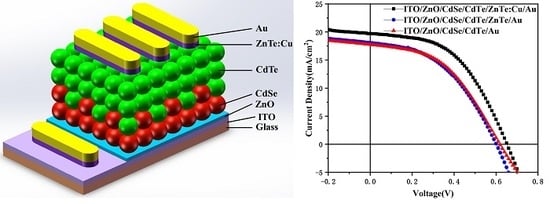

The Effects of ZnTe:Cu Back Contact on the Performance of CdTe Nanocrystal Solar Cells with Inverted Structure

Abstract

:1. Introduction

2. Experiments

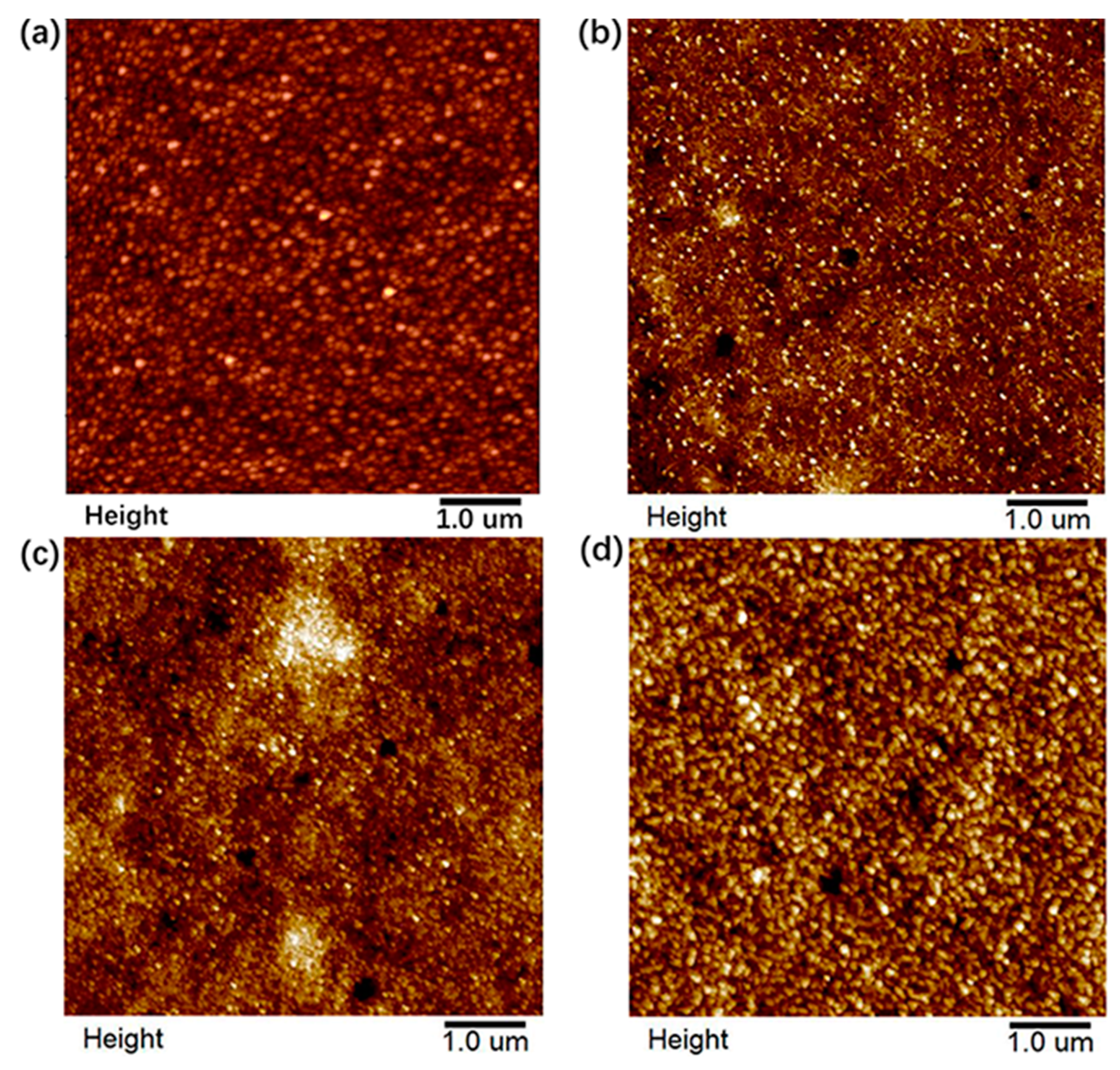

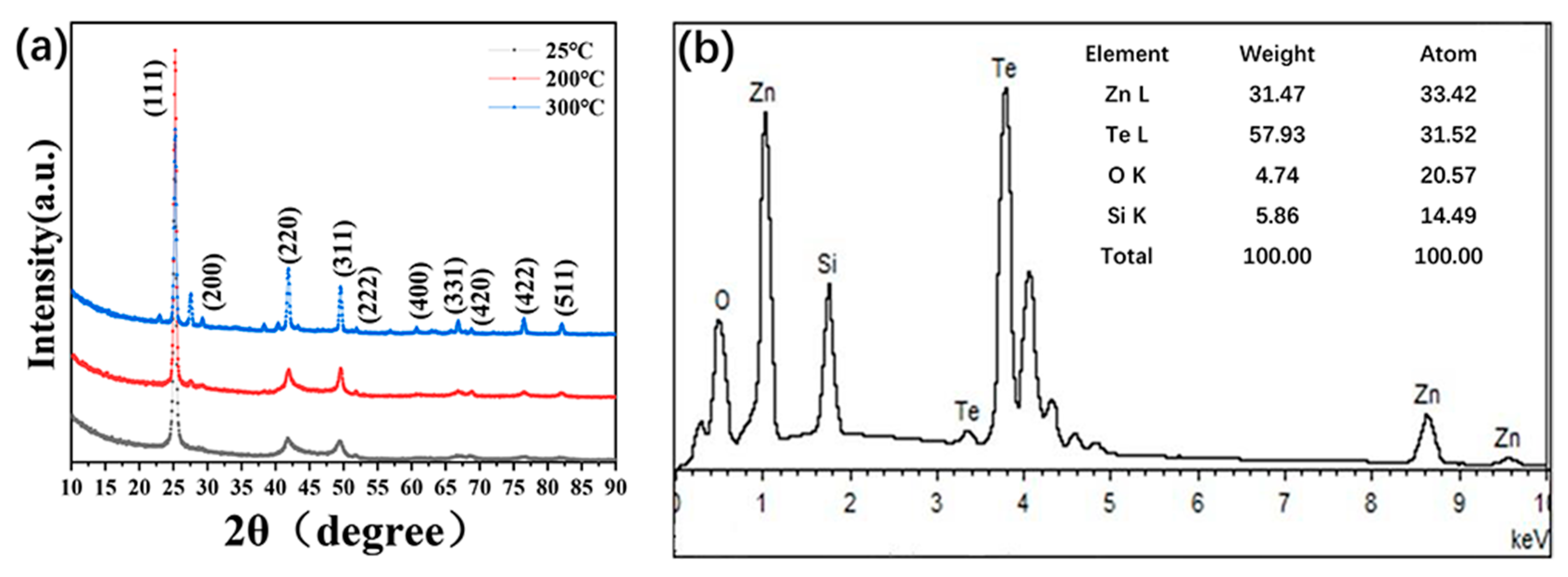

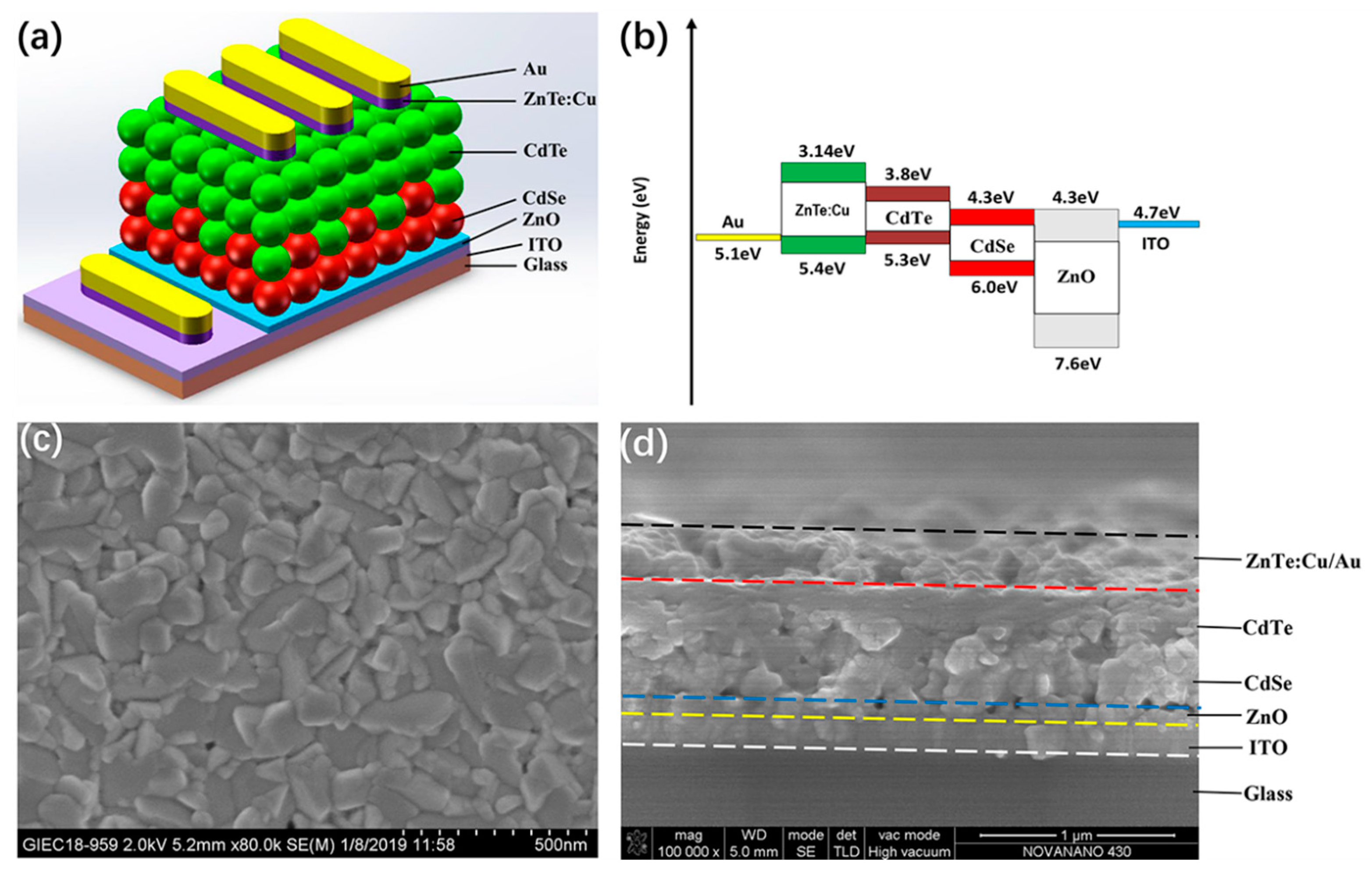

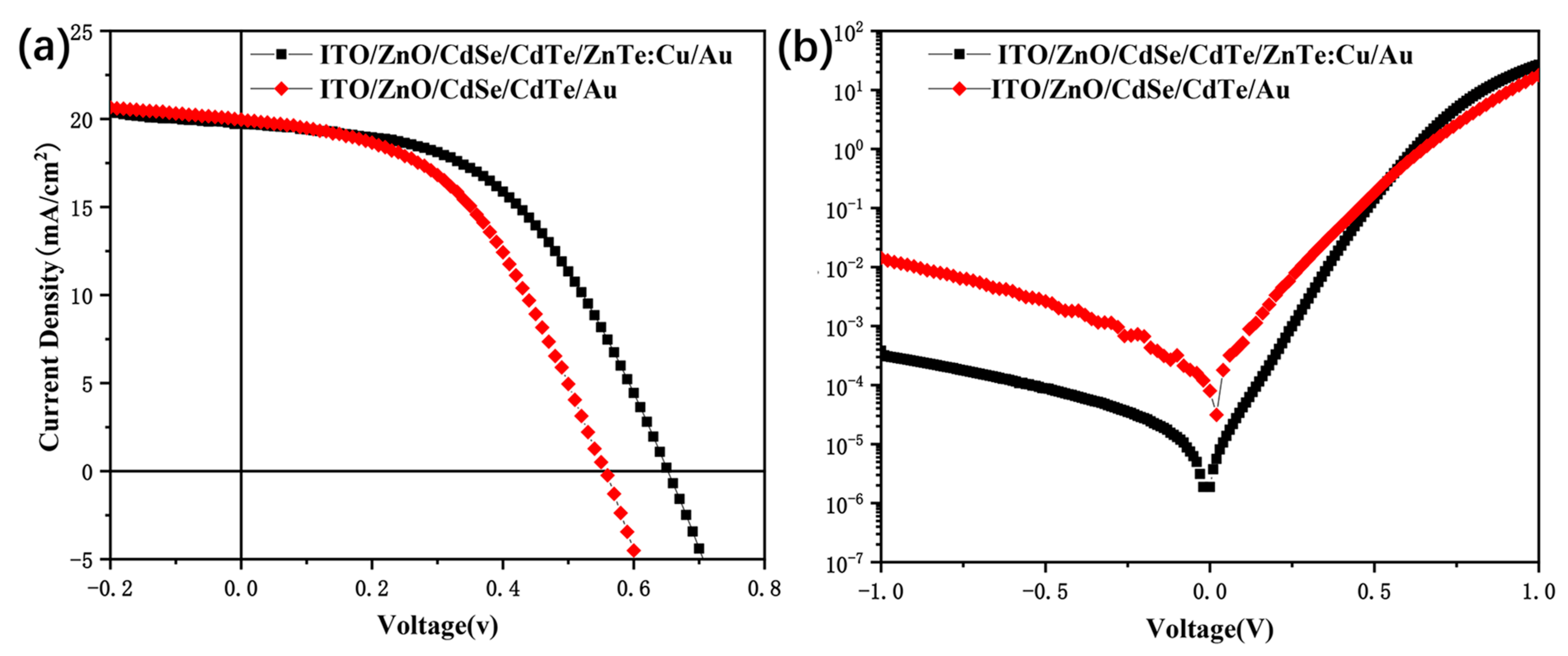

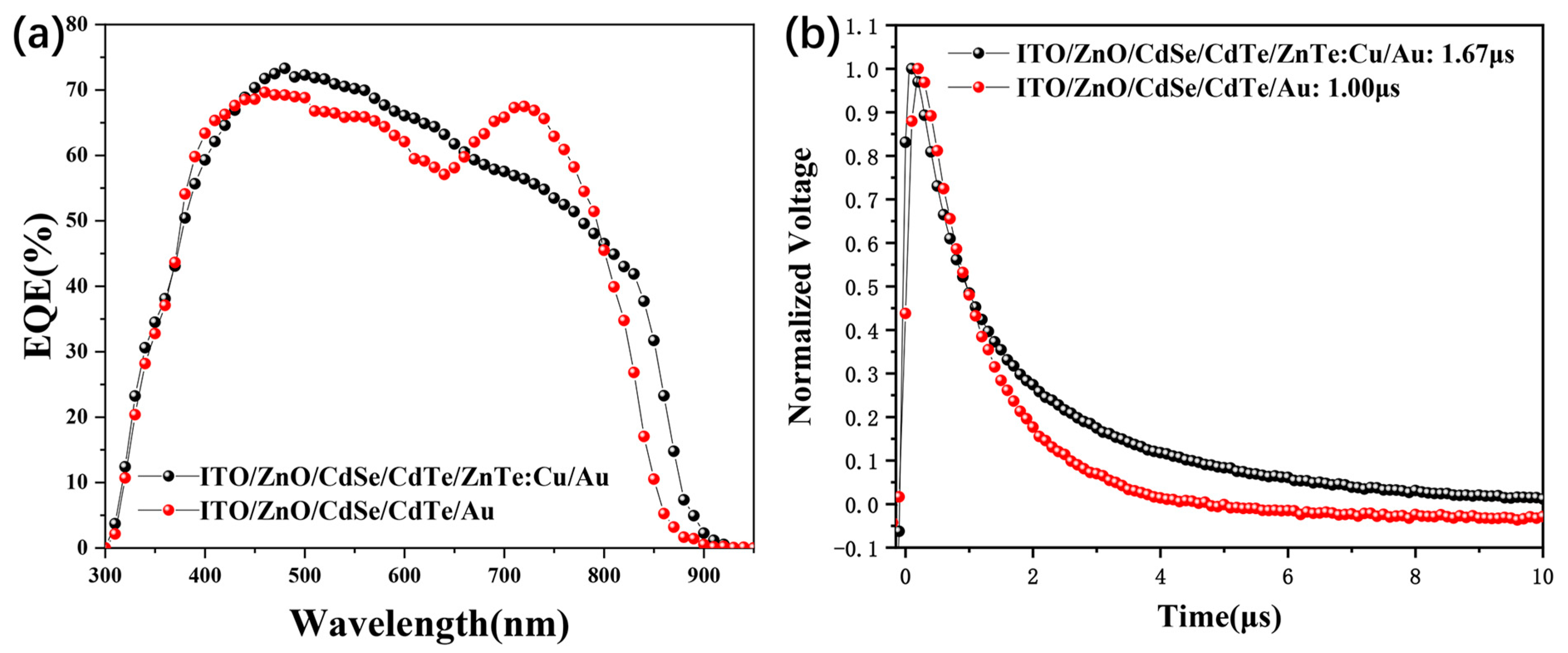

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Morales-Acevedo, A. Physical basis for the design of Cds/CdTe thin film solar cells. Sol. Energy Mater. Sol. Cells 2006, 90, 678–685. [Google Scholar] [CrossRef]

- Woodhouse, M.; Goodrich, A.; Margolis, R.; James, T.; Dhere, R.; Gessert, T.; Barnes, T.; Eggert, R.; Albin, D. Perspectives on the pathways for cadmium telluride photovoltaic module manufacturers to address expected increases in the price for tellurium. Sol. Mater. Sol. Cells 2013, 115, 199–212. [Google Scholar] [CrossRef]

- Green, M.A.; Emery, K.; Hishikawa, Y.; Warta, W.; Dunlop, E.D.; Levi, D.H.; Ho-Baillie, A.W.Y. Solar cell efficiency tables (version 49). Prog. Photovolt. Res. Appl. 2017, 25, 3–13. [Google Scholar] [CrossRef]

- Fahrenbruch, A.L. Ohmic contacts and doping of CdTe. Sol. Cells 1987, 21, 399–412. [Google Scholar] [CrossRef]

- Paudel, N.R.; Compaan, A.D.; Yan, Y. Sputtered CdS/CdTe solar cells with MoO3−X/Au back contacts. J. Electr. Mater. 2013, 113, 26–30. [Google Scholar]

- Zhang, M.; Qiu, L.; Li, W.; Zhang, J.; Wu, L.; Feng, L. Copper doping of MoOx thin films for CdTe solar cells. Mater. Sci. Semicond. Process. 2018, 86, 49–57. [Google Scholar] [CrossRef]

- Paudel, N.R.; Xiao, C.; Yan, Y. CdS/CdTe thin-film solar cells with Cu-free transition metal oxide/Au back contacts. Prog. Photovolt. Res. Appl. 2015, 23, 437–442. [Google Scholar] [CrossRef]

- Paudel, N.R.; Yan, Y. Application of copper thiocyanate for high open-circuit voltages of CdTe solar cells. Prog. Photovolt. Res. Appl. 2016, 24, 94–101. [Google Scholar] [CrossRef]

- Paudel, N.R.; Yan, Y. CdTe thin-film solar cells with cobalt-phthalocyanine back contacts. Appl. Phys. Lett. 2014, 104, 1–9. [Google Scholar] [CrossRef]

- Fiederle, M.; Ebling, D.; Eiche, C.; Hug, P.; Joerger, W.; Laasch, M.; Schwarz, R.; Salk, M.; Benz, K. Studies of the compensation mechanism in CdTe grown from the vapour phase. J. Cryst. Growth 1995, 146, 142–147. [Google Scholar] [CrossRef]

- Wang, T.; Du, S.; Li, W.; Liu, C.; Zhang, J.; Wu, L.; Li, B.; Zeng, G. Control of Cu doping and CdTe/Te interface modification for CdTe solar cells. Mater. Sci. Semicond. Process. 2017, 72, 46–51. [Google Scholar] [CrossRef]

- Kuhn, T.A.; Ossau, W.; Waag, A.; Bicknell-Tassius, R.N.; Landwehr, G. Evidence of a deep donor in CdTe. J. Cryst. Growth 1992, 117, 660–665. [Google Scholar] [CrossRef]

- Biglari, B.; Samimi, M.; Hageali, M.; Koebel, J.M.; Siffert, P. Effect of copper in high resistivity cadmium telluride. J. Cryst. Growth 1998, 89, 428–434. [Google Scholar] [CrossRef]

- Desnica, U.V. Doping Limits in II–VI Compounds-Challenenges, Problems and Solutions. Prog. Cryst. Growth Charact. Mater. 1998, 36, 291–357. [Google Scholar] [CrossRef]

- Jones, E.D.; Stewart, N.M.; Mullin, J.B. The diffusion of copper in cadmium telluride. J. Cryst. Growth 1992, 117, 244–248. [Google Scholar] [CrossRef]

- Yang, B.; Ishikawa, Y.; Miki, T.; Doumae, Y.; Isshiki, M. Aging behavior of some residual impurities in CdTe single crystals. J. Cryst. Growth 1997, 179, 410–414. [Google Scholar] [CrossRef]

- Ahn, B.T.; Yun, J.H.; Cha, E.S.; Park, K.C. Understanding the junction degradation mechanism in CdS/CdTe solar cells using a Cd-deficient CdTe layer. Curr. Appl. Phys. 2012, 12, 174–178. [Google Scholar] [CrossRef]

- Han, J.; Fan, C.; Spanheimer, C.; Fu, G.; Zhao, K.; Klein, A.; Jaegermann, W. Electrical properties of the CdTe back contact: A new chemically etching process based on nitric acid/acetic acid mixtures. Appl. Surf. Sci. 2010, 256, 5803–5806. [Google Scholar] [CrossRef]

- Durose, K.; Edwards, P.R.; Halliday, D.P. Materials aspects of CdTe/CdS solar cells. J. Cryst. Growth 1999, 197, 733–742. [Google Scholar] [CrossRef]

- Uličná, S.; Isherwood, P.J.M.; Kaminski, P.M.; Walls, J.M.; Li, J.; Wolden, C.A. Development of ZnTe as a back contact material for thin film cadmium telluride solar cells. Vacuum 2017, 139, 159–163. [Google Scholar] [CrossRef] [Green Version]

- Gul, Q.; Zakria, M.; Khan, T.M.; Mahmood, A.; Iqbal, A. Effects of Cu incorporation on physical properties of ZnTe thin films deposited by thermal evaporation. Mater. Sci. Semicond. Process. 2014, 19, 17–23. [Google Scholar] [CrossRef]

- Park, K.C.; Cha, E.S.; Ahn, B.T. Sodium-doping of ZnTe film by close-spaced sublimation for back contact of CdTe solar cell. Curr. Appl. Phys. 2011, 11, S109–S112. [Google Scholar] [CrossRef]

- Jin, G.; Wei, H.; Cheng, Z.; Sun, H.; Sun, H.; Yang, B. Aqueous-Processed Polymer/Nanocrystal Hybrid Solar Cells with Efficiency of 5.64%: The Impact of Device Structure, Polymer Content, and Film Thickness. J. Phys. Chem. 2017, 121, 2025–2034. [Google Scholar] [CrossRef]

- Townsend, T.K.; Foos, E.E. Fully solution processed all inorganic nanocrystal solar cells. Phys. Chem. Chem. Phys. 2014, 16, 16458. [Google Scholar] [CrossRef] [PubMed]

- Yoon, W.; Townsend, T.K.; Lumb, M.P.; Tischler, J.G.; Foos, E.E. Sintered CdTe Nanocrystal Thin Films: Determination of Optical Constants and Application in Novel Inverted Heterojunction Solar Cells. IEEE Trans. Nanotechnol. 2014, 13, 551–556. [Google Scholar] [CrossRef]

- Panthani, M.G.; Kurley, J.M.; Crisp, R.W.; Dietz, T.C.; Ezzyat, T.; Luther, J.M.; Talapin, D.V. High Efficiency Solution Processed Sintered CdTe Nanocrystal Solar Cells: The Role of Interfaces. Nano Lett. 2014, 14, 670–675. [Google Scholar] [CrossRef]

- Lin, H.; Xia, W.; Wu, H.N.; Tang, C.W. CdS/CdTe solar cells with MoOx as back contact buffers. Appl. Phys. Lett. 2010, 97, 69. [Google Scholar] [CrossRef]

- Wen, S.; Li, M.; Yang, J.; Mei, X.; Wu, B.; Liu, X.; Heng, J.; Qin, D.; Hou, L.; Xu, W.; Wang, D. Rationally Controlled Synthesis of CdSexTe1−x Alloy Nanocrystals and Their Application in Efficient Graded Bandgap Solar Cells. Nanomaterials 2017, 7, 380. [Google Scholar] [CrossRef]

- Du, X.; Chen, Z.; Liu, F.; Zeng, Q.; Jin, G.; Li, F.; Yao, D.; Yang, B. Improvement in Open-Circuit Voltage of Thin Film Solar Cells from Aqueous Nanocrystals by interface Engineering. ACS Appl. Mater. Interfaces 2016, 8, 900–907. [Google Scholar] [CrossRef] [PubMed]

- Zeng, Q.; Hu, L.; Cui, J.; Feng, T.; Du, X.; Jin, G.; Liu, F.; Ji, T.; Li, F.; Zhang, H.; et al. High-Efficiency Aqueous-Processed Polymer/CdTe Nanocrystals Planar Heterojunction Solar Cells with Optimized Band Alignment and Reduced Interfacial Charge Recombination. ACS Appl. Mater. Interfaces 2017, 9, 31345–31351. [Google Scholar] [CrossRef] [PubMed]

- Guo, X.; Tan, Q.; Liu, S.; Qin, D.; Mo, Y.; Hou, L.; Liu, A.; Wu, H.; Ma, Y. High-efficiency solution-processed CdTe nanocrystal solar cells incorporating a novel crosslinkable conjugated polymer as the hole transport layer. Nano Energy 2018, 46, 150–157. [Google Scholar] [CrossRef]

- Crisp, R.W.; Panthani, M.G.; Rance, W.L.; Duenow, J.N.; Parilla, P.A.; Callahan, R.; Dabney, M.S.; Berry, J.J.; Talapin, D.V.; Luther, J.M. Nanocrystal Grain Growth and Device Architectures for High-Efficiency CdTe Ink-Based Photovoltaics. ACS Nano 2014, 8, 9063–9072. [Google Scholar] [CrossRef]

- Liu, H.; Tian, Y.; Gao, K.; Lu, K.; Wu, R.; Qin, D.; Wu, H.; Peng, Z.; Hou, L.; Huang, W. Solution processed CdTe/CdSe nanocrystal solar cells with more than 5.5% efficiency by using an inverted device structure. J. Mater. Chem. 2015, 3, 4227–4234. [Google Scholar] [CrossRef]

- Liu, S.; Liu, W.; Heng, J.; Zhou, W.; Chen, Y.; Wen, S.; Qin, D.; Hou, L.; Wang, D.; Xu, H. Solution-Processed Efficient Nanocrystal Solar Cells Based on CdTe and CdS Nanocrystals. Coatings 2018, 8, 26. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, H.; Zeng, Q.; Wang, Y.; Xu, D.; Wang, L.; Wang, H.; Yang, B. In Situ Construction of Nanoscale CdTe-CdS Bulk Heterojunctions for Inorganic Nanocrystal Solar Cells. Adv. Mater. 2014, 4, 1400235. [Google Scholar] [CrossRef]

- Qin, D.; Tan, Q.; Lu, K.; Li, M.; Hou, L.; Xie, Y.; Zhang, Z.; Xu, W.; Wu, H. Improving performance in CdTe/CdSe nanocrystals solar cells by using bulk nano-heterojunctions. J. Mater. Chem. C 2016, 4, 6483–6491. [Google Scholar]

- Tian, Y.; Zhang, Y.; Lin, Y.; Gao, K.; Zhang, Y.; Liu, K.; Yang, Q.; Zhou, X.; Qin, D.; Wu, H.; et al. Solution-processed efficient CdTe nanocrystal/CBD-CdS hetero-junction solar cells with ZnO interlayer. J. Nanopart. 2013, 15, 1–9. [Google Scholar] [CrossRef]

- Zeng, Q.; Chen, Z.; Zhao, Y.; Du, X.; Liu, F.; Jin, G.; Dong, F.; Zhang, H.; Yang, B. Aqueous-Processed Inorganic Thin-Film Solar Cells Based on CdSexTe1–x Nanocrystals: The Impact of Composition on Photovoltaic Performance. ACS Appl. Mater. Interfaces 2015, 7, 23223–23230. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Zeng, Q.; Liu, F.; Jin, G.; Du, X.; Du, J.; Zhang, H.; Yang, B. Efficient inorganic solar cells from aqueous nanocrystals: The impact of composition on carrier dynamics. RSC Adv. 2015, 5, 74263. [Google Scholar] [CrossRef]

- Rimmaudo, I.; Salavei, A.; Bing, L.X.; Mare, S.D.; Romeo, A. Superior stability of ultra thin CdTe solar cells with simple Cu/Au back contact. Thin Solid Films 2015, 582, 105–109. [Google Scholar] [CrossRef]

- Demtsu, S.H.; Sites, J.R. Effect of back-contact barrier on thin-film CdTe solar cells. Thin Solid Films 2006, 510, 320–324. [Google Scholar] [CrossRef]

- Yang, T.; Cai, W.; Qin, D.; Wang, E.; Lan, L.; Gong, X.; Peng, J.; Cao, Y. Solution-Processed Zinc Oxide Thin Film as a Buffer Layer for Polymer Solar Cells with an Inverted Device Structure. J. Phys. Chem. C 2010, 114, 6849–6853. [Google Scholar] [CrossRef]

- Dobson, K.D.; Visoly-Fisher, I.; Hodes, G.; Cahen, D. Stability of CdTe/CdS thin-film solar cells. Sol. Energy Mater. Sol. Cells 2000, 62, 295–325. [Google Scholar] [CrossRef]

| Annealing Temperature (°C) | ZnTe Layer Thickness (nm) | Cu Layer Thickness (nm) | Voc (V) | Jsc (mA/cm2) | FF (%) | PCE (%) | Rs (Ω·cm2) | Rsh (Ω·cm2) |

|---|---|---|---|---|---|---|---|---|

| 200 | 10 | 1 | 0.57 | 14.36 | 45.61 | 3.73 | 20.65 | 387.55 |

| 200 | 30 | 1 | 0.63 | 16.21 | 50.12 | 5.12 | 12.70 | 425.71 |

| 200 | 50 | 1 | 0.62 | 14.94 | 48.55 | 4.5 | 15.63 | 380.11 |

| 200 | 100 | 1 | 0.59 | 14.40 | 41.37 | 3.51 | 20.11 | 250.08 |

| no | 20 | 1 | 0.49 | 11.64 | 32.94 | 1.88 | 30.94 | 111.04 |

| 100 | 20 | 1 | 0.59 | 13.40 | 40.37 | 3.19 | 23.70 | 213.32 |

| 160 | 20 | 1 | 0.60 | 18.08 | 44.66 | 4.84 | 12.70 | 245.71 |

| 180 | 20 | 1 | 0.64 | 18.63 | 47.23 | 5.63 | 11.84 | 346.00 |

| 200 | 20 | 1 | 0.65 | 19.73 | 49.75 | 6.38 | 11.24 | 349.59 |

| 220 | 20 | 1 | 0.61 | 18.03 | 48.73 | 5.36 | 13.80 | 201.84 |

| 240 | 20 | 1 | 0.60 | 15.97 | 45.60 | 4.37 | 15.95 | 381.51 |

| 260 | 20 | 1 | 0.61 | 14.29 | 41.64 | 3.63 | 29.22 | 261.08 |

| no | 0 | 0 | 0.56 | 19.97 | 47.15 | 5.27 | 11.11 | 209.99 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, B.; Liu, J.; Cai, Z.; Xu, A.; Liu, X.; Rong, Z.; Qin, D.; Xu, W.; Hou, L.; Liang, Q. The Effects of ZnTe:Cu Back Contact on the Performance of CdTe Nanocrystal Solar Cells with Inverted Structure. Nanomaterials 2019, 9, 626. https://doi.org/10.3390/nano9040626

Chen B, Liu J, Cai Z, Xu A, Liu X, Rong Z, Qin D, Xu W, Hou L, Liang Q. The Effects of ZnTe:Cu Back Contact on the Performance of CdTe Nanocrystal Solar Cells with Inverted Structure. Nanomaterials. 2019; 9(4):626. https://doi.org/10.3390/nano9040626

Chicago/Turabian StyleChen, Bingchang, Junhong Liu, Zexin Cai, Ao Xu, Xiaolin Liu, Zhitao Rong, Donghuan Qin, Wei Xu, Lintao Hou, and Quanbin Liang. 2019. "The Effects of ZnTe:Cu Back Contact on the Performance of CdTe Nanocrystal Solar Cells with Inverted Structure" Nanomaterials 9, no. 4: 626. https://doi.org/10.3390/nano9040626

APA StyleChen, B., Liu, J., Cai, Z., Xu, A., Liu, X., Rong, Z., Qin, D., Xu, W., Hou, L., & Liang, Q. (2019). The Effects of ZnTe:Cu Back Contact on the Performance of CdTe Nanocrystal Solar Cells with Inverted Structure. Nanomaterials, 9(4), 626. https://doi.org/10.3390/nano9040626