Notable Enhancement of Phase Transition Performance and Luminous Transmittance in VO2 Films via Simple Method of Ar/O Plasma Post-Treatment

Abstract

1. Introduction

2. Experimental Details

3. Results and Discussion

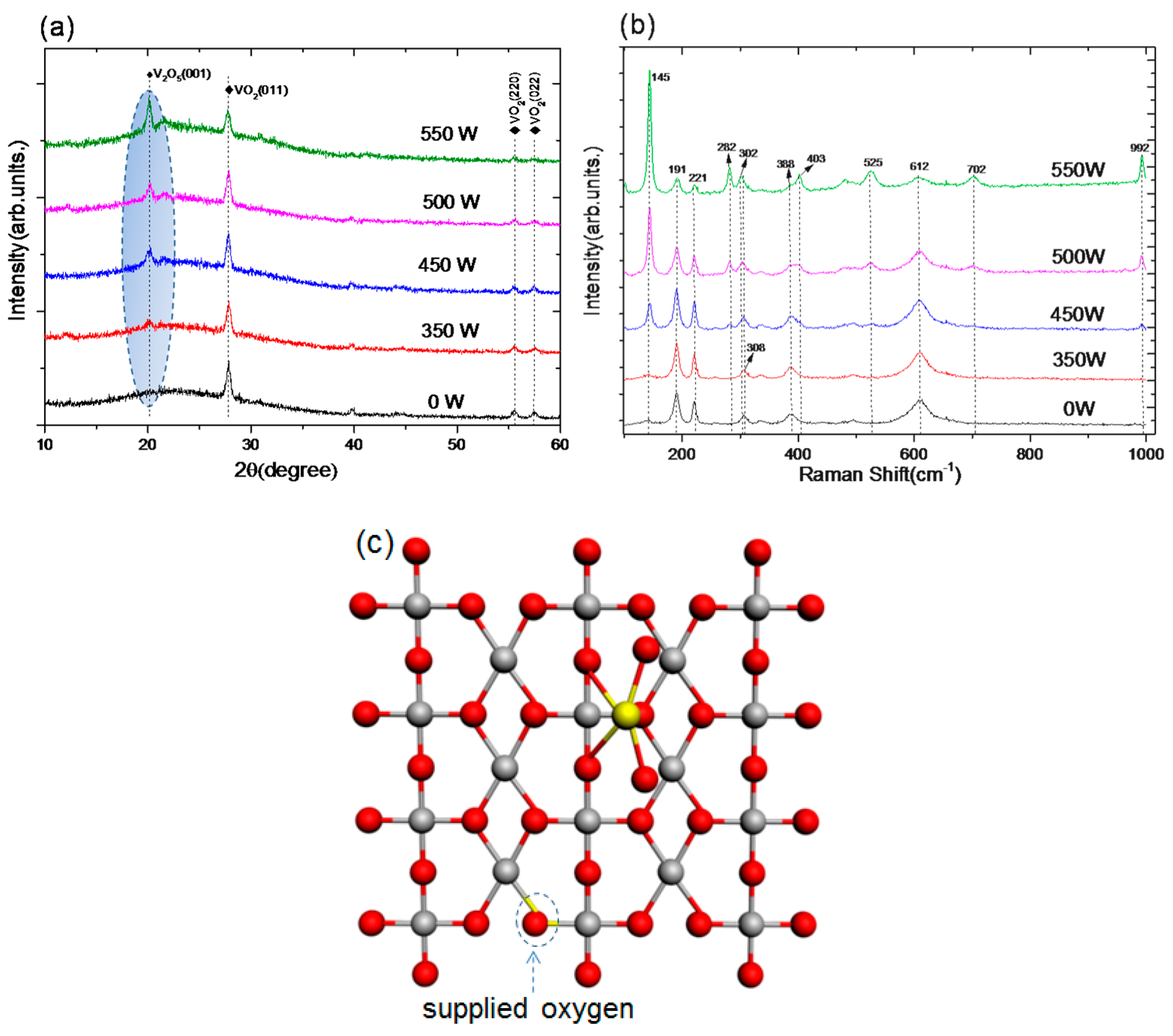

3.1. Structure Characteristic

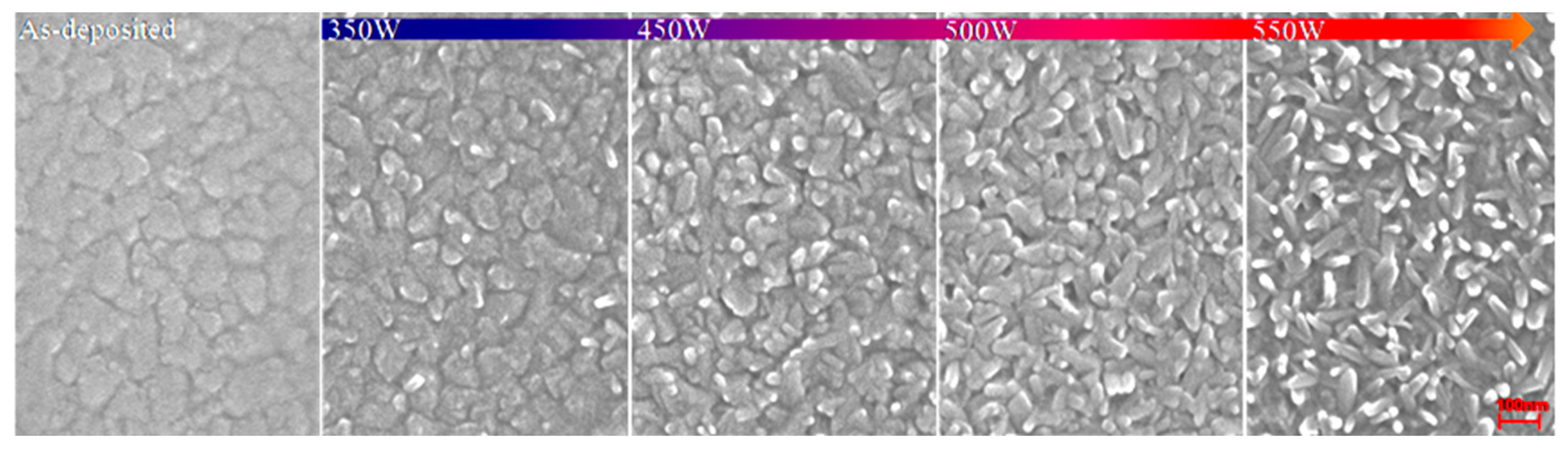

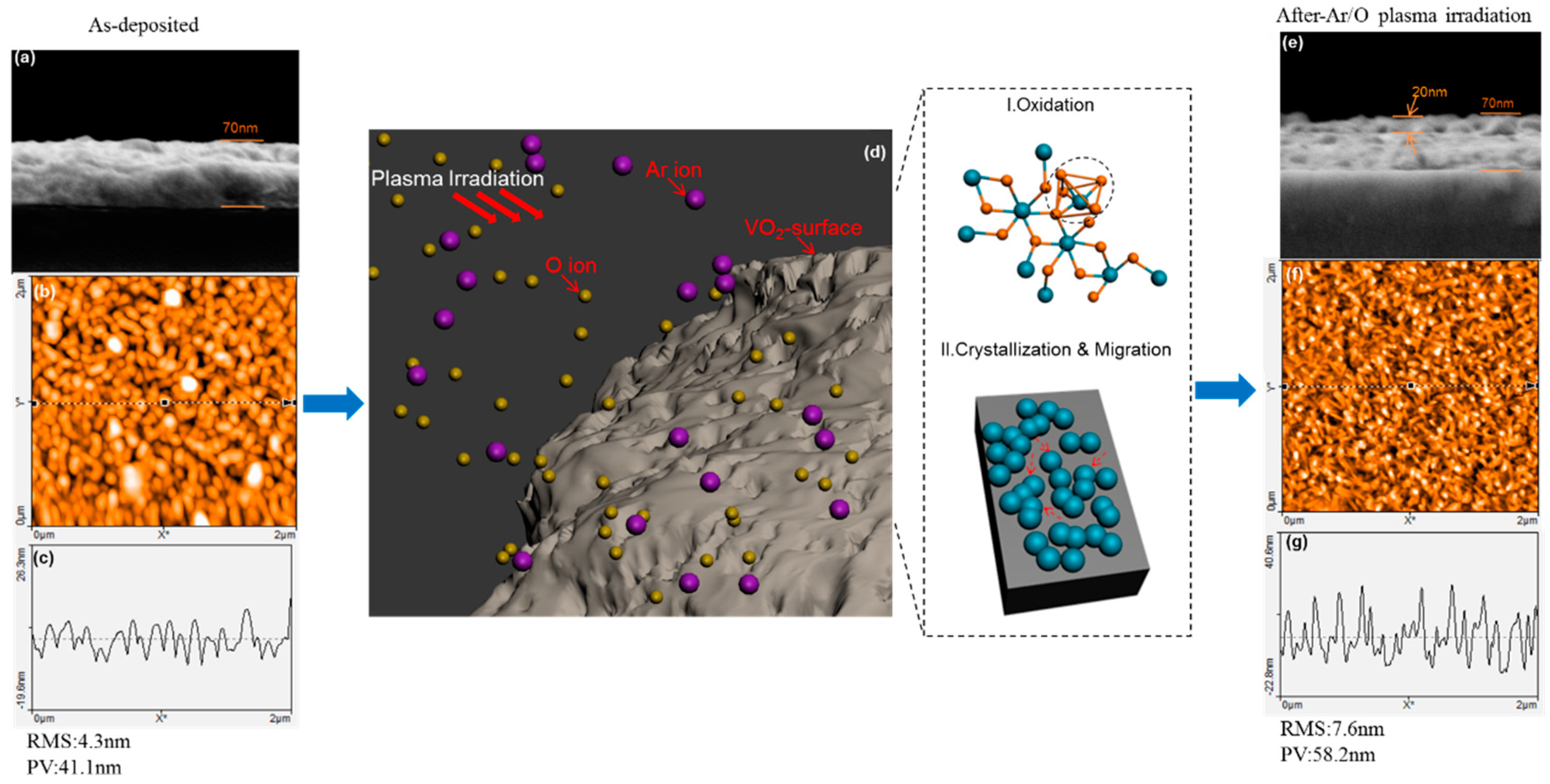

3.2. Surface Morphology

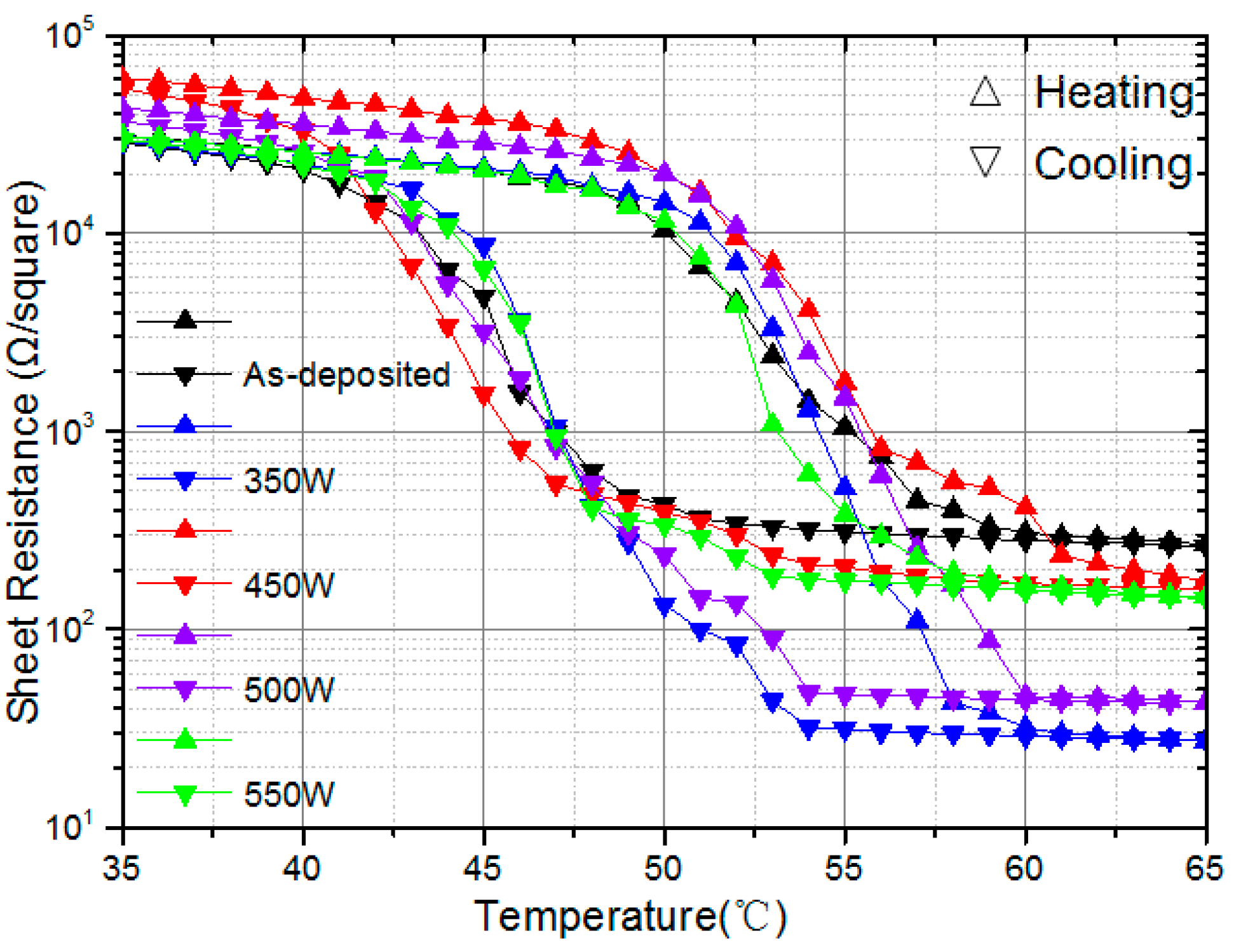

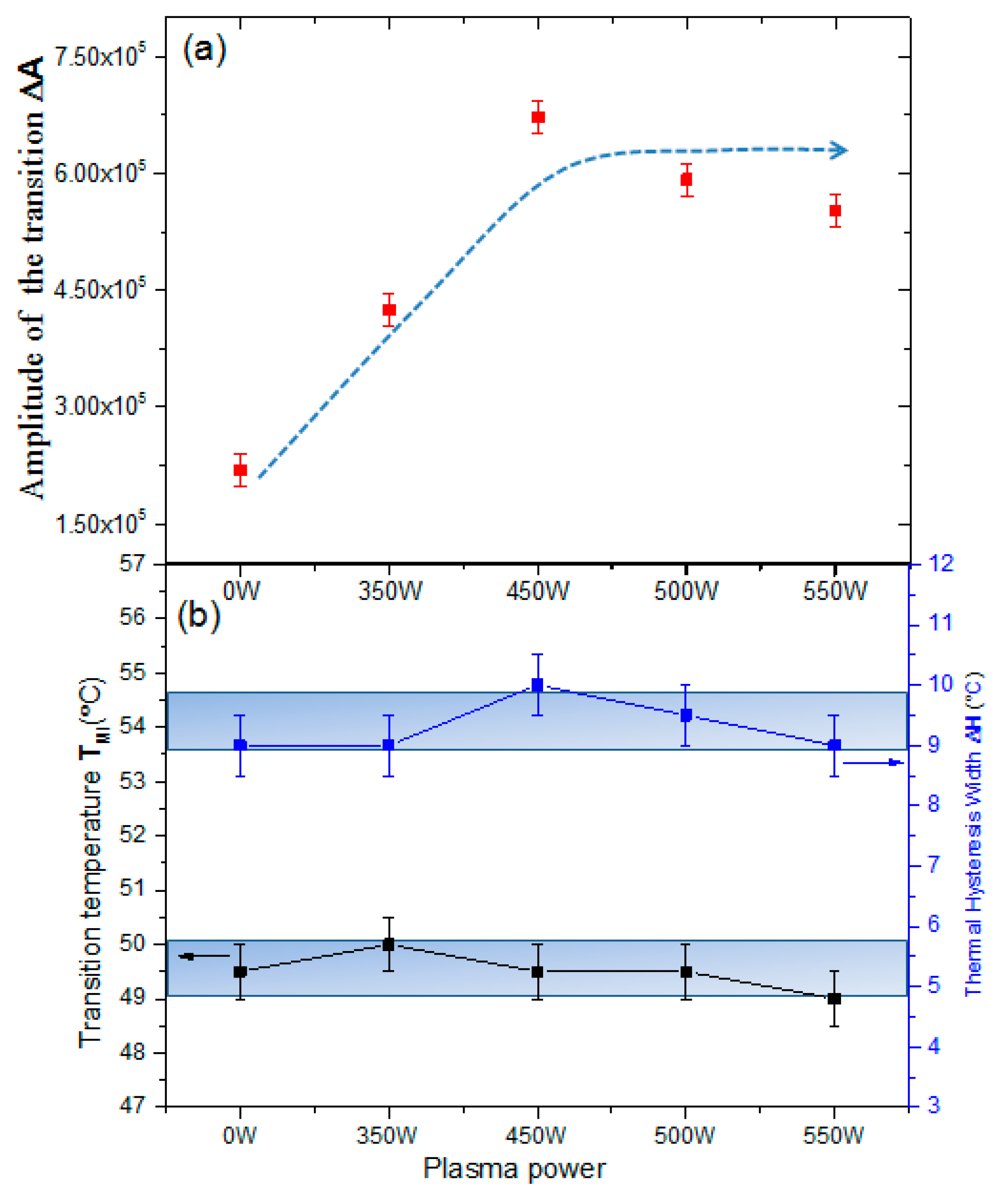

3.3. Thermochromic Property

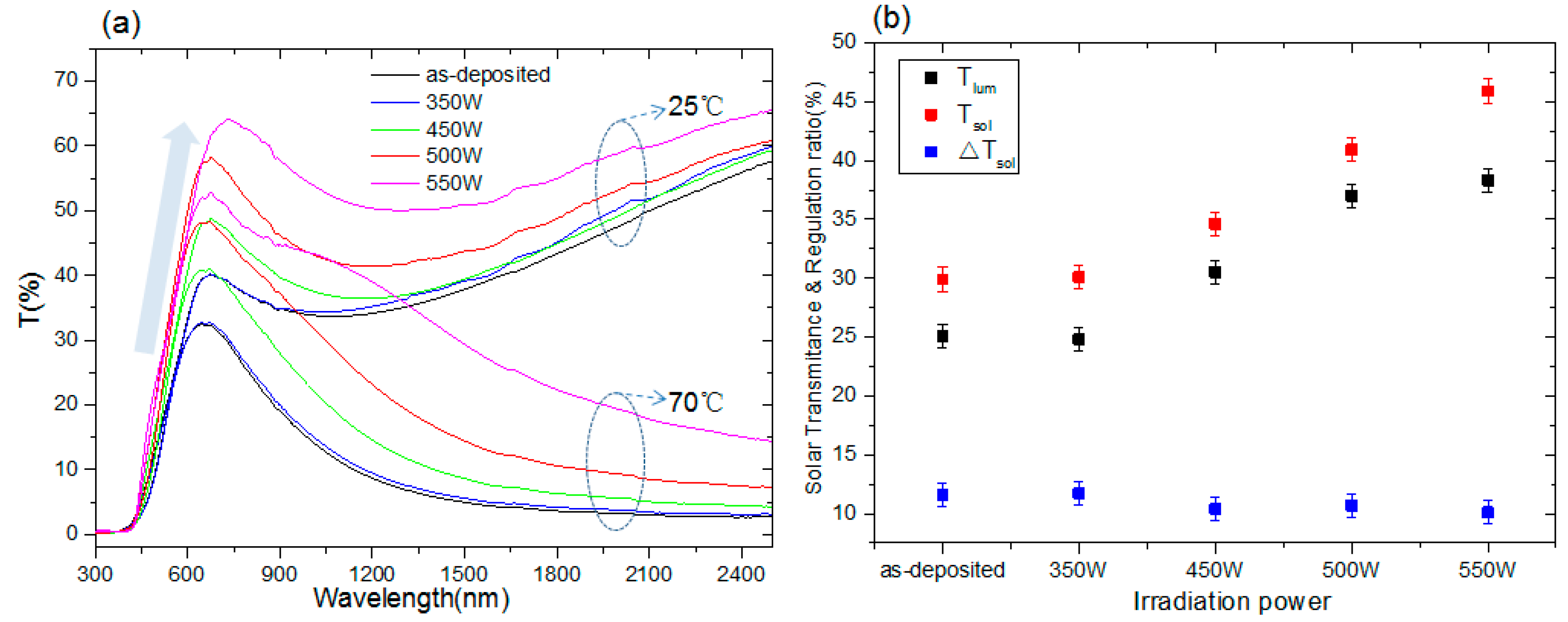

3.4. Optical Performance

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Morin, F.J. Oxides which show a metal-to-insulator transition at the neel temperature. Phys. Rev. Lett. 1959, 3, 34–36. [Google Scholar] [CrossRef]

- Gea, L.A.; Boatner, L.A. Optical switching of coherent VO2 precipitates formed in sapphire by ion implantation and annealing. Appl. Phys. Lett. 1996, 68, 3081–3083. [Google Scholar] [CrossRef]

- Gao, Y.; Luo, H.; Zhang, Z.; Kang, L.; Chen, Z.; Du, J.; Kanehira, M.; Cao, C. Nanoceramic VO2 thermochromic smart glass: A review on progress in solution processing. Nano Energy 2012, 1, 221–246. [Google Scholar] [CrossRef]

- Huang, Z.; Chen, S.; Lv, C.; Huang, Y.; Lai, J. Infrared characteristics of VO2 thin films for smart window and laser protection applications. Appl. Phys. Lett. 2012, 101, 191905. [Google Scholar] [CrossRef]

- Sun, G.; Cao, X.; Gao, X.; Long, S.; Liang, M.; Jin, P. Structure and enhanced thermochromic performance of low-temperature fabricated VO2/V2O3 thin film. Appl. Phys. Lett. 2016, 109, 34. [Google Scholar] [CrossRef]

- Zheng, J.; Bao, S.; Jin, P. TiO2(R)/VO2(M)/TiO2(A) multilayer film as smart window: Combination of energy-saving, antifogging and self-cleaning functions. Nano Energy 2015, 11, 136–145. [Google Scholar] [CrossRef]

- Long, S.; Zhou, H.; Bao, S.; Xin, Y.; Cao, X.; Jin, P. Thermochromic multilayer films of WO3/VO2/WO3 sandwich structure with enhanced luminous transmittance and durability. RSC Adv. 2016, 6, 106435–106442. [Google Scholar] [CrossRef]

- Tian, R.; Sun, J.; Qi, Y.; Zhang, B.; Guo, S.; Zhao, M. Influence of VO2 Nanoparticle Morphology on the Colorimetric Assay of H2O2 and Glucose. Nanomaterials 2017, 7, 347. [Google Scholar] [CrossRef] [PubMed]

- Hao, Q.; Li, W.; Xu, H.; Wang, J.; Yin, Y.; Wang, H.; Ma, L.; Ma, F.; Jiang, X.; Schmidt, O.G.; Chu, P.K. VO2/tin plasmonic thermochromic smart coatings for room-temperature applications. Adv. Mater. 2018, 30, 1705421. [Google Scholar] [CrossRef]

- Liu, H.; Wan, D.; Ishaq, A.; Chen, L.; Guo, B.; Shi, S.; Luo, H.; Gao, Y. Sputtering deposition of sandwich-structured V2O5/metal (v, w)/V2O5 multilayers for the preparation of high-performance thermally sensitive VO2 thin films with selectivity of VO2 (b) and VO2 (m) polymorph. Appl. Mater. Interfaces 2016, 8, 7884–7890. [Google Scholar] [CrossRef]

- Öksüzoğlu, R.M.; Bilgiç, P.; Yildirim, M.; Deniz, O. Influence of post-annealing on electrical, structural and optical properties of vanadium oxide thin films. Opt. Laser. Technol. 2013, 48, 102–109. [Google Scholar] [CrossRef]

- Zimmers, A.; Aigouy, L.; Mortier, M.; Sharoni, A.; Wang, S.; West, K.G.; Ramirez, J.G.; Schuller, I.K. Role of thermal heating on the voltage induced insulator-metal transition in VO2. Phys. Rev. Lett. 2013, 110, 056601. [Google Scholar] [CrossRef] [PubMed]

- Jung, D.H.; So, H.S.; Ahn, J.S.; Lee, H.; Nguyen, T.T.T.; Yoon, S.; Kim, S.Y.; Jung, H.Y. Low temperature growth of amorphous VO2 films on flexible polyimide substrates with a TiO2 buffer layer. J. Vac. Sci. Technol. A 2018, 36, 3E102. [Google Scholar] [CrossRef]

- Brassard, D.; Fourmaux, S.; Jean-Jacques, M.; Kieffer, J.C.; El Khakani, M.A. Grain size effect on the semiconductor-metal phase transition characteristics of magnetron-sputtered VO2 thin films. Appl. Phys. Lett. 2005, 87, 34. [Google Scholar] [CrossRef]

- Vernardou, D.; Pemble, M.E.; Sheel, D.W. In-situ Fourier transform infrared spectroscopy gas phase studies of vanadium (IV) oxide coating by atmospheric pressure chemical vapour deposition using vanadyl (IV) acetylacetonate. Thin Solid Films 2008, 516, 4502–4507. [Google Scholar] [CrossRef]

- Cui, Y.J.; Ramanathan, S. Substrate effects on metal-insulator transition characteristics of rf-sputtered epitaxial VO2 thin films. J. Vac. Sci. Technol. A 2011, 29, 041502. [Google Scholar] [CrossRef]

- Louloudakis, D.; Vernardou, D.; Spanakis, E.; Katsarakis, N.; Koudoumas, E. Thermochromic Vanadium Oxide Coatings Grown by APCVD at Low Temperatures. Phys. Procedia 2013, 46, 137–141. [Google Scholar] [CrossRef]

- Huang, Y.; Zhang, D.; Liu, Y.; Jin, J.; Yang, Y.; Chen, T.; Guan, H.; Fan, P.; Lv, W. Phase transition analysis of thermochromic VO2 thin films by temperature-dependent Raman scattering and ellipsometry. Appl. Surf. Sci. 2018, 456, 545–551. [Google Scholar] [CrossRef]

- Srivastava, A.; Herng, T.S.; Saha, S.; Nina, B.; Annadi, A.; Naomi, N.; Liu, Z.Q.; Dhar, S.; Ariando Ding, J.; Venkatesan, T. Coherently coupled ZnO and VO2 interface studied by photoluminescence and electrical transport across a phase transition. Appl. Phys. Lett. 2012, 100, 241907. [Google Scholar] [CrossRef]

- Perl, E.E.; Mcmahon, W.E.; Farrell, R.M.; Denbaars, S.P.; Speck, J.S.; Bowers, J.E. Surface structured optical coatings with near-perfect broadband and wide-angle antireflective properties. Nano Lett. 2014, 14, 5960–5964. [Google Scholar] [CrossRef]

- Li, S.Y.; Niklasson, G.A.; Granqvist, C.G. Nanothermochromics: Calculations for VO2 nanoparticles in dielectric hosts show much improved luminous transmittance and solar energy transmittance modulation. J. Appl. Phys. 2010, 108, 063525. [Google Scholar] [CrossRef]

- Min, W.L.; Jiang, B.; Peng, J. Bioinspired self-cleaning antireflection coatings. Adv. Mater. 2010, 20, 3914–3918. [Google Scholar] [CrossRef]

- Gagaoudakis, E.; Kortidis, I.; Michail, G.; Tsagaraki, K.; Binas, V.; Kiriakidis, G.; Aperathitis, E. Study of low temperature rf-sputtered mg-doped vanadium dioxide thermochromic films deposited on low-emissivity substrates. Thin Solid Films 2016, 601, 99–105. [Google Scholar] [CrossRef]

- Chang, T.; Cao, X.; Jin, P. Atomic layer deposition of VO2 thin films, largely enhanced luminous transmittance, solar modulation. Appl. Mater. Interfaces 2018, 10, 26814–26817. [Google Scholar] [CrossRef]

- Melnik, V.; Khatsevych, I.; Kladko, V.; Kuchuk, A.; Nikirin, V.; Romanyuk, B. Low-temperature method for thermochromic high ordered VO2 phase formation. Mater. Lett. 2012, 68, 215–217. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, J.; Zhang, D.; Qin, X.; Yang, Y.; Huang, Y.; Guan, H.; He, Q.; Fan, P.; Lv, W. Notable Enhancement of Phase Transition Performance and Luminous Transmittance in VO2 Films via Simple Method of Ar/O Plasma Post-Treatment. Nanomaterials 2019, 9, 102. https://doi.org/10.3390/nano9010102

Jin J, Zhang D, Qin X, Yang Y, Huang Y, Guan H, He Q, Fan P, Lv W. Notable Enhancement of Phase Transition Performance and Luminous Transmittance in VO2 Films via Simple Method of Ar/O Plasma Post-Treatment. Nanomaterials. 2019; 9(1):102. https://doi.org/10.3390/nano9010102

Chicago/Turabian StyleJin, Jingcheng, Dongping Zhang, Xiaonan Qin, Yu Yang, Ying Huang, Huan Guan, Qicong He, Ping Fan, and Weizhong Lv. 2019. "Notable Enhancement of Phase Transition Performance and Luminous Transmittance in VO2 Films via Simple Method of Ar/O Plasma Post-Treatment" Nanomaterials 9, no. 1: 102. https://doi.org/10.3390/nano9010102

APA StyleJin, J., Zhang, D., Qin, X., Yang, Y., Huang, Y., Guan, H., He, Q., Fan, P., & Lv, W. (2019). Notable Enhancement of Phase Transition Performance and Luminous Transmittance in VO2 Films via Simple Method of Ar/O Plasma Post-Treatment. Nanomaterials, 9(1), 102. https://doi.org/10.3390/nano9010102