The Role of Nano-TiO2 Lubricating Fluid on the Hot Rolled Surface and Metallographic Structure of SS41 Steel

Abstract

:1. Introduction

2. Experimental

2.1. Materials

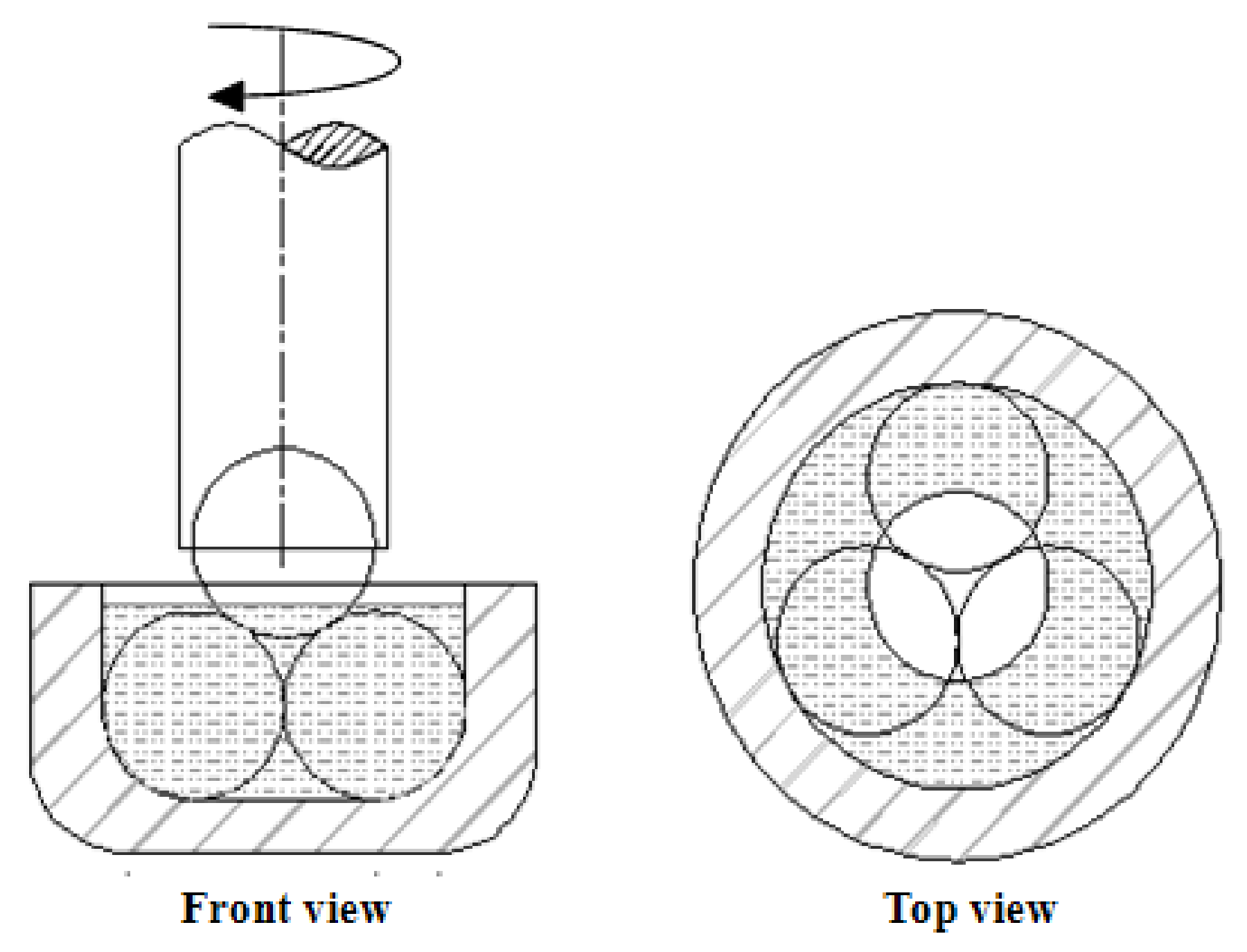

2.2. Tribological Test

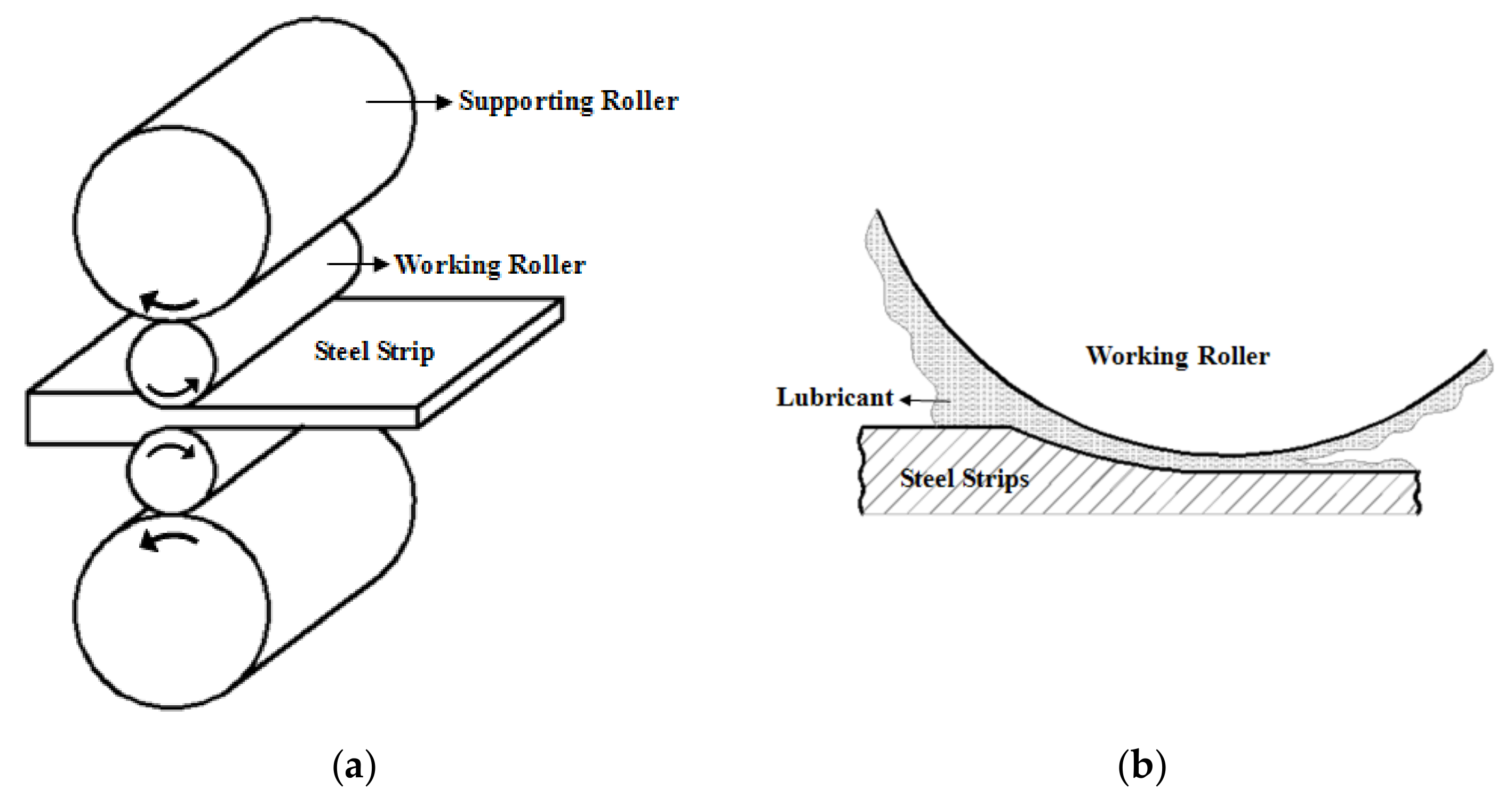

2.3. Hot Rolling Test

2.4. Characterization Methods

3. Results and Discussion

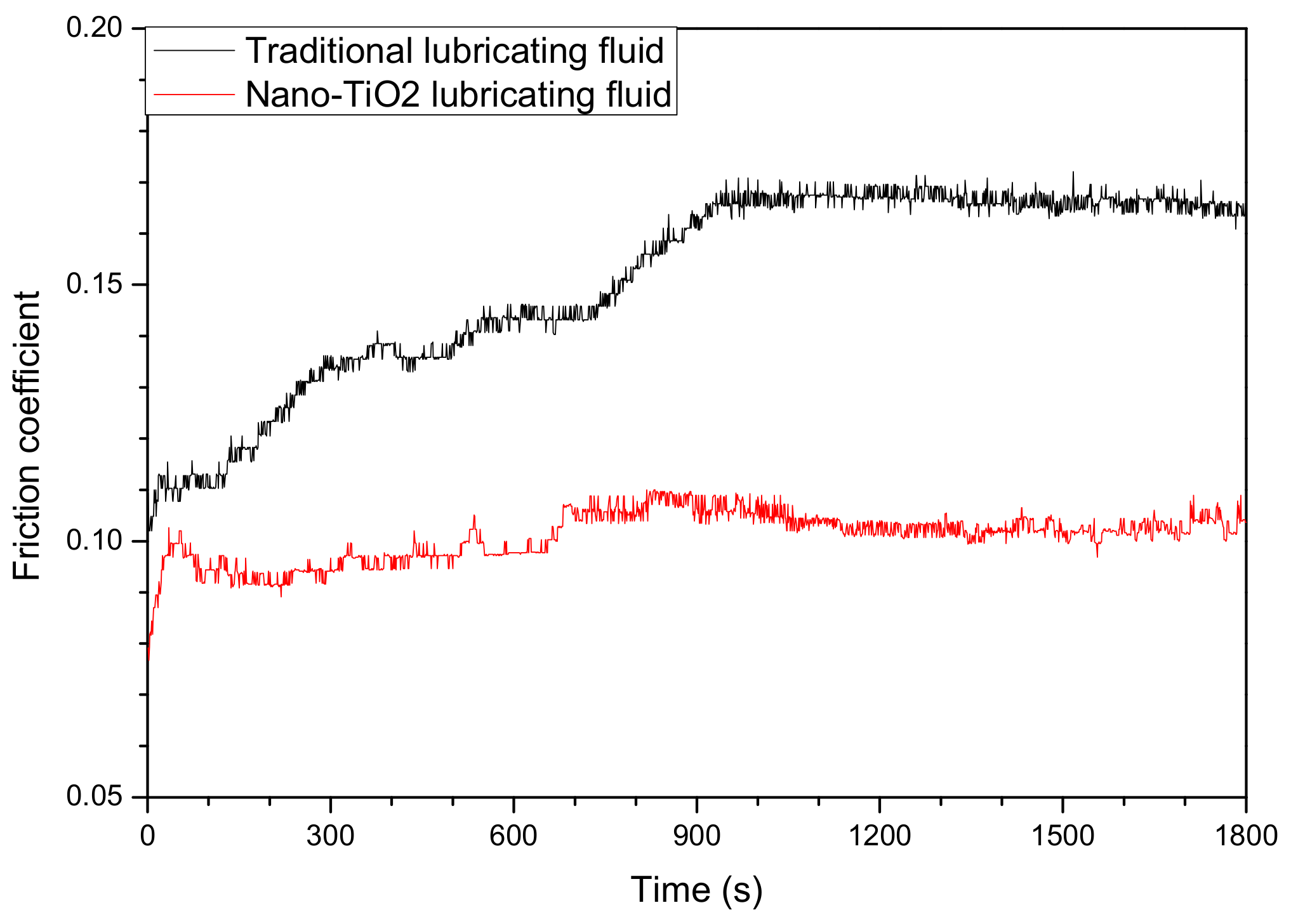

3.1. Tribology Performance

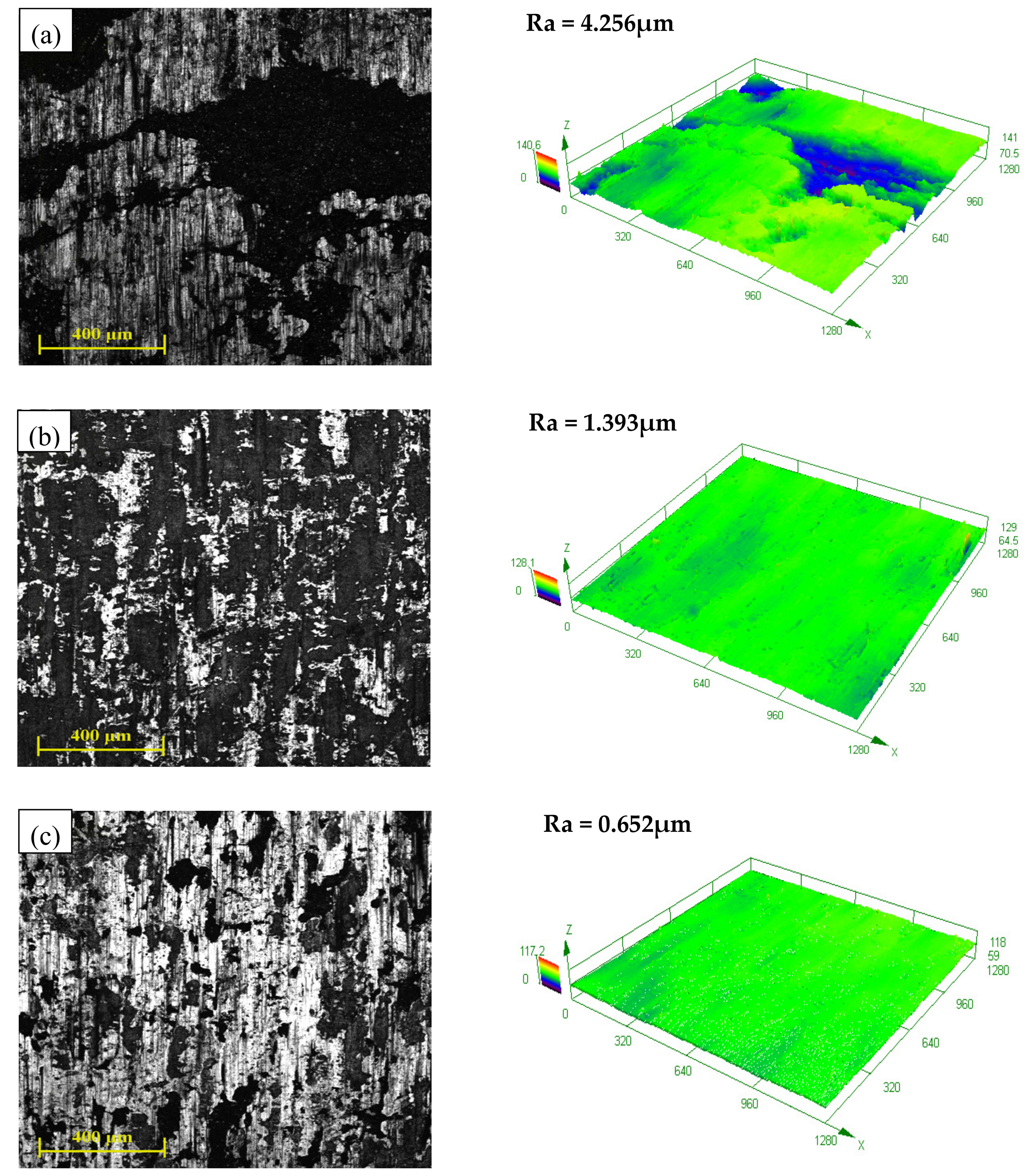

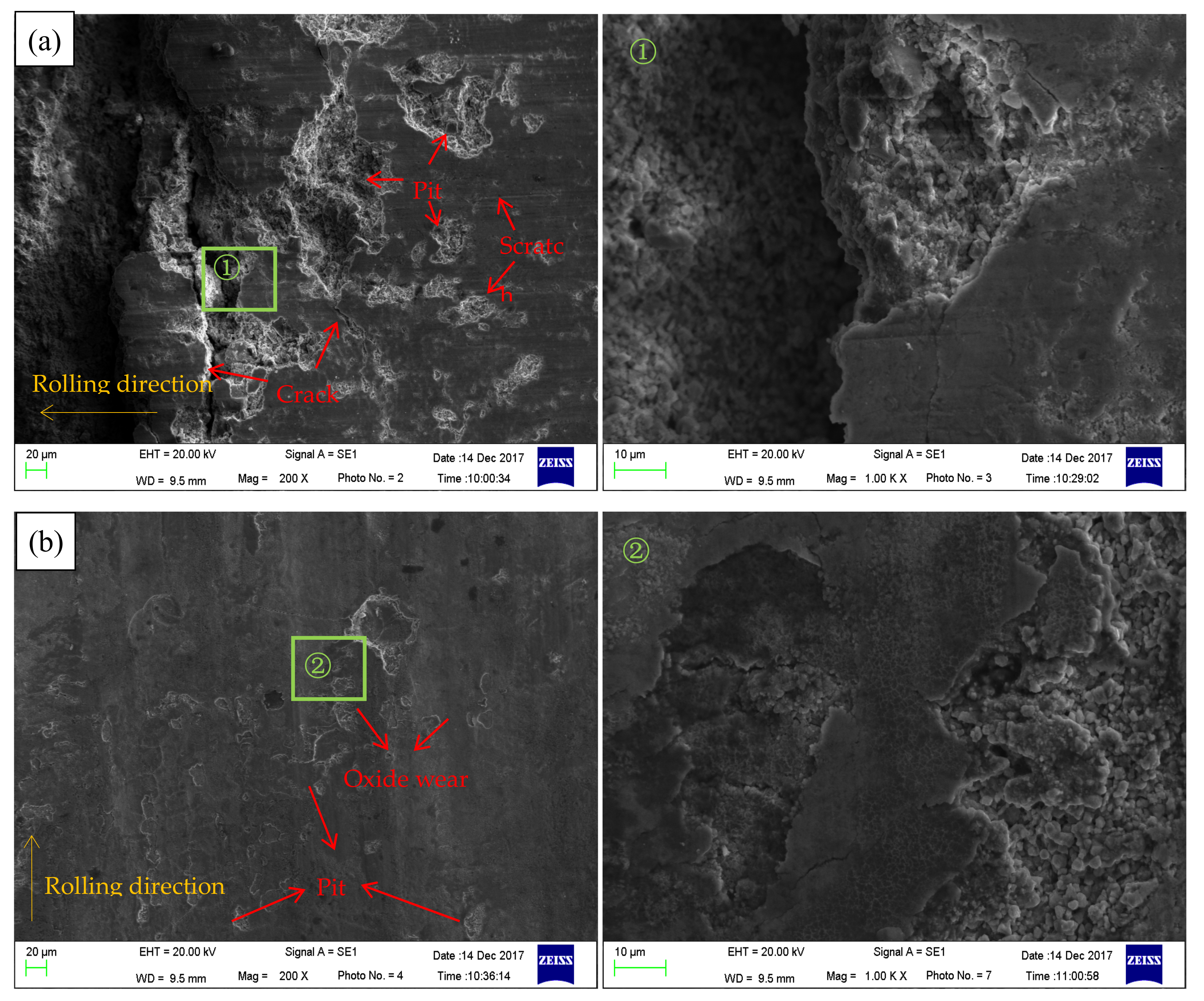

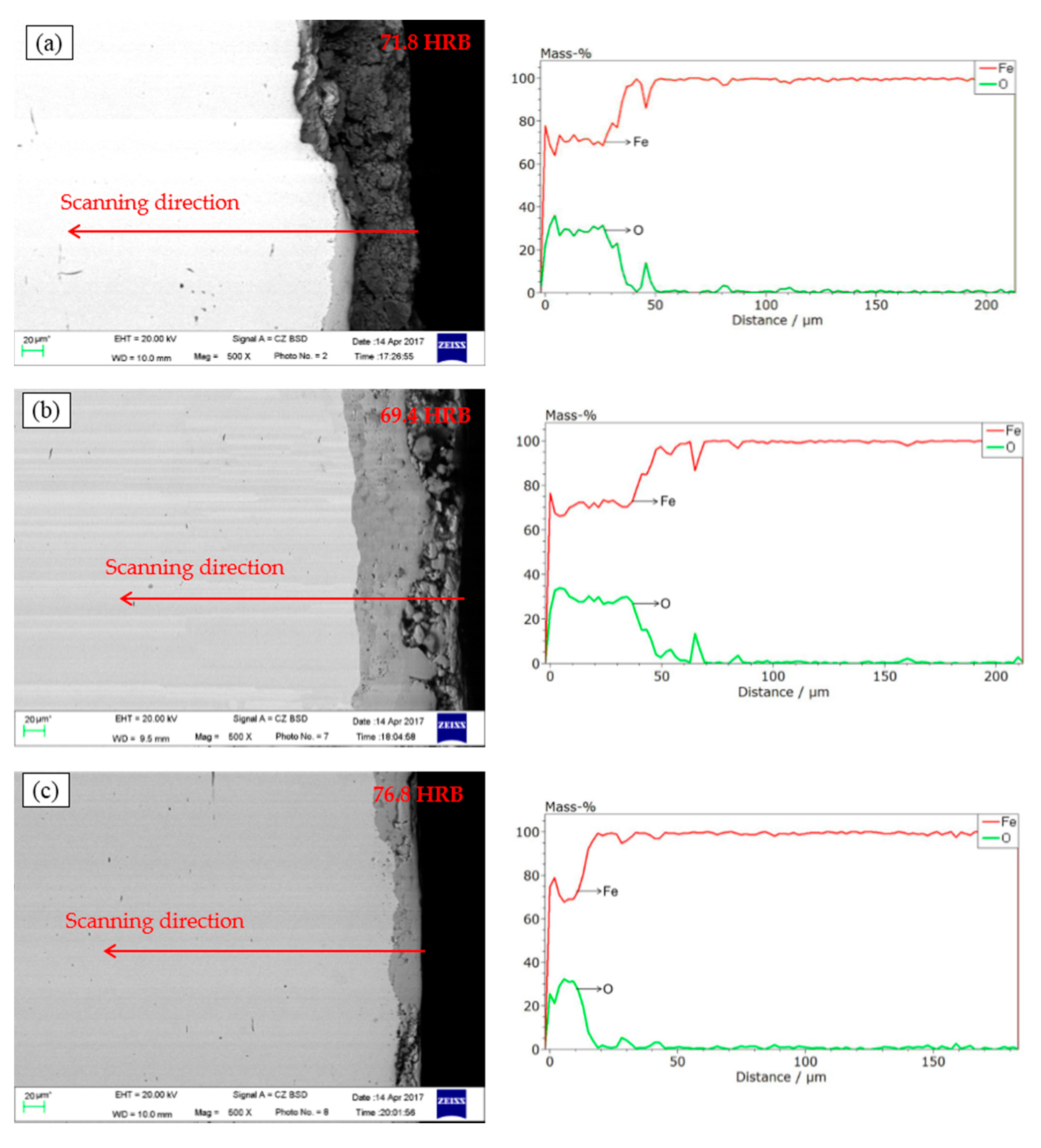

3.2. Surface Morphology

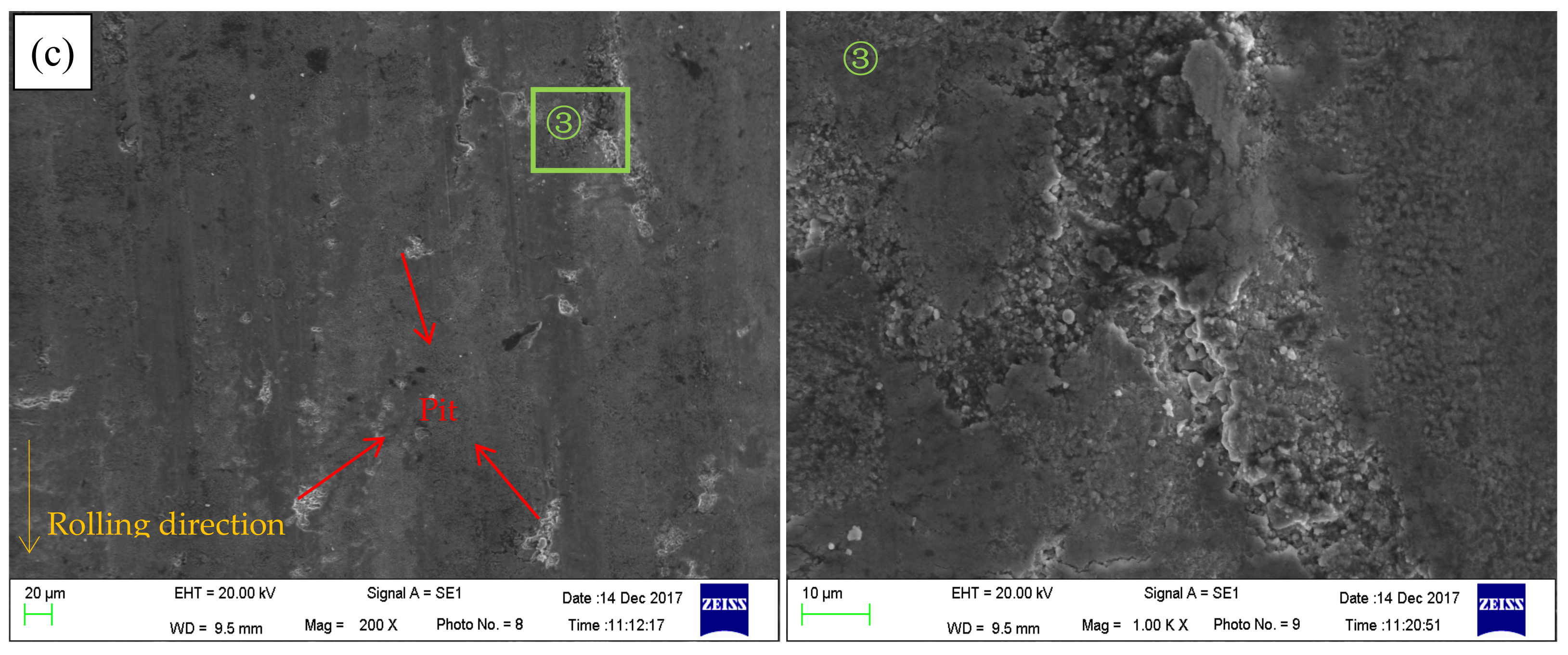

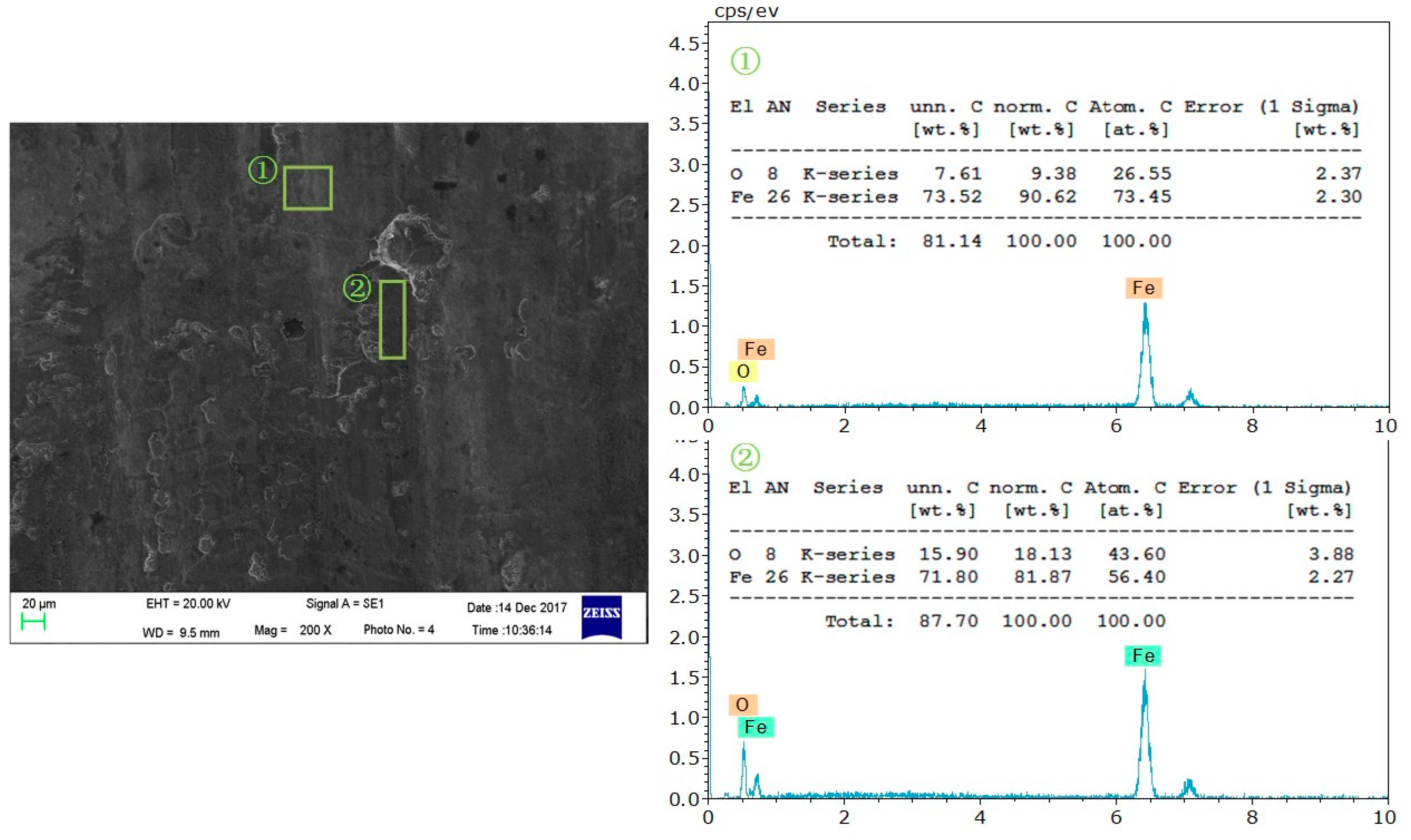

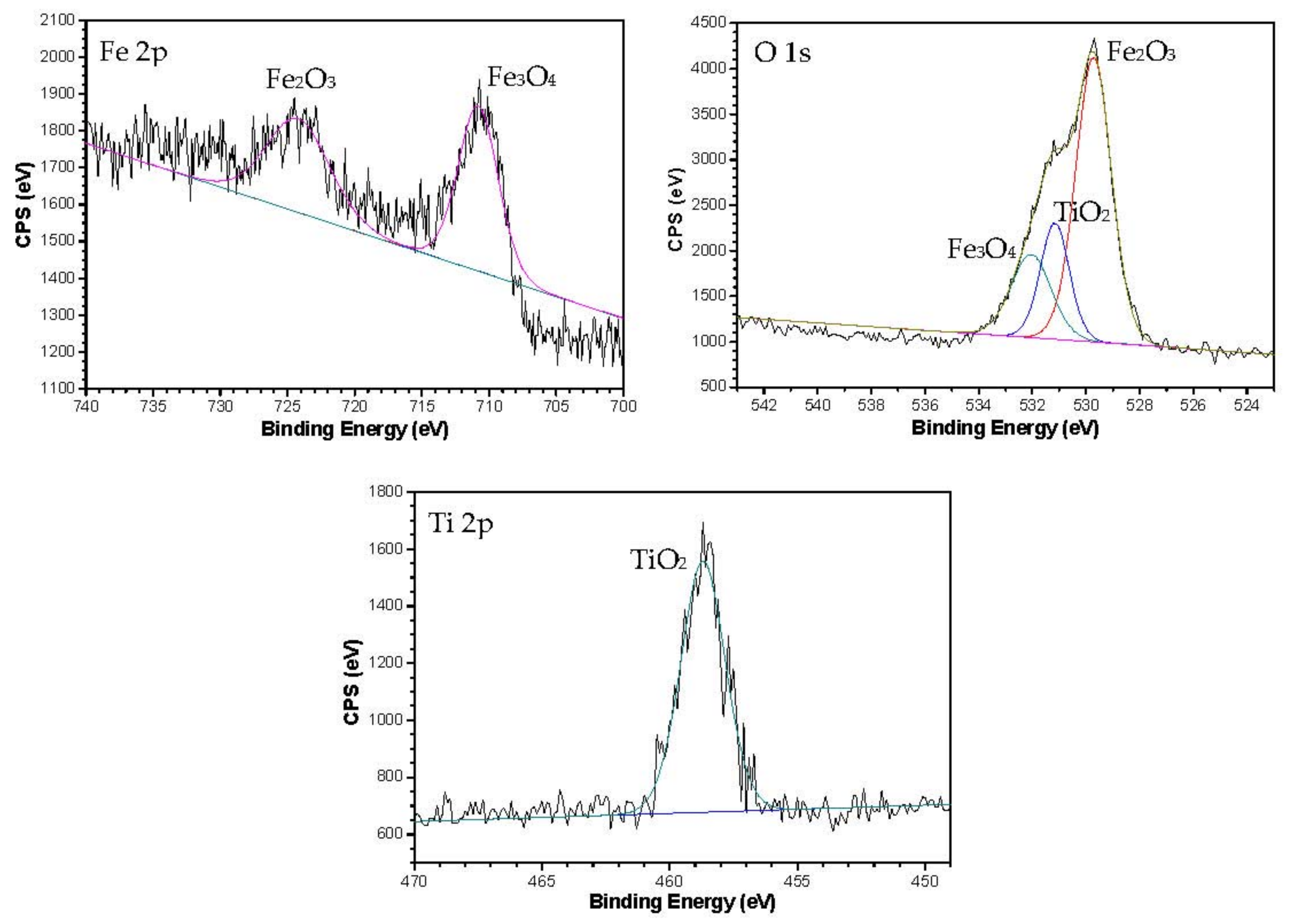

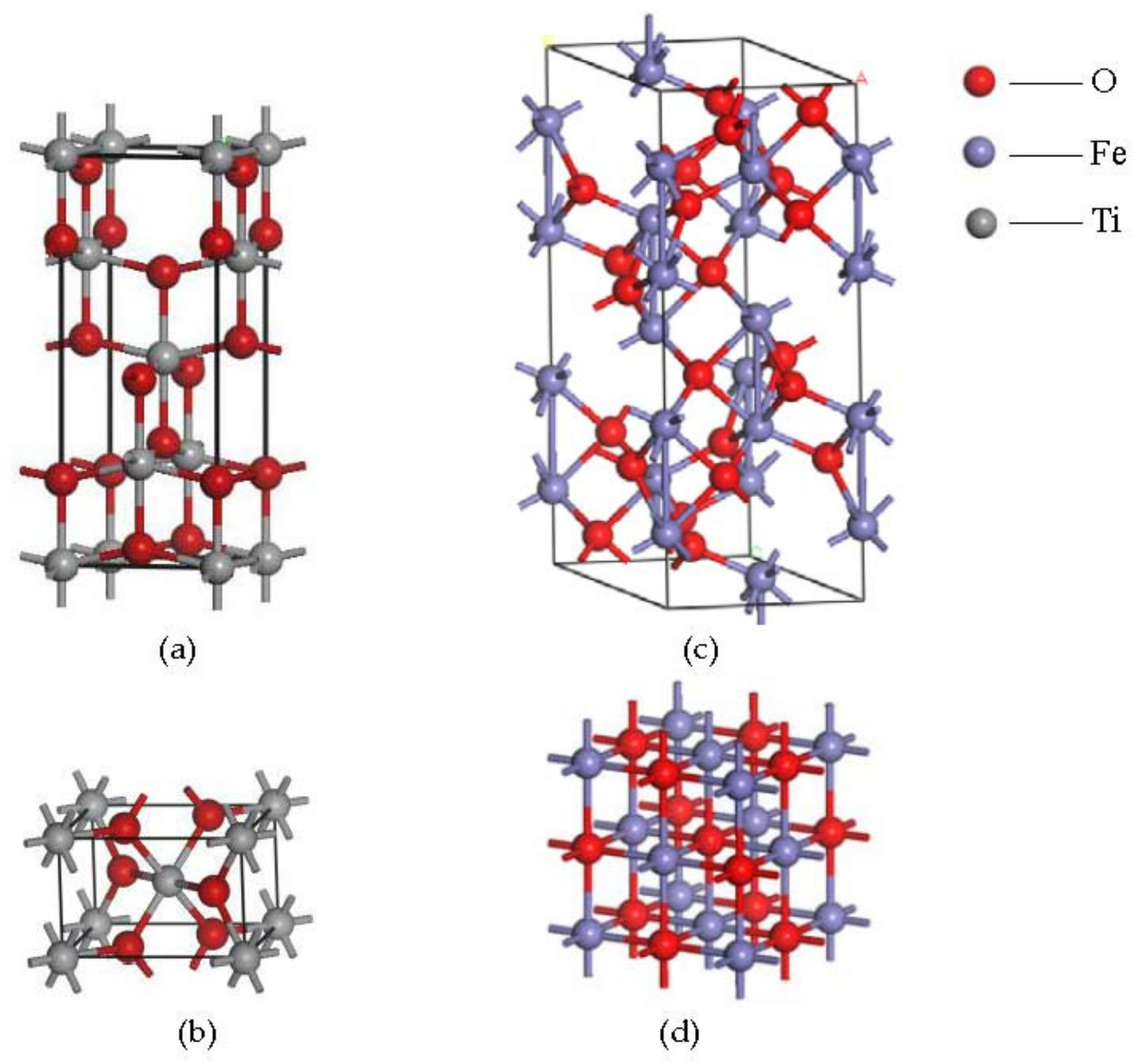

3.3. Oxide Scales

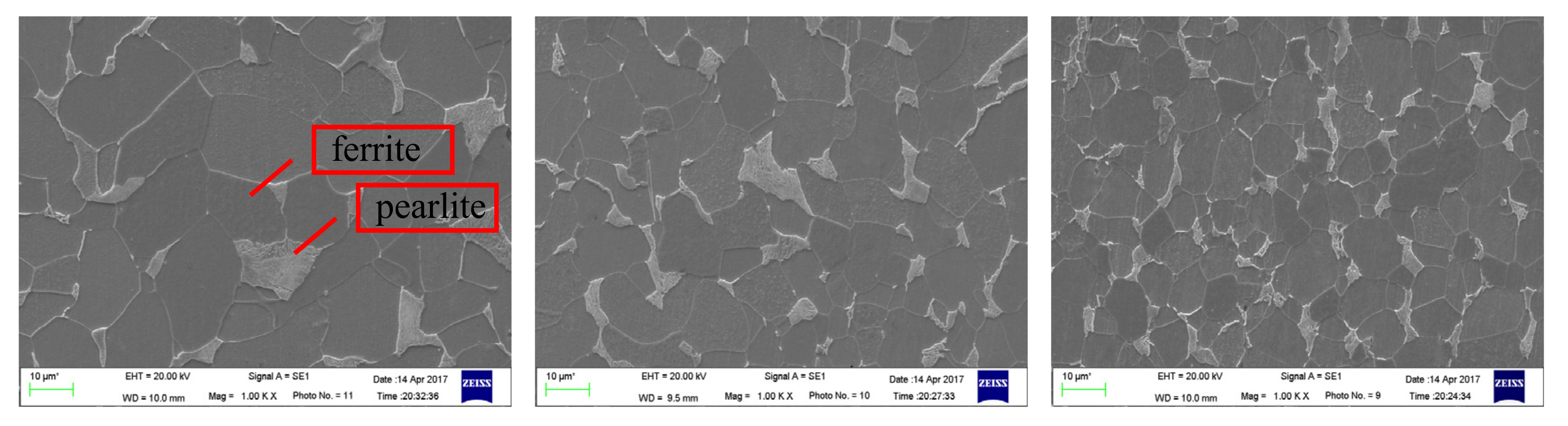

3.4. Metallographic Structure

4. Conclusions

- (1)

- Adding nano-TiO2 in lubricating fluid was associated with a 62.5% increase in the maximum non-seizure load, a 33.8% reduction in the friction coefficient and a 47.4% reduction in the wear extent, compared with traditional lubricating fluid. Moreover, the friction coefficient-time curve of nano-TiO2 lubricating fluid became smooth in only 50 s, while that of traditional lubricating fluid presented a remarkably increasing trend till 900 s.

- (2)

- The grain size of rolled steel strips lubricated with nano-TiO2 lubricating fluid decreased from 18.51 μm to 7.46 μm. Additionally, the phase composition of the surface still appeared as a mixture of ferrite and pearlite. There was no iron micro-alloyed phenomenon with titanium. The homogeneity of the metal base was not destroyed.

- (3)

- TiO2 nanoparticles could deposit on worn surfaces in the hot rolling process. With the generation of iron oxides, nano-TiO2 was distributed in the oxide scales diffusely. The compactness of the oxide scales could be drastically enhanced, which caused a slightly increase in Rockwell hardness and a decrease in the thickness of the oxide scales, from 60 μm to 20 μm. There were fewer surface defects on the hot rolled surface.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Wu, H.; Zhao, J.W.; Xia, W.Z.; Cheng, X.W.; He, A.S.; Jung, H.Y.; Wang, L.Z.; Huang, H.; Jiao, S.H.; Huang, L.; et al. A study of the tribological behaviour of TiO2 nano-additive water-based lubricants. Tribol. Int. 2017, 109, 398–408. [Google Scholar] [CrossRef]

- Hsu, S.M. Nano-lubrication: Concept and design. Tribol. Int. 2004, 37, 537–545. [Google Scholar] [CrossRef]

- Xie, H.M.; Jiang, B.; Hu, X.Y.; Peng, C.; Guo, H.L.; Pan, F.S. Synergistic effect of MoS2 and SiO2 nanoparticles as lubricant additives for magnesium alloy–steel contacts. Nanomaterials 2017, 7, 154. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.R.; Hu, K.H.; Hu, E.Z.; Guo, J.H.; Han, C.L.; Hu, X.G. Double hollow MoS2 nano-spheres: Synthesis, tribological properties, and functional conversion from lubrication to photocatalysis. Appl. Surf. Sci. 2017, 392, 1144–1152. [Google Scholar]

- Sayuti, M.; Sarhan, A.D.D.; Salem, F. Novel uses of SiO2 nano-lubrication system in hard turning process of hardened steel AISI4140 for less tool wear, surface roughness and oil consumption. J. Clean. Prod. 2014, 67, 265–276. [Google Scholar] [CrossRef]

- Hu, K.H.; Xu, Y.; Hu, E.Z.; Guo, J.H.; Hu, X.G. Rolling friction performance and functional conversion from lubrication to photocatalysis of hollow spherical nano-MoS2/nano-TiO2. Tribol. Int. 2016, 104, 131–139. [Google Scholar] [CrossRef]

- Xia, W.Z.; Zhao, J.W.; Wu, H.; Jiao, S.H.; Jiang, Z.Y. Effects of oil-in-water based nanolubricant containing TiO2 nanoparticles on the tribological behaviour of oxidized high-speed steel. Tribol. Int. 2017, 1, 77–85. [Google Scholar] [CrossRef]

- Luo, T.; Wei, X.W.; Zhao, H.Y.; Cai, G.Y.; Zheng, X.Y. Tribology properties of Al2O3/TiO2 nanocomposites as lubricant additives. Ceram. Int. 2014, 40, 10103–10109. [Google Scholar] [CrossRef]

- Totka, B.; Lucie, S.; Petra, R.; Karolína, B.; Lukas, V.; Petr, L. The application potential of SiO2, TiO2 or Ag nanoparticles as fillers in machining process fluids. J. Clean. Prod. 2017, 142, 2237–2243. [Google Scholar]

- Sun, J.L.; Zhu, Z.X.; Xu, P.F. Study on the lubricating performance of nano-TiO2 in water-based cold rolling fluid. Mater. Sci. Forum 2015, 817, 219–224. [Google Scholar] [CrossRef]

- Zhu, Z.X.; Sun, J.L.; Niu, T.L.; Liu, N.N. Experimental research on tribological performance of water-based rolling liquid containing nano-TiO2. Proc. Inst. Mech. Eng. Part N J. Nanoeng. Nanosyst. 2015, 229, 104–109. [Google Scholar] [CrossRef]

- Kumar, A.S.; Kumar, A.T.; Kumar, R.S.; Rai, A.D. Tribological investigation of TiO2 nanoparticle based cutting fluid in machining under minimum quantity lubrication (MQL). Mater. Today Proc. 2015, 3, 2155–2162. [Google Scholar]

- Najiha, M.S.; Rahman, M.M.; Kadirgama, K. Performance of water-based TiO2nanofluid during the minimum quantity lubrication machining of aluminium alloy AA6061-T6. J. Clean. Prod. 2016, 135, 1623–1636. [Google Scholar] [CrossRef]

- Chetan; Behera, B.C.; Ghosh, S.; Rao, P.V. Application of nanofluids during minimum quantity lubrication: A case study in turning process. Tribol. Int. 2016, 101, 234–246. [Google Scholar]

- Jung, S.N.; Hoon, D.K.; Chung, H.; Lee, S.W. Optimization of environmentally benign micro-drilling process with nanofluid minimum quantity lubrication using response surface methodology and genetic algorithm. J. Clean. Prod. 2015, 102, 428–436. [Google Scholar]

- Xia, W.Z.; Zhao, J.W.; Wu, H.S.; Jiao, H.; Zhao, X.M.; Zhang, X.M.; Jiang, Z.Y. A novel nano-TiO2 additive oil-in-water lubricant for hot steel rolling. Mater. Sci. Forum 2016, 861, 201–206. [Google Scholar] [CrossRef]

- Zhu, Z.X.; Sun, J.L.; Wei, H.R.; Niu, T.L.; Zhu, Z.L. Research on lubrication behaviors of nano-TiO2 in water-based hot rolling liquid. Adv. Mater. Res. 2013, 643, 139–143. [Google Scholar] [CrossRef]

- Okeke, G.; Hammond, R.B.; Antony, S.J. Effects of heat treatment on the atomic structure and surface energy of rutile and anatase TiO2 nanoparticles under vacuum and water environments. Chem. Eng. Sci. 2016, 146, 144–158. [Google Scholar] [CrossRef]

- Nicholas, T.N.; Michael, K.S.; Steven, J.H.; Linda, F.H.; Suresh, C.P. A systematic study of the effect of silver on the chelation of formic acid to a titanium precursor and the resulting effect on the anatase to rutile transformation of TiO2. J. Phys. Chem. 2010, 114, 13026–13034. [Google Scholar]

- Eleana, K.; Vassileios, D.; Tiverios, V.; Kyriakos, B.; Alexis, L.; Christos, K. Comparative study of phase transition and textural changes upon calcination of two commercial titania samples: A pure anatase and a mixed anatase-rutil. J. Solid State Chem. 2015, 232, 42–49. [Google Scholar]

- Cheng, L.W.; Weng, S.H.; Hsueh, L.C.; Huey, J.L.; Horng, H.K.; Moo, C.W. Kinetics of anatase transition to rutile TiO2 from titanium dioxide precursor powders synthesized by a sol-gel process. Ceram. Int. 2016, 42, 13136–13143. [Google Scholar]

- Sajad, Z.; Reza, J.N.; Masoud, A. The sources of the micro stress and strain inhomogeneity in dual phase steels. Mater. Sci. Eng. A 2016, 674, 384–396. [Google Scholar]

- Ingole, S.; Charanpahari, A.; Kakade, A.; Umare, S.S.; Bhatt, D.V.; Menghani, J. Tribological behavior of nano TiO2 as an additive in base oil. Wear 2013, 301, 776–785. [Google Scholar] [CrossRef]

- Kumara, P.; Banerjee, M.K.; Hodgson, P.; Choudhray, A.R. Warm working characterization of low carbon steel in hot rolling. Mater. Today Proc. 2017, 4, 9505–9508. [Google Scholar] [CrossRef]

- Dwivedi, D.K. Adhesive wear behaviour of cast aluminium–silicon alloys: Overview. Mater. Des. 2010, 31, 2517–2531. [Google Scholar] [CrossRef]

- Zhang, C.; Wu, R.; Song, C.; Zhang, Y.F.; Li, S.L.; Tan, J.M. The grain refining and strengthening mechanism of C-Mn steel by CSP. Adv. Mater. Res. 2011, 1278, 261–263. [Google Scholar] [CrossRef]

- Hong, Y.S.; Hai, T.L.; Hui, H.L.; Hao, Z.L.; Wen, Q.L.; Xiao, M.Z.; Guo, D.W. Effect of hot rolling reduction on microstructure, texture and ductility of strip-cast grain-oriented silicon steel with different solidification structures. Mater. Sci. Eng. A 2014, 605, 260–269. [Google Scholar]

- Ouyang, W.Y.; Kuna, E.; Yepez, A.; Balu, A.M.; Romero, A.A.; Colmenares, J.C.; Luque, R. Mechanochemical synthesis of TiO2nanocompositesas photocatalysts for benzyl alcohol photo-oxidation. Nanomaterials 2016, 6, 93. [Google Scholar] [CrossRef] [PubMed]

| Additive | Content (%) |

|---|---|

| anatase nano-TiO2 | 0.50–1.50 |

| Glycerin | 4.00–8.00 |

| triethanolamine (TEA) | 2.00–5.00 |

| sodium polyacrylate (PAAS) | 0.02–0.08 |

| sodium hexametaphosphate (SHMP) | 0.20–0.60 |

| sodium dodecyl benzene sulfonate (SDBS) | 0.50–1.00 |

| Element | C | Si | Mn | S | P | Cr | Ni | Cu |

|---|---|---|---|---|---|---|---|---|

| Content (wt %) | 0.20 | 0.35 | 1.40 | 0.045 | 0.045 | 0.030 | 0.030 | 0.030 |

| Condition | PB/N | Friction Coefficient | Wear Scar Diameter/mm | |||

|---|---|---|---|---|---|---|

| 1# | 2# | 3# | Mean Value | |||

| traditional lubricating fluid | 392 | 0.1519 | 1.182 | 1.179 | 1.138 | 1.166 |

| nano-TiO2 lubricating fluid | 637 | 0.1006 | 0.645 | 0.580 | 0.613 | 0.613 |

| Condition | Average Diameters/μm |

|---|---|

| non-lubricant | 18.51 |

| traditional lubricating fluid | 13.86 |

| nano-TiO2 lubricating fluid | 7.46 |

| Condition | Finishing Thickness/mm | Spring-Back/% | Overall Reduction/% |

|---|---|---|---|

| non-lubricant | 4.98 | 24.50 | 83.4 |

| traditional lubricating fluid | 4.57 | 14.25 | 84.8 |

| nano-TiO2 lubricating fluid | 4.13 | 3.25 | 86.2 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meng, Y.; Sun, J.; Wu, P.; Dong, C.; Yan, X. The Role of Nano-TiO2 Lubricating Fluid on the Hot Rolled Surface and Metallographic Structure of SS41 Steel. Nanomaterials 2018, 8, 111. https://doi.org/10.3390/nano8020111

Meng Y, Sun J, Wu P, Dong C, Yan X. The Role of Nano-TiO2 Lubricating Fluid on the Hot Rolled Surface and Metallographic Structure of SS41 Steel. Nanomaterials. 2018; 8(2):111. https://doi.org/10.3390/nano8020111

Chicago/Turabian StyleMeng, Yanan, Jianlin Sun, Ping Wu, Chang Dong, and Xudong Yan. 2018. "The Role of Nano-TiO2 Lubricating Fluid on the Hot Rolled Surface and Metallographic Structure of SS41 Steel" Nanomaterials 8, no. 2: 111. https://doi.org/10.3390/nano8020111

APA StyleMeng, Y., Sun, J., Wu, P., Dong, C., & Yan, X. (2018). The Role of Nano-TiO2 Lubricating Fluid on the Hot Rolled Surface and Metallographic Structure of SS41 Steel. Nanomaterials, 8(2), 111. https://doi.org/10.3390/nano8020111