Uniform Molecular Alignment on Ag-Doped Nickel Oxide Films

Abstract

1. Introduction

2. Materials and Methods

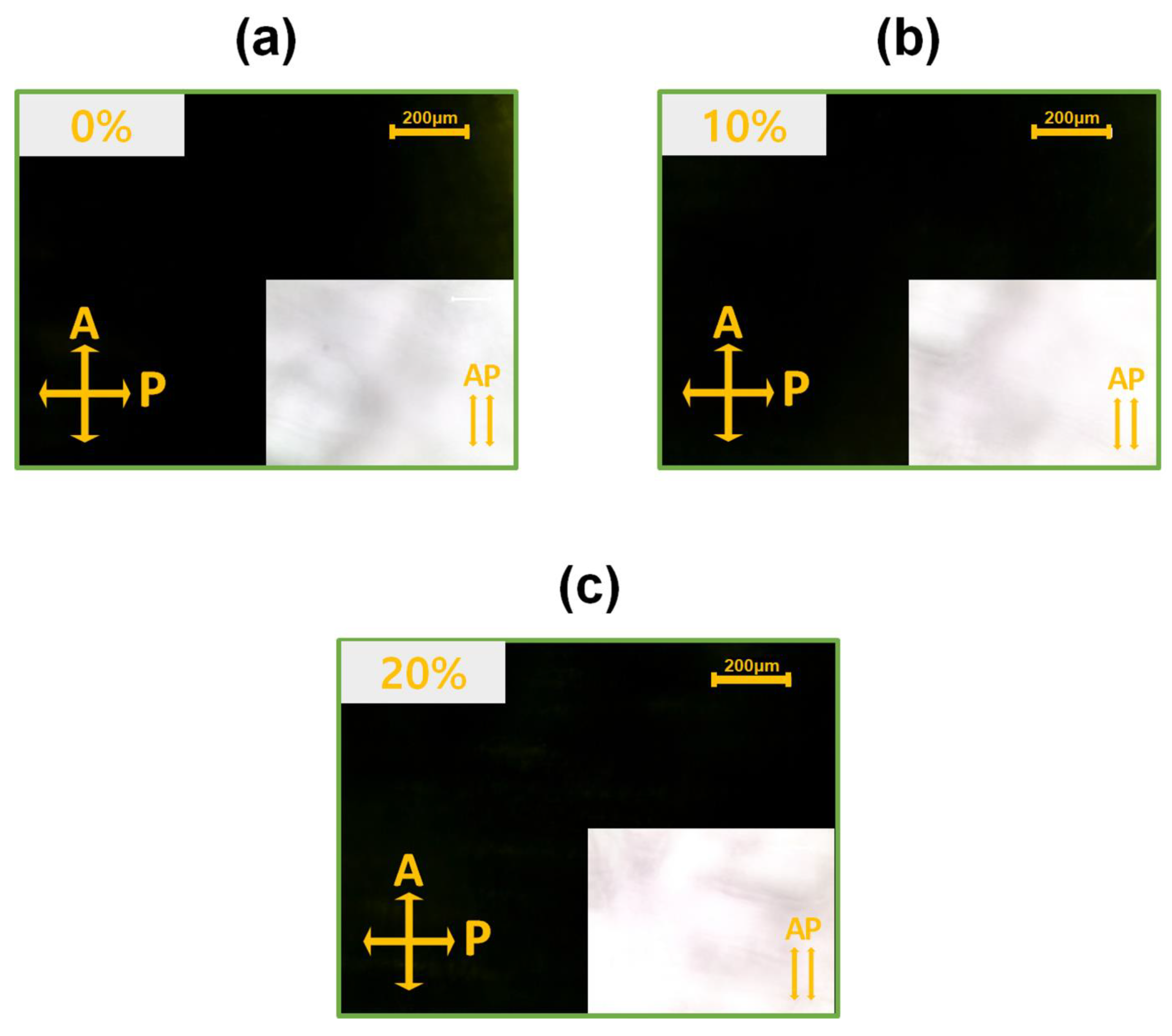

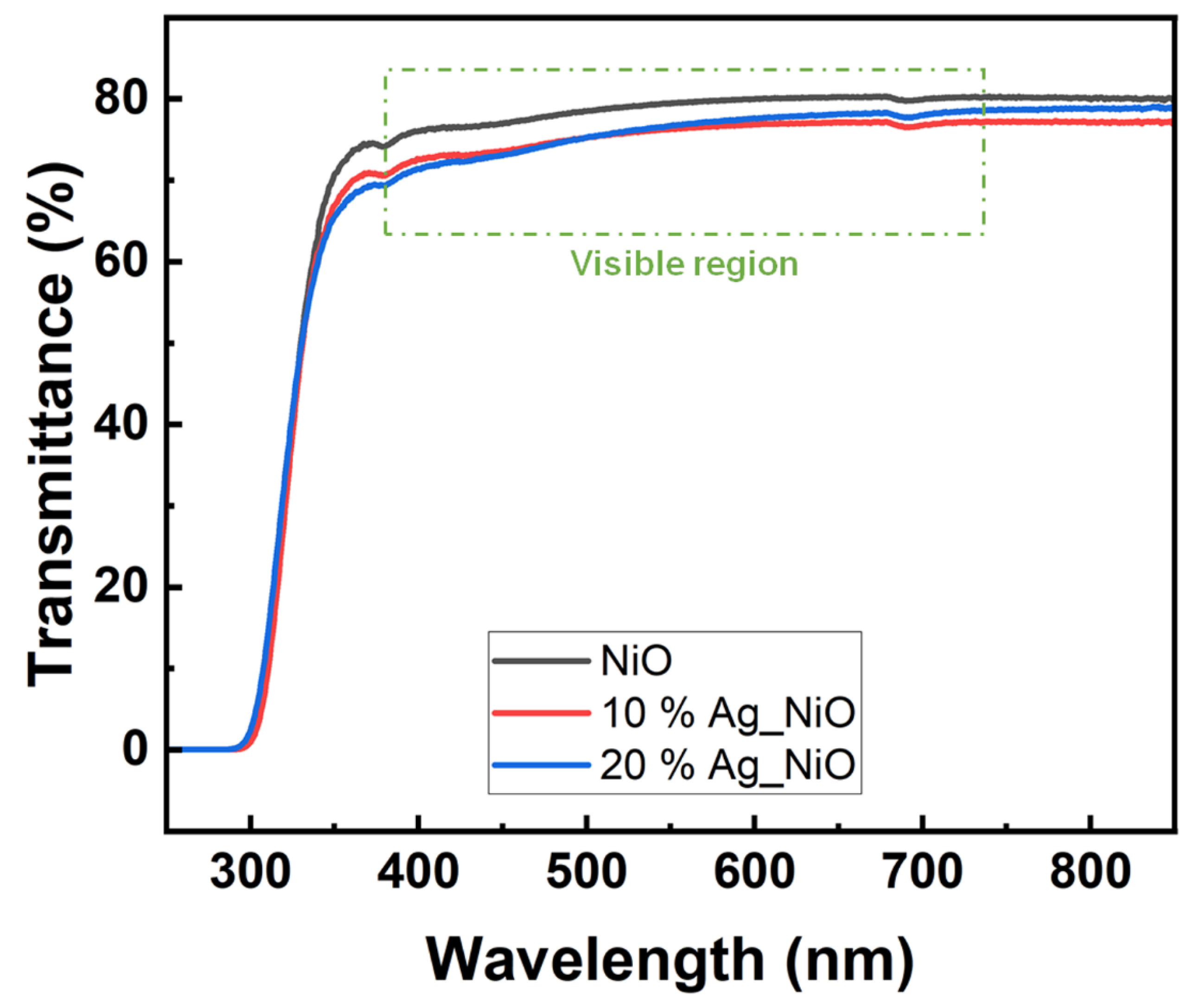

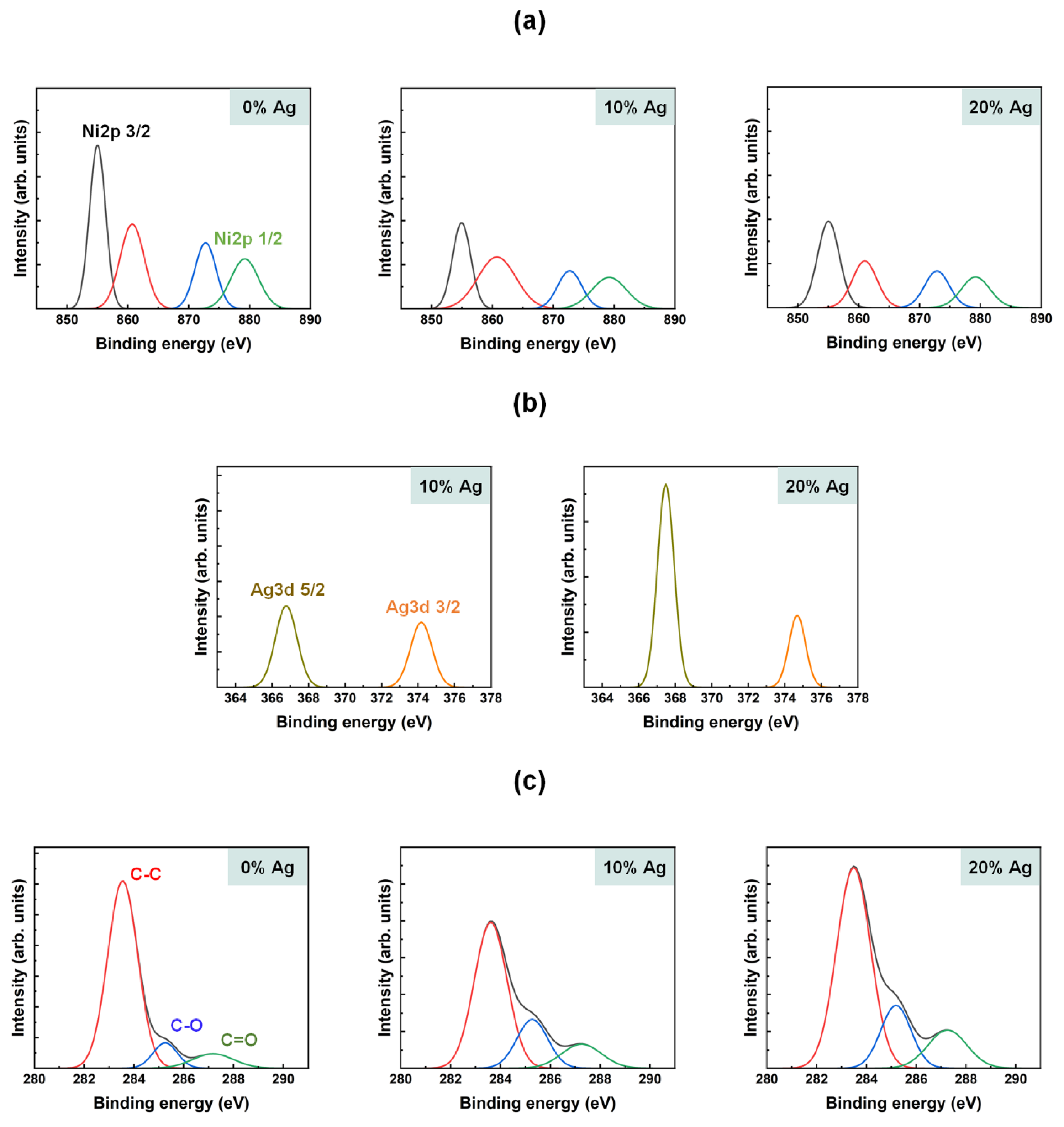

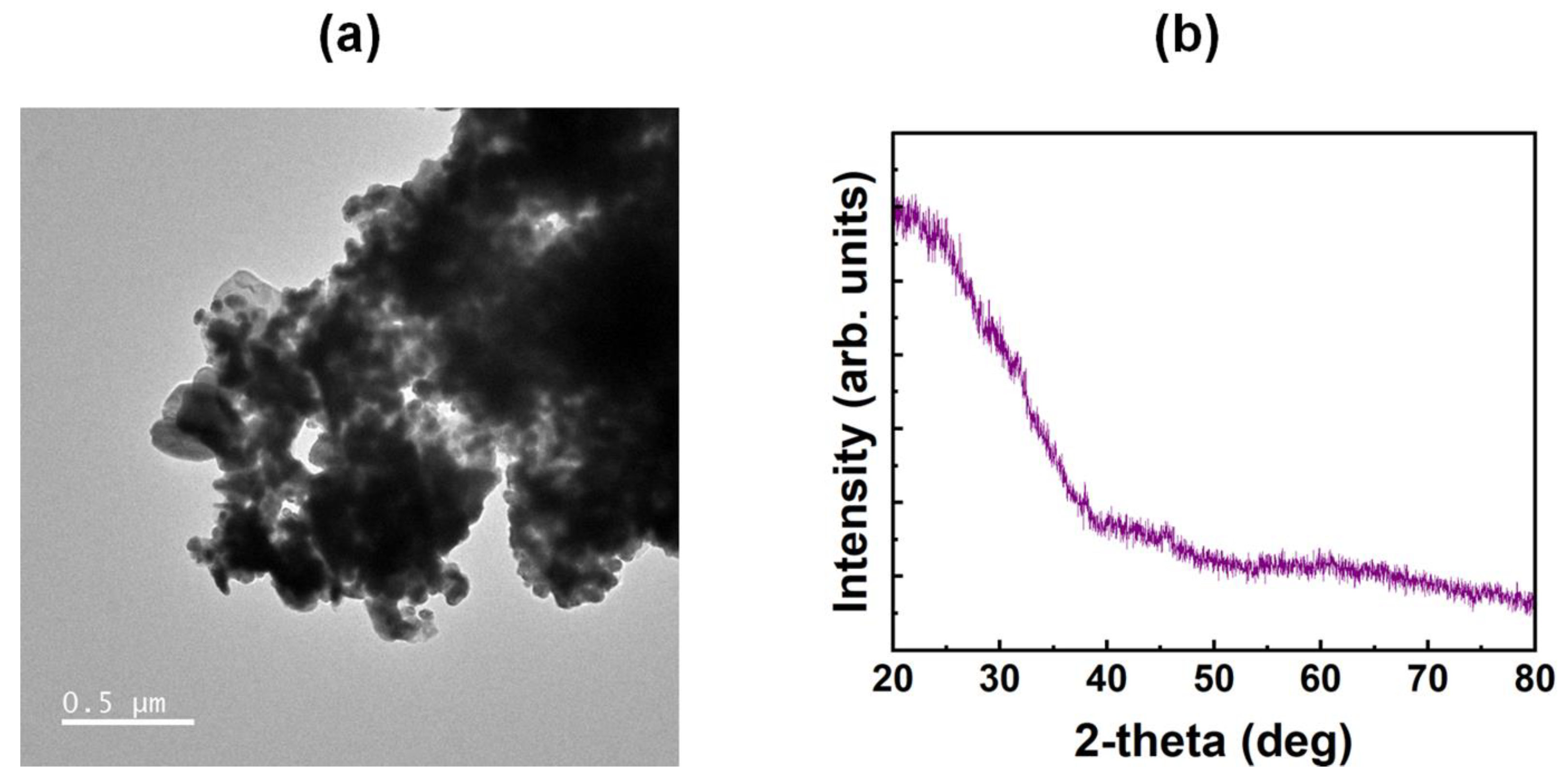

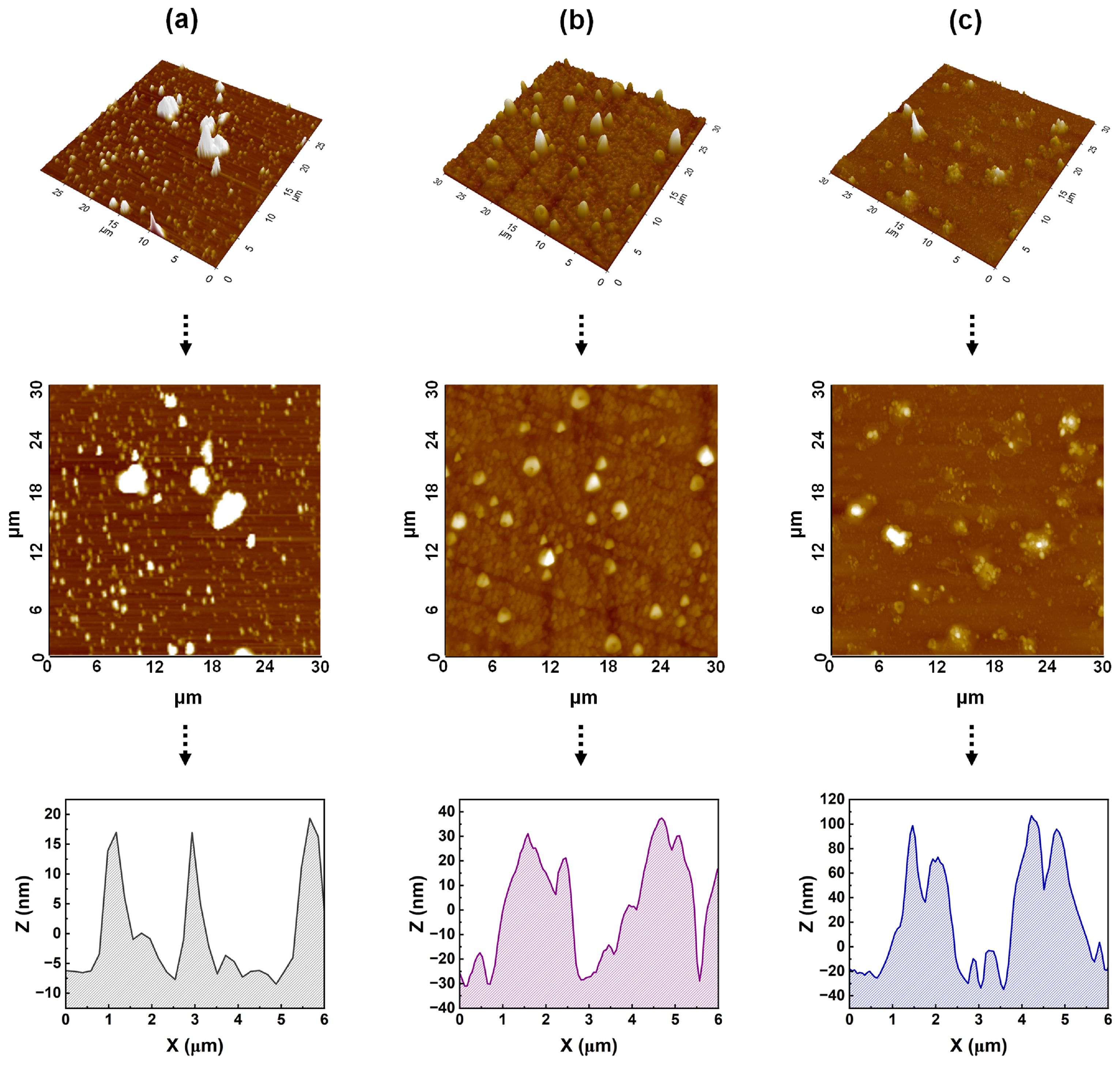

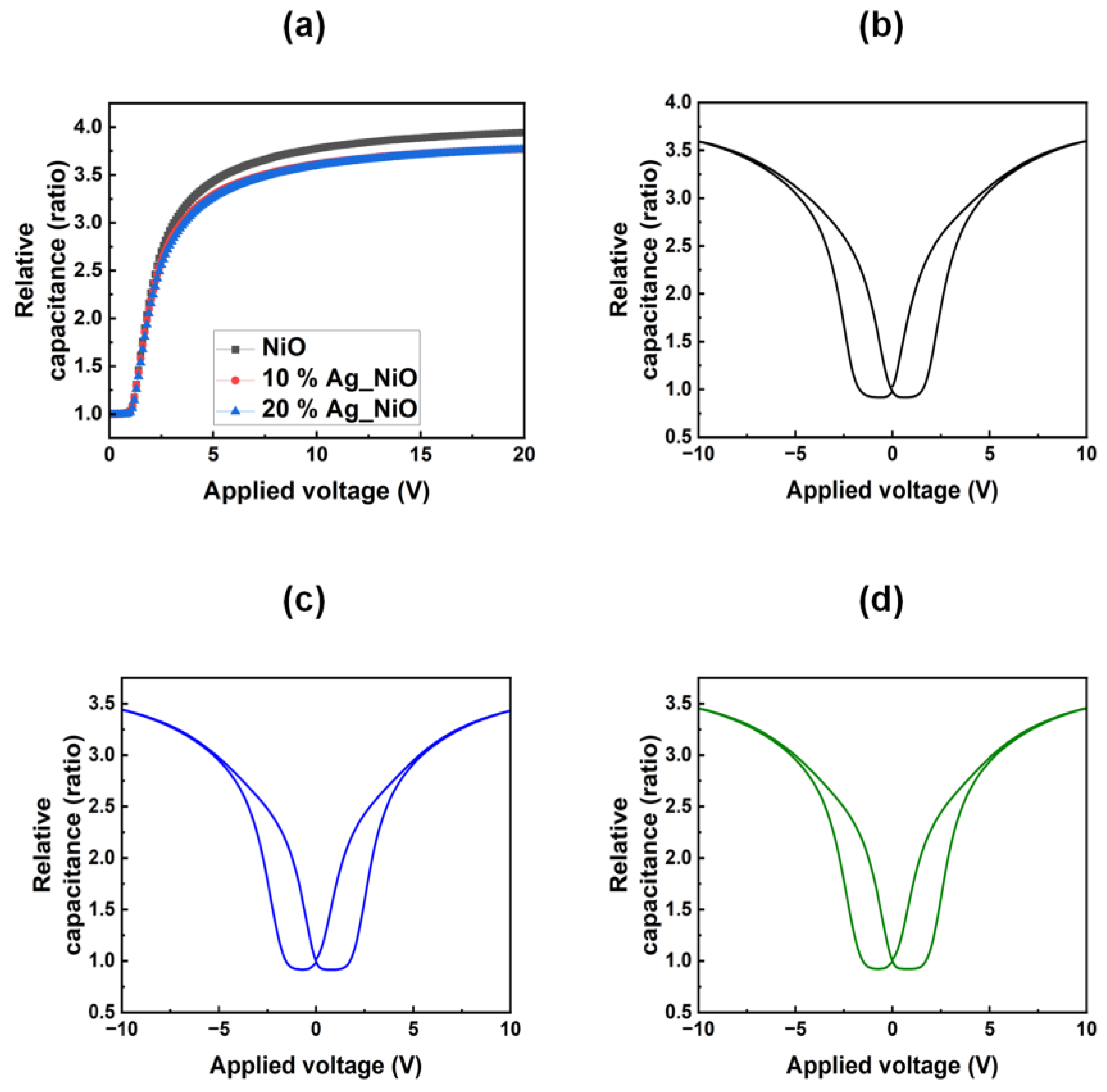

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Dogra, A.R.; Sharma, V.; Gahrotra, R.; Kumar, P. Evaporation induced self-assembly of silica nanoparticles on ITO substrates in a confined cell for vertical alignment of liquid crystals and performance analysis. Colloids Surf. A Physicochem. Eng. 2022, 642, 128712. [Google Scholar] [CrossRef]

- Sharma, V.; Kumar, P. Electro-optically oriented Kerr and orientational phase study of normal mode polymer dispersed liquid crystals—Effect of dispersion of nanoparticles. J. Mol. Liq. 2022, 348, 118030. [Google Scholar] [CrossRef]

- Nguyen, T.-T.-T.; Luu, T.-N.; Nguyen, D.-H.; Duong, T.-T. Comparative study on backlighting unit using CsPbBr3 nanocrystals/KSFM phosphor + blue LED and commercial WLED in liquid crystal display. J. Electron. Mater. 2021, 50, 1827–1834. [Google Scholar] [CrossRef]

- Son, S.-R.; An, J.; Choi, J.-W.; Kim, S.; Park, J.; Lee, J.H. Surface-anchored alkylated graphene oxide as a two-dimensional homeotropic alignment layer for nematic liquid crystals. Mater. Today Commun. 2021, 28, 10253. [Google Scholar] [CrossRef]

- Yan, X.; Mont, F.W.; Poxson, D.J.; Schubert, M.F.; Kim, J.K.; Cho, J.; Schubert, E.F. Refractive-index-matched indium–tin-oxide electrodes for liquid crystal displays. Jpn. J. Appl. Phys. 2009, 48, 120203. [Google Scholar] [CrossRef]

- Kocakülah, G.; Köysal, O. Electro-optical, dielectric and morphological properties of a cholesteric liquid crystal light shutter: The influence of azo dye and quantum dot nanoparticles. J. Electron. Mater. 2022, 51, 6864–6876. [Google Scholar] [CrossRef]

- Lin, T.-H.; Jau, H.-C. Electrically controllable laser based on cholesteric liquid crystal with negative dielectric anisotropy. Appl. Phys. Lett. 2006, 88, 061122. [Google Scholar] [CrossRef]

- Oh, Y.S.; Lee, K.H.; Kim, H.; Jeon, D.Y.; Ko, S.H.; Grigoropoulos, C.P.; Sung, H.J. Direct micro/nano patterning of multiple colored quantum dots by large-area and multilayer imprinting. J. Phys. Chem. C 2012, 116, 11728–11733. [Google Scholar] [CrossRef]

- Kim, D.H.; Lee, D.W.; Oh, J.Y.; Won, J.; Liu, Y.; Seo, D.-S. Self-aligned liquid crystals and enhanced electro-optical properties on solution-processed aluminum gallium tin zinc oxide surfaces. J. Mater. Res. Technol. 2022, 20, 291–302. [Google Scholar] [CrossRef]

- Kim, K.; Lee, C.; Yoon, D.K. Patterned hydrophobic liquid crystalline fibers fabricated from defect arrays of reactive mesogens via electric field modulation. ACS Appl. Mater. Interfaces 2023, 15, 8387–8392. [Google Scholar] [CrossRef]

- Liu, C.-K.; Chang, S.-C.; Juang, Y.-S.; Cheng, K.-T. Hiding private information in private information protection liquid crystal displays using periodical waveplates and pixel quaternity. Opt. Express 2023, 31, 2445–2455. [Google Scholar] [CrossRef] [PubMed]

- Chan, G.G.; Koch, C.M.; Connors, L.H. Blood proteomic profiling in inherited (ATTRm) and acquired (ATTRwt) forms of transthyretin-associated cardiac amyloidosis. J. Proteome Res. 2017, 16, 1659–1668. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.H.; Kim, D.H.; Won, J.; Lee, D.W.; Oh, J.Y.; Liu, Y.; Park, Y.-P.; Jeong, H.-C.; Seo, D.-S. High-quality nano structures fabrication on organic/inorganic hybrid thin films by using UV nanoimprint lithography. Mater. Chem. Phys. 2021, 269, 124771. [Google Scholar] [CrossRef]

- You, R.; Choi, Y.S.; Shin, M.J.; Seo, M.K.; Yoon, D.K. Reconfigurable periodic liquid crystal defect array via modulation of electric field. Adv. Mater. Technol. 2019, 4, 1900454. [Google Scholar] [CrossRef]

- Song, I.H.; Jeong, H.C.; Lee, J.H.; Won, J.; Kim, D.H.; Lee, D.W.; Oh, J.Y.; Jang, J.I.; Liu, Y.; Seo, D.-S. Selective liquid crystal driving mode achieved by controlling the pretilt angle via a nanopatterned organic/inorganic hybrid thin film. Adv. Opt. Mater. 2021, 9, 2001639. [Google Scholar] [CrossRef]

- Guo, C.; Gao, X.; Lin, F.J.; Wang, Q.; Meng, L.; Bian, R.; Sun, Y.; Jiang, L.; Liu, H. In situ characterization of the triphase contact line in a brush-coating process: Toward the enhanced efficiency of polymer solar cells. ACS Appl. Mater. Interfaces 2018, 10, 39448–39454. [Google Scholar] [CrossRef]

- Lee, D.W.; Seo, D.-S. Surface functionalization of Ag-doped zirconium oxide layers for molecular alignment. Flatchem 2025, 50, 100831. [Google Scholar] [CrossRef]

- Lin, J.; Chen, H.H.; Tao, Y.T. Molecularly aligned hexa-peri-hexabenzocoronene films by brush-coating and their application in thin-film transistors. ACS Appl. Mater. Interfaces 2019, 11, 10801–10809. [Google Scholar] [CrossRef]

- Li, L.; Yang, T.; Wang, K.; Fan, H.; Hou, C.; Zhang, Q.; Li, Y.; Yu, H.; Wang, H. Mechanical design of brush coating technology for the alignment of one-dimension nanomaterials. J. Colloid Interface Sci. 2021, 583, 188–195. [Google Scholar] [CrossRef]

- Rao, K.V.; Smakula, A. Dielectric properties of cobalt oxide, nickel oxide, and their mixed crystals. J. Appl. Phys. 1965, 36, 2031–2038. [Google Scholar] [CrossRef]

- Liu, P.; Ng, V.M.H.; Yao, Z.; Zhou, J.; Lei, Y.; Yang, Z.; Lv, H.; Kong, L.B. Facile Synthesis and Hierarchical Assembly of Flowerlike NiO Structures with Enhanced Dielectric and Microwave Absorption Properties. ACS Appl. Mater. Interfaces 2017, 9, 16404–16416. [Google Scholar] [CrossRef] [PubMed]

- Hrostea, L.; Lisnic, P.; Mallet, R.; Leontie, L.; Girtan, M. Studies on the Physical Properties of TiO2:Nb/Ag/TiO2:Nb and NiO/Ag/NiO Three-Layer Structures on Glass and Plastic Substrates as Transparent Conductive Electrodes for Solar Cells. Nanomaterials 2021, 11, 1416. [Google Scholar] [CrossRef]

- Ghasemi, F.; Ghasemi, M.; Eftekhari, L.; Soleimanian, V. Comparison and influence of metal dopants on the opto-electrical, microstructure and gas sensing properties of nanostructured indium oxide films. Opt. Laser Technol. 2022, 146, 107564. [Google Scholar] [CrossRef]

- Atilgan, A.; Ozel, K.; Sbeta, M.; Yildiz, A. Engineering the visible light absorption of one-dimensional photonic crystals based on multilayers of Al-doped ZnO (AZO) thin films. Mater. Sci. Semicond. Process. 2023, 166, 107747. [Google Scholar] [CrossRef]

- Thouti, E.; Chander, N.; Dutta, V.; Komarala, V.K. Optical properties of Ag nanoparticle layers deposited on silicon substrates. J. Opt. 2013, 15, 035005. [Google Scholar] [CrossRef]

- Huang, P.-S.; Qin, F.; Lee, J.-K. Role of the interface between Ag and ZnO in the electric conductivity of Ag nanoparticle-embedded ZnO. ACS Appl. Mater. Interfaces 2020, 12, 4715–4721. [Google Scholar] [CrossRef]

- Li, J.; Pan, Y.; Xiang, C.; Ge, Q.; Guo, J. Low temperature synthesis of ultrafine α-Al2O3 powder by a simple aqueous sol–gel process. Ceram. Int. 2006, 32, 587–591. [Google Scholar] [CrossRef]

- Mell, C.C.; Finn, S.R. Forces exerted during the brushing of a paint. Rheol. Acta 1965, 4, 260–261. [Google Scholar] [CrossRef]

- Kim, S.-S.; Na, S.-I.; Jo, J.; Tae, G.; Kim, D.-Y. Efficient polymer solar cells fabricated by simple brush painting. Adv. Mater. 2007, 19, 4410–4415. [Google Scholar] [CrossRef]

- Fukuda, J.I.; Yoneya, M.; Yokoyama, H. Surface-groove-induced azimuthal anchoring of a nematic liquid crystal: Berreman’s model reexamined. Phys. Rev. Lett. 2007, 98, 187803. [Google Scholar] [CrossRef]

- Berreman, D.W. Solid surface shape and the alignment of an adjacent nematic liquid crystal. Phys. Rev. Lett. 1972, 28, 1683–1686. [Google Scholar] [CrossRef]

- Kikuchi, H.; Logan, J.A.; Yoon, D.Y. Study of local stress, morphology, and liquid-crystal alignment on buffed polyimide surfaces. J. Appl. Phys. 1996, 79, 6811–6817. [Google Scholar] [CrossRef]

- Chae, B.; Kim, S.B.; Lee, S.W.; Kim, S.I.; Choi, W.; Lee, B.; Ree, M.; Lee, K.H.; Jung, J.C. Surface morphology, molecular reorientation, and liquid crystal alignment properties of rubbed nanofilms of a well-defined brush polyimide with a fully rodlike backbone. Macromolecules 2002, 35, 10119–10130. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, D.W.; Kim, T.-H.; Kim, Y.K.; Seo, D.-S. Uniform Molecular Alignment on Ag-Doped Nickel Oxide Films. Nanomaterials 2025, 15, 449. https://doi.org/10.3390/nano15060449

Lee DW, Kim T-H, Kim YK, Seo D-S. Uniform Molecular Alignment on Ag-Doped Nickel Oxide Films. Nanomaterials. 2025; 15(6):449. https://doi.org/10.3390/nano15060449

Chicago/Turabian StyleLee, Dong Wook, Tae-Hyun Kim, Young Kwon Kim, and Dae-Shik Seo. 2025. "Uniform Molecular Alignment on Ag-Doped Nickel Oxide Films" Nanomaterials 15, no. 6: 449. https://doi.org/10.3390/nano15060449

APA StyleLee, D. W., Kim, T.-H., Kim, Y. K., & Seo, D.-S. (2025). Uniform Molecular Alignment on Ag-Doped Nickel Oxide Films. Nanomaterials, 15(6), 449. https://doi.org/10.3390/nano15060449