Structural and Stress Properties of AlGaN Epilayers Grown on AlN-Nanopatterned Sapphire Templates by Hydride Vapor Phase Epitaxy

Abstract

1. Introduction

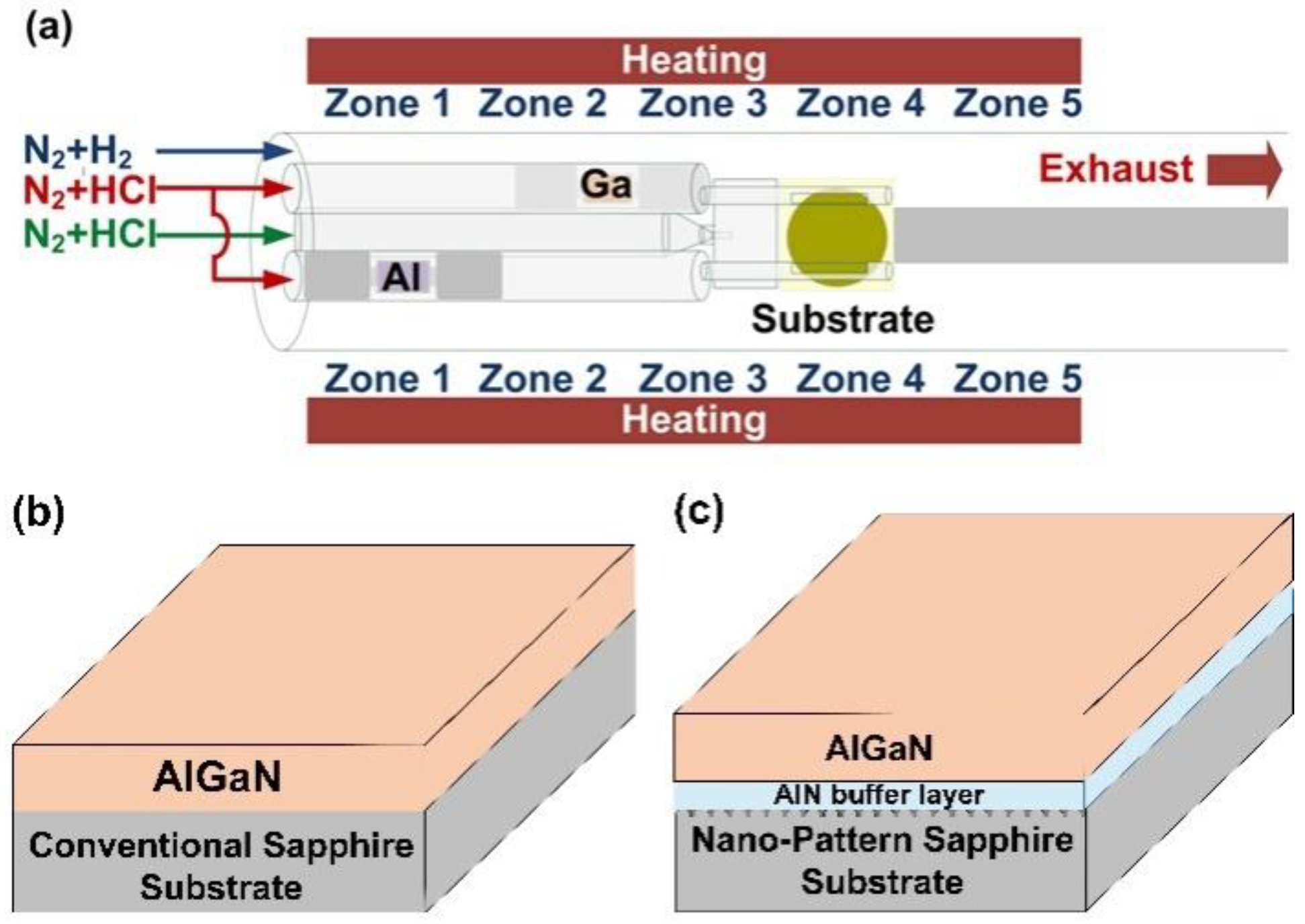

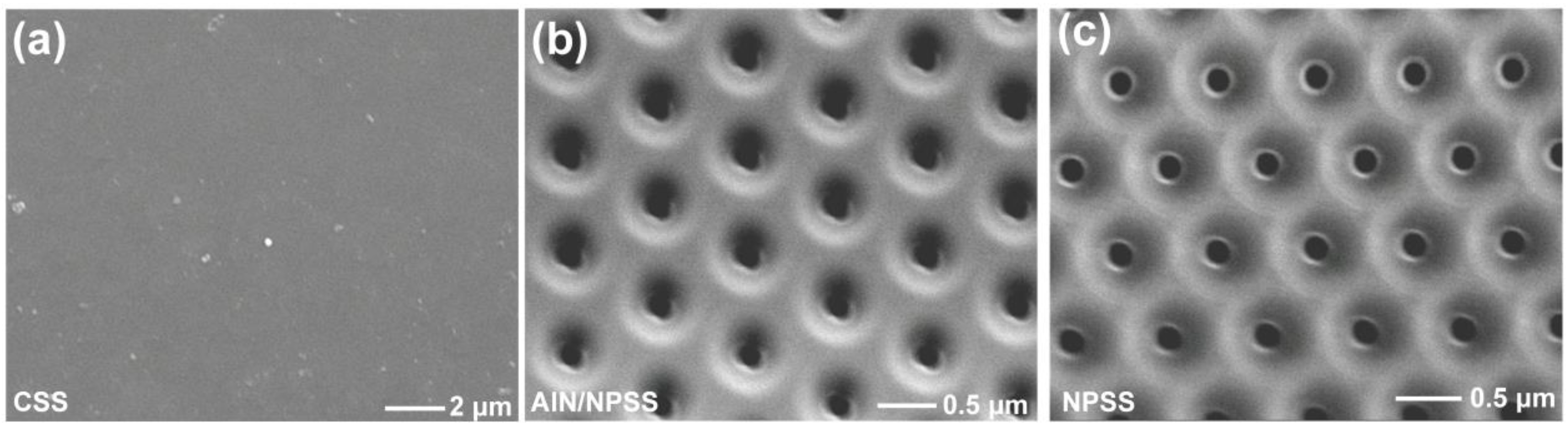

2. Materials and Methods

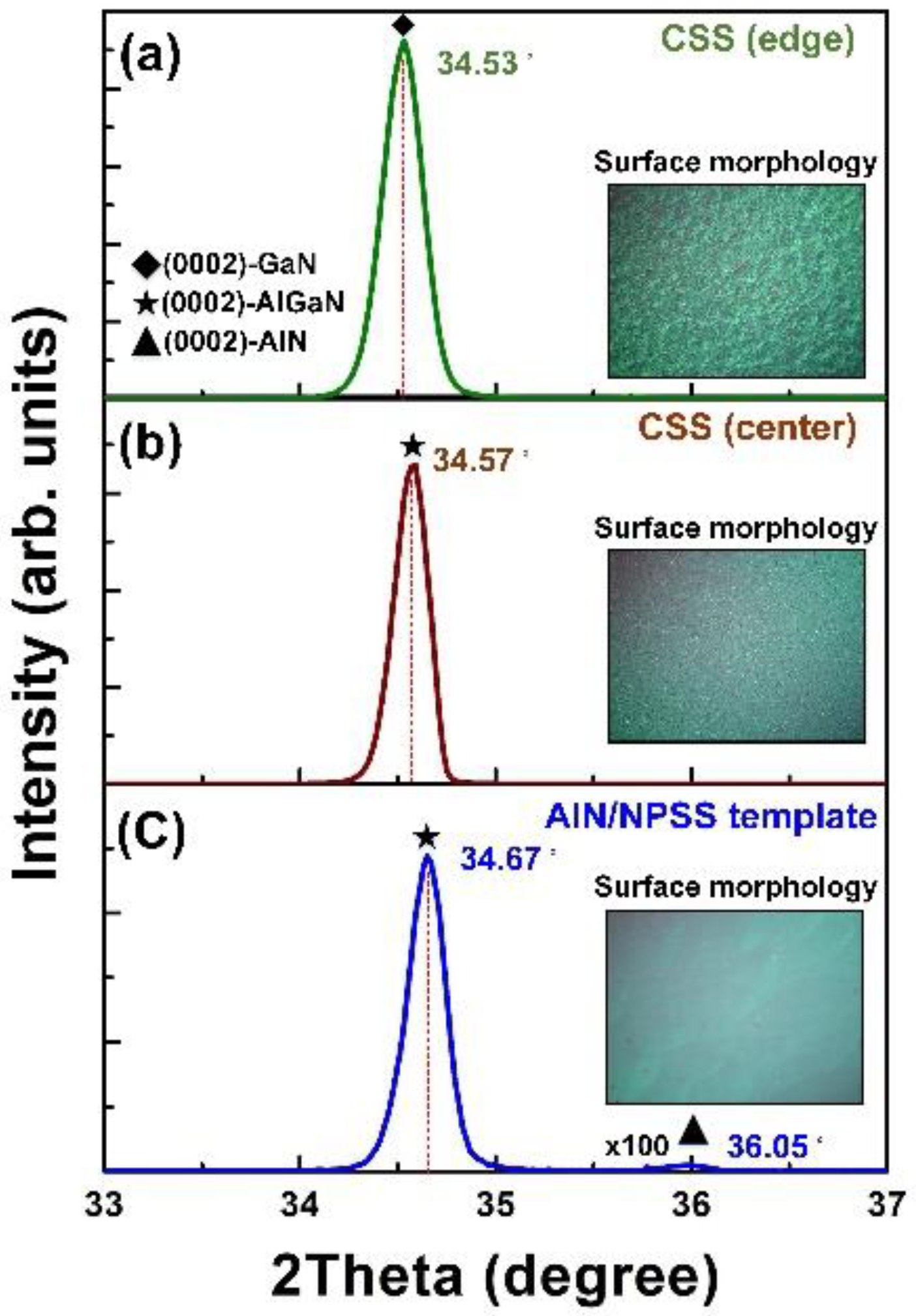

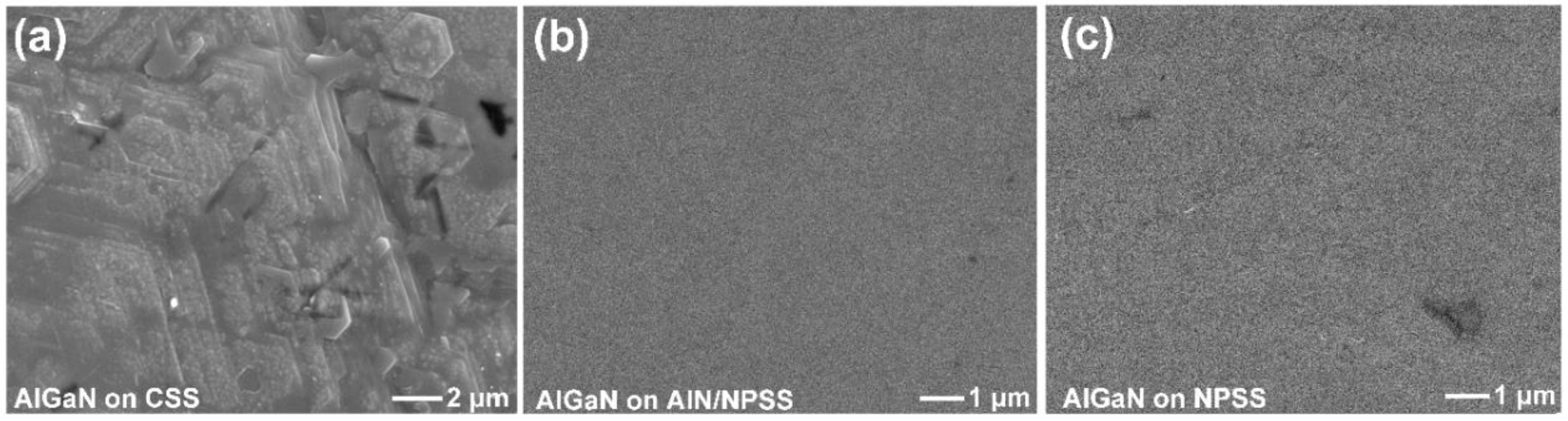

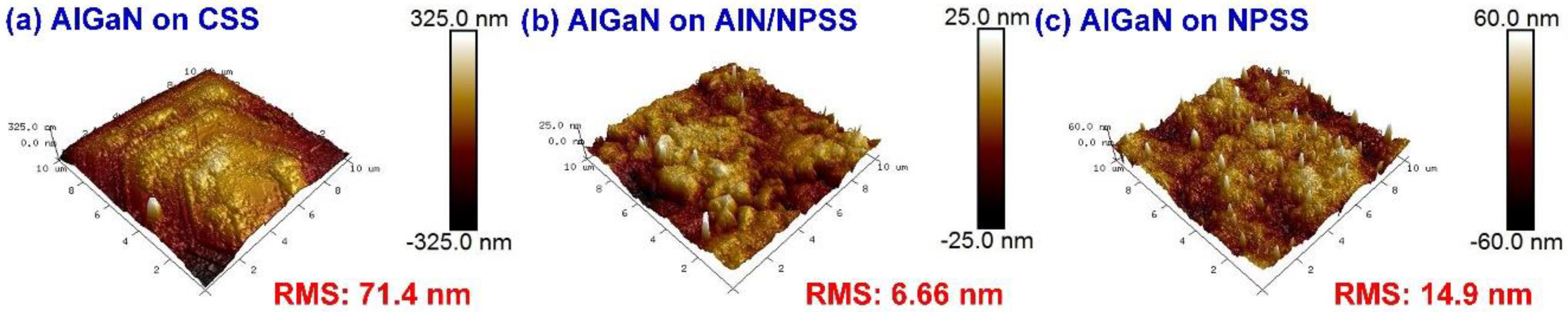

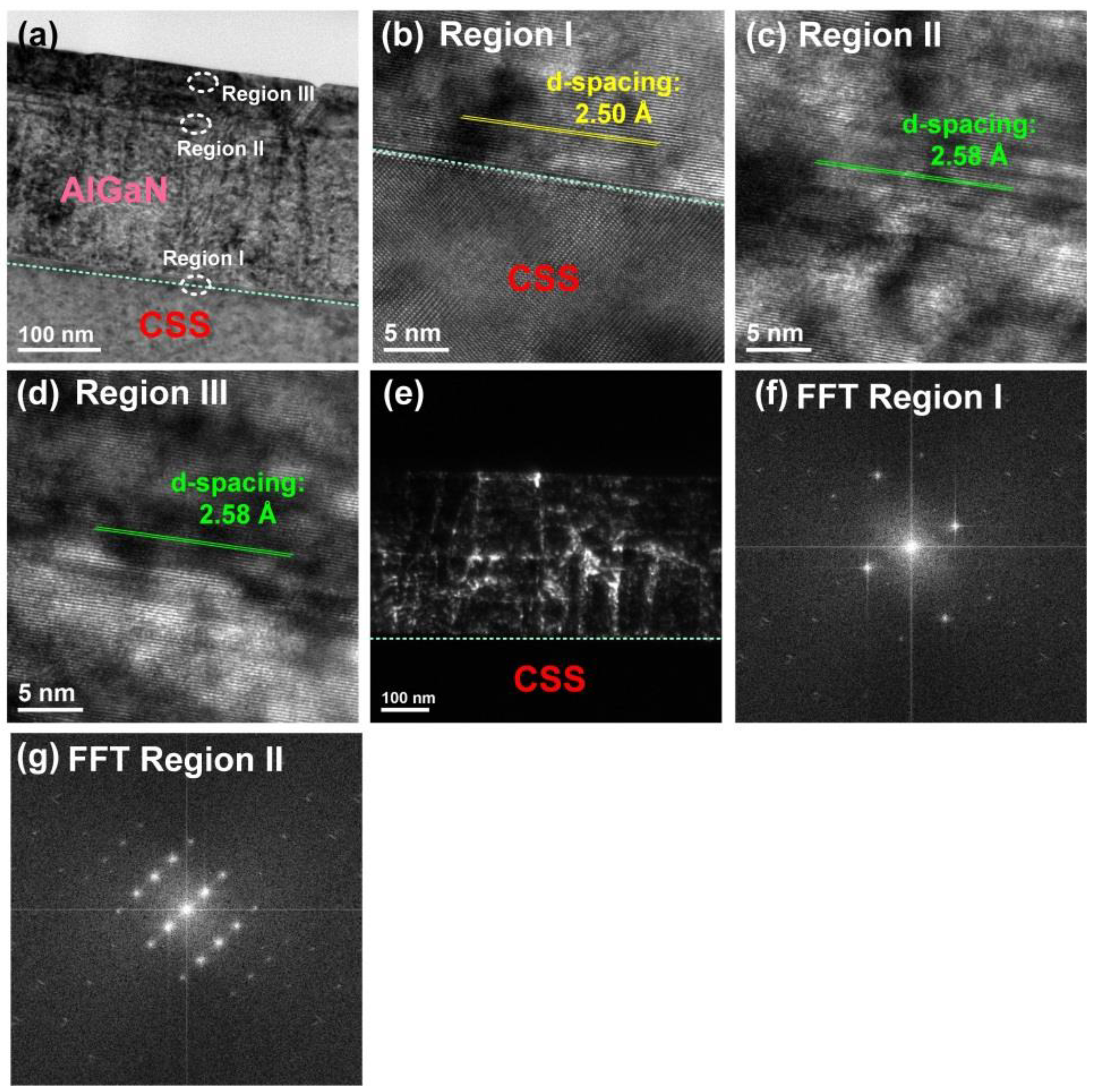

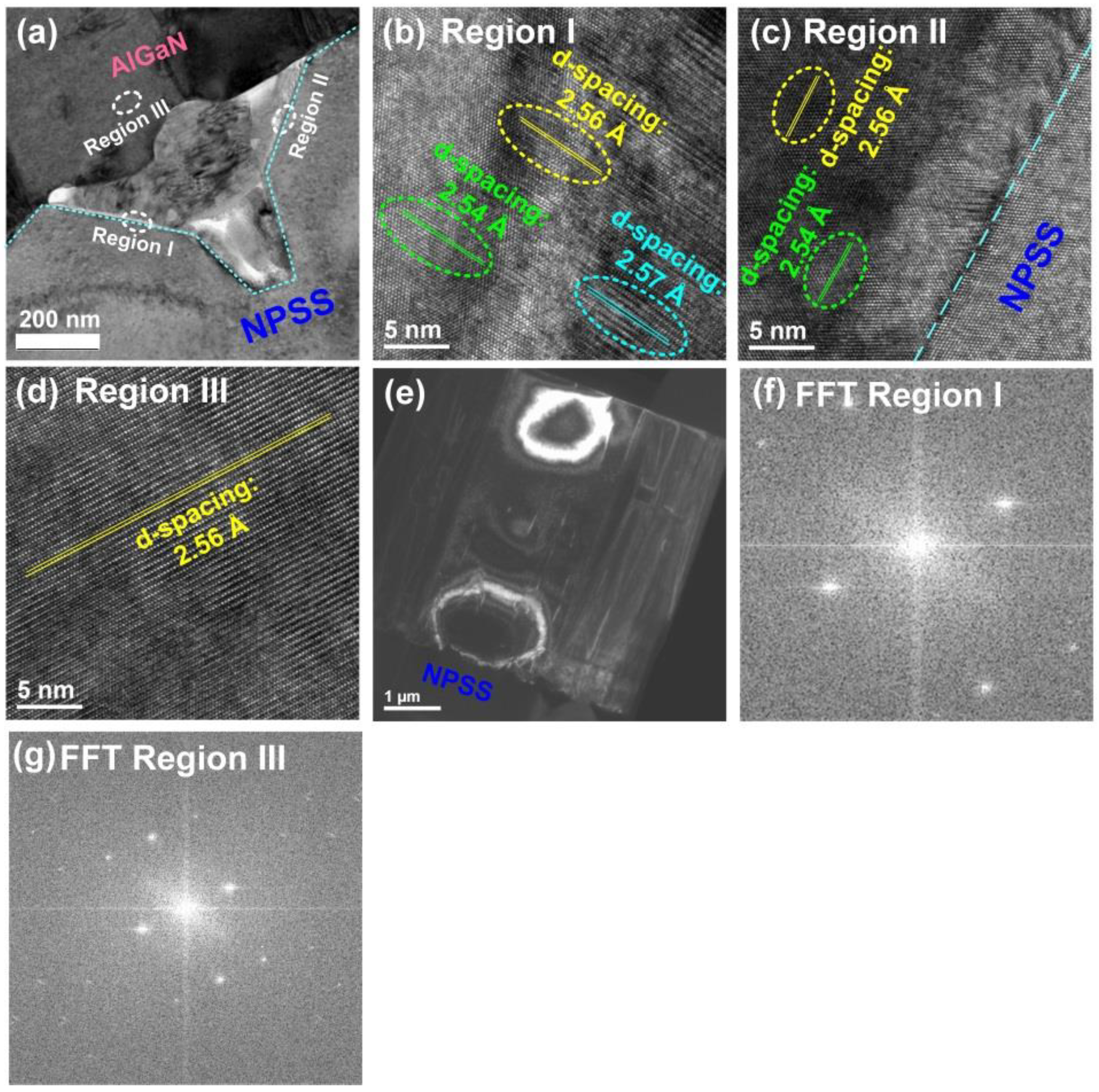

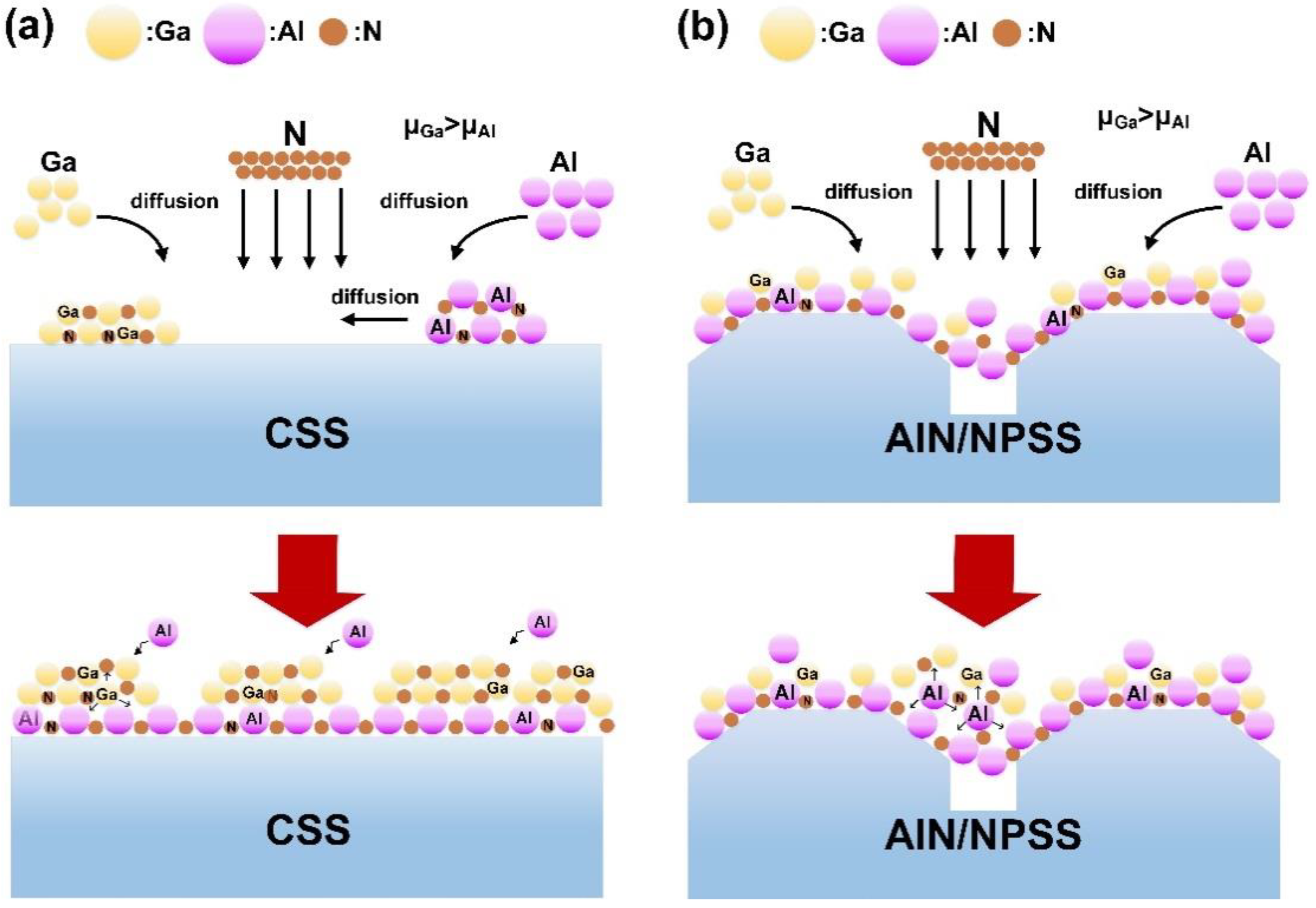

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Nagamatsua, M.; Okadaa, N.; Sugimuraa, H.; Tsuzukia, H.; Moria, F.; Iidaa, K.; Bandob, A.; Iwayaa, M.; Kamiyamaa, S.; Amanoa, H.; et al. High-efficiency AlGaN-based UV light-emitting diode on laterally overgrown AlN. J. Cryst. Growth 2008, 310, 2326–2329. [Google Scholar] [CrossRef]

- Pernot, C.; Kim, M.; Shinya Fukahori, S.; Inazu, T.; Fujita, T.; Nagasawa, Y.; Hirano, A.; Ippommatsu, M.; Iwaya, M.; Kamiyama, S.; et al. Improved efficiency of 255–280 nm AlGaN-based light-emitting diodes. Appl. Phys. Express 2010, 3, 061044. [Google Scholar] [CrossRef]

- Yeh, C.T.; Wang, W.K.; Shen, Y.S.; Horng, R.H. 1.48-kV enhancement-mode AlGaN/GaN high-mobility transistors fabricated on 6-in. silicon by fluoride-based plasma treatment. Jpn. J. Appl. Phys. 2016, 55, 05FK06. [Google Scholar] [CrossRef]

- Tonisch, K.; Jatal, W.; Niebelschuetz, F.; Romanus, H.; Baumann, U.; Schwierz, F.; Pezoldt, J. AlGaN/GaN-heterostructures on (111) 3C-SiC/Si pseudo substrates for high frequency applications. Thin Solid Films 2011, 520, 491–496. [Google Scholar] [CrossRef]

- Mi, M.H.; Ma, X.H.; Yang, L.; Bin, H.; Zhu, J.J.; He, Y.L.; Zhang, M.; Wu, S.; Hao, Y. 90 nm gate length enhancement-mode AlGaN/GaN HEMTs with plasma oxidation technology for high-frequency application. Appl. Phys. Lett. 2017, 111, 173502. [Google Scholar] [CrossRef]

- Hirayama, H.; Noguchi, N.; Kamata, N. 222 nm deep-ultraviolet AlGaN quantum well light-emitting diode with vertical emission properties. Appl. Phys. Express 2010, 3, 032102. [Google Scholar] [CrossRef]

- Muramoto, Y.; Kimura, M.; Nouda, S. Development and future of ultraviolet light-emitting diodes: UV-LED will replace the UV lamp. Semicond. Sci. Technol. 2014, 29, 084004. [Google Scholar] [CrossRef]

- Kneissl, M. A Brief Review of III-Nitride UV Emitters in III-Nitride Ultraviolet Emitters: Technologies and Applications, Chap. 1; Kneissl, M., Rass, J., Eds.; Springer: Berlin, Germany, 2016. [Google Scholar]

- Koide, Y.; Itoh, N.; Itoh, N.; Sawaki, N.; Akasaki, I. Effect of AlN buffer layer on AlGaN/Al2O3 heteroepitaxial growth by metalorganic vapor phase epitaxy. Jpn. J. Appl. Phys. 1988, 3, 1156–1161. [Google Scholar] [CrossRef]

- Wu, X.H.; Fini, P.; Tarsa, E.J.; Heying, B.; Keller, S.; Mishra, U.K.; DenBaars, S.P.; Speck, J.S. Dislocation generation in GaN heteroepitaxy. J. Cryst. Growth 1998, 189/190, 231–243. [Google Scholar] [CrossRef]

- Amano, H.; Miyazaki, A.; Iida, K.; Kawashima, T.; Iwaya, M.; Kamiyama, S.; Akasaki, I.; Liu, R.; Bell, A.; Ponce, F.A.; et al. Defect and stress control of AlGaN for fabrication of high performance UV light emitters. Phys. Stat. Sol. 2004, 12, 2679–2685. [Google Scholar] [CrossRef]

- Jiang, H.; Egawa, T.; Hao, M.; Liu, Y. Reduction of threading dislocations in AlGaN layers grown on AlN/sapphire templates using high-temperature GaN interlayer. Appl. Phys. Lett. 2005, 87, 241911. [Google Scholar] [CrossRef]

- Ren, Z.; Sun, Q.; Kwon, S.Y.; Han, J.; Davitt, K.; Song, Y.K.; Nurmikko, A.V.; Cho, H.K.; Liu, W.; Smart, J.A.; et al. Heteroepitaxy of AlGaN on bulk AlN substrates for deep ultraviolet light emitting diodes. Appl. Phys. Lett. 2007, 91, 051116. [Google Scholar] [CrossRef]

- Fleischmann, S.; Mogilatenko, A.; Hagedorn, S.; Richter, E.; Goran, D.; Schäfer, P.; Zeimer, U.; Weyers, M.; Tränkle, G. Triangular-shaped sapphire patterning for HVPE grown AlGaN layers. Phys. Stat. Sol. 2017, 214, 1600751. [Google Scholar] [CrossRef]

- Richter, E.; Fleischmann, S.; Goran, D.; Hagedorn, S.; John, W.; Mogilatenko, A.; Prasai, D.; Zeimer, U.; Weyers, M.; Traenkle, G. Hydride vapor-phase epitaxy of c-plane AlGaN layers on patterned sapphire substrates. J. Electron. Mater. 2014, 43, 814–818. [Google Scholar] [CrossRef]

- Mogilatenko, A.; Hagedorn, S.; Richter, E.; Zeimer, U.; Goran, D.; Weyers, M.; Trankle, G. Predominant growth of non-polar a-plane (Al,Ga)N on patterned c-plane sapphire by hydride vapor phase epitaxy. J. Appl. Phys. 2013, 113, 093505. [Google Scholar] [CrossRef]

- Tasi, C.T.; Wang, W.K.; Tsai, T.Y.; Huang, S.Y.; Horng, R.H.; Wuu, D.S. Reduction of defects in AlGaN grown on nanoscale-patterned sapphire substrates by hydride vapor phase epitaxy. Materials 2017, 10, 605. [Google Scholar] [CrossRef] [PubMed]

- Hagedorn, S.; Richter, E.; Zeimer, U.; Weyers, M. HVPE of AlxGa1−xN layers on planar and trench patterned sapphire. J. Cryst. Growth 2012, 353, 129–133. [Google Scholar] [CrossRef]

- Hagedorn, S.; Richter, E.; Zeimer, U.; Weyers, M. HVPE growth of thick Al0.45Ga0.55N layers on trench patterned sapphire substrates. Phys. Status Solidi 2013, 10, 355–358. [Google Scholar] [CrossRef]

- Fleischmann, S.; Mogilatenko, A.; Hagedorn, S.; Richter, E.; Goran, D.; Schäfer, P.; Zeimer, U.; Weyers, M.; Tränkle, G. Analysis of HVPE grown AlGaN layers on honeycomb patterned sapphire. J. Cryst. Growth 2015, 414, 32–37. [Google Scholar] [CrossRef]

- Fu, Q.M.; Peng, T.; Mei, F.; Pan, Y.; Liao, L.; Liu, C. Relaxation of compressive strain by inclining threading dislocations in Al0.45Ga0.55N epilayer grown on AlN/sapphire templates using graded-AlxGa1−xN/AlN multi-buffer layers. J. Phys. D Appl. 2009, 42, 035311. [Google Scholar] [CrossRef]

- Fleischmann, S.; Richter, E.; Mogilatenko, A.; Weyers, M.; Trankle, G. Influence of AlN buffer layer on growth of AlGaN by HVPE. Phys. Stat. Sol. 2017, 254, 1600696. [Google Scholar] [CrossRef]

- Schowalter, L.J.; Rojo, J.C.; Slack, G.A.; Shusterman, Y.; Wang, R.; Bhat, I.; Arunmozhi, G. Epitaxial growth of AlN and Al0.5Ca0.5N layers on aluminum nitride substrates. J. Cryst. Growth 2000, 211, 78–81. [Google Scholar] [CrossRef]

- Wang, T.Y.; Tasi, C.T.; Lin, K.Y.; Ou, S.L.; Horng, R.H.; Wuu, D.S. Surface evolution and effect of V/III ratio modulation on etch-pit-density improvement of thin AlN templates on nano-patterned sapphire substrates by metalorganic chemical vapor deposition. Appl. Surf. Sci. 2018, 455, 1123–1130. [Google Scholar] [CrossRef]

- Zhang, L.; Xu, F.; Wang, J.; He, C.; Guo, W.; Wang, M.; Sheng, B.; Lu, L.; Qin, Z.; Wang, X.; et al. High-quality AlN epitaxy on nano-patterned sapphire substrates prepared by nano-imprint lithography. Sci. Rep. 2016, 6, 35934. [Google Scholar] [CrossRef] [PubMed]

- Dong, P.; Yan, J.; Wang, J.; Zhang, Y.; Geng, C.; Wei, T.; Cong, P.; Zhang, Y.; Zeng, J.; Tian, Y.; et al. 282-nm AlGaN-based deep ultraviolet light-emitting diodes with improved performance on nano-patterned sapphire substrates. Appl. Phys. Lett. 2013, 102, 241113. [Google Scholar] [CrossRef]

- Qin, Z.X.; Luo, H.J.; Chen, Z.Z.; Yu, T.J.; Yang, Z.J.; Xu, K.; Zhang, G.Y. Effect of AlN interlayer on incorporation efficiency of Al composition in AlGaN grown by MOVPE. J. Cryst. Growth 2007, 298, 345–356. [Google Scholar] [CrossRef]

- Kusch, G.; Li, H.; Edwards, P.R.; Bruckbauer, J.; Sadler, T.C.; Parbrook, P.J.; Martin, R.W. Influence of substrate miscut angle on surface morphology and luminescence properties of AlGaN. Appl. Phys. Lett. 2014, 104, 092114. [Google Scholar] [CrossRef]

- Gallinat, C.S.; Koblmüller, G.; Wu, F.; Speck, J.S. Evaluation of threading dislocation densities in In- and N-face InN. J. Appl. Phys. 2010, 107, 053517. [Google Scholar] [CrossRef]

- Jin, R.Q.; Liu, J.P.; Zhang, J.C.; Yang, H. Growth of crack-free AlGaN film on thin AlN interlayer by MOCVD. J. Cryst. Growth 2004, 268, 35–40. [Google Scholar] [CrossRef]

- Mallick, P.; Dash, B.N. X-ray diffraction and UV-Visible characterizations of α-Fe2O3 nanoparticles annealed at different temperature. J. Nanosci. Nanotechnol. 2013, 3, 130–134. [Google Scholar]

- Gong, J.R.; Liao, W.T.; Hsieh, S.L.; Lin, P.H.; Tsai, Y.L. Strain-induced effect on the Al incorporation in AlGaN films and the properties of AlGaN/GaN heterostructures grown by metalorganic chemical vapor deposition. J. Cryst. Growth 2003, 249, 28–36. [Google Scholar] [CrossRef]

- Chandolu, A.; Nikishin, S.; Holtz, M.; Temkin, H. X-ray diffraction study of AlN/AlGaN short period superlattices. J. Appl. Phys. 2007, 102, 114909. [Google Scholar] [CrossRef]

- Zhao, D.G.; Liu, Z.S.; Zhu, J.J.; Zhang, S.M.; Jiang, D.S.; Yang, H.; Liang, J.W.; Li, X.Y.; Gong, H.M. Effect of Al incorporation on the AlGaN growth by metalorganic chemical vapor deposition. Appl. Surf. Sci. 2006, 253, 2452–2455. [Google Scholar] [CrossRef]

- Bryan, I.; Bryan, Z.; Mita, S.; Rice, A.; Hussey, L.; Shelton, C.; Tweedie, J.; Mara, J.P.; Collazo, R.; Sitar, Z. The role of surface kinetics on composition and quality of AlGaN. J. Cryst. Growth 2016, 451, 65–71. [Google Scholar] [CrossRef]

| AlGaN-(002) | Substrate | 2 Theta (°) | FWHM (°) | ε | σ (MPa) |

|---|---|---|---|---|---|

| CSS | 34.57 | 0.583 | −1.6 × 10−5 | 1187 | |

| AlN/NPSS | 34.65 | 0.235 | −4.7 × 10−5 | 38.41 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tasi, C.-T.; Wang, W.-K.; Ou, S.-L.; Huang, S.-Y.; Horng, R.-H.; Wuu, D.-S. Structural and Stress Properties of AlGaN Epilayers Grown on AlN-Nanopatterned Sapphire Templates by Hydride Vapor Phase Epitaxy. Nanomaterials 2018, 8, 704. https://doi.org/10.3390/nano8090704

Tasi C-T, Wang W-K, Ou S-L, Huang S-Y, Horng R-H, Wuu D-S. Structural and Stress Properties of AlGaN Epilayers Grown on AlN-Nanopatterned Sapphire Templates by Hydride Vapor Phase Epitaxy. Nanomaterials. 2018; 8(9):704. https://doi.org/10.3390/nano8090704

Chicago/Turabian StyleTasi, Chi-Tsung, Wei-Kai Wang, Sin-Liang Ou, Shih-Yung Huang, Ray-Hua Horng, and Dong-Sing Wuu. 2018. "Structural and Stress Properties of AlGaN Epilayers Grown on AlN-Nanopatterned Sapphire Templates by Hydride Vapor Phase Epitaxy" Nanomaterials 8, no. 9: 704. https://doi.org/10.3390/nano8090704

APA StyleTasi, C.-T., Wang, W.-K., Ou, S.-L., Huang, S.-Y., Horng, R.-H., & Wuu, D.-S. (2018). Structural and Stress Properties of AlGaN Epilayers Grown on AlN-Nanopatterned Sapphire Templates by Hydride Vapor Phase Epitaxy. Nanomaterials, 8(9), 704. https://doi.org/10.3390/nano8090704