High Dielectric Tunability and Figure of Merit at Low Voltage in (001)-Oriented Epitaxial Tetragonal Pb0.52Zr0.48TiO3 Thin Films

Abstract

1. Introduction

2. Materials and Methods

2.1. Dielectric Tunability of a (00l)-Oriented Tetragonal Ferroelectric Film

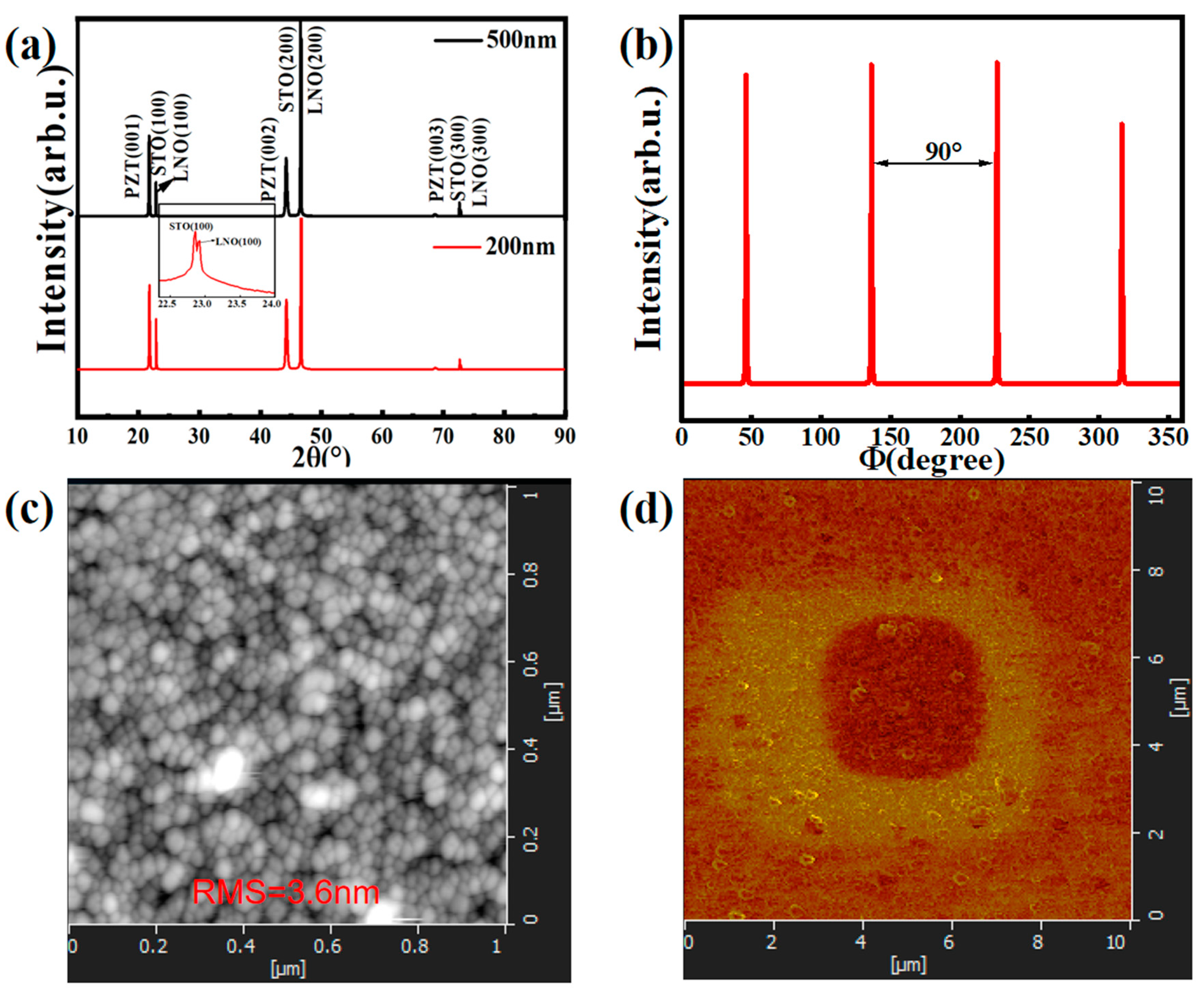

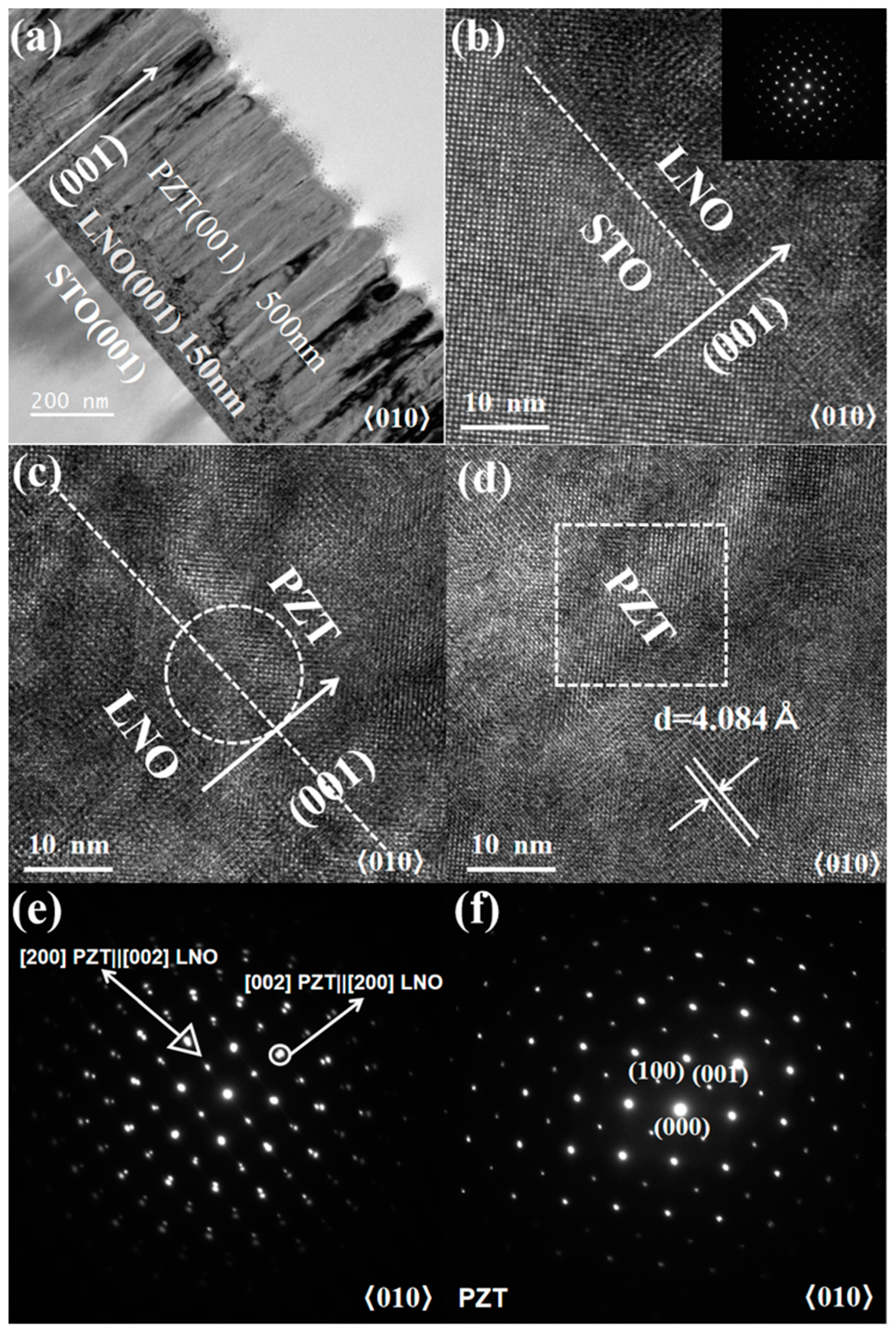

2.2. Deposition of the PZT Film

2.3. Characterization of the PZT Films

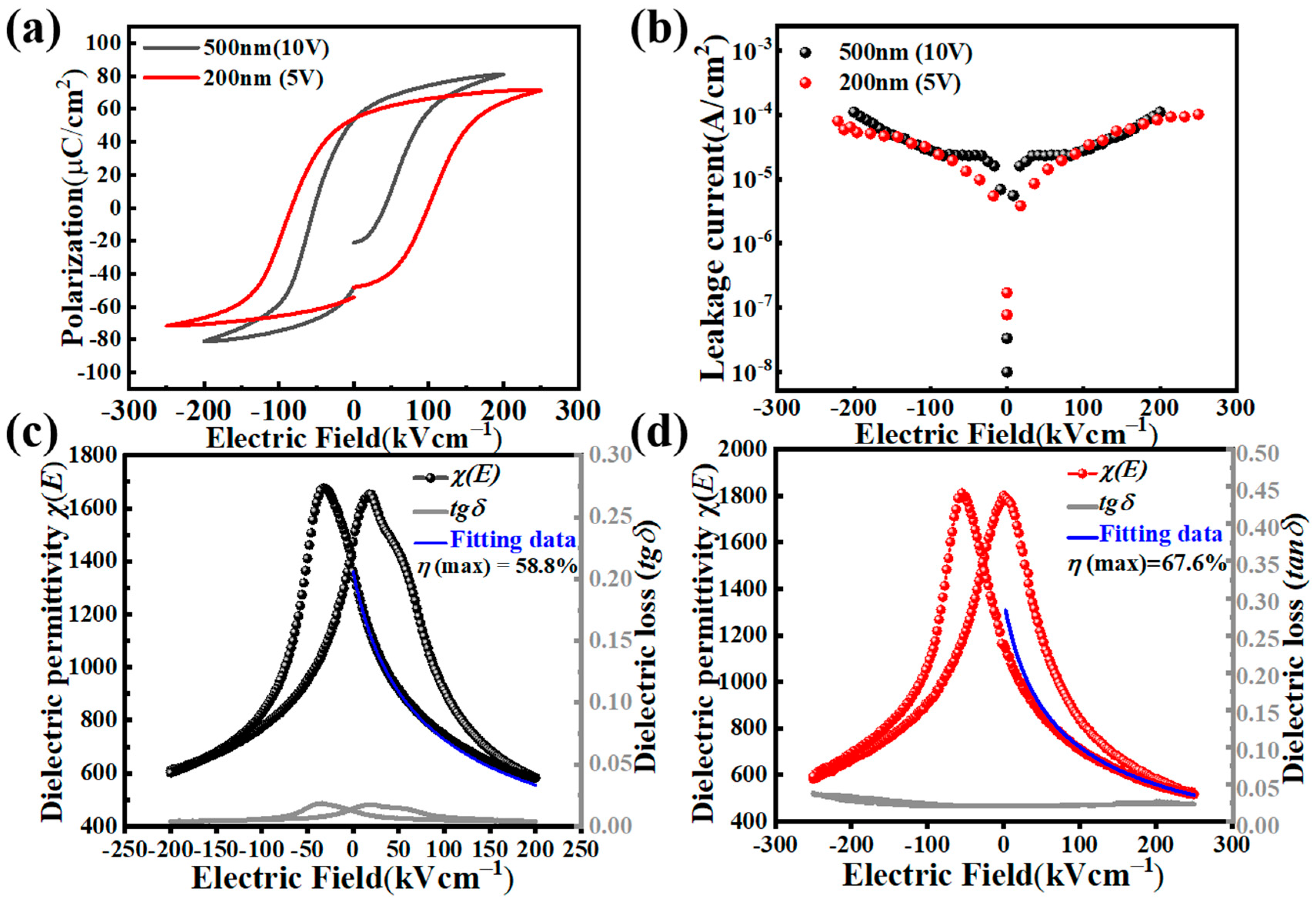

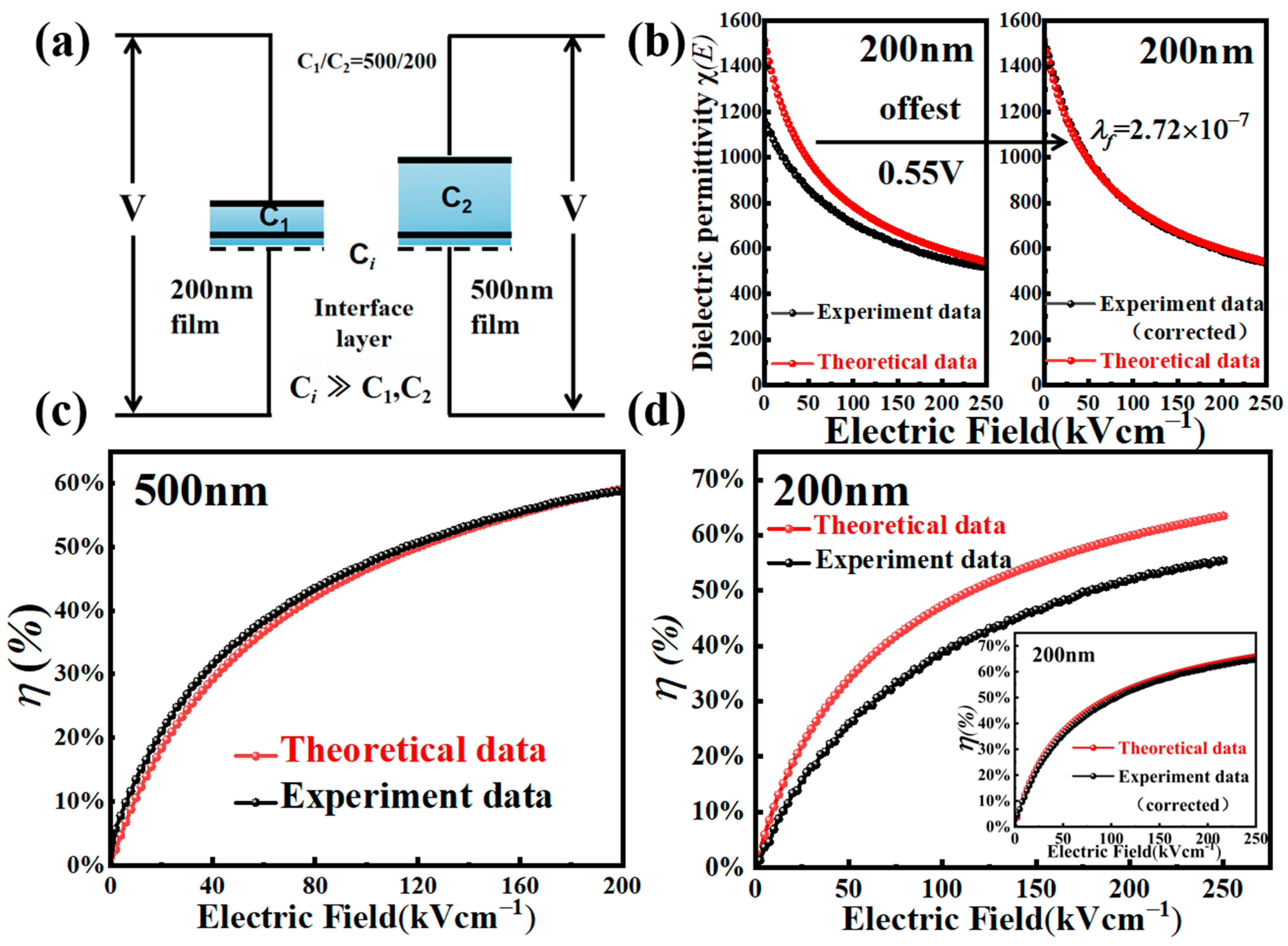

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wu, J.; Zhu, J.; Xiao, D.; Zhu, J.; Tan, J.; Zhang, Q. Preparation and Properties of Highly (100)-Oriented Pb (Zr0.2Ti0.8)O3 Thin Film Prepared by Rf Magnetron Sputtering with a PbOx Buffer Layer. J. Appl. Phys. 2007, 101, 094107. [Google Scholar] [CrossRef]

- Li, R.; Xu, D.; Du, C.; Ma, Q.; Zhang, F.; Liang, X.; Wang, D.; Shi, Z.; Liu, W.; Zhou, D. Giant Dielectric Tunability in Ferroelectric Ceramics with Ultralow Loss by Ion Substitution Design. Nat. Commun. 2024, 15, 3754. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Yang, T.; Wei, K.; Li, G.; Chen, S. Bi-Tunable Dielectric Constant of Antiferroelectric PZT Ceramics Under DC Electric Field. J. Am. Ceram. Soc. 2012, 95, 1483–1485. [Google Scholar] [CrossRef]

- Peng, B.; Fan, H.; Zhang, Q. High Tunability in (111)-Oriented Relaxor Pb0.8Ba0.2ZrO3 Thin Film with Antiferroelectric and Ferroelectric Two-Phase Coexistence. J. Am. Ceram. Soc. 2013, 96, 1852–1856. [Google Scholar] [CrossRef]

- James, A.R.; Kumar, A.; Prasad, V.V.B.; Kamat, S.V.; Singh, V.; Ghoshal, P.; Pandey, A. Tunability, Ferroelectric and Leakage Studies on Pulsed Laser Ablated (Pb0.92La0.08)(Zr0.60Ti0.40)O3 Thin Films. Mater. Chem. Phys. 2018, 211, 295–301. [Google Scholar] [CrossRef]

- Jakoby, R.; Scheele, P.; Muller, S.; Weil, C. Nonlinear Dielectrics for Tunable Microwave Components. In Proceedings of the 15th International Conference on Microwaves, Radar and Wireless Communications (IEEE Cat. No.04EX824), Warsaw, Poland, 17–19 May 2004; IEEE: Warsaw, Poland, 2004; pp. 369–378. [Google Scholar]

- Pervez, N.K.; Hansen, P.J.; York, R.A. High Tunability Barium Strontium Titanate Thin Films for Rf Circuit Applications. Appl. Phys. Lett. 2004, 85, 4451–4453. [Google Scholar] [CrossRef]

- Aymen, S.; Mascot, M.; Jomni, F.; Carru, J.-C. High Tunability in Lead-Free Ba0.85Sr0.15TiO3 thick Films for Microwave Tunable Applications. Ceram. Int. 2019, 45, 23084–23088. [Google Scholar] [CrossRef]

- Liu, S.W.; Weaver, J.; Yuan, Z.; Donner, W.; Chen, C.L.; Jiang, J.C.; Meletis, E.I.; Chang, W.; Kirchoefer, S.W.; Horwitz, J.; et al. Ferroelectric (Pb,Sr)TiO3 Epitaxial Thin Films on (001) MgO for Room Temperature High-Frequency Tunable Microwave Elements. Appl. Phys. Lett. 2005, 87, 142905. [Google Scholar] [CrossRef]

- Calzada, M.L.; Bretos, I.; Jiménez, R.; Ricote, J.; Mendiola, J.; García-López, J.; Respaldiza, M.A. Chemical Solution Deposition of (Pb1− xCax)TiO3 Thin Films with x ∼0.5 as New Dielectrics for Tunable Components and Dynamic Random Access Memories. J. Am. Ceram. Soc. 2005, 88, 3388–3396. [Google Scholar] [CrossRef]

- Lu, S.G.; Xu, Z.K. Tunability and Permittivity-Temperature Characteristics of Highly (100) Oriented Compositionally Graded (Ba0.7Sr0.3)(SnxTi1−x)O3 Thin Films Grown by Pulse-Laser Deposition. Appl. Phys. Lett. 2006, 89, 152907. [Google Scholar] [CrossRef]

- Ballan, H.; Declercq, M.; Krummenacher, F. Design and Optimization of High Voltage Analog and Digital Circuits Built in a Standard 5 V CMOS Technology. In Proceedings of the IEEE Custom Integrated Circuits Conference—CICC ’94, San Diego, CA, USA, 1–4 May 1994; IEEE: San Diego, CA, USA, 1994; pp. 574–577. [Google Scholar]

- Albrecht, M.; Erlbacher, T.; Bauer, A.J.; Frey, L. Improving 5V Digital 4H-SiC CMOS ICs for Operating at 400 °C Using PMOS Channel Implantation. Mater. Sci. Forum 2019, 963, 827–831. [Google Scholar] [CrossRef]

- Lu, J.; Stemmer, S. Low-Loss, Tunable Bismuth Zinc Niobate Films Deposited by Rf Magnetron Sputtering. Appl. Phys. Lett. 2003, 83, 2411–2413. [Google Scholar] [CrossRef]

- Luo, B.; Xu, Y.; Zhang, F.; Wang, T.; Yao, Y. Dielectric Tunability Properties in (110)-Oriented Epitaxial 0.5Ba(Ti0.8Zr0.2)O3-0.5(Ba0.7Ca0.3)TiO3 Thin Films Prepared by PLD Method. Materials 2020, 13, 4771. [Google Scholar] [CrossRef]

- Hao, L.; Yang, Y.; Huan, Y.; Cheng, H.; Zhao, Y.-Y.; Wang, Y.; Yan, J.; Ren, W.; Ouyang, J. Achieving a High Dielectric Tunability in Strain-Engineered Tetragonal K0.5Na0.5NbO3 Films. Npj Comput. Mater. 2021, 7, 62. [Google Scholar] [CrossRef]

- Hu, G.; Gao, F.; Liu, L.; Xu, B.; Liu, Z. Microstructure and Dielectric Properties of Highly Tunable Ba0.6Sr0.4TiO3/MgO/Al2O3/ZnO Composite. J. Alloys Compd. 2012, 518, 44–50. [Google Scholar] [CrossRef]

- Ahmed, A.; Goldthorpe, I.A.; Khandani, A.K. Electrically Tunable Materials for Microwave Applications. Appl. Phys. Rev. 2015, 2, 011302. [Google Scholar] [CrossRef]

- Lin, Y.; Chen, X.; Liu, J.; Yuan, Z.; Collins, G.; Chen, C.L.; Jiang, J.C.; Meletis, E.I.; Chen, C.L.P.; Bhalla, A.; et al. Highly Epitaxial Ferroelectric Lead Strontium Titanate ((Pb,Sr)TiO3) Thin Films With Extra Large Dielectric Tunability: A Good Candidate For Room Temperature Tunable Microwave Elements. Integr. Ferroelectr. 2008, 100, 1–15. [Google Scholar] [CrossRef]

- Wang, F.; Ma, W. Phase Stability and Dielectric Properties of (011) Epitaxial (Ba0.6Sr0.4)TiO3 Films. J. Appl. Phys. 2019, 125, 082528. [Google Scholar] [CrossRef]

- Ambika, D.; Kumar, V.; Tomioka, K.; Kanno, I. Deposition of PZT Thin Films With (001), (110), and (111) Crystallographic Orientations And Their Transverse Piezoelectric Characteristics. Adv. Mater. Lett. 2012, 3, 102–106. [Google Scholar] [CrossRef]

- Chen, L.; Nagarajan, V.; Ramesh, R.; Roytburd, A.L. Nonlinear Electric Field Dependence of Piezoresponse in Epitaxial Ferroelectric Lead Zirconate Titanate Thin Films. J. Appl. Phys. 2003, 94, 5147–5152. [Google Scholar] [CrossRef]

- Mtebwa, M.; Tagantsev, A.K.; Setter, N. Effect of Elastic Compliances and Higher Order Landau Coefficients on the Phase Diagram of Single Domain Epitaxial Pb(Zr,Ti)O3 (PZT) Thin Films. AIP Adv. 2014, 4, 127150. [Google Scholar] [CrossRef]

- Haun, M.J.; Furman, E.; Jang, S.J.; Cross, L.E. Thermodynamic Theory of the Lead Zirconate-Titanate Solid Solution System, Part V: Theoretical Calculations. Ferroelectrics 1989, 99, 63–86. [Google Scholar] [CrossRef]

- Chang, W.; Gilmore, C.M.; Kim, W.-J.; Pond, J.M.; Kirchoefer, S.W.; Qadri, S.B.; Chirsey, D.B.; Horwitz, J.S. Influence of Strain on Microwave Dielectric Properties of (Ba,Sr)TiO3 Thin Films. J. Appl. Phys. 2000, 87, 3044–3049. [Google Scholar] [CrossRef]

- Zhang, W.; Cheng, H.; Yang, Q.; Hu, F.; Ouyang, J. Crystallographic Orientation Dependent Dielectric Properties of Epitaxial BaTiO3 Thin Films. Ceram. Int. 2016, 42, 4400–4405. [Google Scholar] [CrossRef]

- Noheda, B.; Gonzalo, J.A.; Cross, L.E.; Guo, R.; Park, S.-E.; Cox, D.E.; Shirane, G. Tetragonal-to-Monoclinic Phase Transition in a Ferroelectric Perovskite: The Structure of PbZr0.52Ti0.48O3. Phys. Rev. B 2000, 61, 8687–8695. [Google Scholar] [CrossRef]

- Aruchamy, N.; Schenk, T.; Girod, S.; Glinsek, S.; Defay, E.; Granzow, T. Influence of Substrate Stress on In-Plane and out-of-Plane Ferroelectric Properties of PZT Films. J. Appl. Phys. 2022, 131, 014101. [Google Scholar] [CrossRef]

- Aruchamy, N.; Schenk, T.; Kovacova, V.; Glinsek, S.; Defay, E.; Granzow, T. Influence of Tensile vs. Compressive Stress on Fatigue of Lead Zirconate Titanate Thin Films. J. Eur. Ceram. Soc. 2021, 41, 6991–6999. [Google Scholar] [CrossRef]

- Scott, J.F.; Gardner, J. Ferroelectrics, Multiferroics and Artifacts: Lozenge-Shaped Hysteresis and Things That Go Bump in the Night. Mater. Today 2018, 21, 553–562. [Google Scholar] [CrossRef]

- Chan, N.Y.; Wang, D.Y.; Wang, Y.; Dai, J.Y.; Chan, H.L.W. The Structural and In-Plane Dielectric/Ferroelectric Properties of the Epitaxial (Ba, Sr)(Zr, Ti)O3 Thin Films. J. Appl. Phys. 2014, 115, 234102. [Google Scholar] [CrossRef]

- Elissalde, C.; Ravez, J. Ferroelectric Ceramics: Defects and Dielectric Relaxations. J. Mater. Chem. 2001, 11, 1957–1967. [Google Scholar] [CrossRef]

- Yuan, M.; Zhang, W.; Wang, X.; Pan, W.; Wang, L.; Ouyang, J. In Situ Preparation of High Dielectric Constant, Low-Loss Ferroelectric BaTiO3 Films on Si at 500 °C. Appl. Surf. Sci. 2013, 270, 319–323. [Google Scholar] [CrossRef]

- Zhang, W.; Gao, Y.; Kang, L.; Yuan, M.; Yang, Q.; Cheng, H.; Pan, W.; Ouyang, J. Space-Charge Dominated Epitaxial BaTiO3 Heterostructures. Acta Mater. 2015, 85, 207–215. [Google Scholar] [CrossRef]

- Kim, K. Dielectric Properties of Highly (100) Oriented (Pb0.5, Sr0.5)TiO3 Thin Films Grown on LaNiO3 Electrodes. Thin Solid Film. 2004, 447–448, 651–655. [Google Scholar] [CrossRef]

- Shao, Q.-Y.; Li, A.-D.; Xia, Y.-D.; Wu, D.; Liu, Z.-G.; Ming, N.-B. Strontium-Modified Lead Zirconate Titanate Thin Films for Electrically Tunable Device Applications. J. Appl. Phys. 2006, 100, 036102. [Google Scholar] [CrossRef]

- Wu, Z.; Zhou, J.; Chen, W.; Shen, J.; Yang, H.; Zhang, S.; Liu, Y. Improvement in Temperature Dependence and Dielectric Tunability Properties of PbZr0.52Ti0.48O3 Thin Films Using Ba(Mg1/3Ta2/3)O3 Buffer Layer. Appl. Surf. Sci. 2016, 388, 579–583. [Google Scholar] [CrossRef]

- Dong, H.; Jian, J.; Li, H.; Jin, D.; Chen, J.; Cheng, J. Improved Dielectric Tunability of PZT/BST Multilayer Thin Films on Ti Substrates. J. Alloys Compd. 2017, 725, 54–59. [Google Scholar] [CrossRef]

- Wu, M.-H.; Wu, J.-M. Lead Barium Zirconate Perovskite Films for Electrically Tunable Applications. Appl. Phys. Lett. 2005, 86, 022909. [Google Scholar] [CrossRef]

| Parameters | α1 (107) | α11 (108) | α111 (109) | Q12 | S | ||||

| −4.887 | 0.4764 | 1.336 | −0.046 | 0.5 | 0.535 | 0.0135 | 8.3 × 10−12 | ||

| Units | C−2m2 N | C−4m6 N | C−6m10 N | mV−1 | |||||

| −5.374 | 1.205 | 8.016 | 2.5 | ||||||

| Sample | Orientation | E-Field (kV/mm)/ Frequency | η; Tunability (%) @ Voltage (Volts) | T0 (mm/kV) | FOM | Ref. No |

|---|---|---|---|---|---|---|

| PZT (52/48) 500 nm thick (this work) | 001 | 20 @1 kHz 10@1 kHz | 58.8% @10 V 47.0% @5 V | 0.0294 0.047 | 49 39.2 | - |

| 20 @1 MHz 10 @1 MHz | 55.4% @ 10 V 43.5% @5 V | 0.0277 0.0435 | 11.79 9.06 | - | ||

| PZT (52/48) 200 nm thick (this work) | 001 | 25 @1 kHz 12.5 @1 kHz | 67.6% @ 5 V 54.2% @2.5 V Note: η(−max) data | 0.0269 0.0431 | 32 25.67 | - |

| BSSnT 300 nm thick | 100 | 30 @10 kHz 15 @10 kHz | 31% @8 V 13.2% @4 V | 0.0103 0.0088 | 6.2 2.64 | [11] |

| Bi1.5Zn1.0Nb1.5O7 170 nm thick | random | 240 @1 MHz 120 @1 MHz | 55% @40.8 V 28% @20.4 V | 0.0022 0.0023 | 1617 820 | [14] |

| PST 200 nm thick | 100 | 25 @1 MHz 12.5 @1 MHz | 60.1% @ 5 V 37.8% @2.5 V | 0.0240 0.0303 | 29.5 18.9 | [35] |

| Pb0.4Sr0.6Zr0.52Ti0.48O3 400 nm thick | random | 37.5 @1 MHz | 48% @15 V | 0.0128 | 24 | [36] |

| BTO 300 nm thick | 001 | 100 @5 kHz 50 @5 kHz | 25.6% @30 V 15% @15 V | 0.00256 0.003 | 12.2 7.14 | [26] |

| PZT/BMT 640 nm thick | 110 | 20 @1 kHz 10 @1 kHz | 56.52% @13 V 38.1% @6.5 V | 0.0282 0.0381 | 12.03 8.106 | [37] |

| PZT/BST 300 nm thick | 110 | 40 @1 MHz 20 @1 MHz | 41.1% @12 V 20.2% @ 6 V | 0.0103 0.0101 | 4.11 2.02 | [38] |

| Pb0.6Ba0.4ZrO3 200 nm thick | 001 | 50 @1 MHz 25 @1 MHz | 43% @10 V 26.8% @5 V | 0.0086 0.0107 | 61.43 38.28 | [39] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Liu, C.; Ouyang, J. High Dielectric Tunability and Figure of Merit at Low Voltage in (001)-Oriented Epitaxial Tetragonal Pb0.52Zr0.48TiO3 Thin Films. Nanomaterials 2025, 15, 695. https://doi.org/10.3390/nano15090695

Li H, Liu C, Ouyang J. High Dielectric Tunability and Figure of Merit at Low Voltage in (001)-Oriented Epitaxial Tetragonal Pb0.52Zr0.48TiO3 Thin Films. Nanomaterials. 2025; 15(9):695. https://doi.org/10.3390/nano15090695

Chicago/Turabian StyleLi, Hongwang, Chao Liu, and Jun Ouyang. 2025. "High Dielectric Tunability and Figure of Merit at Low Voltage in (001)-Oriented Epitaxial Tetragonal Pb0.52Zr0.48TiO3 Thin Films" Nanomaterials 15, no. 9: 695. https://doi.org/10.3390/nano15090695

APA StyleLi, H., Liu, C., & Ouyang, J. (2025). High Dielectric Tunability and Figure of Merit at Low Voltage in (001)-Oriented Epitaxial Tetragonal Pb0.52Zr0.48TiO3 Thin Films. Nanomaterials, 15(9), 695. https://doi.org/10.3390/nano15090695