Efficient Removal of Lead, Copper and Cadmium Ions from Water by a Porous Calcium Alginate/Graphene Oxide Composite Aerogel

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Instruments

2.3. Preparation of PS Colloidal Particles

2.4. Preparation of mp-CA/GO

2.5. Adsorption and Desorption Tests

3. Results and Discussion

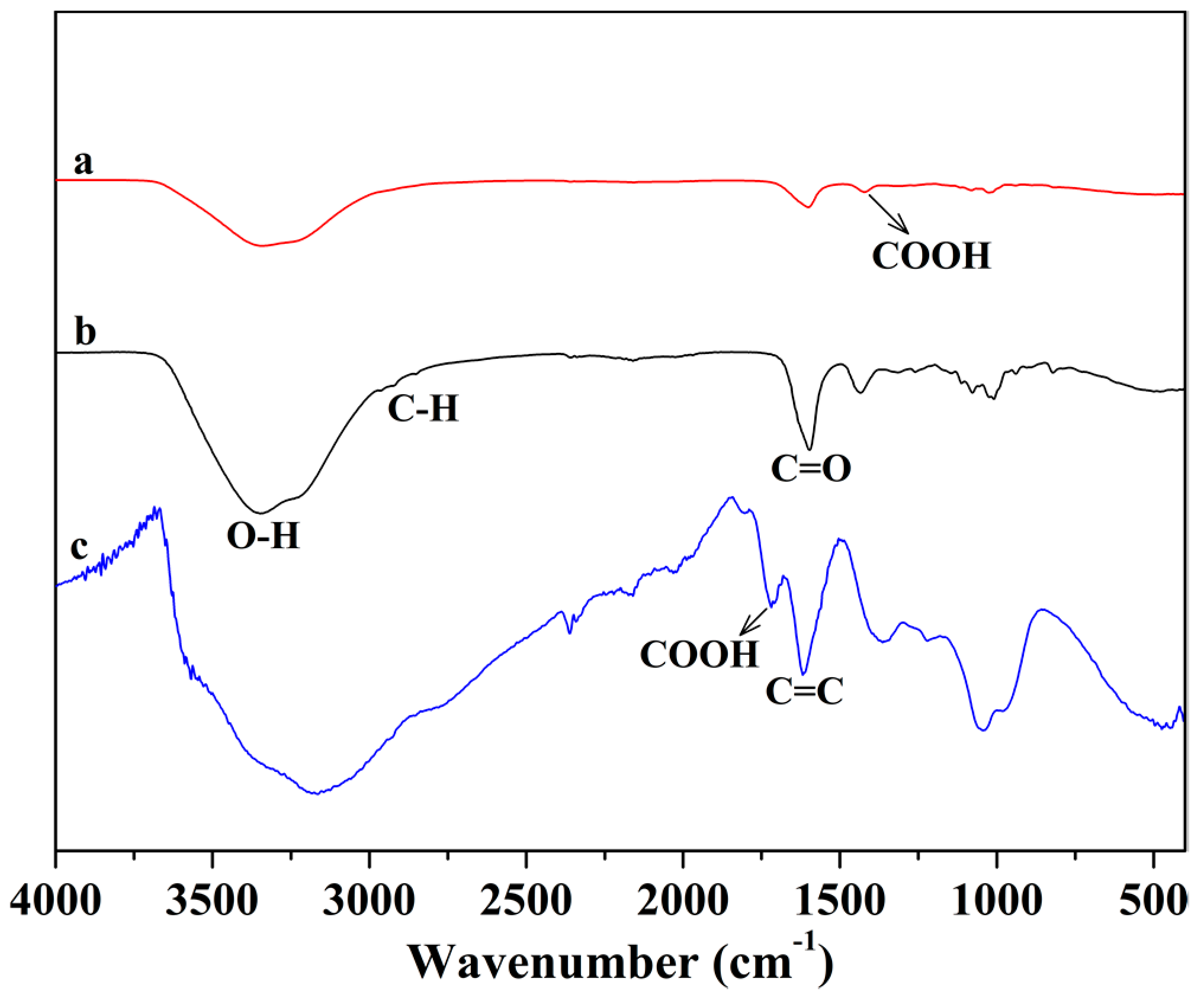

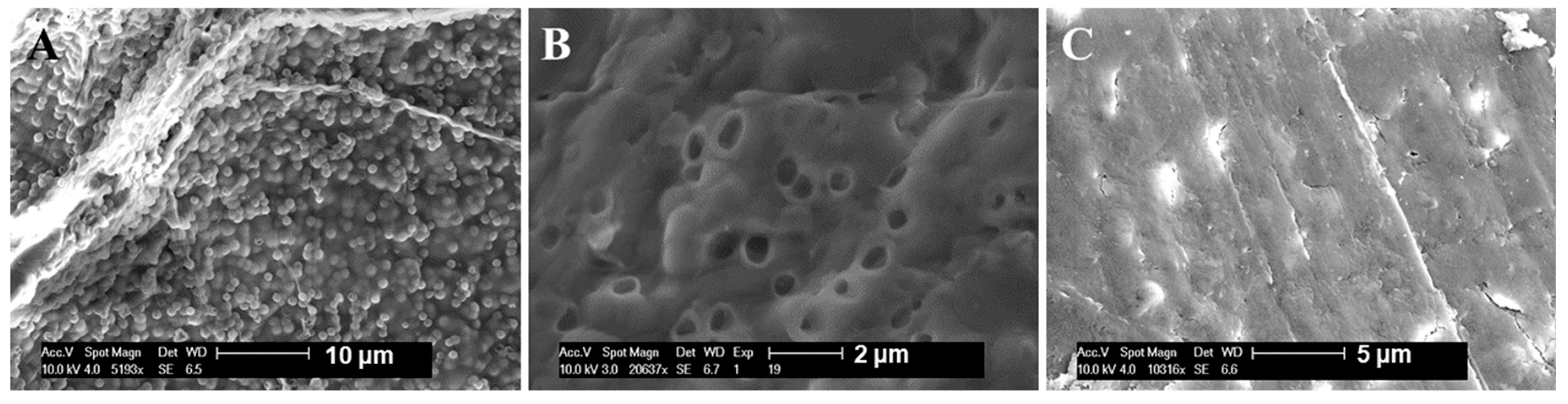

3.1. Material Characterizations

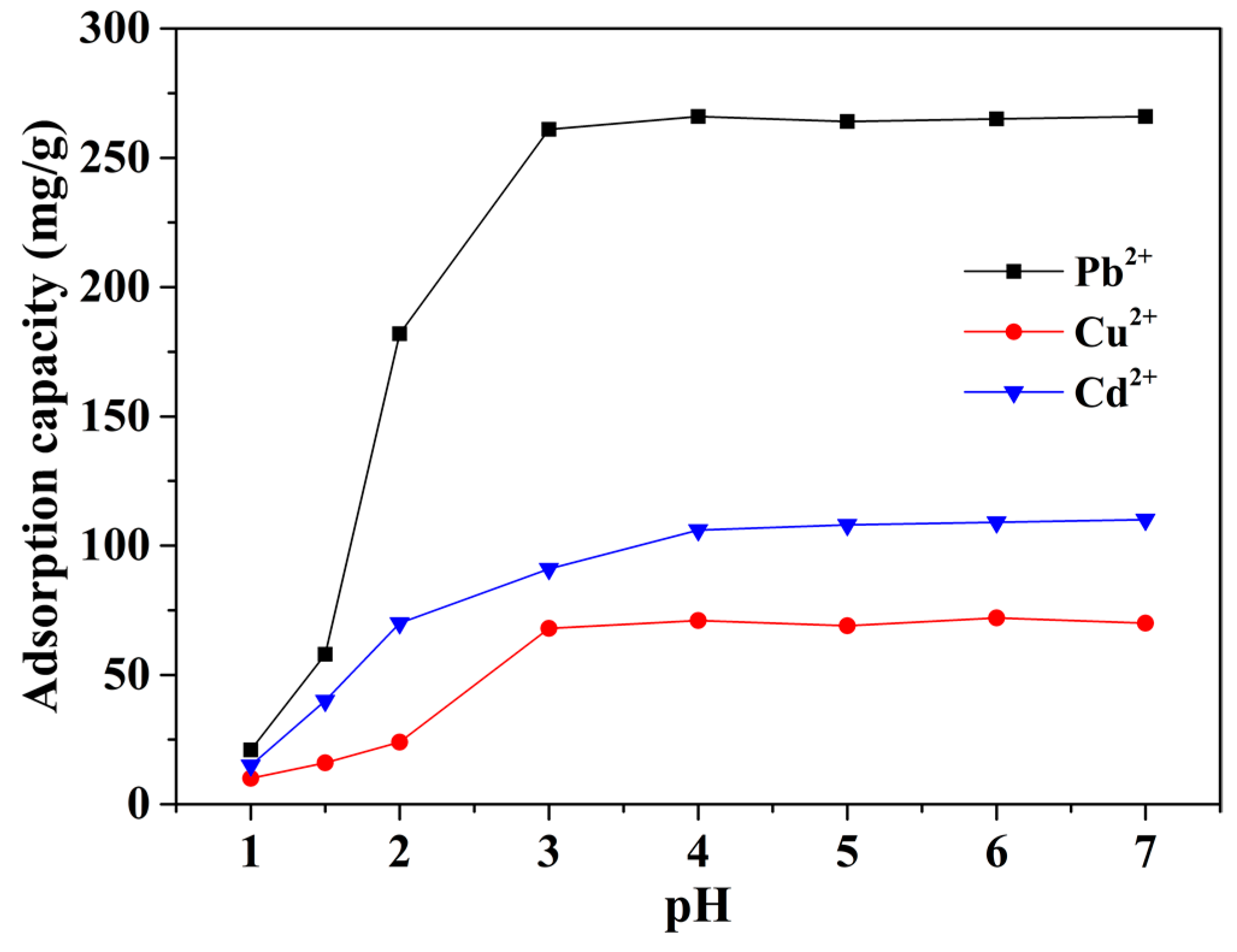

3.2. Effect of pH

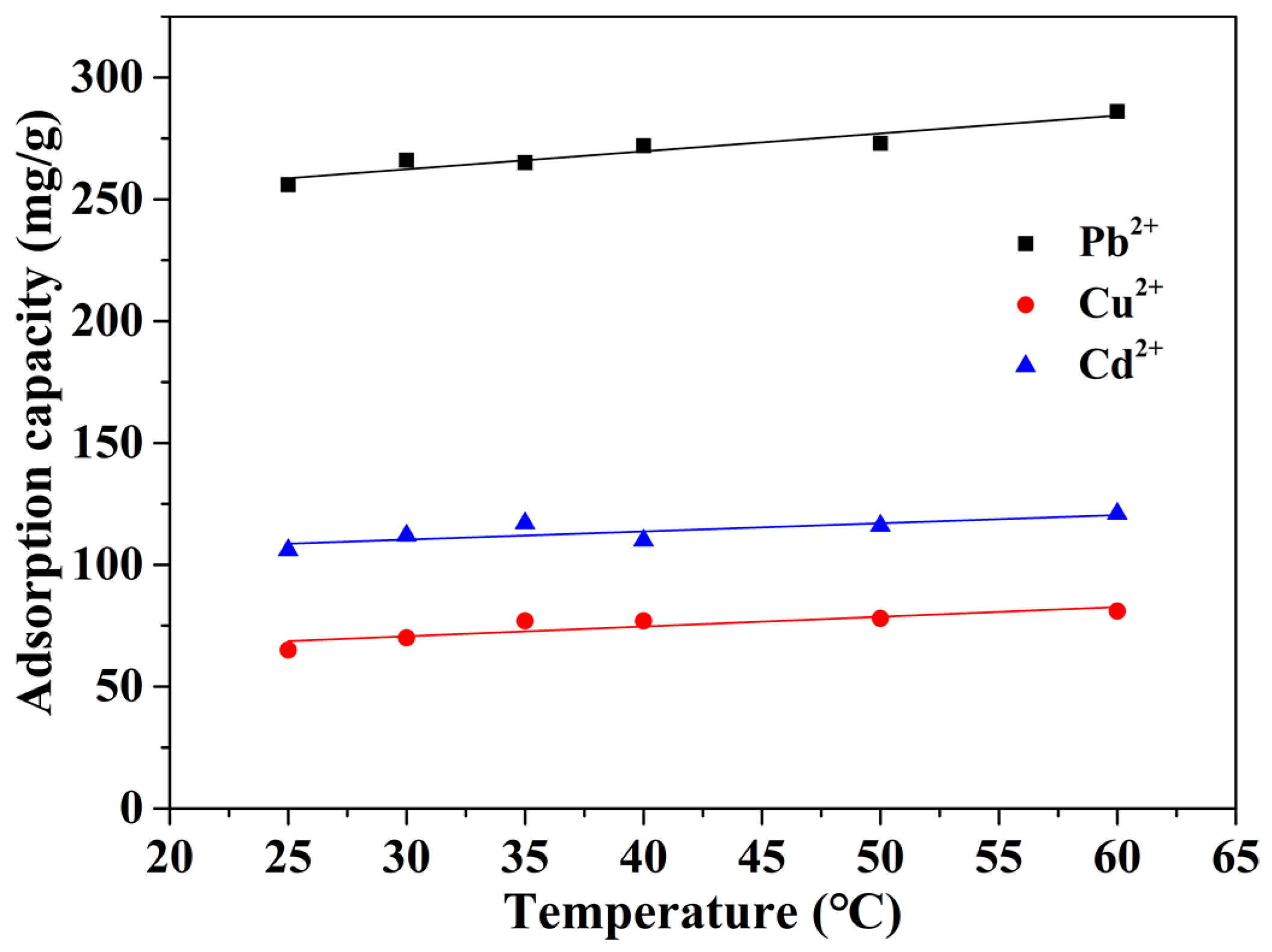

3.3. Effect of the Contact Time and Environmental Temperature

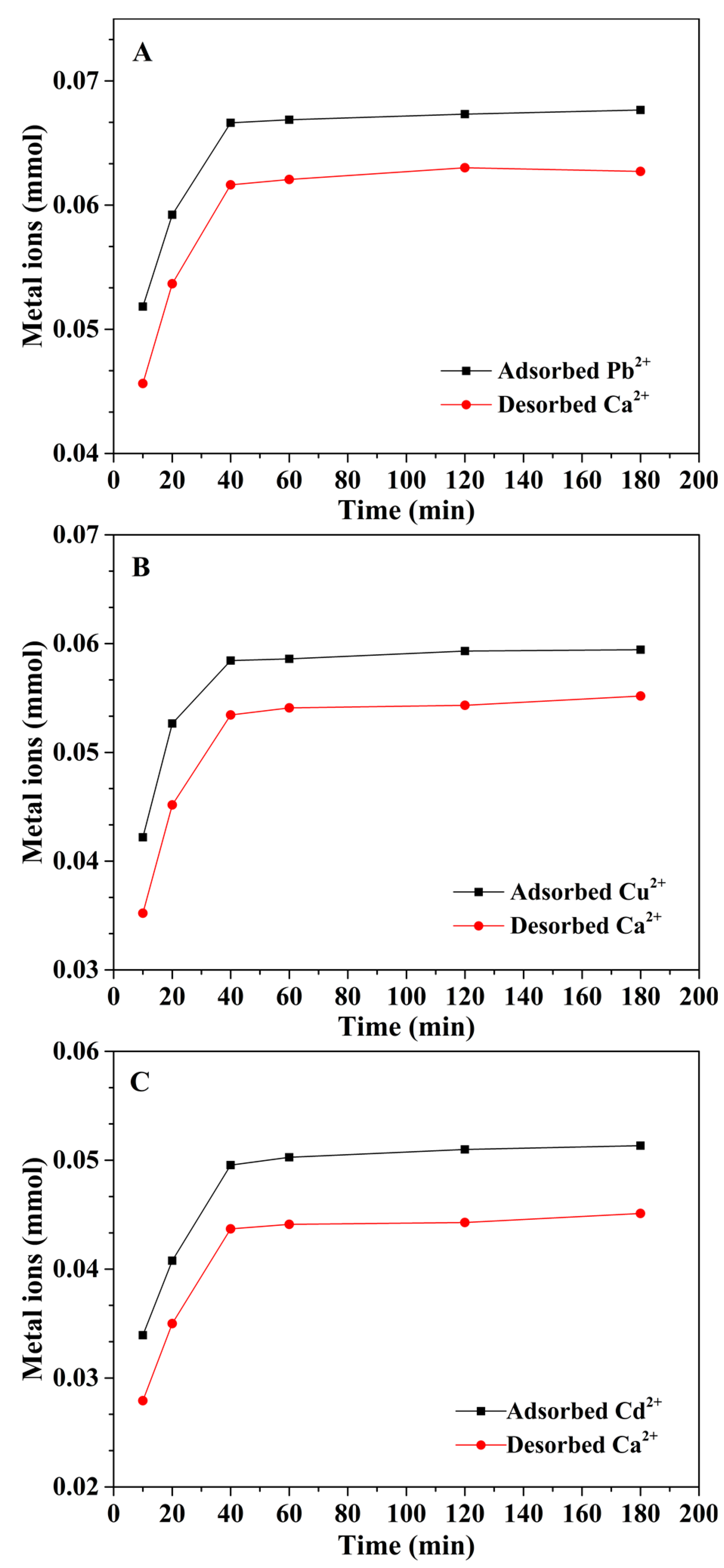

3.4. Maximum Adsorption Capacity of the mp-CA/GO

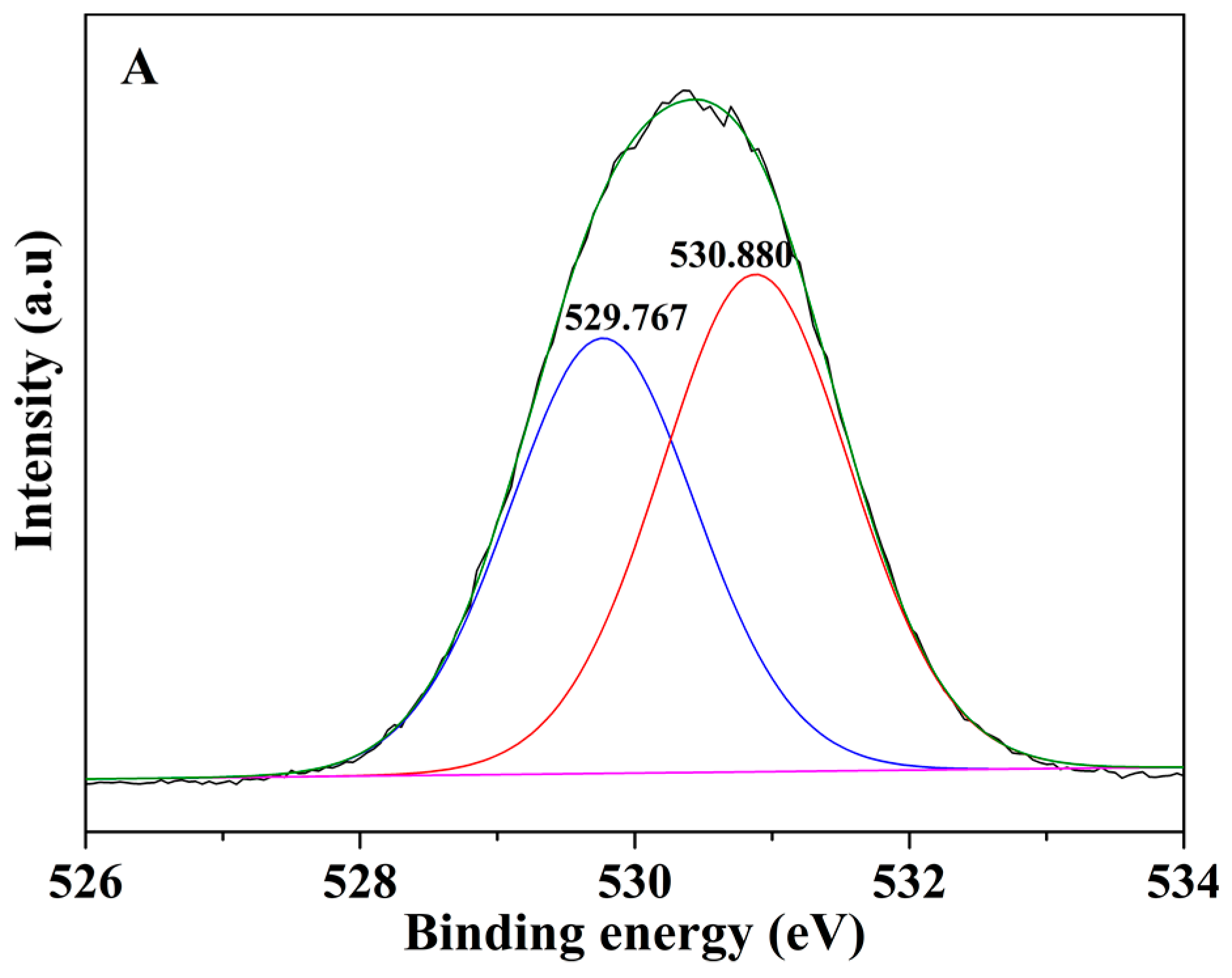

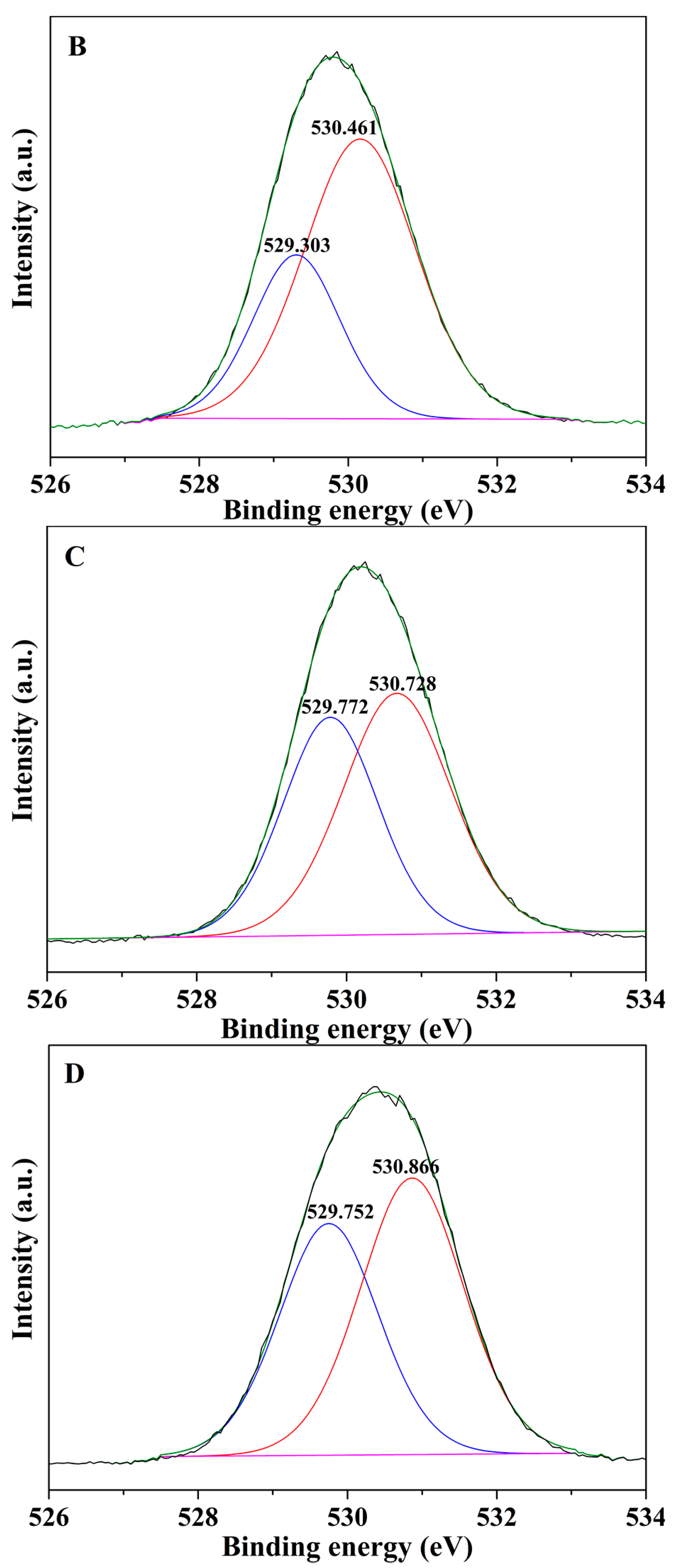

3.5. Adsorption Mechanism

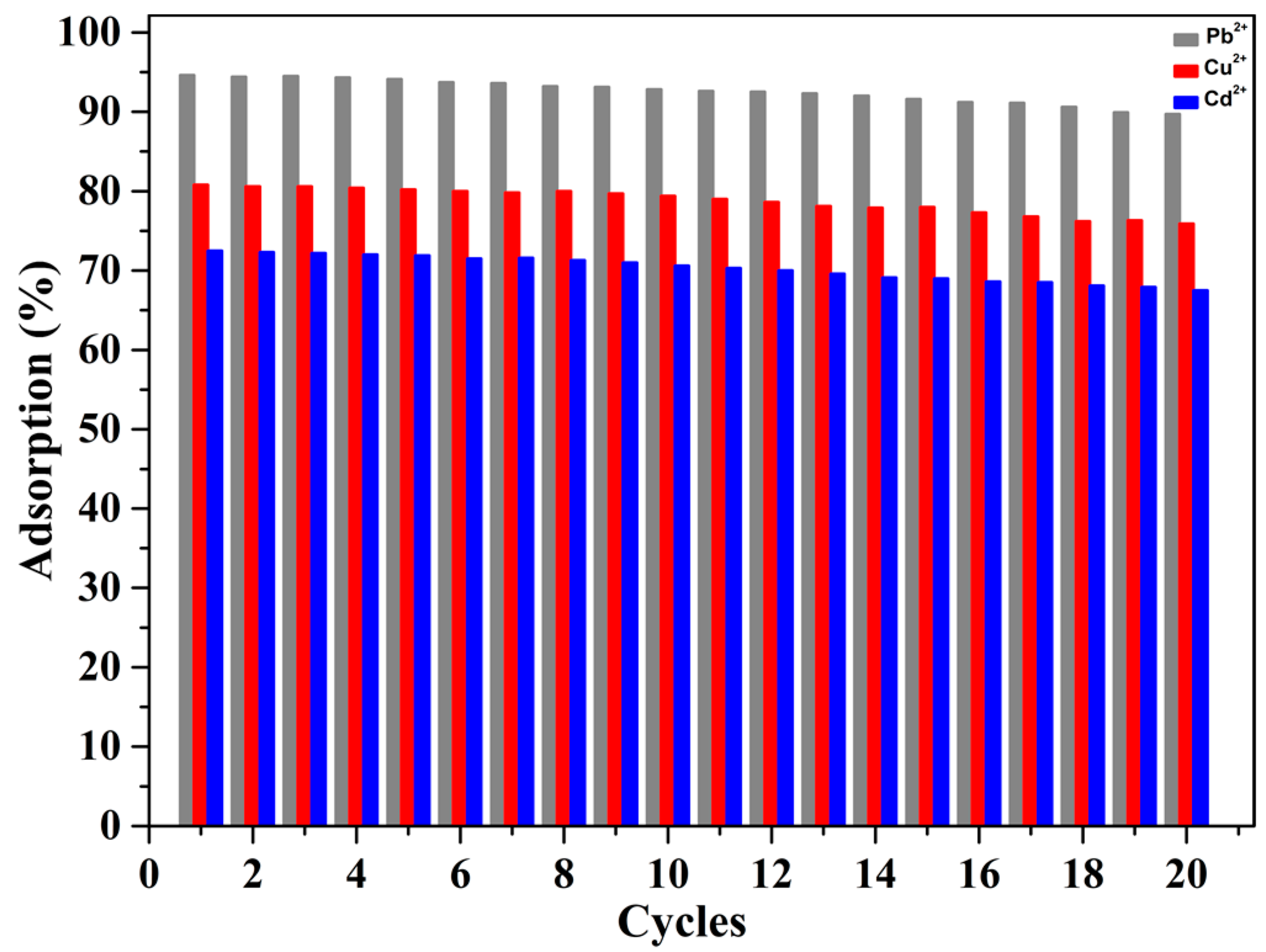

3.6. Regeneration Research

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Volesky, B. Detoxification of metal-bearing effluents: Biosorption for the next century. Hydrometallurgy 2001, 59, 203–216. [Google Scholar] [CrossRef]

- Voisin, H.; Bergstrom, L.; Liu, P.; Mathew, A.P. Nanocellulose-based materials for water purification. Nanomaterials 2017, 7, 57. [Google Scholar] [CrossRef] [PubMed]

- Babel, S.; Kurniawan, T.A. Low-cost adsorbents for heavy metals uptake from contaminated water: A review. J. Hazard. Mater. 2003, 97, 219–243. [Google Scholar] [CrossRef]

- Wang, Z.Q.; Wu, A.G.; Ciacchi, L.C.; Wei, G. Recent advances in nanoporous membranes for water purification. Nanomaterials 2018, 8, 65. [Google Scholar] [CrossRef] [PubMed]

- Cataldo, S.; Lazzara, G.; Massaro, M.; Muratore, N.; Pettignano, A.; Riela, S. Functionalized halloysite nanotubes for enhanced removal of lead(II) ions from aqueous solutions. Appl. Clay Sci. 2018, 156, 87–95. [Google Scholar] [CrossRef]

- Hepel, M.; Dentrone, L. Controlled incorporation of heavy metals from aqueous solutions and their electrorelease using composite polypyrrole films. Electroanalysis 1996, 8, 996–1005. [Google Scholar] [CrossRef]

- Hepel, M.; Zhang, X.M.; Stephenson, R.; Perkins, S. Use of electrochemical quartz crystal microbalance technique to track electrochemically assisted removal of heavy metals from aqueous solutions by cation-exchange composite polypyrrole-modified electrodes. Microchem. J. 1997, 56, 79–92. [Google Scholar] [CrossRef]

- Cavallaro, G.; Gianguzza, A.; Lazzara, G.; Milioto, S.; Piazzese, D. Alginate gel beads filled with halloysite nanotubes. Appl. Clay Sci. 2013, 72, 132–137. [Google Scholar] [CrossRef]

- Deze, E.G.; Papageorgiou, S.K.; Favvas, E.P.; Katsaros, F.K. Porous alginate aerogel beads for effective and rapid heavy metal sorption from aqueous solutions: Effect of porosity in Cu2+ and Cd2+ ion sorption. Chem. Eng. J. 2012, 209, 537–546. [Google Scholar] [CrossRef]

- Wang, Z.Q.; Huang, Y.G.; Wang, M.; Wu, G.H.; Geng, T.M.; Zhao, Y.G.; Wu, A.G. Macroporous calcium alginate aerogel as sorbent for Pb2+ removal from water media. J. Environ. Chem. Eng. 2016, 4, 3185–3192. [Google Scholar] [CrossRef]

- Wang, Z.Q.; Jin, P.X.; Wang, M.; Wu, G.H.; Sun, J.Y.; Zhang, Y.J.; Dong, C.; Wu, A.G. Highly efficient removal of toxic Pb2+ from wastewater by an alginate-chitosan hybrid adsorbent. J. Chem. Technol. Biot. 2018, 93, 2691–2700. [Google Scholar] [CrossRef]

- Lagoa, R.; Rodrigues, J.R. Kinetic analysis of metal uptake by dry and gel alginate particles. Biochem. Eng. J. 2009, 46, 320–326. [Google Scholar] [CrossRef]

- Jiao, C.L.; Xiong, P.G.; Tao, J.; Xu, S.J.; Zhang, D.S.; Lin, H.; Chen, Y.Y. Sodium alginate/graphene oxide aerogel with enhanced strength-toughness and its heavy metal adsorption study. Int. J. Biol. Macromol. 2016, 83, 133–141. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.Z.; Zhou, T.Z.; Ren, B.Z.; Hursthouse, A.; Zhang, Y.Z. Removal of Mn(II) by sodium alginate/graphene oxide composite double-network hydrogel beads from aqueous solutions. Sci. Rep. 2018, 8, 10717. [Google Scholar] [CrossRef] [PubMed]

- Lui, G.; Li, G.; Wang, X.L.; Jiang, G.P.; Lin, E.; Fowler, M.; Yu, A.P.; Chen, Z.W. Flexible, three-dimensional ordered macroporous TiO2 electrode with enhanced electrode electrolyte interaction in high-power li-ion batteries. Nano Energy 2016, 24, 72–77. [Google Scholar] [CrossRef]

- Choi, B.G.; Yang, M.; Hong, W.H.; Choi, J.W.; Huh, Y.S. 3D macroporous graphene frameworks for supercapacitors with high energy and power densities. Acs Nano 2012, 6, 4020–4028. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.Y.; Kim, M.; Kim, D.W.; Suk, J.; Park, J.J.; Park, O.O.; Kang, Y. Graphene paper with controlled pore structure for high-performance cathodes in LiO2 batteries. Carbon 2016, 100, 265–272. [Google Scholar] [CrossRef]

- Song, N.J.; Chen, C.M.; Lu, C.X.; Liu, Z.; Kong, Q.Q.; Cai, R. Thermally reduced graphene oxide films as flexible lateral heat spreaders. J. Mater. Chem. A 2014, 2, 16563–16568. [Google Scholar] [CrossRef]

- Xiao, F.; Yang, S.X.; Zhang, Z.Y.; Liu, H.F.; Xiao, J.W.; Wan, L.; Luo, J.; Wang, S.; Liu, Y.Q. Scalable synthesis of freestanding sandwich-structured graphene/polyaniline/graphene nanocomposite paper for flexible all-solid-state supercapacitor. Sci. Rep. 2015, 5, 9359. [Google Scholar] [CrossRef] [PubMed]

- He, Y.Q.; Zhang, N.N.; Gong, Q.J.; Qiu, H.X.; Wang, W.; Liu, Y.; Gao, J.P. Alginate/graphene oxide fibers with enhanced mechanical strength prepared by wet spinning. Carbohydr. Polym. 2012, 88, 1100–1108. [Google Scholar] [CrossRef]

- Maria, H.; Dustin, B.; Matthew, M.; Magdalena, S.; Kaitlin, C. Assembly of Gold Nanoparticles Induced by Metal Ions. In Functional Nanoparticles for Bioanalysis, Nanomedicine, and Bioelectronic Devices; Hepel, M., Zhong, C.J., Eds.; ACS Symposium Series; Oxford University Press: Oxford, UK, 2012; Volume 1, pp. 207–240. [Google Scholar]

- Braccini, I.; Perez, S. Molecular basis of Ca2+-induced gelation in alginates and pectins: The egg-box model revisited. Biomacromolecules 2001, 2, 1089–1096. [Google Scholar] [CrossRef] [PubMed]

- Wan, Y.Z.; Chen, X.Q.; Xiong, G.Y.; Guo, R.S.; Luo, H.L. Synthesis and characterization of three-dimensional porous graphene oxide/sodium alginate scaffolds with enhanced mechanical properties. Mater. Express 2014, 4, 429–434. [Google Scholar] [CrossRef]

- Huang, Y.G.; Wang, Z.Q. Preparation of composite aerogels based on sodium alginate, and its application in removal of Pb2+ and Cu2+ from water. Int. J. Biol. Macromol. 2018, 107, 741–747. [Google Scholar] [CrossRef] [PubMed]

- Heidari, A.; Younesi, H.; Mehraban, Z. Removal of Ni(II), Cd(II), and Pb(II) from a ternary aqueous solution by amino functionalized mesoporous and nano mesoporous silica. Chem. Eng. J. 2009, 153, 70–79. [Google Scholar] [CrossRef]

- Afkhami, A.; Saber-Tehrani, M.; Bagheri, H. Simultaneous removal of heavy-metal ions in wastewater samples using nano-alumina modified with 2,4-dinitrophenylhydrazine. J. Hazard. Mater. 2010, 181, 836–844. [Google Scholar] [CrossRef] [PubMed]

- Guo, X.Y.; Du, B.; Wei, Q.; Yang, J.; Hu, L.H.; Yan, L.G.; Xu, W.Y. Synthesis of amino functionalized magnetic graphenes composite material and its application to remove Cr(VI), Pb(II), Hg(II), Cd(II) and Ni(II) from contaminated water. J. Hazard. Mater. 2014, 278, 211–220. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.R.; Yang, Q.G.; Phanlavong, P.; Li, Y.X.; Wang, Z.K.; Jiao, T.F.; Peng, Q.M. Highly efficient lead(II) sequestration using size-controllable polydopamine microspheres with superior application capability and rapid capture. ACS Sustain. Chem. Eng. 2017, 5, 4161–4170. [Google Scholar] [CrossRef]

- Chu, L.; Liu, C.B.; Zhou, G.Y.; Xu, R.; Tang, Y.H.; Zeng, Z.B.; Luo, S.L. A double network gel as low cost and easy recycle adsorbent: Highly efficient removal of Cd(II) and Pb(II) pollutants from wastewater. J. Hazard. Mater. 2015, 300, 153–160. [Google Scholar] [CrossRef] [PubMed]

- Do, X.H.; Lee, B.K. Removal of Pb2+ using a biochar-alginate capsule in aqueous solution and capsule regeneration. J. Environ. Manage. 2013, 131, 375–382. [Google Scholar] [CrossRef] [PubMed]

- Jiang, N.N.; Xu, Y.T.; Dai, Y.Q.; Luo, W.A.; Dai, L.Z. Polyaniline nanofibers assembled on alginate microsphere for Cu2+ and Pb2+ uptake. J. Hazard. Mater. 2012, 215, 17–24. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Xu, F.; Wang, Y.F.; Zhang, W.Z.; Peng, X.L.; Pepe, F. Silica modified calcium alginate-xanthan gum hybrid bead composites for the removal and recovery of pb(ii) from aqueous solution. Chem. Eng. J. 2013, 234, 33–42. [Google Scholar] [CrossRef]

- Cataldo, S.; Gianguzza, A.; Milea, D.; Muratore, N.; Pettignano, A. Pb(II) adsorption by a novel activated carbon—alginate composite material. A kinetic and equilibrium study. Int. J. Biol. Macromol. 2016, 92, 769–778. [Google Scholar] [CrossRef] [PubMed]

- Cheraghali, R.; Tavakoli, H.; Sepehrian, H. Preparation, characterization and lead sorption performance of alginate-SBA-15 composite as a novel adsorbent. Sci. Iran. 2013, 20, 1028–1034. [Google Scholar]

- Liu, D.G.; Li, Z.H.; Li, W.; Zhong, Z.R.; Xu, J.Q.; Ren, J.J.; Ma, Z.S. Adsorption behavior of heavy metal ions from aqueous solution by soy protein hollow microspheres. Ind. Eng. Chem. Res. 2013, 52, 11036–11044. [Google Scholar] [CrossRef]

- Idris, A.; Ismail, N.S.M.; Hassan, N.; Misran, E.; Ngomsik, A.F. Synthesis of magnetic alginate beads based on maghemite nanoparticles for Pb(II) removal in aqueous solution. J. Ind. Eng. Chem. 2012, 18, 1582–1589. [Google Scholar] [CrossRef]

- Rajput, S.; Singh, L.P.; Pittman, C.U.; Mohan, D. Lead (Pb2+) and copper (Cu2+) remediation from water using superparamagnetic maghemite (γ-Fe2O3) nanoparticles synthesized by flame spray pyrolysis. J. Colloid Interface Sci. 2017, 492, 176–190. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.H.; Li, L.L.; Luo, C.N.; Wang, X.J.; Duan, H.M. Removal of Pb2+ from water environment using a novel magnetic chitosan/graphene oxide imprinted Pb2+. Int. J. Biol. Macromol. 2016, 86, 505–511. [Google Scholar] [CrossRef] [PubMed]

- Mousa, N.E.; Simonescu, C.M.; Patescu, R.E.; Onose, C.; Tardei, C.; Culita, D.C.; Oprea, O.; Patroi, D.; Lavric, V. Pb2+ removal from aqueous synthetic solutions by calcium alginate and chitosan coated calcium alginate. React. Funct. Polym. 2016, 109, 137–150. [Google Scholar] [CrossRef]

- Lei, Y.; Guan, J.J.; Chen, W.; Ke, Q.F.; Zhang, C.Q.; Guo, Y.P. Fabrication of hydroxyapatite/chitosan porous materials for Pb(II) removal from aqueous solution. RSC Adv. 2015, 5, 25462–25470. [Google Scholar] [CrossRef]

- Marzo, A.M.L.; Pons, J.; Merkoci, A. Multifunctional system based on hybrid nanostructured rod formation, for sensoremoval applications of Pb2+ as a model toxic metal. J. Mater. Chem. A 2013, 1, 13532–13541. [Google Scholar]

- Lopez-Marzo, A.M.; Pons, J.; Merkoci, A. Extremely fast and high Pb2+ removal capacity using a nanostructured hybrid material. J. Mater. Chem. A 2014, 2, 8766–8772. [Google Scholar] [CrossRef]

- Li, K.T.; Wu, G.H.; Wang, M.; Zhou, X.H.; Wang, Z.Q. Efficient removal of lead ions from water by a low-cost alginate-melamine hybrid sorbent. Appl. Sci. 2018, 8, 1518. [Google Scholar] [CrossRef]

| Kinetic Model | Formula | Parameters | Pb2+ | Cu2+ | Cd2+ |

|---|---|---|---|---|---|

| pseudo-first-order | qt = qe(1 − exp(−k1t)) | qe (mg g−1) | 257.849 | 65.779 | 105.737 |

| k1 (L min−1) | 0.158 | 0.124 | 0.113 | ||

| R2 | 0.962 | 0.975 | 0.968 | ||

| pseudo-second-order | qt = qe(1 − 1/(1 + qek2t)) | qe (mg g−1) | 268.284 | 69.985 | 109.589 |

| k2 (L min−1) | 0.004 | 0.002 | 0.002 | ||

| R2 | 0.996 | 0.992 | 0.991 |

| Adsorbent | Heavy Metals (Adsorbate) | Maximum Adsorption Capacity (mg/g) | Year of Publication | Reference |

|---|---|---|---|---|

| Amino functionalized mesoporous silica | Pb2+, Ni2+, Cd2+ | 57.7 (Pb2+), 12.4 (Ni2+), 18.3 (Cd2+) | 2009 | [25] |

| Nano-alumina | Pb2+, Cr3+, Cd2+ | 100.0 (Pb2+), 100.0 (Cr3+), 83.3 (Cd2+) | 2010 | [26] |

| Amino functionalized magnetic graphenes composite | Pb2+, Hg2+, Cr6+, Cd2+ | 28.0 (Pb2+), 23.0 (Hg2+), 17.3 (Cr6+), 27.8 (Cd2+) | 2014 | [27] |

| Polydopamine microspheres | Pb2+ | 165.8 | 2017 | [28] |

| Polyving alcohol/polyacrylic acid double network gel | Pb2+, Cd2+ | 195.0 (Pb2+), 115.9 (Cd2+) | 2015 | [29] |

| Biochar-alginate capsule | Pb2+ | 263.2 | 2013 | [30] |

| Polyaniline/calcium alginate composite | Pb2+, Cu2+ | 357.0 (Pb2+), 79.0 (Cu2+) | 2012 | [31] |

| Silica modified calcium alginate-xanthan gum hybrid bead composite | Pb2+ | 18.9 | 2013 | [32] |

| Activated carbon-calcium alginate composite | Pb2+ | 15.7 | 2016 | [33] |

| Alginate-SBA-15 composite | Pb2+ | 222.2 | 2013 | [34] |

| Soy protein hollow microspheres | Pb2+, Zn2+, Cr3+, Cd2+, Cu2+, Ni2+ | 235.6 (Pb2+), 255.0 (Zn2+), 52.9 (Cr3+), 120.8 (Cd2+), 115.0 (Cu2+), 177.1 (Ni2+) | 2013 | [35] |

| Magnetic alginate beads | Pb2+ | 50 | 2012 | [36] |

| γ-Fe2O3 nanoparticles | Pb2+, Cu2+ | 69.0 (Pb2+), 34.0 (Cu2+) | 2017 | [37] |

| Magnetic chitosan/graphene oxide imprinted Pb2+ | Pb2+ | 79.0 | 2016 | [37] |

| Chitosan coated calcium alginate | Pb2+ | 106.9 | 2016 | [39] |

| Hydroxyapatite/chitosan porous material | Pb2+ | 264.4 | 2015 | [40] |

| Calcite-poly(ethyleneimine) nanostructured rod | Pb2+ | 240 | 2013 | [41] |

| Nanostructured vaterite-poly(ethyleneimine) hybrid | Pb2+ | 2762 | 2014 | [42] |

| Alginate-melamine hybrid | Pb2+ | 287.7 | 2018 | [43] |

| mp-CA/GO | Pb2+, Cu2+, Cd2+ | 368.2 (Pb2+), 98.1 (Cu2+), 183.6 (Cd2+) | This work | This work |

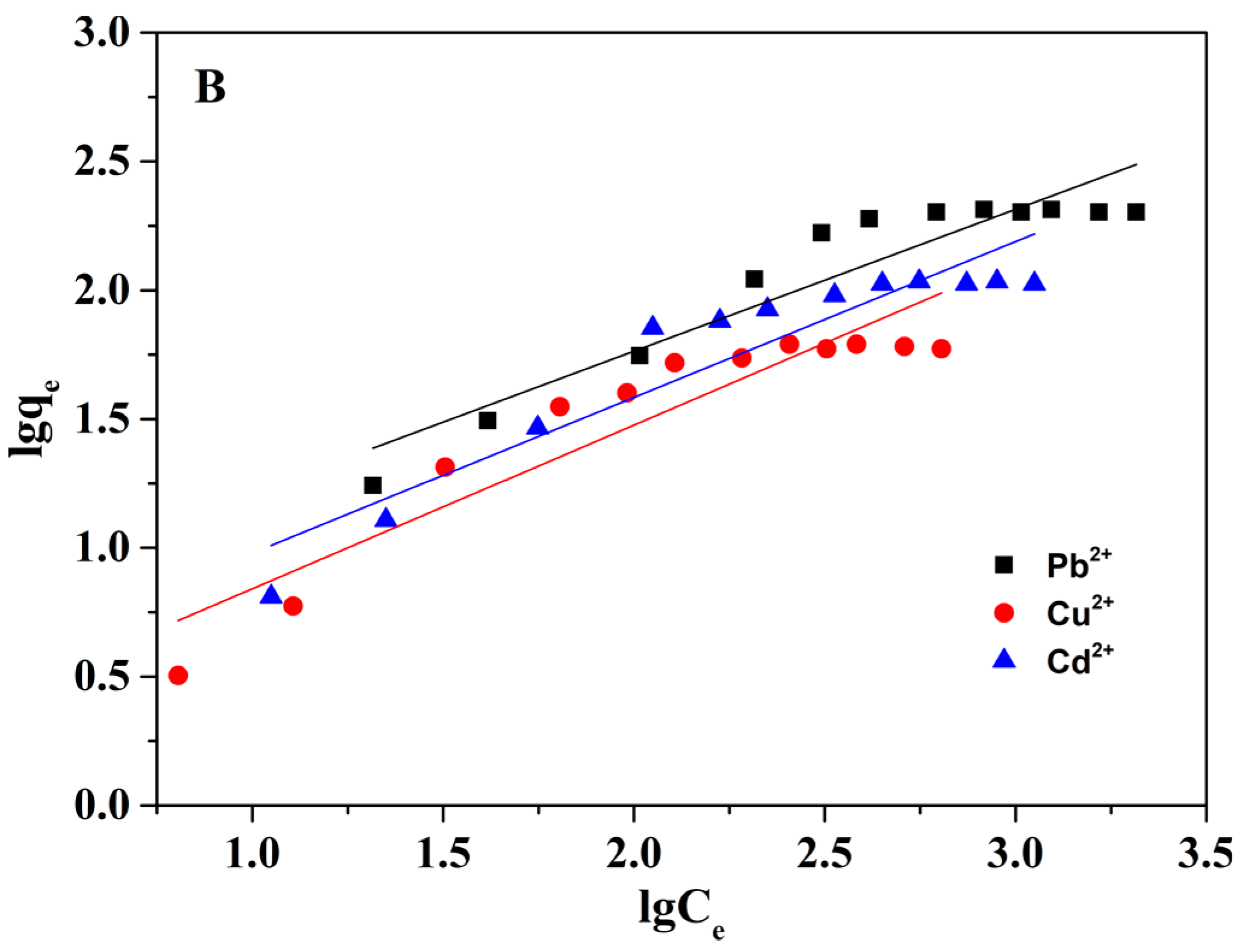

| Isotherm Model | Formula | Parameters | Pb2+ | Cu2+ | Cd2+ |

|---|---|---|---|---|---|

| Langmuir | C/q = C/qe + 1/(qeb) | qe (mg/g) | 366.835 | 180.274 | 96.693 |

| b (L/mg) | 0.493 | 0.473 | 0.415 | ||

| R2 | 0.994 | 0.998 | 0.995 | ||

| Freundlich | lgq = lgK + 1/nlgC | K (L/mg) | 5.263 | 3.863 | 3.573 |

| n | 2.163 | 1.663 | 1.862 | ||

| R2 | 0.878 | 0.873 | 0.864 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, L.; Wang, Z.; Yang, Q.; Huang, R. Efficient Removal of Lead, Copper and Cadmium Ions from Water by a Porous Calcium Alginate/Graphene Oxide Composite Aerogel. Nanomaterials 2018, 8, 957. https://doi.org/10.3390/nano8110957

Pan L, Wang Z, Yang Q, Huang R. Efficient Removal of Lead, Copper and Cadmium Ions from Water by a Porous Calcium Alginate/Graphene Oxide Composite Aerogel. Nanomaterials. 2018; 8(11):957. https://doi.org/10.3390/nano8110957

Chicago/Turabian StylePan, Linhai, Zhuqing Wang, Qi Yang, and Rongyi Huang. 2018. "Efficient Removal of Lead, Copper and Cadmium Ions from Water by a Porous Calcium Alginate/Graphene Oxide Composite Aerogel" Nanomaterials 8, no. 11: 957. https://doi.org/10.3390/nano8110957

APA StylePan, L., Wang, Z., Yang, Q., & Huang, R. (2018). Efficient Removal of Lead, Copper and Cadmium Ions from Water by a Porous Calcium Alginate/Graphene Oxide Composite Aerogel. Nanomaterials, 8(11), 957. https://doi.org/10.3390/nano8110957