Experimental Investigation of the Effect of Nanofluid Utilization on Heat Transfer Performance in Unmanned Aircraft Radiators with Various Spring-Type Fins

Abstract

1. Introduction

2. Materials and Methods

2.1. Nanofluid Preparation

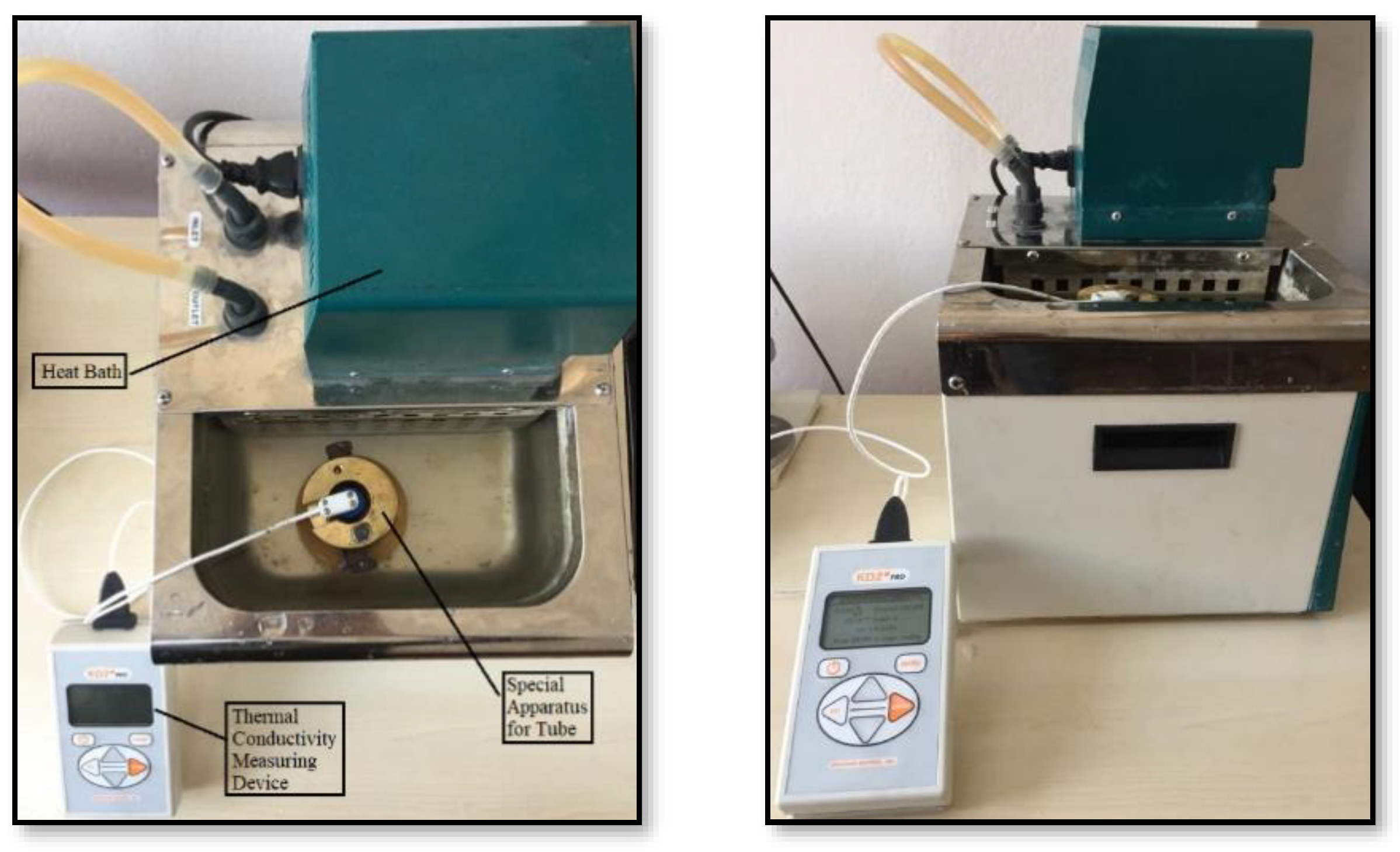

2.2. Thermal Conductivity Measurements

2.3. Viscosity Measurements

2.4. Density Measurements

2.5. Specific Heat Measurements

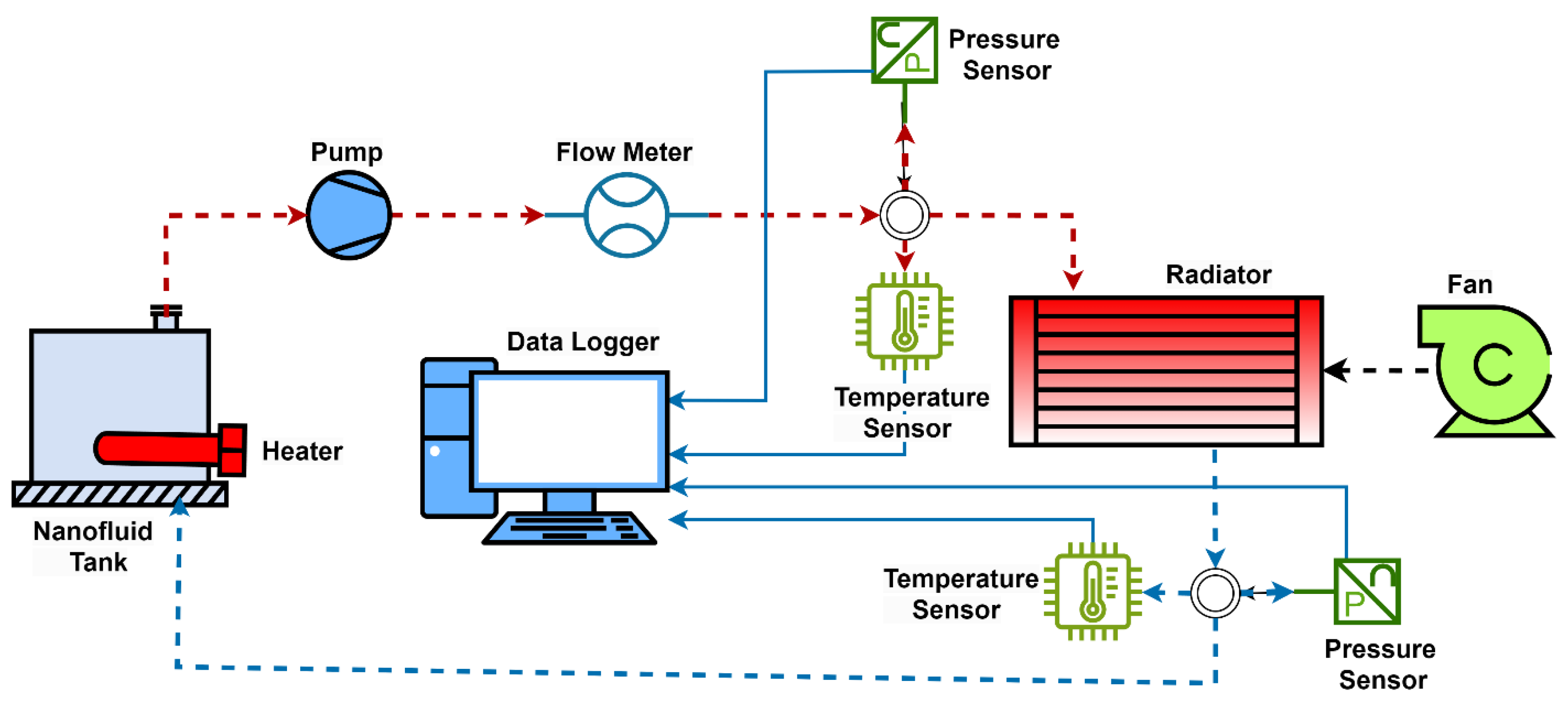

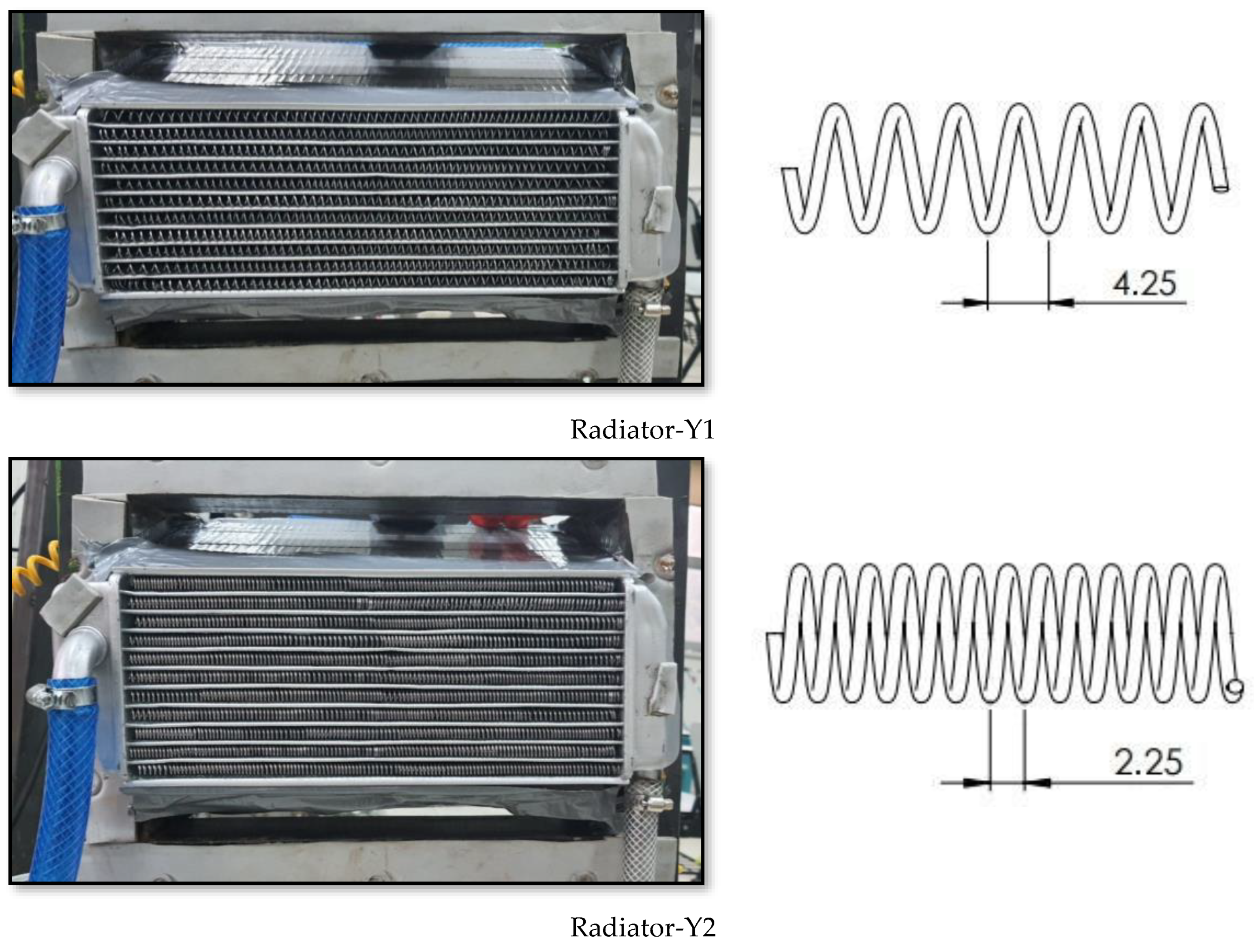

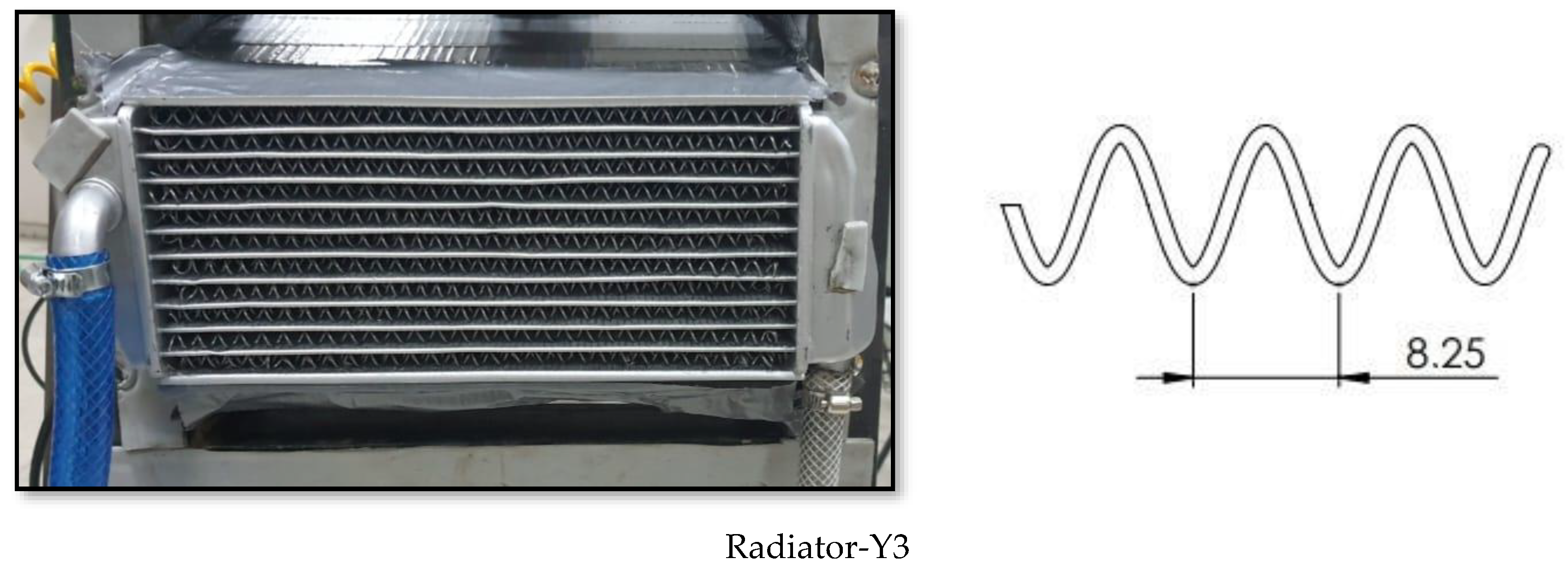

2.6. Conducting the Experiments

2.7. Heat Tansfer Analyis

3. Research Findings and Discussion

4. Conclusions

5. Uncertainty Analysis

6. Suggestions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Adun, H.; Adedeji, M.; Dagbasi, M.; Babatunde, A. Amelioration of thermodynamic performance and environmental analysis of an integrated solar power generation system with storage capacities using optimized ternary hybrid nanofluids. J. Energy Storage 2022, 51, 104531. [Google Scholar] [CrossRef]

- Sekhar, Y.R.; Sharma, K.V.; Naik, M.T.; Sundar, L.S. Experimental investigations on thermal conductivity of water and Al2O3 nanofluids at low concentrations. Int. J. Nanoparticles 2012, 5, 300–315. [Google Scholar] [CrossRef]

- Bozorgan, N.; Krishnakumar, K.; Bozorgan, N. Numerical Study on Application of CuO-Water Nanofluid in Automotive Diesel Engine Radiator. MME 2012, 2, 130–136. [Google Scholar] [CrossRef]

- Madhukesh, J.K.; Sarris, I.E.; Prasannakumara, B.C.; Abdulrahman, A. Investigation of thermal performance of ternary hybrid nanofluid flow in a permeable inclined cylinder/plate. Energies 2023, 16, 2630. [Google Scholar] [CrossRef]

- Saba, F.; Ahmed, N.; Khan, U.; Mohyud-Din, S.T. A novel coupling of (CNT-Fe3O4/H2O) hybrid nanofluid for improvements in heat transfer for flow in an asymmetric channel with dilating/squeezing walls. Int. J. Heat Mass Transf. 2019, 136, 186–195. [Google Scholar] [CrossRef]

- Nabil, M.F.; Azmi, W.H.; Hamid, K.A.; Mamat, R.; Hagos, F.Y. An experimental study on the thermal conductivity and dynamic viscosity of TiO2-SiO2 nanofluids in water: Ethylene glycol mixture. Int. Commun. Heat Mass Transf. 2017, 86, 181–189. [Google Scholar] [CrossRef]

- Soylu, S.K.; Atmaca, İ.; Asiltürk, M.; Doğan, A. Improving heat transfer performance of an automobile radiator using Cu and Ag doped TiO2 based nanofluids. Appl. Therm. Eng. 2019, 157, 113743. [Google Scholar] [CrossRef]

- Asadi, A.; Asadi, M.; Rezaniakolaei, A.; Rosendahl, L.A.; Afrand, M.; Wongwises, S. Heat transfer efficiency of Al2O3-MWCNT/thermal oil hybrid nanofluid as a cooling fluid in thermal and energy management applications: An experimental and theoretical investigation. Int. J. Heat Mass Transf. 2018, 117, 474–486. [Google Scholar] [CrossRef]

- Jibhakate, R.; Nirwan, N.; Nandanwar, Y.; Rambhad, K.S. Thermal analysis of hybrid nanofluid flowing inside the automobile radiator. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Jilte, R.; Afzal, A.; Ağbulut, Ü.; Shaik, S.; Khan, S.A.; Linul, E.; Asif, M. Battery thermal management of a novel helical channeled cylindrical Li-ion battery with nanofluid and hybrid nanoparticle-enhanced phase change material. Int. J. Heat Mass Transf. 2023, 216, 124547. [Google Scholar] [CrossRef]

- Bhogare, R.A.; Kothawale, B.S. Performance investigation of automobile radiator operated with Al2O3 based nanofluid. IOSR J. Mech. Civ. Eng. 2014, 11, 23–30. [Google Scholar]

- Ambreen, T.; Saleem, A.; Park, C.W. Thermal efficiency of eco-friendly MXene based nanofluid for performance enhancement of a pin-fin heat sink: Experimental and numerical analyses. Int. J. Heat Mass Transf. 2022, 186, 122451. [Google Scholar]

- Nirnjalkuma, S.; Gopal, P. Design and development of an automobile radiator test rig and development of heat transfer correlations for nanofluid solutions. J. Chem. Pharm. Sci. 2015, 297–299. [Google Scholar]

- Duangthongsuk, W.; Wongwises, S. A comparison of the heat transfer performance and pressure drop of nanofluid-cooled heat sinks with different miniature pin fin configurations. Exp. Therm. Fluid Sci. 2015, 69, 111–118. [Google Scholar]

- Topuz, A.; Engin, T.; Alper Özalp, A.; Erdoğan, B.; Mert, S.; Yeter, A. Experimental investigation of optimum thermal performance and pressure drop of water-based Al2O3, TiO2 and ZnO nanofluids flowing inside a circular microchannel. J. Therm. Anal. Calorim. 2018, 131, 2843–2863. [Google Scholar]

- Topuz, A.; Engin, T.; Erdoğan, B.; Mert, S.; Yeter, A. Experimental investigation of pressure drop and cooling performance of an automobile radiator using Al2O3-water+ ethylene glycol nanofluid. Heat Mass Transf. 2020, 56, 2923–2937. [Google Scholar]

- Wang, X.; Wen, Q.; Yang, J.; Shittu, S.; Wang, X.; Zhao, X.; Wang, Z. Heat transfer and flow characteristic of a flat confined loop thermosyphon with ternary hybrid nanofluids for electronic devices cooling. Appl. Therm. Eng. 2023, 221, 119758. [Google Scholar]

- Sarvar-Ardeh, S.; Rafee, R.; Rashidi, S. Hybrid nanofluids with temperature-dependent properties for use in double-layered microchannel heat sink; hydrothermal investigation. J. Taiwan Inst. Chem. Eng. 2021, 124, 53–62. [Google Scholar]

- Selimefendigil, F.; Oztop, H.F. Cooling of a hot elastic plate by using hybrid channel-jet impingement system with ternary nanofluid and efficient computations by using ANN assisted CFD. Eng. Anal. Bound. Elem. 2024, 166, 105807. [Google Scholar]

- Abbasi, A.; Khan, S.U.; Gulzar, S.; Khan, M.I.; Abdullaev, S.; Farooq, W.; Ali, S. Comparative thermal examination of water conveying aluminum oxide, copper and nickel nanoparticles subject to stagnation point flow. S. Afr. J. Chem. Eng. 2024, 48, 103–111. [Google Scholar]

- Kumar, V.; Sarkar, J. Particle ratio optimization of Al2O3-MWCNT hybrid nanofluid in minichannel heat sink for best hydrothermal performance. Appl. Therm. Eng. 2020, 165, 114546. [Google Scholar]

- Kumar, A.; Chand, P.; Hassan, M.A. Louvered finned car radiator with MWCNT-SiO2 hybrid nanofluid: An experimental approach. Powder Technol. 2023, 415, 118176. [Google Scholar]

- Kumar, A.; Hassan, M.A.; Chand, P. Heat transport in nanofluid coolant car radiator with louvered fins. Powder Technol. 2020, 376, 631–642. [Google Scholar]

- Habibian, S.H.; Abolmaali, A.M.; Afshin HJ AT, E. Numerical investigation of the effects of fin shape, antifreeze and nanoparticles on the performance of compact finned-tube heat exchangers for automobile radiator. Appl. Therm. Eng. 2018, 133, 248–260. [Google Scholar]

- Feleke, D.S.; Getie, M.Z.; Minale, T.A. Numerical investigation of louver edges effect on the performances of louvered fin compact heat exchanger. Heliyon 2024, 10, e27254. [Google Scholar]

- Subhedar, D.G.; Ramani, B.M.; Gupta, A. Experimental investigation of heat transfer potential of Al2O3/Water-Mono Ethylene Glycol nanofluids as a car radiator coolant. Case Stud. Therm. Eng. 2018, 11, 26–34. [Google Scholar]

- Lavate, R.S.; Sutar, K.B.; Saini, A.; Shakshi, A.; Sethi, P. Heat Transfer Enhancement in Micro-fin Tube Using Coil Wire Insertions of Different Lengths. In Proceedings of the Techno-Societal 2016, International Conference on Advanced Technologies for Societal Applications, Pandharpur, India, 20–21 December 2016; Springer International Publishing: Cham, Switzerland, 2022; pp. 797–805. [Google Scholar]

- Ravisankar, R. Application of nanotechnology to improve the performance of tractor radiator using cu-water nanofluid. J. Therm. Eng. 2018, 4, 2188–2200. [Google Scholar]

- Madhesh, D.; Kalaiselvam, S. Experimental analysis of hybrid nanofluid as a coolant. Procedia Eng. 2014, 97, 1667–1675. [Google Scholar]

- Moghadassi, A.; Ghomi, E.; Parvizian, F. A numerical study of water based Al2O3 and Al2O3–Cu hybrid nanofluid effect on forced convective heat transfer. Int. J. Therm. Sci. 2015, 92, 50–57. [Google Scholar]

- Erdoğan, B.; Zengin, I.; Mert, S.; Topuz, A.; Engin, T. The experimental study of the entropy generation and energy performance of nano-fluid flow for automotive radiators. Eng. Sci. Technol. Int. J. 2021, 24, 655–664. [Google Scholar]

- Palaniappan, B.; Ramasamy, V. Thermodynamic analysis of fly ash nanofluid for automobile (heavy vehicle) radiators. J. Therm. Anal. Calorim. 2019, 136, 223–233. [Google Scholar]

- Elsaid, A.M. Experimental study on the heat transfer performance and friction factor characteristics of Co3O4 and Al2O3 based H2O/(CH2OH)2 nanofluids in a vehicle engine radiator. Int. Commun. Heat Mass Transf. 2019, 108, 104263. [Google Scholar]

- Ben-Mansour, R.; Habib, M.A. Use of nanofluids for improved natural cooling of discretely heated cavities. Adv. Mech. Eng. 2013, 5, 383267. [Google Scholar]

- Rostamani, M.; Hosseinizadeh, S.F.; Gorji, M.; Khodadadi, J.M. Numerical study of turbulent forced convection flow of nanofluids in a long horizontal duct considering variable properties. Int. Commun. Heat Mass Transf. 2010, 37, 1426–1431. [Google Scholar]

- Bianco, V.; Manca, O.; Nardini, S. Numerical investigation on nanofluids turbulent convection heat transfer inside a circular tube. Int. J. Therm. Sci. 2011, 50, 341–349. [Google Scholar]

- Sajid, M.U.; Ali, H.M. Thermal conductivity of hybrid nanofluids: A critical review. Int. J. Heat Mass Transf. 2018, 126, 211–234. [Google Scholar]

- Wei, B.; Zou, C.; Yuan, X.; Li, X. Thermo-physical property evaluation of diathermic oil based hybrid nanofluids for heat transfer applications. Int. J. Heat Mass Transf. 2017, 107, 281–287. [Google Scholar]

- Megatif, L.; Ghozatloo, A.; Arimi, A.; Shariati-Niasar, M. Investigation of laminar convective heat transfer of a novel TiO2–carbon nanotube hybrid water-based nanofluid. Exp. Heat Transf. 2016, 29, 124–138. [Google Scholar]

- Farbod, M.; Ahangarpour, A. Improved thermal conductivity of Ag decorated carbon nanotubes water based nanofluids. Phys. Lett. A 2016, 380, 4044–4048. [Google Scholar]

- Ramachandran, R.N.; Ganesan, K.; Asirvatham, L.G. The role of hybrid nanofluids in improving the thermal characteristics of screen mesh cylindrical heat pipes. Therm. Sci. 2016, 20, 2027–2035. [Google Scholar]

- Senthilraja, S.; Vijayakumar, K.; Gangadevi, R. A comparative study on thermal conductivity of Al2O3/water, CuO/water and Al2O3–CuO/water nanofluids. Dig. J. Nanomater. Biostructures 2015, 10, 1449–1458. [Google Scholar]

- Suresh, S.; Venkitaraj, K.P.; Selvakumar, P.; Chandrasekar, M. Synthesis of Al2O3–Cu/water hybrid nanofluids using two step method and its thermo physical properties. Colloids Surf. A Physicochem. Eng. Asp. 2011, 388, 41–48. [Google Scholar] [CrossRef]

- Han, Z.H.; Yang, B.; Kim, S.H.; Zachariah, M.R. Application of hybrid sphere/carbon nanotube particles in nanofluids. Nanotechnology 2007, 18, 105701. [Google Scholar] [CrossRef]

- Botha, S.S.; Ndungu, P.; Bladergroen, B.J. Physicochemical properties of oil-based nanofluids containing hybrid structures of silver nanoparticles supported on silica. Ind. Eng. Chem. Res. 2011, 50, 3071–3077. [Google Scholar] [CrossRef]

- Usman, M.; Hamid, M.; Zubair, T.; Haq, R.U.; Wang, W. Cu-Al2O3/Water hybrid nanofluid through a permeable surface in the presence of nonlinear radiation and variable thermal conductivity via LSM. Int. J. Heat Mass Transf. 2018, 126, 1347–1356. [Google Scholar] [CrossRef]

- Baghbanzadeh, M.; Rashidi, A.; Rashtchian, D.; Lotfi, R.; Amrollahi, A. Synthesis of spherical silica/multiwall carbon nanotubes hybrid nanostructures and investigation of thermal conductivity of related nanofluids. Thermochim. Acta 2012, 549, 87–94. [Google Scholar] [CrossRef]

- Jana, S.; Salehi-Khojin, A.; Zhong, W.H. Enhancement of fluid thermal conductivity by the addition of single and hybrid nano-additives. Thermochim. Acta 2007, 462, 45–55. [Google Scholar] [CrossRef]

- Pathak, S.; Verma, R.; Kumar, P.; Singh, A.; Singhal, S.; Sharma, P.; Jain, K.; Pant, R.P.; Wang, X. Facile synthesis, static, and dynamic magnetic characteristics of varying size double-surfactant-coated mesoscopic magnetic nanoparticles dispersed stable aqueous magnetic fluids. Nanomaterials 2021, 11, 3009. [Google Scholar] [CrossRef]

- Pathak, S.; Jain, K.; Kumar, P.; Wang, X.; Pant, R.P. Improved thermal performance of annular fin-shell tube storage system using magnetic fluid. Appl. Energy 2019, 239, 1524–1535. [Google Scholar] [CrossRef]

- Elsebay, M.; Elbadawy, I.; Shedid, M.H.; Fatouh, M. Numerical resizing study of Al2O3 and CuO nanofluids in the flat tubes of a radiator. Appl. Math. Model. 2016, 40, 6437–6450. [Google Scholar] [CrossRef]

- Arif, U.; Nawaz, M.; Alharbi, S.O.; Saleem, S. Investigation on the impact of thermal performance of fluid due to hybrid nano-structures. J. Therm. Anal. Calorim. 2021, 144, 729–737. [Google Scholar]

- Sahoo, R.R. Thermo-hydraulic characteristics of radiator with various shape nanoparticle-based ternary hybrid nanofluid. Powder Technol. 2020, 370, 19–28. [Google Scholar]

- Rekha Sahoo, R. Effect of various shape and nanoparticle concentration based ternary hybrid nanofluid coolant on the thermal performance for automotive radiator. Heat Mass Transf. 2021, 57, 873–887. [Google Scholar]

- Garayev, A.; Yazgan, E.; Koruyucu, E. Uçak Performans Parametrelerinin Ağirliklandirilmasinda Swara Metodu. Mühendis Ve Makina 2023, 64, 396–416. [Google Scholar]

- Wole-Osho, I.; Okonkwo, E.C.; Abbasoglu, S.; Kavaz, D. Nanofluids in solar thermal collectors: Review and limitations. Int. J. Thermophys. 2020, 41, 157. [Google Scholar]

- Cengel, Y.; Cimbala, J.; Mechanics, F. Heat and Mass Transfer Fundamentals and Application. Mc Graw Hill google schola Feng YT/2014/Discrete element modeling of large scale particle systems-I: Exact scaling laws/Comp. Part Mech 2006, 1, 159–168. [Google Scholar]

- Jang, S.P.; Choi, S.U. Role of Brownian motion in the enhanced thermal conductivity of nanofluids. Appl. Phys. Lett. 2004, 84, 4316–4318. [Google Scholar]

- Shah, R.K.; Sekulic, D.P. Fundamentals of Heat Exchanger Design; John Wiley & Sons: Hoboken, NJ, USA, 2003. [Google Scholar]

- Holman, J.P. Experimental Methods for Engineers, 8th ed.; McGraw-Hill: New York, NY, USA, 2012. [Google Scholar]

| Coolant | Volumetric Concentration Ratio (%) | Density (kg/m3) | Specific Heat (J/kgK) | Thermal Conductivity (W/mK) | Dynamic Viscosity (mPa.s) |

|---|---|---|---|---|---|

| Pure water | 100 | 998.20 | 4190.00 | 0.650 | 1.002 |

| Al2O3 Nanofluid | 0.3 | 1003.80 | 3541.05 | 0.727 | 1.170 |

| ZnO Nanofluid | 0.3 | 999.00 | 3541.44 | 0.769 | 1.090 |

| Hybrid (ZnO-CuO) Nanofluid | 0.15 ZnO 0.15 CuO | 998.20 | 3528.56 | 0.651 | 1.020 |

| Features | Value |

|---|---|

| Brand | Brazing |

| Width × height × depth | 330 mm × 125 mm × 34 mm |

| Channel dimensions (external) | 2.2 mm × 32 mm |

| Channel wall thickness | 0.3 |

| Channel dimensions (internal) | 1.6 mm × 32 mm |

| Number of channels Fin type | 10 Spring |

| Fin pitch | 9 fpi |

| Channel and fin material | Aluminum |

| Fluid Flow Rate | (L/min) | 22 | 20 | |||||

|---|---|---|---|---|---|---|---|---|

| Air Velocity | (m/s) | 8 | 10 | 12 | 8 | 10 | 12 | |

| Radiator-Y1 | Pure water | Cooling power (kW) | 9.475 | 10.086 | 10.545 | 8.197 | 8.336 | 8.614 |

| Fluid outlet temp. (°C) | 63.8 | 63.4 | 63.1 | 64.1 | 64 | 63.8 | ||

| Al2O3 Nanofluid | Cooling power (kW) | 9.779 | 9.909 | 11.337 | 8.182 | 8.654 | 9.480 | |

| Fluid outlet temp. (°C) | 62.5 | 62.4 | 61.3 | 63.1 | 62.7 | 62 | ||

| ZnO Nanofluid | Cooling power (kW) | 9.086 | 9.215 | 9.991 | 7.554 | 7.907 | 8.495 | |

| Fluid outlet temp. (°C) | 63 | 62.9 | 62.3 | 63.6 | 63.3 | 62.8 | ||

| Hibrit (ZnO-CuO) Nanofluid | Cooling power (kW) | 9.978 | 10.107 | 10.623 | 8.249 | 8.719 | 9.540 | |

| Fluid outlet temp. (°C) | 62.3 | 62.2 | 61.8 | 63 | 62.6 | 61.9 | ||

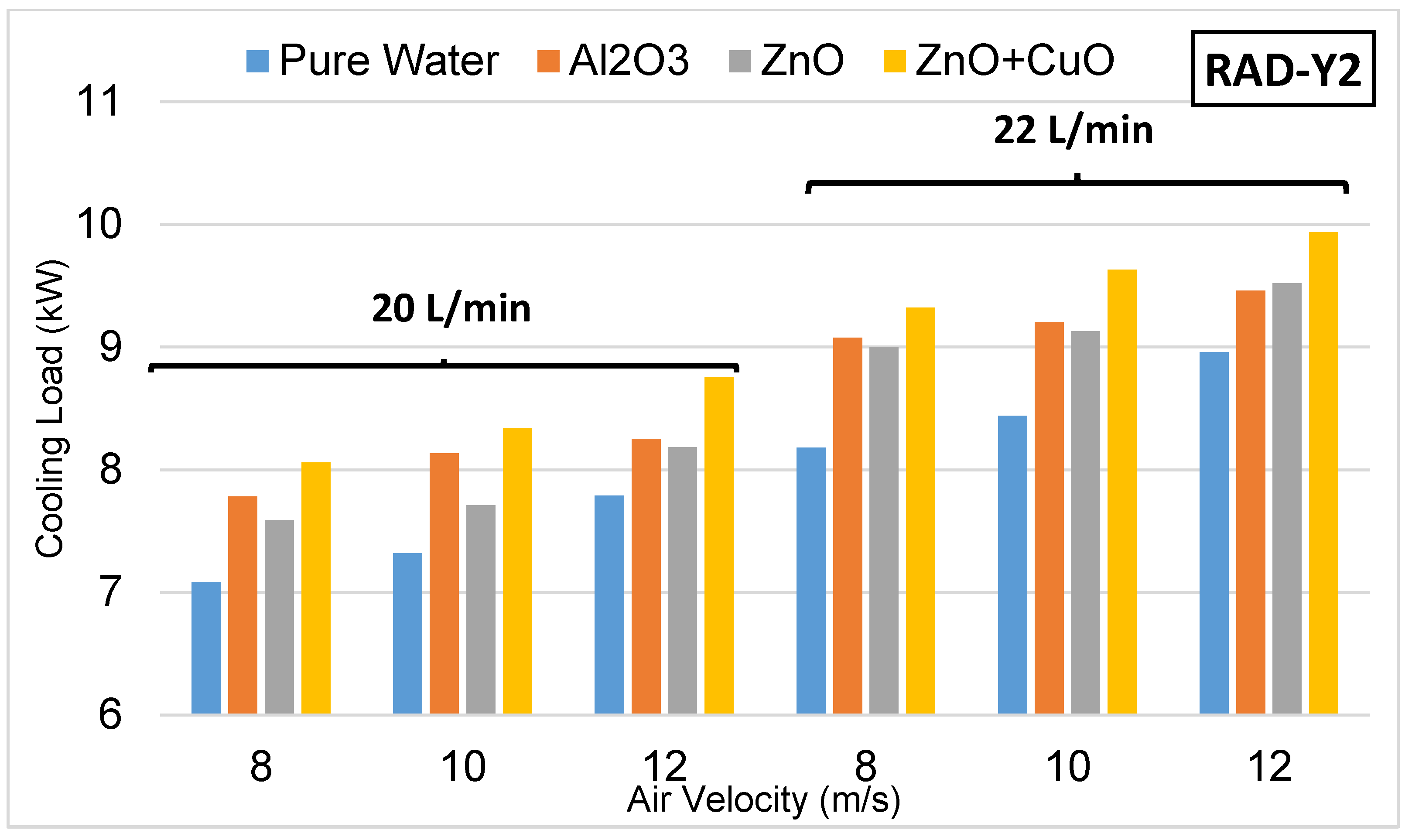

| Fluid Flow Rate | (L/min) | 22 | 20 | |||||

|---|---|---|---|---|---|---|---|---|

| Air Velocity | (m/s) | 8 | 10 | 12 | 8 | 10 | 12 | |

| Radiator-Y2 | Pure water | Cooling power (kW) | 9.322 | 9.628 | 9.934 | 8.058 | 8.336 | 8.753 |

| Fluid outlet temp. (°C) | 63.9 | 63.7 | 63.5 | 64.2 | 64 | 63.7 | ||

| Al2O3 Nanofluid | Cooling power | 9.000 | 9.130 | 9.519 | 7.591 | 7.709 | 8.182 | |

| Fluid outlet temp. (°C) | 63.1 | 63 | 62.7 | 63.6 | 63.5 | 63.1 | ||

| ZnO Nanofluid | Cooling power (kW) | 8.181 | 8.439 | 8.957 | 7.084 | 7.319 | 7.790 | |

| Fluid outlet temp. (°C) | 63.7 | 63.5 | 63.1 | 64 | 63.8 | 63.4 | ||

| Hybrid (ZnO-CuO) Nanofluid | Cooling power (kW) | 9.074 | 9.203 | 9.462 | 7.780 | 8.132 | 8.249 | |

| Fluid outlet temp. (°C) | 63 | 62.9 | 62.7 | 63.4 | 63.1 | 63 | ||

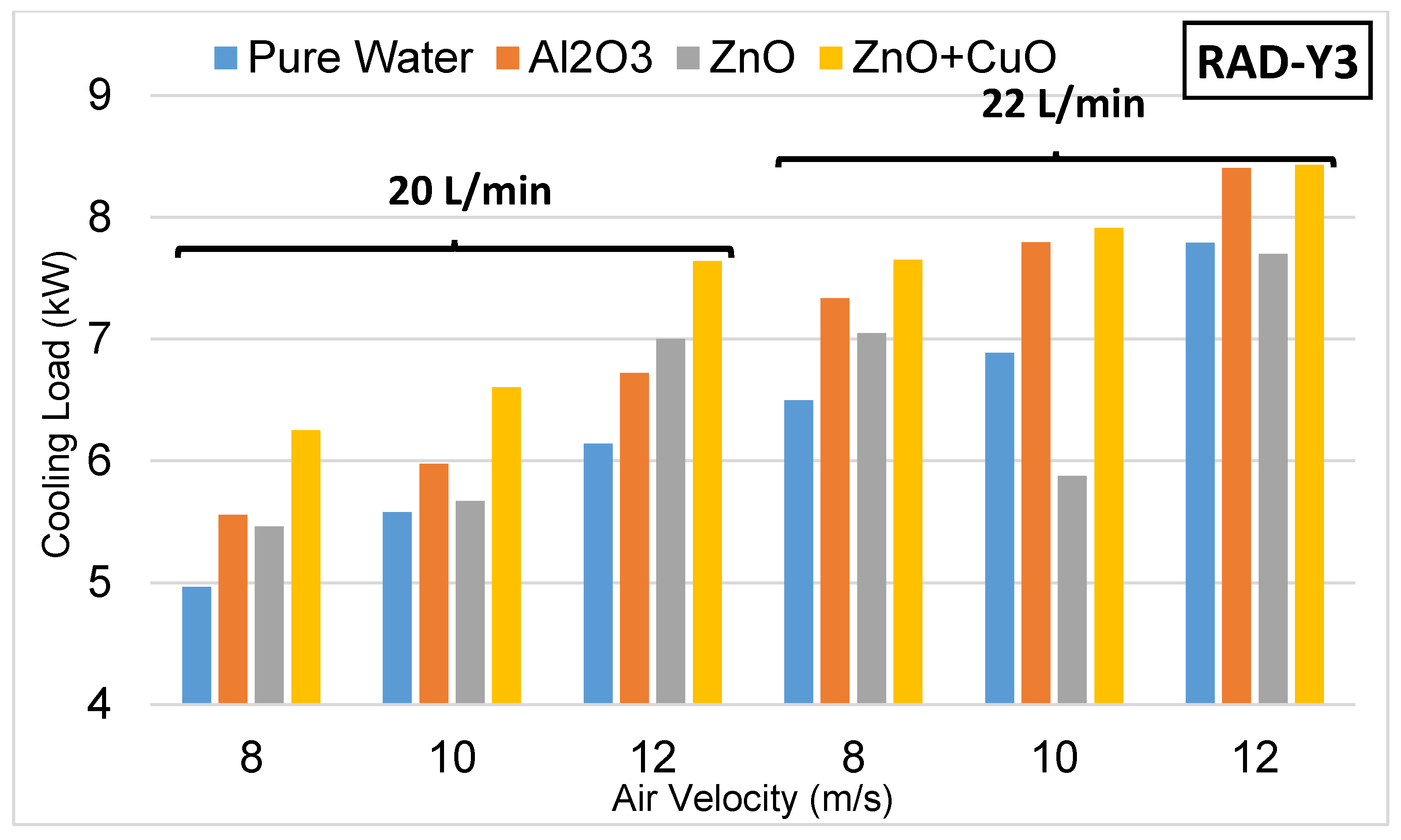

| Fluid Flow Rate | (L/min) | 22 | 20 | |||||

|---|---|---|---|---|---|---|---|---|

| Air Velocity | (m/s) | 8 | 10 | 12 | 8 | 10 | 12 | |

| Radiator-Y3 | Pure water | Cooling power (kW) | 7.335 | 7.794 | 8.405 | 5.557 | 5.974 | 7.641 |

| Fluid outlet temp. (°C) | 65.2 | 64.9 | 64.5 | 66 | 65.7 | 64.5 | ||

| Al2O3 Nanofluid | Cooling power (kW) | 7.049 | 5.877 | 7.700 | 5.461 | 5.579 | 7.000 | |

| Fluid outlet temp. (°C) | 64.6 | 65.5 | 64.1 | 65.4 | 65.3 | 64.1 | ||

| ZnO Nanofluid | Cooling power (kW) | 6.497 | 6.886 | 7.792 | 4.963 | 5.671 | 6.142 | |

| Fluid outlet temp. (°C) | 65 | 64.7 | 64 | 65.8 | 65.2 | 64.8 | ||

| Hybrid (ZnO-CuO) Nanofluid | Cooling power (kW) | 7.653 | 7.911 | 8.428 | 6.252 | 6.604 | 6.722 | |

| Fluid outlet temp. (°C) | 64.1 | 63.9 | 63.5 | 64.7 | 64.4 | 64.3 | ||

| No | Instrument | Range | Variable Measured | Total Uncertainty | Uncertainty | |

|---|---|---|---|---|---|---|

| Min | Max | |||||

| 1 | Temperature sensor | −40 + 125 °C | Fluid inlet temperature, Tin | ±1.02 °C | 1.0726% | 1.0759% |

| 2 | Temperature sensor | −40 + 125 °C | Fluid outlet temperature, Tout | ±1.02 °C | 1.1384% | 1.3747% |

| 3 | Pressure transmitter | 0–1 bar | Pressure drop, ΔP | × (90−20) ±0.028 bar | 12.727% | - |

| 4 | Flowmeter | 1–90 L/min | Volume flow rate, ∀˙ | ±0.1 L/min | 0.04% | 1.0% |

| 5 | Thermophysical properties | Thermal conductivity, k Dynamic viscosity, µ Specific heat, Cp | ±6.13% ±7.26% ±0.19% ±2.5% | 0.19% | 7.26% | |

| No | Result | Maximum Uncertainty |

|---|---|---|

| 1 | Mass flow rate, = | = [(0.03%)2 +(1.0%)2]0.5 = 1.00% |

| 2 | Temperature difference of fluid from inlet to outlet, ΔT = Tout − Tin | = = = 26.23% |

| 3 | Heat transfer, = cpΔT | = = = 26.25% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Erdoğan, B.; Güneş, A.; Çakmak, G. Experimental Investigation of the Effect of Nanofluid Utilization on Heat Transfer Performance in Unmanned Aircraft Radiators with Various Spring-Type Fins. Nanomaterials 2025, 15, 489. https://doi.org/10.3390/nano15070489

Erdoğan B, Güneş A, Çakmak G. Experimental Investigation of the Effect of Nanofluid Utilization on Heat Transfer Performance in Unmanned Aircraft Radiators with Various Spring-Type Fins. Nanomaterials. 2025; 15(7):489. https://doi.org/10.3390/nano15070489

Chicago/Turabian StyleErdoğan, Beytullah, Abdulsamed Güneş, and Gülşah Çakmak. 2025. "Experimental Investigation of the Effect of Nanofluid Utilization on Heat Transfer Performance in Unmanned Aircraft Radiators with Various Spring-Type Fins" Nanomaterials 15, no. 7: 489. https://doi.org/10.3390/nano15070489

APA StyleErdoğan, B., Güneş, A., & Çakmak, G. (2025). Experimental Investigation of the Effect of Nanofluid Utilization on Heat Transfer Performance in Unmanned Aircraft Radiators with Various Spring-Type Fins. Nanomaterials, 15(7), 489. https://doi.org/10.3390/nano15070489