Fabrication and Highly Efficient Dye Removal Characterization of Beta-Cyclodextrin-Based Composite Polymer Fibers by Electrospinning

Abstract

1. Introduction

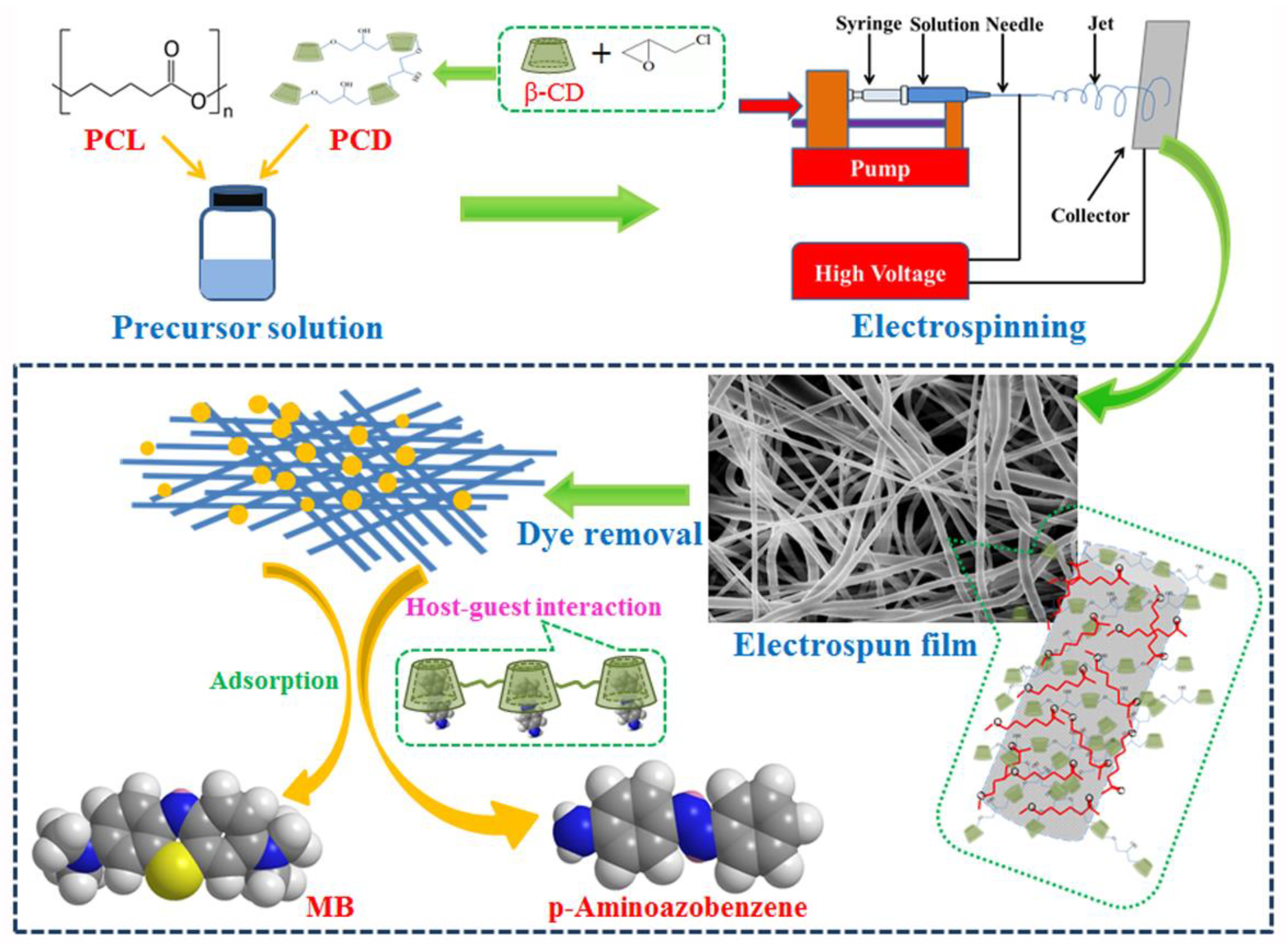

2. Materials and Methods

2.1. Materials

2.2. Preparation of β-Cyclodextrin Polymer (PCD)

2.3. Preparation of Electrospun Composite Fibers

2.4. Dye Removal Tests

2.5. Characterization

3. Results and Discussion

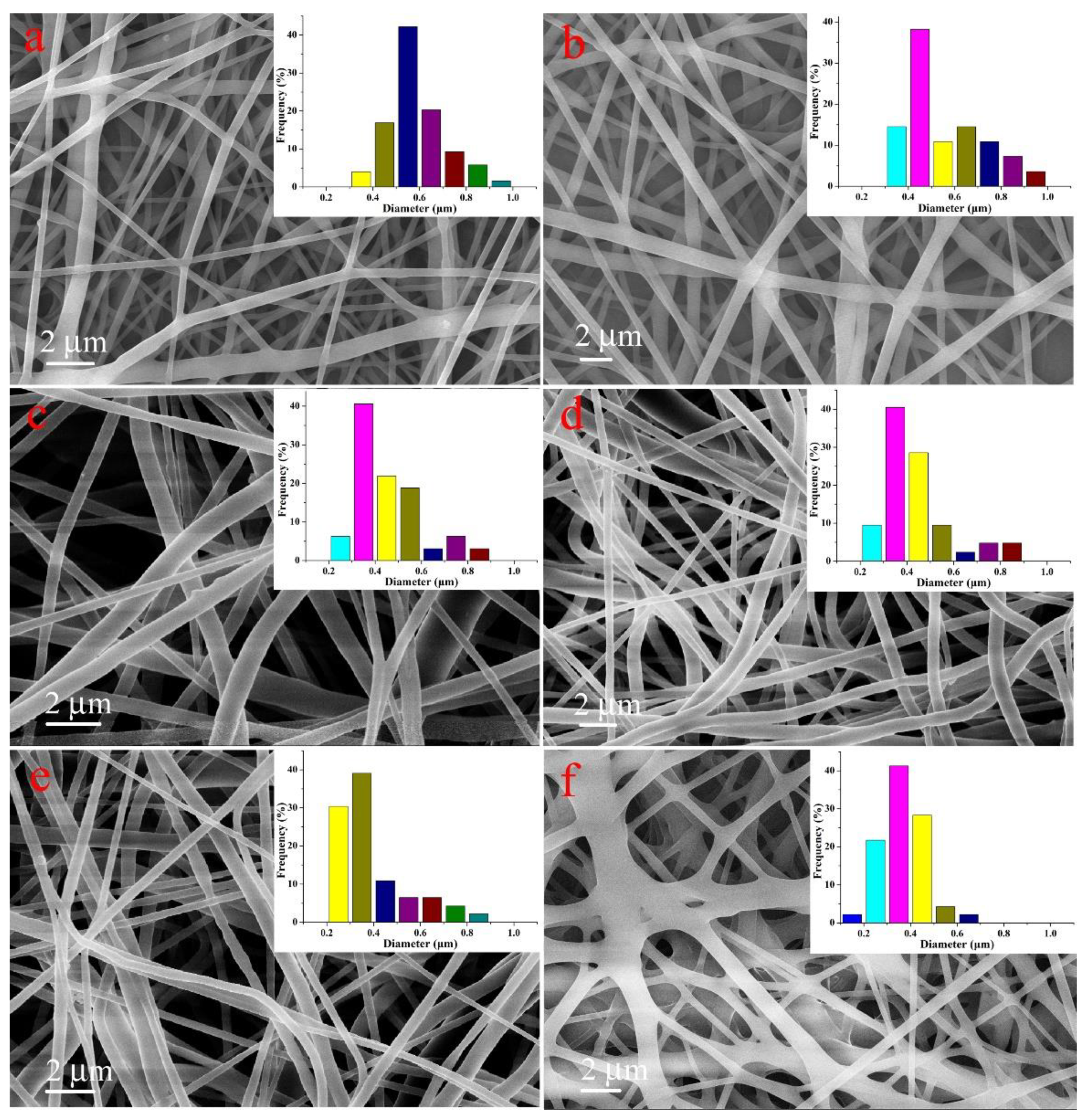

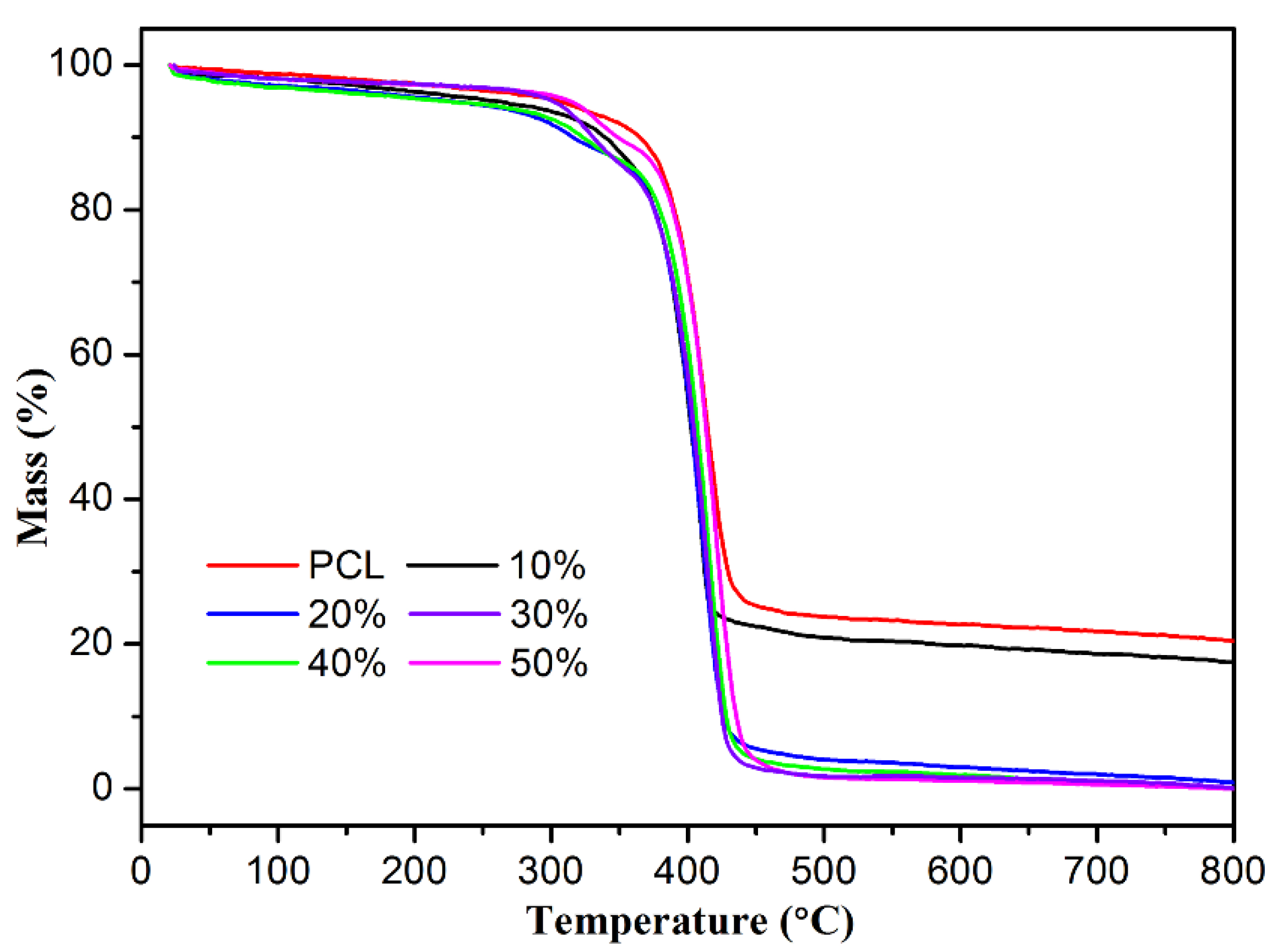

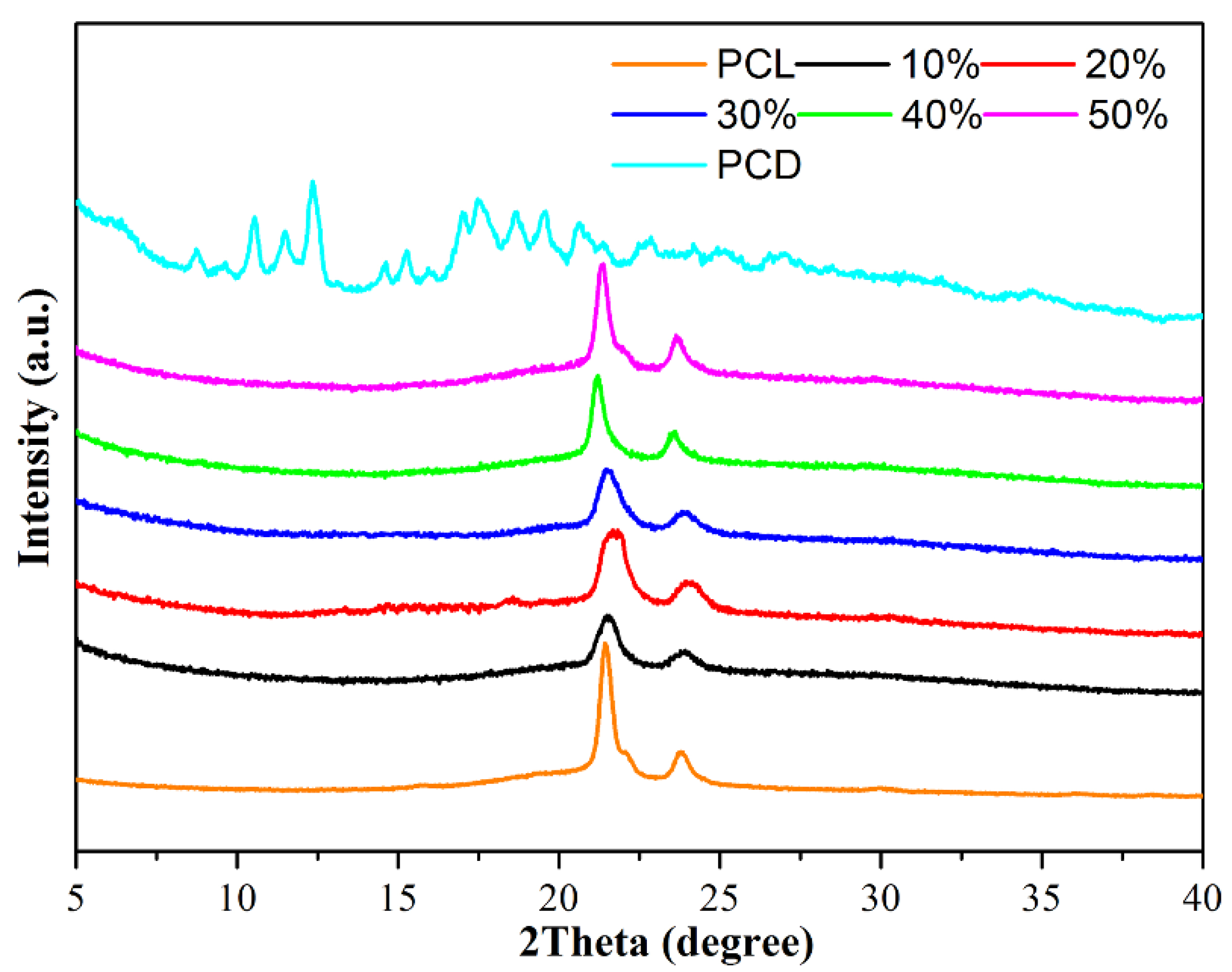

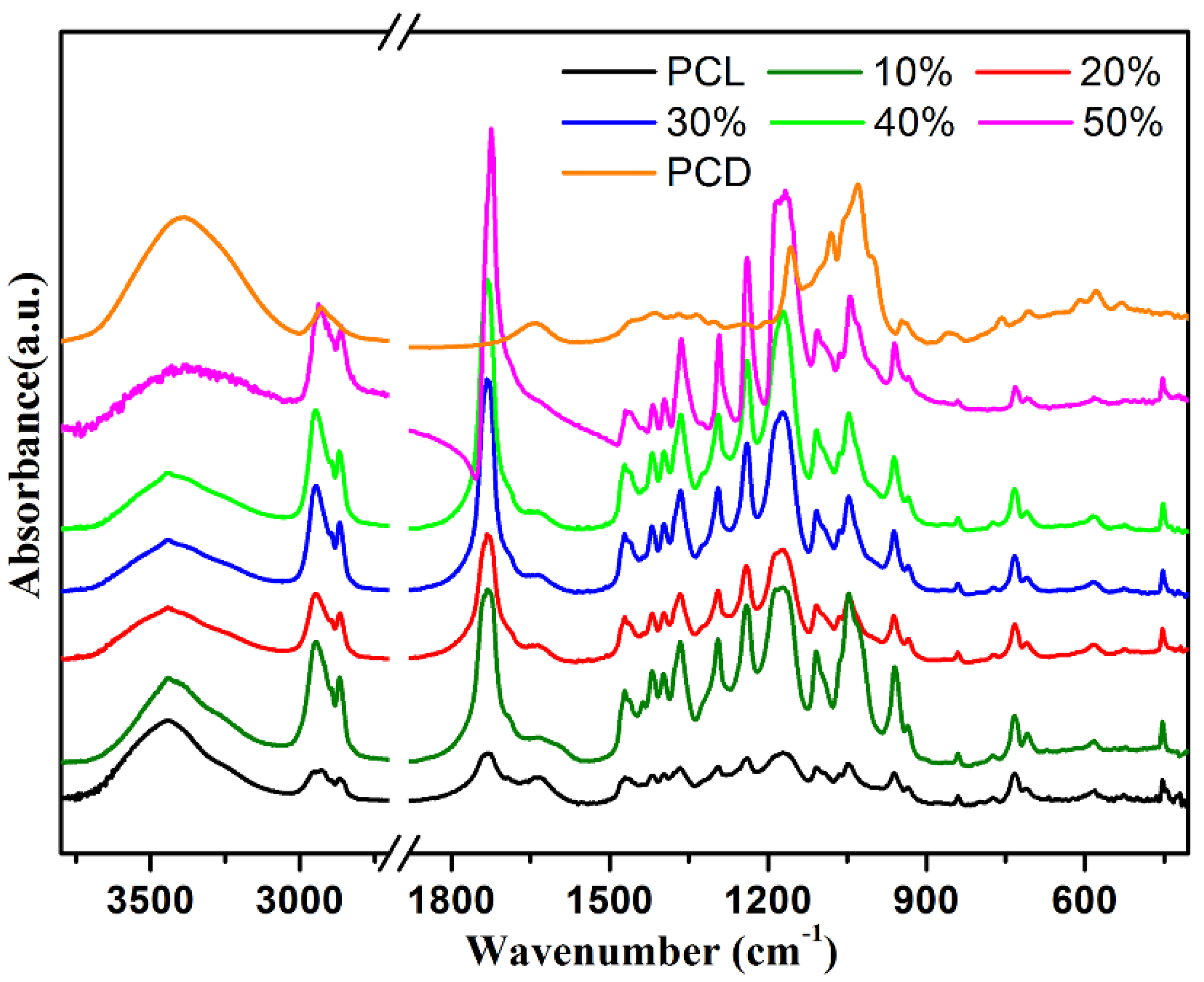

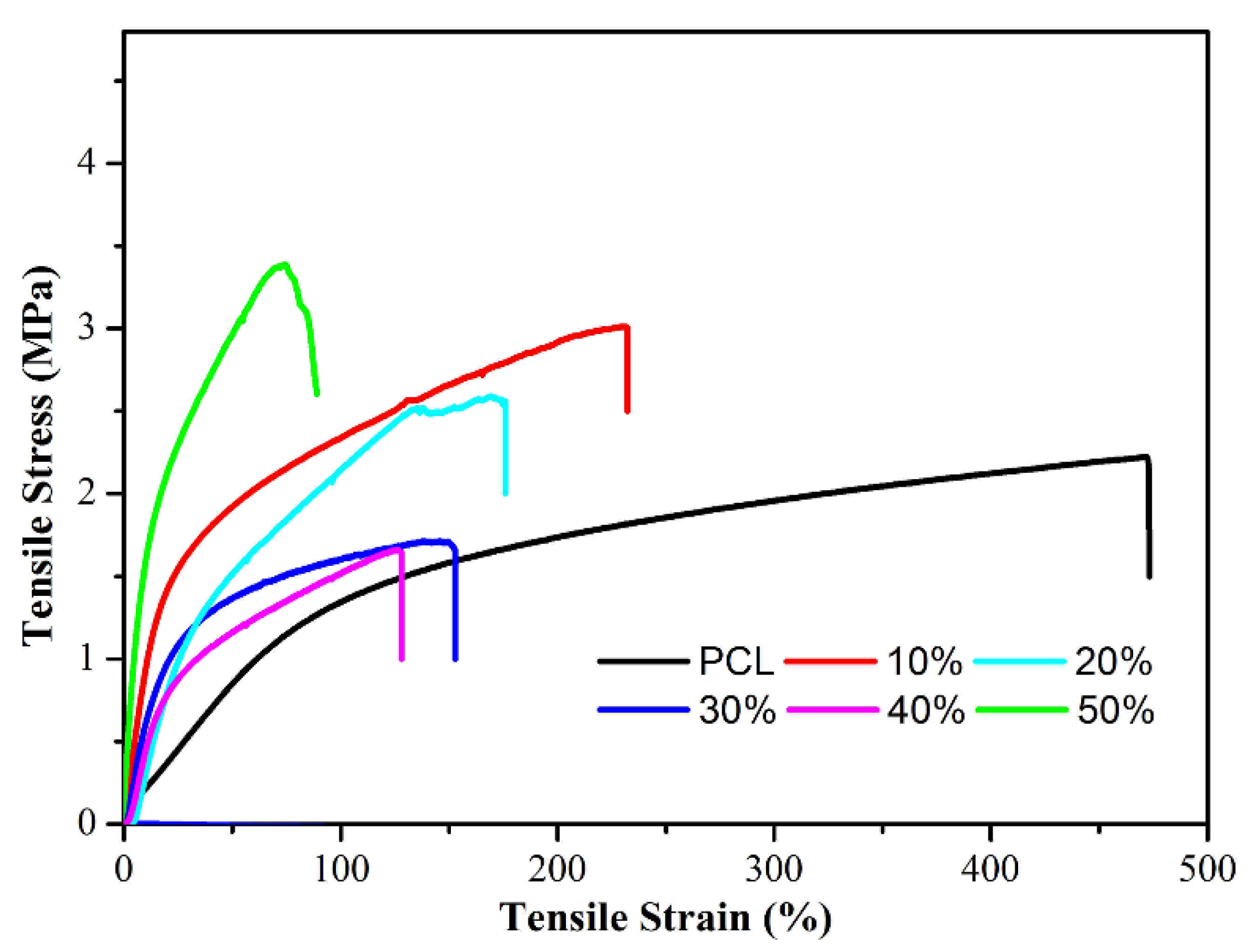

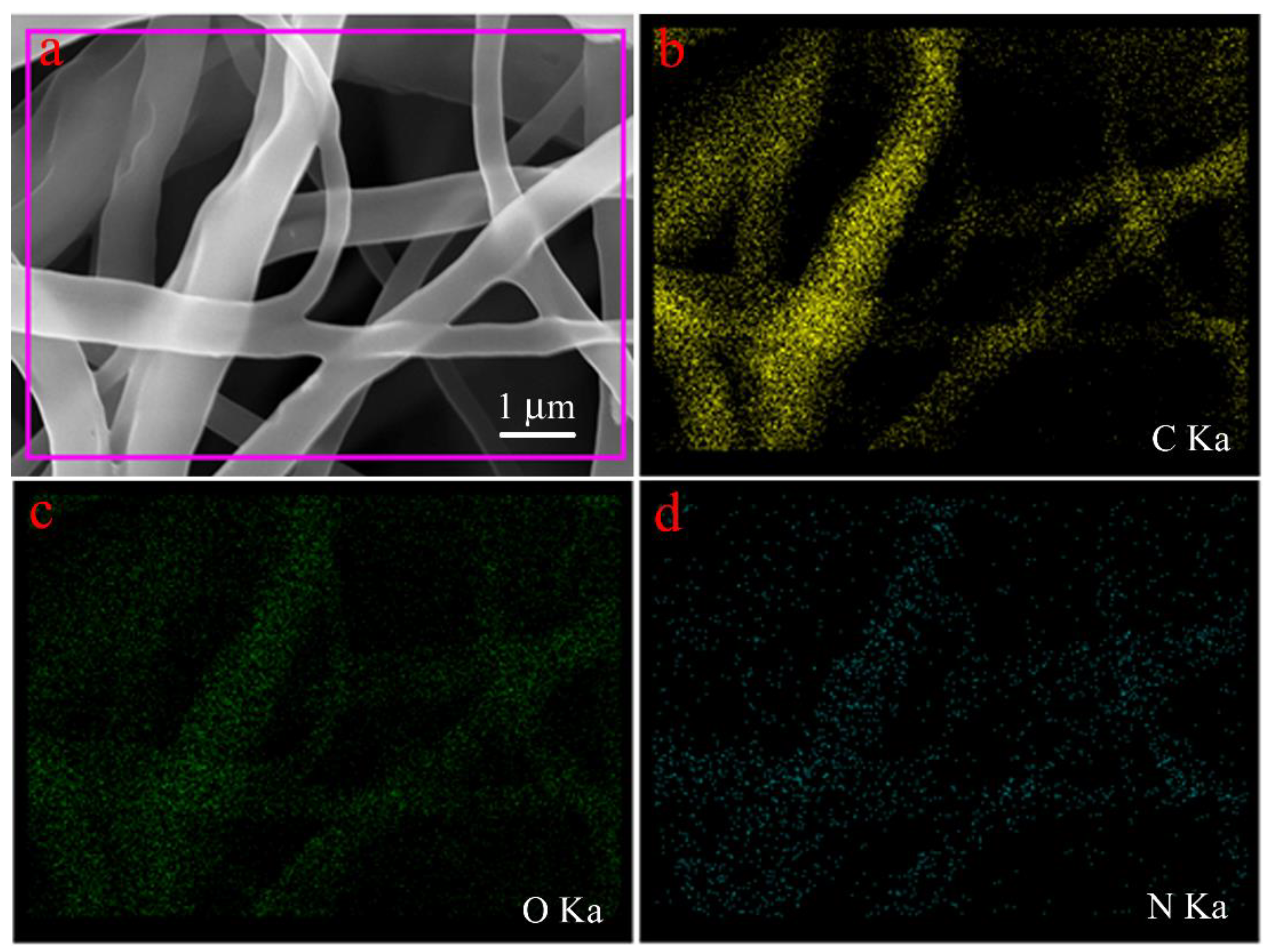

3.1. Structural Characterization of the Composite Polymer Fibers

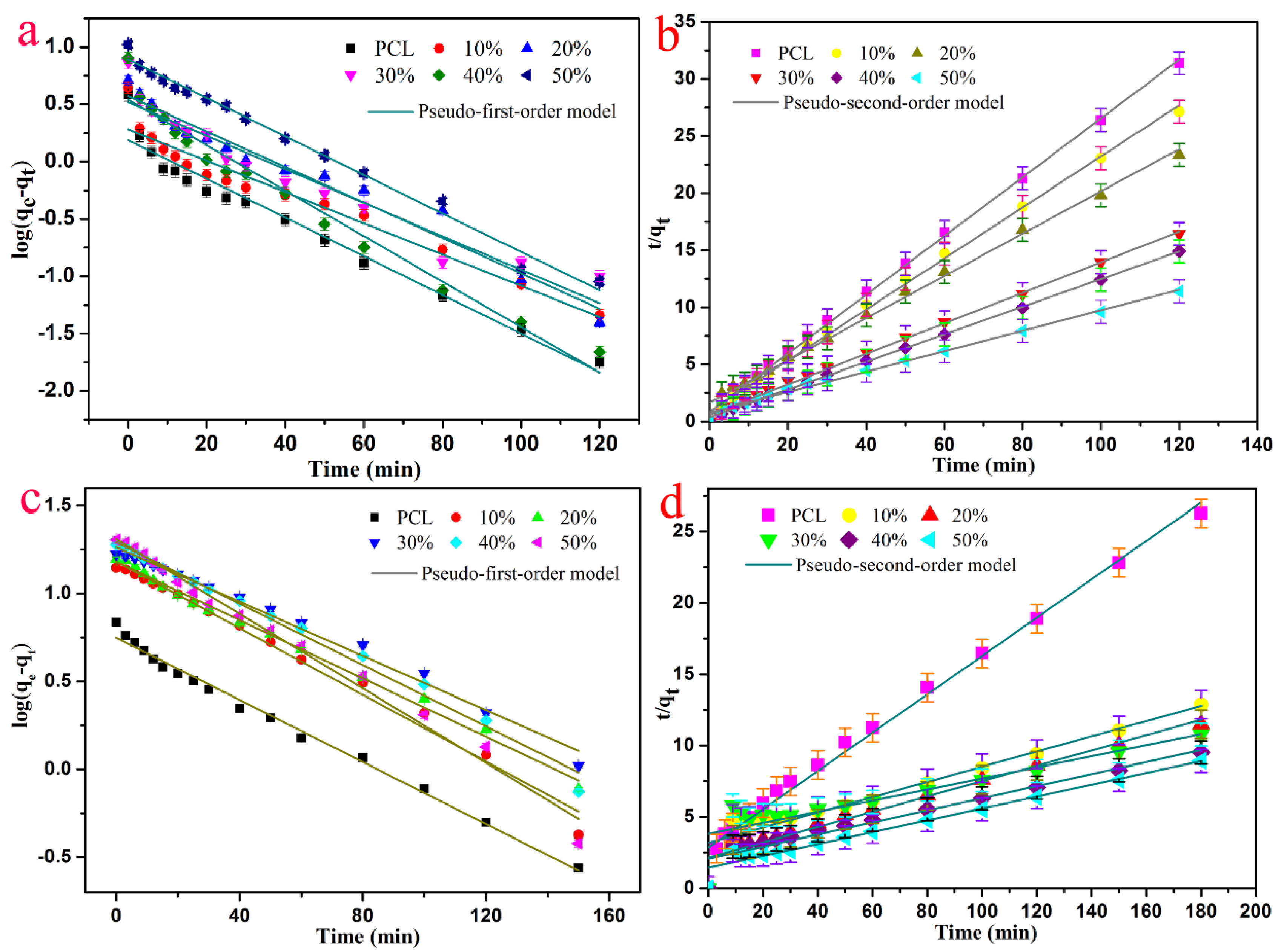

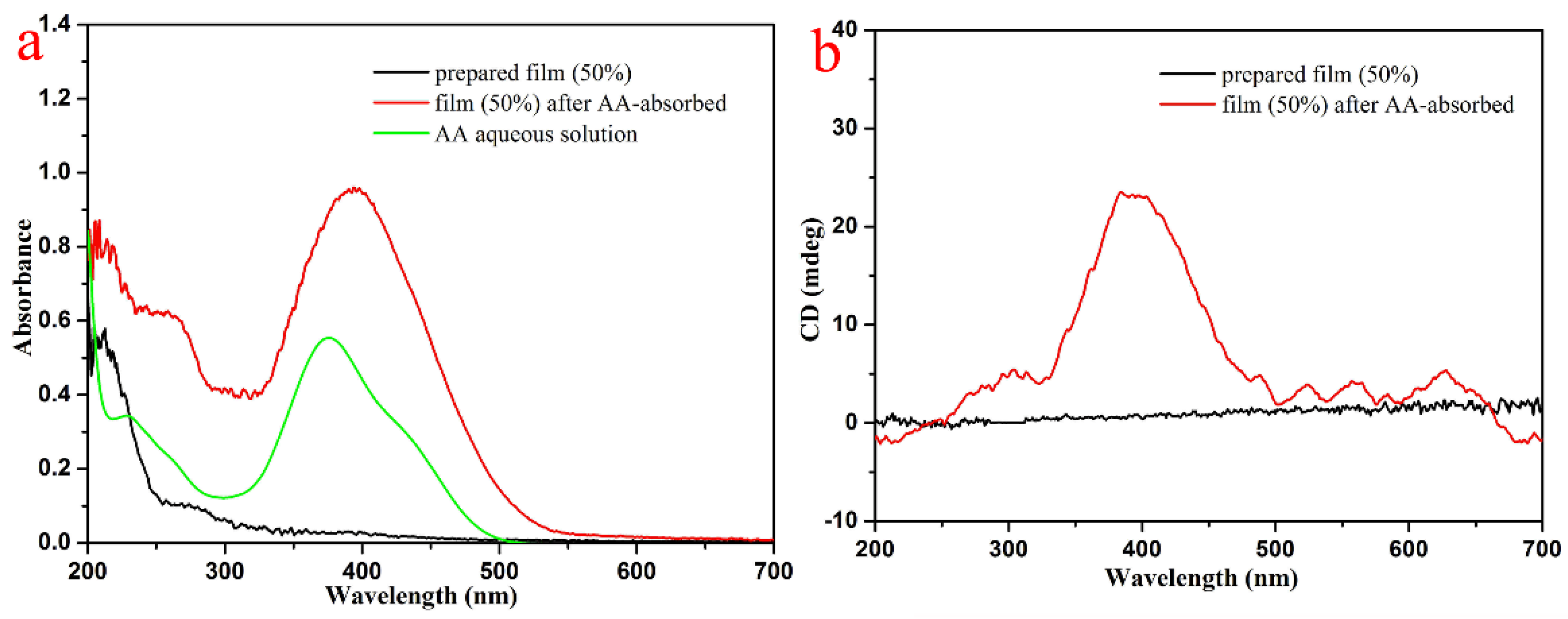

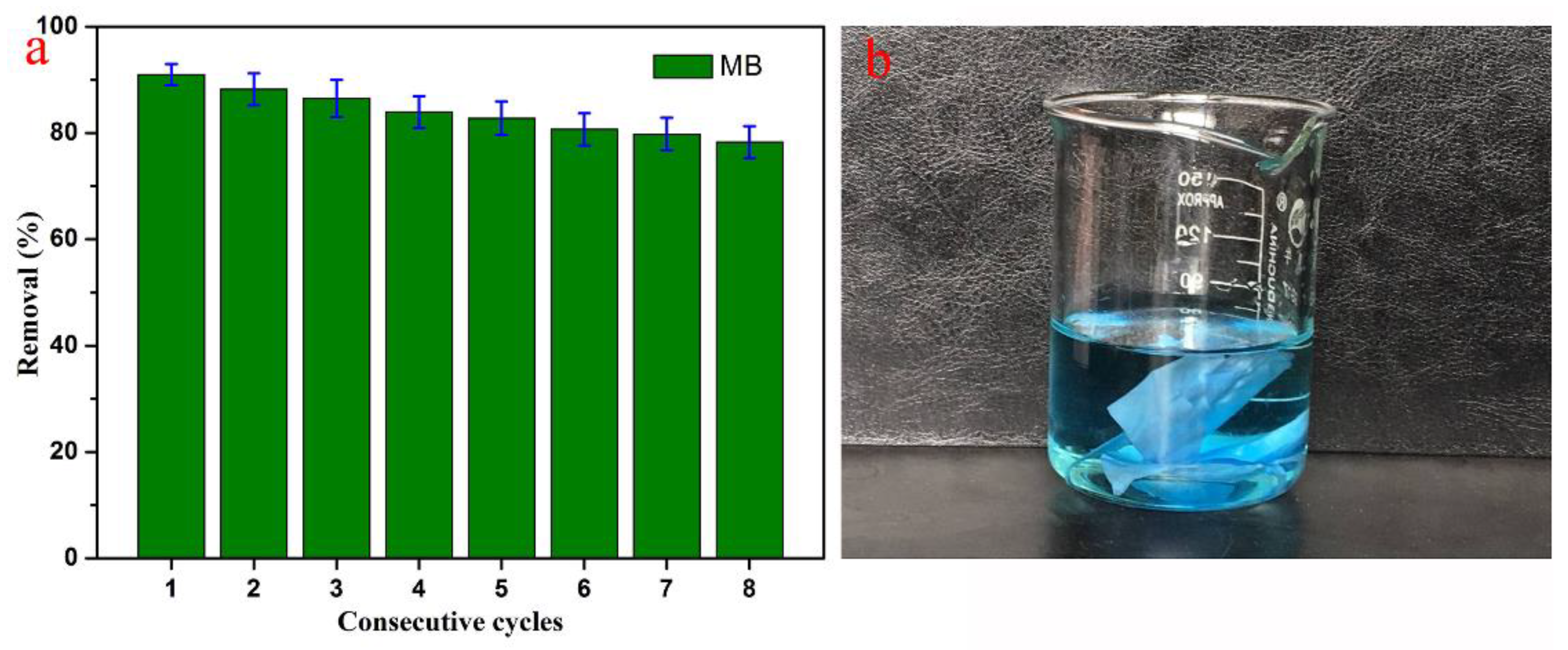

3.2. Dye Removal Performance of the Composite Fibers

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- De Oliveira, G.A.R.; de Lapuente, J.; Teixidó, E.; Porredón, C.; Borràs, M.; de Oliveira, D.P. Textile dyes induce toxicity on zebrafish early life stages. Environ. Toxicol. Chem. 2016, 35, 429–434. [Google Scholar] [CrossRef] [PubMed]

- Chong, M.N.; Jin, B.; Chow, C.W.; Saint, C. Recent developments in photocatalytic water treatment technology: A review. Water Res. 2010, 44, 2997–3027. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, G.A.R.; Leme, D.M.; de Lapuente, J.; Brito, L.B.; Porredón, C.; Rodrigues, L.B.; Brull, N.; Serret, J.T.; Borras, M.; Disner, G.R.; et al. A test battery for assessing the ecotoxic effects of textile dyes. Chem. Biol. Interact. 2018, 291, 171–179. [Google Scholar] [CrossRef] [PubMed]

- Li, D.; Li, Q.; Mao, D.; Bai, N.; Dong, H. A versatile bio-based material for efficiently removing toxic dyes, heavy metal ions and emulsified oil droplets from water simultaneously. Bioresour. Technol. 2017, 245, 649–655. [Google Scholar] [CrossRef] [PubMed]

- Zhu, W.; Li, Y.; Dai, L.; Li, J.W.; Li, X.; Li, W. Bioassembly of fungal hyphae/carbon nanotubes composite as a versatile adsorbent for water pollution control. Chem. Eng. J. 2018, 339, 214–222. [Google Scholar] [CrossRef]

- Zhao, H.; Jiao, T.F.; Zhang, L.X.; Zhou, J.X.; Zhang, Q.R.; Peng, Q.M.; Yan, X.H. Preparation and adsorption capacity evaluation of graphene oxide-chitosan composite hydrogels. Sci. China Mater. 2015, 58, 811–818. [Google Scholar] [CrossRef]

- Li, K.K.; Jiao, T.F.; Xing, R.R.; Zou, G.Y.; Zhou, J.X.; Zhang, L.X.; Peng, Q.M. Fabrication of tunable hierarchical MXene@AuNPs nanocomposites constructed by self-reduction reactions with enhanced catalytic performances. Sci. China Mater. 2018, 61, 728–736. [Google Scholar] [CrossRef]

- Guo, R.; Jiao, T.F.; Li, R.F.; Chen, Y.; Guo, W.C.; Zhang, L.X.; Zhou, J.X.; Zhang, Q.R.; Peng, Q.M. Sandwiched Fe3O4/carboxylate graphene oxide nanostructures constructed by layer-by-layer assembly for highly efficient and magnetically recyclable dye removal. ACS Sustain. Chem. Eng. 2018, 6, 1279–1288. [Google Scholar] [CrossRef]

- Zhao, X.; Ma, K.; Jiao, T.; Xing, R.; Ma, X.; Hu, J.; Huang, H.; Zhang, L.; Yan, X. Fabrication of hierarchical layer-by-layer assembled diamond based core-shell nanocomposites as highly efficient dye absorbents for wastewater treatment. Sci. Rep. 2017, 7, 44076. [Google Scholar] [CrossRef]

- Guo, H.; Jiao, T.; Zhang, Q.; Guo, W.; Peng, Q.; Yan, X. Preparation of graphene oxide-based hydrogels as efficient dye adsorbents for wastewater treatment. Nanoscale Res. Lett. 2015, 10, 272. [Google Scholar] [CrossRef]

- Sun, S.; Wang, C.; Han, S.; Jiao, T.; Wang, R.; Yin, J.; Li, Q.; Wang, Y.; Geng, L.; Yu, X.; et al. Interfacial nanostructures and acidichromism behaviors in self-assembled terpyridine derivatives Langmuir-Blodgett films. Colloid Surf. A Physicochem. Eng. Asp. 2019, 564, 1–9. [Google Scholar] [CrossRef]

- Xu, Y.; Ren, B.; Wang, R.; Zhang, L.; Jiao, T.; Liu, Z. Facile preparation of rod-like MnO nanomixtures via hydrothermal approach and highly efficient removal of methylene blue for wastewater Treatment. Nanomaterials 2019, 9, 10. [Google Scholar] [CrossRef] [PubMed]

- Chen, K.; Li, J.; Zhang, L.; Xing, R.; Jiao, T.; Gao, F.; Peng, Q. Facile synthesis of self-assembled carbon nanotubes/dye composite films for sensitive electrochemical determination of Cd(II) ions. Nanotechnology 2018, 29, 445603. [Google Scholar] [CrossRef] [PubMed]

- Paul, D. Research on heavy metal pollution of river Ganga: A review. Ann. Agrar. Sci. 2017, 15, 278–286. [Google Scholar] [CrossRef]

- Dargo, H.; Gabbiye, N.; Ayalew, A. Removal of methylene blue dye from textile wastewater using activated carbon prepared from rice husk. Can. Entomol. 2014, 9, 317–325. [Google Scholar]

- Dotto, G.L.; Santos, J.M.N.; Tanabe, E.H.; Bertuol, D.A.; Foletto, E.L.; Lima, E.C.; Pavan, F.A. Chitosan/polyamide nanofibers prepared by Forcespinning® technology: A new adsorbent to remove anionic dyes from aqueous solutions. J. Clean Prod. 2017, 144, 120–129. [Google Scholar] [CrossRef]

- Zhang, D.; Zeng, F. Synthesis of an Ag-ZnO nanocomposite catalyst for visible light-assisted degradation of a textile dye in aqueous solution. Res. Chem. Intermed. 2010, 36, 1055–1063. [Google Scholar] [CrossRef]

- Fei, B.L.; Zhong, J.K.; Deng, N.P.; Wang, J.H.; Liu, Q.B.; Li, Y.G.; Mei, X. A novel 3D heteropoly blue type photo-Fenton-like catalyst and its ability to remove dye pollution. Chemosphere 2018, 197, 241–250. [Google Scholar] [CrossRef]

- Fei, B.L.; Deng, N.P.; Wang, J.H.; Liu, Q.B.; Lang, G.Y.; Li, Y.G.; Mei, X. A heteropoly blue as environmental friendly material: An excellent heterogeneous Fenton-like catalyst and flocculent. J. Hazard. Mater. 2017, 340, 326–335. [Google Scholar] [CrossRef]

- Jin, X.; Li, N.; Weng, X.; Li, C.; Chen, Z. Green reduction of graphene oxide using eucalyptus leaf extract and its application to remove dye. Chemosphere 2018, 208, 417–424. [Google Scholar] [CrossRef]

- Zhang, J.; Dang, L.; Zhang, M.; Zhao, S.; Lu, Q. Micro/nanoscale magnesium silicate with hierarchical structure for removing dyes in water. Mater. Lett. 2017, 196, 194–197. [Google Scholar] [CrossRef]

- Farrokhi, M.; Hosseini, S.C.; Yang, J.K.; Shirzadsiboni, M. Application of ZnO-Fe3O4 nanocomposite on the removal of azo dye from aqueous solutions: kinetics and equilibrium studies. Water Air Soil Pollut. 2014, 225, 2113. [Google Scholar] [CrossRef]

- Ince, N.H.; Stefan, M.I.; Bolton, J.R. UV/H2O2 degradation and toxicity reduction of textile azo dyes: remazol black-B, a case study. J. Adv. Oxid. Technol. 2017, 2, 442–448. [Google Scholar] [CrossRef]

- Harisha, S.; Keshavayya, J.; Swamy, B.E.K.; Viswanath, C.C. Synthesis, characterization and electrochemical studies of azo dyes derived from barbituric acid. Dyes Pigment. 2017, 136, 742–753. [Google Scholar] [CrossRef]

- Levine, W.G. Metabolism of azo dyes: Implication for detoxication and activation. Drug Metab. Rev. 1991, 23, 253–309. [Google Scholar] [CrossRef] [PubMed]

- Gupta, V.K.; Jain, R.; Mittal, A.; Saleh, T.A.; Nayak, A.; Agarwal, S.; Sikarwas, S. Photo-catalytic degradation of toxic dye amaranth on TiO2/UV in aqueous suspensions. Mater. Sci. Eng. C Mater. 2012, 32, 12–17. [Google Scholar] [CrossRef] [PubMed]

- Koutsogeorgopoulou, L.; Maravelias, C.; Methenitou, G.; Loutselinis, A. Immunological aspects of the common food colorants, amaranth and tartrazine. Vet. Hum. Toxicol. 1998, 40, 1–4. [Google Scholar]

- Kadirvelu, K.; Palanival, M.; Kalpana, R.; Rajeswari, S. Activated carbon from an agricultural by-product, for the treatment of dyeing industry wastewater. Bioresour. Technol. 2000, 74, 263–265. [Google Scholar] [CrossRef]

- Bantle, J.A.; Fort, D.J.; Rayburn, J.R.; Deyoung, D.J.; Bush, S.J. Further validation of FETAX: Evaluation of the developmental toxicity of five known mammalian teratogens and non-teratogens. Drug Chem. Toxicol. 1990, 13, 267–282. [Google Scholar] [CrossRef]

- Mittal, A. Adsorption kinetics of removal of a toxic dye, Malachite Green, from wastewater by using hen feathers. J. Hazard. Mater. 2006, 133, 196–202. [Google Scholar] [CrossRef]

- Sweeney, E.A.; Chipman, J.K.; Forsythe, S.J. Evidence for Direct-Acting Oxidative Genotoxicity by Reduction Products of Azo Dyes. Environ. Health Perspect. 1994, 102, 119–122. [Google Scholar] [PubMed]

- Gottlieb, A.; Shaw, C.; Smith, A.; Wheatley, A.; Forsythe, S. The toxicity of textile reactive azo dyes after hydrolysis and decolourisation. J. Biotechnol. 2003, 101, 49–56. [Google Scholar] [CrossRef]

- Papic, S.; Koprivanac, N.; Metes, A. Optimizing Polymer-Induced Flocculation Process to Remove Reactive Dyes from Wastewater. Environ. Technol. Lett. 2000, 21, 97–105. [Google Scholar] [CrossRef]

- Kadirvelu, K.; Kavipriya, M.; Karthika, C.; Radhika, M.; Vennilamani, N.; Pattabhi, S. Utilization of various agricultural wastes for activated carbon preparation and application for the removal of dyes and metal ions from aqueous solutions. Bioresour. Technol. 2003, 87, 129–132. [Google Scholar] [CrossRef]

- Shen, D.Z.; Fan, J.; Zhou, W.; Gao, B.Y.; Yue, Q.Y.; Qi, K. Adsorption kinetics and isotherm of anionic dyes onto organo-bentonite from single and multisolute systems. J. Hazard. Mater. 2009, 172, 99–107. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Yin, J.; Wang, R.; Jiao, T.; Huang, H.; Zhou, J.; Zhang, L.; Peng, Q. Facile preparation of self-assembled polydopamine-modified electrospun fibers for highly effective removal of organic dyes. Nanomaterials 2019, 9, 116. [Google Scholar] [CrossRef]

- Zheng, Y.; Yu, S.; Shuai, S.; Zhou, Q.; Chen, Q.; Liu, M.; Gao, C.J. Color removal and COD reduction of biologically treated textile effluent through submerged filtration using hollow fiber nanofiltration membrane. Desalination 2013, 314, 89–95. [Google Scholar] [CrossRef]

- Balapure, K.; Bhatt, N.; Madamwar, D. Mineralization of reactive azo dyes present in simulated textile waste water using down flow microaerophilic fixed film bioreactor. Bioresour. Technol. 2015, 175, 1–7. [Google Scholar] [CrossRef]

- Konicki, W.; Aleksandrzak, M.; Moszyński, D.; Mijowsika, E. Adsorption of anionic azo-dyes from aqueous solutions onto graphene oxide: Equilibrium, kinetic and thermodynamic studies. J. Colloid Interface Sci. 2017, 496, 188–200. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, G.M.D.; Hespanhol, M.C.; Rezende, J.D.P.; Pires, A.C.D.S.; Gurgel, L.V.A.; Silva, L.H.M. Adsorption of red azo dyes on multi-walled carbon nanotubes and activated carbon: A thermodynamic study. Colloid Surf. A 2017, 529, 531–540. [Google Scholar] [CrossRef]

- Li, L.; Guo, X.; Fu, L.; Prudhomme, R.K.; Lincoln, S.F. Complexation Behavior of α-, β-, and γ-Cyclodextrin in Modulating and Constructing Polymer Networks. Langmuir 2008, 24, 8290–8296. [Google Scholar] [CrossRef] [PubMed]

- Guo, X.; Wang, J.; Li, L.; Chen, Q.; Li, Z.; Pham, D.T.; May, B.L.; Prud’homme, R.K.; Easton, C.J. Tunable polymeric hydrogels assembled by competitive complexation between cyclodextrin dimers and adamantyl substituted poly(acrylate)s. AIChE J. 2010, 56, 3021–3024. [Google Scholar] [CrossRef]

- Wang, J.; Pham, D.T.; Guo, X.; Li, L.; Pham, D.T.; Luo, Z.F.; Ke, H.L.; Zheng, L.; Prud’homme, R.K. Polymeric Networks Assembled by Adamantyl and β-Cyclodextrin Substituted Poly(acrylate)s: Host-Guest Interactions, and the Effects of Ionic Strength and Extent of Substitution. Ind. Eng. Chem. Res. 2009, 49, 609–612. [Google Scholar] [CrossRef]

- Theron, J.; Walker, J.A.; Cloete, T.E. Nanotechnology and Water Treatment: Applications and Emerging Opportunities. Criti. Rev. Microbiol. 2008, 34, 43–69. [Google Scholar] [CrossRef] [PubMed]

- Leudjo, T.A.; Pillay, K.; Yangkou, M.X. Nanosponge cyclodextrin polyurethanes and their modification with nanomaterials for the removal of pollutants from waste water: A review. Carbohyd. Polym. 2017, 159, 94–107. [Google Scholar] [CrossRef] [PubMed]

- Khaoulani, S.; Chaker, H.; Cadet, C.; Bychkov, E.; Cherifaouali, L.; Bengueddach, A.; Fourmentin, S. Wastewater treatment by cyclodextrin polymers and noble metal/mesoporous TiO2 photocatalysts. C. R. Chim. 2015, 18, 23–31. [Google Scholar] [CrossRef]

- Yamasaki, H.; Makihata, Y.; Fukunaga, K. Efficient phenol removal of wastewater from phenolic resin plants using crosslinked cyclodextrin particles. J. Chem. Technol. Biotechnol. 2010, 81, 1271–1276. [Google Scholar] [CrossRef]

- Chai, K.; Ji, H. Dual functional adsorption of benzoic acid from wastewater by biological-based chitosan grafted β-cyclodextrin. Chem. Eng. J. 2012, 203, 309–318. [Google Scholar] [CrossRef]

- Li, J.; Loh, X.J. Cyclodextrin-based supramolecular architectures: Syntheses, structures, and applications for drug and gene delivery. Adv. Drug Deliv. Rev. 2008, 60, 1000–1017. [Google Scholar] [CrossRef]

- Yilmaz, E.; Memon, S.; Yilmaz, M. Removal of direct azo dyes and aromatic amines from aqueous solutions using two β-cyclodextrin-based polymers. J. Hazard. Mater. 2010, 174, 592–597. [Google Scholar] [CrossRef]

- Ozmen, E.Y.; Sezgin, M.; Yilmaz, A.; Yilmaz, M. Synthesis of beta-cyclodextrin and starch based polymers for sorption of azo dyes from aqueous solutions. Bioresour. Technol. 2008, 99, 526–531. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Hou, C.; Jiao, T.; Song, J.; Zhang, X.; Xing, R.; Zhou, J.; Zhang, L.; Peng, Q. Self-assembled AgNP-containing nanocomposites constructed by electrospinning as efficient dye photocatalyst materials for wastewater treatment. Nanomaterials 2018, 8, 35. [Google Scholar] [CrossRef] [PubMed]

- Xing, R.; Wang, W.; Jiao, T.; Ma, K.; Zhang, Q.; Hong, W.; Qiu, H.; Zhou, J.; Zhang, L.; Peng, Q. Bioinspired polydopamine sheathed nanofibers containing carboxylate graphene oxide nanosheet for high-efficient dyes scavenger. ACS Sustain. Chem. Eng. 2017, 5, 4948–4956. [Google Scholar] [CrossRef]

- Wang, C.; Sun, S.; Zhang, L.; Yin, J.; Jiao, T.; Zhang, L.; Xu, Y.; Zhou, J.; Peng, Q. Facile preparation and catalytic performance characterization of AuNPs-loaded hierarchical electrospun composite fibers by solvent vapor annealing treatment. Colloid Surf. A Physicochem. Eng. Asp. 2019, 561, 283–291. [Google Scholar] [CrossRef]

- Zhou, J.; Liu, Y.; Jiao, T.; Xing, R.; Yang, Z.; Fan, J.; Liu, J.; Li, B.; Peng, Q. Preparation and enhanced structural integrity of electrospun poly(ε-caprolactone)-based fibers by freezing amorphous chains through thiol-ene click reaction. Colloid Surf. A Physicochem. Eng. Asp. 2018, 538, 7–13. [Google Scholar] [CrossRef]

- Huang, X.; Jiao, T.; Liu, Q.; Zhang, L.; Zhou, J.; Li, B.; Peng, Q. Hierarchical electrospun nanofibers treated by solvent vapor annealing as air filtration mat for high-efficiency PM2.5 capture. Sci. China Mater. 2019, 62, 423–436. [Google Scholar] [CrossRef]

- Cui, H.Y.; Bai, M.; Lin, L. Plasma-treated poly(ethylene oxide) nanofibers containing tea tree oil/beta-cyclodextrin inclusion complex for antibacterial packaging. Carbohyd. Polym. 2018, 179, 360–369. [Google Scholar] [CrossRef] [PubMed]

- Celebioglu, A.; Uyar, T. Antioxidant Vitamin E/cyclodextrin inclusion complex electrospun nanofibers: Enhanced water solubility, prolonged shelf life, and photostability of Vitamin E. J. Agric. Food Chem. 2017, 65, 5404–5412. [Google Scholar] [CrossRef] [PubMed]

- Aytac, Z.; Ipek, S.; Durgun, E.; Tekinay, T.; Uyar, T. Antibacterial electrospun zein nanofibrous web encapsulating thymol/cyclodextrin-inclusion complex for food packaging. Food Chem. 2017, 233, 117–124. [Google Scholar] [CrossRef]

- Lin, L.; Dai, Y.J.; Cui, H.Y. Antibacterial poly(ethylene oxide) electrospun nanofibers containing cinnamon essential oil/beta-cyclodextrin proteoliposomes. Carbohyd. Polym. 2017, 178, 131–140. [Google Scholar] [CrossRef]

- Zhang, H.R.; Chen, G.; Wang, L.; Ding, L.; Tian, Y.; Jin, W.Q.; Zhang, H.Q. Study on the inclusion complexes of cyclodextrin and sulphonated azo dyes by electrospray ionization mass spectrometry. Int. J. Mass Spectrom. 2006, 252, 1–10. [Google Scholar] [CrossRef]

- Koopmans, C.; Ritter, H. Formation of physical hydrogels via host–guest interactions of β-cyclodextrin polymers and copolymers bearing adamantyl groups. Macromolecules 2008, 41, 7418–7422. [Google Scholar] [CrossRef]

- Jiang, Q.; Zhang, Y.; Zhuo, R.; Jiang, X. Supramolecular host–guest polycationic gene delivery system based on poly(cyclodextrin) and azobenzene-terminated polycations. Colloid Surf. B 2016, 147, 25–35. [Google Scholar] [CrossRef] [PubMed]

- Bauer, A.J.P.; Grim, Z.B.; Li, B.B. Hierarchical polymer blend fibers of high structural regularity prepared by facile solvent vapor annealing treatment. Macromol. Mater. Eng. 2018, 303, 1700489. [Google Scholar] [CrossRef]

- Liu, J.Z.; Bauer, A.J.P.; Li, B.B. Solvent vapor annealing: An efficient approach for inscribing secondary nanostructures onto electrospun fibers. Macromol. Rapid Comm. 2014, 35, 1503–1508. [Google Scholar] [CrossRef]

- Narayanan, G.; Aguda, R.; Hartman, M.; Chung, C.C.; Boy, R.; Gupta, B.S.; Tonelli, A.E. Fabrication and characterization of poly(ε-caprolactone)/α-cyclodextrin pseudorotaxane nanofibers. Biomacromolecules 2015, 17, 271–279. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.H.; Chen, S.H.; Shalumon, K.T.; Chen, J.P. Prevention of peritendinous adhesions with electrospun polyethylene glycol/polycaprolactone nanofibrous membranes. Colloids Surf. B 2015, 133, 221–230. [Google Scholar] [CrossRef] [PubMed]

- Narayanan, G.; Ormond, B.R.; Gupta, B.S.; Tonelli, A.E. Efficient wound odor removal by β-cyclodextrin functionalized poly (ε-caprolactone) nanofibers. J. Appl. Polym. Sci. 2015, 132, 42782. [Google Scholar] [CrossRef]

- Narayanan, G.; Gupta, B.S.; Tonelli, A.E. Enhanced mechanical properties of poly (ε-caprolactone) nanofibers produced by the addition of non-stoichiometric inclusion complexes of poly (ε-caprolactone) and α-cyclodextrin. Polymer 2015, 76, 321–330. [Google Scholar] [CrossRef]

- Huang, X.N.; Huang, Y.G.; Chai, X.S.; Wei, W. Study of adsorption kinetics for fluorescent whitening agent on fiber surfaces. Sci. China Chem. 2008, 51, 473–478. [Google Scholar] [CrossRef]

- Chen, B.L.; Zhou, D.D.; Zhu, L.Z.; Shen, X.Y. Sorption characteristics and mechanisms of organic contaminant to carbonaceous biosorbents in aqueous solution. Sci. China Chem. 2008, 51, 464–472. [Google Scholar] [CrossRef]

- Zhan, F.; Wang, R.; Yin, J.; Han, Z.; Zhang, L.; Jiao, T.; Zhou, J.; Zhang, L.; Peng, Q. Facile solvothermal preparation of Fe3O4–Ag nanocomposite with excellent catalytic performance. RSC Adv. 2019, 9, 878–883. [Google Scholar] [CrossRef]

- Huo, S.; Duan, P.; Jiao, T.; Peng, Q.; Liu, M. Self-assembled luminescent quantum dots to generate full-color and white circularly polarized light. Angew. Chem. Int. Ed. 2017, 56, 12174–12178. [Google Scholar] [CrossRef] [PubMed]

- Xing, R.; Liu, K.; Jiao, T.; Zhang, N.; Ma, K.; Zhang, R.; Zou, Q.; Ma, G.; Yan, X. An injectable self-assembling collagen-gold hybrid hydrogel for combinatorial antitumor photothermal/photodynamic therapy. Adv. Mater. 2016, 28, 3669–3676. [Google Scholar] [CrossRef] [PubMed]

- Luo, X.; Ma, K.; Jiao, T.; Xing, R.; Zhang, L.; Zhou, J.; Li, B. Graphene oxide-polymer composite Langmuir films constructed by interfacial thiol-ene photopolymerization. Nanoscale Res. Lett. 2017, 12, 99. [Google Scholar] [CrossRef] [PubMed]

- Zhang, R.Y.; Xing, R.R.; Jiao, T.F.; Ma, K.; Chen, C.J.; Ma, G.H.; Yan, X.H. Synergistic in vivo photodynamic and photothermal antitumor therapy based on collagen-gold hybrid hydrogels with inclusion of photosensitive drugs Colloids and Surfaces A: Physicochemical and Engineering Aspects. ACS Appl. Mater. Interfaces 2016, 8, 13262–13269. [Google Scholar] [CrossRef] [PubMed]

- Xing, R.; Jiao, T.; Liu, Y.; Ma, K.; Zou, Q.; Ma, G.; Yan, X. Co-assembly of graphene oxide and albumin/photosensitizer nanohybrids towards enhanced photodynamic therapy. Polymers 2016, 8, 181. [Google Scholar] [CrossRef]

- Liu, K.; Yuan, C.Q.; Zou, Q.L.; Xie, Z.C.; Yan, X.H. Self-assembled Zinc/cystine-based chloroplast mimics capable of photoenzymatic reactions for sustainable fuel synthesis. Angew. Chem. Int. Ed. 2017, 56, 7876–7880. [Google Scholar] [CrossRef]

- Liu, K.; Xing, R.R.; Li, Y.X.; Zou, Q.L.; Möhwald, H.; Yan, X.H. Mimicking primitive photobacteria: Sustainable hydrogen evolution based on peptide-porphyrin co-assemblies with self-mineralized reaction center. Angew. Chem. Int. Ed. 2016, 55, 12503–12507. [Google Scholar] [CrossRef]

- Liu, K.; Xing, R.R.; Chen, C.J.; Shen, G.Z.; Yan, L.Y.; Zou, Q.L.; Ma, G.H.; Möhwald, H.; Yan, X.H. Peptide-induced hierarchical long-range order and photocatalytic activity of porphyrin assemblies. Angew. Chem. Int. Ed. 2015, 54, 500–505. [Google Scholar] [CrossRef]

| PCD Concentration (wt%) | 0 | 10 | 20 | 30 | 40 | 50 |

|---|---|---|---|---|---|---|

| PCL (g) | 1.20 | 1.20 | 1.20 | 1.20 | 1.20 | 1.20 |

| CCl4 (mL) | 4.17 | 4.11 | 4.02 | 3.92 | 3.78 | 3.60 |

| DMF (mL) | 2.78 | 2.74 | 2.68 | 2.61 | 2.52 | 2.40 |

| Samples | Specific Surface Area (m2·g−1) | Average Pore Diameter (nm) | Pore Volume (cm3·g−1) |

|---|---|---|---|

| PCL fiber | 7.50 | 20.1 | 0.008231 |

| PCL/(10%)PCD | 7.82 | 20.5 | 0.008464 |

| PCL/(20%)PCD | 7.96 | 21.0 | 0.008576 |

| PCL/(30%)PCD | 8.45 | 22.5 | 0.009125 |

| PCL/(40%)PCD | 10.85 | 23.6 | 0.009277 |

| PCL/(50%)PCD | 11.52 | 23.6 | 0.009446 |

| MB | Pseudo-First-Order Model | Pseudo-Second-Order Model | ||||

| qe (mg/g) | R2 | K1 (min−1) | qe (mg/g) | R2 | K2 (g/mg min) | |

| PCL | 3.8246 | 0.9337 | 0.0393 | 3.8879 | 0.9989 | 0.0811 |

| PCL/(10%)PCD | 4.4238 | 0.9129 | 0.0317 | 4.4767 | 0.9979 | 0.0568 |

| PCL/(20%)PCD | 5.1414 | 0.9498 | 0.0337 | 5.4077 | 0.9936 | 0.0206 |

| PCL/(30%)PCD | 7.3002 | 0.9404 | 0.0376 | 7.4862 | 0.9980 | 0.0303 |

| PCL/(40%)PCD | 8.0465 | 0.9398 | 0.0550 | 8.2740 | 0.9991 | 0.0373 |

| PCL/(50%)PCD | 10.5238 | 0.9837 | 0.0399 | 11.1632 | 0.9931 | 0.0102 |

| 4-aminoazobenzene | Pseudo-first-order model | Pseudo-second-order model | ||||

| qe (mg/g) | R2 | K1 (min−1) | qe (mg/g) | R2 | K2 (g/mg min) | |

| PCL | 6.8517 | 0.9916 | 0.0203 | 7.4427 | 0.9868 | 0.0064 |

| PCL/(10%)PCD | 13.9828 | 0.9872 | 0.0218 | 18.7512 | 0.9981 | 0.0090 |

| PCL/(20%)PCD | 15.6643 | 0.9941 | 0.0191 | 18.6324 | 0.9931 | 0.0014 |

| PCL/(30%)PCD | 16.7213 | 0.9986 | 0.0178 | 25.7070 | 0.9986 | 0.0004 |

| PCL/(40%)PCD | 18.9147 | 0.9895 | 0.0201 | 23.6183 | 0.9978 | 0.0009 |

| PCL/(50%)PCD | 20.1740 | 0.9870 | 0.0244 | 24.0674 | 0.9943 | 0.0012 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, R.; Wang, R.; Yin, J.; Jiao, T.; Huang, H.; Zhao, X.; Zhang, L.; Li, Q.; Zhou, J.; Peng, Q. Fabrication and Highly Efficient Dye Removal Characterization of Beta-Cyclodextrin-Based Composite Polymer Fibers by Electrospinning. Nanomaterials 2019, 9, 127. https://doi.org/10.3390/nano9010127

Guo R, Wang R, Yin J, Jiao T, Huang H, Zhao X, Zhang L, Li Q, Zhou J, Peng Q. Fabrication and Highly Efficient Dye Removal Characterization of Beta-Cyclodextrin-Based Composite Polymer Fibers by Electrospinning. Nanomaterials. 2019; 9(1):127. https://doi.org/10.3390/nano9010127

Chicago/Turabian StyleGuo, Rong, Ran Wang, Juanjuan Yin, Tifeng Jiao, Haiming Huang, Xinmei Zhao, Lexin Zhang, Qing Li, Jingxin Zhou, and Qiuming Peng. 2019. "Fabrication and Highly Efficient Dye Removal Characterization of Beta-Cyclodextrin-Based Composite Polymer Fibers by Electrospinning" Nanomaterials 9, no. 1: 127. https://doi.org/10.3390/nano9010127

APA StyleGuo, R., Wang, R., Yin, J., Jiao, T., Huang, H., Zhao, X., Zhang, L., Li, Q., Zhou, J., & Peng, Q. (2019). Fabrication and Highly Efficient Dye Removal Characterization of Beta-Cyclodextrin-Based Composite Polymer Fibers by Electrospinning. Nanomaterials, 9(1), 127. https://doi.org/10.3390/nano9010127