Flower-like Cu2SnS3 Nanostructure Materials with High Crystallinity for Sodium Storage

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of Materials

2.2. Characterizations of Materials

2.3. Electrochemical Measurements

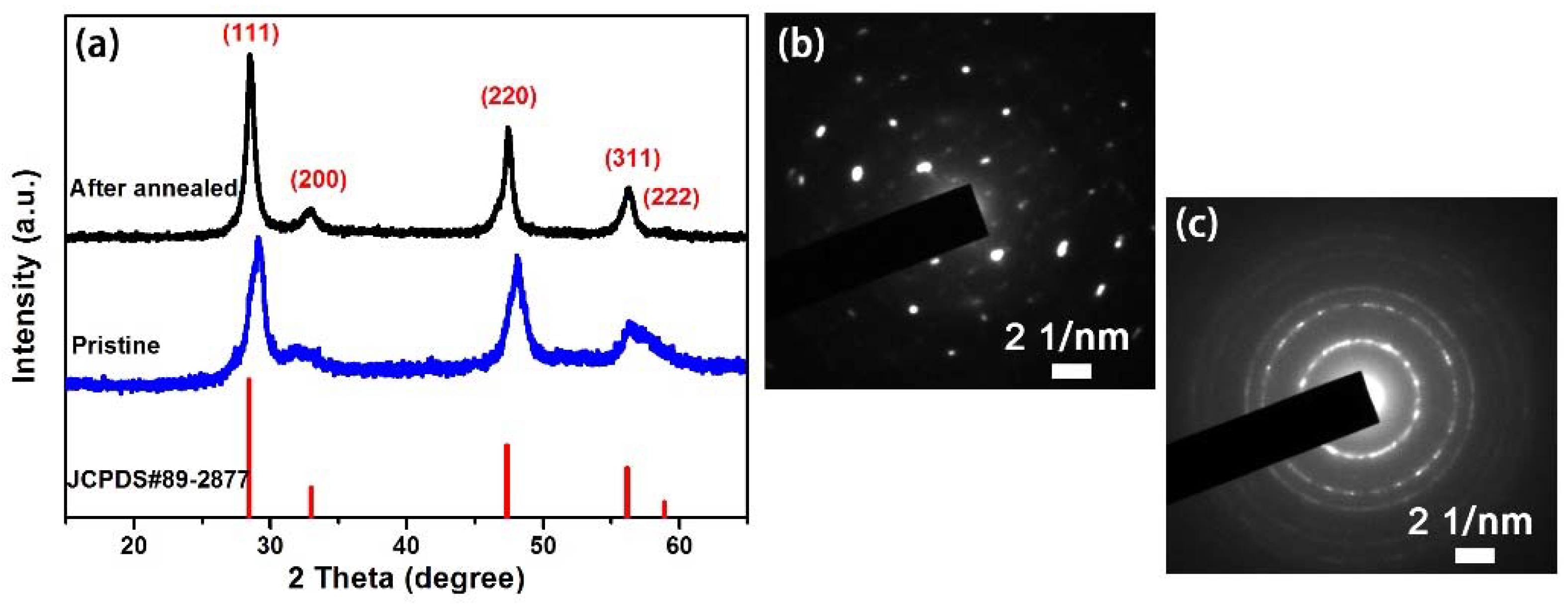

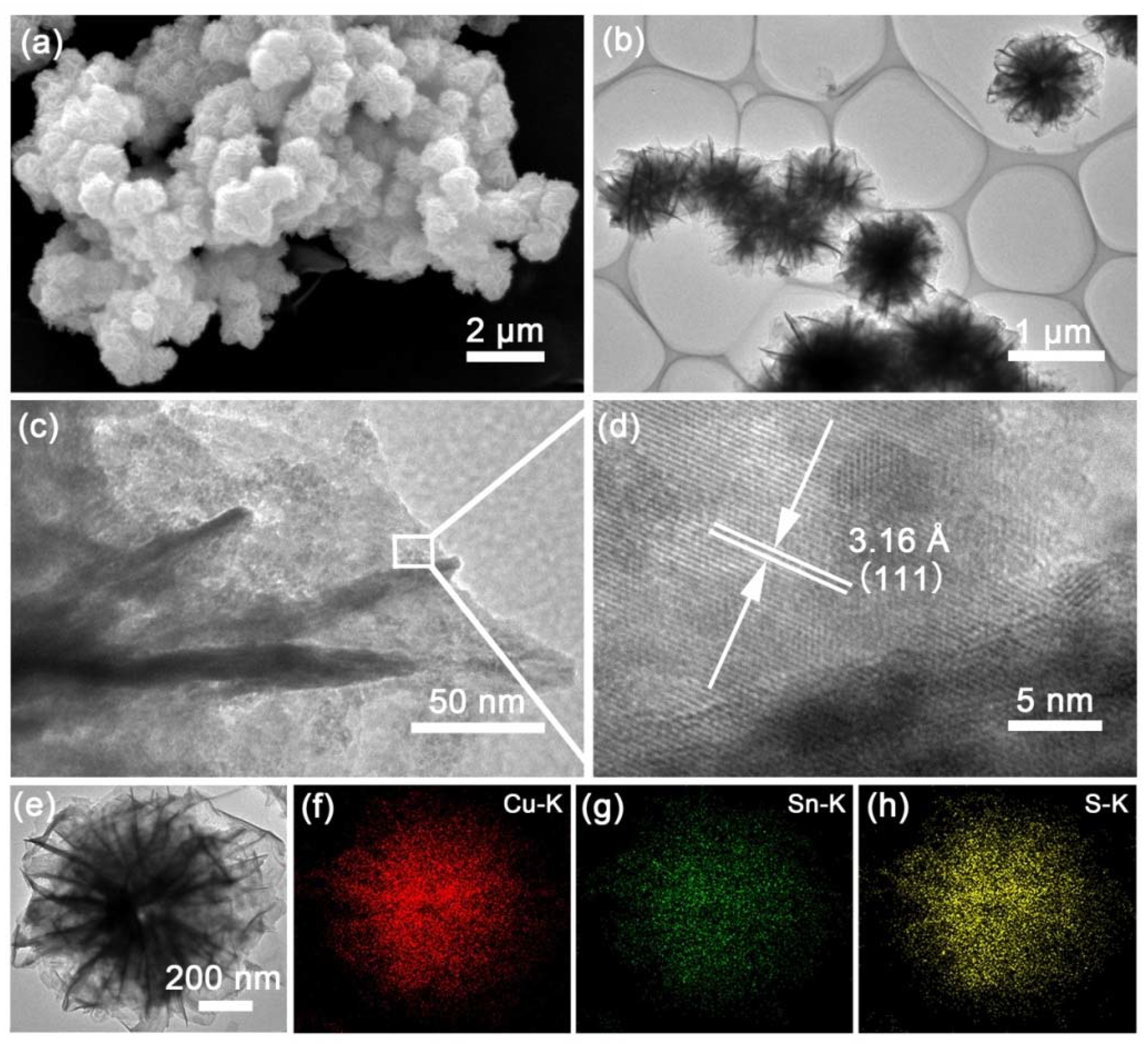

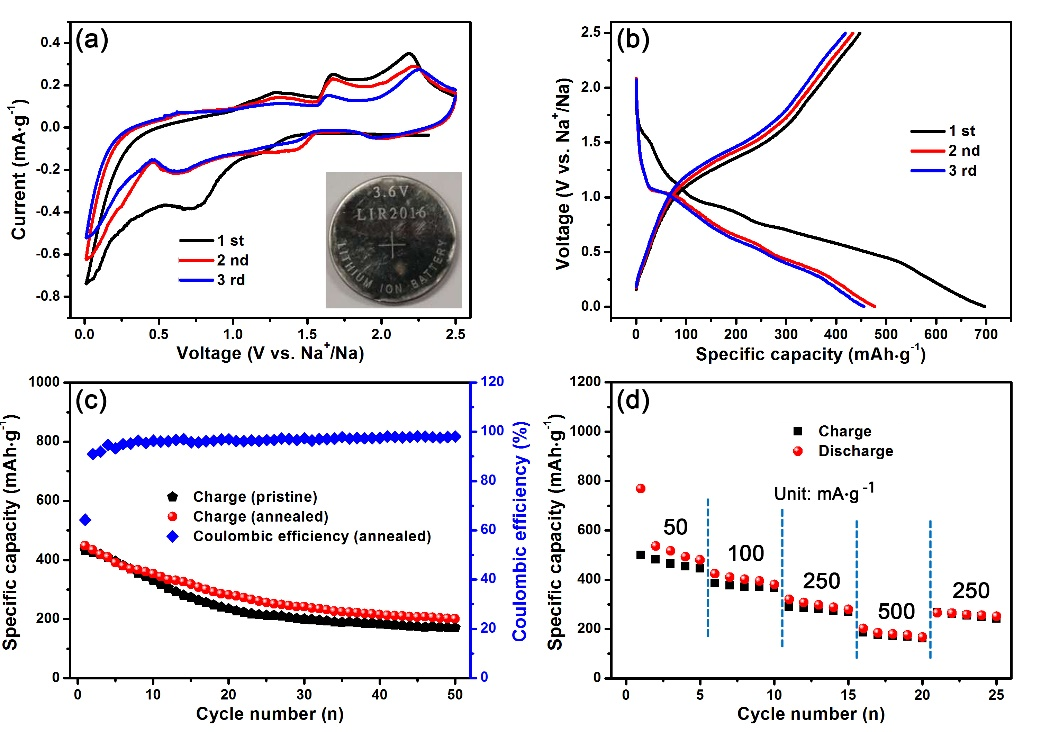

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Park, C.M.; Kim, J.H.; Kim, H.; Sohn, H.J. Li-alloy based anode materials for Li secondary batteries. Chem. Soc. Rev. 2010, 39, 3115–3141. [Google Scholar] [CrossRef] [PubMed]

- Yin, F.; Liu, Z.; Zhao, Y.; Feng, Y.; Zhang, Y. Electrochemical Properties of an Na4Mn9O18-Reduced Graphene Oxide Composite Synthesized via Spray Drying for an Aqueous Sodium-Ion Battery. Nanomaterials 2017, 7, 253. [Google Scholar] [CrossRef] [PubMed]

- Iturrondobeitia, A.; Goni, A.; Gil de Muro, I.; Lezama, L.; Rojo, T. Physico-Chemical and Electrochemical Properties of Nanoparticulate NiO/C Composites for High Performance Lithium and Sodium Ion Battery Anodes. Nanomaterials 2017, 7, 423. [Google Scholar] [CrossRef] [PubMed]

- Repp, S.; Harputlu, E.; Gurgen, S.; Castellano, M.; Kremer, N.; Pompe, N.; Worner, J.; Hoffmann, A.; Thomann, R.; Emen, F.M.; et al. Synergetic effects of Fe3+ doped spinel Li4Ti5O12 nanoparticles on reduced graphene oxide for high surface electrode hybrid supercapacitors. Nanoscale 2018, 10, 1877. [Google Scholar] [CrossRef] [PubMed]

- Genc, R.; Alas, M.O.; Harputlu, E.; Repp, S.; Kremer, N.; Castellano, M.; Colak, S.G.; Ocakoglu, K.; Erdem, E. High-Capacitance Hybrid Supercapacitor Based on Multi-Colored Fluorescent Carbon-Dots. Sci. Rep. 2017, 7, 11222. [Google Scholar] [CrossRef] [PubMed]

- Yu, X.Y.; Lou, X.W. Mixed Metal Sulfides for Electrochemical Energy Storage and Conversion. Adv. Energy Mater. 2018, 8, 1701592. [Google Scholar] [CrossRef]

- Li, D.; Feng, C.; Liu, H.K.; Guo, Z. Unique Urchin-like Ca2Ge7O16 Hierarchical Hollow Microspheres as Anode Material for the Lithium Ion Battery. Sci. Rep. 2015, 5, 11326. [Google Scholar] [CrossRef] [PubMed]

- Liang, X.; Cai, Q.; Xiang, W.; Chen, Z.; Zhong, J.; Wang, Y.; Shao, M.; Li, Z. Preparation and Characterization of Flower-like Cu2SnS3 Nanostructures by Solvothermal Route. J. Mater. Sci. Technol. 2013, 29, 231–236. [Google Scholar] [CrossRef]

- Li, B.; Xie, Y.; Huang, J.; Qian, Y. Synthesis, Characterization, and Properties of Nanocrystalline Cu2SnS3. J. Solid State Chem. 2000, 153, 170–173. [Google Scholar] [CrossRef]

- Wu, C.; Hu, Z.; Wang, C.; Sheng, H.; Yang, J.; Xie, Y. Hexagonal Cu2SnS3 with metallic character: Another category of conducting sulfides. Appl. Phys. Lett. 2007, 91, 143104. [Google Scholar] [CrossRef]

- Fu, L.; Zhang, C.; Chen, B.; Zhang, Z.; Wang, X.; Zhao, J.; He, J.; Du, H.; Cui, G. Graphene boosted Cu2GeS3 for advanced lithium-ion batteries. Inorg. Chem. Front. 2017, 4, 541–546. [Google Scholar] [CrossRef]

- Qu, B.; Li, H.; Zhang, M.; Mei, L.; Chen, L.; Wang, Y.; Li, Q.; Wang, T. Ternary Cu2SnS3 cabbage-like nanostructures: Large-scale synthesis and their application in Li-ion batteries with superior reversible capacity. Nanoscale 2011, 3, 4389. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Zhou, C.; Jia, M.; Fu, Y.; Li, J.; Lai, Y. Synthesis of copper tin sulfide/reduced graphene oxide composites and their electrochemical properties for lithium ion batteries. Electrochim. Acta 2014, 143, 305–311. [Google Scholar] [CrossRef]

- Lokhande, A.C.; Gurav, K.V.; Jo, E.; Lokhande, C.D.; Kim, J.H. Chemical synthesis of Cu2SnS3 (CTS) nanoparticles: A status review. J. Alloy. Compd. 2016, 656, 295–310. [Google Scholar] [CrossRef]

- Fu, L.; Shang, C.; Ma, J.; Zhang, C.; Zang, X.; Chai, J.; Li, J.; Cui, G. Cu2GeS3 derived ultrafine nanoparticles as high-performance anode for sodium ion battery. Sci. China Mater. 2018. [Google Scholar] [CrossRef]

- Shi, L.; Wang, W.; Wu, C.; Ding, J.; Li, Q. Synthesis of Cu2SnS3 nanosheets as an anode material for sodium ion batteries. J. Alloy. Compd. 2017, 699, 517–520. [Google Scholar] [CrossRef]

- Wei, Y.; Huang, L.; He, J.; Guo, Y.; Qin, R.; Li, H.; Zhai, T. Healable Structure Triggered by Thermal/Electrochemical Force in Layered GeSe2 for High Performance Li-Ion Batteries. Adv. Energy Mater. 2018. [Google Scholar] [CrossRef]

- Kwon, N.H.; Yin, H.; Vavrova, T.; Lim, J.H.W.; Steiner, U.; Grobéty, B.; Fromm, K.M. Nanoparticle shapes of LiMnPO4, Li+ diffusion orientation and diffusion coefficients for high volumetric energy Li+ ion cathodes. J. Power Sources 2017, 342, 231–240. [Google Scholar] [CrossRef]

- Xu, D.; Hai, Y.; Zhang, X.; Zhang, S.; He, R. Bi2O3 cocatalyst improving photocatalytic hydrogen evolution performance of TiO2. Appl. Surf. Sci. 2017, 400, 530–536. [Google Scholar] [CrossRef]

- Yuan, S.; Wang, S.; Li, L.; Zhu, Y.H.; Zhang, X.B.; Yan, J.M. Integrating 3D Flower-Like Hierarchical Cu2NiSnS4 with Reduced Graphene Oxide as Advanced Anode Materials for Na-Ion Batteries. ACS Appl. Mater. Interfaces 2016, 8, 9178–9184. [Google Scholar] [CrossRef] [PubMed]

- Nie, L.; Zhang, Y.; Ye, K.; Han, J.; Wang, Y.; Rakesh, G.; Li, Y.; Xu, R.; Yan, Q.; Zhang, Q. A crystalline Cu–Sn–S framework for high-performance lithium storage. J. Mater. Chem. A 2015, 3, 19410–19416. [Google Scholar] [CrossRef]

- Yuan, S.; Zhu, Y.H.; Li, W.; Wang, S.; Xu, D.; Li, L.; Zhang, Y.; Zhang, X.B. Surfactant-Free Aqueous Synthesis of Pure Single-Crystalline SnSe Nanosheet Clusters as Anode for High Energy- and Power-Density Sodium-Ion Batteries. Adv. Mater. 2017, 29, 1602469. [Google Scholar] [CrossRef] [PubMed]

- Qu, B.; Ma, C.; Ji, G.; Xu, C.; Xu, J.; Meng, Y.S.; Wang, T.; Lee, J.Y. Layered SnS2-reduced graphene oxide composite-a high-capacity, high-rate, and long-cycle life sodium-ion battery anode material. Adv. Mater. 2014, 26, 3854–3859. [Google Scholar] [CrossRef] [PubMed]

- Sun, Q.; Fu, L.; Shang, C. A Novel Open-Framework Cu-Ge-Based Chalcogenide Anode Material for Sodium-Ion Battery. Scanning 2017, 2017, 3876525. [Google Scholar] [CrossRef] [PubMed]

- Fu, L.; Wang, X.; Ma, J.; Zhang, C.; He, J.; Xu, H.; Chai, J.; Li, S.; Chai, F.; Cui, G. Graphene-Encapsulated Copper tin Sulfide Submicron Spheres as High-Capacity Binder-Free Anode for Lithium-Ion Batteries. ChemElectroChem 2017, 4, 1124–1129. [Google Scholar] [CrossRef]

- Xia, C.; Zhang, F.; Liang, H.; Alshareef, H.N. Layered SnS sodium ion battery anodes synthesized near room temperature. Nano Res. 2017, 10, 4368–4377. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fu, L.; Bi, Z.; Wei, B.; Huang, L.; Zhang, X.; Chen, Z.; Liao, H.; Li, M.; Shang, C.; Wang, X. Flower-like Cu2SnS3 Nanostructure Materials with High Crystallinity for Sodium Storage. Nanomaterials 2018, 8, 475. https://doi.org/10.3390/nano8070475

Fu L, Bi Z, Wei B, Huang L, Zhang X, Chen Z, Liao H, Li M, Shang C, Wang X. Flower-like Cu2SnS3 Nanostructure Materials with High Crystallinity for Sodium Storage. Nanomaterials. 2018; 8(7):475. https://doi.org/10.3390/nano8070475

Chicago/Turabian StyleFu, Lin, Zhen Bi, Benben Wei, Lanyan Huang, Xuzi Zhang, Zhihong Chen, Hua Liao, Ming Li, Chaoqun Shang, and Xin Wang. 2018. "Flower-like Cu2SnS3 Nanostructure Materials with High Crystallinity for Sodium Storage" Nanomaterials 8, no. 7: 475. https://doi.org/10.3390/nano8070475

APA StyleFu, L., Bi, Z., Wei, B., Huang, L., Zhang, X., Chen, Z., Liao, H., Li, M., Shang, C., & Wang, X. (2018). Flower-like Cu2SnS3 Nanostructure Materials with High Crystallinity for Sodium Storage. Nanomaterials, 8(7), 475. https://doi.org/10.3390/nano8070475