Improved Ferroelectric and Magnetic Properties of Bismuth Ferrite-Based Ceramics by Introduction of Non-Isovalent Ions and Grain Engineering

Abstract

1. Introduction

2. Experimental Procedure

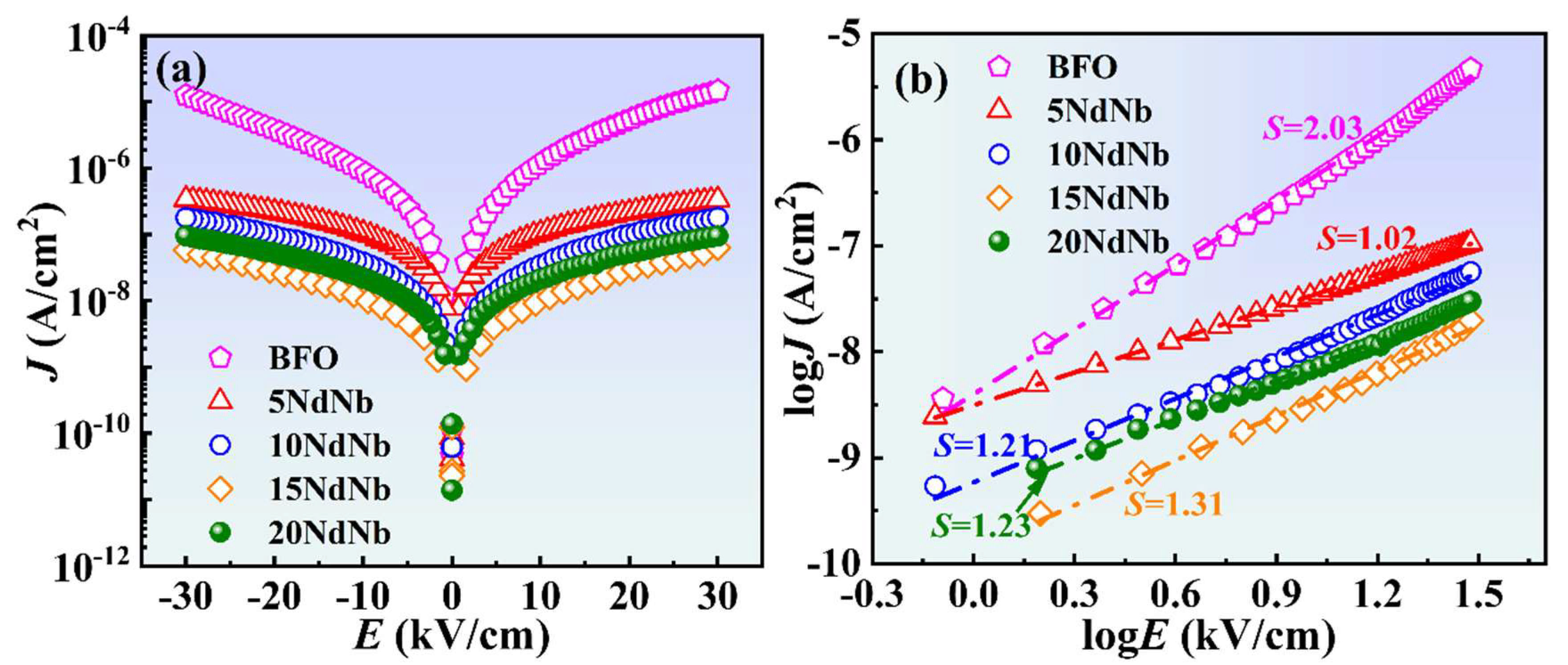

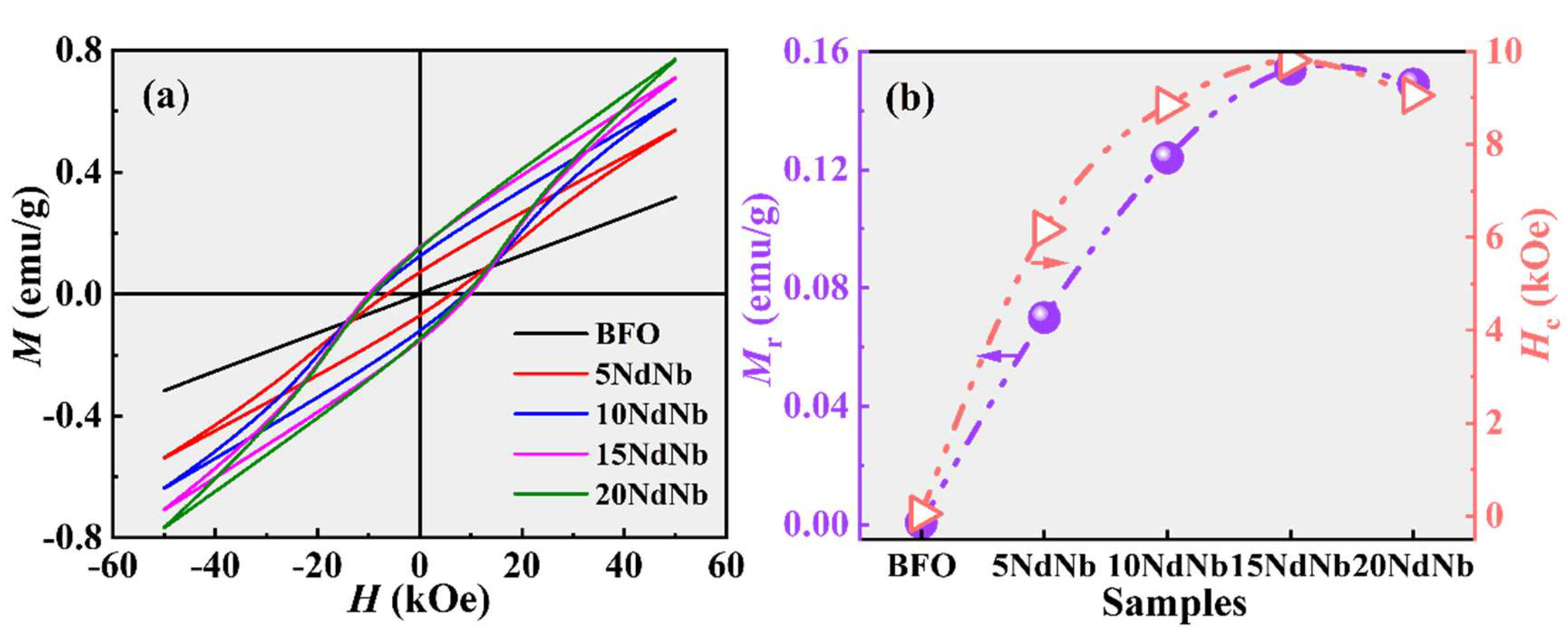

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hu, Z.; Stenning, G.B.G.; Zhang, H.; Shi, Y.; Koval, V.; Hu, W.; Zhou, Z.; Jia, C.; Abrahams, I.; Yan, H. Non-volatile voltage-controlled magnetization in single-phase multiferroic ceramics at room temperature. J. Mater. 2025, 11, 100857. [Google Scholar] [CrossRef]

- Sun, Y.; Liu, J.; Sun, T.; Yu, Z.; Zheng, Z.; Ge, M.; Bai, L. Structural evolution and enhanced multiferroicity in BiFeO3-based ceramics via rare earth element co-substitution. J. Eur. Ceram. Soc. 2025, 45, 117021. [Google Scholar] [CrossRef]

- Billah, A.; Matsuno, Y.; Anju, A.N.; Koike, K.; Kubota, S.; Hirose, F.; Ahmmad, B. Unusual behavior of magnetic coercive fields with temperature and applied field in La-doped BiFeO3 ceramics. ACS Appl. Electron. Mater. 2023, 5, 4261–4267. [Google Scholar] [CrossRef]

- Liu, L.; Zhu, X.L.; Chen, X.M. Improved ferroelectricity and magnetoelectric coupling effect of multielements co-substituted BiFeO3 ceramics. J. Am. Ceram. Soc. 2023, 107, 933–944. [Google Scholar] [CrossRef]

- Selbach, S.M.; Tybell, T.; Einarsrud, M.A.; Grande, T. The ferroic phase transitions of BiFeO3. Adv. Mater. 2008, 20, 3692–3696. [Google Scholar] [CrossRef]

- Catalan, G.; Scott, J.F. Physics and applications of bismuth ferrite. Adv. Mater. 2009, 21, 2463–2485. [Google Scholar] [CrossRef]

- Gao, X.; Zhang, L.; Wang, C.; Shen, Q. Enhanced magnetic and ferroelectric properties of textured multiferroic Bi5Ti3FeO15-CoFe2O4 ceramics prepared by plasma activated sintering. Ceram. Int. 2017, 43, 6607–6611. [Google Scholar] [CrossRef]

- Fiebig, M. Revival of the magnetoelectric effect. J. Phys. D Appl. Phys. 2005, 38, R123–R152. [Google Scholar] [CrossRef]

- Teague, J.R.; Gerson, R.; James, W.J. Dielectric hysteresis in single crystal BiFeO3. Solid. State Commun. 1970, 8, 1073–1074. [Google Scholar] [CrossRef]

- Shi, X.X.; Liu, X.Q.; Chen, X.M. Readdressing of magnetoelectric effect in bulk BiFeO3. Adv. Funct. Mater. 2017, 27, 1604037. [Google Scholar] [CrossRef]

- Boukhari, M.; Abdelkafi, Z.; Abdelmoula, N.; Khemakhem, H.; Randrianantoandro, N. Enhanced dielectric and optical properties in Zn2+ and Zr4+ co-doping BiFeO3 ceramic. J. Mater. Sci. Mater. Electron. 2023, 34, 1218. [Google Scholar] [CrossRef]

- Lakshmi, S.D.; Banu, I.B.S. Multiferroism and magnetoelectric coupling in single-phase Yb and X (X = Nb, Mn, Mo) co-doped BiFeO3 ceramics. J. Sol-Gel Sci. Technol. 2018, 89, 713–721. [Google Scholar] [CrossRef]

- Abe, K.; Sakai, N.; Takahashi, J.; Itoh, H.; Adachi, N.; Ota, T. Leakage current properties of cation-substituted BiFeO3 ceramics. Jpn. J. Appl. Phys. 2010, 49, 09MB01. [Google Scholar] [CrossRef]

- Yamamoto, H.; Kihara, T.; Oka, K.; Tokunaga, M.; Mibu, K.; Azuma, M. Spin structure change in co-substituted BiFeO3. J. Phys. Soc. Jpn. 2016, 85, 064704. [Google Scholar] [CrossRef]

- Quan, Z.; Liu, W.; Hu, H.; Xu, S.; Sebo, B.; Fang, G.; Li, M.; Zhao, X. Microstructure, electrical and magnetic properties of Ce-doped BiFeO3 thin films. J. Appl. Phys. 2008, 104, 084106. [Google Scholar] [CrossRef]

- Chen, J.; Xu, B.; Liu, X.Q.; Gao, T.T.; Bellaiche, L.; Chen, X.M. Symmetry modulation and enhanced multiferroic characteristics in Bi1−xNdxFeO3 ceramics. Adv. Funct. Mater. 2019, 29, 1806399. [Google Scholar] [CrossRef]

- Chen, J.; Liu, L.; Zhu, X.L.; Gareeva, Z.; Zvezdin, A.; Chen, X.M. The involvement of Pna21 phase in the multiferroic characteristics of La/Lu co-substituted BiFeO3 ceramics. Appl. Phys. Lett. 2021, 119, 112901. [Google Scholar] [CrossRef]

- Chen, J.; Su, N.; Zhu, X.L.; Liu, X.Q.; Zhang, J.-X.; Chen, X.M. Electric-field-controlled magnetism due to field-induced transition of Pna21/R3c in Bi1−xGdxFeO3 ceramics. J. Mater. 2021, 7, 967–975. [Google Scholar] [CrossRef]

- Liu, L.; Zhu, X.L.; Gareeva, Z.; Zvezdin, A.; Eiras, J.A.; Chen, X.M. Symmetry evolution and modulation of multiferroic characteristics in Bi1-xLaxFeO3 ceramics. Appl. Phys. Lett. 2022, 120, 13904. [Google Scholar] [CrossRef]

- Liu, L.; Chen, J.; Zhu, X.L.; Chen, X.M. Structure evidence of Pna21 phase and field-induced transition of Pna21/R3c in Bi1−xSmxFe0.99Ti0.01O3 ceramics. Appl. Phys. Lett. 2021, 118, 142904. [Google Scholar] [CrossRef]

- Petkov, V.; Zafar, A.; Kenesei, P.; Shastri, S. Chemical compression and ferroic orders in La substituted BiFeO3. Phys. Rev. Mater. 2023, 7, 054404. [Google Scholar] [CrossRef]

- Ke, H.; Zhang, L.; Zhang, H.; Li, F.; Luo, H.; Cao, L.; Wang, W.; Wang, F.; Jia, D.; Zhou, Y. Electric/magnetic behaviors of Nd/Ti co-doped BiFeO3 ceramics with morphotropic phase boundary. Scr. Mater. 2019, 164, 6–11. [Google Scholar] [CrossRef]

- Gumiel, C.; Jardiel, T.; Bernardo, M.S.; Villanueva, P.G.; Urdiroz, U.; Cebollada, F.; Aragó, C.; Caballero, A.C.; Peiteado, M. Combination of structural and microstructural effects in the multiferroic response of Nd and Ti co-doped BiFeO3 bulk ceramics. Ceram. Int. 2019, 45, 5276–5283. [Google Scholar] [CrossRef]

- Wang, T.; Song, S.H.; Ma, Q.; Tan, M.L.; Chen, J.J. Highly improved multiferroic properties of Sm and Nb co-doped BiFeO3 ceramics prepared by spark plasma sintering combined with sol-gel powders. J. Alloys Compd. 2019, 795, 60–68. [Google Scholar] [CrossRef]

- Gao, X.; Li, Y.; Chen, J.; Yuan, C.; Zeng, M.; Zhang, A.; Gao, X.; Lu, X.; Li, Q.; Liu, J.-M. High energy storage performances of Bi1−xSmxFe0.95Sc0.05O3 lead-free ceramics synthesized by rapid hot press sintering. J. Eur. Ceram. Soc. 2019, 39, 2331–2338. [Google Scholar] [CrossRef]

- Lin, F.; Yu, Q.; Deng, L.; Zhang, Z.; He, X.; Liu, A.; Shi, W. Effect of La/Cr codoping on structural transformation, leakage, dielectric and magnetic properties of BiFeO3 ceramics. J. Mater. Sci. 2017, 52, 7118–7129. [Google Scholar] [CrossRef]

- Wang, C.A.; Pang, H.Z.; Zhang, A.H.; Lu, X.B.; Gao, X.S.; Zeng, M.; Liu, J.M. Enhanced ferroelectric polarization and magnetization in BiFe1−xScxO3 ceramics. Mater. Res. Bull. 2015, 70, 595–599. [Google Scholar] [CrossRef]

- Perez-Maqueda, L.A.; Gil-Gonzalez, E.; Wassel, M.A.; Jha, S.K.; Perejon, A.; Charalambous, H.; Okasinski, J.; Sanchez-Jimenez, P.E.; Tsakalakos, T. Insight into the BiFeO3 flash sintering process by in-situ energy dispersive X-ray diffraction (ED-XRD). Ceram. Int. 2019, 45, 2828–2834. [Google Scholar] [CrossRef]

- Bernardo, M.S.; Jardiel, T.; Caballero, A.C.; Bram, M.; Gonzalez-Julian, J.; Peiteado, M. Electric current activated sintering (ECAS) of undoped and titanium-doped BiFeO3 bulk ceramics with homogeneous microstructure. J. Eur. Ceram. Soc. 2019, 39, 2042–2049. [Google Scholar] [CrossRef]

- Cai, W.; Gao, R.; Fu, C.; Yao, L.; Chen, G.; Deng, X.; Wang, Z.; Cao, X.; Wang, F. Microstructure, enhanced electric and magnetic properties of Bi0.9La0.1FeO3 ceramics prepared by microwave sintering. J. Alloys Compd. 2019, 774, 61–68. [Google Scholar] [CrossRef]

- Yu, C.; Viola, G.; Zhang, D.; Zhou, K.; Koval, V.; Mahajan, A.; Wilson, R.M.; Tarakina, N.V.; Abrahams, I.; Yan, H. Phase evolution and electrical behaviour of samarium-substituted bismuth ferrite ceramics. J. Eur. Ceram. Soc. 2018, 38, 1374–1380. [Google Scholar] [CrossRef]

- Koval, V.; Skorvanek, I.; Durisin, J.; Viola, G.; Kovalcikova, A.; Svec, P.; Saksl, K.; Yan, H. Terbium-induced phase transitions and weak ferromagnetism in multiferroic bismuth ferrite ceramics. J. Mater. Chem. C 2017, 5, 2669–2685. [Google Scholar] [CrossRef]

- Wang, T.; Song, S.H.; Wang, M.; Li, J.Q.; Ravi, M. Effect of annealing atmosphere on the structural and electrical properties of BiFeO3 multiferroic ceramics prepared by sol–gel and spark plasma sintering techniques. Ceram. Int. 2016, 42, 7328–7335. [Google Scholar] [CrossRef]

- Wang, T.; Xu, T.; Gao, S.; Song, S.H. Effect of Nd and Nb co-doping on the structural, magnetic and optical properties of multiferroic BiFeO3 nanoparticles prepared by sol-gel method. Ceram. Int. 2017, 43, 4489–4495. [Google Scholar] [CrossRef]

- Wang, T.; Wang, X.L.; Song, S.H.; Ma, Q. Effect of rare-earth Nd/Sm doping on the structural and multiferroic properties of BiFeO3 ceramics prepared by spark plasma sintering. Ceram. Int. 2020, 46, 15228–15235. [Google Scholar] [CrossRef]

- Zhang, S.X.; Wang, L.; Chen, Y.; Wang, D.L.; Yao, Y.B.; Ma, Y.W. Observation of room temperature saturated ferroelectric polarization in Dy substituted BiFeO3 ceramics. J. Appl. Phys. 2012, 111, 074105. [Google Scholar] [CrossRef]

- Khomchenko, V.A.; Paixao, J.A.; Shvartsman, V.V.; Borisov, P.; Kleemann, W.; Karpinsky, D.V.; Kholkin, A.L. Effect of Sm substitution on ferroelectric and magnetic properties of BiFeO3. Scr. Mater. 2010, 62, 238–241. [Google Scholar] [CrossRef]

- Islam, M.R.; Islam, M.S.; Zubair, M.A.; Usama, H.M.; Azam, M.S.; Sharif, A. Evidence of superparamagnetism and improved electrical properties in Ba and Ta co-doped BiFeO3 ceramics. J. Alloys Compd. 2018, 735, 2584–2596. [Google Scholar] [CrossRef]

- Durga Rao, T.; Raja Kandula, K.; Kumar, A.; Asthana, S. Improved magnetization and reduced leakage current in Sm and Sc co-substituted BiFeO3. J. Appl. Phys. 2018, 123, 244104. [Google Scholar] [CrossRef]

- Habib, M.; Tang, L.; Xue, G.; Rahman, A.; Kim, M.-H.; Lee, S.; Zhou, X.; Zhang, Y.; Zhang, D. Design and development of a new lead-free BiFeO3-BaTiO3 quenched ceramics for high piezoelectric strain performance. Chem. Eng. J. 2023, 473, 145387. [Google Scholar] [CrossRef]

- Park, T.-J.; Papaefthymiou, G.C.; Viescas, A.J.; Moodenbaugh, A.R.; Wong, S. Size-dependent magnetic properties of single-crystalline multiferroic BiFeO3 nanoparticles. Nano Lett. 2007, 7, 766–772. [Google Scholar] [CrossRef] [PubMed]

- Wu, X.; Luo, H.; Guo, H.; Liu, J.; Bai, Y.; Zhao, S. Tuning of multiferroic traits in BiFeO3 ceramics by electronic structure. Ceram. Int. 2024, 50, 18853–18867. [Google Scholar] [CrossRef]

- Wang, B.; Liu, W.; Zhao, T.L.; Peng, W.; Ci, P.H.; Dong, S.X. Promising lead-free BiFeO3-BaTiO3 ferroelectric ceramics: Optimization strategies and diverse device applications. Progress Mater. Sci. 2024, 146, 101333. [Google Scholar] [CrossRef]

- Radojković, A.; Luković-Golić, D.; Orsini, N.J.; Nikolić, N.; Ćirković, J.; Lazarević, S.; Despotović, Ž. Evolution of ferroelectric and piezoelectric properties of BiFeO3 ceramics doped with lanthanum and zirconium. J. Alloys Compd. 2024, 1009, 176901. [Google Scholar] [CrossRef]

- Zhang, L.; Ke, H.; Zhang, H.; Li, F.; Zhao, J.; Luo, H.; Cao, L.; Zeng, G.; Li, X.; Wang, W.; et al. Effects of morphotropic phase boundary on the electric behavior of Er/Ti co-doped BiFeO3 ceramics. Scr. Mater. 2019, 158, 71–76. [Google Scholar] [CrossRef]

- Zhang, W.; Zhu, X.; Wang, L.; Xu, X.; Yao, Q.; Mao, W.; Li, X. Study on the magnetic and ferroelectric properties of Bi0.95Dy0.05Fe0.95M0.05O3 (M=Mn, Co) ceramics. J. Supercond. Nov. Magn. 2017, 30, 3001–3005. [Google Scholar] [CrossRef]

- Hua, H.; Bao, G.; Li, C.; Zhu, Y.; Yang, J.; Li, X. Effect of Ho, Mn co-doping on the structural, optical and ferroelectric properties of BiFeO3 nanoparticles. J. Mater. Sci. Mater. Electron. 2017, 28, 17283–17287. [Google Scholar] [CrossRef]

- Chen, X.; Wang, J.; Yuan, G.; Wu, D.; Liu, J.; Yin, J.; Liu, Z. Structure, ferroelectric and piezoelectric properties of multiferroic Bi0.875Sm0.125FeO3 ceramics. J. Alloys Compd. 2012, 541, 173–176. [Google Scholar] [CrossRef]

- Jeong, J.; Le, M.D.; Bourges, P.; Petit, S.; Furukawa, S.; Kim, S.A.; Lee, S.; Cheong, S.W.; Park, J.G. Temperature-dependent interplay of Dzyaloshinskii-Moriya interaction and single-ion anisotropy in multiferroic BiFeO3. Phys. Rev. Lett. 2014, 113, 107202. [Google Scholar] [CrossRef]

- Yuan, G.L.; Or, S.W.; Liu, J.M.; Liu, Z.G. Structural transformation and ferroelectromagnetic behavior in single-phase Bi1−xNdxFeO3 multiferroic ceramics. Appl. Phys. Lett. 2006, 89, 052905. [Google Scholar] [CrossRef]

- Karpinsky, D.V.; Silibin, M.V.; Latushka, S.I.; Zhaludkevich, D.V.; Sikolenko, V.V.; Svetogorov, R.; Sayyed, M.I.; Almousa, N.; Trukhanov, A.; Trukhanov, S.; et al. Temperature-driven transformation of the crystal and magnetic structures of BiFe0.7Mn0.3O3 ceramics. Nanomaterials 2022, 12, 2813. [Google Scholar] [CrossRef] [PubMed]

- Abdel Monem, A.M.; Abd-Elmohssen, N.; El-Bahnasawy, H.H.; Makram, N.; Sedeek, K. Comparative studies by X-ray diffraction, Raman, vibrating sample magnetometer and Mössbauer spectroscopy of pure, Sr doped and Sr, Co co-doped BiFeO3 ceramic synthesized via tartaric acid-assisted technique. Ceram. Int. 2023, 49, 15213–15220. [Google Scholar] [CrossRef]

- Yadav, M.; Agarwal, A.; Sanghi, S.; Kotnala, R.K.; Shah, J.; Bhasin, T.; Tuteja, M.; Singh, J. Crystal structure refinement, dielectric and magnetic properties of A-site and B-site co-substituted Bi0.90Nd0.10Fe1-xTixO3 (x=0.00, 0.02, 0.05 & 0.07) ceramics. J. Alloys Compd. 2018, 750, 848–856. [Google Scholar]

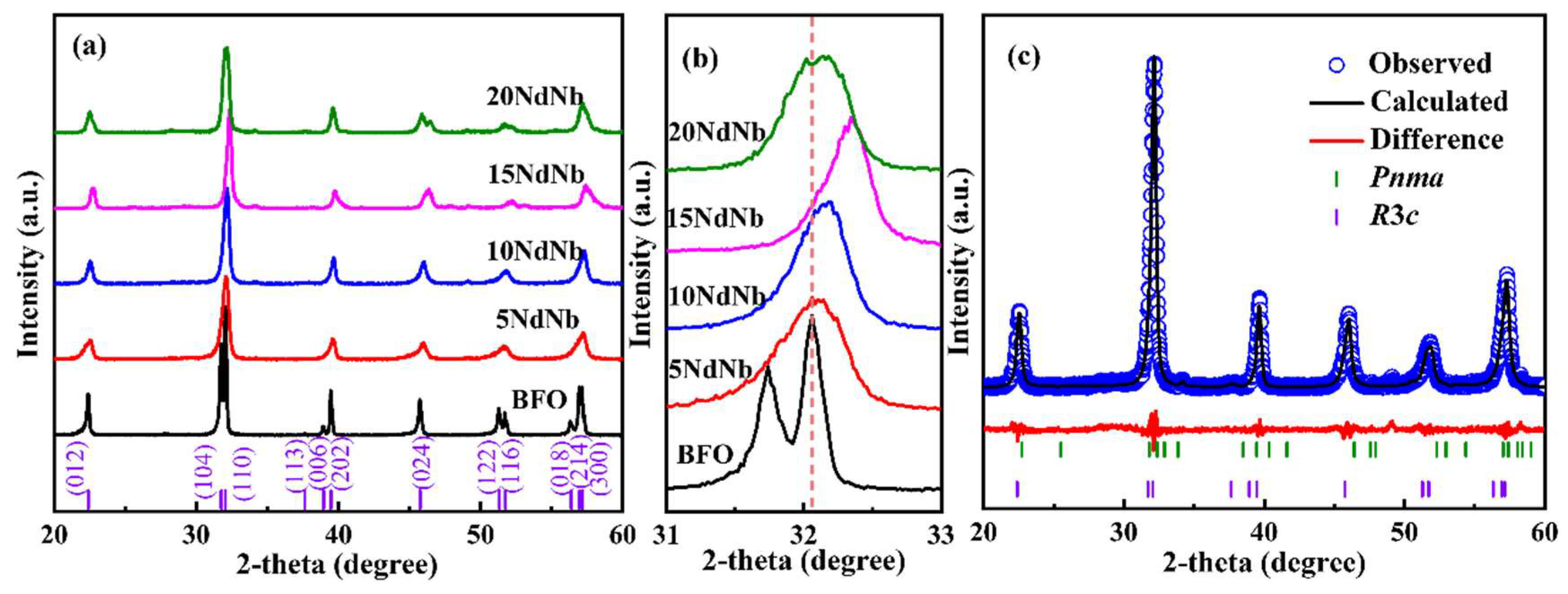

| Samples | Space Group | Phase Constitution (%) | Lattice Parameters (Å) | R-Factors |

|---|---|---|---|---|

| BFO | R3c | 100 | a = 5.571 c = 13.872 | Rexp = 7.36 Rwp = 11.34 GOF = 1.54 |

| 5NdNb | R3c | 97.45 | a = 5.578 c = 13.821 | Rexp = 6.57 Rwp = 8.67 GOF = 1.32 |

| Pnma | 2.55 | a = 5.623 b = 7.946 c = 5.858 | ||

| 10NdNb | R3c | 90.29 | a = 5.587 c = 13.796 | Rexp = 5.82 Rwp = 7.68 GOF = 1.32 |

| Pnma | 9.71 | a = 5.572 b = 7.874 c = 5.869 | ||

| 15NdNb | R3c | 85.46 | a = 5.592 c = 13.774 | Rexp = 6.13 Rwp = 8.65 GOF = 1.41 |

| Pnma | 14.54 | a = 5.569 b = 7.866 c = 5.883 | ||

| 20NdNb | R3c | 75.12 | a = 5.597 c = 13.721 | Rexp = 5.59 Rwp = 7.95 GOF = 1.42 |

| Pnma | 24.88 | a = 5.546 b = 7.810 c = 5.912 |

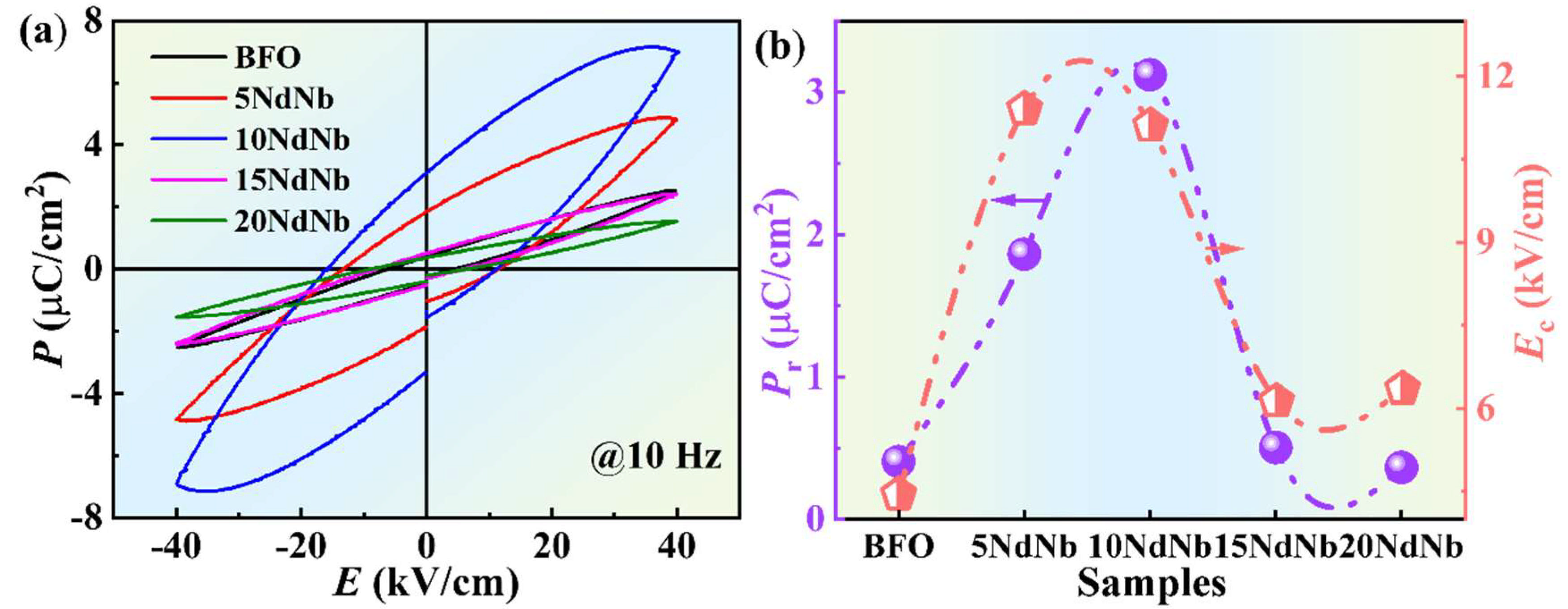

| Parameter | BFO | 5NdNb | 10NdNb | 15NdNb | 20NdNb |

|---|---|---|---|---|---|

| Pr (μC/cm2) | 0.41 | 1.86 | 3.12 | 0.51 | 0.36 |

| Ec (kV/cm) | 4.45 | 11.40 | 11.10 | 6.13 | 6.36 |

| Mr (emu/g) | 5.67 × 10−4 | 0.070 | 0.12 | 0.15 | 0.14 |

| Hc (kOe) | 0.050 | 6.17 | 8.84 | 9.80 | 9.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, T.; Ye, H.; Wang, X.; Cui, Y.; Mei, H.; Song, S.; Zhao, Z.; Wang, M.; Rosaiah, P.; Ma, Q. Improved Ferroelectric and Magnetic Properties of Bismuth Ferrite-Based Ceramics by Introduction of Non-Isovalent Ions and Grain Engineering. Nanomaterials 2025, 15, 215. https://doi.org/10.3390/nano15030215

Wang T, Ye H, Wang X, Cui Y, Mei H, Song S, Zhao Z, Wang M, Rosaiah P, Ma Q. Improved Ferroelectric and Magnetic Properties of Bismuth Ferrite-Based Ceramics by Introduction of Non-Isovalent Ions and Grain Engineering. Nanomaterials. 2025; 15(3):215. https://doi.org/10.3390/nano15030215

Chicago/Turabian StyleWang, Ting, Huojuan Ye, Xiaoling Wang, Yuhan Cui, Haijuan Mei, Shenhua Song, Zhenting Zhao, Meng Wang, Pitcheri Rosaiah, and Qing Ma. 2025. "Improved Ferroelectric and Magnetic Properties of Bismuth Ferrite-Based Ceramics by Introduction of Non-Isovalent Ions and Grain Engineering" Nanomaterials 15, no. 3: 215. https://doi.org/10.3390/nano15030215

APA StyleWang, T., Ye, H., Wang, X., Cui, Y., Mei, H., Song, S., Zhao, Z., Wang, M., Rosaiah, P., & Ma, Q. (2025). Improved Ferroelectric and Magnetic Properties of Bismuth Ferrite-Based Ceramics by Introduction of Non-Isovalent Ions and Grain Engineering. Nanomaterials, 15(3), 215. https://doi.org/10.3390/nano15030215