High-Temperature Oxidation and Wear Resistance of TiAlSiN/AlCrN Multilayer Coatings Prepared by Multi-Arc Ion Plating

Abstract

1. Introduction

2. Materials and Methods

2.1. Coating Deposition

2.2. Coating Characterization

3. Results and Discussion

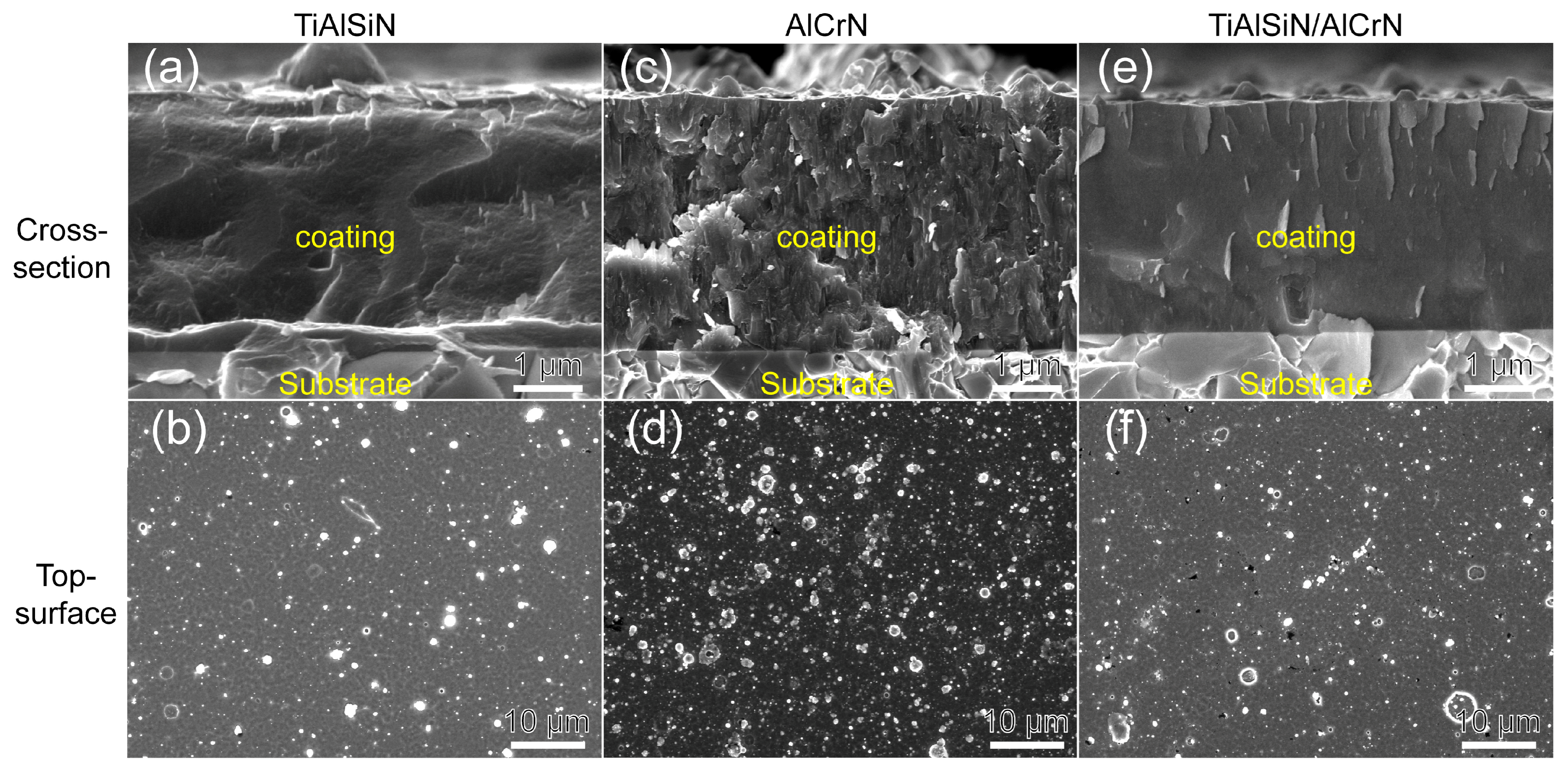

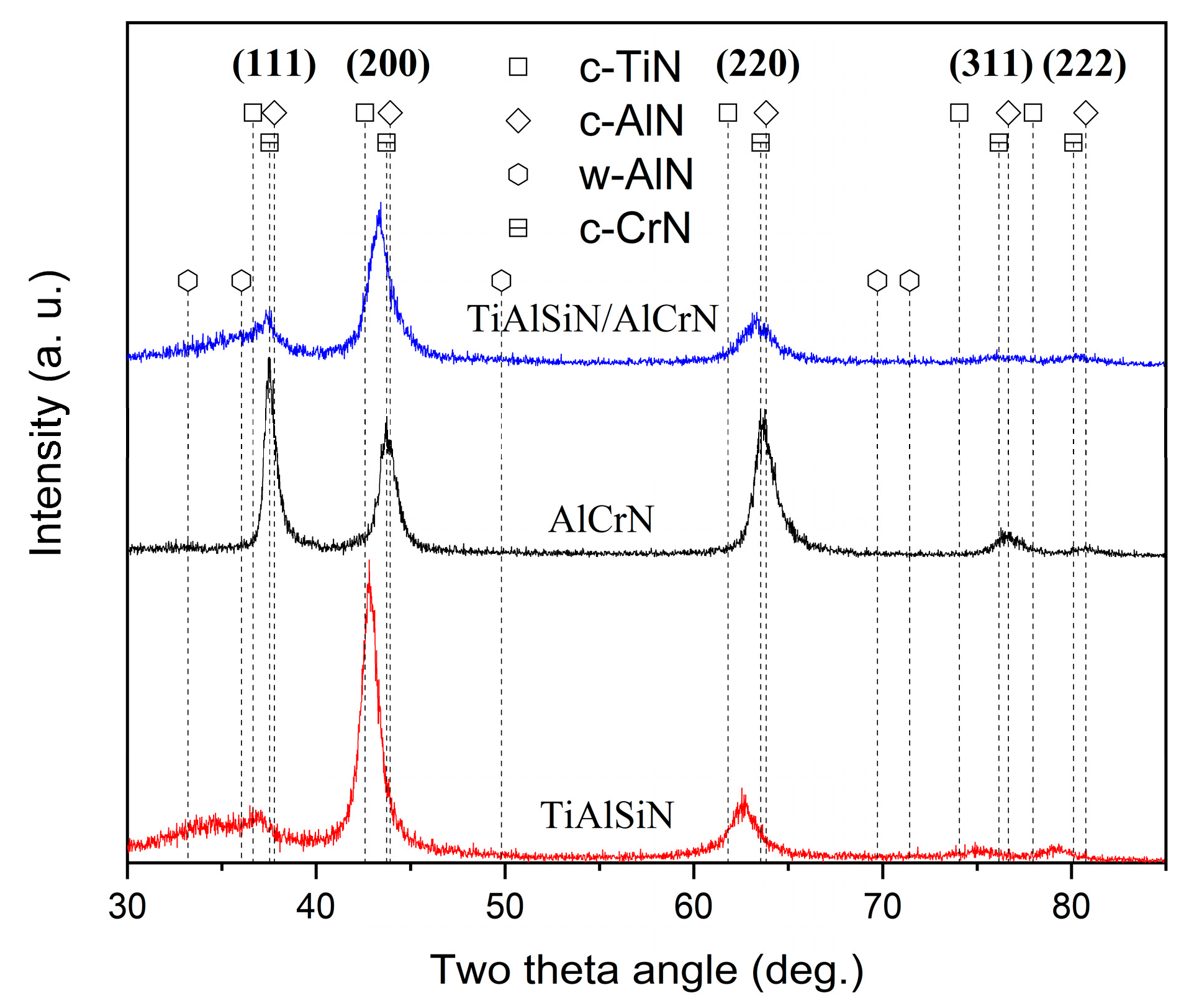

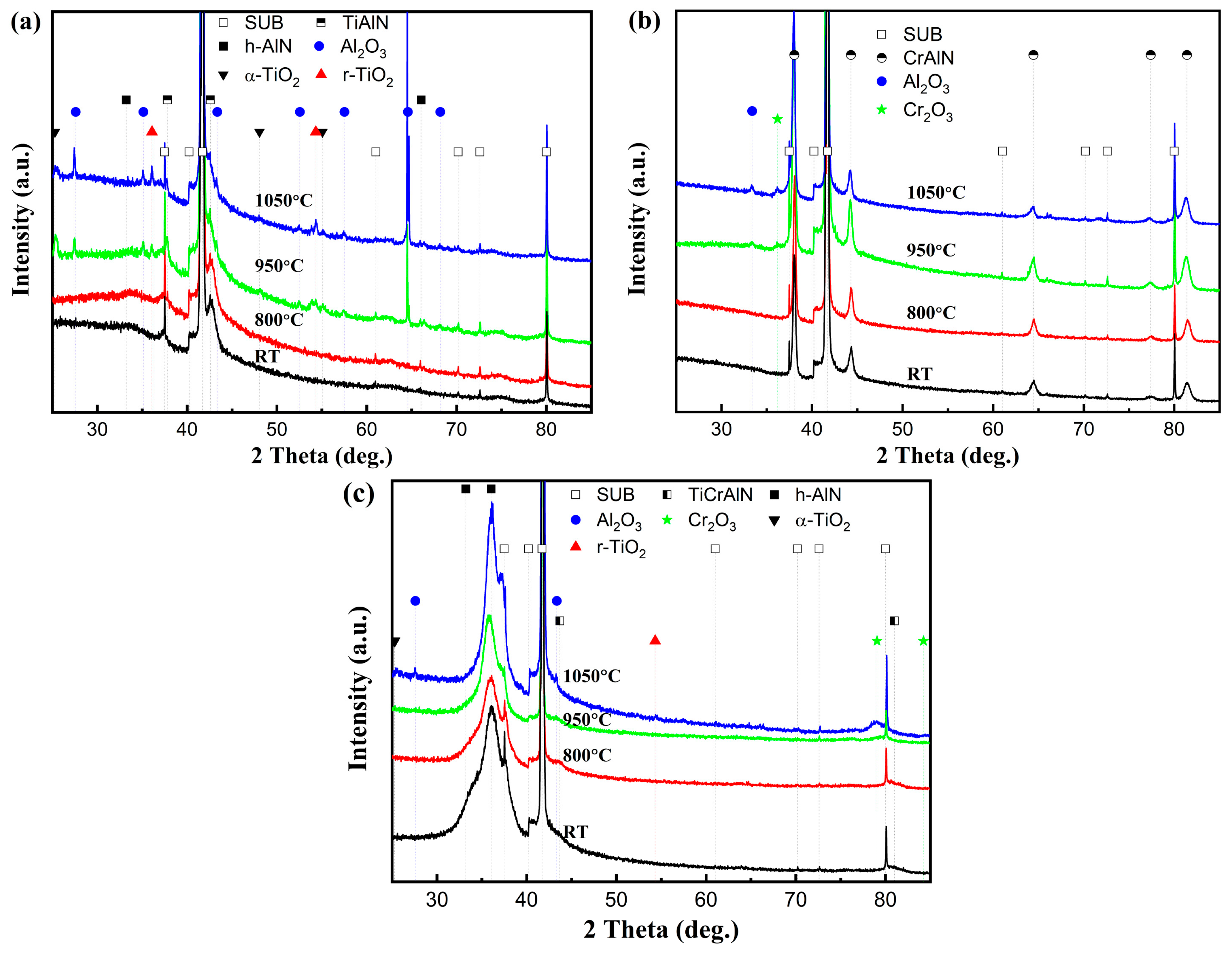

3.1. Phase and Microstructure

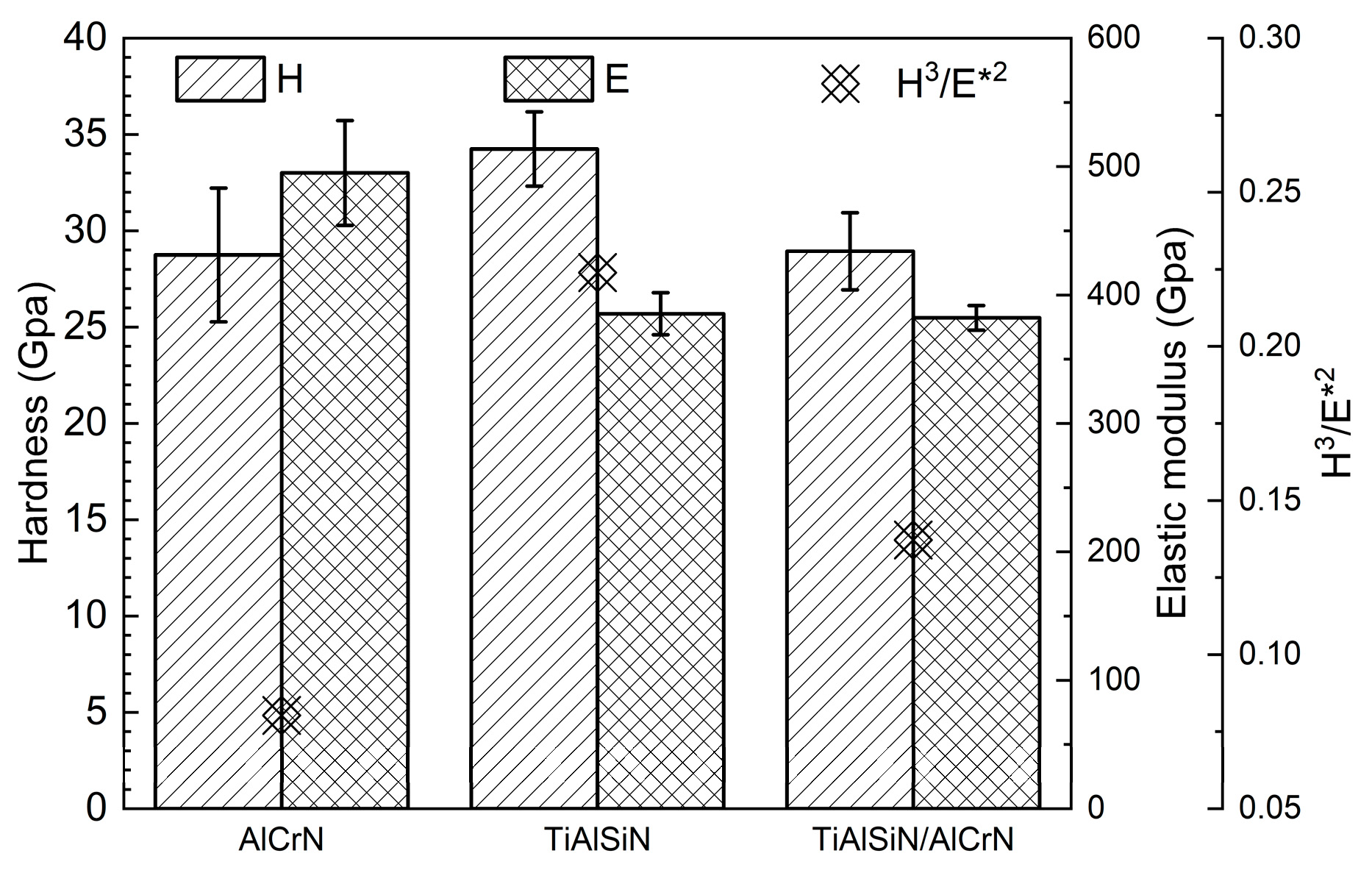

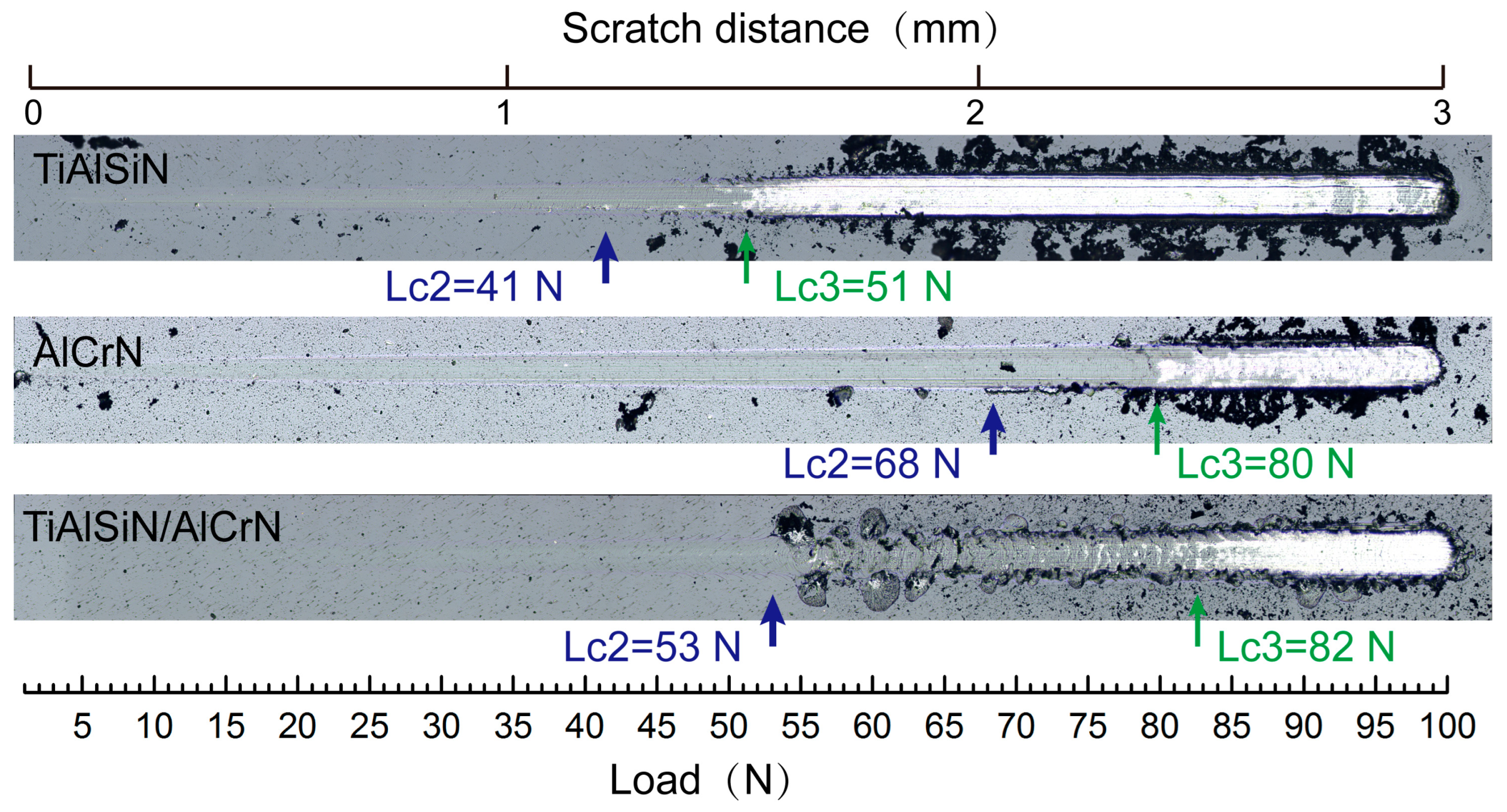

3.2. Mechanical Properties

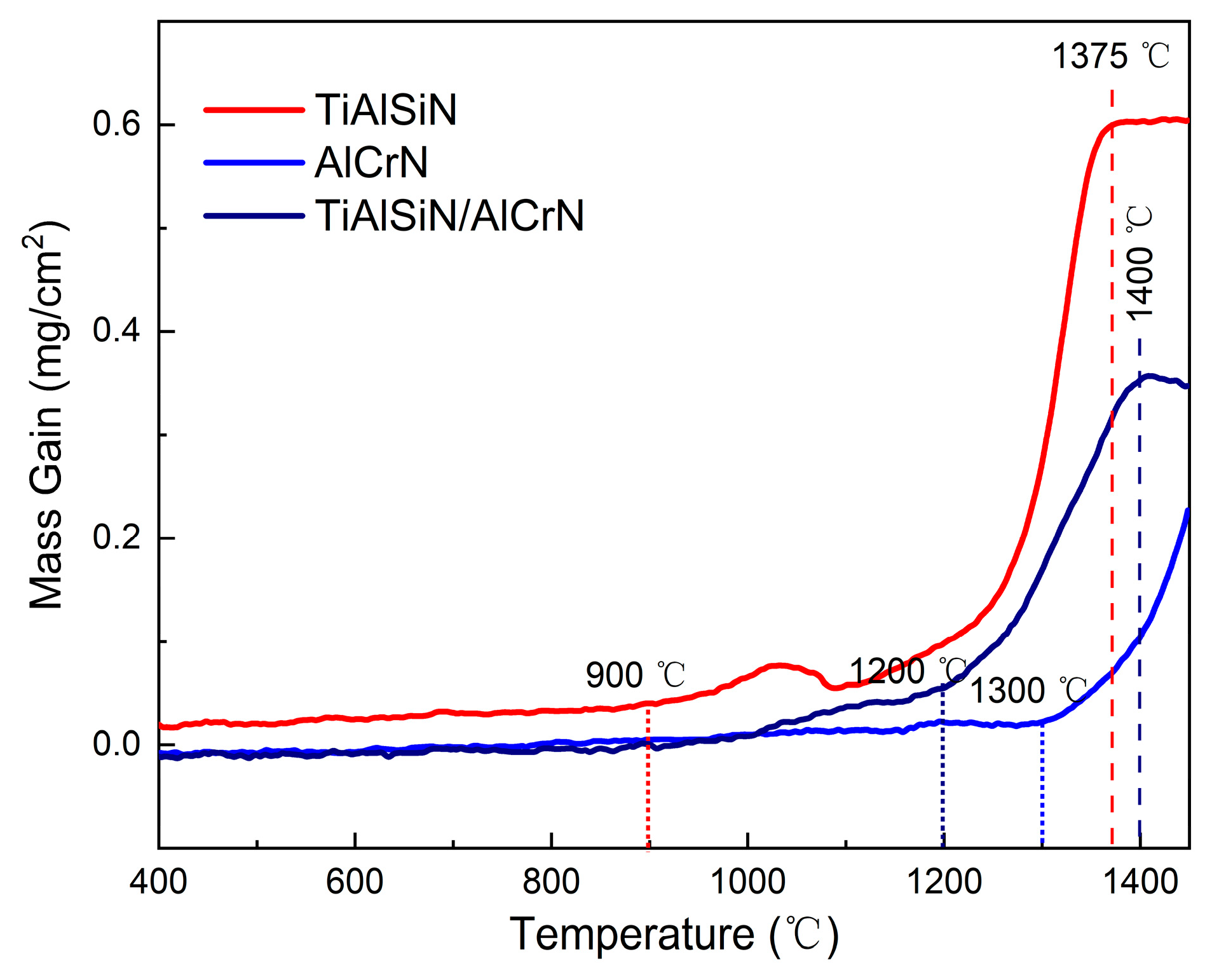

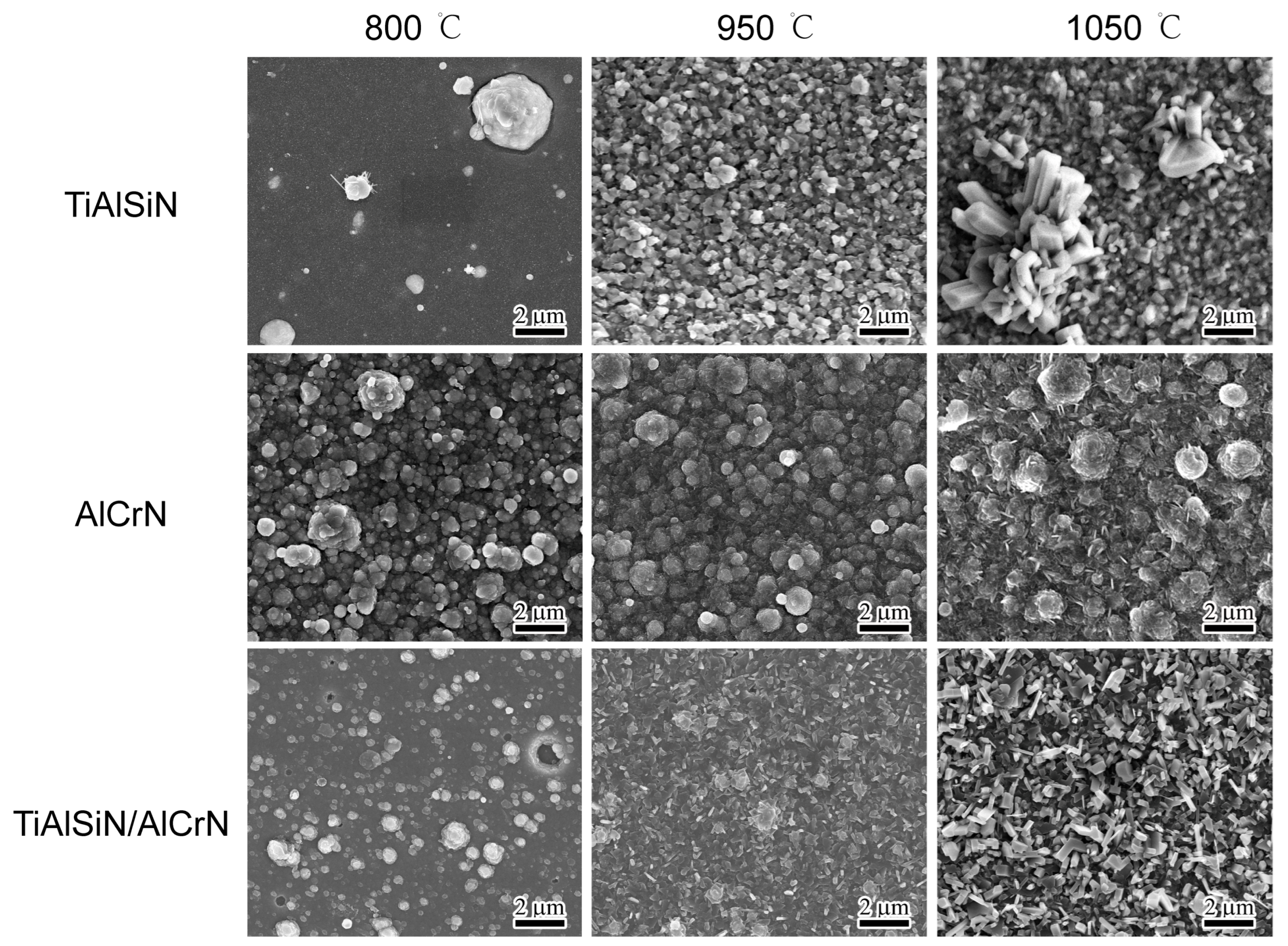

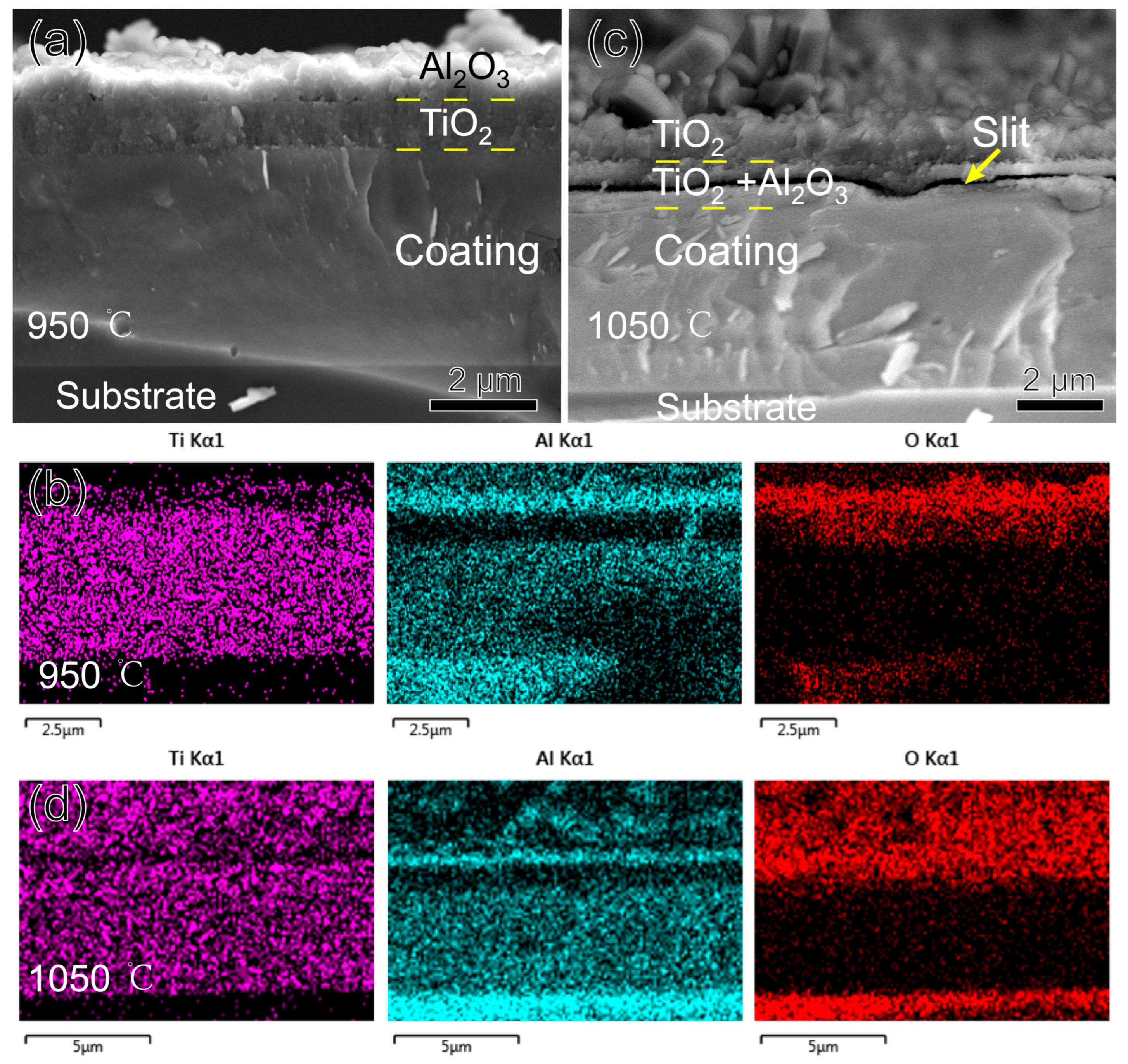

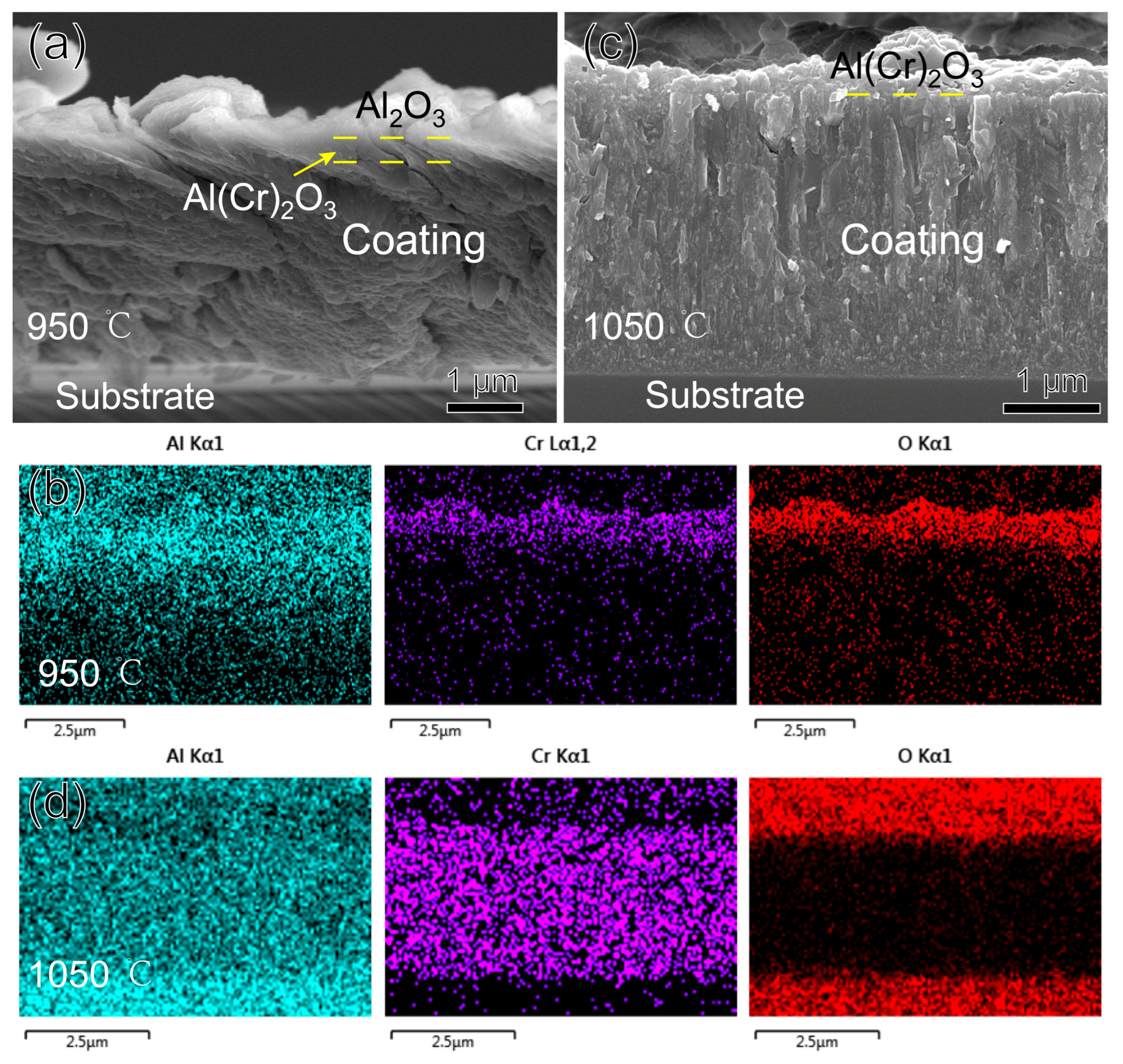

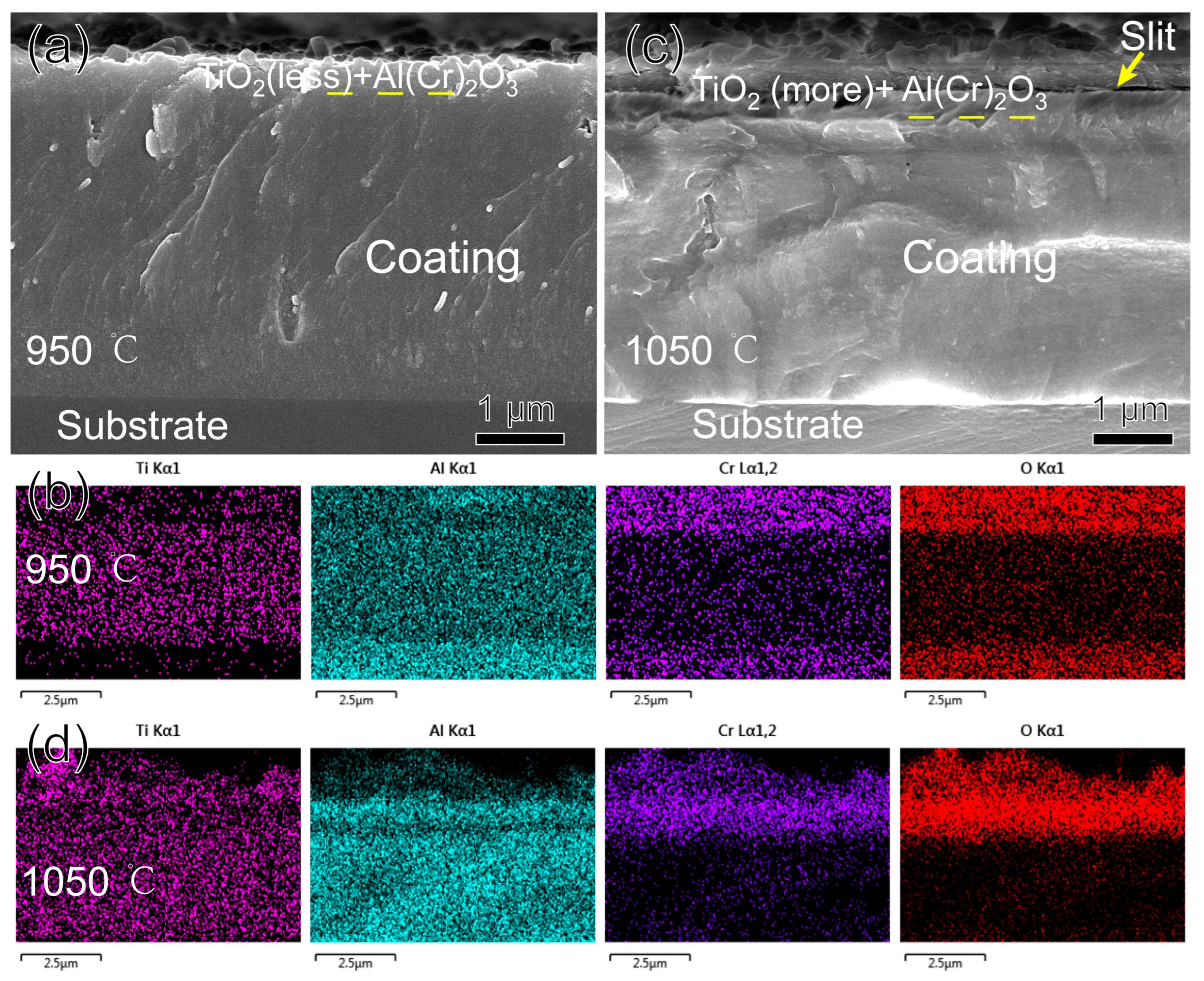

3.3. High-Temperature Oxidation Resistance

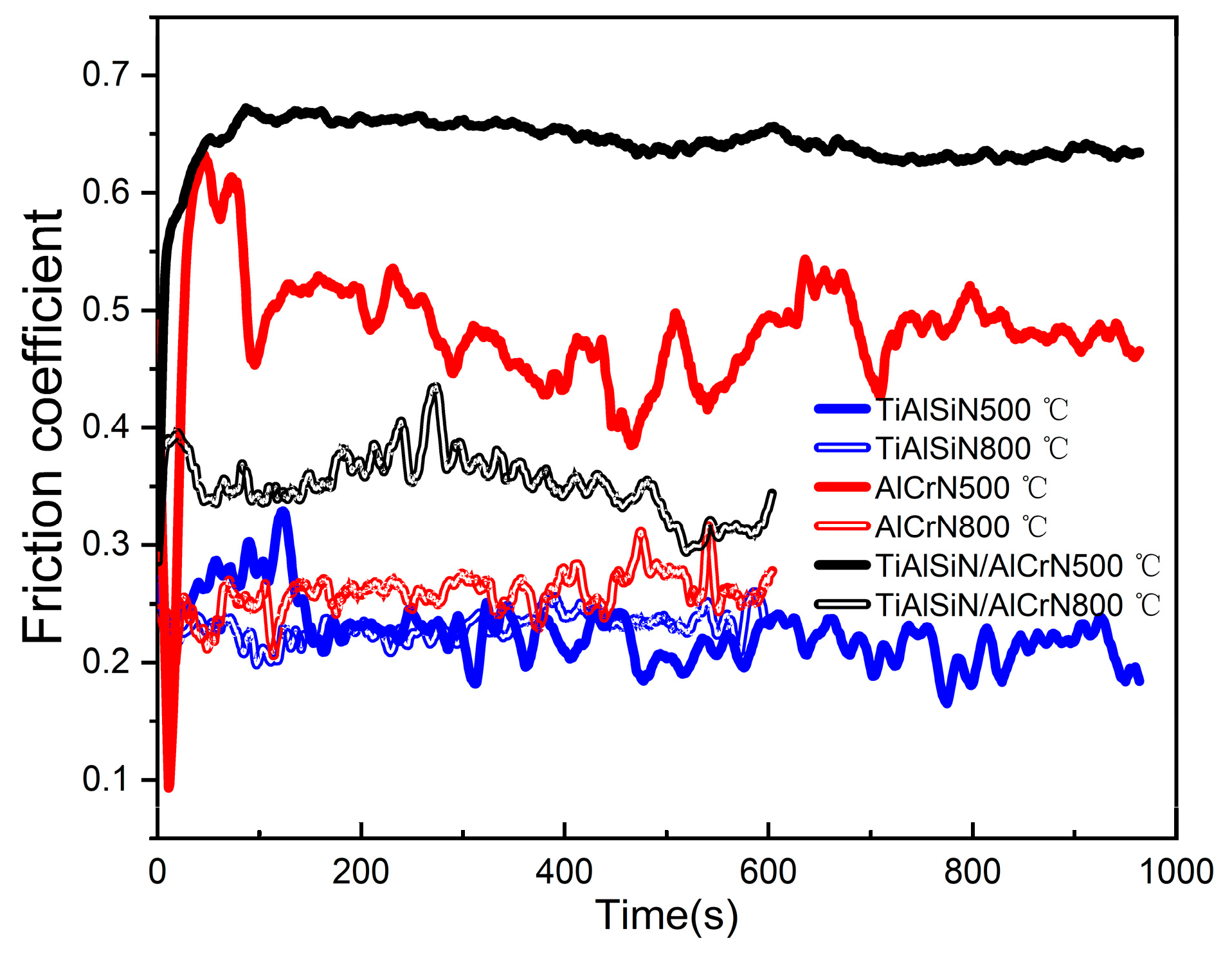

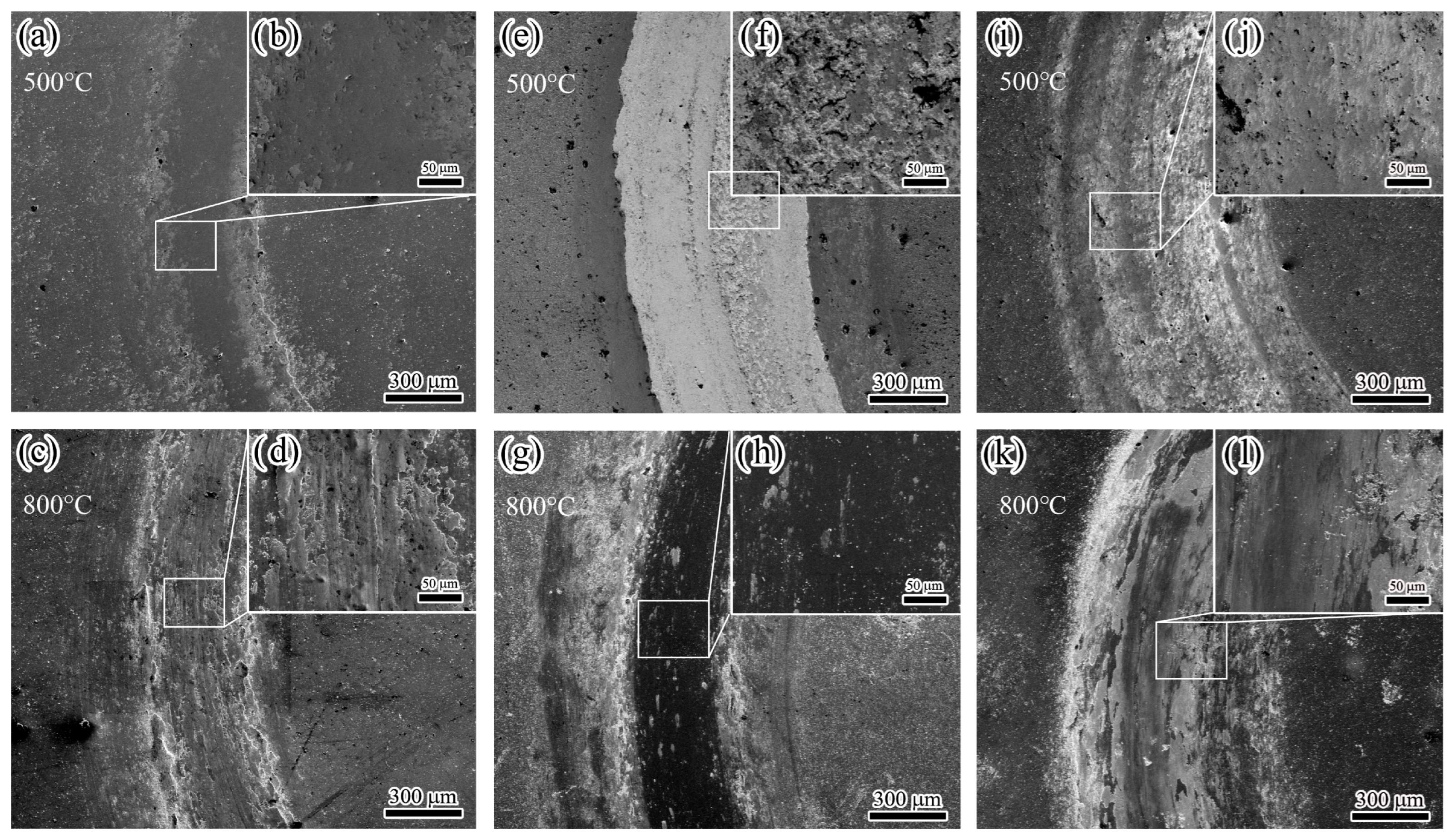

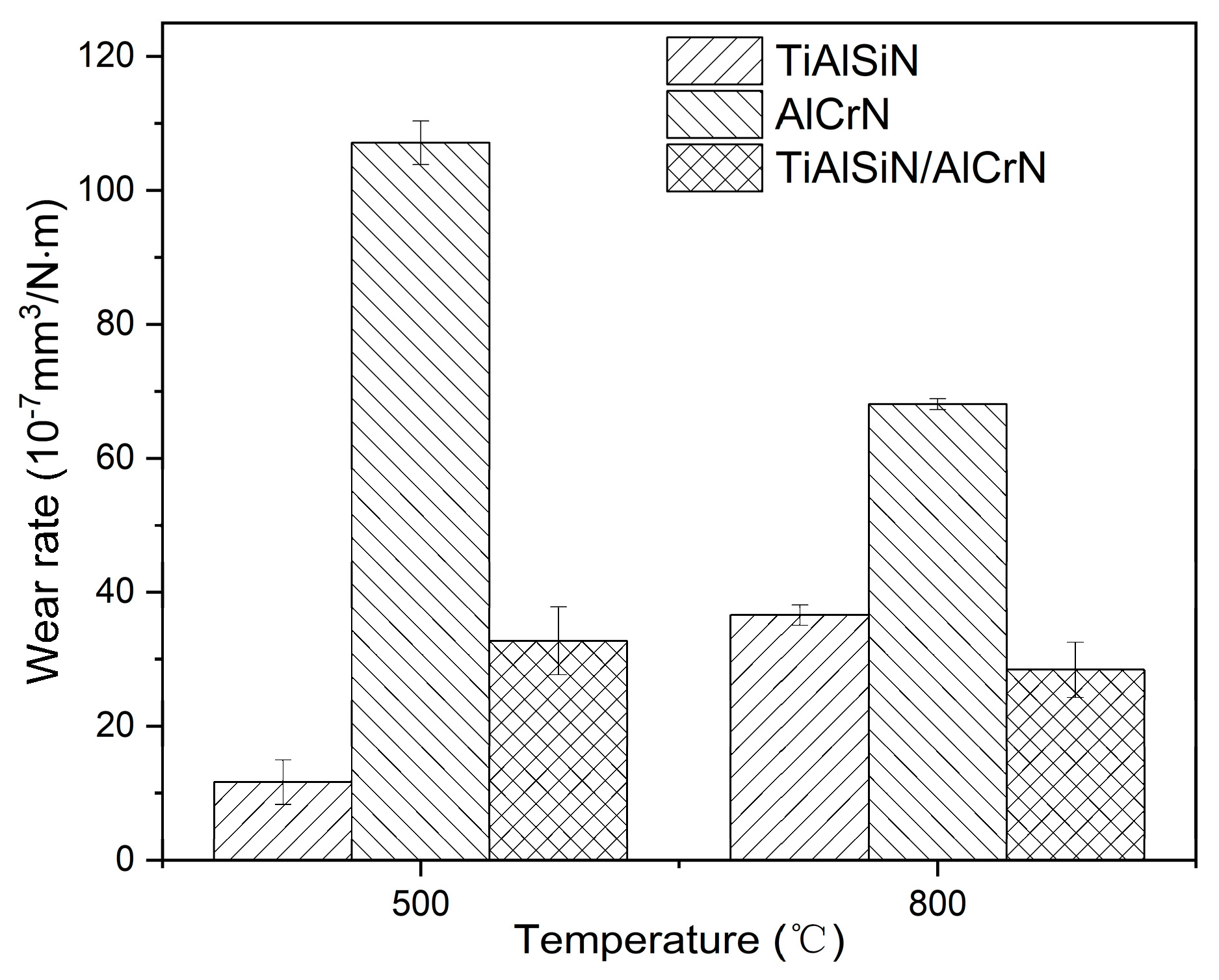

3.4. High-Temperature Wear Resistance

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- He, Q.; Saciotto, V.; DePaiva, J.M.; Guimaraes, M.C.; Kohlscheen, J.; Martins, M.M.; Veldhuis, S.C. Enhancing Tool Performance in High-Speed End Milling of Ti-6Al-4V Alloy: The Role of AlCrN PVD Coatings and Resistance to Chipping Wear. J. Manuf. Mater. Process. 2024, 8, 68. [Google Scholar] [CrossRef]

- Zou, S.; Luo, Z.; Li, Y.; Yuan, L.; Tang, Y.; Zhou, J.; Li, H. Effect of Arc Current on the Microstructure of AlTiN-Coated Tools and Milling of 304 Stainless Steel. Coatings 2024, 14, 704. [Google Scholar] [CrossRef]

- Zhao, F.; Wang, L.; Wang, X. Microstructure and properties of TiAlSiN ultra-hard coatings prepared by plasma immersion ion implantation and deposition with TiAlSi alloy cathodes. Vacuum 2020, 174, 109194. [Google Scholar] [CrossRef]

- Das, C.R.; Rangwala, M.; Ghosh, A. Effect of Si contents on microstructure and mechanical characteristics of TiAlSiN thin film deposited by HiPIMS using different TiSi target compositions. Surf. Coat. Technol. 2024, 476, 130212. [Google Scholar] [CrossRef]

- Das, C.R.; Rangwala, M.; Ghosh, A. Influence of substrate bias voltage on microstructure and mechanical characteristics of TiAlSiN coating deposited by High Power Impulse Magnetron Sputtering (HiPIMS). Surf. Coat. Technol. 2023, 458, 129351. [Google Scholar] [CrossRef]

- Ji, L.; Liu, H.; Huang, C.; Li, S.; Yin, M.; Liu, Z.; Zhao, J.; Xu, L. Effect of TiAlSiN gradient structure design on mechanical properties and microstructure of coatings. Surf. Coat. Technol. 2025, 496, 131617. [Google Scholar] [CrossRef]

- Yin, Z.; Wu, S.; Zhang, Y.; Yan, W.; Dai, S.; Peng, X.; Liao, B.; Zhang, X.; Wang, J.; Ouyang, X. A comparative study on the structure and properties of TiAlSiN coatings deposited by FCVA and HiPIMS. J. Alloys Compd. 2024, 1005, 175844. [Google Scholar] [CrossRef]

- Wan, W.; Zhou, Q.; Liang, M.; Wang, P.; Rao, C.; Ji, S.; Fan, K.; Song, J. Study on the high temperature wear behavior of TiAlSiN coatings deposited on WC-TaC-Co cemented carbides. Tribol. Int. 2024, 200, 110115. [Google Scholar] [CrossRef]

- Liu, Z.R.; Pei, F.; Chen, L.; Mayrhofer, P.H. Effect of Si-addition on structure and thermal stability of Ti-Al-N coatings. J. Alloys Compd. 2022, 917, 165483. [Google Scholar] [CrossRef]

- Sousa, V.F.; Silva, F.; Alexandre, R.; Fecheira, J.; Silva, F. Study of the wear behaviour of TiAlSiN and TiAlN PVD coated tools on milling operations of pre-hardened tool steel. Wear 2021, 476, 203695. [Google Scholar] [CrossRef]

- Liu, J.; Zhu, S.-S.; Deng, X.; Liu, J.-Y.; Wang, Z.-P.; Qu, Z. Cutting performance and wear behavior of AlTiN-and TiAlSiN-coated carbide tools during dry milling of Ti–6Al–4V. Acta Metall. Sin. (Engl. Lett.) 2020, 33, 459–470. [Google Scholar] [CrossRef]

- Kameneva, A.; Kichigin, V. Corrosion, wear, and friction behavior of a number of multilayer two-, three-and multicomponent nitride coatings on different substrates, depending on the phase and elemental composition gradient. Appl. Surf. Sci. 2019, 489, 165–174. [Google Scholar]

- Vorontsov, A.; Filippov, A.; Shamarin, N.; Moskvichev, E.; Novitskaya, O.; Knyazhev, E.; Denisova, Y.; Leonov, A.; Denisov, V.; Tarasov, S. High-Temperature Oxidation of CrN/ZrN Multilayer Coatings. Metals 2022, 12, 1746. [Google Scholar] [CrossRef]

- Liu, H.; Yang, F.-C.; Tsai, Y.-J.; Wang, X.; Li, W.; Chang, C.-L. Effect of modulation structure on the microstructural and mechanical properties of TiAlSiN/CrN thin films prepared by high power impulse magnetron sputtering. Surf. Coat. Technol. 2019, 358, 577–585. [Google Scholar]

- Chang, Y.-Y.; Chang, C.-E. Mechanical properties and tribological performance of multilayered AlCrBN/AlTiBN coatings. Surf. Coat. Technol. 2025, 496, 131691. [Google Scholar]

- Xiao, B.; Zhang, T.F.; Guo, Z.; Li, Z.; Fan, B.; Chen, G.; Xiong, Z.; Wang, Q. Mechanical, oxidation, and cutting properties of AlCrN/AlTiSiN nano-multilayer coatings. Surf. Coat. Technol. 2022, 433, 128094. [Google Scholar]

- Liu, J.; Wang, Y.; Liu, G.; Hua, J.; Deng, X. Properties and Performance of TiAlSiN and AlCrN Monolayer and Multilayer Coatings for Turning Ti-6Al-4V. Coatings 2023, 13, 1229. [Google Scholar] [CrossRef]

- Chen, P.-Y.; Wang, W.-C.; Wu, Y.-T. Experimental investigation of thin film stress by Stoney’s formula. Measurement 2019, 143, 39–50. [Google Scholar]

- Yousaf, M.; Pelenovich, V.; Yang, B.; Liu, C.; Fu, D. Effect of bilayer period on structural and mechanical properties of nanocomposite TiAlN/MoN multilayer films synthesized by cathodic arc ion-plating. Surf. Coat. Technol. 2015, 282, 94–102. [Google Scholar]

- Mei, H.; Yan, K.; Wang, R.; Peng, W.; Huang, K.; Shi, J.; Zhang, D.; Gong, W.; Ren, F.; Wang, Q. Microstructure and mechanical properties of nanomultilayered AlTiN/Cu coatings prepared by a hybrid system of AIP and PDCMS. Ceram. Int. 2023, 49, 226–235. [Google Scholar]

- Kimura, A.; Kawate, M.; Hasegawa, H.; Suzuki, T. Anisotropic lattice expansion and shrinkage of hexagonal TiAlN and CrAlN films. Surf. Coat. Technol. 2003, 169, 367–370. [Google Scholar] [CrossRef]

- Mayrhofer, P.H.; Mitterer, C.; Musil, J. Structure–property relationships in single- and dual-phase nanocrystalline hard coatings. Surf. Coat. Technol. 2003, 174–175, 725–731. [Google Scholar] [CrossRef]

- Philippon, D.; Godinho, V.; Nagy, P.M.; Delplancke-Ogletree, M.P.; Fernández, A. Endurance of TiAlSiN coatings: Effect of Si and bias on wear and adhesion. Wear 2011, 270, 541–549. [Google Scholar] [CrossRef]

- Kumar, P.N.; Kannan, S. Sequential elucidation of the β-Ca3(PO4)2/TiO2 composite development from the solution precursors. Dalton Trans. 2017, 46, 3229–3239. [Google Scholar]

- Shi, T.; Duan, Y.; Lv, K.; Hu, Z.; Li, Q.; Li, M.; Li, X. Photocatalytic oxidation of acetone over high thermally stable TiO2 nanosheets with exposed (001) facets. Front. Chem. 2018, 6, 175. [Google Scholar]

- Xin, L.; Chen, Q.; Teng, Y.; Wang, W.; Sun, A.; Zhu, S.; Wang, F. Effects of silicon and multilayer structure of TiAl (Si) N coatings on the oxidation resistance of Ti6Al4V. Surf. Coat. Technol. 2013, 228, 48–58. [Google Scholar]

- Chang, Y.-Y.; Hsiao, C.-Y. High temperature oxidation resistance of multicomponent Cr–Ti–Al–Si–N coatings. Surf. Coat. Technol. 2009, 204, 992–996. [Google Scholar] [CrossRef]

- Pfeiler, M.; Zechner, J.; Penoy, M.; Michotte, C.; Mitterer, C.; Kathrein, M. Improved oxidation resistance of TiAlN coatings by doping with Si or B. Surf. Coat. Technol. 2009, 203, 3104–3110. [Google Scholar]

- Vennemann, A.; Stock, H.R.; Kohlscheen, J.; Rambadt, S.; Erkens, G. Oxidation resistance of titanium–aluminium–silicon nitride coatings. Surf. Coat. Technol. 2003, 174–175, 408–415. [Google Scholar]

- Zhang, X.D.; Chen, L.; Wang, G.Y.; Hu, C.; Du, J.W. Influence of CrAlN layers on the microstructure, thermal stability, oxidation and corrosion resistance of AlN/CrAlN multilayers. Mater. Charact. 2024, 214, 114051. [Google Scholar]

- Reiter, A.; Mitterer, C.; Sartory, B. Oxidation of arc-evaporated Al1− xCrxN coatings. J. Vac. Sci. Technol. A 2007, 25, 711–720. [Google Scholar] [CrossRef]

- Xu, Y.; Chen, L.; Liu, Z.; Pei, F.; Du, Y. Influence of Ti on the mechanical properties, thermal stability and oxidation resistance of Al–Cr–N coatings. Vacuum 2015, 120, 127–131. [Google Scholar] [CrossRef]

- Jie, S.; An, S.; Pengjiao, Z.; Junzhou, L. Microstructure, mechanical performance, thermal stability, and oxidation resistance of AlCrN/AlCrBN nano-multilayer coating. Surf. Coat. Technol. 2024, 493, 131301. [Google Scholar]

- Polcar, T.; Cavaleiro, A. High-temperature tribological properties of CrAlN, CrAlSiN and AlCrSiN coatings. Surf. Coat. Technol. 2011, 206, 1244–1251. [Google Scholar] [CrossRef]

| Target | Coating | Thickness (μm) | Chemical Composition (at.%) | ||||

|---|---|---|---|---|---|---|---|

| Al | Cr | Ti | Si | N | |||

| Ti0.45Al0.45Si0.10 | TiAlSiN | 3.69 | 20.22 | − | 22.66 | 3.89 | 53.23 |

| Al0.7Cr0.3 | AlCrN | 3.63 | 33.81 | 18.14 | − | − | 48.05 |

| Ti0.45Al0.45Si0.10 and Al0.7Cr0.3 | TiAlSiN/AlCrN | 3.52 | 27.43 | 7.38 | 11.71 | 2.27 | 51.21 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Mei, H.; Hua, J.; Wang, J.; Wang, Y.; Yi, G.; Deng, X. High-Temperature Oxidation and Wear Resistance of TiAlSiN/AlCrN Multilayer Coatings Prepared by Multi-Arc Ion Plating. Nanomaterials 2025, 15, 503. https://doi.org/10.3390/nano15070503

Liu J, Mei H, Hua J, Wang J, Wang Y, Yi G, Deng X. High-Temperature Oxidation and Wear Resistance of TiAlSiN/AlCrN Multilayer Coatings Prepared by Multi-Arc Ion Plating. Nanomaterials. 2025; 15(7):503. https://doi.org/10.3390/nano15070503

Chicago/Turabian StyleLiu, Jie, Haijuan Mei, Junfang Hua, Juan Wang, Yongchao Wang, Genmiao Yi, and Xin Deng. 2025. "High-Temperature Oxidation and Wear Resistance of TiAlSiN/AlCrN Multilayer Coatings Prepared by Multi-Arc Ion Plating" Nanomaterials 15, no. 7: 503. https://doi.org/10.3390/nano15070503

APA StyleLiu, J., Mei, H., Hua, J., Wang, J., Wang, Y., Yi, G., & Deng, X. (2025). High-Temperature Oxidation and Wear Resistance of TiAlSiN/AlCrN Multilayer Coatings Prepared by Multi-Arc Ion Plating. Nanomaterials, 15(7), 503. https://doi.org/10.3390/nano15070503