Upgrading the Properties of Reduced Graphene Oxide and Nitrogen-Doped Reduced Graphene Oxide Produced by Thermal Reduction toward Efficient ORR Electrocatalysts

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation and Characterization of Graphenic Materials

2.2. ORR Electrocatalytic Activities

3. Results and Discussion

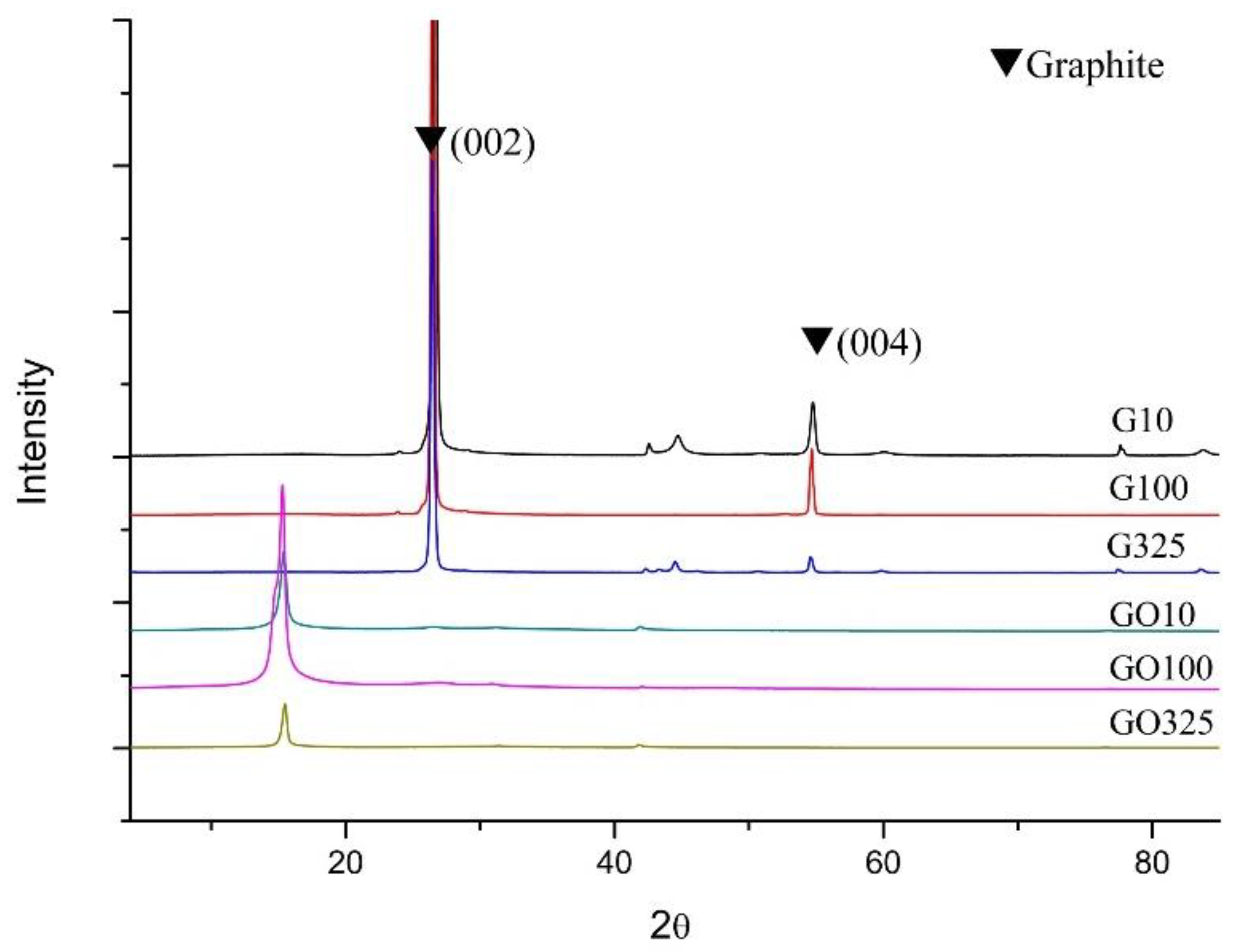

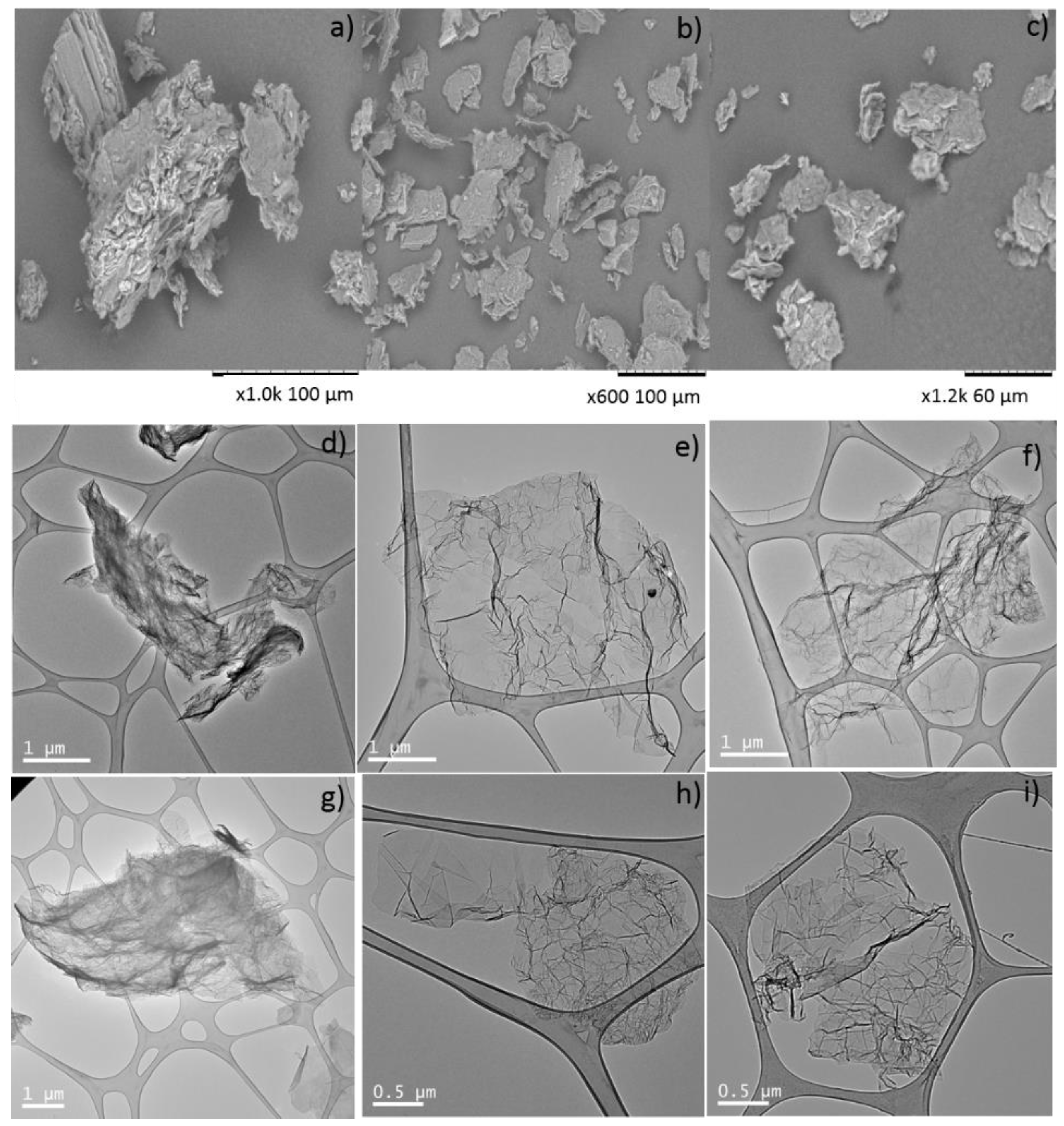

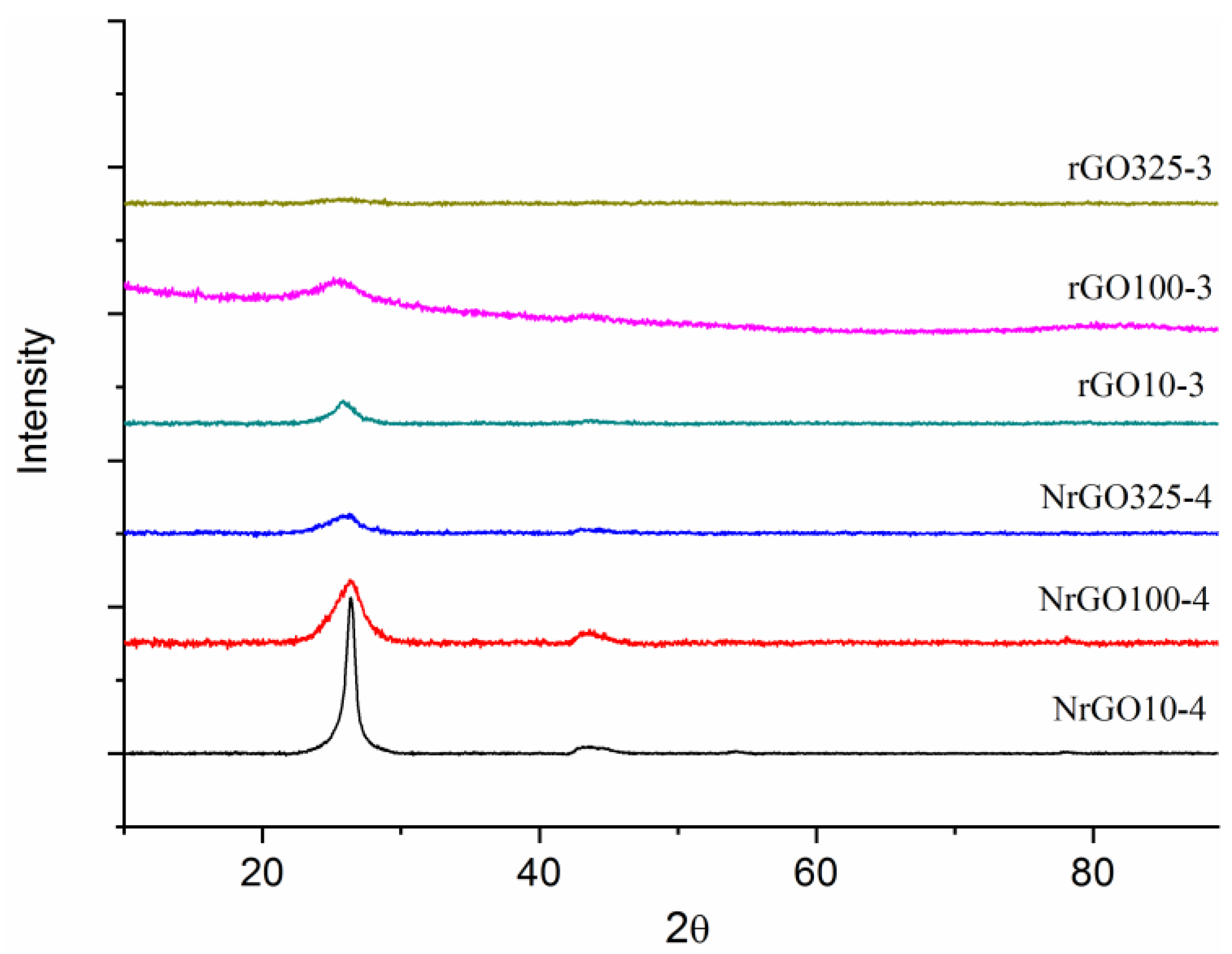

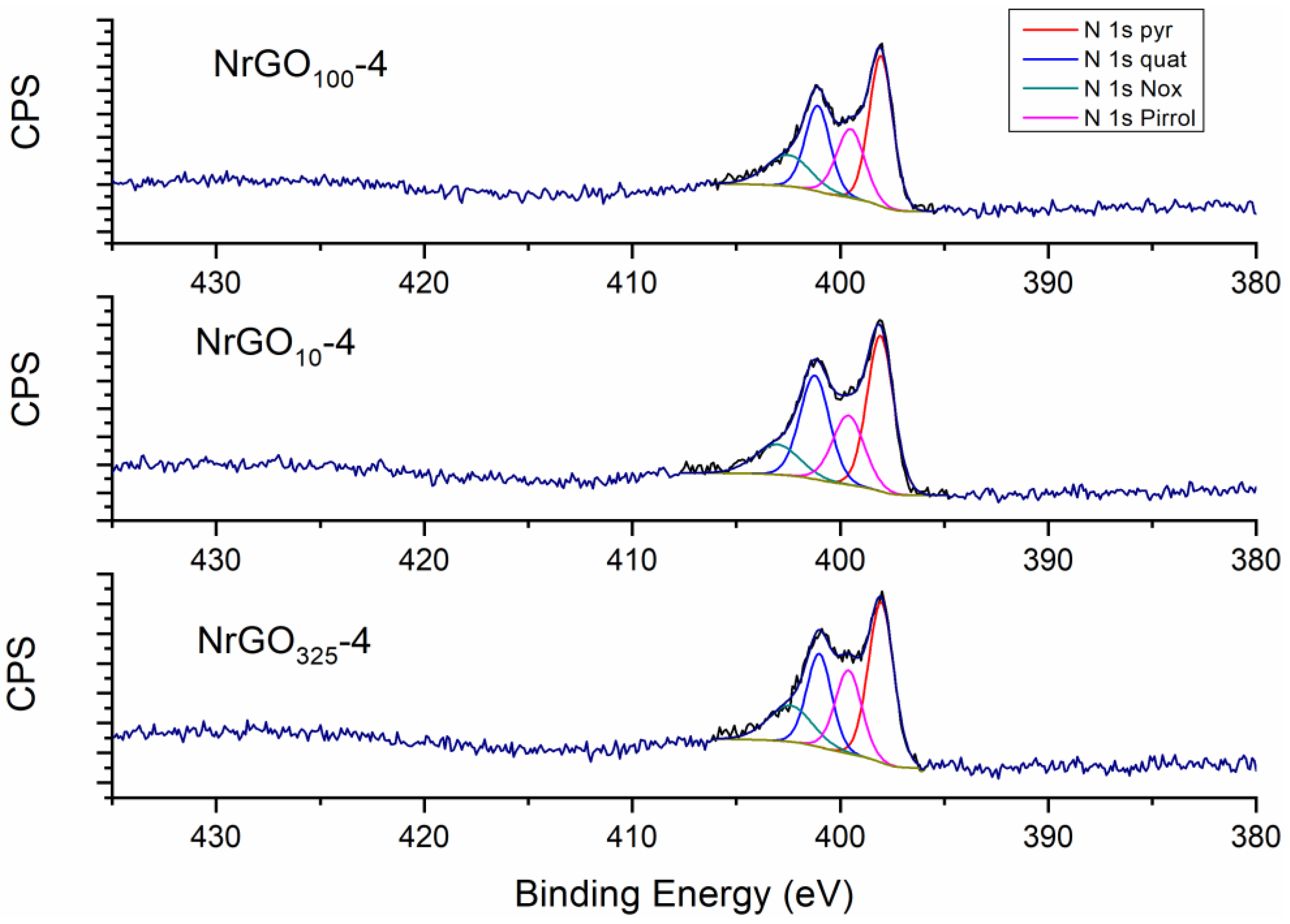

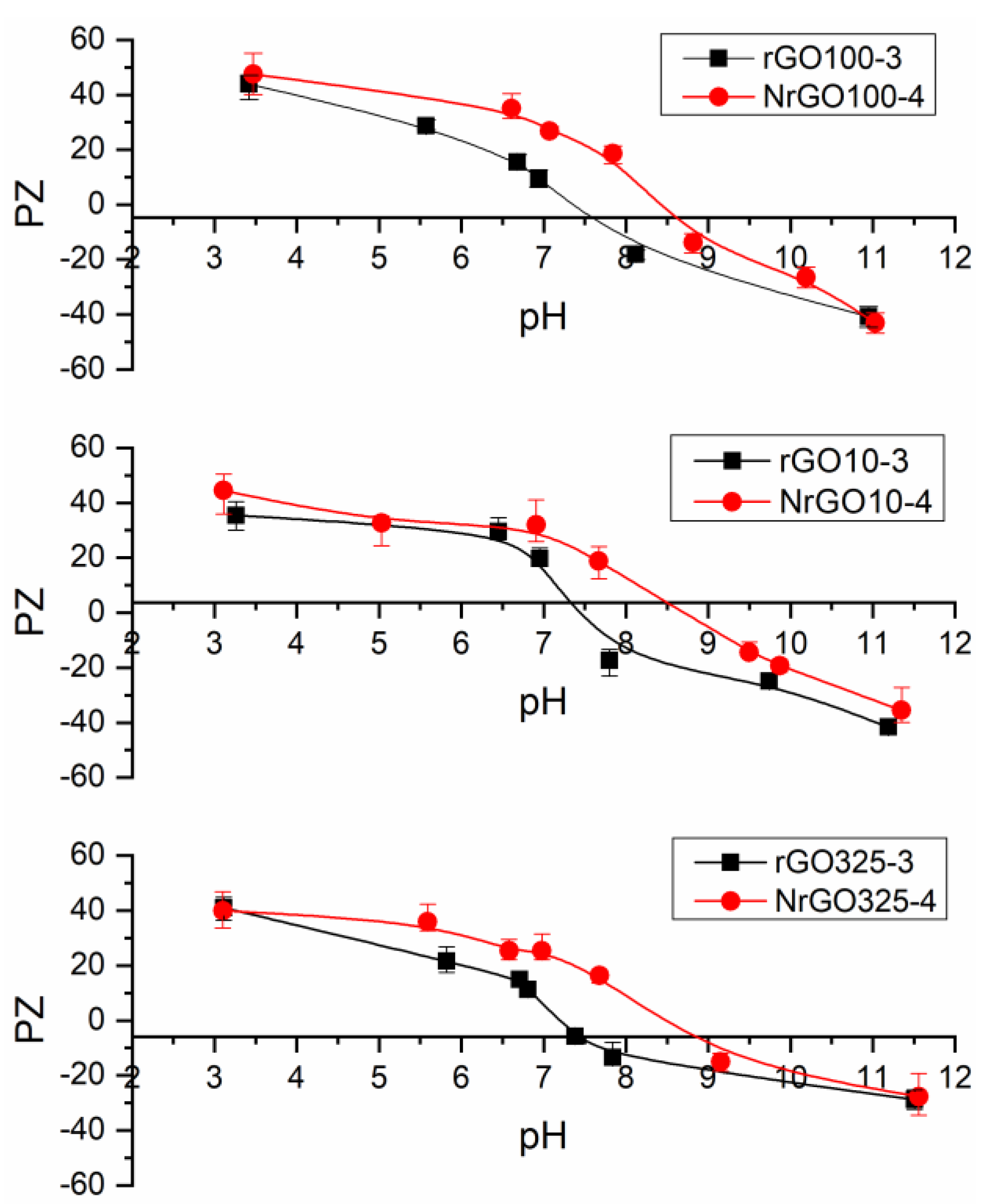

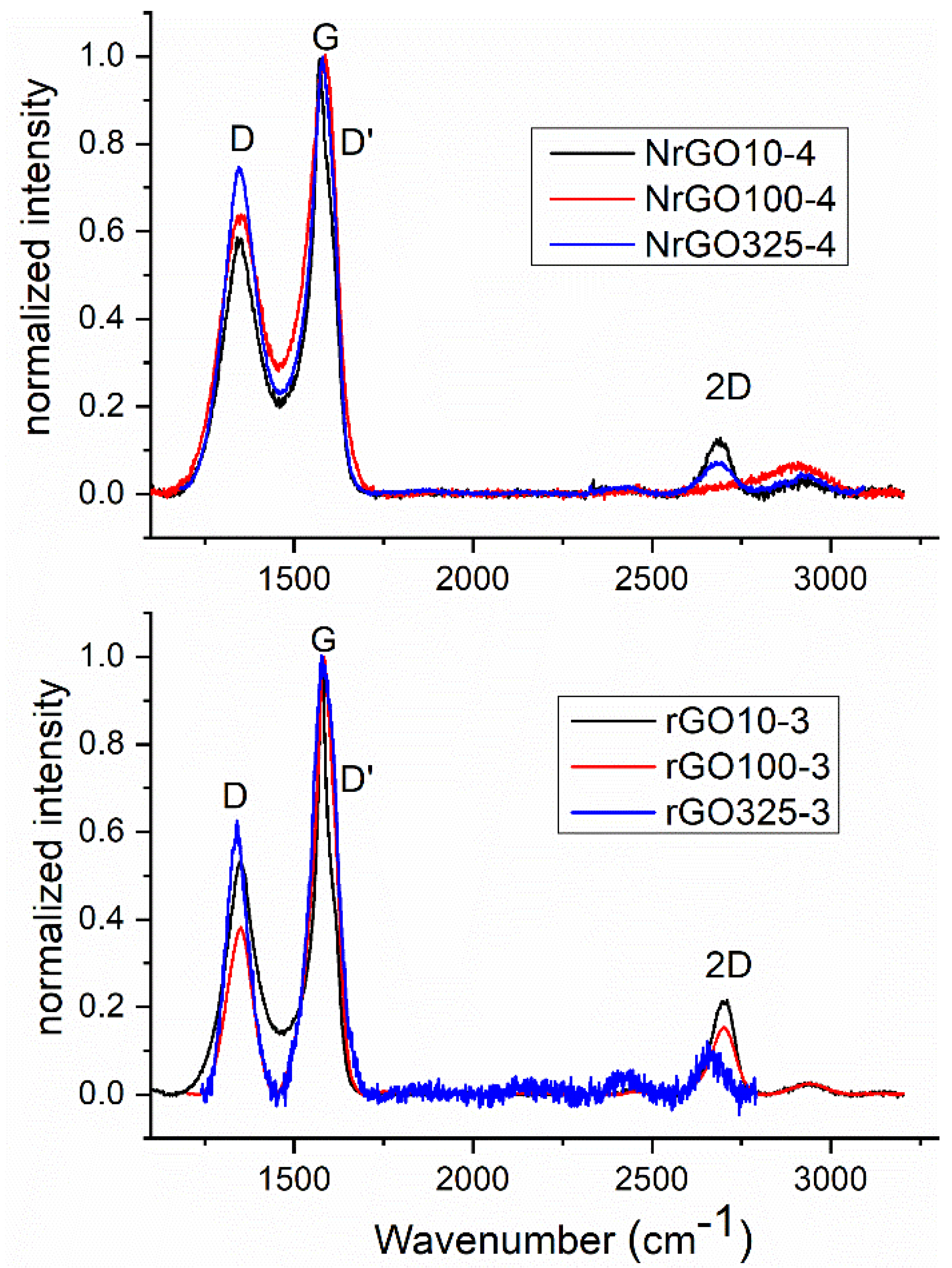

3.1. Characteristics of the Graphenic Materials

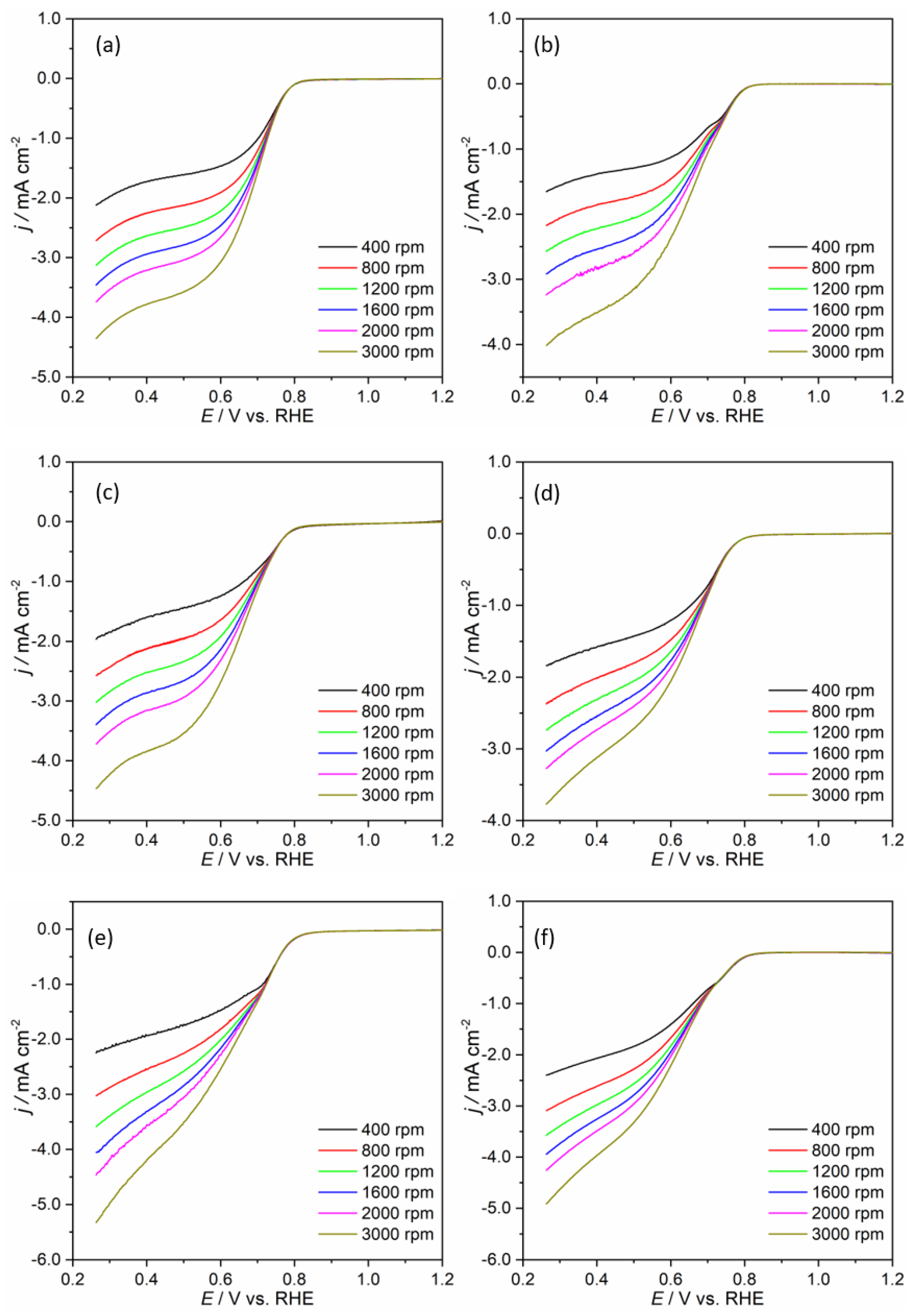

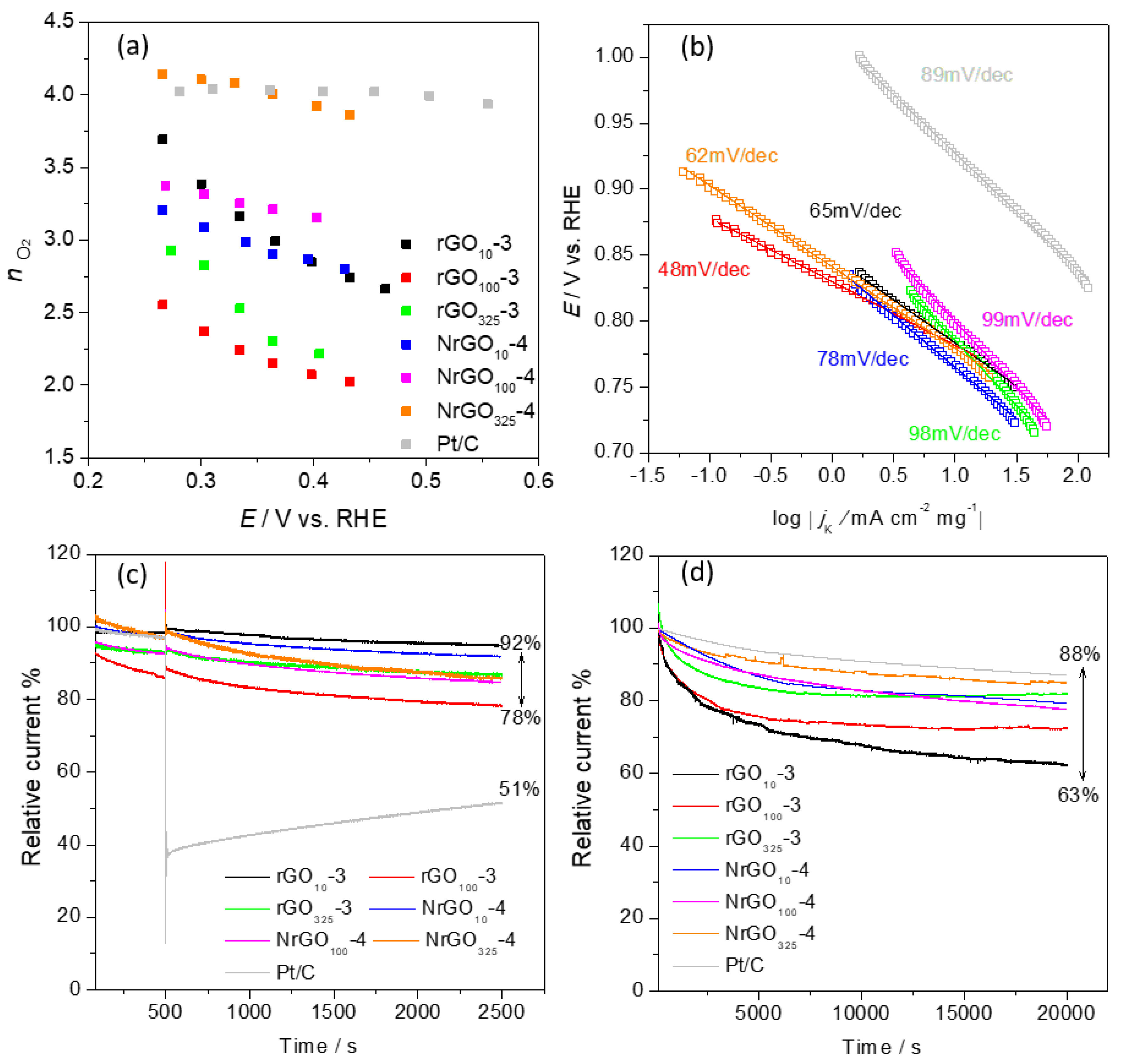

3.2. ORR Electrocatalytic Activities

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Geim, A.K.; Novoselov, K.S. The Rise of Graphene. Nat. Mater. 2007, 6, 183–191. [Google Scholar] [CrossRef] [PubMed]

- Stoller, M.D.; Park, S.; Zhu, Y.; An, J.; Ruoff, R.S. Graphene-Based Ultracapacitors. Nano Lett. 2008, 8, 3498–3502. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Wu, Q.; Shi, G. Graphene based new energy materials. Energy Environ. Sci. 2011, 4, 1113–1132. [Google Scholar] [CrossRef]

- Raccichini, R.; Varzi, A.; Passerini, S.; Scrosati, B. The role of graphene for electrochemical energy storage. Nat. Mater. 2015, 14, 271–279. [Google Scholar] [CrossRef] [PubMed]

- Bonaccorso, F.; Colombo, L.; Yu, G.; Stoller, M.; Tozzini, V.; Ferrari, A.C.; Ruoff, R.S.; Pellegrini, V. Graphene, Related Two-Dimensional Crystals, and Hybrid Systems for Energy Conversion and Storage. Science 2015, 347, 1246501. [Google Scholar] [CrossRef]

- Weiss, N.O.; Zhou, H.; Liao, L.; Liu, Y.; Jiang, S.; Huang, Y.; Duan, X. Graphene: An Emerging Electronic Material. Adv. Mater. 2012, 24, 5782–5825. [Google Scholar] [CrossRef]

- Soldano, C.; Mahmood, A.; Dujardin, E. Production, Properties and Potential of Graphene. Carbon 2010, 48, 2127–2150. [Google Scholar] [CrossRef]

- Machado, B.F.; Serp, P. Graphene-Based Materials for Catalysis. Catal. Sci. Technol. 2012, 2, 54–75. [Google Scholar] [CrossRef]

- Serp, P.; Figueiredo, J.L. Carbon Materials for Catalysis; John Wiley & Sons, Inc: Hoboken, NJ, USA, 2008. [Google Scholar]

- Asedegbega-Nieto, E.; Perez-Cadenas, M.; Morales, M.V.; Bachiller-Baeza, B.; Gallegos-Suarez, E.; Rodriguez-Ramos, I.; Guerrero-Ruiz, A. High Nitrogen Doped Graphenes and their Applicability as Basic Catalysts. Diam. Relat. Mater. 2014, 44, 26–32. [Google Scholar] [CrossRef]

- Castillejos-Lopez, E.; Bachiller-Baeza, B.; Asedegbega-Nieto, E.; Guerrero-Ruiz, A.; Rodriguez-Ramos, I. Selective 1,3-butadiene Hydrogenation by Gold Nanoparticles Deposited & Precipitated onto Nano-Carbon Materials. RSC Adv. 2015, 5, 81583–81598. [Google Scholar]

- Geng, D.; Yang, S.; Zhang, Y.; Yang, J.; Liu, J.; Li, R.; Sham, T.-K.; Sun, X.; Ye, S.; Knights, S. Nitrogen doping effects on the structure of graphene. Appl. Surf. Sci. 2011, 257, 9193–9198. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric Field Effect in Atomically Thin Carbon Films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.S.; Zhao, Y.; Jang, H.; Lee, S.Y.; Kim, J.M.; Kim, K.S.; Ahn, J.-H.; Kim, P.; Choi, J.-Y.; Hong, B.H. Large-Scale Pattern Growth of Graphene Films for Stretchable Transparent Electrodes. Nature 2009, 457, 706–710. [Google Scholar] [CrossRef] [PubMed]

- Berger, C.; Song, Z.; Li, X.; Wu, X.; Brown, N.; Naud, C.; Mayou, D.; Li, T.; Hass, J.; Marchenkov, A.N.; et al. Electronic Confinement and Coherence in Patterned Epitaxial Graphene. Science 2006, 312, 1191–1196. [Google Scholar] [CrossRef] [PubMed]

- Hummers, W.S.; Offeman, R.E. Preparation of Graphitic Oxide. J. Am. Chem. Soc. 1958, 80, 1339. [Google Scholar] [CrossRef]

- Brodie, B.C. On the Atomic Weight of Graphite. Philos. Trans. R. Soc. 1859, 149, 249–259. [Google Scholar]

- Stankovich, S.; Dikin, D.A.; Piner, R.D.; Kohlhaas, K.A.; Kleinhammes, A.; Jia, Y.; Wu, Y.; Nguyen, S.T.; Ruoff, R.S. Synthesis of graphene-based nanosheets via chemical reduction of exfoliated graphite oxide. Carbon 2007, 45, 1558–1565. [Google Scholar] [CrossRef]

- Shin, H.-J.; Kim, K.K.; Benayad, A.; Yoon, S.-M.; Park, H.K.; Jung, I.-S.; Jin, M.H.; Jeong, H.-K.; Kim, J.M.; Choi, J.-Y.; et al. Efficient Reduction of Graphite Oxide by Sodium Borohydride and Its Effect on Electrical Conductance. Adv. Funct. Mater. 2009, 19, 1987–1992. [Google Scholar] [CrossRef]

- Zhou, M.; Wang, Y.; Zhai, Y.; Zhai, J.; Ren, W.; Wang, F.; Dong, S. Controlled Synthesis of Large-Area and Patterned Electrochemically Reduced Graphene Oxide Films. Chem. A Eur. J. 2009, 15, 6116–6120. [Google Scholar] [CrossRef]

- Sundaram, R.S.; Gómez-Navarro, C.; Balasubramanian, K.; Burghard, M.; Kern, K. Electrochemical Modification of Graphene. Adv. Mater. 2008, 20, 3050–3053. [Google Scholar] [CrossRef]

- Choucair, M.; Thordarson, P.; Stride, J.A. Gram-scale Production of Graphene Based on Solvothermal Synthesis and Sonication. Nat. Nanotechnol. 2009, 4, 30–33. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Robinson, J.T.; Li, X.; Dai, H. Solvothermal Reduction of Chemically Exfoliated Graphene Sheets. J. Am. Chem. Soc. 2009, 131, 9910–9911. [Google Scholar] [CrossRef] [PubMed]

- McAllister, M.J.; Li, J.-L.; Adamson, D.H.; Schniepp, H.C.; Abdala, A.A.; Liu, J.; Herrera-Alonso, M.; Milius, D.L.; Car, R.; Prud’homme, R.K.; et al. Single Sheet Functionalized Graphene by Oxidation and Thermal Expansion of Graphite. Chem. Mater. 2007, 19, 4396–4404. [Google Scholar] [CrossRef]

- Botas, C.; Álvarez, P.; Blanco, C.; Santamaría, R.; Granda, M.; Gutiérrez, M.D.; Rodriguez-Reinoso, F.; Menéndez, R. Critical Temperatures in the Synthesis of Graphene-like Materials by Thermal Exfoliation-Reduction of Graphite Oxide. Carbon 2013, 52, 476–485. [Google Scholar] [CrossRef]

- Luo, Z.; Lim, S.; Tian, Z.; Shang, J.; Lai, L.; MacDonald, B.; Fu, C.; Shen, Z.; Yu, T.; Lin, J. Pyridinic N Doped Graphene: Synthesis, Electronic Structure, and Electrocatalytic Property. J. Mater. Chem. 2011, 21, 8038–8044. [Google Scholar] [CrossRef]

- Reddy, A.L.M.; Srivastava, A.; Gowda, S.R.; Gullapalli, H.; Dubey, M.; Ajayan, P.M. Synthesis of Nitrogen-Doped Graphene Films for Lithium Battery Application. ACS Nano 2010, 4, 6337–6342. [Google Scholar] [CrossRef] [PubMed]

- Jin, Z.; Yao, J.; Kittrell, C.; Tour, J.M. Large-Scale Growth and Characterizations of Nitrogen-Doped Monolayer Graphene Sheets. ACS Nano 2011, 5, 4112–4117. [Google Scholar] [CrossRef] [PubMed]

- Panchakarla, L.S.; Subrahmanyam, K.S.; Saha, S.K.; Govindaraj, A.; Krishnamurthy, H.R.; Waghmare, U.V.; Rao, C.N.R. Synthesis, Structure and Properties of Boron and Nitrogen Doped Graphene. Adv. Mater. 2009, 21, 4726–4738. [Google Scholar] [CrossRef]

- Wang, Y.; Shao, Y.; Matson, D.W.; Li, J.; Lin, Y. Nitrogen-Doped Graphene and Its Application in Electrochemical Biosensing. ACS Nano 2010, 4, 1790–1798. [Google Scholar] [CrossRef]

- Lin, Z.; Song, M.; Ding, Y.; Liu, Y.; Wong, C. Facile Preparation of Nitrogen-Doped Graphene as a Metal-Free Catalyst for Oxygen Reduction Reaction. Phys. Chem. Chem. Phys. 2012, 14, 3381–3387. [Google Scholar] [CrossRef]

- Sheng, Z.H.; Shao, L.; Chen, J.J.; Bao, W.J.; Wang, F.B.; Xia, X.H. Catalyst-Free Synthesis of Nitrogen-Doped Graphene Via Thermal Annealing Graphite Oxide with Melamine and its Excellent Electrocatalysis. ACS Nano 2011, 5, 4350–4358. [Google Scholar] [CrossRef] [PubMed]

- Canty, R.; Gonzalez, E.; MacDonald, C.; Osswald, S.; Zea, H.; Luhrs, C.C. Reduction Expansion Synthesis as Strategy to Control Nitrogen Doping Level and Surface Area in Graphene. Materials 2015, 8, 7048–7058. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Wang, H.; Robinson, J.T.; Sanchez, H.; Diankov, G.; Dai, H. Simultaneous Nitrogen Doping and Reduction of Graphene Oxide. J. Am. Chem. Soc. 2009, 131, 15939–15944. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.S.; Ren, W.; Gao, L.; Liu, B.; Jiang, C.; Cheng, H.M. Synthesis of High-Quality Graphene with a Pre-Determined Number of Layers. Carbon 2009, 47, 493–499. [Google Scholar] [CrossRef]

- Paez, A.; Jesús, G.; Alvarez, P.; Granda, M.; Blanco, C.; Santamaria, P.; Blanco, R.; Fernandez, L.; Menendez, R.M.; Calle, F. Methods for Producing Graphene with Tunable Properties by a Multi-Step Thermal Reduction Process. WO 2016042099 A1, 18 September 2014. [Google Scholar]

- Zhang, C.; Lv, W.; Xie, X.; Tang, D.; Liu, C.; Yang, Q.-H. Towards Low Temperature Thermal Exfoliation of Graphite Oxide for Graphene Production. Carbon 2013, 62, 11–24. [Google Scholar] [CrossRef]

- Dao, T.D.; Jeong, H.M. Graphene Prepared by Thermal Reduction—Exfoliation of Graphite Oxide: Effect of Raw Graphite Particle Size on the Properties of Graphite Oxide and Graphene. Mater. Res. Bull. 2015, 70, 651–657. [Google Scholar] [CrossRef]

- Muthuswamy, N.; Buan, M.E.M.; Walmsley, J.C.; Rønning, M. Evaluation of ORR Active Sites in Nitrogen-Doped Carbon Nanofibers by KOH Post Treatment. Catal. Today 2018, 301, 11–16. [Google Scholar] [CrossRef]

- Wang, H.; Maiyalagan, T.; Wang, X. Review on Recent Progress in Nitrogen-Doped Graphene: Synthesis, Characterization, and Its Potential Applications. ACS Catal. 2012, 2, 781–794. [Google Scholar] [CrossRef]

- Serp, P.; Machado, B.F. Nanostructured Carbon Materials for Catalysis, Royal Society of Chemistry; Royal Society of Chemistry: Cambridge, UK, 2015. [Google Scholar]

- Wepasnick, K.A.; Smith, B.A.; Bitter, J.L.; Fairbrother, D.H. Chemical and Structural Characterization of Carbon Nanotube Surfaces. Anal. Bioanal. Chem. 2010, 396, 1003–1014. [Google Scholar] [CrossRef]

- Desimoni, E.; Casella, G.I.; Morone, A.; Salvi, A.M. XPS Determination of Oxygen-Containing Functional Groups on Carbon-Fibre Surfaces and the Cleaning of these Surfaces. Surf. Interface Anal. 1990, 15, 627–634. [Google Scholar] [CrossRef]

- Matter, P.H.; Zhang, L.; Ozkan, U.S. The Role of Nanostructure in Nitrogen-Containing Carbon Catalysts for the Oxygen Reduction Reaction. J. Catal. 2006, 239, 83–96. [Google Scholar] [CrossRef]

- Pels, J.R.; Kapteijn, F.; Moulijn, J.A.; Zhu, Q.; Thomas, K.M. Evolution of Nitrogen Functionalities in Carbonaceous Materials during Pyrolysis. Carbon 1995, 33, 1641–1653. [Google Scholar] [CrossRef]

- Biniak, S.; Szymański, G.; Siedlewski, J.; Światkoski, A. The Characterization of Activated Carbons with Oxygen and Nitrogen Surface Groups. Carbon 1997, 35, 1799–1810. [Google Scholar] [CrossRef]

- Faba, L.; Criado, Y.A.; Gallegos-Suarez, E.; Pérez-Cadenas, M.; Díaz, E.; Rodriguez-Ramos, I.; Guerrero-Ruiz, A.; Ordóñez, S. Preparation of Nitrogen-Containing Carbon Nanotubes and Study of their Performance as Basic Catalysts. Appl. Catal. A Gen. 2013, 458, 155–161. [Google Scholar] [CrossRef]

- García-García, F.R.; Álvarez-Rodríguez, J.; Rodriguez-Ramos, I.; Guerrero-Ruiz, A. The Use of Carbon Nanotubes with and without Nitrogen Doping as Support for Ruthenium Catalysts in the Ammonia Decomposition Reaction. Carbon 2010, 48, 267–276. [Google Scholar] [CrossRef]

- van Dommele, S.; de Jong, K.P.; Bitter, J.H. Nitrogen-Containing Carbon Nanotubes as Solid Base Catalysts. Chem. Commun. 2006, 76, 4859–4861. [Google Scholar] [CrossRef]

- Dongil, A.B.; Bachiller-Baeza, B.; Guerrero-Ruiz, A.; Rodríguez-Ramos, I.; Martínez-Alonso, A.; Tascón, J.M.D. Surface Chemical Modifications Induced on High Surface Area Graphite and Carbon Nanofibers Using Different Oxidation and Functionalization Treatments. J. Colloid Interface Sci. 2011, 355, 179–189. [Google Scholar] [CrossRef]

- Figueiredo, J.L.; Pereira, M.F.R.; Freitas, M.M.A.; Órfão, J.J.M. Modification of the Surface Chemistry of Activated Carbons. Carbon 1999, 37, 1379–1389. [Google Scholar] [CrossRef]

- Zielke, U.; Hüttinger, K.J.; Hoffman, W.P. Surface-Oxidized Carbon Fibers: I. Surface Structure and Chemistry. Carbon 1996, 34, 983–998. [Google Scholar] [CrossRef]

- Chen, C.-M.; Zhang, Q.; Zhao, X.-C.; Zhang, B.; Kong, Q.-Q.; Yang, M.-G.; Yang, Q.-H.; Wang, M.-Z.; Yang, Y.-G.; Schlögl, R.; et al. Hierarchically Aminated Graphene Honeycombs for Electrochemical Capacitive Energy Storage. J. Mater. Chem. 2012, 22, 14076–14084. [Google Scholar] [CrossRef]

- Tuinstra, F.; Koenig, J.L. Raman Spectrum of Graphite. J. Chem. Phys. 1970, 53, 1126–1130. [Google Scholar] [CrossRef]

- Pimenta, M.A.; Dresselhaus, G.; Dresselhaus, M.S.; Cançado, L.G.; Jorio, A.; Saito, R. Studying Disorder in Graphite-Based Systems by Raman Spectroscopy. Phys. Chem. Chem. Phys. 2007, 9, 1276–1290. [Google Scholar] [CrossRef] [PubMed]

- Qu, L.T.; Liu, Y.; Baek, J.B.; Dai, L.M. Nitrogen-Doped Graphene as Efficient Metal-Free Electrocatalyst for Oxygen Reduction in Fuel Cells. ACS Nano 2010, 4, 1321–1326. [Google Scholar] [CrossRef] [PubMed]

- Rocha, I.M.; Soares, O.G.P.; Fernandes, D.M.; Freire, C.; Figueiredo, J.L.; Pereira, M.F.R. N-Doped Carbon Nanotubes for the Oxygen Reduction Reaction in Alkaline Medium: Synergistic Relationship between Pyridinic and Quaternary Nitrogen. Chem. Sel. 2016, 1, 2522–2530. [Google Scholar] [CrossRef]

- Kim, D.-W.; Lia, O.L.; Saito, N. Enhancement of ORR catalytic activity by multiple heteroatom-doped carbon materials. Phys. Chem. Chem. Phys. 2015, 17, 407–413. [Google Scholar] [CrossRef]

- Fernandes, D.M.; Novais, H.C.; Bacsa, R.; Serp, P.; Bachiller-Baeza, B.; Rodríguez-Ramos, I.; Guerrero-Ruiz, A.; Freire, C. Polyoxotungstate@Carbon Nanocomposites as Oxygen Reduction Reaction (ORR) Electrocatalysts. Langmuir 2018, 34, 6376–6387. [Google Scholar] [CrossRef]

- Li, H.; Liu, H.; Jong, Z.; Qu, W.; Geng, D.S.; Sun, X.; Wang, H. Nitrogen-doped carbon nanotubes with high activity for oxygen reduction in alkaline media. Int. J. Hydrogen Energy 2011, 36, 2258–2265. [Google Scholar] [CrossRef]

- O’Hayre, R.; Cha, S.; Colella, W.; Prinz, F. Fuel Cell Fundamentals; John Wiley & Sons: New York, NY, USA, 2005. [Google Scholar]

- Subramanian, N.P.; Li, X.G.; Nallathambi, V.; Kumaraguru, S.P.; Colon-Mercado, H.; Wu, G.; Lee, J.W.; Popov, B.N. Nitrogen-Modified Carbon-based Catalysts for Oxygen Reduction Reaction in Polymer Electrolyte Membrane Fuel Cells. J. Power Sources 2009, 188, 38–44. [Google Scholar] [CrossRef]

- Shinagawa, T.; Garcia-Escudero, A.T.; Takanabe, K. Insight on Tafel Slopes from a Microkinetic Analysis of Aqueous Electrocatalysis for Energy Conversion. Sci. Rep. 2015, 5, 13801. [Google Scholar] [CrossRef]

- Chlistunoff, J. RRDE and Voltammetric Study of ORR on Pyrolyzed Fe/Polyaniline Catalyst. On the Origins of Variable Tafel Slopes. J. Phys. Chem. C 2011, 115, 6496–6507. [Google Scholar]

| GOm | Ramp | Atmosphere | Sample | d(002) (nm) | NL* | SBET (m2 g−1) | N (%) |

|---|---|---|---|---|---|---|---|

| GO325 | 1 | Inert | rGO325-1 | 0.35 | 13 | 767 | - |

| 2 | rGO325-2 | 0.35 | 10 | 804 | - | ||

| 3 | rGO325-3 | 0.34 | 12 | 867 | - | ||

| 4 | rGO325-4 | 0.35 | 17 | 667 | - | ||

| 5 | rGO325-5 | 0.36 | 26 | 866 | - | ||

| GO100 | 3 | Inert | rGO100-3 | 0.35 | 10 | 778 | - |

| GO10 | 3 | Inert | rGO10-3 | 0.34 | 18 | 505 | - |

| GO325 | 1 | Ammonia | NrGO325-1 | 0.34 | 14 | 428 | 4.8 |

| 2 | NrGO325-2 | 0.35 | 9 | 427 | 4.4 | ||

| 3 | NrGO325-3 | 0.34 | 14 | 460 | 5.0 | ||

| 4 | NrGO325-4 | 0.34 | 14 | 492 | 5.0 | ||

| 5 | NrGO325-5 | 0.34 | 13 | 476 | 4.1 | ||

| GO100 | 4 | Ammonia | NrGO100-4 | 0.35 | 10 | 420 | 3.8 |

| GO10 | 4 | Ammonia | NrGO10-4 | 0.34 | 40 | 236 | 1.8 |

| Sample | O (at %) | N (at %) | O 1s | N1s | ID/IG | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| C–O | C=O | COOH | H2O | Pyr | Pyrr | Quat | Nox | ||||

| rGO325-3 | 7.0 | - | 57.0 | 21.1 | 15.7 | 6.2 | - | - | - | - | 0.63 |

| rGO100-3 | 7.0 | - | 63.1 | 17.0 | 13.7 | 6.3 | - | - | - | - | 0.39 |

| rGO10-3 | 6.8 | - | 54.6 | 20.7 | 18.7 | 6.0 | - | - | - | - | 0.53 |

| NrGO325-4 | 4.1 | 3.4 | 54.7 | 23.5 | 17.6 | 4.2 | 40.0 | 21.7 | 22.7 | 15.6 | 0.75 |

| NrGO100-4 | 3.6 | 3.3 | 54.2 | 21.2 | 18.9 | 5.7 | 39.5 | 21.7 | 23.6 | 15.3 | 0.63 |

| NrGO10-4 | 3.6 | 3.2 | 56.2 | 17.4 | 18.7 | 7.6 | 38.5 | 20.5 | 28.5 | 12.4 | 0.58 |

| Sample | Eonset vs. RHE | jL (mA cm−2) | ñO2 | Tafel Slopes (mV dec−1) * |

|---|---|---|---|---|

| Pt/C (20 wt %) | 0.94 | −4.70 | 4.0 | 89 |

| rGO325-3 | 0.81 | −3.40 | 2.6 | 98 |

| rGO100-3 | 0.80 | −2.92 | 2.2 | 48 |

| rGO10-3 | 0.80 | −3.46 | 3.1 | 65 |

| NrGO325-4 | 0.82 | −4.05 | 3.9 | 62 |

| NrGO100-4 | 0.80 | −3.94 | 3.3 | 99 |

| NrGO10-4 | 0.79 | −3.03 | 3.0 | 78 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramirez-Barria, C.S.; Fernandes, D.M.; Freire, C.; Villaro-Abalos, E.; Guerrero-Ruiz, A.; Rodríguez-Ramos, I. Upgrading the Properties of Reduced Graphene Oxide and Nitrogen-Doped Reduced Graphene Oxide Produced by Thermal Reduction toward Efficient ORR Electrocatalysts. Nanomaterials 2019, 9, 1761. https://doi.org/10.3390/nano9121761

Ramirez-Barria CS, Fernandes DM, Freire C, Villaro-Abalos E, Guerrero-Ruiz A, Rodríguez-Ramos I. Upgrading the Properties of Reduced Graphene Oxide and Nitrogen-Doped Reduced Graphene Oxide Produced by Thermal Reduction toward Efficient ORR Electrocatalysts. Nanomaterials. 2019; 9(12):1761. https://doi.org/10.3390/nano9121761

Chicago/Turabian StyleRamirez-Barria, Carolina S., Diana M. Fernandes, Cristina Freire, Elvira Villaro-Abalos, Antonio Guerrero-Ruiz, and Inmaculada Rodríguez-Ramos. 2019. "Upgrading the Properties of Reduced Graphene Oxide and Nitrogen-Doped Reduced Graphene Oxide Produced by Thermal Reduction toward Efficient ORR Electrocatalysts" Nanomaterials 9, no. 12: 1761. https://doi.org/10.3390/nano9121761

APA StyleRamirez-Barria, C. S., Fernandes, D. M., Freire, C., Villaro-Abalos, E., Guerrero-Ruiz, A., & Rodríguez-Ramos, I. (2019). Upgrading the Properties of Reduced Graphene Oxide and Nitrogen-Doped Reduced Graphene Oxide Produced by Thermal Reduction toward Efficient ORR Electrocatalysts. Nanomaterials, 9(12), 1761. https://doi.org/10.3390/nano9121761