Rheological Tunability of Perovskite Precursor Solutions: From Spin Coating to Inkjet Printing Process

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Poly-TPD Solution Preparation

2.2.2. Starch-Perovskite Solution Preparation

2.2.3. Rheological Characterization of Perovskite Precursors Solutions

2.2.4. Surface Tension

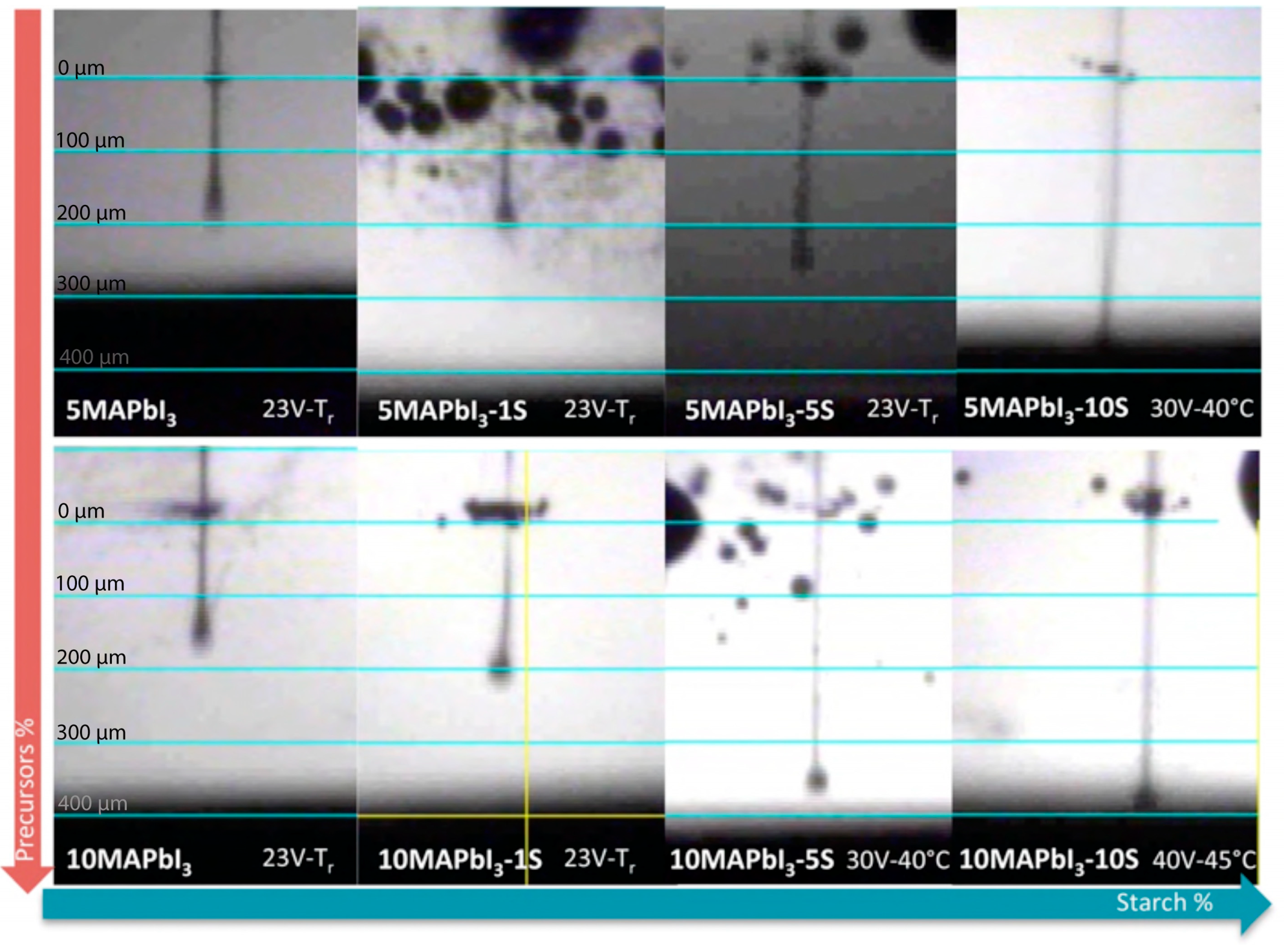

2.2.5. Inkjet Printing Process

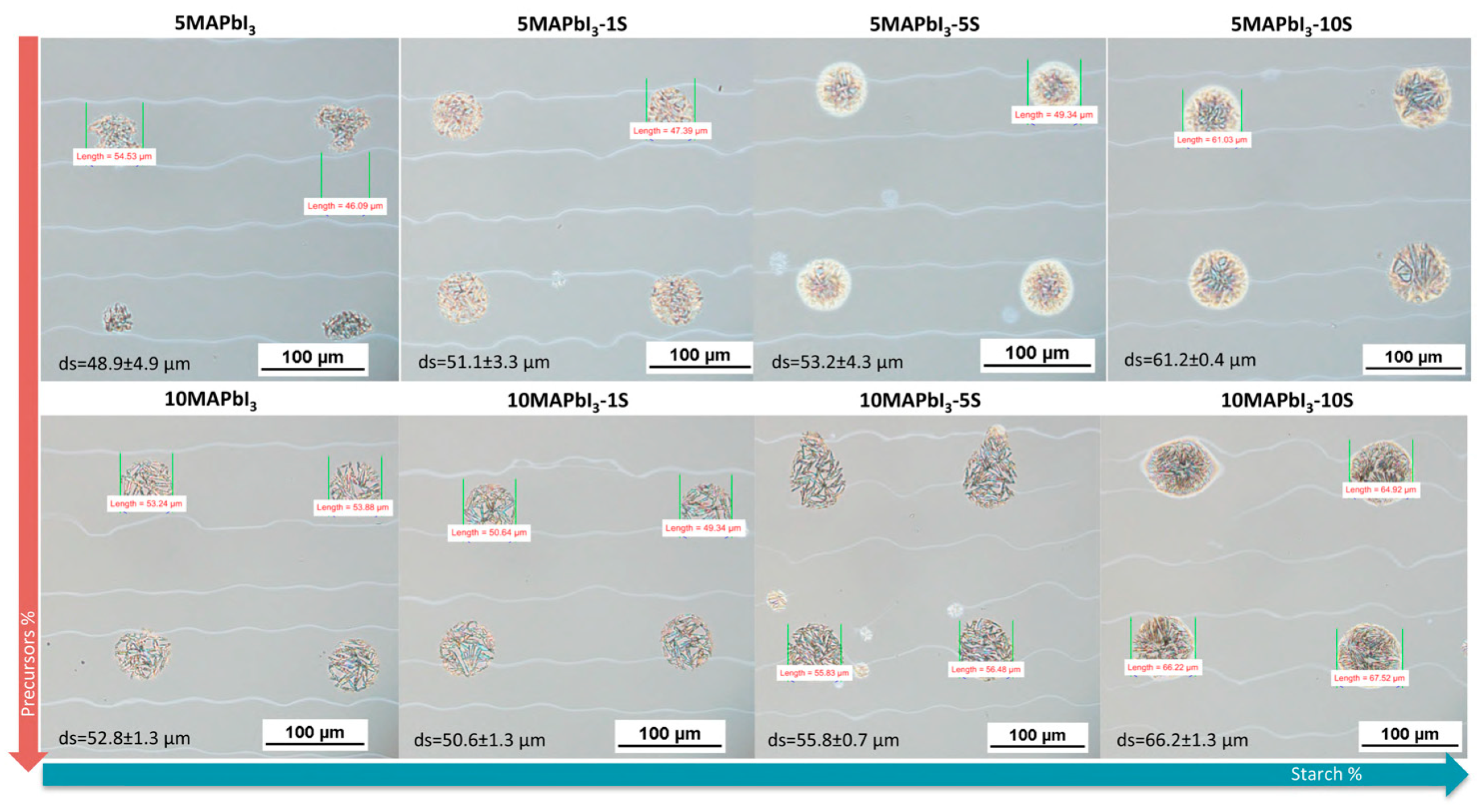

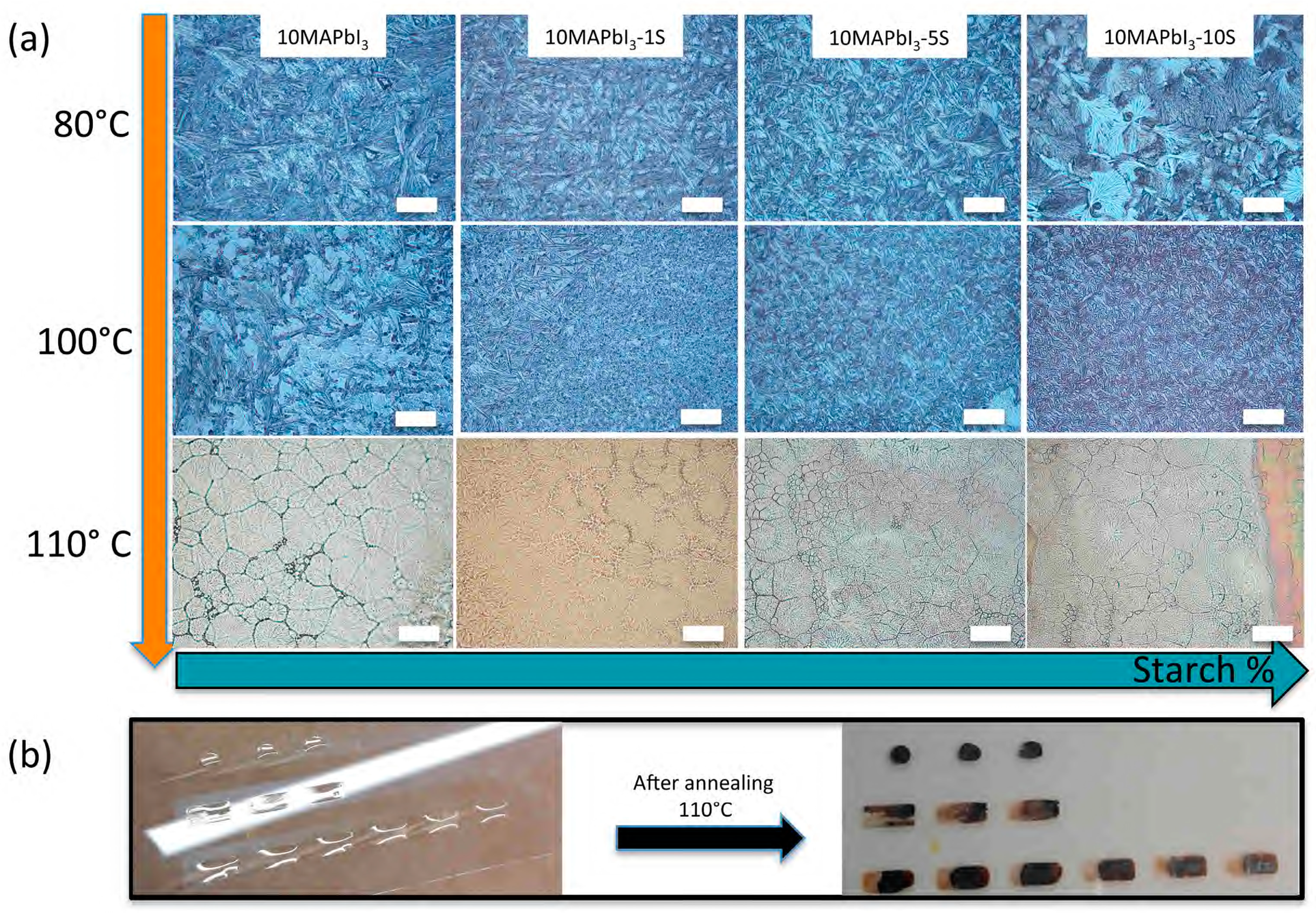

2.2.6. Morphological Characterization

2.2.7. XRD Measurements

2.2.8. UV-vis Absorption

2.2.9. Photoluminescence (PL) Experiments

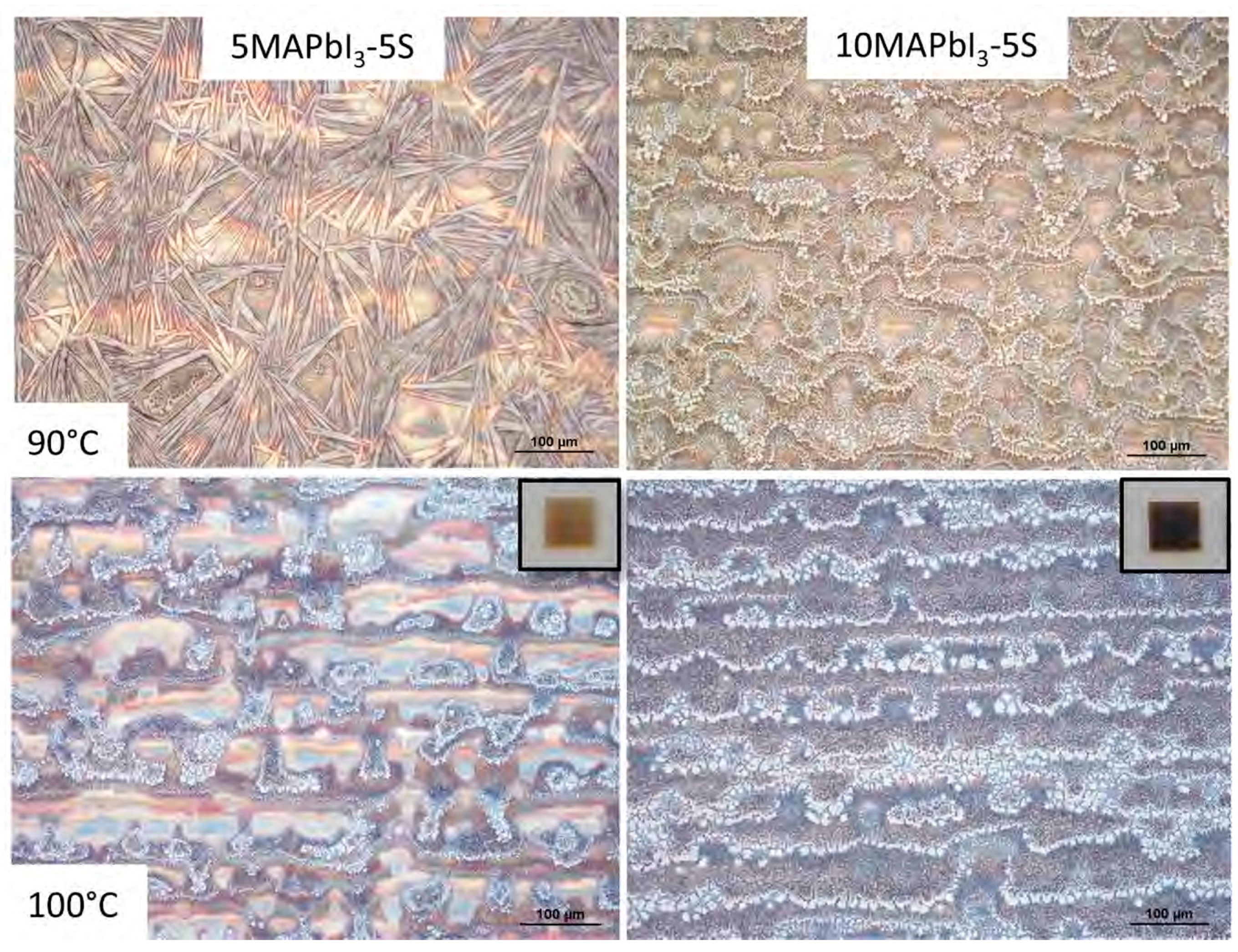

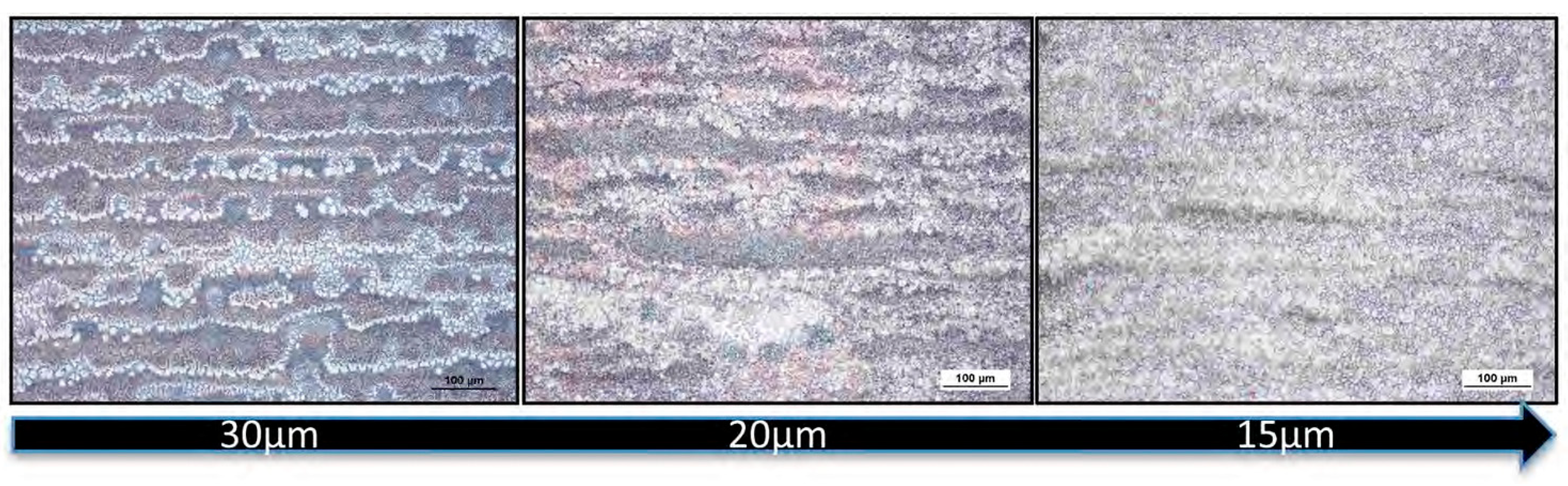

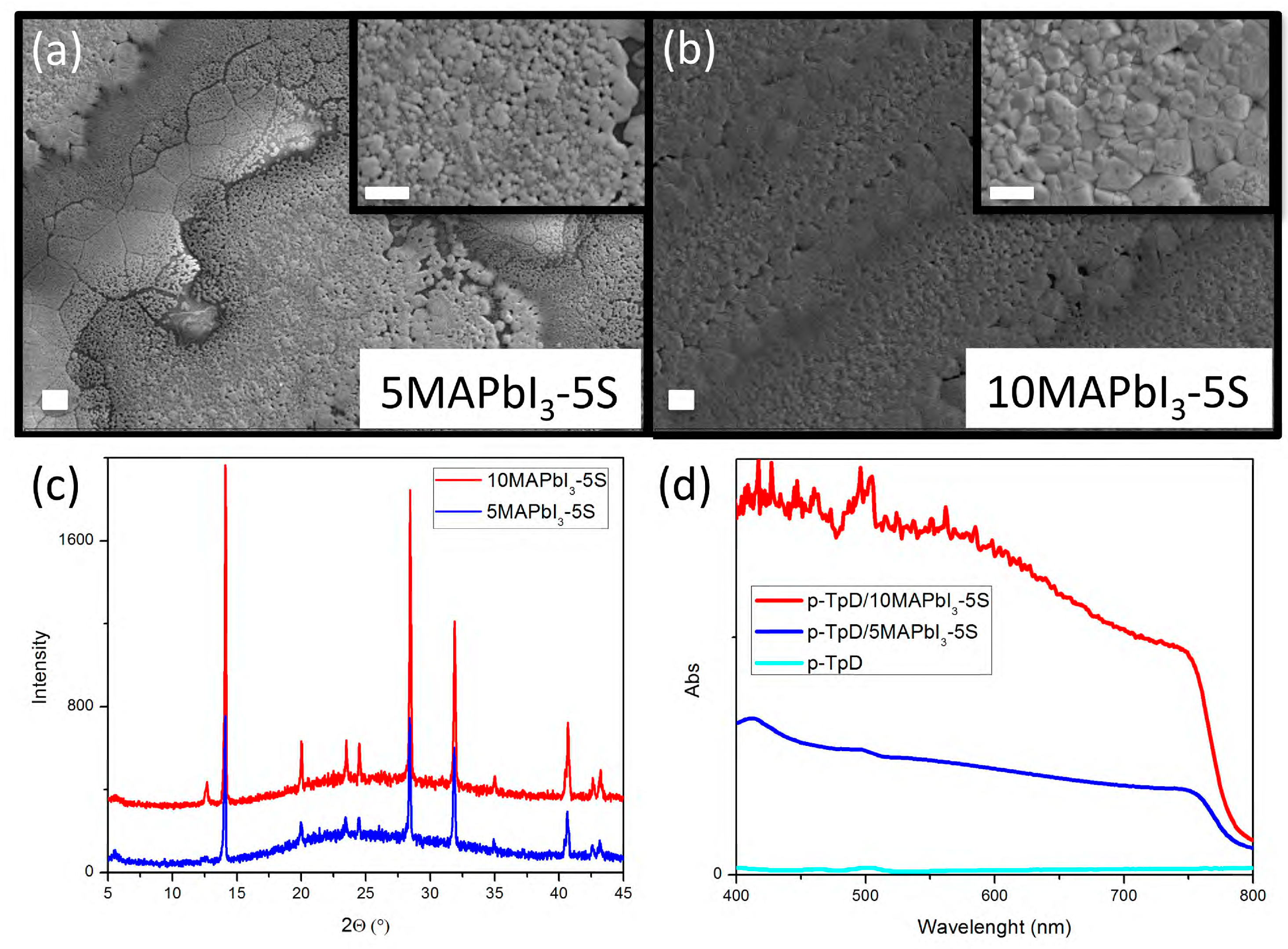

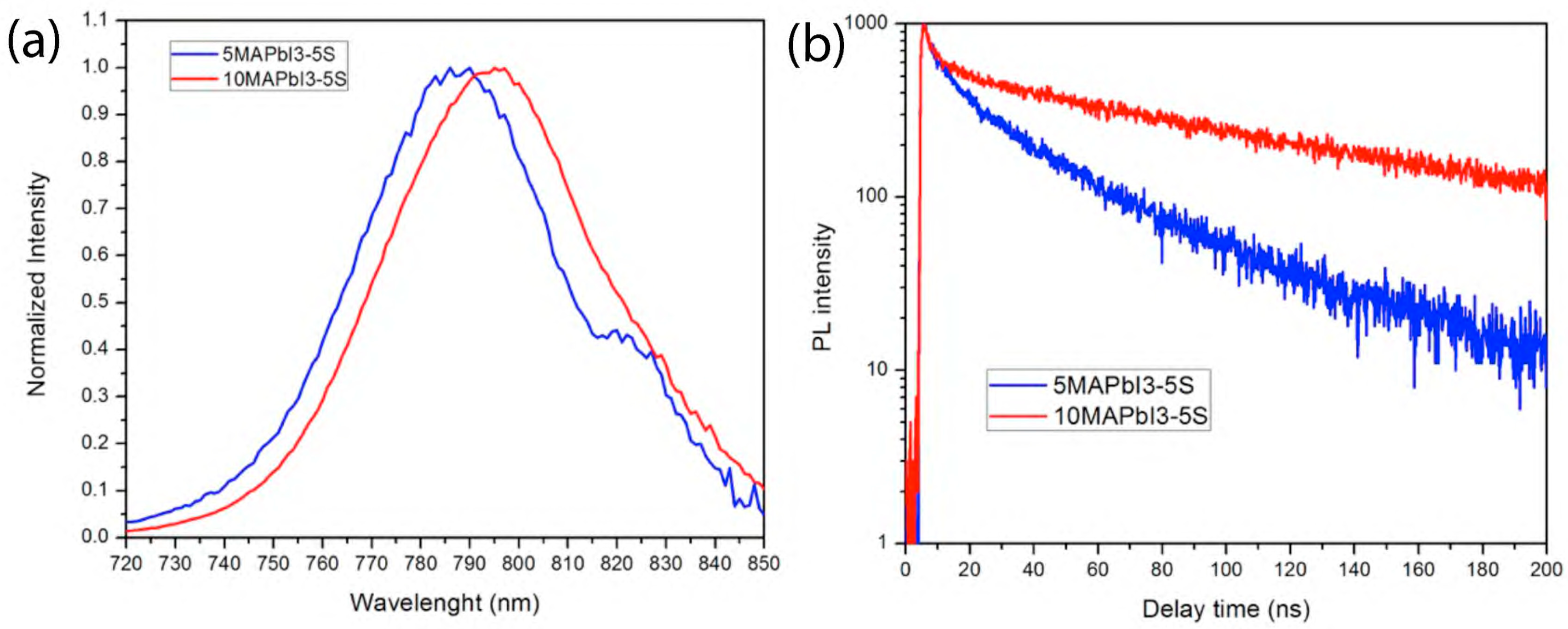

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Peng, X.; Yuan, J.; Shen, S.; Gao, M.; Chesman, A.S.R.; Yin, H.; Cheng, J.; Zhang, Q.; Angmo, D. Perovskite and organic solar cells fabricated by inkjet printing: progress and prospects. Adv. Funct. Mater. 2017, 27, 1703704. [Google Scholar] [CrossRef]

- Giuri, A.; Masi, S.; Listorti, A.; Gigli, G.; Colella, S.; Corcione, C.E.; Rizzo, A. Polymeric rheology modifier allows single-step coating of perovskite ink for highly efficient and stable solar cells. Nano Energy 2018, 54, 400–408. [Google Scholar] [CrossRef]

- Ding, B.; Li, Y.; Huang, S.-Y.; Chu, Q.-Q.; Li, C.-X.; Li, C.-J.; Yang, G.-J. Material nucleation/growth competition tuning towards highly reproducible planar perovskite solar cells with efficiency exceeding 20%. J. Mater. Chem. A 2017, 5, 6840–6848. [Google Scholar] [CrossRef]

- Wang, Z.-K.; Gong, X.; Li, M.; Hu, Y.; Wang, J.-M.; Ma, H.; Liao, L.S. Induced crystallization of perovskites by a perylene underlayer for high-performance solar cells. ACS Nano 2016, 10, 5479–5489. [Google Scholar] [CrossRef]

- Van Franeker, J.J.; Voorthuijzen, W.; Gorter, H.; Hendriks, K.H.; Janssen, R.A.; Hadipour, A.; Andriessen, R.; Galagan, Y. All-solution-processed organic solar cells with conventional architecture. Sol. Mater. Sol. Cells 2013, 117, 267–272. [Google Scholar] [CrossRef]

- Singh, M.; Haverinen, H.M.; Dhagat, P.; Jabbour, G.E. Inkjet printing—Process and its applications. Adv. Mater. 2010, 22, 673–685. [Google Scholar] [CrossRef] [PubMed]

- Wei, Z.; Chen, H.; Yan, K.; Yang, S. Inkjet printing and instant chemical transformation of a CH3NH3PbI3/nanocarbon electrode and interface for planar perovskite solar cells. Angew. Chem. Int. Ed. 2014, 53, 13239–13243. [Google Scholar] [CrossRef] [PubMed]

- Li, S.-G.; Jiang, K.-J.; Su, M.-J.; Cui, X.-P.; Huang, J.-H.; Zhang, Q.-Q.; Zhou, X.-Q.; Yang, L.-M.; Song, Y.-L. Inkjet printing of CH3NH3PbI3 on a mesoscopic TiO2 film for highly efficient perovskite solar cells. J. Mater. Chem. A 2015, 3, 9092–9097. [Google Scholar] [CrossRef]

- Hashmi, S.G.; Martineau, D.; Li, X.; Ozkan, M.; Tiihonen, A.; Dar, M.I.; Sarikka, T.; Zakeeruddin, S.M.; Paltakari, J.; Lund, P.D.; et al. Air processed inkjet infiltrated carbon based printed perovskite solar cells with high stability and reproducibility. Adv. Mater. Technol. 2017, 2, 1600183. [Google Scholar] [CrossRef]

- Bag, M.; Jiang, Z.; Renna, L.A.; Jeong, S.P.; Rotello, V.M.; Venkataraman, D. Rapid combinatorial screening of inkjet-printed alkyl-ammonium cations in perovskite solar cells. Mater. Lett. 2016, 164, 472–475. [Google Scholar] [CrossRef]

- Mathies, F.; Abzieher, T.; Hochstuhl, A.; Glaser, K.; Colsmann, A.; Paetzold, U.W.; Hernandez-Sosa, G.; Lemmer, U.; Quintilla, A. Multipass inkjet printed planar methylammonium lead iodide perovskite solar cells. J. Mater. Chem. A 2016, 4, 19207–19213. [Google Scholar] [CrossRef]

- Liang, C.; Li, P.; Gu, H.; Zhang, Y.; Li, F.; Song, Y.; Shao, G.; Mathews, N.; Xing, G. One-Step Inkjet Printed Perovskite in Air for Efficient Light Harvesting. Sol. RRL. 2018, 2, 1700217. [Google Scholar] [CrossRef]

- Li, P.; Liang, C.; Bao, B.; Li, Y.; Hu, X.; Wang, Y.; Zhang, Y.; Li, F.; Shao, G.; Song, Y. Inkjet manipulated homogeneous large size perovskite grains for efficient and large-area perovskite solar cells. Nano Energy 2018, 46, 203–211. [Google Scholar] [CrossRef]

- Giuri, A.; Colella, S.; Listorti, A.; Rizzo, A.; Corcione, C.E. Biodegradable extruded thermoplastic maize starch for outdoor applications. J. Therm. Anal. 2018, 134, 549–558. [Google Scholar] [CrossRef]

- Masi, S.; Aiello, F.; Listorti, A.; Balzano, F.; Altamura, D.; Giannini, C.; Caliandro, R.; Uccello-Barretta, G.; Rizzo, A.; Colella, S. Connecting the solution chemistry of PbI2 and MAI: A cyclodextrin-based supramolecular approach to the formation of hybrid halide perovskites. Chem. Sci. 2018, 9, 3200–3208. [Google Scholar] [CrossRef]

- Zhang, F.; Tuck, C.; Hague, R.; He, Y.; Saleh, E.; Li, Y.; Sturgess, C.; Wildman, R. Inkjet printing of polyimide insulators for the 3D printing of dielectric materials for microelectronic applications. J. Appl. Polym. Sci. 2016, 133. [Google Scholar] [CrossRef]

- Gheno, A.; Huang, Y.; Bouclé, J.; Ratier, B.; Rolland, A.; Even, J.; Vedraine, S. Toward Highly Efficient Inkjet-Printed Perovskite Solar Cells Fully Processed Under Ambient Conditions and at Low Temperature. Sol. RRL 2018, 2, 1800191. [Google Scholar] [CrossRef]

- Zhumekenov, A.A.; Burlakov, V.M.; Saidaminov, M.I.; Alofi, A.; Haque, M.A.; Turedi, B.; Davaasuren, B.; Dursun, I.; Cho, N.; El-Zohry, A.M.; et al. The Role of Surface Tension in the Crystallization of Metal Halide Perovskites. ACS Lett. 2017, 2, 1782–1788. [Google Scholar] [CrossRef]

- Tai, J.; Gan, H.Y.; Liang, Y.N.; Lok, B.K. Control of Droplet Formation in Inkjet Printing Using Ohnesorge Number Category: Materials and Processes. Presented at the 2008 10th Electronics Packaging Technology Conference (EPTC 2008), Singapore, Singapore, 9–12 December 2008; pp. 761–766. [Google Scholar]

- Jang, D.; Kim, D.; Moon, J. Influence of Fluid Physical Properties on Ink-Jet Printability. Langmuir 2009, 25, 2629–2635. [Google Scholar] [CrossRef]

- Saleh, E.; Woolliams, P.; Clarke, B.; Gregory, A.; Greedy, S.; Smartt, C.; Wildman, R.; Ashcroft, I.; Hague, R.; Dickens, P.; et al. 3D inkjet-printed UV-curable inks for multi-functional electromagnetic applications. Addit. Manuf. 2017, 13, 143–148. [Google Scholar] [CrossRef]

- De Gans, B.; Duineveld, P.C.; Schubert, U.S. Inkjet printing of polymers: State of the art and future developments. Adv. Mater. 2004, 16, 203–213. [Google Scholar] [CrossRef]

- Vaithilingam, J.; Simonelli, M.; Saleh, E.; Senin, N.; Wildman, R.D.; Leach, R.K.; Tuck, C.J.; Hague, R.J. Combined Inkjet Printing and Infra-red Sintering of Silver Nanoparticles using a Swathe-by-swathe and Layer-by-layer approach for 3-dimensional Structures. ACS Appl. Mater. Interfaces 2017, 9, 6560–6570. [Google Scholar] [CrossRef]

- Jeon, N.J.; Noh, J.H.; Kim, Y.C.; Yang, W.S.; Ryu, S.; Seok, S.I. Solvent engineering for high-performance inorganic–organic hybrid perovskite solar cells. Nat. Mater. 2014, 13, 897–903. [Google Scholar] [CrossRef]

- Giuri, A.; Yuan, Z.; Miao, Y.; Wang, J.; Gao, F.; Sestu, N.; Saba, M.; Bongiovanni, G.; Colella, S.; Corcione, C.E.; et al. Ultra-Bright Near-Infrared Perovskite Light-Emitting Diodes with Reduced Efficiency Roll-off. Sci. Rep. 2018, 8, 15496. [Google Scholar] [CrossRef]

| Sample ID | MAPbI3/DMSO (wt%) | Starch/MAPbI3 (wt%) |

|---|---|---|

| 5MAPbI3 | 5 | 0 |

| 5MAPbI3-1S | 5 | 1 |

| 5MAPbI3-5S | 5 | 5 |

| 5MAPbI3-10S | 5 | 10 |

| 5MAPbI3-15S | 5 | 15 |

| 10MAPbI3 | 10 | 0 |

| 10MAPbI3-1S | 10 | 1 |

| 10MAPbI3-5S | 10 | 5 |

| 10MAPbI3-10S | 10 | 10 |

| 10MAPbI3-15S | 10 | 15 |

| 10MAPbI3-20S | 10 | 20 |

| 20MAPbI3 | 20 | 0 |

| 20MAPbI3-1S | 20 | 1 |

| 20MAPbI3-5S | 20 | 5 |

| 20MAPbI3-10S | 20 | 10 |

| 20MAPbI3-15S | 20 | 15 |

| 20MAPbI3-20S | 20 | 20 |

| 30MAPbI3 | 30 | 0 |

| 30MAPbI3-1S | 30 | 1 |

| 30MAPbI3-5S | 30 | 5 |

| 30MAPbI3-10S | 30 | 10 |

| 30MAPbI3-15S | 30 | 15 |

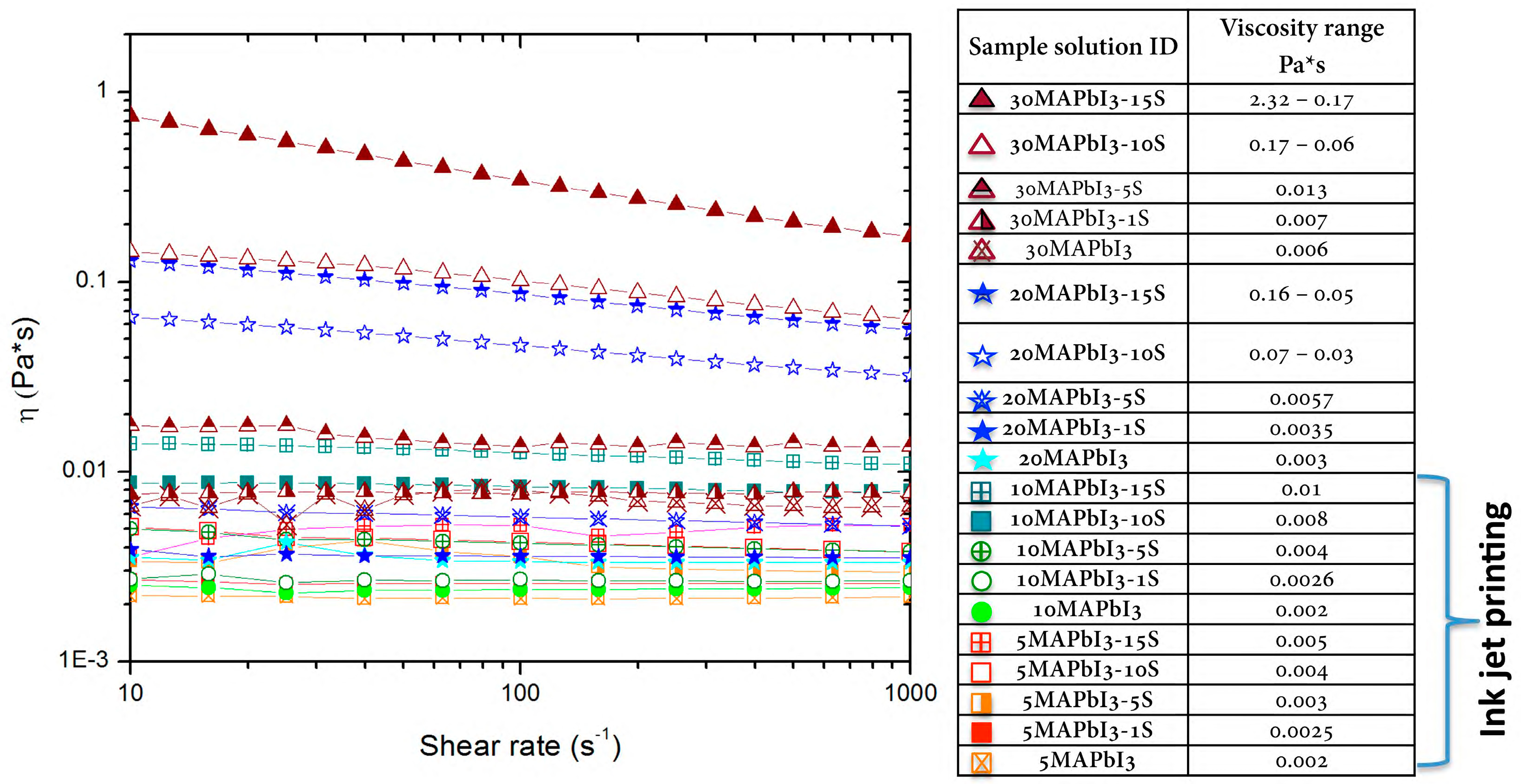

| Ink | Density (g/mL) | Surface Tension (mN/m) | Viscosity at 23 °C (mPa s) | Z |

|---|---|---|---|---|

| 5MAPbI3 | 1.095 | 44.24 ± 0.15 | 2 | 15.94 |

| 5MAPbI3-5S | 1.369 | 53.34 ± 0.15 | 3 | 13.05 |

| 5MAPbI3-10S | 1.365 | 53.15 ± 0.27 | 4 | 9.75 |

| 10MAPbI3 | 1.375 | 53.39 ± 0.32 | 2 | 19.63 |

| 10MAPbI3-5S | 1.392 | 53.32 ± 0.16 | 4 | 9.86 |

| 10MAPbI3-10S | 1.410 | 53.30 ± 0.33 | 8 | 4.96 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Giuri, A.; Saleh, E.; Listorti, A.; Colella, S.; Rizzo, A.; Tuck, C.; Esposito Corcione, C. Rheological Tunability of Perovskite Precursor Solutions: From Spin Coating to Inkjet Printing Process. Nanomaterials 2019, 9, 582. https://doi.org/10.3390/nano9040582

Giuri A, Saleh E, Listorti A, Colella S, Rizzo A, Tuck C, Esposito Corcione C. Rheological Tunability of Perovskite Precursor Solutions: From Spin Coating to Inkjet Printing Process. Nanomaterials. 2019; 9(4):582. https://doi.org/10.3390/nano9040582

Chicago/Turabian StyleGiuri, Antonella, Ehab Saleh, Andrea Listorti, Silvia Colella, Aurora Rizzo, Christopher Tuck, and Carola Esposito Corcione. 2019. "Rheological Tunability of Perovskite Precursor Solutions: From Spin Coating to Inkjet Printing Process" Nanomaterials 9, no. 4: 582. https://doi.org/10.3390/nano9040582

APA StyleGiuri, A., Saleh, E., Listorti, A., Colella, S., Rizzo, A., Tuck, C., & Esposito Corcione, C. (2019). Rheological Tunability of Perovskite Precursor Solutions: From Spin Coating to Inkjet Printing Process. Nanomaterials, 9(4), 582. https://doi.org/10.3390/nano9040582