Advances in Through-Hole Anodic Aluminum Oxide (AAO) Membrane and Its Applications: A Review

Abstract

1. Introduction to Nanoporous Membrane for Science and Engineering

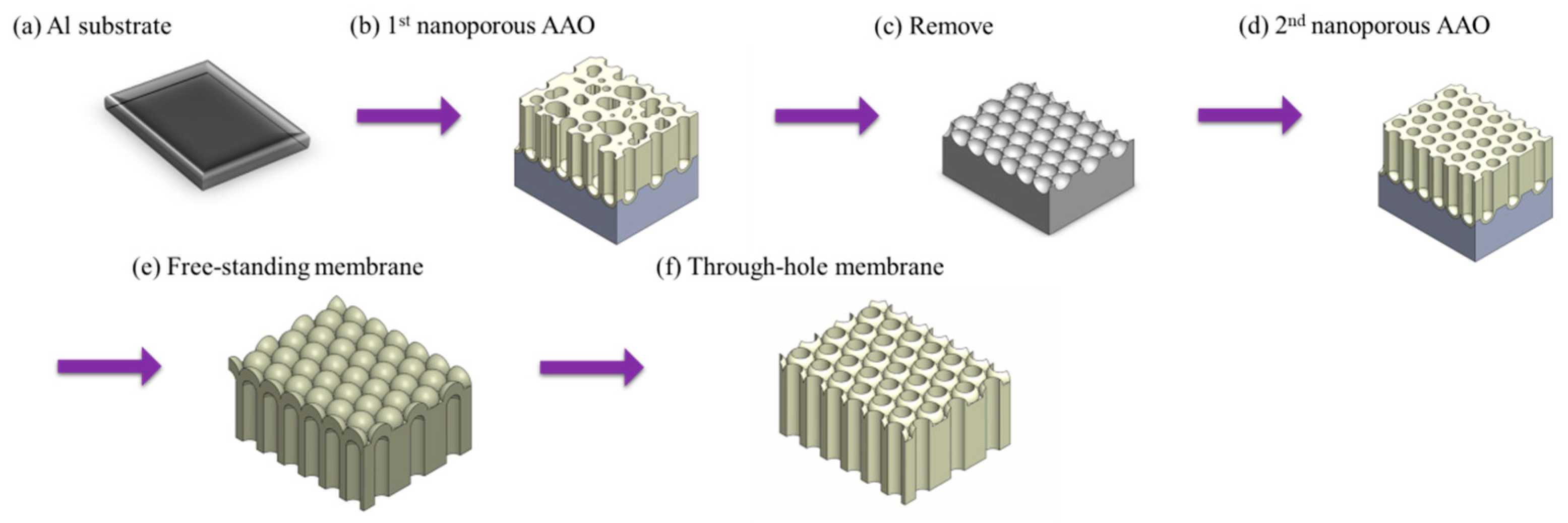

1.1. Anodic Aluminum Oxide (AAO) Through-Hole Membrane

1.2. Brief Development of AAO

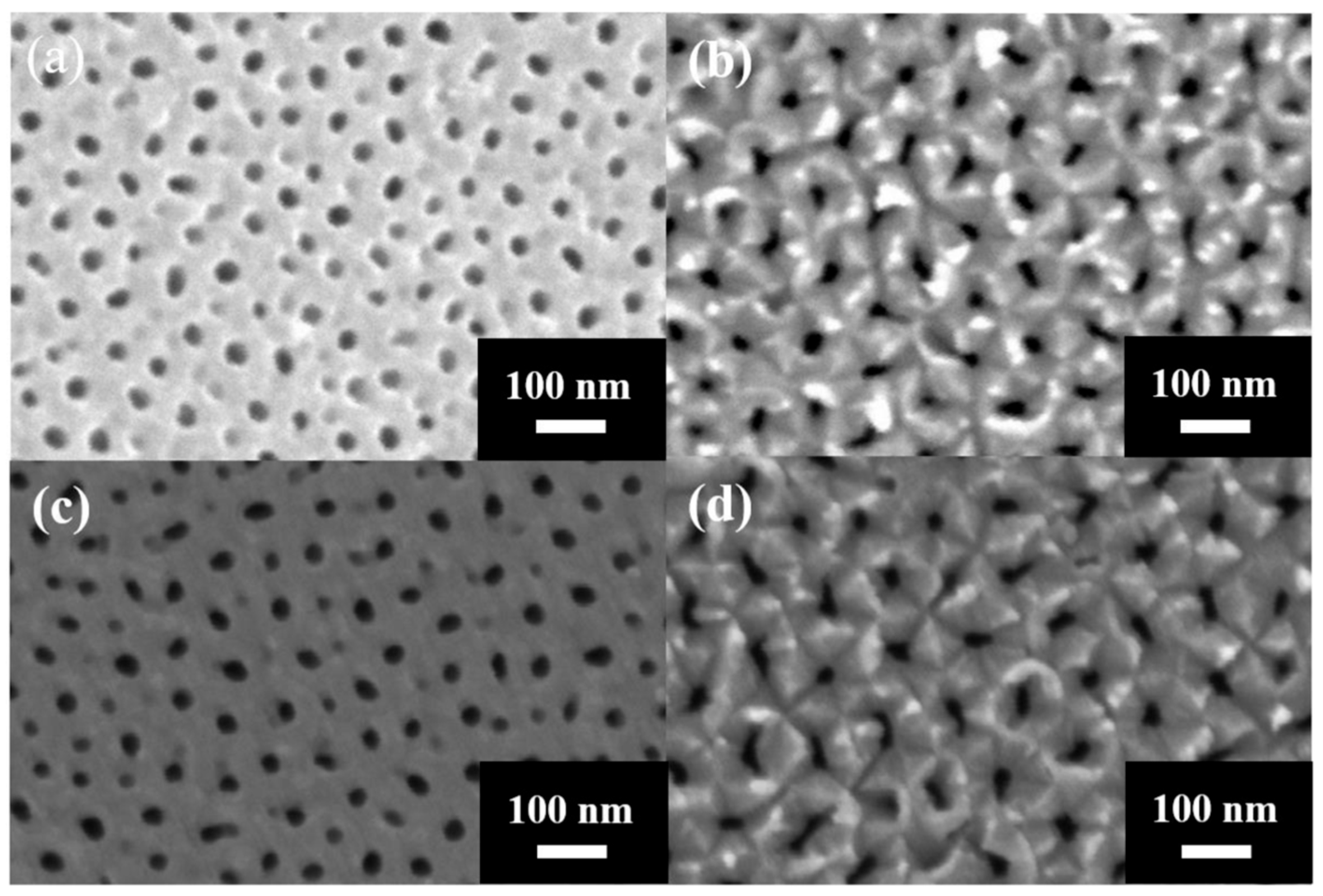

1.3. Post-Treatments After Anodization

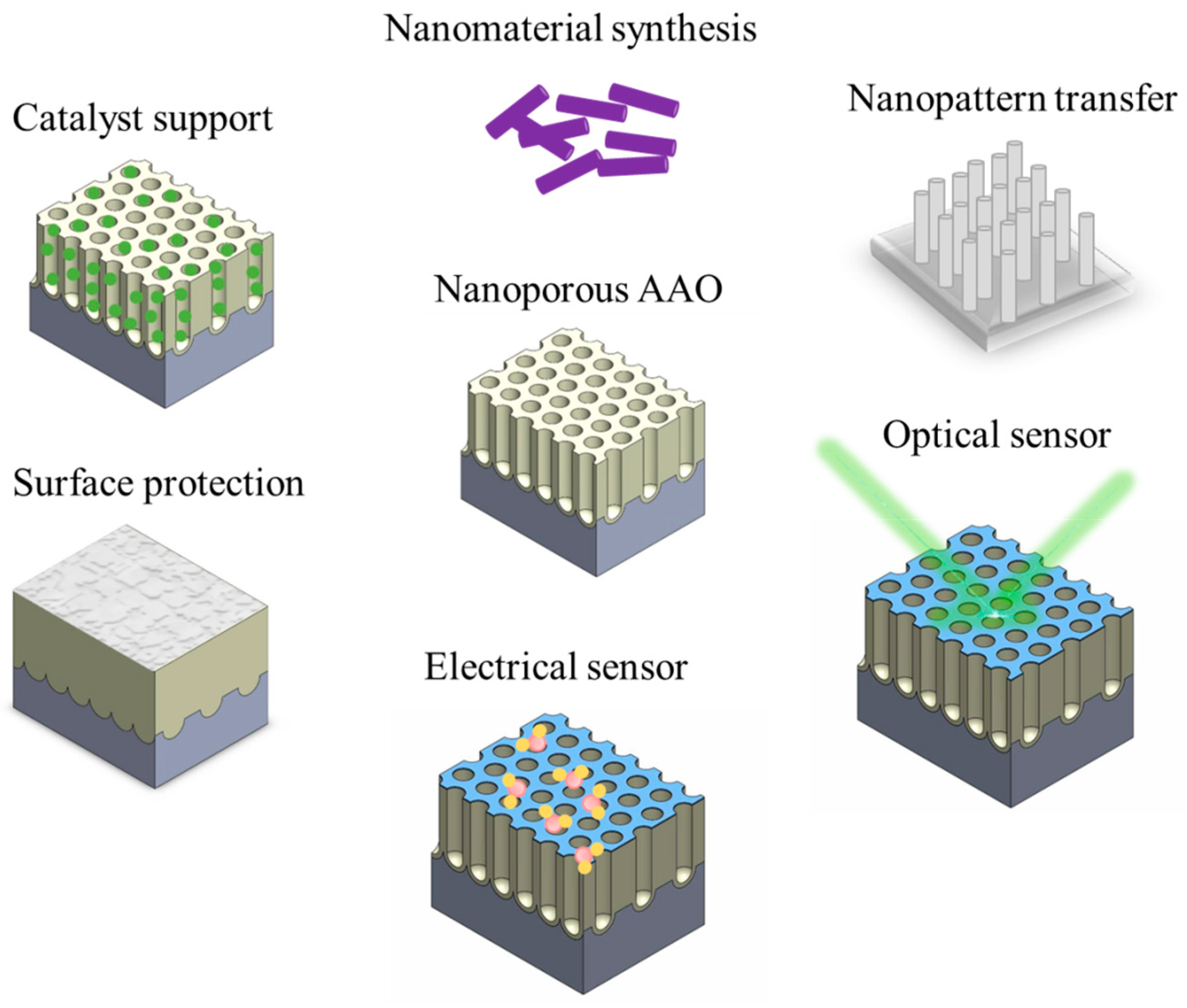

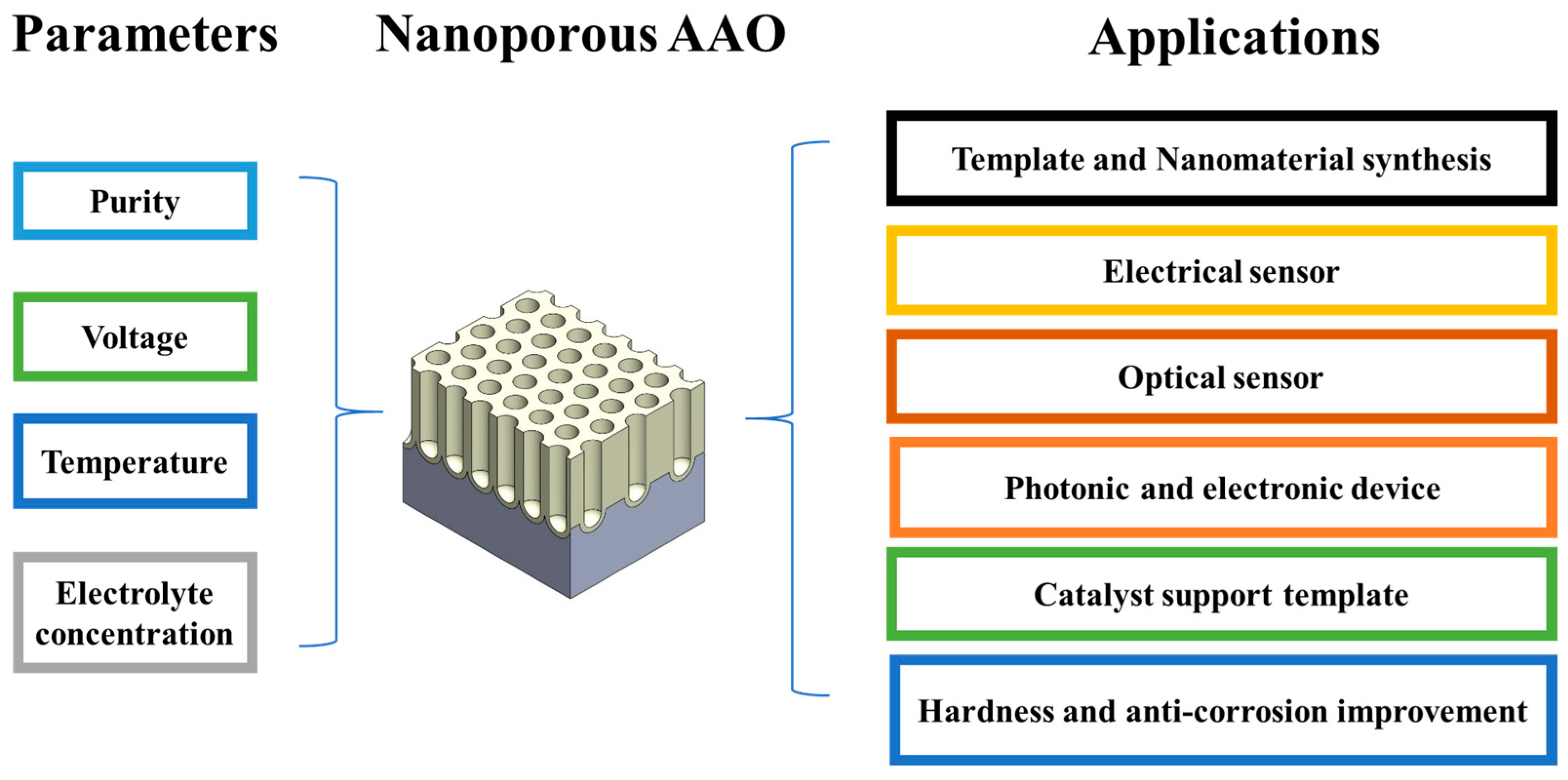

1.4. Applications Based on AAO Through-Hole Membrane

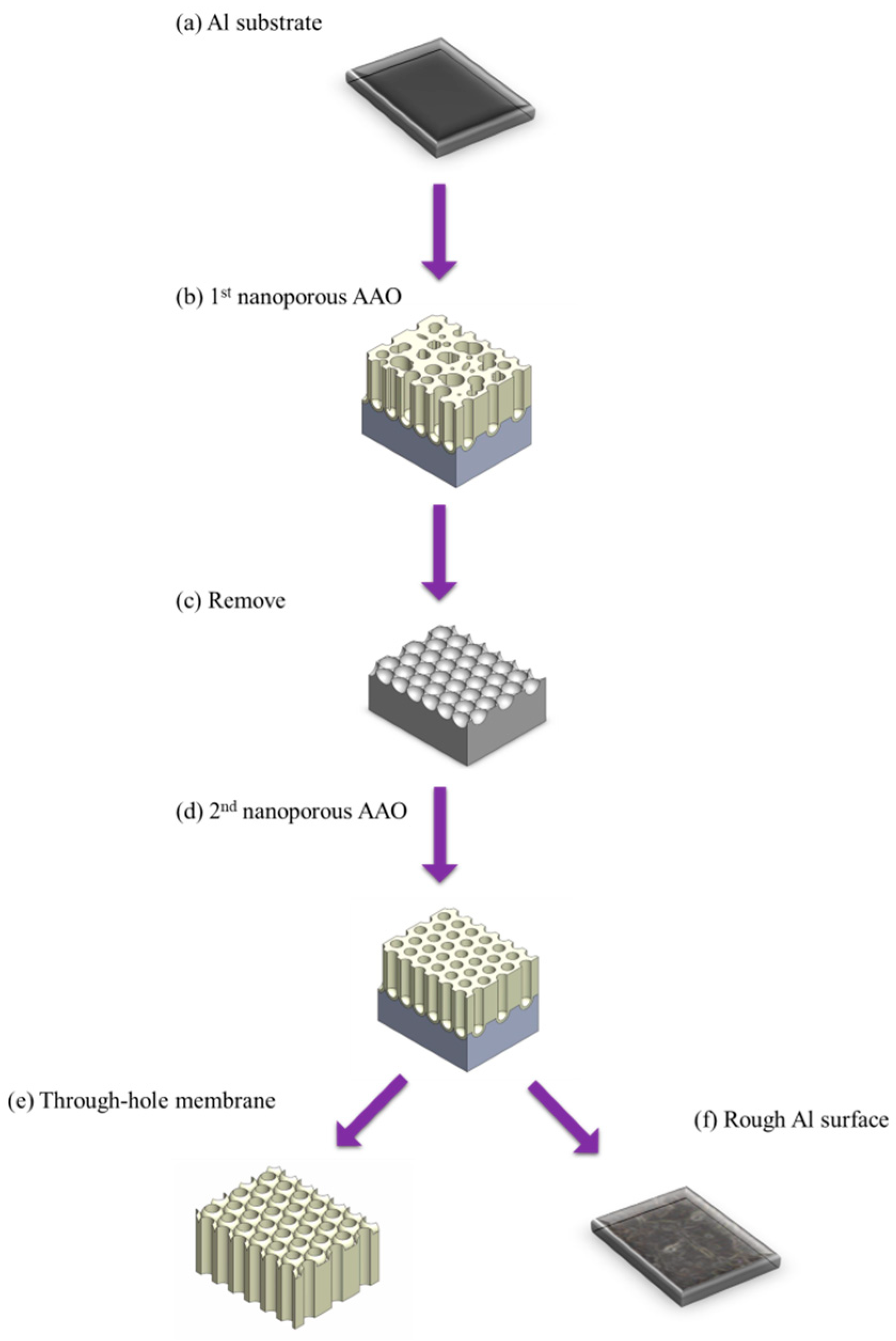

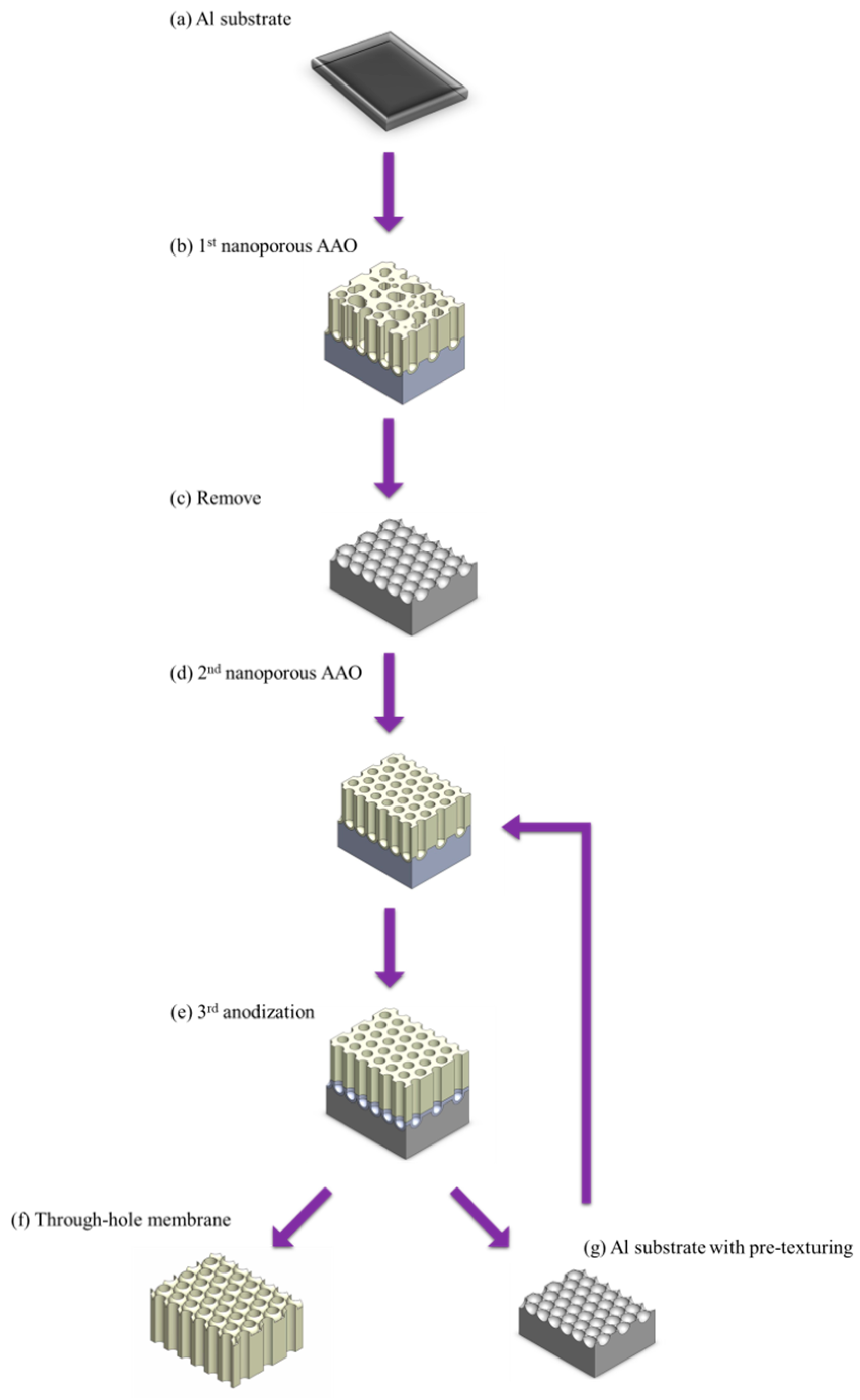

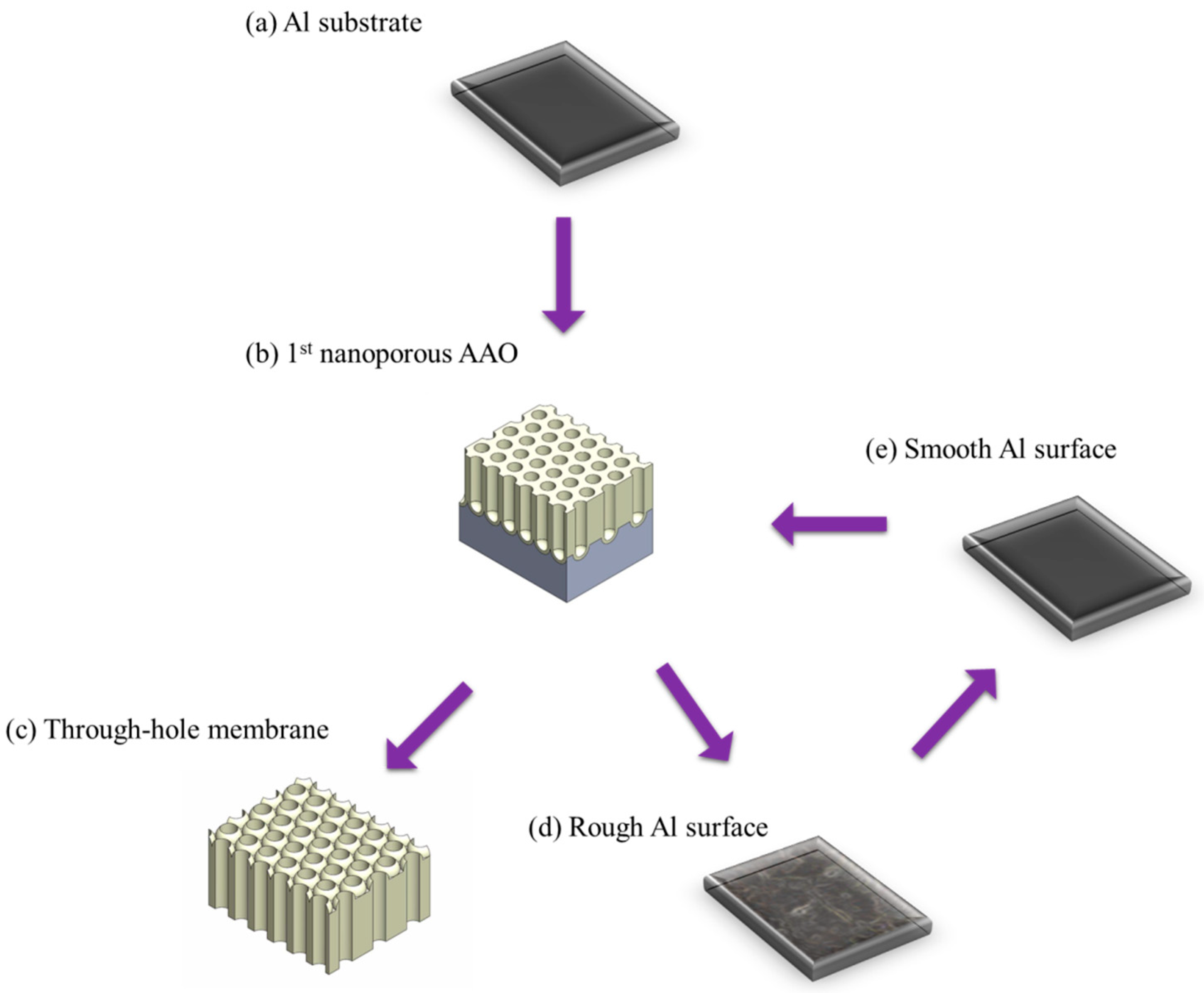

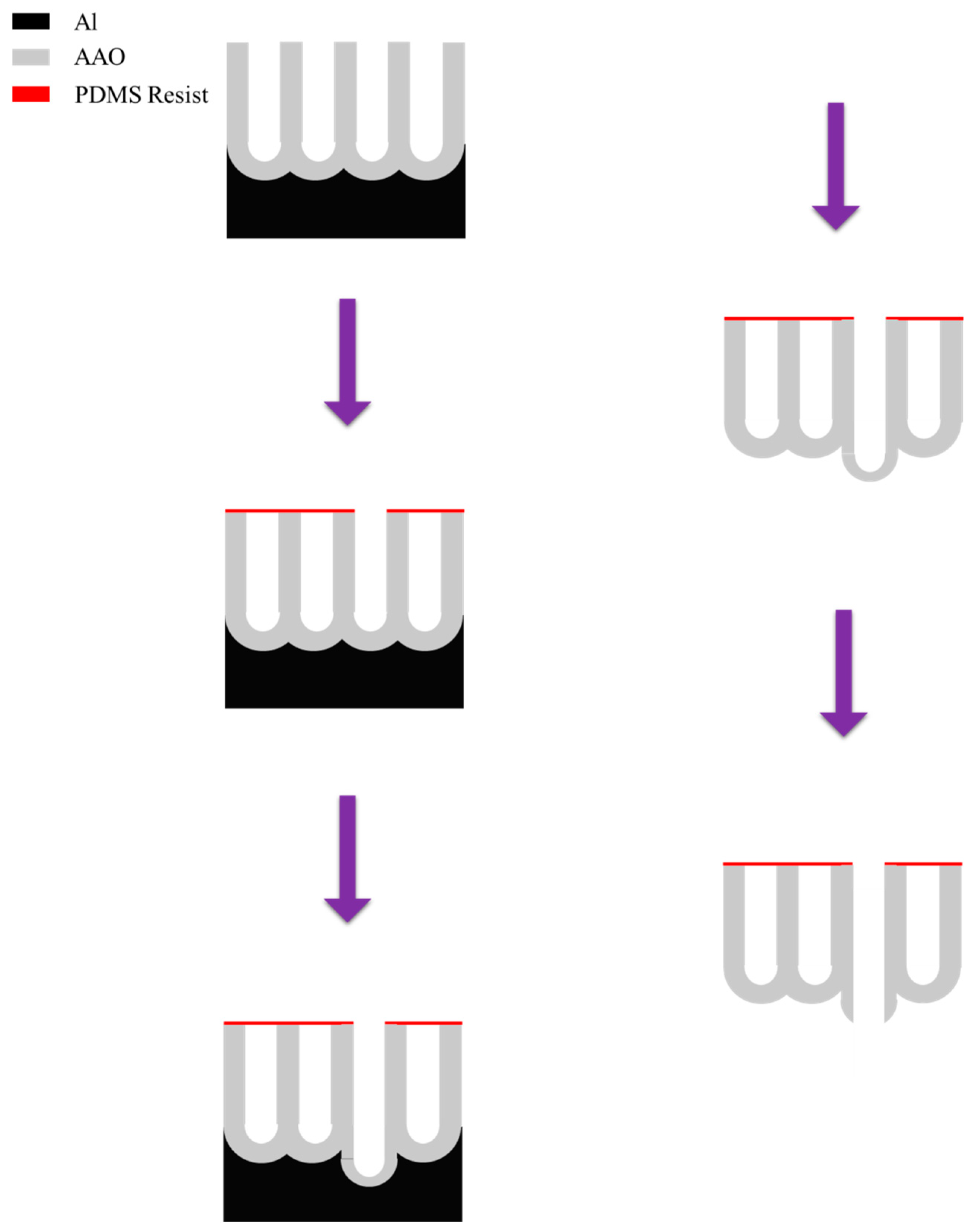

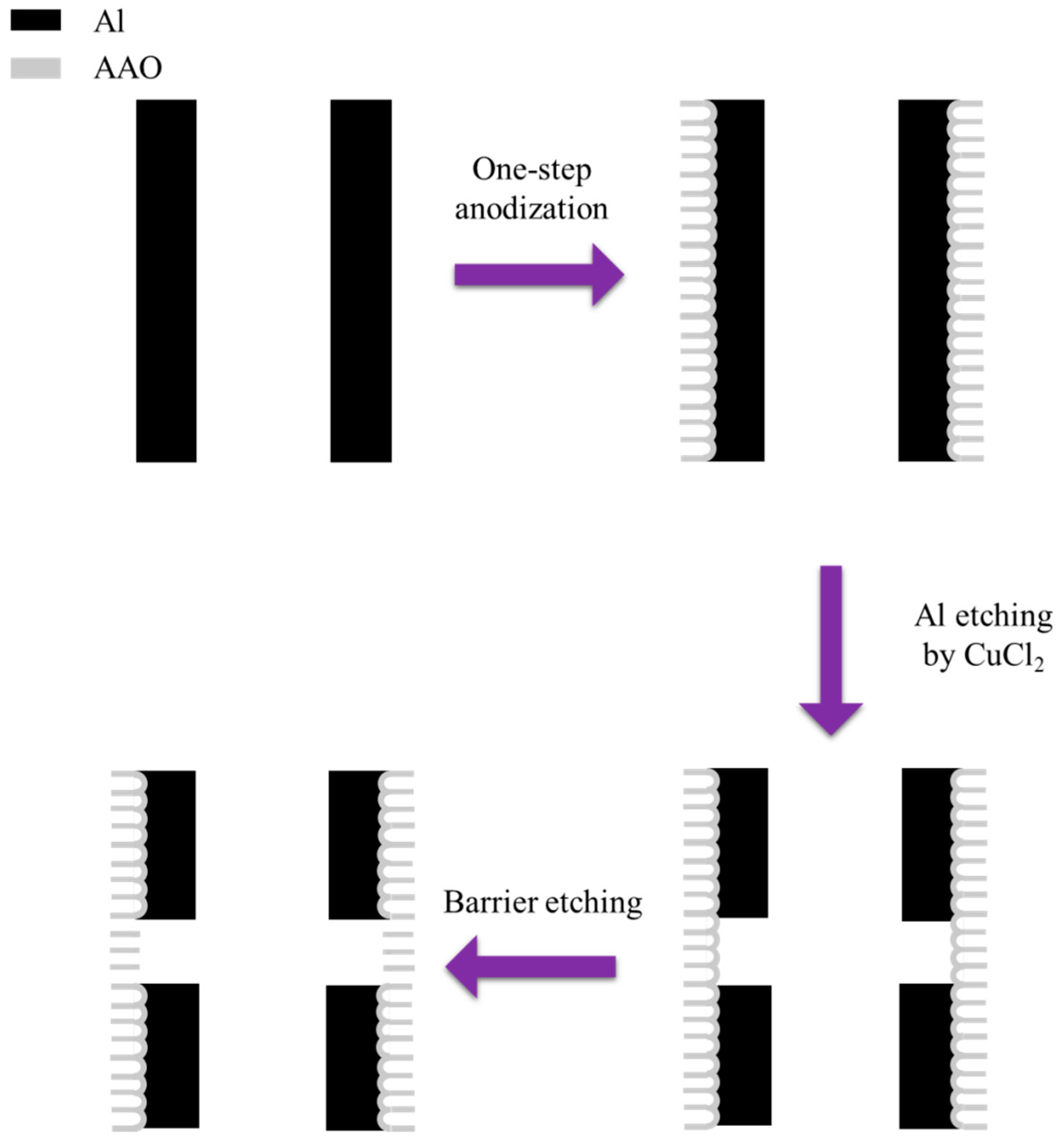

2. AAO Membrane Detachment Methods

2.1. Traditional Etching Method

2.2. Voltage Reduction Method

2.3. Reverse Bias Voltage Detachment Method

2.4. Pulse Voltage Detachment Method

2.5. Two-Layer Anodization Method

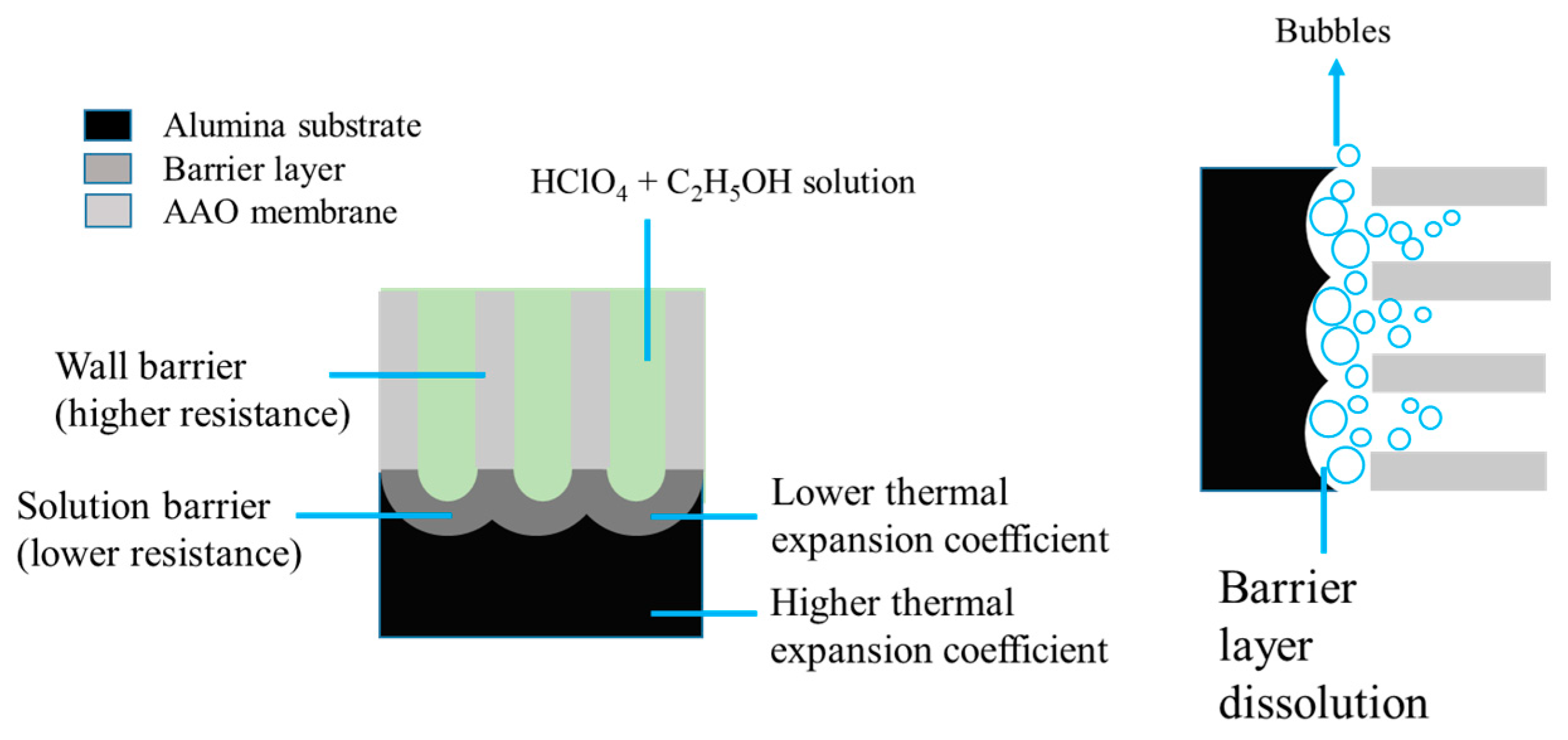

2.6. Constant Voltage Detachment Method

2.7. Summary of AAO Membrane Detachment Methods

3. Applications of Through-Hole AAO Membranes

3.1. Humidity Sensor

3.2. Nanomaterial Synthesis

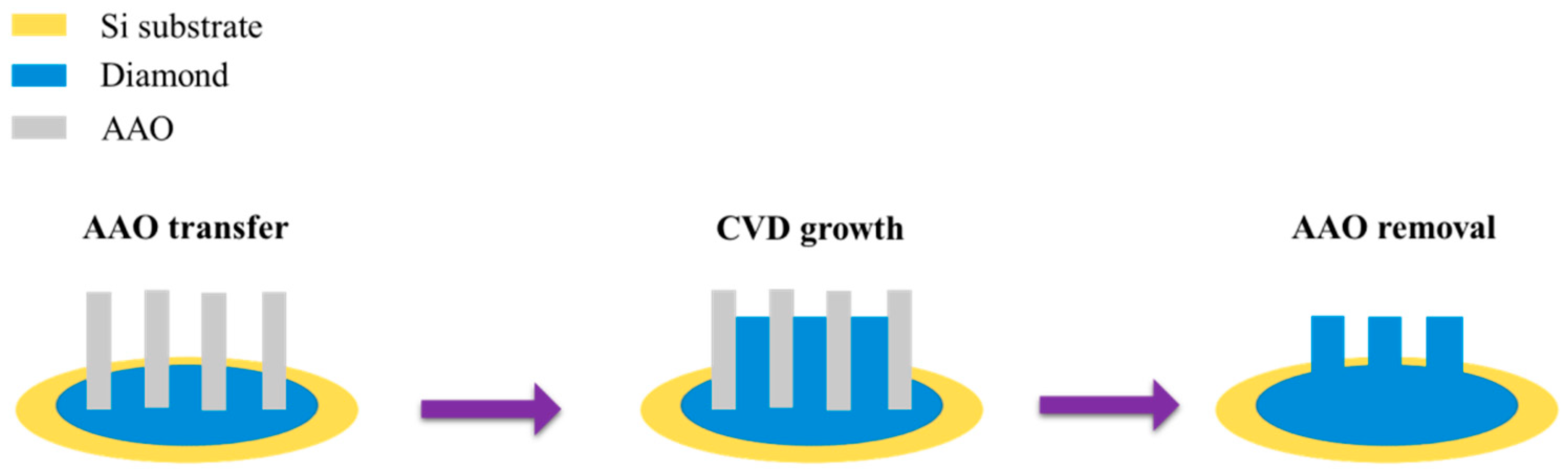

3.3. Mask

3.4. Filtration

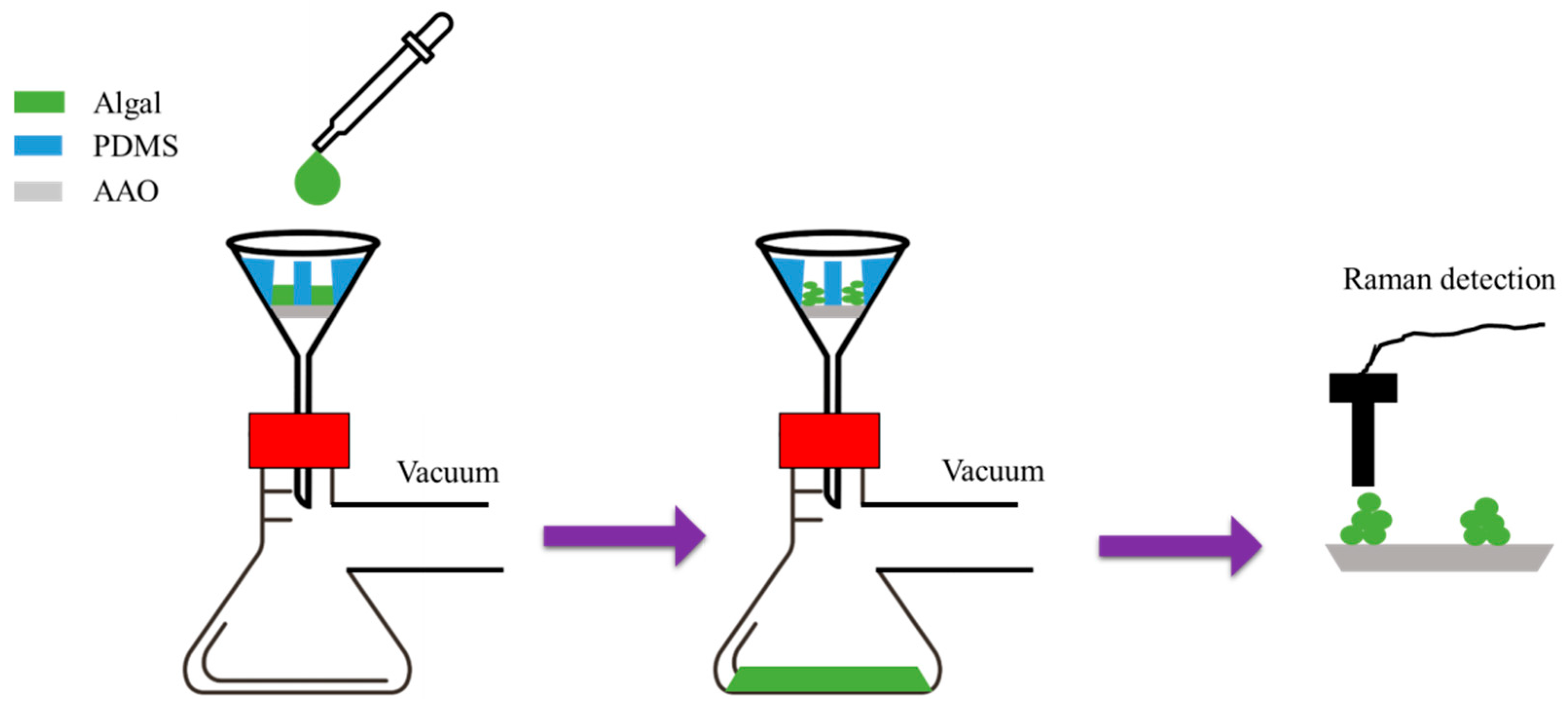

3.5. Raman and Surface-Enhanced Raman Scattering (SERS) Applications

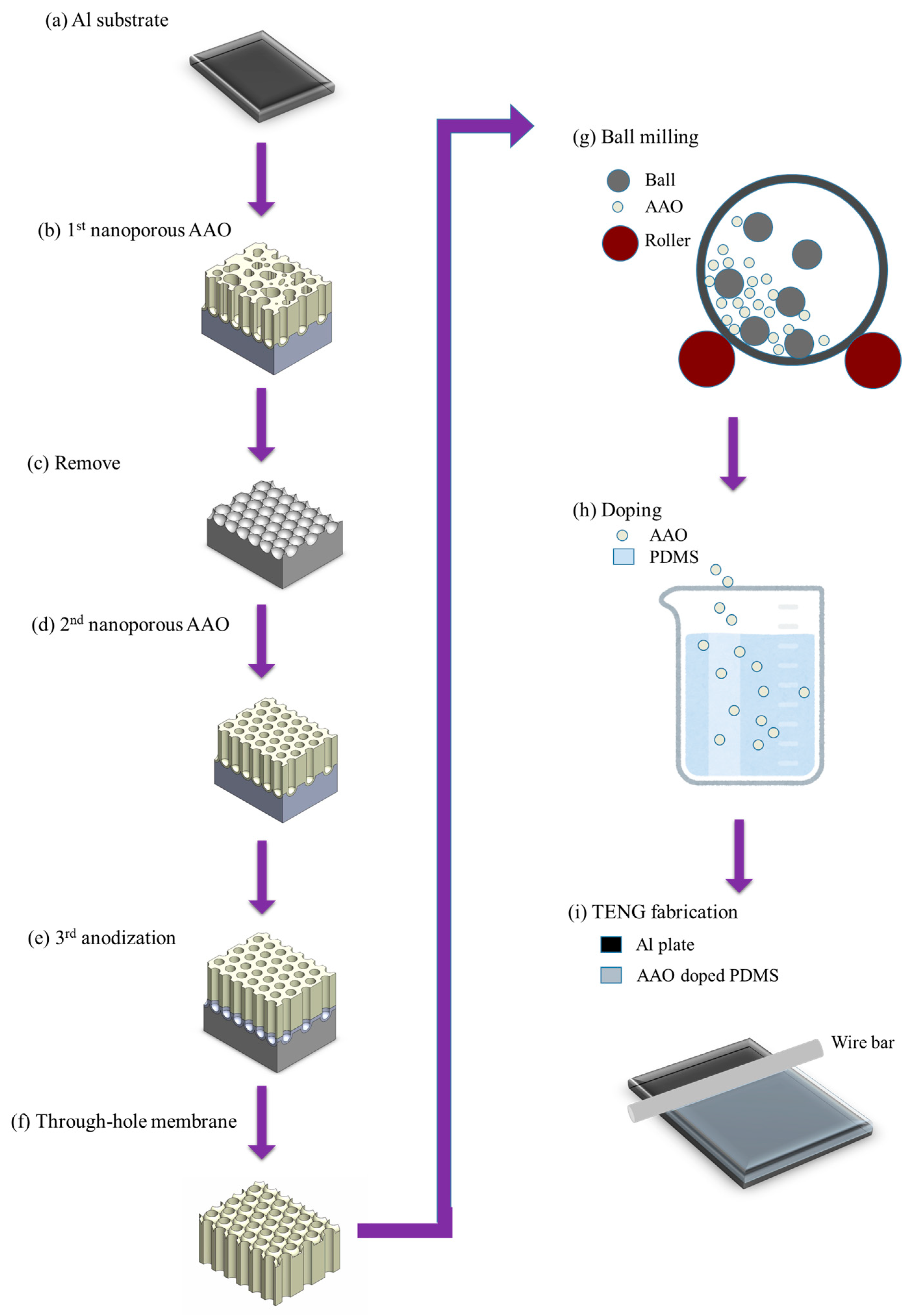

3.6. Tribo-Electrical Nano-Generators (TENG)

3.7. Summary of Applications of Through-Hole AAO Membranes

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Priya, A.K.; Gnanasekaran, L.; Kumar, P.S.; Jalil, A.A.; Hoang, T.K.; Rajendran, S.; Soto-Moscoso, M.; Balakrishnan, D. Recent trends and advancements in nanoporous membranes for water purification. Chemosphere 2022, 303, 135205. [Google Scholar] [CrossRef] [PubMed]

- Sun, M.; Han, K.; Hu, R.; Liu, D.; Fu, W.; Liu, W. Advances in micro/nanoporous membranes for biomedical engineering. Adv. Healthc. Mater. 2021, 10, 2001545. [Google Scholar] [CrossRef]

- Hussain, A.; Gul, H.; Raza, W.; Qadir, S.; Rehan, M.; Raza, N.; Helal, A.; Shaikh, M.N.; Aziz, M.A. Micro and nanoporous membrane platforms for carbon neutrality: Membrane gas separation prospects. Chem. Rec. 2024, 24, e202300352. [Google Scholar] [CrossRef]

- Asif, M.B.; Iftekhar, S.; Maqbool, T.; Pramanik, B.K.; Tabraiz, S.; Sillanpää, M.; Zhang, Z. Two-dimensional nanoporous and lamellar membranes for water purification: Reality or a myth? Chem. Eng. J. 2022, 432, 134335. [Google Scholar] [CrossRef]

- Kausar, A.; Ahmad, I.; Aldaghri, O.; Ibnaouf, K.H.; Eisa, M.H.; Lam, T.D. Potential of nanoporous graphene and functionalized nanoporous graphene derived nanocomposites for environmental membranes—A review. Nanocomposites 2024, 10, 138–158. [Google Scholar] [CrossRef]

- Zeng, M.; Chen, M.; Huang, D.; Lei, S.; Zhang, X.; Wang, L.; Cheng, Z. Engineered two-dimensional nanomaterials: An emerging paradigm for water purification and monitoring. Mater. Horiz. 2021, 8, 758–802. [Google Scholar] [CrossRef] [PubMed]

- Shiohara, A.; Prieto-Simon, B.; Voelcker, N.H. Porous polymeric membranes: Fabrication techniques and biomedical applications. J. Mater. Chem. B 2021, 9, 2129–2154. [Google Scholar] [CrossRef] [PubMed]

- Huang, J.; Zhang, Y.; Guo, J.; Yang, F.; Ma, J.; Bai, Y.; Shao, L.; Liu, S.; Wang, H. Polymeric membranes with highly homogenized nanopores for ultrafast water purification. Nat. Sustain. 2024, 7, 901–909. [Google Scholar] [CrossRef]

- Guo, Z.; Li, F.; Wu, X.; Liang, Z.; Junaid, M.; Xie, J.; Lu, L.; Duan, J.; Liu, J.; Yao, H. Efficient ion sieving and ion transport properties in sub-nanoporous polyetherimide membranes. Desalination 2024, 573, 117192. [Google Scholar] [CrossRef]

- Lin, Y.C.; Lee, L.R.; Liu, Y.C.; Gautam, B.; Ho, J.H.; Tsai, T.H.; Lin, J.; Zheng, Y.H.; Chen, J.T. Advancing Nanopore Technology: Anodic Aluminum Oxide Membranes with Anisotropic Pores through Controlled Stretching for Applications in Nanopatterning. ACS Appl. Nano Mater. 2024, 7, 14707–14718. [Google Scholar] [CrossRef]

- Osama, L.; Handal, H.T.; El-Sayed, S.A.; Elzayat, E.M.; Mabrouk, M. Fabrication and optimisation of alumina nanoporous membranes for drug delivery applications: A comparative study. Nanomaterials 2024, 14, 1078. [Google Scholar] [CrossRef]

- Anis, S.F.; Lalia, B.S.; Hashaikeh, R.; Hilal, N. Titanium coating on ultrafiltration inorganic membranes for fouling control. Sep. Purif. Technol. 2022, 282, 119997. [Google Scholar] [CrossRef]

- Almohammedi, A.; Shaban, M.; Mostafa, H.; Rabia, M. Nanoporous TiN/TiO2/alumina membrane for photoelectrochemical hydrogen production from sewage water. Nanomaterials 2021, 11, 2617. [Google Scholar] [CrossRef]

- Zhou, X.; Heiranian, M.; Yang, M.; Epsztein, R.; Gong, K.; White, C.E.; Hu, S.; Kim, J.H.; Elimelech, M. Selective fluoride transport in subnanometer TiO2 pores. ACS Nano 2021, 15, 16828–16838. [Google Scholar] [CrossRef]

- Amaraweera, S.M.; Gunathilake, C.A.; Gunawardene, O.H.; Dassanayake, R.S.; Cho, E.B.; Du, Y. Carbon capture using porous silica materials. Nanomaterials 2023, 13, 2050. [Google Scholar] [CrossRef] [PubMed]

- O’Connell, K.C.; Landers, J.P. Integrated membranes within centrifugal microfluidic devices: A review. Lab A Chip 2023, 23, 3130–3159. [Google Scholar] [CrossRef] [PubMed]

- Imad, M.; Castro-Muñoz, R. Ongoing progress on pervaporation membranes for ethanol separation. Membranes 2023, 13, 848. [Google Scholar] [CrossRef]

- Singh, H.; Saxena, P.; Puri, Y.M. The manufacturing and applications of the porous metal membranes: A critical review. CIRP J. Manuf. Sci. Technol. 2021, 33, 339–368. [Google Scholar] [CrossRef]

- Koya, A.N.; Zhu, X.; Ohannesian, N.; Yanik, A.A.; Alabastri, A.; Proietti Zaccaria, R.; Krahne, R.; Shih, W.C.; Garoli, D. Nanoporous metals: From plasmonic properties to applications in enhanced spectroscopy and photocatalysis. ACS Nano 2021, 15, 6038–6060. [Google Scholar] [CrossRef] [PubMed]

- Masuda, H.; Fukuda, K. Ordered metal nanohole arrays made by a two-step replication of honeycomb structures of anodic alumina. Science 1995, 268, 1466–1468. [Google Scholar] [CrossRef]

- Yu, C.Y.; Chung, C.K. Novel irregular pore peripheral plasmonic mechanism of nanocomposite metal-nanoporous AAO using new facile one-step anodization and pore widening for high SERS enhancement. Appl. Surf. Sci. 2022, 580, 152252. [Google Scholar] [CrossRef]

- Xiong, H.; Liu, H.; Feng, X.; Sun, Y.; Huang, Q.; Xiao, C. A review of two-dimensional porous graphene with in-plane pores: Pore construction and membrane applications. Carbon 2024, 229, 119547. [Google Scholar] [CrossRef]

- Zhang, W.H.; Yin, M.J.; Zhao, Q.; Jin, C.G.; Wang, N.; Ji, S.; Ritt, C.L.; Elimelech, M.; An, Q.F. Graphene oxide membranes with stable porous structure for ultrafast water transport. Nat. Nanotechnol. 2021, 16, 337–343. [Google Scholar] [CrossRef] [PubMed]

- Han, Z.Y.; Huang, L.J.; Qu, H.J.; Wang, Y.X.; Zhang, Z.J.; Rong, Q.L.; Sang, Z.; Wang, Y.; Kipper, M.J.; Tang, J.G. A review of performance improvement strategies for graphene oxide-based and graphene-based membranes in water treatment. J. Mater. Sci. 2021, 56, 9545–9574. [Google Scholar] [CrossRef]

- Kim, J.; Kang, J.; Kim, J.P.; Kim, J.Y.; Kim, J.H.; Kwon, O.; Kim, D.W. Scalable fabrication of nanoporous multilayer graphene oxide membrane for organic solvent nanofiltration. Carbon 2023, 207, 162–171. [Google Scholar] [CrossRef]

- Joshi, D.J.; Koduru, J.R.; Malek, N.I.; Hussain, C.M.; Kailasa, S.K. Surface modifications and analytical applications of graphene oxide: A review. TrAC Trends Anal. Chem. 2021, 144, 116448. [Google Scholar] [CrossRef]

- Nitodas, S.F.; Das, M.; Shah, R. Applications of polymeric membranes with carbon nanotubes: A review. Membranes 2022, 12, 454. [Google Scholar] [CrossRef]

- Yusmaidi, N.; Wahab, R.A.; Lau, W.J.; Ur-Rehman, G. The future of microporous membranes modified by functionalized carbon nanotubes (CNTs) for water and wastewater treatment: A review. React. Funct. Polym. 2025, 215, 106364. [Google Scholar] [CrossRef]

- Barrejón, M.; Prato, M. Carbon nanotube membranes in water treatment applications. Adv. Mater. Interfaces 2022, 9, 2101260. [Google Scholar] [CrossRef]

- Zhang, Z.; Simon, A.; Abetz, C.; Held, M.; Höhme, A.L.; Schneider, E.S.; Segal-Peretz, T.; Abetz, V. Hybrid organic–inorganic–organic isoporous membranes with tunable pore sizes and functionalities for molecular separation. Adv. Mater. 2021, 33, 2105251. [Google Scholar] [CrossRef]

- Mansour, N.B.; Djeridi, W.; Mir, L.E. Preparation, properties and applications of the hybrid organic/inorganic nanocomposite based on nanoporous carbon matrix. J. Inorg. Organomet. Polym. Mater. 2021, 31, 4360–4371. [Google Scholar] [CrossRef]

- Manawi, Y.; Jawad, J.; Hussain, A.; Aljlil, S.; Lawler, J.; Kochkodan, V. Enhancement of membrane distillation performance by porous organic and inorganic materials: A state-of-the-art review. Appl. Water Sci. 2025, 15, 117. [Google Scholar] [CrossRef]

- Lv, X.W.; Weng, C.C.; Zhu, Y.P.; Yuan, Z.Y. Nanoporous metal phosphonate hybrid materials as a novel platform for emerging applications: A critical review. Small 2021, 17, 2005304. [Google Scholar] [CrossRef] [PubMed]

- Chongdar, S.; Bhattacharjee, S.; Bhanja, P.; Bhaumik, A. Porous organic–inorganic hybrid materials for catalysis, energy and environmental applications. Chem. Commun. 2022, 58, 3429–3460. [Google Scholar] [CrossRef] [PubMed]

- Wu, Q.; Zhang, S.; Zuo, X.; Liu, L.; Xiong, J.; He, J.; Zhou, Y.; Ma, C.; Chen, Z.; Yu, S. Preparation and characterization of CeO2@ high silica ZSM-5 inorganic-organic hybrid polyamide nanofiltration membrane. J. Membr. Sci. 2022, 641, 119887. [Google Scholar] [CrossRef]

- Hussain, S.; Peng, X.; Wang, L. Porphyrinic metal–organic frameworks as separation membranes: From synthesis to advanced applications. Mater. Horiz. 2025, 12, 4608–4638. [Google Scholar] [CrossRef]

- Chen, J.; Guo, Z.; Xin, Y.; Gu, Z.; Zhang, L.; Guo, X. Organic–inorganic hybrid nanoflowers: A comprehensive review of current trends, advances, and future perspectives. Coord. Chem. Rev. 2023, 489, 215191. [Google Scholar] [CrossRef]

- Ku, C.A.; Yu, C.Y.; Hung, C.W.; Chung, C.K. Advances in the Fabrication of Nanoporous Anodic Aluminum Oxide and Its Applications to Sensors: A Review. Nanomaterials 2023, 13, 2853. [Google Scholar] [CrossRef]

- Eessaa, A.K.; El-Shamy, A.M. Review on fabrication, characterization, and applications of porous anodic aluminum oxide films with tunable pore sizes for emerging technologies. Microelectron. Eng. 2023, 279, 112061. [Google Scholar] [CrossRef]

- Araujo, J.V.D.S.; Milagre, M.; Costa, I. A historical, statistical and electrochemical approach on the effect of microstructure in the anodizing of Al alloys: A review. Crit. Rev. Solid State Mater. Sci. 2024, 49, 521–581. [Google Scholar] [CrossRef]

- Abd-Elnaiem, A.M.; Mohamed, Z.E.A.; Elshahat, S.; Almokhtar, M.; Norek, M. Recent progress in the fabrication of photonic crystals based on porous anodic materials. Energies 2023, 16, 4032. [Google Scholar] [CrossRef]

- Wang, J.; Vu, K.N.; Abell, A.D.; Santos, A.; Law, C.S. Nanoporous anodic alumina-based iontronics: Fundamentals and applications. J. Mater. Chem. C 2023, 11, 9051–9081. [Google Scholar] [CrossRef]

- Kozhukharov, S.; Girginov, C.; Portolesi, S.; Tsanev, A.; Lilova, V.; Petkov, P. Optimal current density for cathodic CeCC deposition on anodized AA2024-T3 aircraft alloy. J. Appl. Electrochem. 2024, 54, 2887–2918. [Google Scholar] [CrossRef]

- Korzekwa, J. Modification of the structure and properties of oxide layers on aluminium alloys: A review. Rev. Adv. Mater. Sci. 2023, 62, 20230108. [Google Scholar] [CrossRef]

- Jing, C.; Wang, R.; Zhao, F.; Zhang, L.; He, Q.; Tong, X. Preparation of 1060, 2024 and 7075 aluminum alloy anodic oxide films. Coatings 2021, 11, 1498. [Google Scholar] [CrossRef]

- Park, J.; Son, K.; Lee, J.; Kim, D.; Chung, W. Effects of Anodizing conditions on thermal properties of Al 20XX alloys for aircraft. Symmetry 2021, 13, 433. [Google Scholar] [CrossRef]

- Paz Martínez-Viademonte, M.; Abrahami, S.T.; Hack, T.; Burchardt, M.; Terryn, H. A review on anodizing of aerospace aluminum alloys for corrosion protection. Coatings 2020, 10, 1106. [Google Scholar] [CrossRef]

- Belaud, C.; Vercillo, V.; Kolb, M.; Bonaccurso, E. Development of nanostructured icephobic aluminium oxide surfaces for aeronautic applications. Surf. Coat. Technol. 2021, 405, 126652. [Google Scholar] [CrossRef]

- Ku, C.A.; Wu, C.C.; Hung, C.W.; Chung, C.K. Influence of Normal-to-High Anodizing Voltage on AAO Surface Hardness from 1050 Aluminum Alloy in Oxalic Acid. Micromachines 2024, 15, 683. [Google Scholar] [CrossRef]

- Van Pham, H.; Kwon, D.; Kim, J.; Kim, R.; Moon, S. Formation behavior of anodizing films on various aluminum alloys in oxalic acid solution. Mater. Chem. Phys. 2024, 315, 128953. [Google Scholar] [CrossRef]

- Abedini, M.; Hanke, S. Improving the wear resistance of aluminum by a nickel-filled anodized porous alumina layer. Wear 2023, 522, 204858. [Google Scholar] [CrossRef]

- Sundararajan, M.; Devarajan, M.; Jaafar, M. A novel sealing and high scratch resistant nanorod Ni-P coating on anodic aluminum oxide. Mater. Lett. 2021, 289, 129425. [Google Scholar] [CrossRef]

- Sundararajan, M.; Devarajan, M.; Jaafar, M. Electroless Ni–B sealing on nanoporous anodic aluminum oxide pattern: Deposition and evaluation of its characteristic properties. J. Mater. Res. Technol. 2022, 19, 4504–4516. [Google Scholar] [CrossRef]

- He, W.; Liu, Y.; Jia, Y.; Zhao, Y.; Le, H. Corrosion resistance and long-term antibacterial performance of ZnO-Al2O3 nanocomposite coatings on aluminum alloy. Compos. Commun. 2024, 51, 102110. [Google Scholar] [CrossRef]

- Zhou, M.; Dong, Y.; Liu, F.; Yu, Y.; Peng, S. Construction of a superhydrophobic surface with long-term durability on 5052 Aluminium for corrosion protection. Surf. Interfaces 2024, 54, 105159. [Google Scholar] [CrossRef]

- Yun, J.; Lee, S.J. Lubricant-infused anodic aluminum oxide surface (AAO-LIS) for durable slipperiness under harsh conditions. Surf. Coat. Technol. 2024, 477, 130283. [Google Scholar] [CrossRef]

- Portolesi, S.; Girginov, C.; Kozhukharov, S.; Lilova, V.; Petkov, P. Enhancing surface characteristics of AA2024-T3 aircraft alloy through synergistic anodization and cerium conversion coating. Part I: Performance in model corrosive medium. J. Chem. Technol. Metall. 2024, 59, 1289–1304. [Google Scholar] [CrossRef]

- Zhou, Z.; Zheng, S.; Chen, J.; Zhang, T.; He, Z.; Wang, Y. Corrosion and protection of friction stir welding of magnesium alloy. Anti-Corros. Methods Mater. 2024, 71, 47–54. [Google Scholar] [CrossRef]

- Grayeli, A.R.; Balashabadi, P.; Mojtahedzadeh, M. Structural and Hydrophilic Properties of Nanoporous Aluminium Oxide Film as a Function of Voltage Anodization. ECS J. Solid State Sci. Technol. 2024, 13, 113003. [Google Scholar] [CrossRef]

- Kim, J.; Jeong, C. Research on variation in nanopore parameters and surface characteristics of anodic aluminum oxide (AAO) films with time-controlled anodization processes. J. Mater. Sci. 2024, 59, 10556–10571. [Google Scholar] [CrossRef]

- Balasankar, A.; Venkatesan, R.; Jeong, D.Y.; Oh, T.H.; Kim, S.C.; Vetcher, A.A.; Ramasundaram, S. Facile Fabrication of Hierarchical Structured Anodic Aluminum Oxide Molds for Large-Scale Production of Superhydrophobic Polymer Films. Polymers 2024, 16, 2344. [Google Scholar] [CrossRef]

- Hormozi, M.A.; Yaghoubi, M.; Bahrololoom, M.E. A facile method for fabrication of hybrid hydrophobic-hydrophilic surfaces on anodized aluminum template by electrophoretic deposition. Thin Solid Film. 2021, 724, 138597. [Google Scholar] [CrossRef]

- Cho, H.; Kim, T.; Kim, S. Tunable thickness and uniform drop deposition of graphene oxide on porous anodic aluminum oxide and a reliable thickness measurement technique. Surf. Topogr. Metrol. Prop. 2021, 9, 025026. [Google Scholar] [CrossRef]

- Kim, Y.; Kim, W.B. Enhancing the surface hydrophilicity of an aluminum alloy using two-step anodizing and the effect on inkjet printing characteristics. Coatings 2023, 13, 232. [Google Scholar] [CrossRef]

- Baek, S.; Moon, H.S.; Kim, W.; Jeon, S.; Yong, K. Effect of liquid droplet surface tension on impact dynamics over hierarchical nanostructure surfaces. Nanoscale 2018, 10, 17842–17851. [Google Scholar] [CrossRef] [PubMed]

- Chu, C.W.; Tsai, C.H. Surface Modification of Nanopores in an Anodic Aluminum Oxide Membrane through Dopamine-Assisted Codeposition with a Zwitterionic Polymer. Langmuir 2024, 40, 5245–5254. [Google Scholar] [CrossRef]

- Zhang, C.; Liu, Z.; Li, C.; Cao, J.; Buijnsters, J.G. Templated synthesis of diamond nanopillar arrays using porous anodic aluminium oxide (AAO) membranes. Nanomaterials 2023, 13, 888. [Google Scholar] [CrossRef] [PubMed]

- Kang, W.S.; Kim, J.H.; Lee, J.H. Fabrication of various composite nanorods via template-assisted electrochemical synthesis. Mater. Sci. Eng. B 2025, 317, 118229. [Google Scholar] [CrossRef]

- Alqassem, B.; Banat, F.; Palmisano, G.; Haija, M.A. Emerging trends of ferrite-based nanomaterials as photocatalysts for environmental remediation: A review and synthetic perspective. Sustain. Mater. Technol. 2024, 40, e00961. [Google Scholar] [CrossRef]

- Sun, T.; Shui, F.; Yang, X.; Zhou, Z.; Wan, R.; Liu, Y.; Qian, C.; Xu, Z.; Li, H.; Guo, W. High anti-reflection large-scale cup-shaped nano-pillar arrays via thin film anodic aluminum oxide replication. Nanomaterials 2022, 12, 1875. [Google Scholar] [CrossRef] [PubMed]

- Sharma, A.; Aravindan, S.; Rao, P.V. AAO Mould for Fabricating Anti-Reflective Polymer Nanopillar Array on Large Area. Key Eng. Mater. 2022, 931, 3–8. [Google Scholar] [CrossRef]

- Lim, S.H.; Ly, N.H.; Lee, J.A.; Kim, J.E.; La, S.W.; Huong, V.T.; Tran, T.G.; Ho, N.T.; Noh, S.M.; Son, S.J.; et al. Nanopatterned polymer molds using anodized aluminum templates for anti-reflective coatings. Polymers 2021, 13, 3333. [Google Scholar] [CrossRef]

- Gopalakrishnan, S.K.; Trujillo-Torres, M.A.; Xu, C.; Ziegler, K.J. Large-Scale Transfer of Anodic Aluminum Oxide Honeycomb Patterns onto Low-Surface-Energy Polymers. ACS Appl. Eng. Mater. 2022, 1, 616–627. [Google Scholar] [CrossRef]

- Unno, N.; Mäkelä, T. Thermal nanoimprint lithography—A review of the process, mold fabrication, and material. Nanomaterials 2023, 13, 2031. [Google Scholar] [CrossRef]

- Sener, M.; Sisman, O.; Kilinc, N. AAO-assisted nanoporous platinum films for hydrogen sensor application. Catalysts 2023, 13, 459. [Google Scholar] [CrossRef]

- Chung, C.K.; Ku, C.A. An effective resistive-type alcohol vapor sensor using one-step facile nanoporous anodic alumina. Micromachines 2023, 14, 1330. [Google Scholar] [CrossRef]

- Lee, B.; Cho, I.; Kang, M.; Yang, D.; Park, I. Thermally/mechanically robust anodic aluminum oxide (AAO) microheater platform for low power chemoresistive gas sensor. J. Micromech. Microeng. 2023, 33, 085011. [Google Scholar] [CrossRef]

- Chung, C.K.; Ku, C.A.; Wu, Z.E. A high-and-rapid-response capacitive humidity sensor of nanoporous anodic alumina by one-step anodizing commercial 1050 aluminum alloy and its enhancement mechanism. Sens. Actuators B Chem. 2021, 343, 130156. [Google Scholar] [CrossRef]

- Chung, C.K.; Khor, O.K.; Kuo, E.H.; Ku, C.A. Total effective surface area principle for enhancement of capacitive humidity sensor of thick-film nanoporous alumina. Mater. Lett. 2020, 260, 126921. [Google Scholar] [CrossRef]

- Ku, C.A.; Hung, C.W.; Chung, C.K. Influence of Anodic Aluminum Oxide Nanostructures on Resistive Humidity Sensing. Nanomanufacturing 2024, 4, 58–68. [Google Scholar] [CrossRef]

- Xiang, S.; Wang, X.; Pang, Y.; Ge, C.; Xu, Y.; Chen, L.; Li, S.; Wang, L. Porous Au/AAO: A simple and feasible SERS substrate for dynamic monitoring and mechanism analysis of DNA oxidation. Appl. Surf. Sci. 2022, 606, 154842. [Google Scholar] [CrossRef]

- Dong, J.; Li, C.; Wang, Y.; Fan, Y.; Han, Q.; Gao, W.; Wang, Y.; Ren, K.; Qi, J.; He, E. Fabrication of complexed nanostructure using AAO template for ultrasensitive SERS detection. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2024, 312, 124044. [Google Scholar] [CrossRef]

- Yu, C.Y.; Lin, D.Y.; Chung, C.K. Novel dipole-enhancement mechanism and detection of high-sensitivity trace environmental hormone bisphenol A with LiCl as co-adsorbates using simple metal-nanoparticle-free solid SERS substrates. Sens. Actuators B Chem. 2024, 398, 134735. [Google Scholar] [CrossRef]

- Chung, C.K.; Yu, C.Y. Unique high-performance metal-nanoparticle-free SERS substrate with rapid-fabricated hybrid 3D-Nano-Micro-Cavities anodic alumina for label-free detection. Appl. Surf. Sci. 2023, 635, 157731. [Google Scholar] [CrossRef]

- Yan, B.; Wang, S.; Muhammad, M.; Zhu, C.; Sun, K.; Huang, Q. Preparation of transparent SERS substrates based on the stepwise anodization potential AAO-template approach for rapid detection of trace pesticide residues. Opt. Mater. 2024, 149, 114961. [Google Scholar] [CrossRef]

- Wu, Z.; Sha, M.; Ji, D.; Zhao, H.; Li, L.; Lei, Y. Ordered anodic aluminum oxide-based nanostructures for surface-enhanced Raman scattering: A review. ACS Appl. Nano Mater. 2024, 7, 11–31. [Google Scholar] [CrossRef]

- Chung, C.K.; Ku, C.A. Effect of humidity on nanoporous anodic alumina oxide (AAO). World J. Nanosci. Nanotech. 2018, 1, 1003. [Google Scholar]

- Yu, C.Y.; Chung, C.K. Facile nanofabrication and simultaneous color-and-Raman hybrid mechanism of economic SERS substrate with tunable structure color for high enhancement factor. Appl. Surf. Sci. 2025, 681, 161563. [Google Scholar] [CrossRef]

- Manzano, C.V.; Rodríguez-Acevedo, J.; Caballero-Calero, O.; Martín-González, M. Interconnected three-dimensional anodized aluminum oxide (3D-AAO) metamaterials using different waveforms and metal layers for RGB display technology applications. J. Mater. Chem. C 2022, 10, 1787–1797. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, X.; Feng, C.; Liu, Y.; Zhao, Y. Centimeter-scale, low-cost plasmonic structural color device prepared by AAO template method. Opt. Mater. 2024, 152, 115453. [Google Scholar] [CrossRef]

- Li, M.; Feng, C.; Zhu, L.; Zhao, Y. Fabrication of nanoporous anodized aluminum oxide based photonic crystals with multi-band responses in the vis-NIR region. Nanoscale 2025, 17, 4099–4110. [Google Scholar] [CrossRef] [PubMed]

- Hedrich, C.; Burson, A.R.; González-García, S.; Vega, V.; Prida, V.M.; Santos, A.; Blick, R.H.; Zierold, R. Enhancing the Photocatalytic Activity by Tailoring an Anodic Aluminum Oxide Photonic Crystal to the Semiconductor Catalyst: At the Example of Iron Oxide. Adv. Mater. Interfaces 2023, 10, 2300615. [Google Scholar] [CrossRef]

- Yuan, L.J.; Zhao, Z.C.; Wang, W.Q.; Wang, Y.F.; Liu, Y.J. Review of catalysts, substrates, and fabrication methods in catalytic hydrogen combustion with further challenges and applications. Energy Fuels 2024, 38, 4881–4903. [Google Scholar] [CrossRef]

- Kozhukhova, A.E.; du Preez, S.P.; Malakhov, A.A.; Bessarabov, D.G. A thermally conductive Pt/AAO catalyst for hydrogen passive autocatalytic recombination. Catalysts 2021, 11, 491. [Google Scholar] [CrossRef]

- Du, X.; Cai, D.; Ou, Q.; Chen, D.; Zhang, Z.; Liang, P. Fabrication and characterization of the hierarchical AAO film and AAO-MnO2 composite as the anode foil of aluminum electrolytic capacitor. Surf. Coat. Technol. 2021, 419, 127286. [Google Scholar] [CrossRef]

- Wu, R.; Lenz, T.M.; Alfayez, F.A.S.; Zhao, R.; Rupper, P.; Perret, E.; Lehner, S.; Jovic, M.; Gaan, S.; Rieger, B.; et al. Ambient catalytic spinning of polyethylene nanofibers. Angew. Chem. 2024, 136, e202315326. [Google Scholar] [CrossRef]

- Lee, W.J.; Yeh, K.C.; Wang, H.Y.; Hsu, H.Y.; Lin, M.C.; Shen, J.W.; Lin, D.Z.; Huang, N.T. Label-free pathogen DNA sensing based on the anodic aluminum oxide (AAO) transferred localized surface plasmon resonance (LSPR) sensor integrating the automated microfluidics and spectra mapping acquisition. Surf. Interfaces 2025, 56, 105675. [Google Scholar] [CrossRef]

- Hu, Z.; Wang, H.; Chen, H.; Fan, G.C.; Luo, X. Target-triggered cascade signal amplification in nanochannels: An ingenious strategy for ultrasensitive photoelectrochemical DNA bioanalysis. Biosens. Bioelectron. 2023, 242, 115724. [Google Scholar] [CrossRef]

- Yan, X.; Shi, H.; Jia, P.; Gao, B.; Sun, X. Suppression of the plasmonic heating effect in SERS measurement by coating graphene on the Ag@ AAO substrate surface. Opt. Express 2024, 32, 45171–45184. [Google Scholar] [CrossRef]

- Hsieh, C.C.; Lee, W.J.; Yeh, K.C.; Huang, N.T. The anodic aluminum oxide (AAO) template fabricated Localized Surface Plasmon Resonance (LSPR) sensor for the plasmonic coupling effect study. In Proceedings of the 2023 IEEE 18th International Conference on Nano/Micro Engineered and Molecular Systems (NEMS), Jeju Island, Republic of Korea, 14–17 May 2023; IEEE: New York, NY, USA, 2023; pp. 116–119. [Google Scholar]

- Wang, L.; Yuan, L.; Li, Z.H.; Zhang, X.; Leung, K.M.Y.; Sheng, G.P. Extracellular polymeric substances (EPS) associated extracellular antibiotic resistance genes in activated sludge along the AAO process: Distribution and microbial secretors. Sci. Total Environ. 2022, 816, 151575. [Google Scholar] [CrossRef] [PubMed]

- Xu, Q.; Zhang, Y.; Xiao, Y.; Yin, J. Magnetic properties of bamboo-like Ni-Zn-in nanowires using 3D-AAO templates. Vacuum 2024, 230, 113694. [Google Scholar] [CrossRef]

- Xiao, Y.; Xu, Q.; Zhang, J.; Yin, X.; Duan, S. Preparation and magnetic properties of Fe-Co–Ni magnetic nanowire arrays with three-dimensional periodic structures. J. Supercond. Nov. Magn. 2023, 36, 1161–1170. [Google Scholar] [CrossRef]

- Gasco-Owens, A.; Veys-Renaux, D.; Rocca, E. Bipolar pulse anodizing of aluminum: Understanding the fundamental electrochemical mechanisms. Electrochim. Acta 2024, 492, 144303. [Google Scholar] [CrossRef]

- Iwai, M.; Kikuchi, T. Chemical stability of porous anodic aluminum oxide in both acidic and alkaline solutions. Thin Solid Film. 2023, 771, 139784. [Google Scholar] [CrossRef]

- Zhang, X.; Zheng, X.; Hu, X.; Liu, X.; Xue, Y. Three-Dimensional Carbon Nanomaterial/Aluminum Oxide/Aluminum Composite Current Collectors for Flexible Supercapacitors. ACS Appl. Energy Mater. 2024, 7, 3700–3708. [Google Scholar] [CrossRef]

- Swain, N.; Saravanakumar, B.; Kundu, M.; Schmidt-Mende, L.; Ramadoss, A. Recent trends in template assisted 3D porous materials for electrochemical supercapacitors. J. Mater. Chem. A 2021, 9, 25286–25324. [Google Scholar] [CrossRef]

- Nguyen, T.K.N.; Segawa, H.; Grasset, F.; Cordier, S.; Dumait, N.; Uchikoshi, T. Enhanced photoluminescence of hexamolybdenum cluster by anodic aluminum oxide photonic crystals. Mater. Lett. 2024, 361, 136144. [Google Scholar] [CrossRef]

- Roslyakov, I.V.; Sotnichuk, S.V.; Kushnir, S.E.; Trusov, L.A.; Bozhev, I.V.; Napolskii, K.S. Pore ordering in anodic aluminum oxide: Interplay between the pattern of pore nuclei and the crystallographic orientation of aluminum. Nanomaterials 2022, 12, 1417. [Google Scholar] [CrossRef]

- Zaraska, L.; Szuwarzyński, M.; Świerkula, A.; Brzózka, A. Effect of Al polishing conditions on the growth and morphology of porous anodic alumina films. ACS Omega 2023, 8, 34564–34574. [Google Scholar] [CrossRef]

- Bruera, F.A.; Kramer, G.R.; Vera, M.L.; Ares, A.E. Evaluation of surface pretreatment stages of Al 1050 to obtain nanostructured anodic films. Superlattices Microstruct. 2019, 130, 103–116. [Google Scholar] [CrossRef]

- Parkhutik, V.P.; Shershulsky, V.I. Theoretical Modeling of Porous Oxide-Growth on Aluminum. J. Phys. D-Appl. Phys. 1992, 25, 1258–1263. [Google Scholar] [CrossRef]

- Jessensky, O.; Muller, F.; Gosele, U. Self-organized formation of hexagonal pore arrays in anodic alumina. Appl. Phys. Lett. 1998, 72, 1173–1175. [Google Scholar] [CrossRef]

- Masuda, H.; Satoh, M. Fabrication of gold nanodot array using anodic porous alumina as an evaporation mask. Jpn. J. Appl. Phys. Part 2-Lett. 1996, 35, L126–L129. [Google Scholar] [CrossRef]

- Lee, W.; Ji, R.; Gösele, U.; Nielsch, K. Fast fabrication of long-range ordered porous alumina membranes by hard anodization. Nat. Mater. 2006, 5, 741. [Google Scholar] [CrossRef]

- Guo, F.; Cao, Y.; Wang, K.; Zhang, P.; Cui, Y.; Hu, Z.; Xie, Z. Effect of the anodizing temperature on microstructure and tribological properties of 6061 aluminum alloy anodic oxide films. Coatings 2022, 12, 314. [Google Scholar] [CrossRef]

- Sulka, G.D. Introduction to anodization of metals. In Nanostructured Anodic Metal Oxides; Elsevier: Amsterdam, The Netherlands, 2020; pp. 1–34. [Google Scholar]

- Domagalski, J.T.; XifrePerez, E.; Marsal, L.F. Recent advances in nanoporous anodic alumina: Principles, engineering, and applications. Nanomaterials 2021, 11, 430. [Google Scholar] [CrossRef]

- Sulka, G.D.; Stępniowski, W.J. Structural features of self-organized nanopore arrays formed by anodization of aluminum in oxalic acid at relatively high temperatures. Electrochim. Acta 2009, 54, 3683–3691. [Google Scholar] [CrossRef]

- Chung, C.K.; Dhandapani, D.; Syu, C.J.; Liao, M.W.; Chu, B.Y.; Kuo, E.H. Role of oxalate anions on the evolution of widened pore diameter and characteristics of room-temperature anodic aluminum oxide. J. Electrochem. Soc. 2017, 164, C121. [Google Scholar] [CrossRef]

- Zhang, J.; Kielbasa, J.E.; Carroll, D.L. Controllable fabrication of porous alumina templates for nanostructures synthesis. Mater. Chem. Phys. 2010, 122, 295–300. [Google Scholar] [CrossRef]

- Sulka, G.D.; Brzózka, A.; Zaraska, L.; Jaskuła, M. Through-hole membranes of nanoporous alumina formed by anodizing in oxalic acid and their applications in fabrication of nanowire arrays. Electrochim. Acta 2010, 55, 4368–4376. [Google Scholar] [CrossRef]

- Sulka, G.D.; Hnida, K.; Brzózka, A. pH sensors based on polypyrrole nanowire arrays. Electrochim. Acta 2013, 104, 536–541. [Google Scholar] [CrossRef]

- Zaraska, L.; Kurowska, E.; Sulka, G.D.; Jaskuła, M. Porous alumina membranes with branched nanopores as templates for fabrication of Y-shaped nanowire arrays. J. Solid State Electrochem. 2012, 16, 3611–3619. [Google Scholar] [CrossRef]

- Zaraska, L.; Sulka, G.D.; Jaskuła, M. Fabrication of free-standing copper foils covered with highly-ordered copper nanowire arrays. Appl. Surf. Sci. 2012, 258, 7781–7786. [Google Scholar] [CrossRef]

- Gilani, N.; Daryan, J.T.; Rashidi, A.; Omidkhah, M.R. Separation of methane–nitrogen mixtures using synthesis vertically aligned carbon nanotube membranes. Appl. Surf. Sci. 2012, 258, 4819–4825. [Google Scholar] [CrossRef]

- Xu, T.; Zangari, G.; Metzger, R.M. Periodic holes with 10 nm diameter produced by grazing Ar+ milling of the barrier layer in hexagonally ordered nanoporous alumina. Nano Lett. 2002, 2, 37–41. [Google Scholar] [CrossRef]

- Liang, J.; Chik, H.; Yin, A.; Xu, J. Two-dimensional lateral superlattices of nanostructures: Nonlithographic formation by anodic membrane template. J. Appl. Phys. 2002, 91, 2544–2546. [Google Scholar] [CrossRef]

- Cui, J.; Wu, Y.; Wang, Y.; Zheng, H.; Xu, G.; Zhang, X. A facile and efficient approach for pore-opening detection of anodic aluminum oxide membranes. Appl. Surf. Sci. 2012, 258, 5305–5311. [Google Scholar] [CrossRef]

- Xu, T.T.; Piner, R.D.; Ruoff, R.S. An improved method to strip aluminum from porous anodic alumina films. Langmuir 2003, 19, 1443–1445. [Google Scholar] [CrossRef]

- Zhao, Y.; Chen, M.; Zhang, Y.; Xu, T.; Liu, W. A facile approach to formation of through-hole porous anodic aluminum oxide film. Mater. Lett. 2005, 59, 40–43. [Google Scholar] [CrossRef]

- Mardilovich, P.P.; Govyadinov, A.N.; Mukhurov, N.I.; Rzhevskii, A.M.; Paterson, R. New and modified anodic alumina membranes Part I. Thermotreatment of anodic alumina membranes. J. Membr. Sci. 1995, 98, 131–142. [Google Scholar] [CrossRef]

- Teshima, H.; Kojima, K.; Ju, Y. Fabrication of anodic aluminum oxide template and copper nanowire surface fastener. J. Electron. Packag. 2014, 136, 044501. [Google Scholar] [CrossRef]

- Keller, F.; Hunter, M.S.; Robinson, D.L. Structural features of oxide coatings on aluminium. J. Electrochem. Soc. 1953, 100, 411–419. [Google Scholar] [CrossRef]

- Spooner, R.C. Electrolytic Detachment of Anodic Oxide Films on Aluminium Alloys. Nature 1963, 197, 995–996. [Google Scholar] [CrossRef]

- Furneaux, R.; Rigby, C.W.R.; Davidson, A.P. The formation of controlled-porosity membranes from anodically oxidized aluminium. Nature 1989, 337, 147. [Google Scholar] [CrossRef]

- Schneider, J.J.; Engstler, J.; Budna, K.P.; Teichert, C.; Franzka, S. Freestanding, Highly Flexible, Large Area, Nanoporous Alumina Membranes with Complete Through-Hole Pore Morphology. Eur. J. Inorg. Chem. 2005, 2005, 2352–2359. [Google Scholar] [CrossRef]

- Qiu, T.; Zhang, W.; Lang, X.; Zhou, Y.; Cui, T.; Chu, P.K. Controlled Assembly of Highly Raman-Enhancing Silver Nanocap Arrays Templated by Porous Anodic Alumina Membranes. Small 2009, 5, 2333–2337. [Google Scholar] [CrossRef]

- Yanagishita, T.; Masuda, H. High-throughput fabrication process for highly ordered through-hole porous alumina membranes using two-layer anodization. Electrochim. Acta 2015, 184, 80–85. [Google Scholar] [CrossRef]

- Brudzisz, A.; Sulka, G.D.; Brzózka, A. Through-hole AAO-SA templates with a small pore diameter prepared by the voltage pulse detachment method. Microporous Mesoporous Mater. 2019, 283, 73–81. [Google Scholar] [CrossRef]

- Jeong, C.; Jung, J.; Sheppard, K.; Choi, C.H. Control of the nanopore architecture of anodic alumina via stepwise anodization with voltage modulation and pore widening. Nanomaterials 2023, 13, 342. [Google Scholar] [CrossRef]

- Liu, Y.C.; Chen, Y.F.; Lin, Y.C.; Zheng, Y.H.; Lee, L.R.; Chang, M.H.; Ho, J.H.; Lin, Y.L.; Chen, J.T. Tailoring Nanopore Geometry in Anodic Aluminum Oxide Membranes through Physical Stretching and Controlled Anodization. Adv. Mater. Interfaces 2024, 12, 2400699. [Google Scholar] [CrossRef]

- Chang, M.H.; Lee, L.R.; Huang, M.R.; Tsai, T.H.; Chen, Y.F.; Hong, Y.T.; Liu, Y.C.; Chen, J.T. Light-Assisted Fabrication of Hierarchical Azopolymer Structures Using the Breath Figure Method and AAO Templates. Langmuir 2024, 40, 15941–15948. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Guo, Y.; Lu, J.; Li, J.; Ma, Y.; Liu, T.; Liang, R.; Sun, R.; Dong, J. Utilizing cell culture assisted anodization to fabricate aluminium oxide with a gradient microstep and nanopore structure. ACS Omega 2022, 7, 35668–35676. [Google Scholar] [CrossRef]

- Fedel, M.; Franch, J.; Rossi, S. Effect of thickness and sealing treatments on the corrosion protection properties of anodic oxide coatings on AA5005. Surf. Coat. Technol. 2021, 408, 126761. [Google Scholar] [CrossRef]

- Kozhukharov, S.V.; Girginov, C.; Portolesi, S.; Tsanev, A.; Lilova, V.; Georgieva, M.; Lilov, E.; Petkov, P. Sealing of cerium oxide coating primers on anodized AA2024-T3 alloy by boiling in Lourier buffers. J. Electrochem. Sci. Eng. 2024, 14, 559–582. [Google Scholar] [CrossRef]

- Merisalu, M.; Aarik, L.; Kozlova, J.; Mändar, H.; Tarre, A.; Sammelselg, V. Effective corrosion protection of aluminum alloy AA2024-T3 with novel thin nanostructured oxide coating. Surf. Coat. Technol. 2021, 411, 126993. [Google Scholar] [CrossRef]

- Hatakeyama, M.; Nakano, K.; Yoshita, R.; Nakato, D.; Sunada, S.; Nose, M. Improvement of Corrosion Resistance of the AZ91 Magnesium Alloys with Sputtered Aluminum Layer Using Interdiffusion Treatment, Anodic Oxidation Treatment and Sealing Process. Mater. Trans. 2022, 63, 1242–1247. [Google Scholar] [CrossRef]

- Feng, J.; Wang, Y.; Tao, F.; Li, Y.; He, K.; Xu, Z.; Tang, H.; Wang, Z. Effect of tensile cracks on the corrosion protection properties of anodic oxide films on 5083 Al alloy. J. Alloys Compd. 2024, 997, 174950. [Google Scholar] [CrossRef]

- Lin, B.; Yao, Y.; Wang, Y.; Kannan, P.; Chen, L.; Guo, L. A Universal Strategy for the Incorporation of Internal Standards into SERS Substrates to Improve the Reproducibility of Raman Signals. Analyst 2021, 146, 7168–7177. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Yan, H.; Tan, X.; Lu, Z.; Han, H. Cauliflower-inspired 3D SERS substrate for multiple mycotoxins detection. Anal. Chem. 2019, 91, 3885–3892. [Google Scholar] [CrossRef]

- Celik, M.; Altuntas, S.; Buyukserin, F. Fabrication of nanocrater-decorated anodic aluminum oxide membranes as substrates for reproducibly enhanced SERS signals. Sens. Actuators B Chem. 2018, 255, 2871–2877. [Google Scholar] [CrossRef]

- Feng, Y.; He, L.; Wang, L.; Mo, R.; Zhou, C.; Hong, P.; Li, C. Detection of aflatoxin B1 based on a porous anodized aluminum membrane combined with surface-enhanced Raman scattering spectroscopy. Nanomaterials 2020, 10, 1000. [Google Scholar] [CrossRef]

- Xiao, S.; He, Y.; Lu, Y.; Niu, X.; Li, Q.; Wu, J.; Luo, D.; Tian, F.; Wan, G.; Liu, H. An ultrasensitive flexible pressure, temperature, and humidity sensor based on structurally adjustable nano-through-hole array films. J. Mater. Chem. C 2023, 11, 12685–12697. [Google Scholar] [CrossRef]

- Jeong, S.H.; Im, H.L.; Hong, S.; Park, H.; Baek, J.; Park, D.H.; Kim, S.; Hong, Y.K. Massive, eco-friendly, and facile fabrication of multi-functional anodic aluminum oxides: Application to nanoporous templates and sensing platforms. RSC Adv. 2017, 7, 4518–4530. [Google Scholar] [CrossRef]

- Hong, Y.K.; Kim, B.H.; Kim, D.I.; Park, D.H.; Joo, J. High-yield and environment-minded fabrication of nanoporous anodic aluminum oxide templates. RSC Adv. 2015, 5, 26872–26877. [Google Scholar] [CrossRef]

- Tian, M.; Xu, S.; Wang, J.; Kumar, N.; Wertz, E.; Li, Q.; Campbell, P.M.; Chan, M.H.W.; Mallouk, T.E. Penetrating the oxide barrier in situ and separating freestanding porous anodic alumina films in one step. Nano Lett. 2005, 5, 697–703. [Google Scholar] [CrossRef]

- Yanagishita, T.; Okubo, Y.; Kondo, T.; Masuda, H. Selective through-holing of anodic porous alumina membranes with large area. RSC Adv. 2018, 8, 38455–38460. [Google Scholar] [CrossRef]

- Wen, F.Y.; Chen, P.S.; Liao, T.W.; Juang, Y.J. Microwell-assisted filtration with anodic aluminum oxide membrane for Raman analysis of algal cells. Algal Res. 2018, 33, 412–418. [Google Scholar] [CrossRef]

- Dai, L.; Pang, S.; Li, S.; Yi, Z.; Qu, K.; Wang, Y.; Wu, Y.; Li, S.; Lei, L.; Huang, K.; et al. Freestanding two-dimensional nanofluidic membranes modulated by zwitterionic polyelectrolyte for mono-/di-valent ions selectivity transport. J. Membr. Sci. 2023, 677, 121621. [Google Scholar] [CrossRef]

- Belwalkar, A.; Grasing, E.; Van Geertruyden, W.; Huang, Z.; Misiolek, W.Z. Effect of processing parameters on pore structure and thickness of anodic aluminum oxide (AAO) tubular membranes. J. Membr. Sci. 2008, 319, 192–198. [Google Scholar] [CrossRef]

- Hun, C.W.; Chiu, Y.J.; Luo, Z.; Chen, C.C.; Chen, S.H. A new technique for batch production of tubular anodic aluminum oxide films for filtering applications. Appl. Sci. 2018, 8, 1055. [Google Scholar] [CrossRef]

- Chien, Y.C.; Weng, H.C. Cost-effective technique to fabricate a tubular through-hole anodic aluminum oxide membrane using one-step anodization. Microelectron. Eng. 2021, 247, 111589. [Google Scholar] [CrossRef]

- Zhu, H.; Liang, J.; Wang, S.; Huang, J.; Chen, Z. A multimodal PDMS triboelectric nanogenerator sensor based on anodised aluminium oxide template preparation for object recognition. J. Mater. Chem. A 2023, 11, 24158–24168. [Google Scholar] [CrossRef]

- Feng, M.; Ma, S.; Liu, Y.; Zheng, Y.; Feng, Y.; Wang, H.; Cheng, J.; Wang, D. Control of triboelectrification on Al–metal surfaces through microstructural design. Nanoscale 2022, 14, 15129–15140. [Google Scholar] [CrossRef]

- Kam, D.; Gwon, G.; Yoo, D.; Kim, J.; Gwon, H.; La, M.; Park, S.J.; Choi, D. Tailoring dielectric constant via anodic aluminum oxide-based nanoparticle for boosting the output performance of a triboelectric nanogenerator. Chem. Eng. J. 2024, 500, 157123. [Google Scholar] [CrossRef]

- Choudhary, E.; Szalai, V. Two-step cycle for producing multiple anodic aluminum oxide (AAO) films with increasing long-range order. RSC Adv. 2016, 6, 67992–67996. [Google Scholar] [CrossRef] [PubMed]

- Zhao, S.; Chan, K.; Yelon, A.; Veres, T. Preparation of open-through anodized aluminium oxide films with a clean method. Nanotechnology 2007, 18, 245304. [Google Scholar] [CrossRef]

- Yuan, J.H.; Chen, W.; Hui, R.J.; Hu, Y.L.; Xia, X.H. Mechanism of one-step voltage pulse detachment of porous anodic alumina membranes. Electrochim. Acta 2006, 51, 589–4595. [Google Scholar] [CrossRef]

- Brudzisz, A.; Brzózka, A.; Sulka, G.D. Effect of processing parameters on pore opening and mechanism of voltage pulse detachment of nanoporous anodic alumina. Electrochim. Acta 2015, 178, 374–384. [Google Scholar] [CrossRef]

- Zhang, T.; Ling, Z.; Li, Y.; Hu, X. A new method for highly efficient fabrication of through-hole porous anodic alumina membranes. ECS J. Solid State Sci. Technol. 2017, 6, P862. [Google Scholar] [CrossRef]

- Kuroiwa, M.; Yanagishita, T. Short-Time Peeling of Large Anodic Porous Alumina Membranes from Al Substrates by Two-Layer Anodization Using Concentrated Sulfuric Acid. J. Electrochem. Soc. 2025, 172, 013506. [Google Scholar] [CrossRef]

- Miyamoto, K.; Iwai, M.; Kikuchi, T. Rapid electrochemical separation of anodic porous alumina films from aluminum surfaces using a highly safe sodium chloride–ethylene glycol solution. Electrochim. Acta 2022, 427, 140865. [Google Scholar] [CrossRef]

- Kikuchi, T.; Miyamoto, K.; Iwai, M. Electrochemical Separation of Porous Anodic Aluminum Oxide with Thick Barrier Layers. J. Electrochem. Soc. 2023, 170, 073504. [Google Scholar] [CrossRef]

- Ku, C.A.; Hung, C.W.; Chung, C.K. A Rapid, Efficient Method for Anodic Aluminum Oxide Membrane Room-Temperature Multi-Detachment from Commercial 1050 Aluminum Alloy. Nanomaterials 2024, 14, 1216. [Google Scholar] [CrossRef]

- Cai, Y.; Chen, D.; Li, N.; Xu, Q.; Li, H.; He, J.; Lu, J. A smart membrane with antifouling capability and switchable oil wettability for high-efficiency oil/water emulsions separation. J. Membr. Sci. 2018, 555, 69–77. [Google Scholar] [CrossRef]

- Wang, X.; Luo, S.; Wang, K.; Zhao, J.; Guo, Z.; Cui, Y. Fabrication of micro-nano stacked metal structures via surface plasmon excitation in Au-AAO-Au arrays. Opt. Mater. 2025, 162, 116904. [Google Scholar] [CrossRef]

- Kirchner, A.; MacKenzie, K.J.D.; Brown, I.W.M.; Kemmitt, T.; Bowden, M.E. Structural characterisation of heat-treated anodic alumina membranes prepared using a simplified fabrication process. J. Membr. Sci. 2007, 287, 264–270. [Google Scholar] [CrossRef]

- Yanagishita, T.; Maejima, Y.; Nishio, K.; Masuda, H. Monodisperse nanoparticles of metal oxides prepared by membrane emulsification using ordered anodic porous alumina. RSC Adv. 2014, 4, 1538–1542. [Google Scholar] [CrossRef]

- Chahrour, K.M.; Ahmed, N.M.; Hashim, M.R.; Elfadill, N.G.; Maryam, W.; Ahmad, M.A.; Bououdina, M. Effects of the voltage and time of anodization on modulation of the pore dimensions of AAO films for nanomaterials synthesis. Superlattices Microstruct. 2015, 88, 489–500. [Google Scholar] [CrossRef]

- Lira, H.D.L.; Paterson, R. New and modified anodic alumina membranes: Part III. Preparation and characterisation by gas diffusion of 5 nm pore size anodic alumina membranes. J. Membr. Sci. 2002, 206, 375–387. [Google Scholar] [CrossRef]

- Ku, C.A.; Li, G.F.; Chung, C.K. A Capacitive Liquid-Phase Sensor and Its Sensing Mechanism Using Nanoporous Anodic Aluminum Oxide. Nanomanufacturing 2025, 5, 8. [Google Scholar] [CrossRef]

- Chen, W.; Gui, X.; Liang, B.; Yang, R.; Zheng, Y.; Zhao, C.; Li, X.; Zhu, H.; Tang, Z. Structural engineering for high sensitivity, ultrathin pressure sensors based on wrinkled graphene and anodic aluminum oxide membrane. ACS Appl. Mater. Interfaces 2017, 9, 24111–24117. [Google Scholar] [CrossRef]

- Guo, Y.; Gao, S.; Yue, W.; Zhang, C.; Li, Y. Anodized aluminum oxide-assisted low-cost flexible capacitive pressure sensors based on double-sided nanopillars by a facile fabrication method. ACS Appl. Mater. Interfaces 2019, 11, 48594–48603. [Google Scholar] [CrossRef]

- Hwang, T.; Seo, J.; Ko, E.; Yang, C.; Lee, H.S. Synergistic control of engineered nanostructures toward sensitivity and reliability of a flexible piezoresistive pressure sensor. Mater. Adv. 2023, 4, 1326–1334. [Google Scholar] [CrossRef]

- Das, T.M.; Sarmah, D.; Borah, S.M.; Baruah, S. Development of a Capacitive Pressure Sensor Based on Nanoporous Anodic Aluminium Oxide. East Eur. J. Phys. 2024, 3, 379–384. [Google Scholar] [CrossRef]

- Hong, C.; Chu, L.; Lai, W.; Chiang, A.S.; Fang, W. Implementation of a new capacitive touch sensor using the nanoporous anodic aluminum oxide (np-AAO) structure. IEEE Sens. J. 2011, 11, 3409–3416. [Google Scholar] [CrossRef]

- Ku, C.A.; Chung, C.K. Advances in humidity nanosensors and their application. Sensors 2023, 23, 2328. [Google Scholar] [CrossRef]

- Nishihara, H.; Kyotani, T. Templated nanocarbons for energy storage. Adv. Mater. 2012, 24, 4473–4498. [Google Scholar] [CrossRef]

- Nishihara, H.; Kyotani, T. Zeolite-templated carbons–three-dimensional microporous graphene frameworks. Chem. Commun. 2018, 54, 5648–5673. [Google Scholar] [CrossRef]

- Romero, V.; Vega, V.; Garcia, J.; Zierold, R.; Nielsch, K.; Prida, V.M.; Hernando, B.; Benavente, J. Changes in morphology and ionic transport induced by ALD SiO2 coating of nanoporous alumina membranes. ACS Appl. Mater. Interfaces 2013, 5, 3556–3564. [Google Scholar] [CrossRef] [PubMed]

- Vega, V.; Gelde, L.; González, A.S.; Prida, V.M.; Hernando, B.; Benavente, J. Diffusive transport through surface functionalized nanoporous alumina membranes by atomic layer deposition of metal oxides. J. Ind. Eng. Chem. 2017, 52, 66–72. [Google Scholar] [CrossRef]

- Palmero, E.M.; Méndez, M.; González, S.; Bran, C.; Vega, V.; Vázquez, M.; Prida, V.M. Stepwise magnetization reversal of geometrically tuned in diameter Ni and FeCo bi-segmented nanowire arrays. Nano Res. 2019, 12, 1547–1553. [Google Scholar] [CrossRef]

- Boominatha Sellarajan, S.; Ghosh, S.K. Synthesis of highly ordered nanoporous anodic aluminium oxide templates and template-based nanomaterials. In Handbook on Synthesis Strategies for Advanced Materials: Volume-II: Processing and Functionalization of Materials; Springer: Singapore, 2022; pp. 229–276. [Google Scholar]

- Lin, D.Y.; Yu, C.Y.; Ku, C.A.; Chung, C.K. Design, fabrication, and applications of SERS substrates for food safety detection. Micromachines 2023, 14, 1343. [Google Scholar] [CrossRef]

- Li, C.; Zhang, Y.; Ye, Z.; Bell, S.E.; Xu, Y. Combining surface-accessible Ag and Au colloidal nanomaterials with SERS for in situ analysis of molecule–metal interactions in complex solution environments. Nat. Protoc. 2023, 18, 2717–2744. [Google Scholar] [CrossRef]

- Muntean, C.M.; Cuibus, D.; Boca, S.; Falamas, A.; Tosa, N.; Brezeştean, I.A.; Bende, A.; Tudoran, L.B.; Moldovan, R.; Bodoki, E.; et al. Gold vs. silver colloidal nanoparticle films for optimized SERS detection of propranolol and electrochemical-SERS analyses. Biosensors 2023, 13, 530. [Google Scholar] [CrossRef]

- Song, Y.; Zhang, D.; Shi, L.; Yan, P.; Wang, Z.; Deng, S.; Chen, S.; Chen, Y.; Wang, N.; Zeng, Q.; et al. Cerebrospinal fluid-induced stable and reproducible SERS sensing for various meningitis discrimination assisted with machine learning. Biosens. Bioelectron. 2025, 267, 116753. [Google Scholar] [CrossRef] [PubMed]

- Song, C.; Huo, H.; Shi, W.; Xu, J.; Lei, X.; Gu, B.; Han, Z.; Zhang, W. Surface plasmon-coupled Ag nanosphere-internalized nanocavity arrays for ultrasensitive SERS sensing. Sens. Actuators B Chem. 2025, 426, 137069. [Google Scholar] [CrossRef]

- Rahim, A.; Ma, L.; Saleem, M.; Lyu, B.; Shafi, M.; You, Y.; Li, M.; Zhang, X.; Liu, M. V-Shaped Heterostructure Nanocavities Array with CM and EM Coupled Enhancement for Ultra-Sensitive SERS Substrate. Adv. Sci. 2024, 11, 2409838. [Google Scholar] [CrossRef]

- Seo, J.; Shin, G.; Shin, D. Metal-free AAO membranes function as both filters and Raman enhancers for the analysis of nanoplastics. Water Res. 2025, 273, 123043. [Google Scholar] [CrossRef]

- Kim, Y.T.; Schilling, J.; Schweizer, S.L.; Wehrspohn, R.B. High density Ag nanobranches decorated with sputtered Au nanoparticles for surface-enhanced Raman spectroscopy. Appl. Surf. Sci. 2017, 410, 525–529. [Google Scholar] [CrossRef]

- Yu, C.Y.; Hsu, C.C.; Ku, C.A.; Chung, C.K. Stripe-Patterned Al/PDMS Triboelectric Nanogenerator for a High-Sensitive Pressure Sensor and a Novel Two-Digit Switch with Surface-Edge Enhanced Charge Transfer Behavior. Nanomaterials 2025, 15, 760. [Google Scholar] [CrossRef]

- Trinh, V.L.; Chung, C.K. Use of Triboelectric Nanogenerators in Advanced Hybrid Renewable Energy Systems for High Efficiency in Sustainable Energy Production: A Review. Processes 2024, 12, 1964. [Google Scholar] [CrossRef]

- Ahmed, A.A.; Qahtan, T.F.; Owolabi, T.O.; Agunloye, A.O.; Rashid, M.; Ali, M.S.M. Waste to sustainable energy based on TENG technology: A comprehensive review. J. Clean. Prod. 2024, 448, 141354. [Google Scholar] [CrossRef]

- Mehamud, I.; Björling, M.; Marklund, P.; An, R.; Shi, Y. Enhanced Machine Condition Monitoring Based on Triboelectric Nanogenerator (TENG): A Review of Recent Advancements. Adv. Sustain. Syst. 2024, 8, 2400575. [Google Scholar] [CrossRef]

- Duan, Z.; Cai, F.; Chen, Y.; Chen, T.; Lu, P. Advanced Applications of Porous Materials in Triboelectric Nanogenerator Self-Powered Sensors. Sensors 2024, 24, 3812. [Google Scholar] [CrossRef] [PubMed]

- Zhang, R. Machine learning-assisted triboelectric nanogenerator-based self-powered sensors. Cell Rep. Phys. Sci. 2024, 5, 101888. [Google Scholar] [CrossRef]

- Chung, C.K.; Huang, Y.J.; Wang, T.K.; Lo, Y.L. Fiber-based triboelectric nanogenerator for mechanical energy harvesting and its application to a human–machine interface. Sensors 2022, 22, 9632. [Google Scholar] [CrossRef]

- Zhang, S.; Guo, M.; Xia, Y.; Li, S.; Zhi, X.; Wang, X. Noncontact monolayered triboelectric nanogenerator based on stretchable MWCNTs/MXene/Ecoflex film for human–machine interface and high-accuracy handwritten recognition. Chem. Eng. J. 2025, 505, 159562. [Google Scholar] [CrossRef]

- Huang, Y.J.; Tsai, C.H.; Hung, C.W.; Chung, C.K. A PDMS-Al Triboelectric Nanogenerator Using Two-Pulse Laser to Enhance Effective Contact Area and Its Application. Polymers 2024, 16, 3397. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.J.; Chung, C.K. Design and fabrication of polymer triboelectric nanogenerators for self-powered insole applications. Polymers 2023, 15, 4035. [Google Scholar] [CrossRef]

- Xiang, H.; Peng, L.; Yang, Q.; Wang, N.; Cao, X.; Wang, Z.L. Carbon fibre reinforced triboelectric nanogenerator for self-powered sporting events monitoring. Nano Energy 2024, 123, 109403. [Google Scholar] [CrossRef]

| Solution | Parameters | Ref. |

|---|---|---|

| HgCl2 | saturated HgCl2 solution | [113,121,122,123,124,125,126] |

| saturated HgCl2 solution for 10 h | [127] | |

| 2% HgCl2 solution | [128] | |

| CuCl2-based solution | saturated CuCl2 solution | [129] |

| 100 mL HCl (38%) +100 mL H2O +3.4 g CuCl2·2H2O at 15 °C for 3 h | [130] | |

| 100 mL HCl (38%) +100 mL H2O +3.4 g CuCl2·H2O at room temperature for 10 min | [131] | |

| solution of HC1 (32%) and CuCl2 (0.05%) | [132] | |

| solution made up of one part by volume of 0.1 mol/L CuCl2 solution and four parts by volume of 10 wt% HCl | [133] | |

| CuCl2 & HCl solution | [177] | |

| Iodine methanol solution | saturated iodine methanol solution at 50 °C | [178] |

| saturated iodine methanol solution | [179] |

| Ref. | Method | Al Purity | Anodization Step/Solution | AAO Fabrication Time (h) | Detachment Time | Photographs of Complete Membrane | Repetitions of AAO Membrane |

|---|---|---|---|---|---|---|---|

| [176] (Commercial membrane) | Chemical etching method | 99.999% | NA | NA | NA | Complete | NA |

| [136] | Voltage reduction method | 99.95% | 1-step/Phosphoric acid | 1.25 | NA | Complete | NA |

| [156] | Reverse bias voltage method | 99.999% | 2-step/Sulfuric acid | 25 | 20 min | Complete | 6 times |

| [157] | Reverse bias voltage method | 99.999% | 2-step/Sulfuric acid | 44 | 13 min | Local * | NA |

| [167] | Reverse bias voltage method | 99.999% | 2-step/Oxalic acid | 8–32 | 30–90 s | Local * | 5 times |

| [168] | Pulse voltage method | 99.999% | 2-step/Oxalic acid | 28 | 3 s (1 cycle) | Local * | NA |

| [169] | Pulse voltage method | 99.99% | 2-step/Oxalic acid | 5 | 3 s (1 cycle) | Local * | NA |

| [170] | Pulse voltage method | 99.999% | 2-step/Oxalic acid | 5 | 3–60 s (1–10 cycle) | Local * | NA |

| [140] | Pulse voltage method | 99.999% | 2-step/Sulfuric acid | 12–20 | 3–60 s (1–10 cycle) | Partial | NA |

| [139] | Two-layer anodization method | 99.999% | 3-step/Sulfuric acid | 13.5 | 15 min | Complete | 10 times |

| [171] | Two-layer anodization method | 99.999% | 3-step/Oxalic acid | 27 | 75 min | Complete | 4 times |

| [173] | Constant voltage detachment method | 99.999% | NA/Sulfuric acid | NA (thickness of 20~80 μm is controlled) | <10 s | Complete | NA |

| [174] | Constant voltage detachment method | 99.999% | NA/Sulfuric acid and Oxalic acid and Phosphoric acid | NA (thickness of 20 μm is controlled) | 0.5~20 s | Complete | NA |

| [175] | Constant voltage detachment method | Al 1050 alloy (~99.5%) | 1-step/Oxalic acid | 3 | 20 s | Complete | 5 times |

| Ref. | Substrate Material | Fabrication/Detachment Method | Metal Coating | Detection Substance | LOD |

|---|---|---|---|---|---|

| [201] | AAO through-hole membrane | Two-step anodization/etching | NA | PE, PP, PET, PMMA, PS, and PLA nanoparticles | NA |

| [151] | AAO free-standing membrane (with barrier layer) | Two-step anodization/etching | Au | AFB1 ZON DON | 1.8 ng/mL 47.7 ng/mL 24.8 ng/mL |

| [152] | AAO through-hole membrane | Two-step anodization/etching | Au | MB and CR | 10−7 M |

| [153] | AAO through-hole membrane | Two-step anodization/pulse voltage detachment | Ag | AFB1 | 0.01 ng/mL |

| [202] | AAO free-standing membrane | Two-step anodization/etching | Ag and Au | 4-MBT | 1 mM |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ku, C.-A.; Chung, C.-K. Advances in Through-Hole Anodic Aluminum Oxide (AAO) Membrane and Its Applications: A Review. Nanomaterials 2025, 15, 1665. https://doi.org/10.3390/nano15211665

Ku C-A, Chung C-K. Advances in Through-Hole Anodic Aluminum Oxide (AAO) Membrane and Its Applications: A Review. Nanomaterials. 2025; 15(21):1665. https://doi.org/10.3390/nano15211665

Chicago/Turabian StyleKu, Chin-An, and Chen-Kuei Chung. 2025. "Advances in Through-Hole Anodic Aluminum Oxide (AAO) Membrane and Its Applications: A Review" Nanomaterials 15, no. 21: 1665. https://doi.org/10.3390/nano15211665

APA StyleKu, C.-A., & Chung, C.-K. (2025). Advances in Through-Hole Anodic Aluminum Oxide (AAO) Membrane and Its Applications: A Review. Nanomaterials, 15(21), 1665. https://doi.org/10.3390/nano15211665