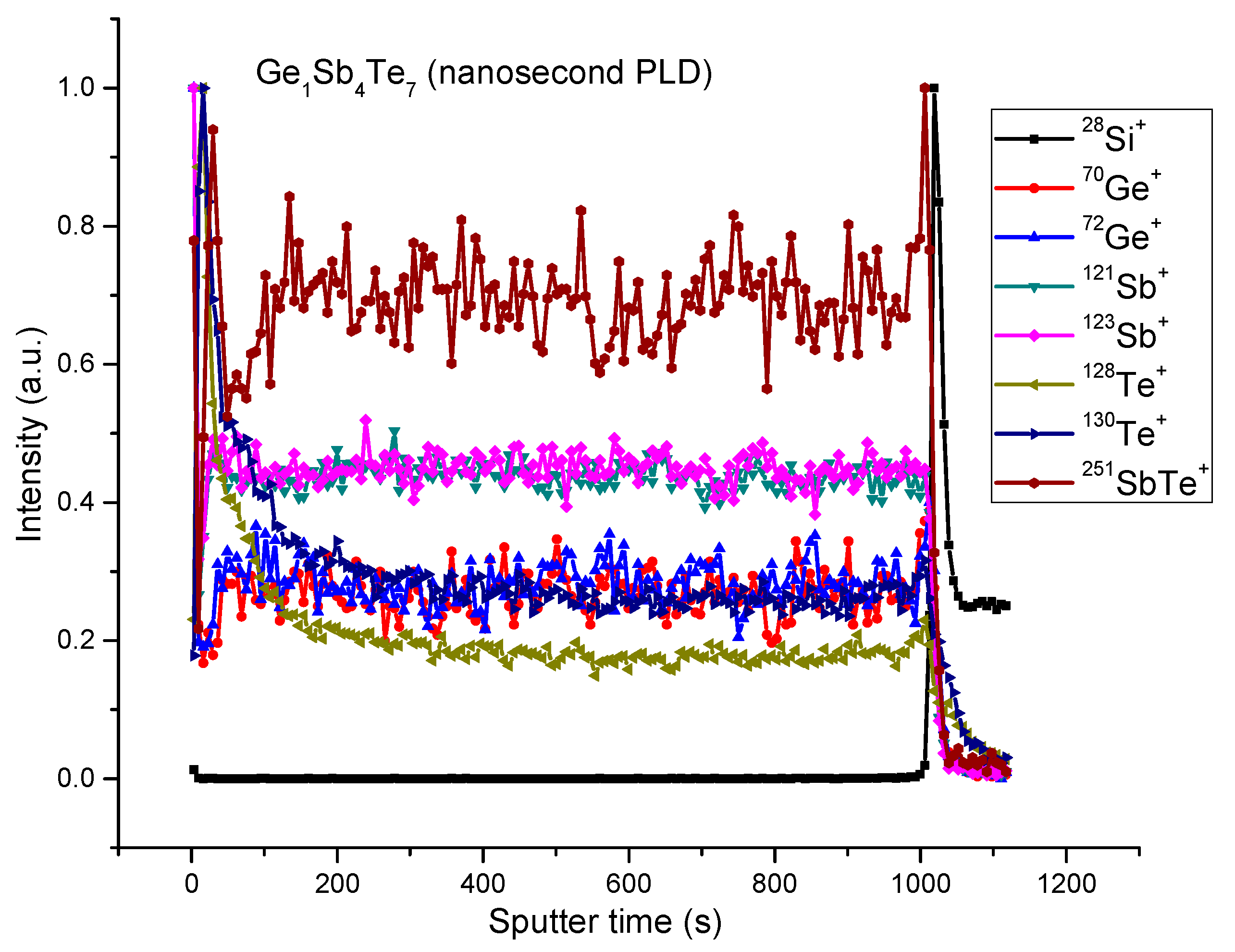

3.1.1. Nanosecond Laser Ablation

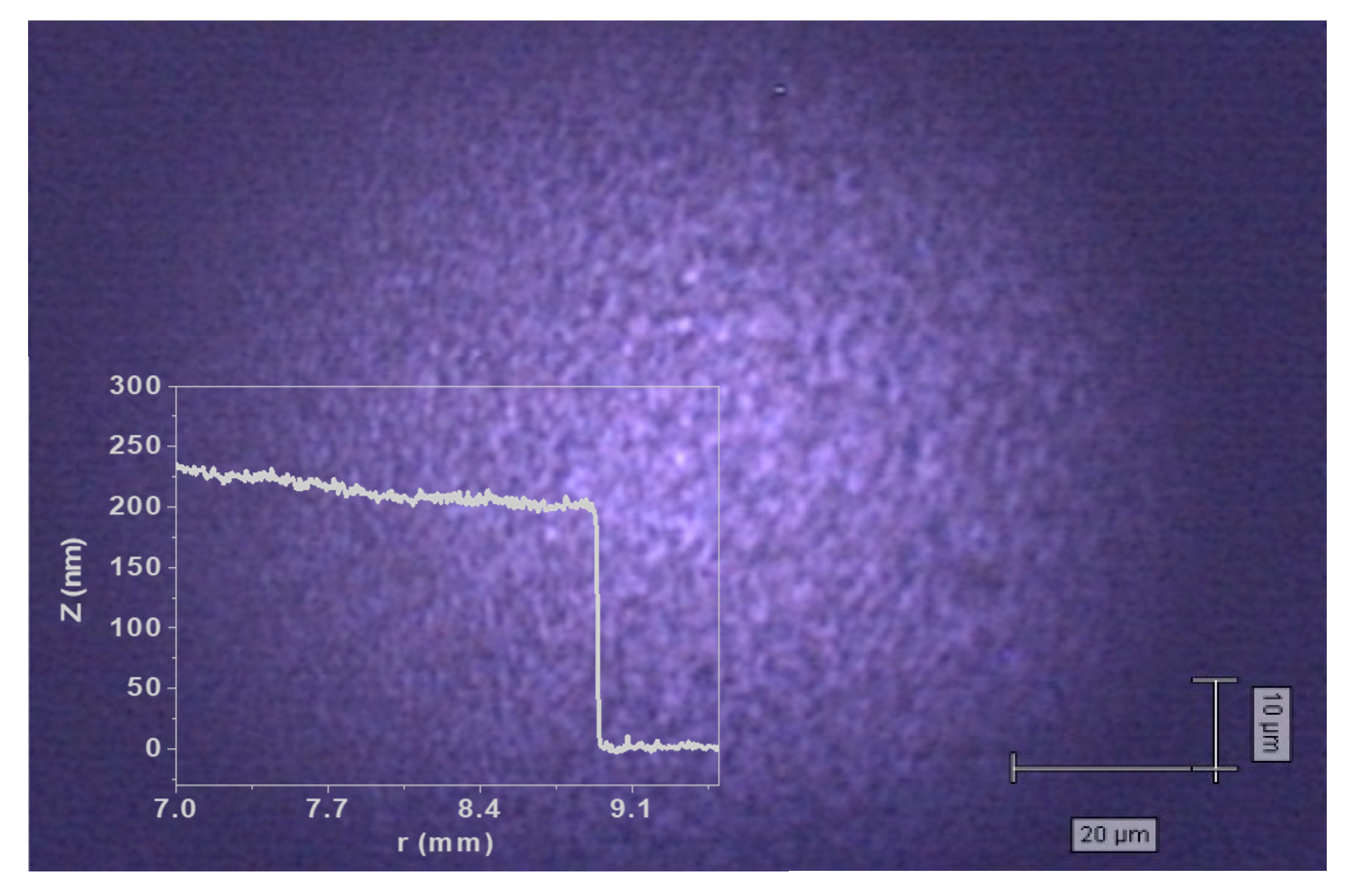

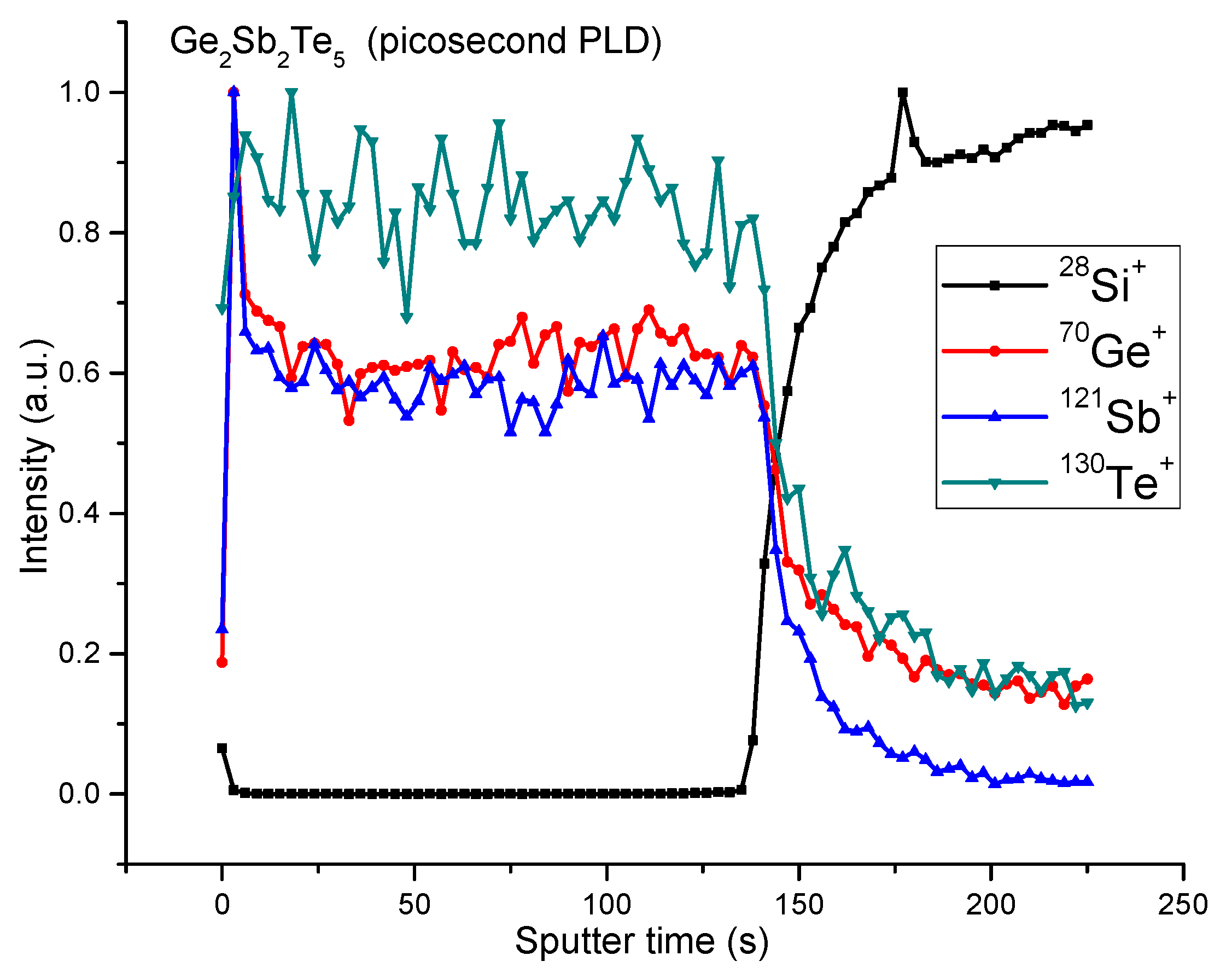

3.1.2. Femtosecond and Picosecond Laser Ablation

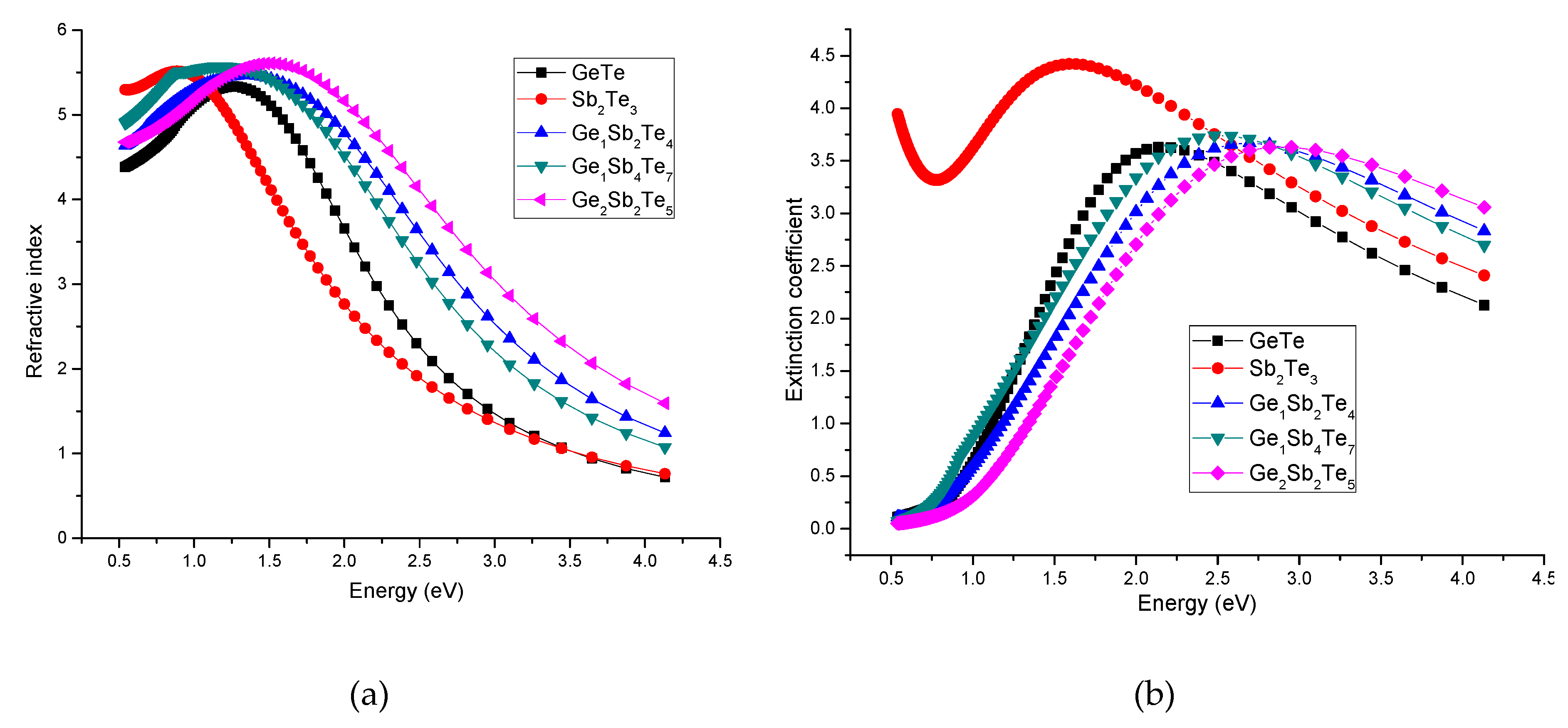

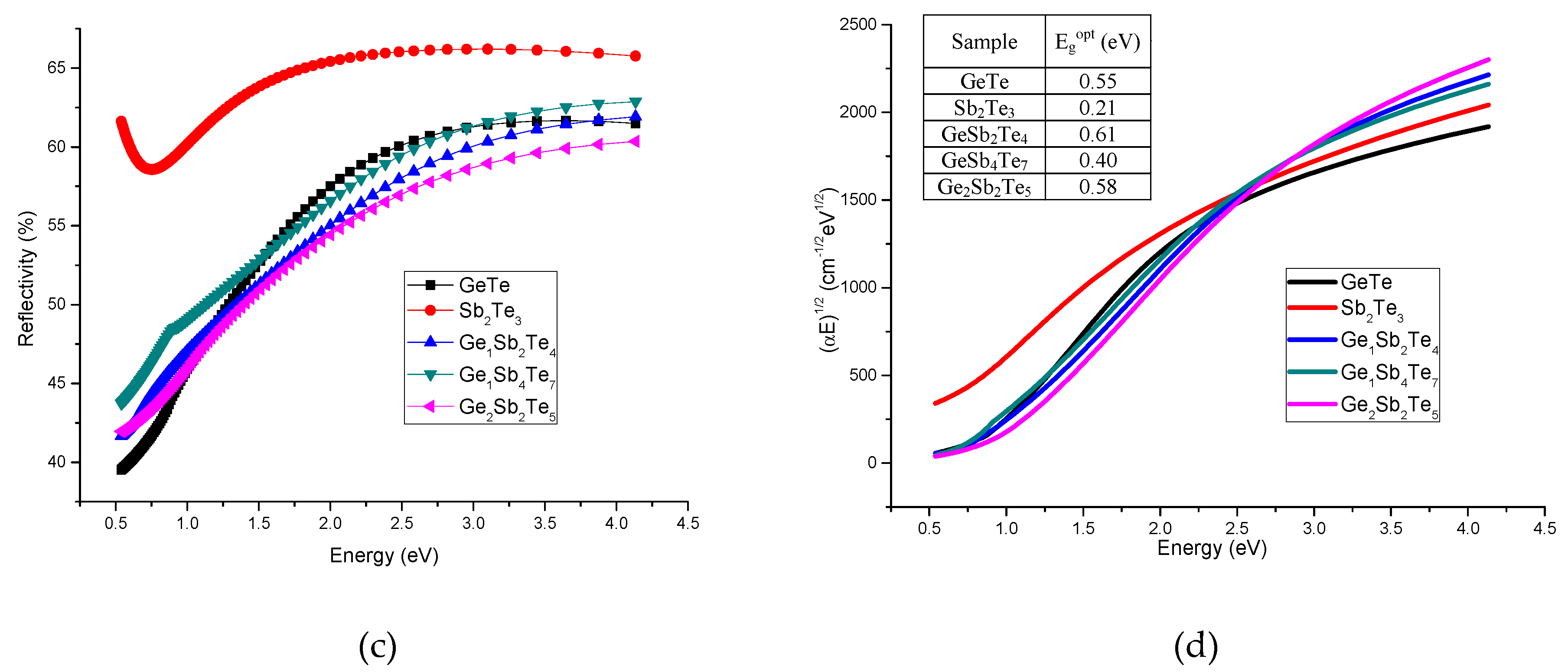

3.2. Optical Properties

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Yamada, N.; Ohno, E.; Akahira, N.; Nishiuchi, K.; Nagata, K.; Takao, M. High Speed Overwritable Phase Change Optical Disk Material. Jpn. J. Appl. Phys. 1987, 26, 61–66. [Google Scholar] [CrossRef]

- Wang, L.; Yang, C.; Wen, J.; Xiong, B. Amorphization Optimization of Ge2Sb2Te5 Media for Electrical Probe Memory Applications. Nanometer 2018, 8, 368. [Google Scholar] [CrossRef] [PubMed]

- Kolobov, A.V.; Fons, P.; Tominaga, J.; Frenkel, A.I.; Ankudinov, A.L.; Yannopoulos, S.N.; Andrikopoulos, K.S.; Uruga, T. Why Phase-Change Media Are Fast and Stable: A New Approach to an Old Problem. Jpn. J. Appl. Phys. 2005, 44, 3345–3349. [Google Scholar] [CrossRef]

- Kolobov, A.V.; Fons, P.; Tominaga, J.; Uruga, T. Why DVDs work the way they do: The nanometer-scale mechanism of phase change in Ge–Sb–Te alloys. J. Non-Cryst. Solids 2006, 352, 1612–1615. [Google Scholar] [CrossRef]

- Kolobov, A.V.; Tominaga, J. Metastability and Phase Change Phenomena. In Chalcogenides; Springer: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Nemec, P.; Nazabal, V.; Moreac, A.; Gutwirth, J.; Beneš, L.; Frumar, M. Amorphous and crystallized Ge–Sb–Te thin films deposited by pulsed laser: Local structure using Raman scattering spectroscopy. Mater. Chem. Phys. 2012, 136, 935–941. [Google Scholar] [CrossRef]

- Raoux, S.; Ielmini, D.; Wuttig, M.; Karpov, I. Phase Change Materials. MRS Bull. 2012, 37, 118–123. [Google Scholar] [CrossRef]

- Zhang, W.; Mazzarello, R.; Wuttig, M.; Ma, E. Designing crystallization in phase-change materials for universal memory and neuro-inspired computing. Nat. Rev. Mater. 2019, 4, 150–168. [Google Scholar] [CrossRef]

- Olivier, M.; Němec, P.; Boudebs, G.; Boidin, R.; Focsa, C.; Nazabal, V. Photosensitivity of pulsed laser deposited Ge-Sb-Se thin films. Opt. Mater. Express 2015, 5, 781. [Google Scholar] [CrossRef]

- Yamada, N. Origin, secret, and application of the ideal phase-change material GeSbTe. Phys. Status Solidi 2012, 249, 1837–1842. [Google Scholar] [CrossRef]

- Wang, J.J.; Xu, Y.Z.; Mazzarello, R.; Wuttig, M.; Zhang, W. A review on disorder-driven metal-insulator transition in crystalline vacancy-rich GeSbTe phase-change materials. Materials 2017, 10, 862. [Google Scholar] [CrossRef]

- Vlček, M.; Schroeter, S.; Čech, J.; Wágner, T.; Glaser, T. Selective etching of chalcogenides and its application for fabrication of diffractive optical elements. J. Non-Cryst. Solids 2003, 326–327, 515–518. [Google Scholar] [CrossRef]

- Gutwirth, J.; Wagner, T.; Bezdicka, P.; Hrdlicka, M.; Vlcek, M.; Frumar, M. On angle resolved RF magnetron sputtering of GeSbTe thin films. J. Non-Cryst. Solids 2009, 355, 1935–1938. [Google Scholar] [CrossRef]

- Nazabal, V.; Charpentier, F.; Adam, J.L.; Nemec, P.; Lhermite, H.; Brandily-Anne, M.L.; Charrier, J.; Guin, J.P.; Moréac, A. Sputtering and pulsed laser deposition for near- and mid-infrared applications: A comparative study of Ge25Sb10S65 and Ge25Sb10Se65 amorphous thin films. Int. J. Appl. Ceram. Technol. 2011, 8, 990–1000. [Google Scholar] [CrossRef]

- Musgraves, J.D.; Carlie, N.; Hu, J.; Petit, L.; Agarwal, A.; Kimerling, L.C.; Richardson, K.A. Comparison of the optical, thermal and structural properties of Ge–Sb–S thin films deposited using thermal evaporation and pulsed laser deposition techniques. Acta Mater. 2011, 59, 5032–5039. [Google Scholar] [CrossRef]

- Lee, J.; Choi, S.; Lee, C.; Kang, Y.; Kim, D. GeSbTe deposition for the PRAM application. Appl. Surf. Sci. 2007, 253, 3969–3976. [Google Scholar] [CrossRef]

- Mussler, G.; Ratajczak, A.; von der Ahe, M.; Du, H.; Grützmacher, D. Metal organic vapor phase epitaxy of Ge1Sb2Te4 thin films on Si(111) substrate. Appl. Phys. A 2019, 125, 1–7. [Google Scholar] [CrossRef]

- Hilmi, I.; Rauschenbach, B.; Gerlach, J.W.; Thelander, E.; Schumacher, P.; Gerlach, J.W.; Rauschenbach, B. Epitaxial Ge2Sb2Te5 films on Si(111) prepared by pulsed laser deposition. Thin Solid Films 2016, 619, 81–85. [Google Scholar] [CrossRef]

- Thelander, E.; Gerlach, J.W.; Ross, U.; Lotnyk, A.; Rauschenbach, B. Low temperature epitaxy of Ge-Sb-Te films on BaF2(111) by pulsed laser deposition. Appl. Phys. Lett. 2014, 105, 1–6. [Google Scholar] [CrossRef]

- Song, J.H.; Susaki, T.; Hwang, H.Y. Enhanced Thermodynamic Stability of Epitaxial Oxide Thin Films. Adv. Mater. 2008, 20, 2528–2532. [Google Scholar] [CrossRef]

- Boschker, J.E.; Folven, E.; Monsen, A.F.; Wahlström, E.; Grepstad, J.K.; Tybell, T. Consequences of high adatom energy during pulsed laser deposition of La0.7Sr0.3MnO3. Cryst. Growth Des. 2012, 12, 562–566. [Google Scholar] [CrossRef]

- Mihesan, C.; Gurlui, S.; Ziskind, M.; Chazallon, B.; Martinelli, G.; Zeghlache, H.; Guignard, M.; Nazabal, V.; Smektala, F.; Focsa, C. Photo-excited desorption of multi-component systems: Application to chalcogenide glasses. Appl. Surf. Sci. 2005, 248, 224–230. [Google Scholar] [CrossRef]

- Irimiciuc, S.; Boidin, R.; Bulai, G.; Gurlui, S.; Nemec, P.; Nazabal, V.; Focsa, C. Laser ablation of (GeSe2)100−x(Sb2Se3)x chalcogenide glasses: Influence of the target composition on the plasma plume dynamics. Appl. Surf. Sci. 2016, 418, 594–600. [Google Scholar] [CrossRef]

- Pompilian, O.G.; Gurlui, S.; Nemec, P.; Nazabal, V.; Ziskind, M.; Focsa, C. Plasma diagnostics in pulsed laser deposition of GaLaS chalcogenides. Appl. Surf. Sci. 2013, 278, 352–356. [Google Scholar] [CrossRef][Green Version]

- Ursu, C.; Pompilian, O.G.; Gurlui, S.; Nica, P.; Agop, M.; Dudeck, M.; Focsa, C. Al2O3 ceramics under high-fluence irradiation: plasma plume dynamics through space- and time-resolved optical emission spectroscopy. Appl. Phys. A 2010, 101, 153–159. [Google Scholar] [CrossRef]

- Pompilian, O.G.; Dascalu, G.; Mihaila, I.; Gurlui, S.; Olivier, M.; Nemec, P.; Nazabal, V.; Cimpoesu, N.; Focsa, C. Pulsed laser deposition of rare-earth-doped gallium lanthanum sulphide chalcogenide glass thin films. Appl. Phys. A 2014, 117, 197–205. [Google Scholar] [CrossRef]

- Dascalu, G.; Pompilian, G.; Chazallon, B.; Caltun, O.F.; Gurlui, S.; Focsa, C. Femtosecond pulsed laser deposition of cobalt ferrite thin films. Appl. Surf. Sci. 2013, 278, 38–42. [Google Scholar] [CrossRef]

- Focsa, C.; Nemec, P.; Ziskind, M.; Ursu, C.; Gurlui, S.; Nazabal, V. Laser ablation of AsxSe100−x chalcogenide glasses: Plume investigations. Appl. Surf. Sci. 2009, 255, 5307–5311. [Google Scholar] [CrossRef]

- Dascalu, G.; Pompilian, G.; Chazallon, B.; Nica, V.; Caltun, O.F.; Gurlui, S.; Focsa, C. Rare earth doped cobalt ferrite thin films deposited by PLD. Appl. Phys. A 2012, 110, 915–922. [Google Scholar] [CrossRef]

- Chrisey, D.B.; Hubler, G.K. Pulsed Laser Deposition of Thin Films; John Wiley & Sons, Inc.: New York, NY, USA, 1994. [Google Scholar]

- Nemec, P.; Přikryl, J.; Nazabal, V.; Frumar, M. Optical characteristics of pulsed laser deposited Ge–Sb–Te thin films studied by spectroscopic ellipsometry. J. Appl. Phys. 2011, 109, 073520. [Google Scholar] [CrossRef]

- Bouška, M.; Pechev, S.; Simon, Q.; Boidin, R.; Nazabal, V.; Gutwirth, J.; Baudet, E.; Němec, P. Pulsed laser deposited GeTe-rich GeTe-Sb2Te3 thin films. Sci. Rep. 2016, 6, 26552. [Google Scholar] [CrossRef]

- Krusin-Elbaum, L.; Cabral, C.; Chen, K.N.; Copel, M.; Abraham, D.W.; Reuter, K.B.; Rossnagel, S.M.; Bruley, J.; Deline, V.R. Evidence for segregation of Te in Ge2Sb2Te5 films: Effect on the “phase-change” stress. Appl. Phys. Lett. 2007, 90, 141902. [Google Scholar] [CrossRef]

- Prokhorov, E.; Gonzalez-Hernandez, J.; Hernandez-Landaverde, M.A.; Chao, B.; Morales-Sanchez, E. Crystallization mechanism in Sb:Te thin film.pdf. J. Phys. Chem. Solids 2007, 68, 883–886. [Google Scholar] [CrossRef]

- Andrikopoulos, K.S.; Yannopoulos, S.N.; Voyiatzis, G.A.; Kolobov, A.V.; Ribes, M.; Tominaga, J. Raman scattering study of the a-GeTe structure and possible mechanism for the amorphous to crystal transition. J. Phys. Condens. Matter 2006, 18, 965–979. [Google Scholar] [CrossRef]

- Sosso, G.C.; Caravati, S.; Bernasconi, M. Vibrational properties of crystalline Sb2Te3 from first principles. J. Phys. Condens. Matter 2009, 21, 095410. [Google Scholar] [CrossRef] [PubMed]

- Xu, Z.; Chen, C.; Wang, Z.; Wu, K.; Chong, H.; Ye, H. Optical constants acquisition and phase change properties of Ge2Sb2Te5 thin films based on spectroscopy. RSC Adv. 2018, 8, 21040–21046. [Google Scholar] [CrossRef]

- Murray, M.; Jose, G.; Richards, B.; Jha, A. Femtosecond pulsed laser deposition of silicon thin films. Nanoscale Res. Lett. 2013, 8, 1–6. [Google Scholar] [CrossRef]

- Katsuno, T.; Godet, C.; Orlianges, J.C.; Loir, A.S.; Garrelie, F.; Catherinot, A. Optical properties of high-density amorphous carbon films grown by nanosecond and femtosecond pulsed laser ablation. Appl. Phys. A 2005, 81, 471–476. [Google Scholar] [CrossRef]

- Anoop, K.K.; Harilal, S.S.; Philip, R.; Bruzzese, R.; Amoruso, S. Laser fluence dependence on emission dynamics of ultrafast laser induced copper plasma. J. Appl. Phys. 2016, 120, 185901. [Google Scholar] [CrossRef]

- Anoop, K.K.; Ni, X.; Wang, X.; Amoruso, S.; Bruzzese, R. Fast ion generation in femtosecond laser ablation of a metallic target at moderate laser intensity. Laser Phys. 2014, 24, 105902. [Google Scholar] [CrossRef]

- Irimiciuc, S.A.; Gurlui, S.; Bulai, G.; Nica, P.; Agop, M.; Focsa, C. Langmuir probe investigation of transient plasmas generated by femtosecond laser ablation of several metals: Influence of the target physical properties on the plume dynamics. Appl. Surf. Sci. 2017, 417, 108–118. [Google Scholar] [CrossRef]

- Nica, P.; Gurlui, S.; Osiac, M.; Agop, M.; Ziskind, M.; Focsa, C. Investigation of femtosecond laser-produced plasma from various metallic targets using the Langmuir probe characteristic. Phys. Plasmas 2017, 24, 103119. [Google Scholar] [CrossRef]

- Vinod, E.M.; Singh, A.K.; Ganesan, R.; Sangunni, K.S. Effect of selenium addition on the GeTe phase change memory alloys. J. Alloys Compd. 2012, 537, 127–132. [Google Scholar] [CrossRef]

- Vinod, E.M.; Naik, R.; Ganesan, R.; Sangunni, K.S. Signatures of Ge2Sb2Te5 film at structural transitions. J. Non-Cryst. Solids 2012, 358, 2927–2930. [Google Scholar] [CrossRef]

- Van Eijk, J.M. Structural Analysis of Phase-Change Materials Using X-ray Absorption Measurements. Ph.D. Thesis, RWTH Aachen University, Aachen, Germany, 17 December 2010. [Google Scholar]

- Wei, S.; Wu, S.; Pei, F.; Li, J.; Wang, S.; Chen, L. Theoretical and Experimental Investigations of the Optical Properties of Ge2Sb2Te5 for Multi-State Optical Data Storage. J. Korean Phys. Soc. 2008, 53, 2265–2269. [Google Scholar]

- Hilton, A.R. Chalcogenide Glasses for Infrared. Optical Materials. Appl. Opt. 1966, 5, 1877–1882. [Google Scholar] [CrossRef] [PubMed]

- Nechache, R.; Harnagea, C.; Li, S.; Cardenas, L.; Huang, W.; Chakrabartty, J.; Rosei, F. Bandgap tuning of multiferroic oxide solar cells. Nat. Photonics 2014, 61, 61–67. [Google Scholar] [CrossRef]

- Nemec, P.; Moreac, A.; Nazabal, V.; Pavlišta, M.; Přikryl, J.; Frumar, M. Ge-Sb-Te thin films deposited by pulsed laser An ellipsometry and Raman scattering spectroscopy study. J. Appl. Phys. 2009, 106, 103509. [Google Scholar] [CrossRef]

- Lee, B.-S.; Abelson, J.R.; Bishop, S.G.; Kang, D.-H.; Cheong, B.; Kim, K.-B. Investigation of the optical and electronic properties of Ge2Sb2Te5 phase change material in its amorphous, cubic, and hexagonal phases. J. Appl. Phys. 2005, 97, 093509. [Google Scholar] [CrossRef]

| Target Nominal at% Composition | Thickness (nm) | EDS Measured Thin Film Composition (at%) | ||

|---|---|---|---|---|

| Ge | Sb | Te | ||

| GeTeGe 50Te50 | 600 | 62.68 | - | 37.32 |

| Sb2Te3 Sb40Te60 | 620 | - | 48.78 | 51.22 |

| GeSb2Te4 Ge14.28Sb28.57Te57.14 | 600 | 13.14 | 35.78 | 51.08 |

| GeSb4Te7 Ge8.33Sb33.33Te58.33 | 600 | 9.57 | 39.8 | 50.63 |

| Ge2Sb2Te5 Ge22.22Sb22.22Te55.55 | 690 | 12.75 | 31.81 | 55.45 |

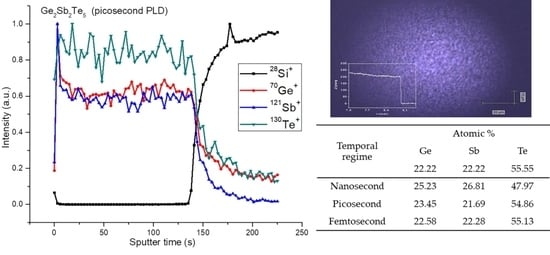

| Pulse Duration | Deposition Conditions | Nominal Composition | ||

|---|---|---|---|---|

| Atomic % | ||||

| Ge | Sb | Te | ||

| 22.22 | 22.22 | 55.55 | ||

| Nanosecond | Nd-YAG laser (266 nm); Target-to-substrate distance = 3 cm; Fluence = 3.8 J/cm2 Deposition time = 30 min | 25.23 | 26.81 | 47.97 |

| Picosecond | Ti-Sa laser; Target-to-substrate distance = 4 cm; Fluence = 0.3 J/cm2; Deposition time = 60 min | 23.45 | 21.69 | 54.86 |

| Femtosecond | Ti-Sa laser; Target-to-substrate distance = 4 cm; Fluence = 0.3 J/cm2; Deposition time = 30 min | 22.58 | 22.28 | 55.13 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bulai, G.; Pompilian, O.; Gurlui, S.; Nemec, P.; Nazabal, V.; Cimpoesu, N.; Chazallon, B.; Focsa, C. Ge-Sb-Te Chalcogenide Thin Films Deposited by Nanosecond, Picosecond, and Femtosecond Laser Ablation. Nanomaterials 2019, 9, 676. https://doi.org/10.3390/nano9050676

Bulai G, Pompilian O, Gurlui S, Nemec P, Nazabal V, Cimpoesu N, Chazallon B, Focsa C. Ge-Sb-Te Chalcogenide Thin Films Deposited by Nanosecond, Picosecond, and Femtosecond Laser Ablation. Nanomaterials. 2019; 9(5):676. https://doi.org/10.3390/nano9050676

Chicago/Turabian StyleBulai, Georgiana, Oana Pompilian, Silviu Gurlui, Petr Nemec, Virginie Nazabal, Nicanor Cimpoesu, Bertrand Chazallon, and Cristian Focsa. 2019. "Ge-Sb-Te Chalcogenide Thin Films Deposited by Nanosecond, Picosecond, and Femtosecond Laser Ablation" Nanomaterials 9, no. 5: 676. https://doi.org/10.3390/nano9050676

APA StyleBulai, G., Pompilian, O., Gurlui, S., Nemec, P., Nazabal, V., Cimpoesu, N., Chazallon, B., & Focsa, C. (2019). Ge-Sb-Te Chalcogenide Thin Films Deposited by Nanosecond, Picosecond, and Femtosecond Laser Ablation. Nanomaterials, 9(5), 676. https://doi.org/10.3390/nano9050676