Interfacial Adhesion and Mechanical Properties of PET Fabric/PVC Composites Enhanced by SiO2/Tributyl Citrate Hybrid Sizing

Abstract

1. Introduction

2. Experimental Section

2.1. Materials

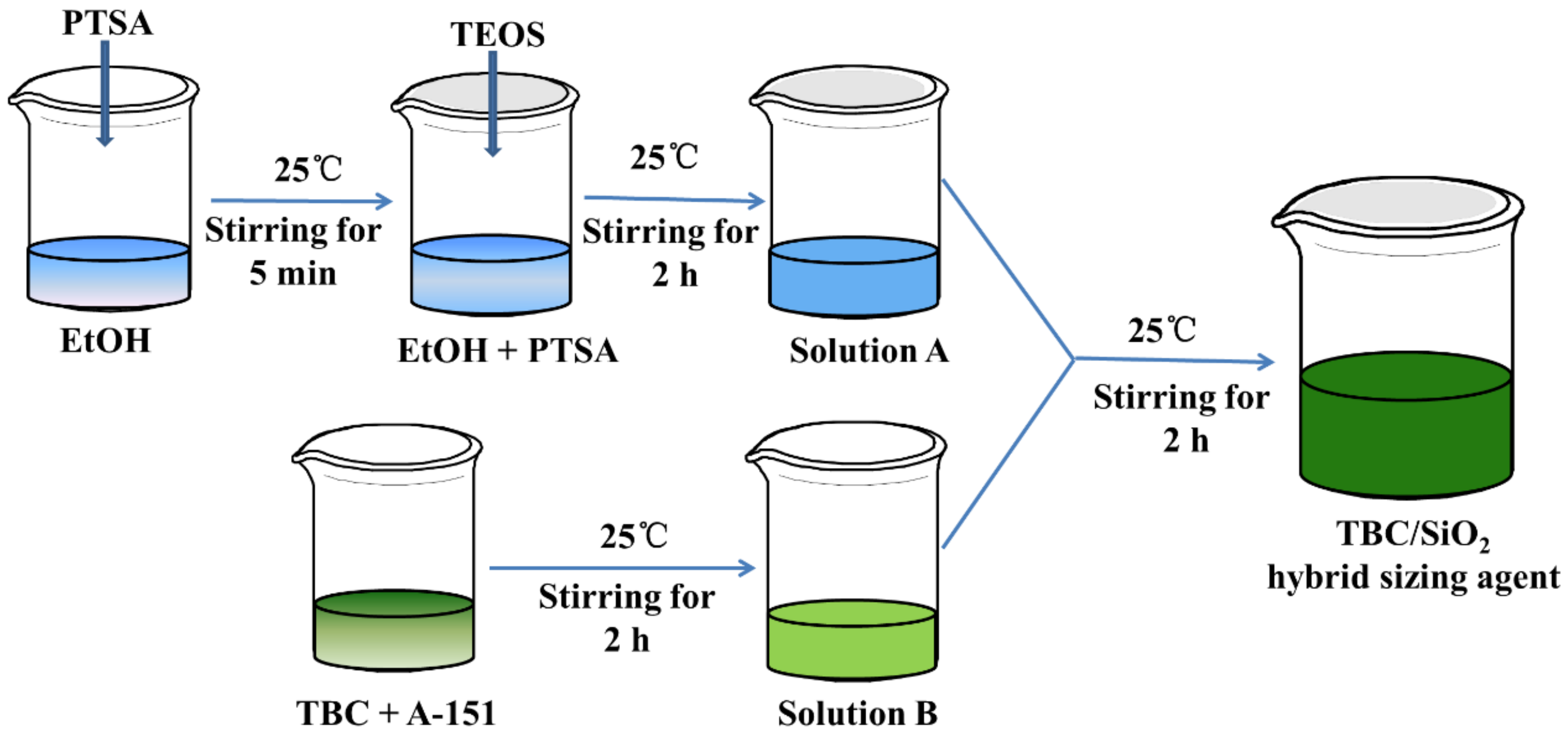

2.2. Synthesis of SiO2/TBC Hybrid Sizing Agent

2.3. Surface Treatment

2.3.1. Degreasing Treatment

2.3.2. Alkali Treatment

2.3.3. Sizing Treatment

2.4. Composite Processing

2.5. Characterization

2.5.1. Morphology and Structural Characterization of PET Filaments

2.5.2. Wettability Test

2.5.3. Tensile Test

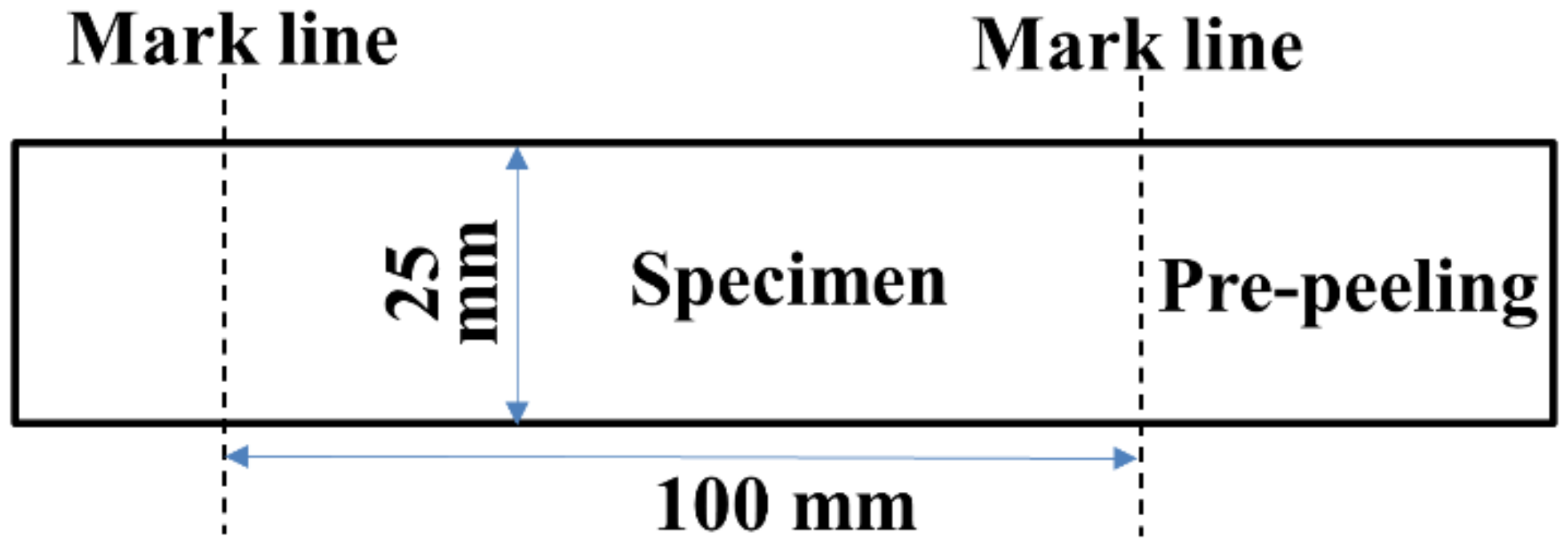

2.5.4. Peeling Strength Measurement

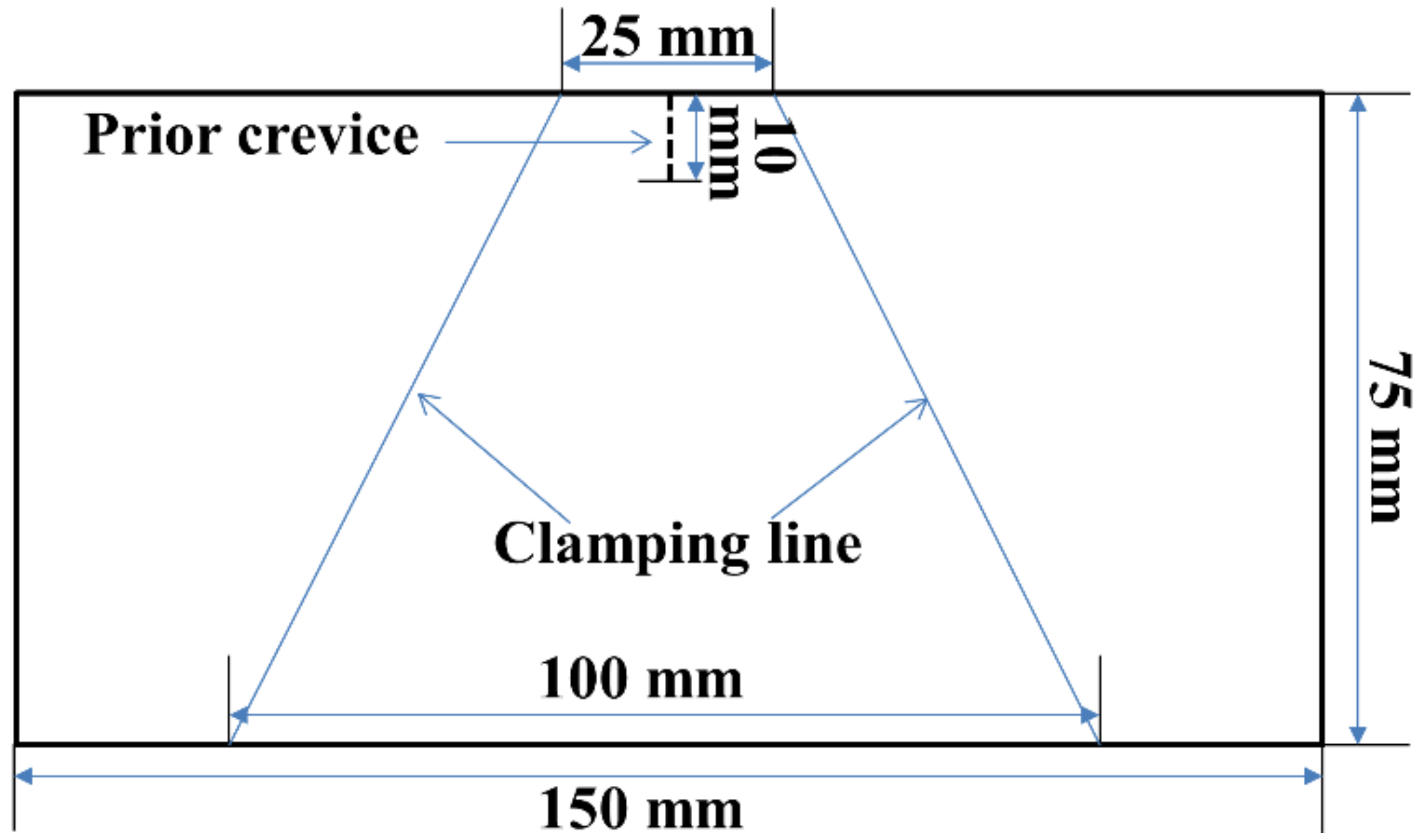

2.5.5. Tearing Test

3. Results and Discussion

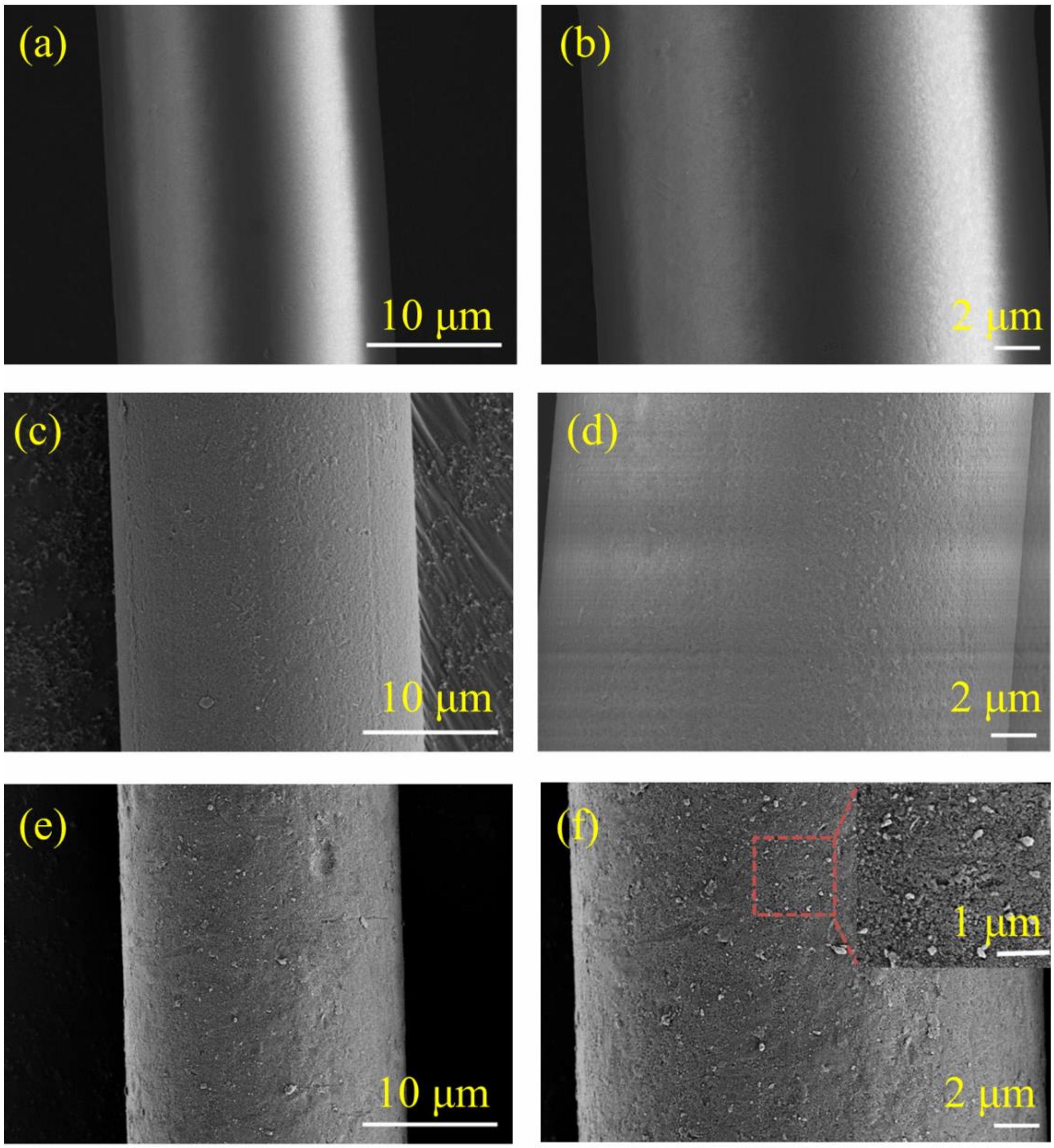

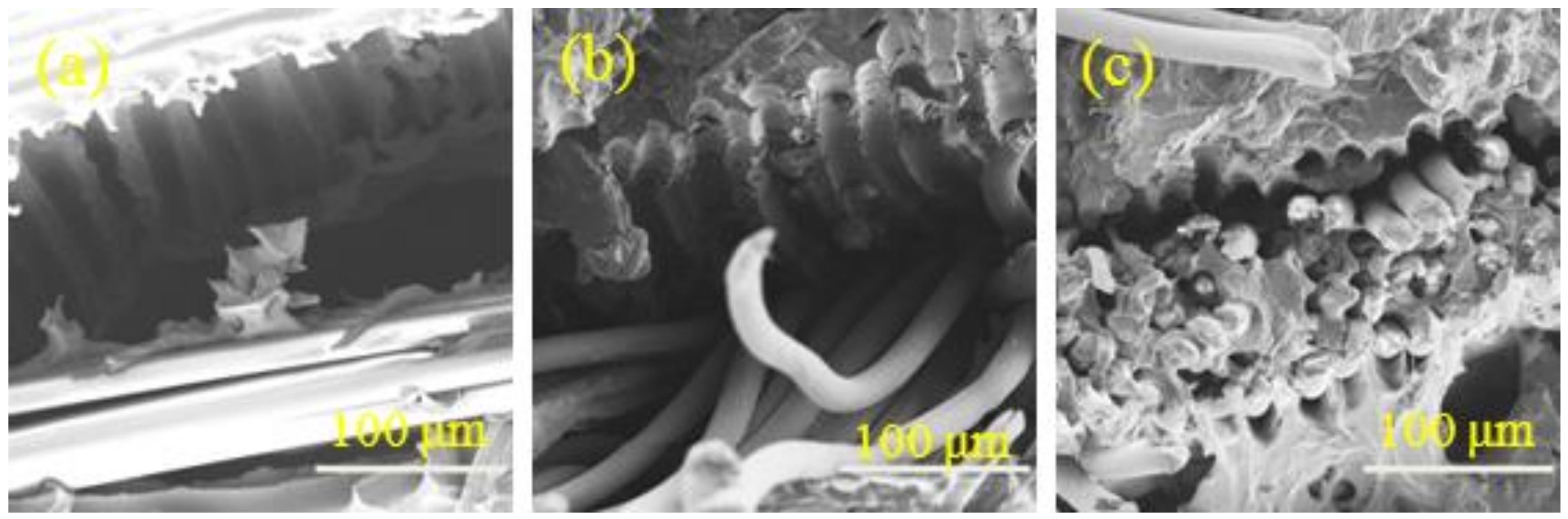

3.1. Surface Morphology of PET Filament

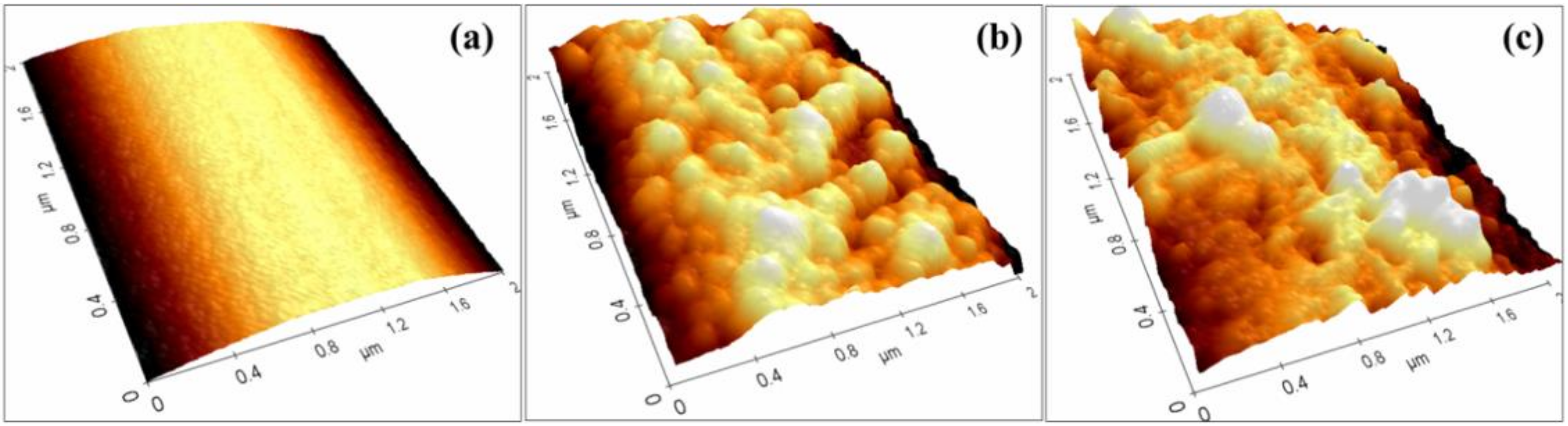

3.2. Surface Roughness of PET Filament

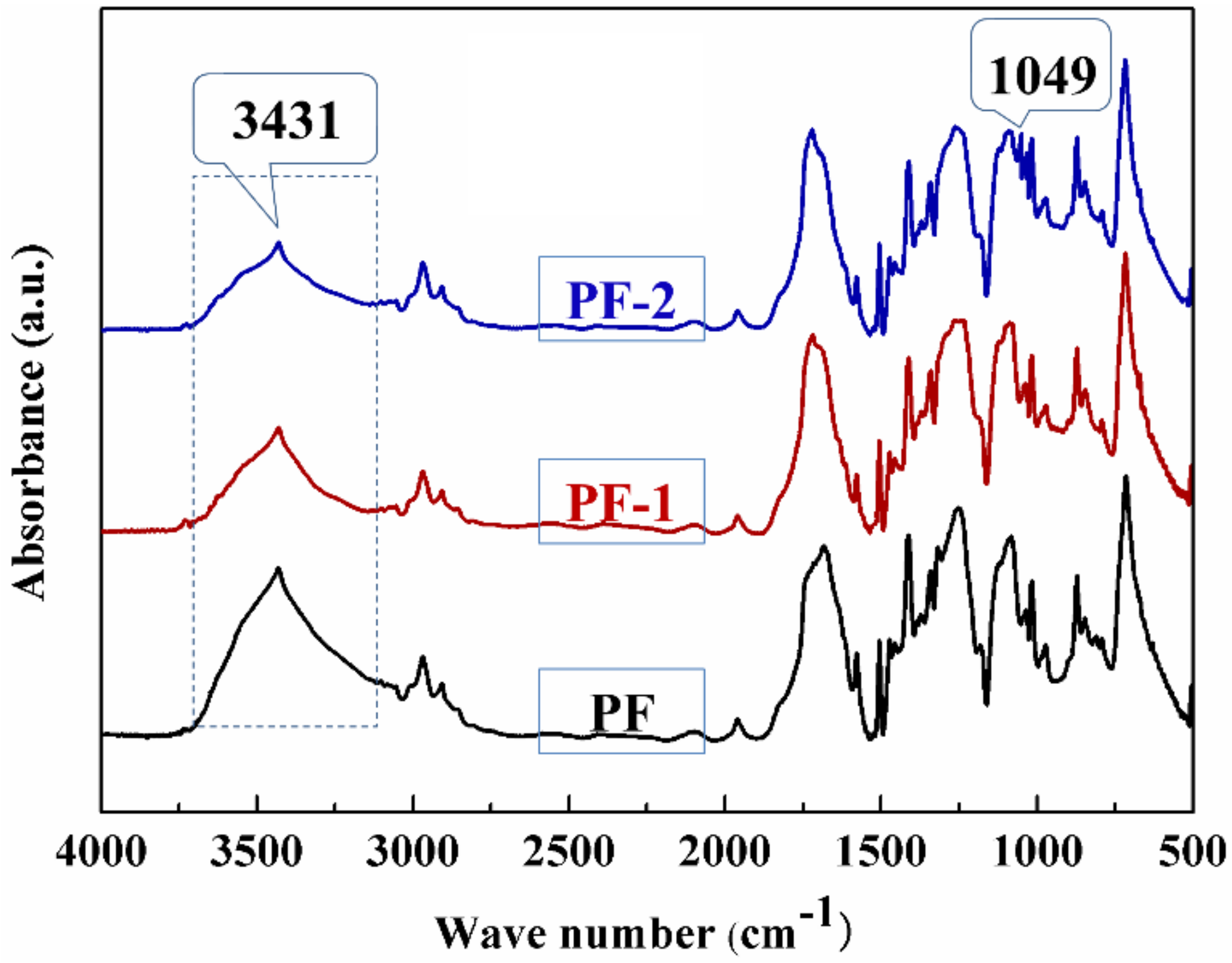

3.3. FT-IR Analysis

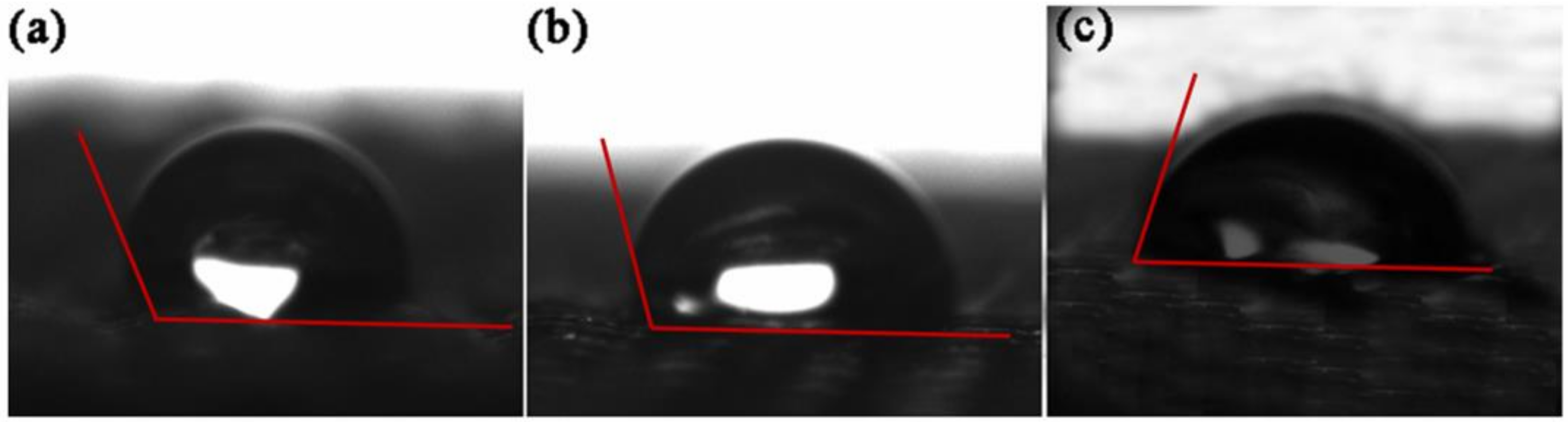

3.4. Wettability of PET Fabrics and TBC

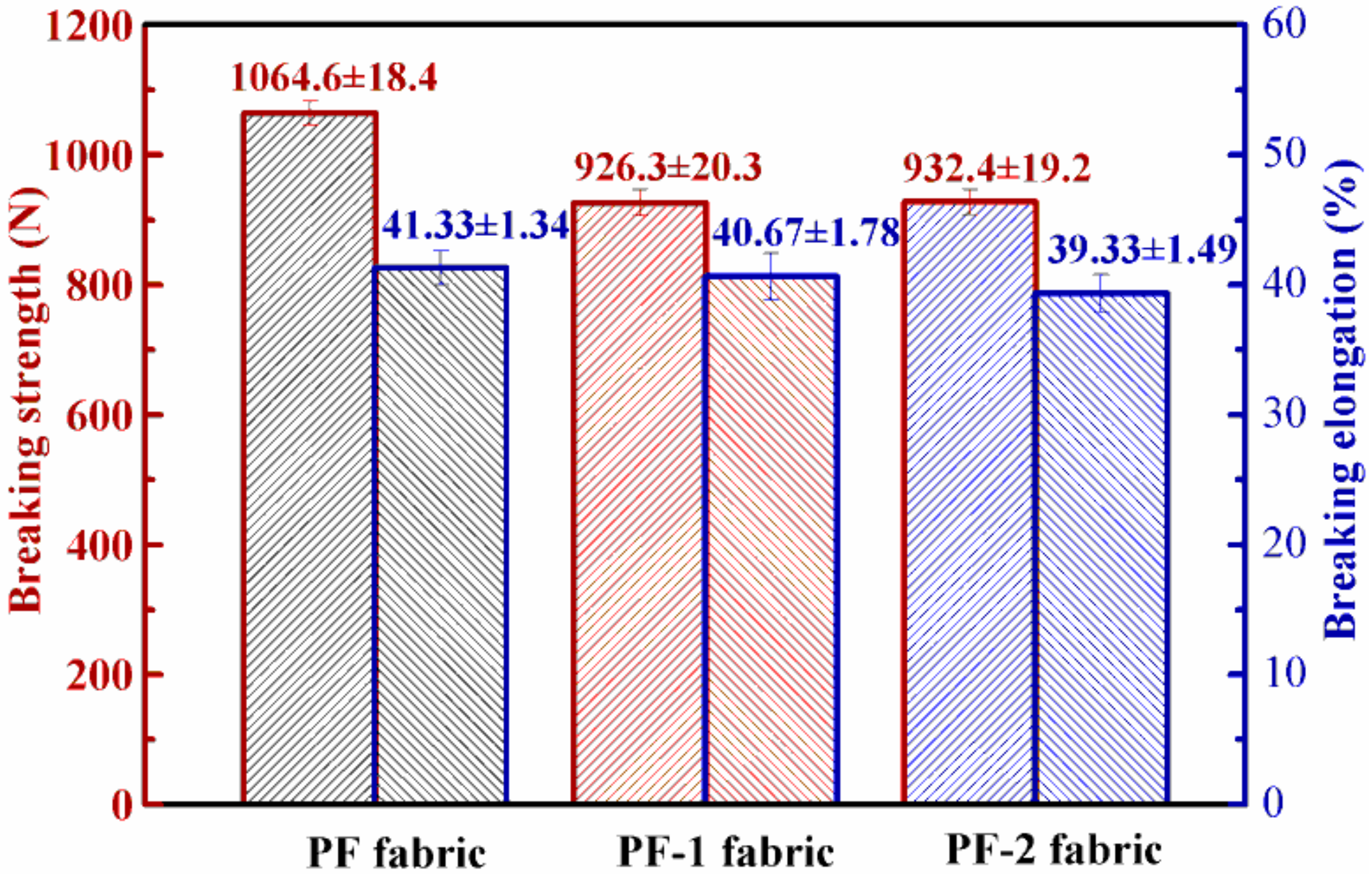

3.5. Tensile Properties of PET Fabrics

3.6. Interfacial Bond Performance of PET Fabric/PVC Composites

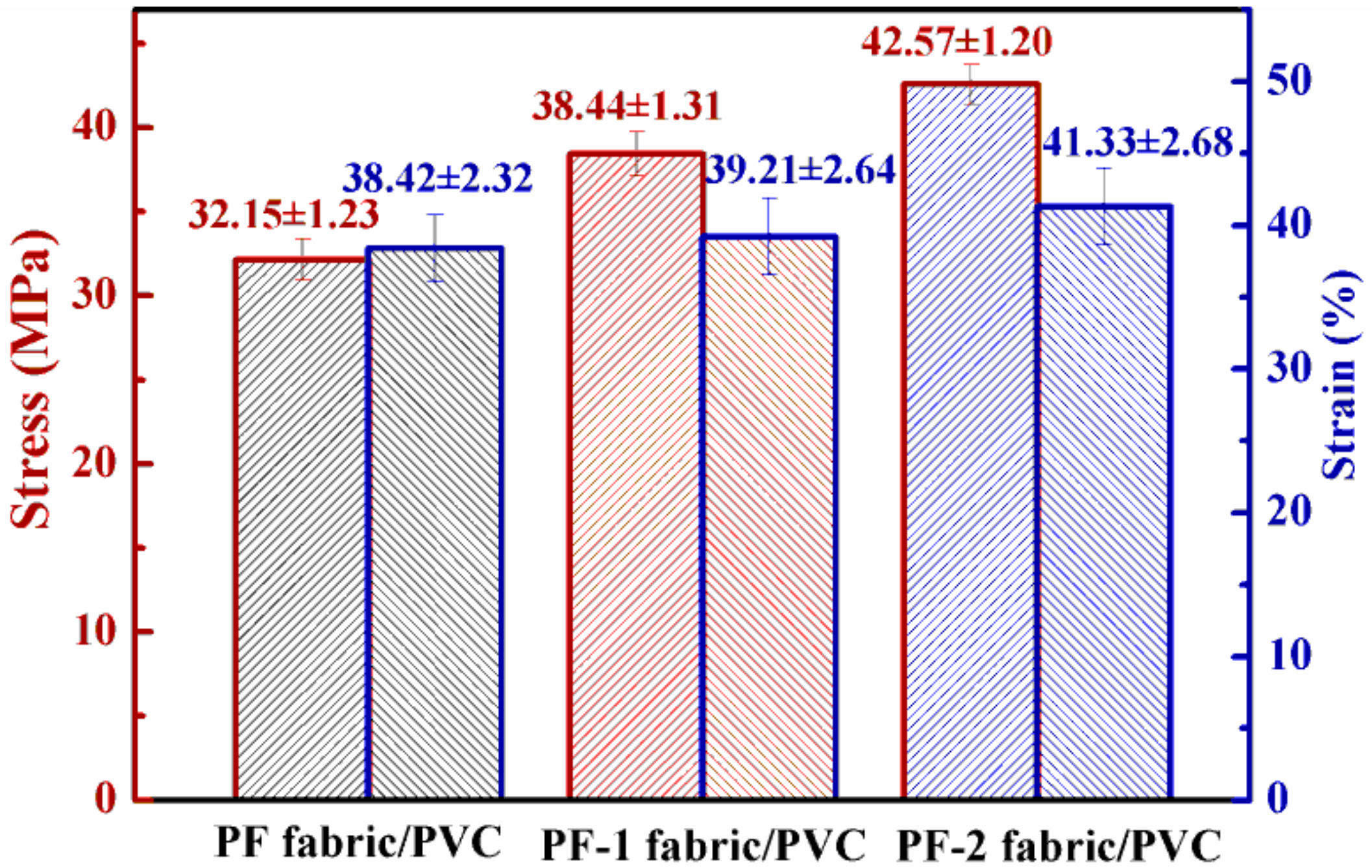

3.7. Tensile Properties of PET Fabric/PVC Composites

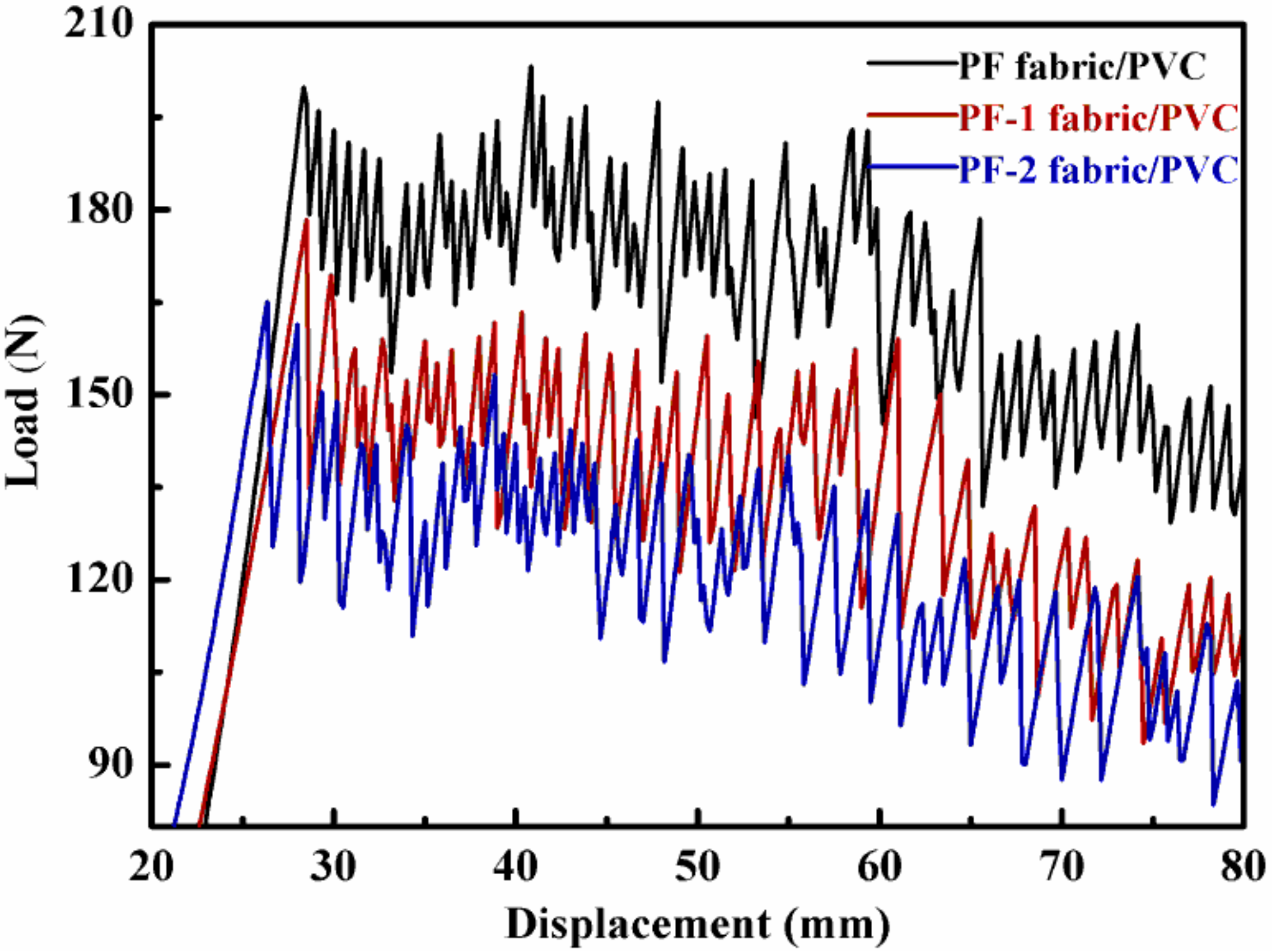

3.8. Tearing Properties of PET Fabric/Composites

4. Conclusions

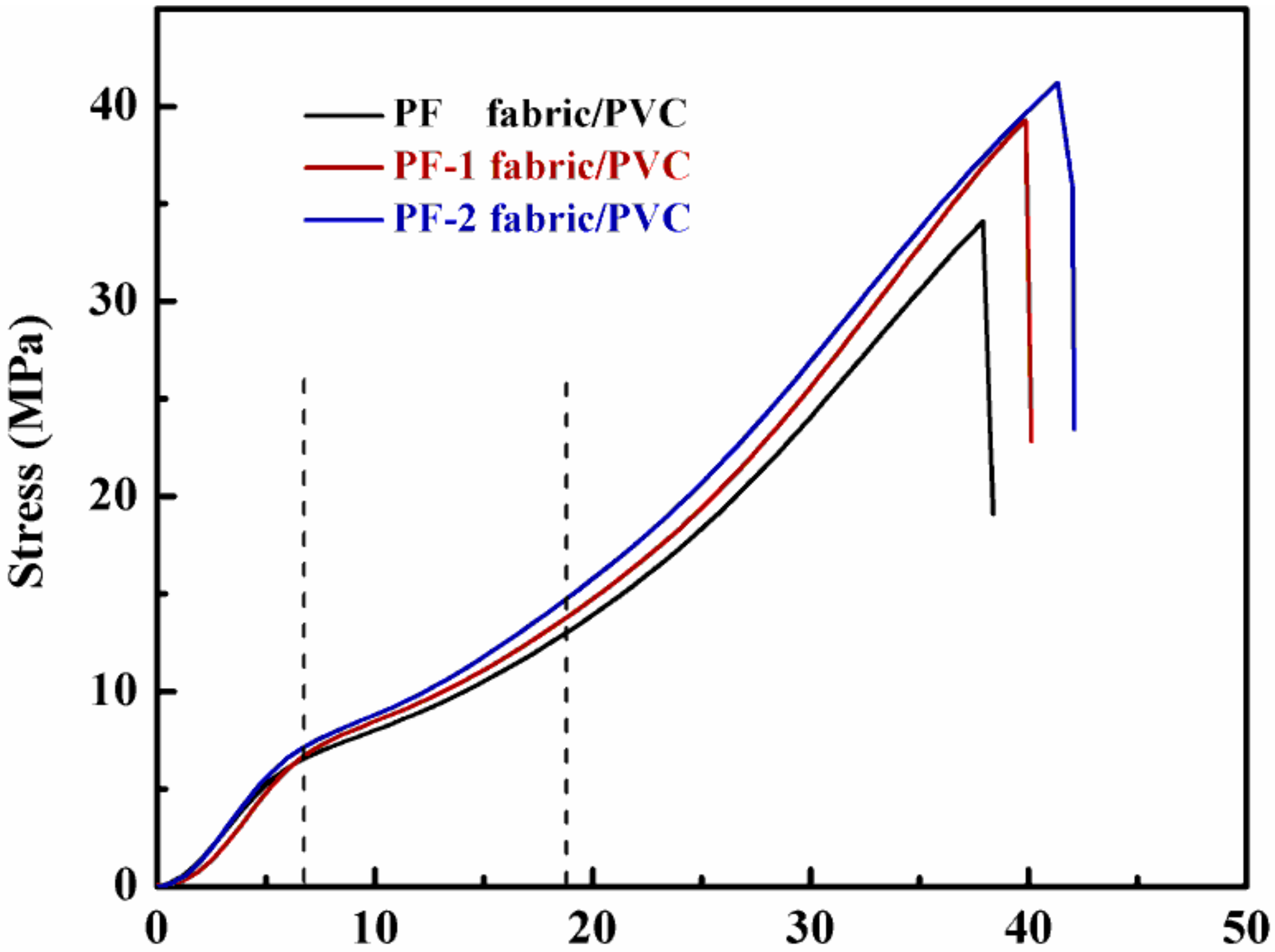

Author Contributions

Funding

Conflicts of Interest

References

- Chen, S.; Ding, X.; Yi, H. On the anisotropic tensile behaviors of flexible polyvinyl chloride-coated fabrics. Textile Res. J. 2007, 77, 369–374. [Google Scholar] [CrossRef]

- Jabbari, M.; Akesson, D.; Skrifvars, M.; Taherzadeh, M.J. Novel lightweight and highly thermally insulative silica aerogel-doped poly (vinyl chloride)-coated fabric composite. J. Reinf. Plast. Comp. 2015, 34, 1581–1592. [Google Scholar] [CrossRef]

- Ambroziak, A.; Klosowski, P. Mechanical properties for preliminary design of structures made from PVC coated fabric. Constr. Build Mater. 2014, 50, 74–81. [Google Scholar] [CrossRef]

- Kumagai, S.; Hirahashi, S.; Grause, G.; Kameda, T.; Toyoda, H.; Yoshioka, T. Alkaline hydrolysis of PVC-coated PET fibers for simultaneous recycling of PET and PVC. J. Mater. Cycles Waste 2018, 20, 439–449. [Google Scholar] [CrossRef]

- Karaca, B.; Ozdogan, E. A study on surface characterization of enzyme treated polyethylene terephthalate fibers by XPS and AFM. Tekst Konfeksiyon 2013, 23, 16–22. [Google Scholar]

- Netravali, A.N.; Bahners, T. Adhesion promotion in fibers and textiles using photonic surface modifications. J. Adhes. Sci. Technol. 2010, 24, 45–75. [Google Scholar] [CrossRef]

- Shishoo, T.D.R. Studies of adhesion mechanisms between PVC coatings and different textile substrates. J. Coat. Fabric 1993, 22, 317–335. [Google Scholar]

- Liu, X.D.; Sheng, D.K.; Gao, X.M.; Li, T.B.; Yang, Y.M. UV-assisted surface modification of PET fiber for adhesion improvement. Appl. Surf. Sci. 2013, 264, 61–69. [Google Scholar] [CrossRef]

- Bessac, B.F.; Sivula, M.; Hehn, C.A.; Caceres, A.I.; Escalera, J.; Jordt, S.E. Transient receptor potential ankyrin 1 antagonists block the noxious effects of toxic industrial isocyanates and tear gases. Faseb. J. 2009, 23, 1102–1114. [Google Scholar] [CrossRef] [PubMed]

- Meng, Y.G.; Huo, R.T.; Qi, C.Z.; Chang, L.Y. Effect of blending with additives on mechanical properties of PVC architectural membrane material. Mater. Sci. Forum 2011, 687, 617–620. [Google Scholar] [CrossRef]

- Collins, M.J.; Zeronian, S.H. The molecular weight distribution and oligomers of sodium hydroxide hydrolyzed poly (ethylene terephthalate). J. Appl. Polym. Sci. 1992, 45, 798–804. [Google Scholar] [CrossRef]

- Dave, J.; Kumar, R.; Srivastava, H.C. Studies on modification of polyester fabrics I: Alkaline hydrolysis. J. Appl. Polym. Sci. 1987, 32, 455–477. [Google Scholar] [CrossRef]

- Collins, M.J.; Zeronian, S.H.; Semmelmeyer, M. The use of aqueous alkaline hydrolysis to reveal the fine structure of poly (ethylene terephthalate) fibers. J. Appl. Polym. Sci. 1991, 42, 2149–2162. [Google Scholar] [CrossRef]

- Salem, T.; Simon, F.; El-Sayed, A.A.; Salama, M. Plasma-assisted surface modification of polyester fabric for developing halochromicproperties. Fiber Polym. 2017, 18, 731–740. [Google Scholar] [CrossRef]

- Wiacek, A.E.; Jurak, M.; Gozdecka, A.; Worzakowska, M. Interfacial properties of PET and PET/starch polymers developed by air plasma processing. Colloid Surface A 2017, 532, 323–331. [Google Scholar] [CrossRef]

- Mehmood, T.; Kaynak, A.; Dai, X.J.; Kouzani, A.; Magniez, K.; Celis, D.R.; Hurren, C.J.; Plessis, J. Study of oxygen plasma pre-treatment of polyester fabric for improved polypyrrole adhesion. Mater. Chem. Phys. 2014, 143, 668–675. [Google Scholar] [CrossRef]

- Wang, X.; Lu, D.; Jonsson, L.J.; Hong, F. Preparation of a PET-hydrolyzing lipase from aspergillusoryzae by the addition of bis(2-hydroxyethyl) terephthalate to the culture medium and enzymatic modification of PET fabrics. Eng. Life Sci. 2008, 8, 268–276. [Google Scholar] [CrossRef]

- Kanelli, M.; Vasilakos, S.; Nikolaivits, E.; Ladas, S.; Christakopoulos, P.; Topakas, E. Surface modification of poly(ethylene terephthalate) (PET) fibers by a cutinase from Fusarium oxysporum. Process Biochem. 2015, 50, 1885–1892. [Google Scholar] [CrossRef]

- Almansa, E.; Heumann, S.; Eberl, A.; Fischer-Colbrie, G.; Martinkova, L.; Marek, J.; Cavaco-Paulo, A.; Guebitz, G.M. Enzymatic surface hydrolysis of PET enhances bonding in PVC coating. Biocatal. Biotransfor. 2008, 26, 365–370. [Google Scholar] [CrossRef]

- Troian-Gautier, L.; Martinez-Tong, D.E.; Hubert, J.; Reniers, F.; Sferrazza, M.; Mattiuzzi, A.; Lagrost, C.; Jabin, I. Controlled modification of polymer surfaces through grafting of calix 4 arene-tetradiazoate salts. J. Phys. Chem. C 2016, 120, 22936–22945. [Google Scholar] [CrossRef]

- Zhang, H.W.; Lu, F.X.; Jiang, Y.; Yu, Q. Adhesion of bacteria on polyester films grafted by siloxane-containing copolymer. Acta Polym. Sin. 2015, 667–672. [Google Scholar]

- Lv, J.C.; Zhou, Q.Q.; Liu, G.L.; Gao, D.W.; Wang, C.X. Preparation and properties of polyester fabrics grafted with O-carboxymethyl chitosan. Carbohydr. Polym. 2014, 113, 344–352. [Google Scholar] [CrossRef] [PubMed]

- Hurley, C.R.; Leggett, G.J. Quantitative investigation of the photodegradation of polyethylene terephthalate film by friction force microscopy, contact-angle Goniometry, and X-ray Photoelectron Spectroscopy. Acs Appl. Mater. Inter. 2009, 1, 1688–1697. [Google Scholar] [CrossRef] [PubMed]

- Mohamed, N.H.; Bahners, T.; Wego, A.; Gutmann, J.S.; Ulbricht, M. Surface modification of poly(ethylene terephthalate) fabric via photo-chemical reaction of dimethylaminopropylmethacrylamide. Appl. Surf. Sci. 2012, 259, 261–269. [Google Scholar] [CrossRef]

- Ahad, I.U.; Fiedorowicz, H.; Budner, B.; Kaldonski, T.J.; Vazquez, M.; Bartnik, A.; Brabazon, D. Extreme ultraviolet surface modification of polyethylene terephthalate (PET) for surface structuring and wettability control. Acta Phys. Pol. A 2016, 129, 241–243. [Google Scholar] [CrossRef]

- Gotoh, K. Modification of poly (ethylene terephthalate) fiber by excimier UV irradiation. Sen-I Gakkaishi 2008, 64, 199–204. [Google Scholar] [CrossRef]

- Bech, L.; Meylheuc, T.; Lepoittevin, B.; Roger, P. Chemical surface modification of poly(ethylene terephthalate) fibers by aminolysis and grafting of carbohydrates. J. Polym. Sci. Pol. Chem. 2007, 45, 2172–2183. [Google Scholar] [CrossRef]

- Dong, Y.B.; Zhu, Y.F.; Zhao, Y.Z.; Liu, F.Y.; Wang, E.L.; Fu, Y.Q. Enhance interfacial properties of glass fiber/epoxy composites with environment-friendly water-based hybrid sizing agent. Composites Part A 2017, 102, 357–367. [Google Scholar] [CrossRef]

- Liu, F.Y.; Shi, Z.; Dong, Y.B. Improved wettability and interfacial adhesion in carbon fibre/epoxy composites via an aqueous epoxy sizing agent. Composites Part A 2018, 112, 337–345. [Google Scholar] [CrossRef]

- Lange, P.J.; Mäder, E.; Mai, K.; Young, R.J.; Ahmad, I. Characterization and micromechanical testing of the interphase of aramid-reinforced epoxy composites. Composites Part A 2001, 32, 331–342. [Google Scholar] [CrossRef]

- Pu, D.D.; Wang, R.; Dong, Y.B.; Zhu, Y.F.; Fu, Y.Q. Influence of surface modification on interfacial properties of polyester fabric/polyvinyl choride composites. J. Text Res. 2017, 38, 102–107. [Google Scholar]

- Cho, J.Y.; Choi, H.M.; Oh, K.W. Rapid hydrophilic modification of poly(ethylene terephthalate) surface by using deep eutectic solvent and microwave irradiation. Text Res. J. 2016, 86, 1318–1327. [Google Scholar] [CrossRef]

- Chen, J.; Zhu, Y.; Ni, Q.; Fu, Y.; Fu, X. Surface modification and characterization of aramid fibers with hybrid coating. Appl. Surf. Sci. 2014, 321, 103–108. [Google Scholar] [CrossRef]

- Zhou, N.T.; Yu, B.; Sun, J.; Yao, L.; Qiu, Y.P. Influence of chemical treatments on the interfacial properties of ramie fiber reinforced Poly(lactic acid) (PLA) composites. J. Biobased Mater. Bio. 2012, 6, 564–568. [Google Scholar] [CrossRef]

- Triki, E.; Phuong, N.T.; Boukehili, H.; Toan, V.K. Investigation of tearing mechanisms of woven textile. Polym. Compos 2012, 33, 1578–1585. [Google Scholar] [CrossRef]

- Krook, C.M.; Fox, K.R. Study of the tongue-tear test. Text Res. J. 1945, 15, 389–396. [Google Scholar] [CrossRef]

| Fabric Weave | Linear Density of Yarn (D/f) | Fabric Count (Threads /10 cm) | Areal Density (g/m2) | ||

|---|---|---|---|---|---|

| Warp | Weft | Warp Count | Weft Count | ||

| Plain weave | 500D/96f | 500D/96f | 120 | 120 | 140.03 |

| Characteristics | PVC Resin | ESO |

|---|---|---|

| Mw | 168000 | 1000 |

| Mn | 70000 | - |

| Polydispersity | 1450 ± 200 | - |

| Viscosity (Pa·s, 25 °C) | - | 0.325 |

| Epoxy value (%) | - | 6.2 |

| Sample | Ra (nm) | RMS (nm) |

|---|---|---|

| PF | 10.51 ± 0.38 | 12.04 ± 0.36 |

| PF-1 | 19.28 ± 0.65 | 24.24 ± 0.74 |

| PF-2 | 32.61 ± 1.39 | 39.12 ± 1.48 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pu, D.; Liu, F.; Dong, Y.; Ni, Q.; Fu, Y. Interfacial Adhesion and Mechanical Properties of PET Fabric/PVC Composites Enhanced by SiO2/Tributyl Citrate Hybrid Sizing. Nanomaterials 2018, 8, 898. https://doi.org/10.3390/nano8110898

Pu D, Liu F, Dong Y, Ni Q, Fu Y. Interfacial Adhesion and Mechanical Properties of PET Fabric/PVC Composites Enhanced by SiO2/Tributyl Citrate Hybrid Sizing. Nanomaterials. 2018; 8(11):898. https://doi.org/10.3390/nano8110898

Chicago/Turabian StylePu, Dandan, Fuyao Liu, Yubing Dong, Qingqing Ni, and Yaqin Fu. 2018. "Interfacial Adhesion and Mechanical Properties of PET Fabric/PVC Composites Enhanced by SiO2/Tributyl Citrate Hybrid Sizing" Nanomaterials 8, no. 11: 898. https://doi.org/10.3390/nano8110898

APA StylePu, D., Liu, F., Dong, Y., Ni, Q., & Fu, Y. (2018). Interfacial Adhesion and Mechanical Properties of PET Fabric/PVC Composites Enhanced by SiO2/Tributyl Citrate Hybrid Sizing. Nanomaterials, 8(11), 898. https://doi.org/10.3390/nano8110898