The Influence of Shape on the Output Potential of ZnO Nanostructures: Sensitivity to Parallel versus Perpendicular Forces

Abstract

:1. Introduction

2. Numerical Methods

3. Results and Discussion

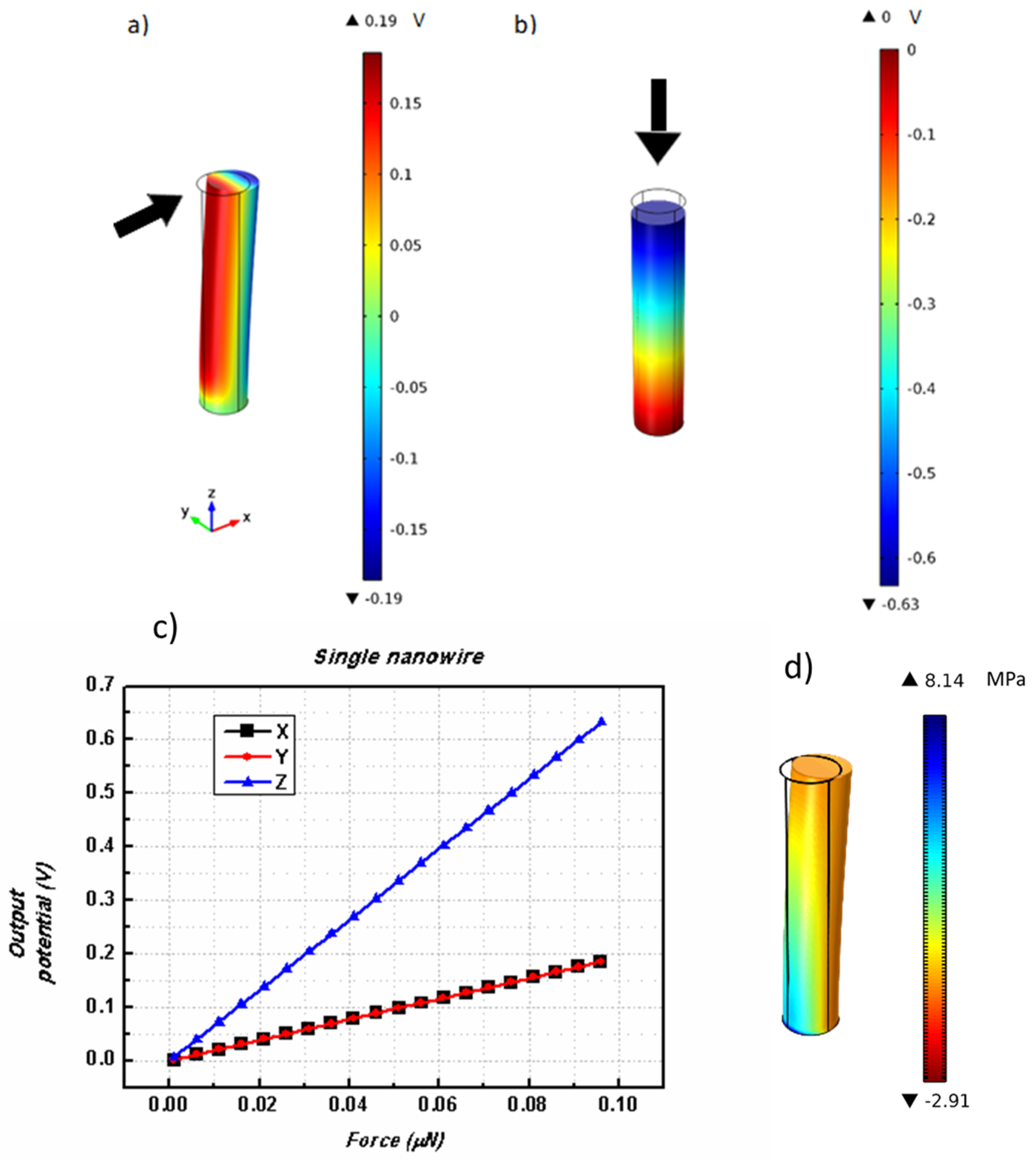

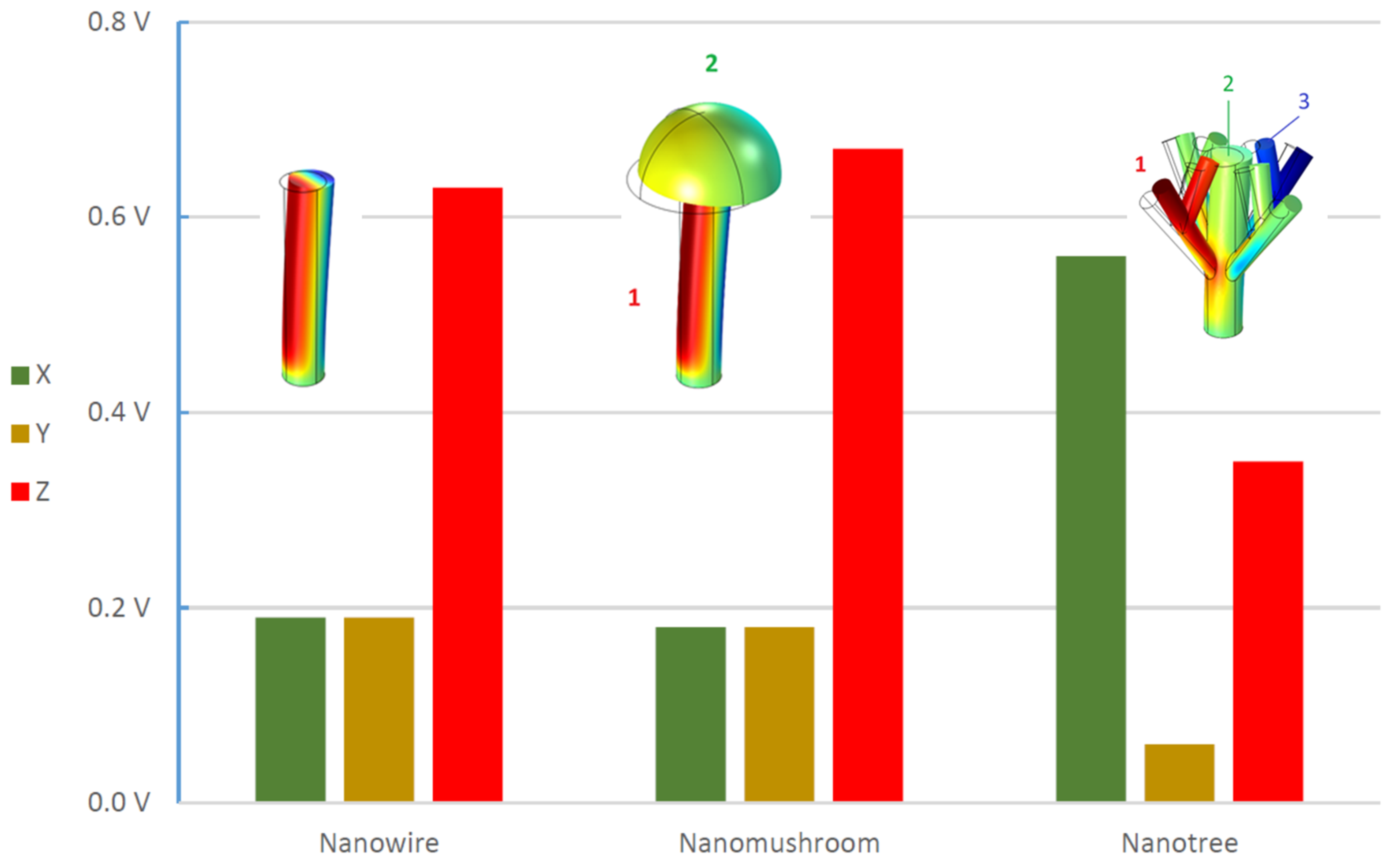

3.1. Cylindrical Nanowire

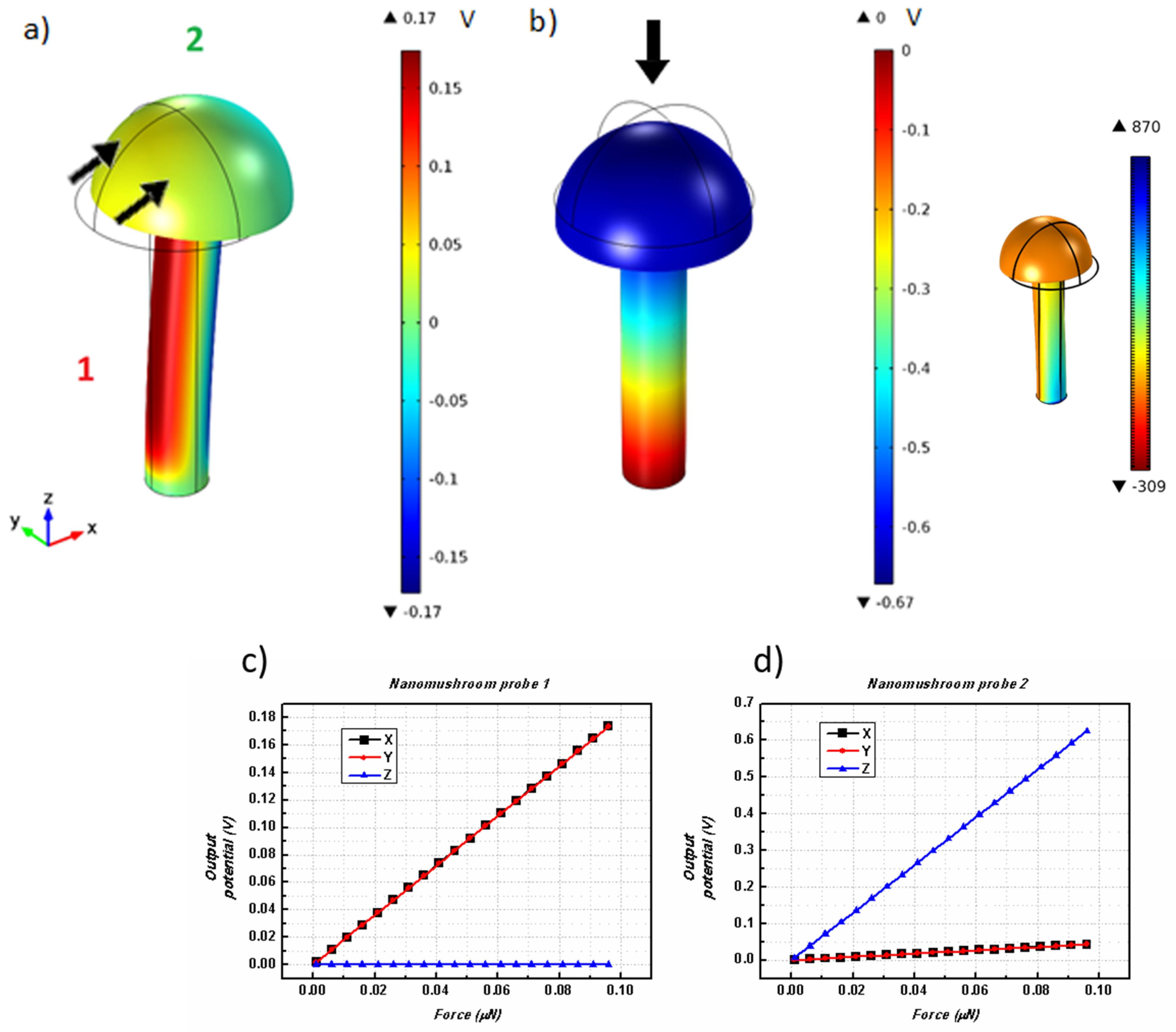

3.2. Nanomushroom

3.3. Nanotree

3.4. Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kim, D.; Lee, K.Y.; Gupta, M.K.; Majumder, S.; Kim, S.-W. Self-Compensated Insulating ZnO-Based Piezoelectric Nanogenerators. Adv. Funct. Mater. 2014, 24, 6949–6955. [Google Scholar] [CrossRef]

- Zi, Y.; Lin, L.; Wang, J.; Wang, S.; Chen, J.; Fan, X.; Yang, P.; Yi, F.; Wang, Z.L. Triboelectric–Pyroelectric–Piezoelectric Hybrid Cell for High-Efficiency Energy-Harvesting and Self-Powered Sensing. Adv. Mater. 2015, 27, 2340–2347. [Google Scholar] [CrossRef] [PubMed]

- Lee, V.C. Energy Harvesting for Wireless Sensor Networks. Master’s Thesis, University of California, Berkeley, CA, USA, 2012. [Google Scholar]

- Yang, Y.; Guo, W.; Pradel, K.C.; Zhu, G.; Zhou, Y.; Zhang, Y.; Hu, Y.; Lin, L.; Wang, Z.L. Pyroelectric Nanogenerators for Harvesting Thermoelectric Energy. Nano Lett. 2012, 12, 2833–2838. [Google Scholar] [CrossRef] [PubMed]

- Xie, Y.; Wang, S.; Lin, L.; Jing, Q.; Lin, Z.-H.; Niu, S.; Wu, Z.; Wang, Z.L. Rotary Triboelectric Nanogenerator Based on a Hybridized Mechanism for Harvesting Wind Energy. ACS Nano 2013, 7, 7119–7125. [Google Scholar] [CrossRef] [PubMed]

- Soin, N.; Shah, T.H.; Anand, S.C.; Geng, J.; Pornwannachai, W.; Mandal, P.; Reid, D.; Sharma, S.; Hadimani, R.L.; Bayramolf, D.V.; et al. Novel “3-D spacer” all fibre piezoelectric textiles for energy harvesting applications. Energy Environ. Sci. 2014, 7, 1670–1679. [Google Scholar] [CrossRef]

- Snyder, G.J.; Toberer, E.S. Complex thermoelectric materials. Nat. Mater. 2008, 7, 105–114. [Google Scholar] [CrossRef] [PubMed]

- Proenca, M.P.; Rosmaninho, M.; Resende, P.M.; Sousa, C.T.; Ventura, J.; Araujo, J.P.; Fernandes, L.; Tavares, P.B.; Pereira, A.M. Tailoring Bi-Te based nanomaterials by electrodeposition: Morphology and crystalline structure. Mater. Design 2017, 118, 168–174. [Google Scholar] [CrossRef]

- Wang, Z.L. Triboelectric Nanogenerators as New Energy Technology for Self-Powered Systems and as Active Mechanical and Chemical Sensors. ACS Nano 2015, 7, 9533–9557. [Google Scholar] [CrossRef] [PubMed]

- Rodrigues, C.; Alves, C.; Puga, J.; Pereira, A.M.; Ventura, J. Triboelectric Driven Turbine to Generate Electricity from the Motion of Water. Nano Energy 2016, 30, 379–386. [Google Scholar] [CrossRef]

- Kwak, S.S.; Kim, H.S.; Seung, W.; Kim, J.; Hinchet, R.; Kim, S.W. Fully Stretchable Textile Triboelectric Nanogenerator with Knitted Fabric Structures. ACS Nano 2017, 11, 10733–10741. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.L.; Song, J. Piezoelectric Nanogenerators Based on Zinc Oxide Nanowire Arrays. Science 2006, 312, 242–246. [Google Scholar] [CrossRef] [PubMed]

- Xu, S.; Wei, Y.; Liu, J.; Yang, R.; Wang, Z.L. Integrated multilayer nanogenerator fabricated using paired nanotip-to-nanowire brushes. Nano Lett. 2008, 8, 4027–4032. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Xu, S.; Yao, N.; Shi, Y. 1.6 V nanogenerator for mechanical energy harvesting using PZT nanofibers. Nano Lett. 2010, 10, 2133–2137. [Google Scholar] [CrossRef] [PubMed]

- Hu, Y.; Xu, C.; Zhang, Y.; Lin, L.; Snyder, R.L.; Wang, Z.L. A nanogenerator for energy harvesting from a rotating tire and its application as a self-powered pressure/speed sensor. Adv. Mater. 2011, 23, 4068–4071. [Google Scholar] [CrossRef] [PubMed]

- Hinchet, R.; Lee, S.; Ardila, G.; Montès, L.; Mouis, M.; Wang, Z.L. Performance Optimization of Vertical Nanowire-based Piezoelectric Nanogenerators. Adv. Funct. Mater. 2014, 24, 971–977. [Google Scholar] [CrossRef]

- Khan, A.; Hussain, M.; Nur, O.; Willander, M.; Broitman, E. Analysis of direct and converse piezoelectric responses from zinc oxide nanowires grown on a conductive fabric. Phys. Status Solidi A 2015, 212, 579–584. [Google Scholar] [CrossRef]

- Xu, S.; Qin, Y.; Xu, C.; Wei, Y.; Yang, R.; Wang, Z.L. Self-powered nanowire devices. Nat. Nanotechnol. 2010, 5, 366–373. [Google Scholar] [CrossRef] [PubMed]

- Janotti, A.; Van de Walle, C.G. Fundamentals of zinc oxide as a semiconductor. Rep. Prog. Phys. 2009, 72, 126501. [Google Scholar] [CrossRef]

- Cui, J. Zinc oxide nanowires. Mater. Charact. 2012, 64, 43–52. [Google Scholar] [CrossRef]

- Lupan, O.; Guérin, V.M.; Tiginyanu, I.M.; Ursaki, V.V.; Chow, L.; Heinrich, H.; Pauporté, T. Well-aligned arrays of vertically oriented ZnO nanowires electrodeposited on ITO-coated glass and their integration in dye sensitized solar cells. J. Photochem. Photobiol. A Chem. 2010, 211, 65–73. [Google Scholar] [CrossRef]

- Taghavi, M.; Mattoli, V.; Mazzolai, B.; Filippeschi, C.; Beccai, L. Synthesizing tubular and trapezoidal shaped ZnO nanowires by an aqueous solution method. Nanoscale 2013, 5, 3505–3513. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Zhai, J.; Liu, H.; Song, Y.; Jiang, L.; Zhu, D. Electrochemical Deposition of Conductive Superhydrophobic Zinc Oxide Thin Films. J. Phys. Chem. B 2003, 107, 9954–9957. [Google Scholar] [CrossRef]

- Mejía-García, C.; Díaz-Valdés, E.; Ayala-Torres, M.A.; Romero-Ibarra, J.; López-López, M. Influence of the Hydrothermal Method Growth Parameters on the Zinc Oxide Nanowires Deposited on Several Substrates. J. Nanomater. 2014, 2014, 609262. [Google Scholar] [CrossRef]

- Quaranta, F.; Valentini, A.; Rizzi, F.; Casamassima, G. Dual-ion-beam sputter deposition of ZnO films. J. Appl. Phys. 1993, 74, 244. [Google Scholar] [CrossRef]

- Oliveira, F.F.; Proenca, M.P.; Araújo, J.P.; Ventura, J. Electrodeposition of ZnO thin films on conducting flexible substrates. J. Mater. Sci. 2016, 51, 5589–5597. [Google Scholar] [CrossRef]

- Park, S.; Lee, J.H.; Kim, H.-D.; Hong, S.M.; An, H.-M.; Kim, T.G. Resistive switching characteristics of sol-gel based ZnO nanorods fabricated on flexible substrates. Phys. Status Solidi Rapid Res. Lett. 2013, 7, 493–496. [Google Scholar] [CrossRef]

- Hossain, M.F.; Takahashi, T. Hydrothermal Synthesis of Novel ZnO Nanomushrooms for Improving the Solar Cells Performance. IEEE Trans. Nanotechnol. 2014, 13, 755–759. [Google Scholar] [CrossRef]

- Qiu, Y.; Yang, D.C.; Yin, B.; Lei, J.X.; Zhang, H.Q.; Zhang, Z.; Chen, H.; Li, Y.P.; Bian, J.M.; Liu, Y.H.; et al. Branched ZnO nanotrees on flexible fiber-paper substrates for self-powered energy-harvesting systems. RSC Adv. 2015, 5, 5941–5945. [Google Scholar] [CrossRef]

- Oliveira, F.; Proenca, M.P.; Araujo, J.P.; Ventura, J. Output potential of ZnO nanowires: Influence of geometrical parameters. J. Nanosci. Nanotechnol. 2016, 16, 8533–8537. [Google Scholar] [CrossRef]

- Hinchet, R. Electromechanical Study of Semiconductor Piezoelectric Nanowires. Application to Mechanical Sensors and Energy Harvesters. Ph.D. Thesis, Université Grenoble Alpes, Grenoble, France, 2014. [Google Scholar]

- Hao, H.; Jenkins, K.; Huang, X.; Xu, Y.; Huang, J.; Yang, R. Piezoelectric Potential in Single-Crystalline ZnO Nanohelices Based on Finite Element Analysis. Nanomaterials 2017, 7, 430. [Google Scholar] [CrossRef] [PubMed]

- Falconi, C.; Mantini, G.; D’Amico, A.; Wang, Z.L. Studying piezoelectric nanowires and nanowalls for energy harvesting. Sens. Actuators B Chem. 2009, 139, 511–519. [Google Scholar] [CrossRef]

- Mantini, G.; Gao, Y.; D’Amico, A.; Falconi, C.; Wang, Z.L. Equilibrium piezoelectric potential distribution in a deformed ZnO nanowire. Nano Res. 2009, 2, 624–629. [Google Scholar] [CrossRef]

- Hu, Y.; Lin, L.; Zhang, Y.; Wang, Z.L. Replacing a Battery by a Nanogenerator with 20 V Output. Adv. Mater. 2012, 24, 110–114. [Google Scholar] [CrossRef] [PubMed]

- Gao, Y.; Wang, Z.L. Electrostatic Potential in a Bent Piezoelectric Nanowire. The Fundamental Theory of Nanogenerator and Nanopiezotronics. Nano Lett. 2007, 7, 2499–2505. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Hu, S.; Shen, S. Effect of flexoelectricity on electrostatic potential in a bent piezoelectric nanowire. Smart Mater. Struct. 2012, 21, 115024. [Google Scholar] [CrossRef]

- Asthana, A.; Momeni, K.; Prasad, A.; Yap, Y.K.; Yassar, R.S. In situ observation of size-scale effects on the mechanical properties of ZnO nanowires. Nanotechnology 2011, 22, 265712. [Google Scholar] [CrossRef] [PubMed]

- Sun, C.; Shi, J.; Wang, X. Fundamental study of mechanical energy harvesting using piezoelectric nanostructures. J. Appl. Phys. 2010, 108, 034309. [Google Scholar] [CrossRef]

- Ikeda, T. Fundamentals of Piezoelectricity; Oxford University Press: Oxford, UK, 1990. [Google Scholar]

- Hinchet, R.; Ferreira, J.; Keraudy, J.; Ardila, G.; Pauliac-Vaujour, E.; Mouis, M.; Montes, L. Scaling rules of piezoelectric nanowires in view of sensor and energy harvester integration. In Proceedings of the 2012 IEEE International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 10–13 December 2012. [Google Scholar]

- Agrawal, R.; Espinosa, H. Giant Piezoelectric Size Effects in Zinc Oxide and Gallium Nitride Nanowires. A First Principles Investigation. Nano Lett. 2011, 11, 786. [Google Scholar] [CrossRef] [PubMed]

- Gao, Z.; Zhou, J.; Gu, Y.; Fei, P.; Hao, Y.; Bao, G.; Wang, Z.L. Effects of piezoelectric potential on the transport characteristics of metal-ZnO nanowire-metal field effect transistor. J. Appl. Phys. 2009, 105, 113707. [Google Scholar] [CrossRef] [PubMed]

- Gao, Y.; Wang, Z.L. Equilibrium potential of free charge carriers in a bent piezoelectric semiconductive nanowire. Nano Lett. 2009, 9, 1103–1110. [Google Scholar] [CrossRef] [PubMed]

- Gao, P.X.; Song, J.; Liu, J.; Wang, Z.L. Nanowire piezoelectric nanogenerators on plastic substrates as flexible power sources for nanodevices. Adv. Mater. 2007, 19, 67–72. [Google Scholar] [CrossRef]

| Constant | Value | Unit |

|---|---|---|

| ε11/ε0 | 8.5 | |

| ε33/ε0 | 10.5 | |

| d33 | 12.4 | 10−12 C/N (10−12 m/V) |

| d33 | −5.0 | |

| d15 | −8.3 | |

| e33 | 1.57 | C/m2 |

| e33 | −0.36 | |

| e15 | −0.36 | |

| c33 | 210 | N/m2 |

| c12 | 121 | |

| c13 | 105 | |

| c33 | 211 | |

| g33 | 0.13 | Vm/N |

| g31 | −0.05 |

| Structure | Applied Force (μN) | Maximum Piezoelectric Potential (V) | Displacement (nm) | ||

|---|---|---|---|---|---|

| x | y | z | |||

| Nanowire | 100 | 0.19 | 5.8 | ||

| 100 | 0.19 | 5.8 | |||

| 100 | 0.63 | 0.03 | |||

| Nanomushroom | 100 | 0.17 (@Probe 1) | 7.0 | ||

| 100 | 0.17 (@Probe 1) | 7.0 | |||

| 100 | 0.63 (@Probe 2) | 0.04 | |||

| Nanotree | 100 | 0.52 (@Probe 1) | 7.2 | ||

| 100 | 0.06 (@Probe 2) | 4.6 | |||

| 100 | 0.34 (@Probe 2) | 0.02 | |||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cardoso, J.; Oliveira, F.F.; Proenca, M.P.; Ventura, J. The Influence of Shape on the Output Potential of ZnO Nanostructures: Sensitivity to Parallel versus Perpendicular Forces. Nanomaterials 2018, 8, 354. https://doi.org/10.3390/nano8050354

Cardoso J, Oliveira FF, Proenca MP, Ventura J. The Influence of Shape on the Output Potential of ZnO Nanostructures: Sensitivity to Parallel versus Perpendicular Forces. Nanomaterials. 2018; 8(5):354. https://doi.org/10.3390/nano8050354

Chicago/Turabian StyleCardoso, José, Filipe F. Oliveira, Mariana P. Proenca, and João Ventura. 2018. "The Influence of Shape on the Output Potential of ZnO Nanostructures: Sensitivity to Parallel versus Perpendicular Forces" Nanomaterials 8, no. 5: 354. https://doi.org/10.3390/nano8050354

APA StyleCardoso, J., Oliveira, F. F., Proenca, M. P., & Ventura, J. (2018). The Influence of Shape on the Output Potential of ZnO Nanostructures: Sensitivity to Parallel versus Perpendicular Forces. Nanomaterials, 8(5), 354. https://doi.org/10.3390/nano8050354