Miniaturized Frustum-Cone Triboelectric Hydrophone Based on a Thin Film Perforated Tube Structure

Abstract

1. Introduction

2. Materials and Methods

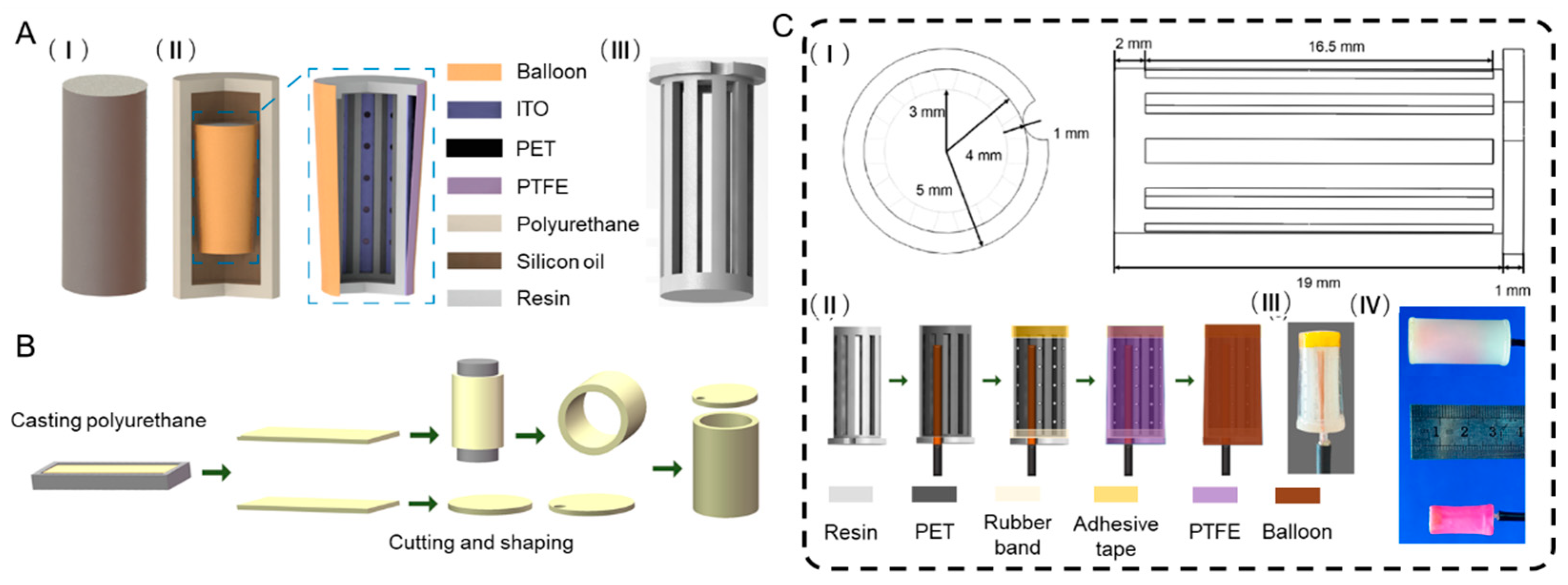

2.1. Structure of the FCTH

2.2. Fabrication of the FCTH

2.2.1. Preparation of the Cylindrical Dome

2.2.2. Fabrication of the Frustum-Cone Triboelectric Sensing Unit

2.2.3. Assembly of the FCTH

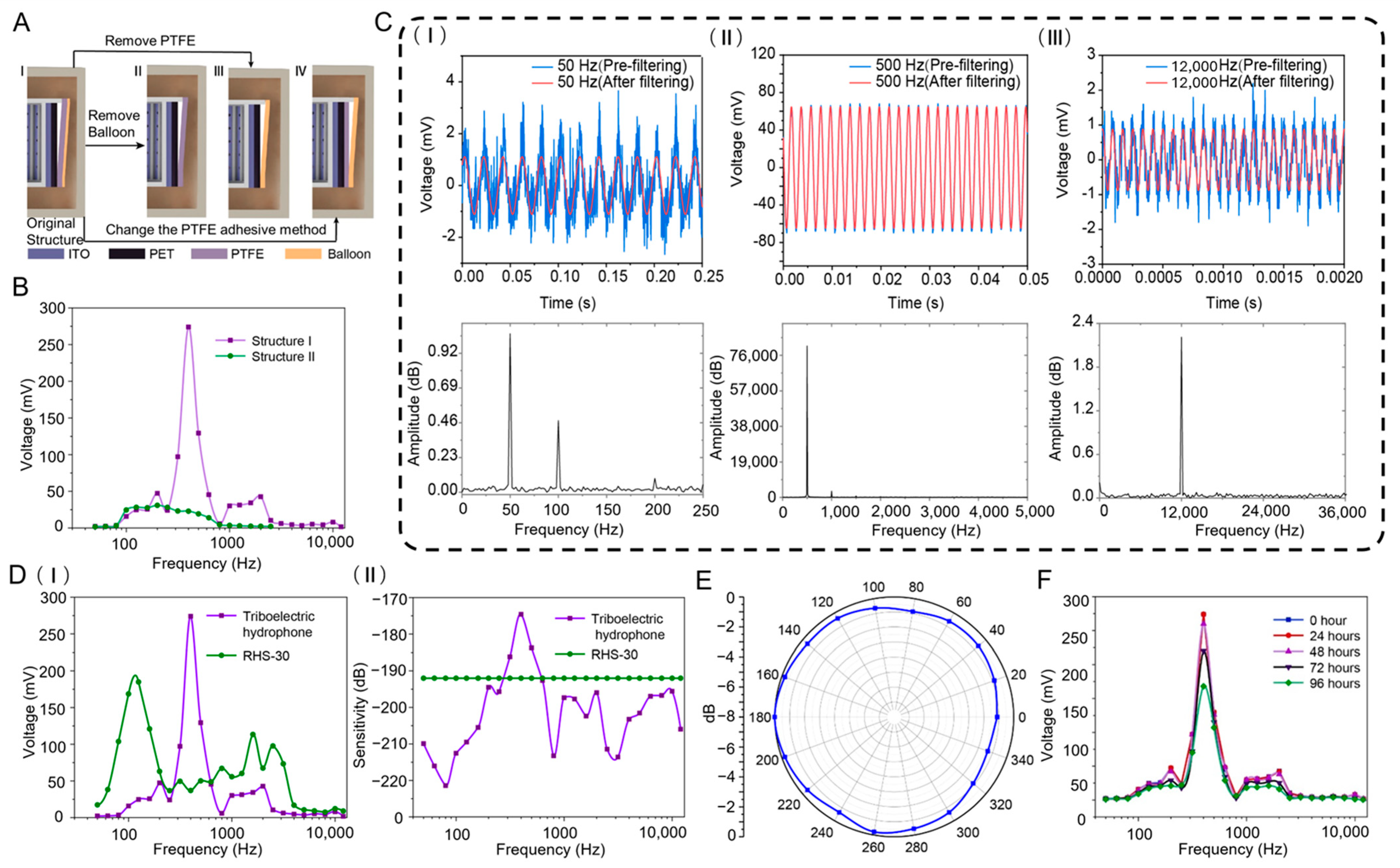

3. Results and Discussion

3.1. Working Principle of the FCTH

3.1.1. Mechanical Characteristics of the FCTH

3.1.2. Electrical Characteristics of the FCTH

3.2. Performance Testing of the FCTH

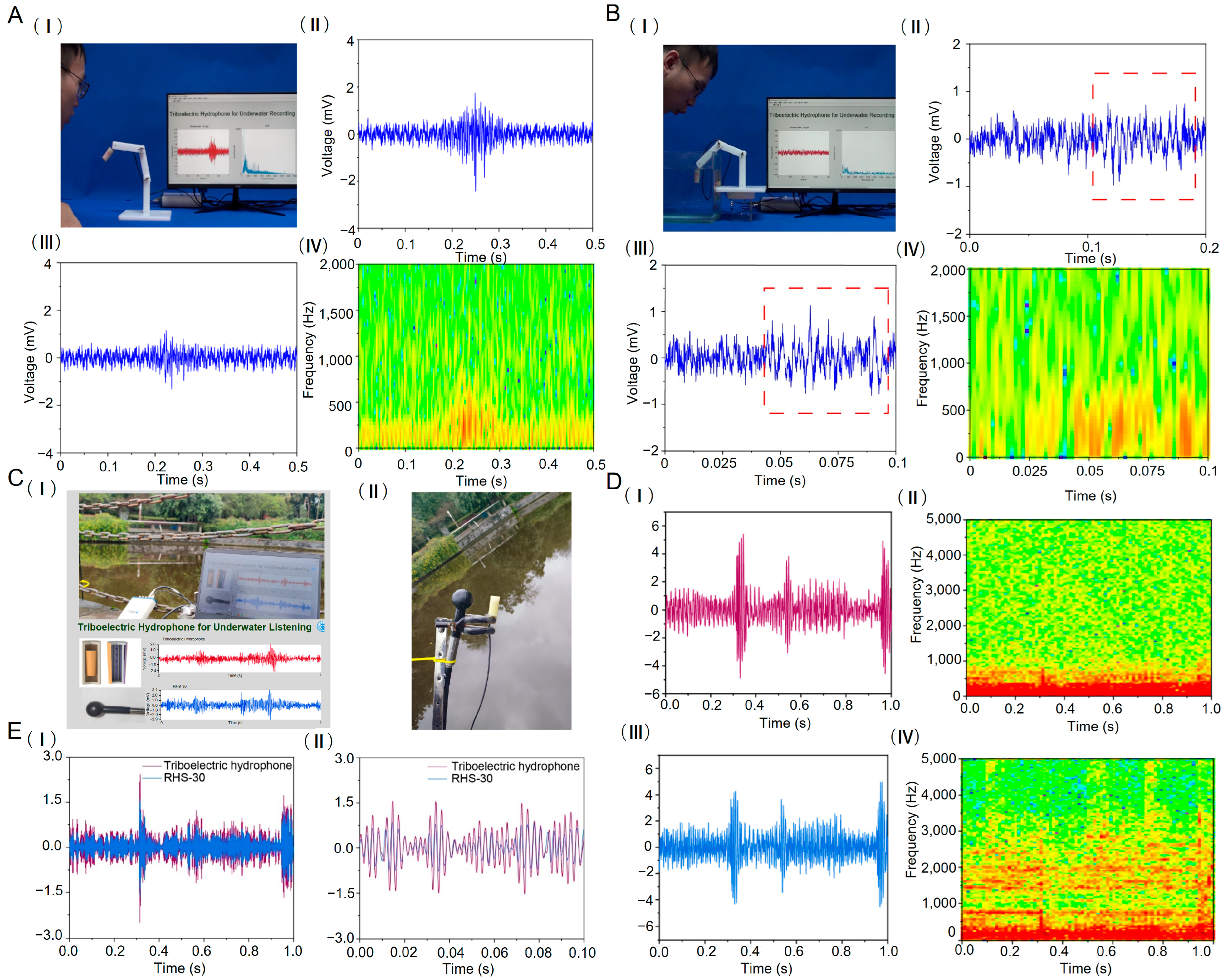

3.3. Acoustic Detection Testing of the FCTH

3.3.1. Detect Airborne Sound Pressure Signals

3.3.2. Detect Acoustic Pressure Signals in Water

3.3.3. Underwater Testing in Outdoor Water Bodies

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Banday, A.H.; ul Azha, N.; Farooq, R.; Sheikh, S.A.; Ganie, M.A.; Parray, M.N.; Mushtaq, H.; Hameed, I.; Lone, M.A. Exploring the potential of marine natural products in drug development: A comprehensive review. Phytochem. Lett. 2024, 59, 124–135. [Google Scholar] [CrossRef]

- Du, K.; Xi, W.; Huang, S.; Zhou, J. Deep-sea mineral resource mining: A historical review, developmental progress, and insights. Min. Metall. Explor. 2024, 41, 173–192. [Google Scholar] [CrossRef]

- Sun, H.; Gao, S.; Liu, J.; Liu, W. Research on comprehensive benefits and reasonable selection of marine resources development types. Open Geosci. 2022, 14, 141–150. [Google Scholar] [CrossRef]

- Yu, Y.; Bao, Y.; Zhang, Q.; Shen, P.; Yang, H.; Xu, Z. Evaluation of marine resources environmental responsibility audit based on PSR framework. Ocean Coast. Manag. 2023, 245, 106742. [Google Scholar] [CrossRef]

- Li, Z.; Chitre, M.; Stojanovic, M. Underwater acoustic communications. Nat. Rev. Electr. Eng. 2025, 2, 83–95. [Google Scholar] [CrossRef]

- Qu, Z.; Lai, M. A review on electromagnetic, acoustic, and new emerging technologies for submarine communication. IEEE Access 2024, 12, 12110–12125. [Google Scholar] [CrossRef]

- Theocharidis, T.; Kavallieratou, E. Underwater communication technologies: A review. Telecommun. Syst. 2025, 88, 54. [Google Scholar] [CrossRef]

- Ridgway, J.L.; Madsen, J.A.; Fischer, J.R.; Calfee, R.D.; Acre, M.R.; Kazyak, D.C. Side-scan sonar as a tool for measuring fish populations: Current state of the science and future directions. Fisheries 2024, 49, 454–462. [Google Scholar] [CrossRef]

- Shi, B.; Cao, T.; Ge, Q.; Lin, Y.; Wang, Z. Sonar image intelligent processing in seabed pipeline detection: Review and application. Meas. Sci. Technol. 2024, 35, 045405. [Google Scholar] [CrossRef]

- Fu, L.; Zhou, M.; Xu, L.; Dong, X.; Kou, Z.; Kang, C. Effective deployment strategies for optimizing area coverage in multistatic sonar detection based on Cassini oval approximation and a virtual force algorithm. Ain Shams Eng. J. 2024, 15, 103147. [Google Scholar] [CrossRef]

- Jia, Y.; Zhang, Z.; Qin, L.; Ma, T.; Lv, B.; Fu, Z.; Xue, C.; Zou, Y. Research of lunar water-ice and exploration for China’s future lunar water-ice exploration. Space Sci. Technol. 2023, 3, 0026. [Google Scholar] [CrossRef]

- Alcázar-Treviño, J.; Lara, G.; Suarez, E.D.; Bou, M.; Domínguez, I.; Buchan, S.; Domínguez, F.; Fraile-Nuez, E. Hydroacoustic sensing of seismic events during the Tajogaite volcanic eruption (La Palma, Spain). Sci. Rep. 2025, 15, 4137. [Google Scholar] [CrossRef]

- Guardato, S.; Donnarumma, G.P.; Riccio, R.; Del Pezzo, E.; Iannaccone, G. Moment magnitude (MW) from hydrophone records of low energy volcanic quakes. J. Seismol. 2022, 26, 875–882. [Google Scholar] [CrossRef]

- Kadri, U.; Abdolali, A.; Filimonov, M. GREAT v1. 0: Global Real-time Early Assessment of Tsunamis. Geosci. Model Dev. Discuss. 2024, 2024, 1–35. [Google Scholar]

- Le Bras, R.J.; Zampolli, M.; Metz, D.; Haralabus, G.; Bittner, P.; Villarroel, M.; Matsumoto, H.; Graham, G.; Meral Özel, N. The Hunga Tonga–Hunga Ha’apai Eruption of 15 January 2022: Observations on the International Monitoring System (IMS) hydroacoustic stations and synergy with seismic and infrasound sensors. Seismol. Soc. Am. 2023, 94, 578–588. [Google Scholar] [CrossRef]

- Ragland, J.; Schwock, F.; Munson, M.; Abadi, S. An overview of ambient sound using Ocean Observatories Initiative hydrophones. J. Acoust. Soc. Am. 2022, 151, 2085–2100. [Google Scholar] [CrossRef]

- Gu, J.; Yan, S.; Zhang, L.; Su, C.; Yin, B.; Qu, S. Superior underwater sound-absorbing metasurface based on wave mode conversion and cavity-plate coupling resonance. Compos. Struct. 2023, 323, 117459. [Google Scholar] [CrossRef]

- Ren, S.; Sun, W.; Zhao, Z.; Liu, Y.; Wang, Q.; Che, F.; Wang, H.; Lei, Y.; Zeng, X. Underwater low-frequency sound absorption of water-saturated porous meta-material with metallic chamber. Appl. Acoust. 2025, 235, 110640. [Google Scholar] [CrossRef]

- Wang, Q.; Fan, X.; Du, Z.; Li, J. Analysis on underwater acoustic countermeasure equipment for submarine. In Proceedings of the Seventh Asia Pacific Conference on Optics Manufacture and 2021 International Forum of Young Scientists on Advanced Optical Manufacturing (APCOM and YSAOM 2021), Bellingham, WA, USA, 15 February 2022; pp. 881–886. [Google Scholar]

- Yazmyradov, S.; Lee, H.; Lee, Y.S.; Kamolov, A.A.; Kang, D.-W. Innovations and Challenges in Submarine Security Systems: A Comprehensive Analysis of Modern Threats and Countermeasures. Int. J. Adv. Smart Converg. 2024, 13, 111–121. [Google Scholar]

- Igbinenikaro, O.P.; Adekoya, O.O.; Etukudoh, E.A. Emerging underwater survey technologies: A review and future outlook. Open Access Res. J. Sci. Technol. 2024, 10, 071–084. [Google Scholar] [CrossRef]

- Nagla, K.; Yadav, S. Sonar sensor advancements. In Handbook of Vibroacoustics, Noise and Harshness; Springer: Berlin/Heidelberg, Germany, 2024; pp. 1031–1050. [Google Scholar]

- Manikandan, C.; Varadarajan, E.; Vijayakumar, P.; Ramesh, R.; Roy, V.; Sarguna, R.; Amaladass, E.P.; Ganesamoorthy, S.; Vinodkumar, T.; Unni, M.N. Realization of high performance PZN-PT single crystal based piezoelectric flexural mode hydrophone for underwater sensor applications. Mater. Res. Express 2023, 10, 066303. [Google Scholar] [CrossRef]

- Motsi, N.; Stamou, G.; Angelopoulos, S.; Ktena, A.; Hristoforou, E. Development of a high sensitivity hydrophone at a spectrum range from 0.1 Hz to 100 kHz. Sens. Actuators A Phys. 2024, 372, 115338. [Google Scholar] [CrossRef]

- Wang, S.; Wang, Y.; Wang, Z.; Wu, Z.; Xin, Y.; Zhou, X. A brief review on hydrophone based on PVDF piezoelectric film. Ferroelectrics 2023, 603, 150–156. [Google Scholar] [CrossRef]

- Bruno, F.; Janneh, M.; Gunda, A.; Kyselica, R.; Stajanca, P.; Werzinger, S.; Gruca, G.; Rijnveld, N.; Persiano, G.; Cutolo, A. Fiber Optic Hydrophones for towed array applications. Opt. Lasers Eng. 2023, 160, 107269. [Google Scholar] [CrossRef]

- Meng, Z.; Chen, W.; Wang, J.; Hu, X.; Chen, M.; Zhang, Y. Recent progress in fiber-optic hydrophones. Photonic Sens. 2021, 11, 109–122. [Google Scholar] [CrossRef]

- Zhang, W.Q.; Nguyen, L.V.; Reja, M.I.; Lancaster, D.G.; Warren-Smith, S.C. Multimode microstructured optical fiber hydrophone. IEEE Sens. J. 2024, 24, 6251–6256. [Google Scholar] [CrossRef]

- Ge, C.; Chen, H. Piezoelectric field effect transistors (piezo-FETs) for bionic MEMS sensors: A literature review. J. Bionic Eng. 2024, 21, 2717–2729. [Google Scholar] [CrossRef]

- Li, T.; Zhang, J.; Al-Hadad, M.; Han, X.; Xu, D.; Tan, Y.; Zhou, Z. Recent Progress in Fiber Optic Acoustic Sensor and Its Applications: A Review. IEEE Sens. J. 2024, 24, 25249–25260. [Google Scholar] [CrossRef]

- Cheng, T.; Shao, J.; Wang, Z.L. Triboelectric nanogenerators. Nat. Rev. Methods Primers 2023, 3, 39. [Google Scholar] [CrossRef]

- Davoudi, M.; An, C.-Y.; Kim, D.-E. A review on triboelectric nanogenerators, recent applications, and challenges. Int. J. Precis. Eng. Manuf.-Green Technol. 2024, 11, 1317–1340. [Google Scholar] [CrossRef]

- Fan, F.-R.; Tian, Z.-Q.; Wang, Z.L. Flexible triboelectric generator. Nano Energy 2012, 1, 328–334. [Google Scholar] [CrossRef]

- Chen, H.; Shi, J.; Yan, L.; Akbarzadeh, A. Multifunctional triboelectric metamaterials with unidirectional charge transfer channels for linear mechanical motion energy harvesting. Adv. Funct. Mater. 2025, 35, 2416749. [Google Scholar] [CrossRef]

- Grover, S.; Kour, A.; Tailor, P.; Minglani, D. Triboelectric generators: A comprehensive review of innovative energy solutions. J. Electrost. 2025, 134, 104037. [Google Scholar] [CrossRef]

- Hasan, M.A.M.; Zhu, W.; Bowen, C.R.; Wang, Z.L.; Yang, Y. Triboelectric nanogenerators for wind energy harvesting. Nat. Rev. Electr. Eng. 2024, 1, 453–465. [Google Scholar] [CrossRef]

- Mu, J.; Zou, J.; Song, J.; He, J.; Hou, X.; Yu, J.; Han, X.; Feng, C.; He, H.; Chou, X. Hybrid enhancement effect of structural and material properties of the triboelectric generator on its performance in integrated energy harvester. Energy Convers. Manag. 2022, 254, 115151. [Google Scholar] [CrossRef]

- Walden, R.; Kumar, C.; Mulvihill, D.M.; Pillai, S.C. Opportunities and challenges in triboelectric nanogenerator (TENG) based sustainable energy generation technologies: A mini-review. Chem. Eng. J. Adv. 2022, 9, 100237. [Google Scholar] [CrossRef]

- Wang, C.; Chai, H.; Li, G.; Wang, W.; Tian, R.; Wen, G.-L.; Wang, C.H.; Lai, S.-K. Boosting biomechanical and wave energy harvesting efficiency through a novel triple hybridization of piezoelectric, electromagnetic, and triboelectric generators. Appl. Energy 2024, 374, 123876. [Google Scholar] [CrossRef]

- Yang, Y.; Zheng, L.; Wen, J.; Xing, F.; Liu, H.; Shang, Y.; Wang, Z.L.; Chen, B. A swing self-regulated triboelectric nanogenerator for high-entropy ocean breaking waves energy harvesting. Adv. Funct. Mater. 2023, 33, 2304366. [Google Scholar] [CrossRef]

- Zhu, B.; Wu, H.; Wang, H.; Quan, Z.; Luo, H.; Yang, L.; Liao, R.; Wang, J. Spherical 3D fractal structured dual-mode triboelectric nanogenerator for multidirectional low-frequency wave energy harvesting. Nano Energy 2024, 124, 109446. [Google Scholar] [CrossRef]

- Miao, Y.; Zhou, M.; Yi, J.; Wang, Y.; Tian, G.; Zhang, H.; Huang, W.; Wang, W.; Wu, R.; Ma, L. Woven fabric triboelectric nanogenerators for human-computer interaction and physical health monitoring. Nano Res. 2024, 17, 5540–5548. [Google Scholar] [CrossRef]

- Navaneeth, M.; Potu, S.; Babu, A.; Lakshakoti, B.; Rajaboina, R.K.; Kumar, K.U.; Divi, H.; Kodali, P.; Balaji, K. Transforming medical plastic waste into high-performance triboelectric nanogenerators for sustainable energy, health monitoring, and sensing applications. ACS Sustain. Chem. Eng. 2023, 11, 12145–12154. [Google Scholar] [CrossRef]

- Nazari-Vanani, R.; Vafaiee, M.; Zamanpour, F.; Asadian, E.; Mohammadpour, R.; Rafii-Tabar, H.; Sasanpour, P. Flexible triboelectric nanogenerator for promoting the proliferation and migration of human fibroblast cells. ACS Appl. Mater. Interfaces 2024, 16, 15773–15782. [Google Scholar] [CrossRef] [PubMed]

- Peng, W.; Zhu, R.; Ni, Q.; Zhao, J.; Zhu, X.; Mei, Q.; Zhang, C.; Liao, L. Functional tactile sensor based on arrayed triboelectric nanogenerators. Adv. Energy Mater. 2024, 14, 2403289. [Google Scholar] [CrossRef]

- Qu, X.; Liu, X.; Yue, Y.; Tang, Y.; Miao, P. Triboelectric nanogenerator-enabled self-powered strategies for sensing applications. TrAC Trends Anal. Chem. 2025, 185, 118191. [Google Scholar] [CrossRef]

- Solanki, S.; Gupta, A.K.; Saha, U.; Krasnoslobodtsev, A.V.; Gupta, R.K.; Malhotra, B.D. Triboelectric Nanogenerator-based smart biomedical sensors for healthcare. Sustain. Energy Technol. Assess. 2023, 57, 103233. [Google Scholar] [CrossRef]

- Venkatesan, H.M.; Arun, A.P. Nickel-oxide-doped polyvinylidene fluoride nanofiber-based flexible triboelectric nanogenerator for energy harvesting and healthcare monitoring applications. ACS Appl. Electron. Mater. 2024, 6, 1161–1173. [Google Scholar] [CrossRef]

- Xiao, Y.; Li, Z.; Xu, B. Flexible triboelectric nanogenerators based on hydrogel/g-C3N4 composites for biomechanical energy harvesting and self-powered sensing. ACS Appl. Mater. Interfaces 2024, 16, 13674–13684. [Google Scholar] [CrossRef]

- Xu, Q.; Gong, J.; Chen, J.; Zhang, Y.; Zhao, H.; Yin, J.; Zhao, R.; Lyu, C.; Ding, W.; Wu, C. Contactless Triboelectric Sensing for Real-Time 3D Motion Recognition in Human-Computer Interaction. Adv. Electron. Mater. 2025, 11, 2400950. [Google Scholar] [CrossRef]

- Xu, S.; Manshaii, F.; Xiao, X.; Chen, J. Artificial intelligence assisted nanogenerator applications. J. Mater. Chem. A 2025, 13, 832–854. [Google Scholar] [CrossRef]

- Bagheri, M.H.; Gu, E.; Khan, A.A.; Zhang, Y.; Xiao, G.; Nankali, M.; Peng, P.; Xi, P.; Ban, D. Machine Learning-Enabled Triboelectric Nanogenerator for Continuous Sound Monitoring and Captioning. Adv. Sens. Res. 2025, 4, 2400156. [Google Scholar] [CrossRef]

- Son, G.; Seo, D.; Kim, D.; Kim, S.; Kong, J.; Kim, K.; Chung, J. Capacitive Structure-Based Acoustic Triboelectric Nanogenerator for Advanced Warning Sound Recognition. Adv. Eng. Mater. 2025, 27, 2402442. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, Y.; Sun, X.; Wen, Z. Advances in triboelectric nanogenerators in acoustics: Energy harvesting and Sound sensing. Nano Trends 2024, 8, 100064. [Google Scholar] [CrossRef]

- Jiang, L.; Jia, H.; Xu, X.; Rong, W.; Wang, Q.; Chen, G.; Fan, J.; Xue, X. Effect of different geometric porosities on aerodynamic characteristics of supersonic parachutes. Space Sci. Technol. 2023, 3, 0062. [Google Scholar] [CrossRef]

- Sujatha, C. Fundamentals of acoustics. In Vibration, Acoustics and Strain Measurement: Theory and Experiments; Springer: Berlin/Heidelberg, Germany, 2023; pp. 161–217. [Google Scholar]

- Roh, T.; Yeo, H.G.; Joh, C.; Roh, Y.; Kim, K.; Seo, H.-s.; Choi, H. Fabrication and underwater testing of a vector hydrophone comprising a triaxial piezoelectric accelerometer and spherical hydrophone. Sensors 2022, 22, 9796. [Google Scholar] [CrossRef] [PubMed]

- Krishnan, K.; Gauni, S.; Manimegalai, C.; Malsawmdawngliana, V. Ambient noise analysis in underwater wireless communication using laser diode. Opt. Laser Technol. 2019, 114, 135–139. [Google Scholar] [CrossRef]

- Shi, S.; Geng, W.; Bi, K.; He, J.; Hou, X.; Mu, J.; Li, F.; Chou, X. Design and fabrication of a novel MEMS piezoelectric hydrophone. Sens. Actuators A Phys. 2020, 313, 112203. [Google Scholar] [CrossRef]

| F (Hz) | Structures I | Structures II | F (Hz) | Structures I | Structures II |

|---|---|---|---|---|---|

| 50 | 2.2 | 1.6 | 1000 | 30.1 | 3.6 |

| 63 | 2.4 | 2.1 | 1250 | 31.2 | 3 |

| 80 | 3.5 | 3.3 | 1600 | 34.3 | 2.5 |

| 100 | 15.8 | 24.5 | 2000 | 42.7 | 2.3 |

| 125 | 24.7 | 28.2 | 2500 | 10.4 | 2.1 |

| 160 | 25.6 | 27.6 | 3150 | 6.1 | N/A |

| 200 | 47.3 | 30.9 | 4000 | 4.6 | N/A |

| 250 | 27.6 | 28.1 | 5000 | 3.5 | N/A |

| 315 | 97.1 | 23.2 | 6300 | 5.2 | N/A |

| 400 | 274 | 22.9 | 8000 | 4.3 | N/A |

| 500 | 129.4 | 19.3 | 10,000 | 8 | N/A |

| 630 | 45.4 | 13.9 | 12,000 | 1.7 | N/A |

| 800 | 5.8 | 4.5 | N/A | N/A | N/A |

| F (Hz) | V (mV) | S (dB) | F (Hz) | V (mV) | S (dB) |

|---|---|---|---|---|---|

| 50 | 2.2 | −209.9 | 1000 | 30.1 | −197.3 |

| 63 | 2.4 | −216 | 1250 | 31.2 | −197.7 |

| 80 | 3.5 | −221.4 | 1600 | 34.3 | −202.4 |

| 100 | 15.8 | −212.6 | 2000 | 42.7 | −196 |

| 125 | 24.7 | −209.5 | 2500 | 10.4 | −211.5 |

| 160 | 25.6 | −205.5 | 3150 | 6.1 | −213.6 |

| 200 | 47.3 | −194.5 | 4000 | 4.6 | −203.3 |

| 250 | 27.6 | −195.7 | 5000 | 3.5 | −201.5 |

| 315 | 97.1 | −186.1 | 6300 | 5.2 | −197 |

| 400 | 274 | −174.6 | 8000 | 4.3 | −196.7 |

| 500 | 129.4 | −183.7 | 10,000 | 8 | −195.6 |

| 630 | 45.4 | −192.7 | 12,000 | 1.7 | −206 |

| 800 | 5.8 | −213.3 | N/A | N/A | N/A |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Y.; Liu, J.; Li, Y.; Na, X.; Qiu, W.; Tan, Q. Miniaturized Frustum-Cone Triboelectric Hydrophone Based on a Thin Film Perforated Tube Structure. Nanomaterials 2025, 15, 1765. https://doi.org/10.3390/nano15231765

Wu Y, Liu J, Li Y, Na X, Qiu W, Tan Q. Miniaturized Frustum-Cone Triboelectric Hydrophone Based on a Thin Film Perforated Tube Structure. Nanomaterials. 2025; 15(23):1765. https://doi.org/10.3390/nano15231765

Chicago/Turabian StyleWu, Yufen, Jing Liu, Yanling Li, Xin Na, Wei Qiu, and Qiang Tan. 2025. "Miniaturized Frustum-Cone Triboelectric Hydrophone Based on a Thin Film Perforated Tube Structure" Nanomaterials 15, no. 23: 1765. https://doi.org/10.3390/nano15231765

APA StyleWu, Y., Liu, J., Li, Y., Na, X., Qiu, W., & Tan, Q. (2025). Miniaturized Frustum-Cone Triboelectric Hydrophone Based on a Thin Film Perforated Tube Structure. Nanomaterials, 15(23), 1765. https://doi.org/10.3390/nano15231765