Structural Optimization and Trap Effects on the Output Performance of 4H-SiC Betavoltaic Cell

Abstract

1. Introduction

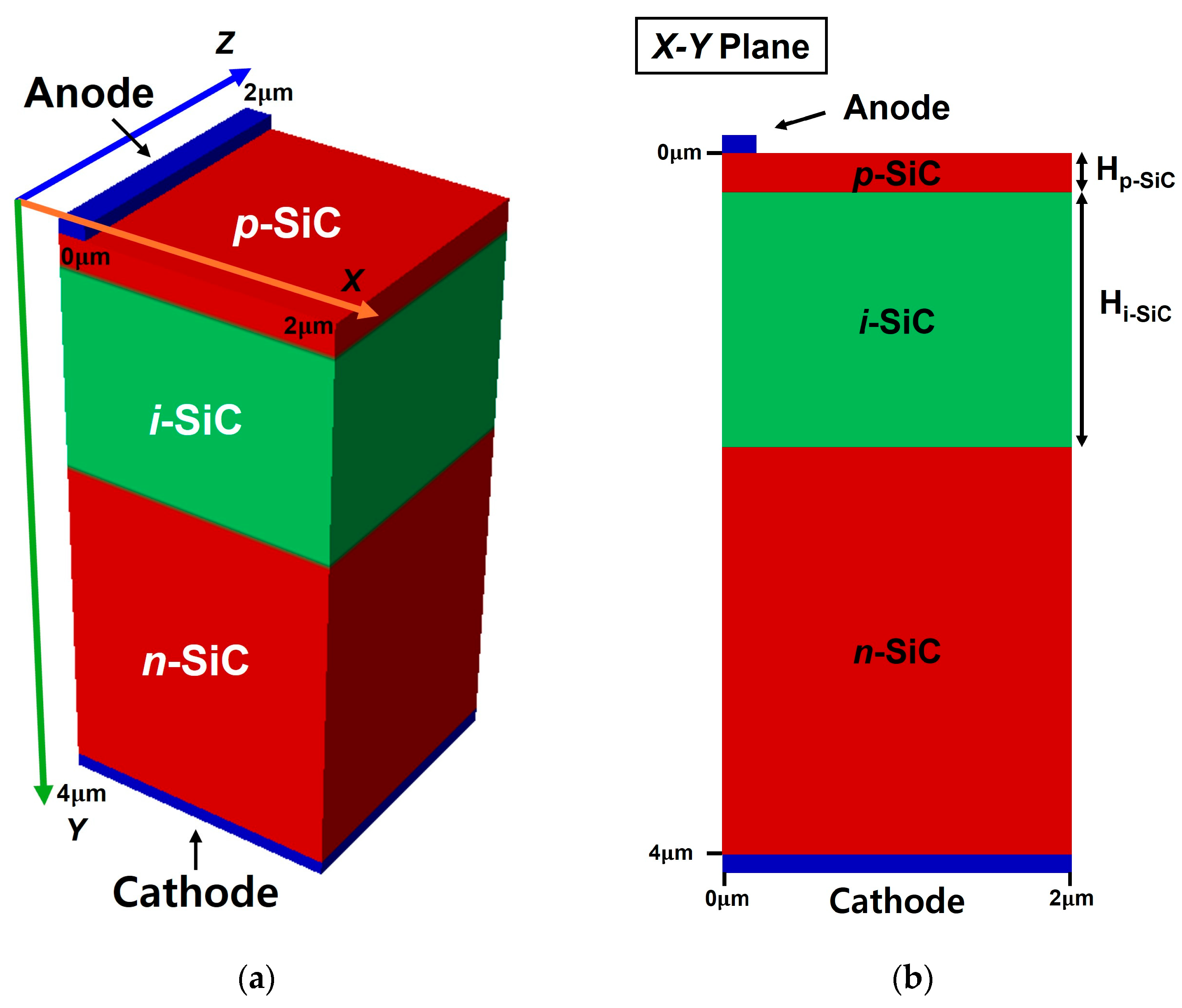

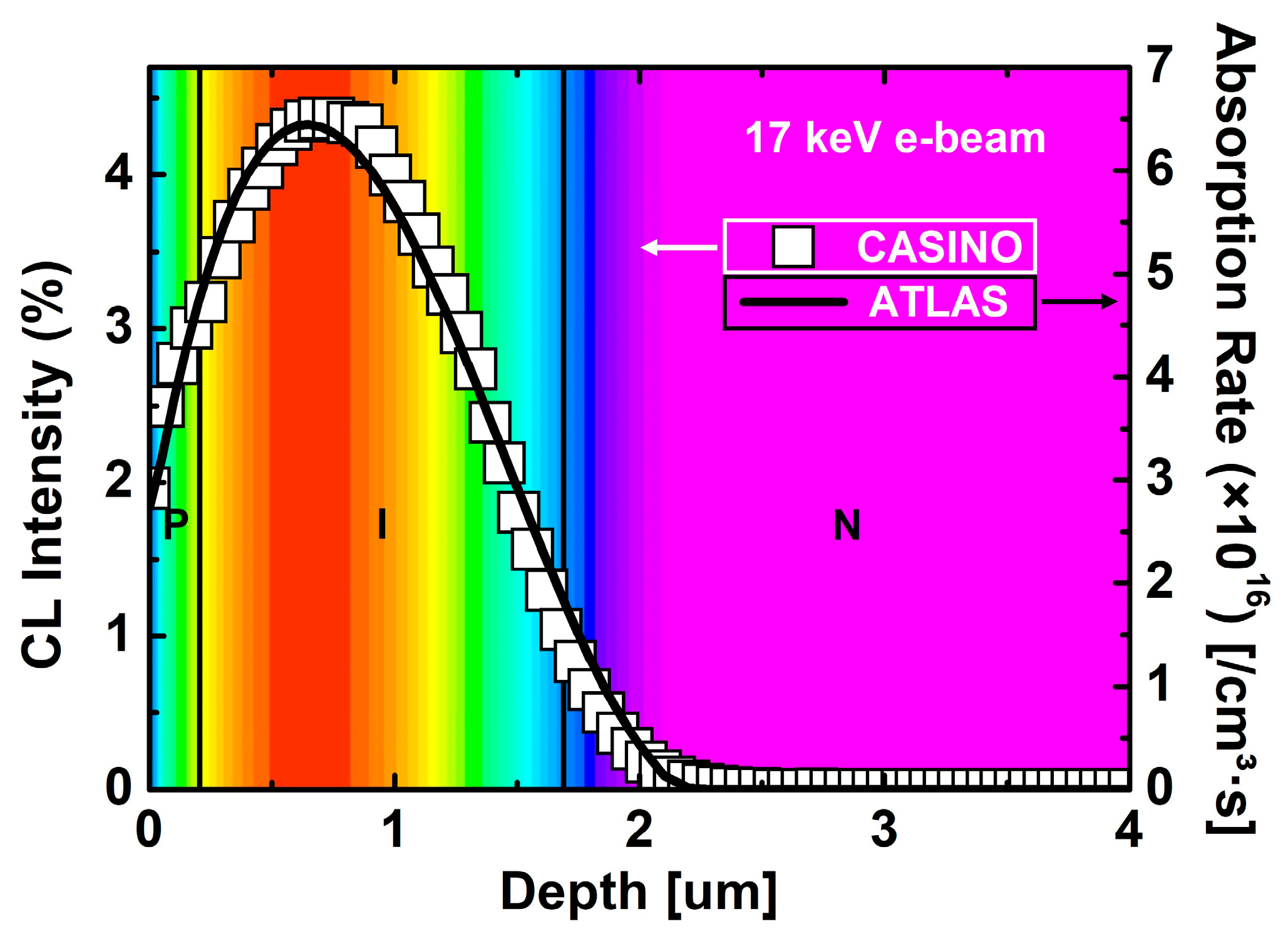

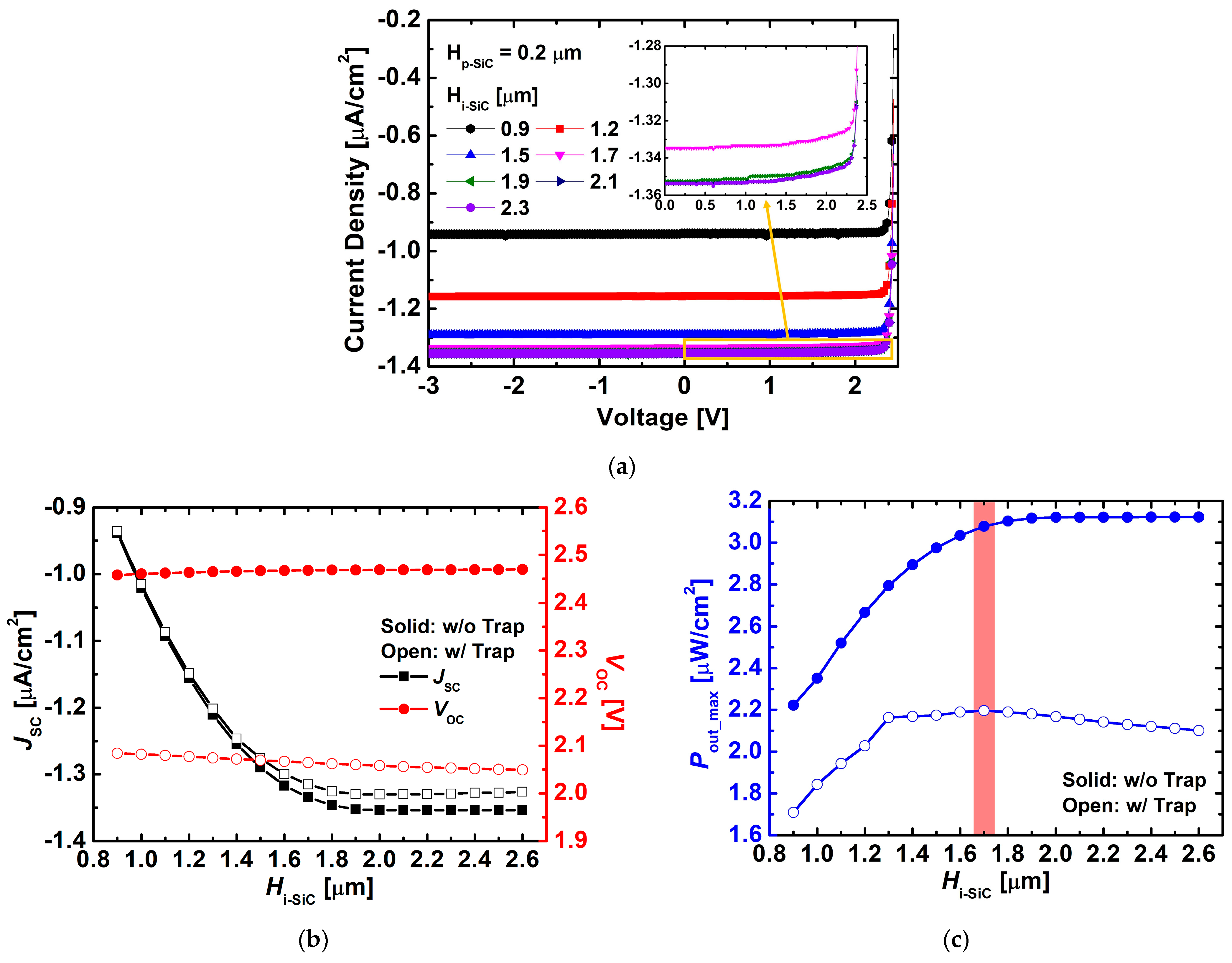

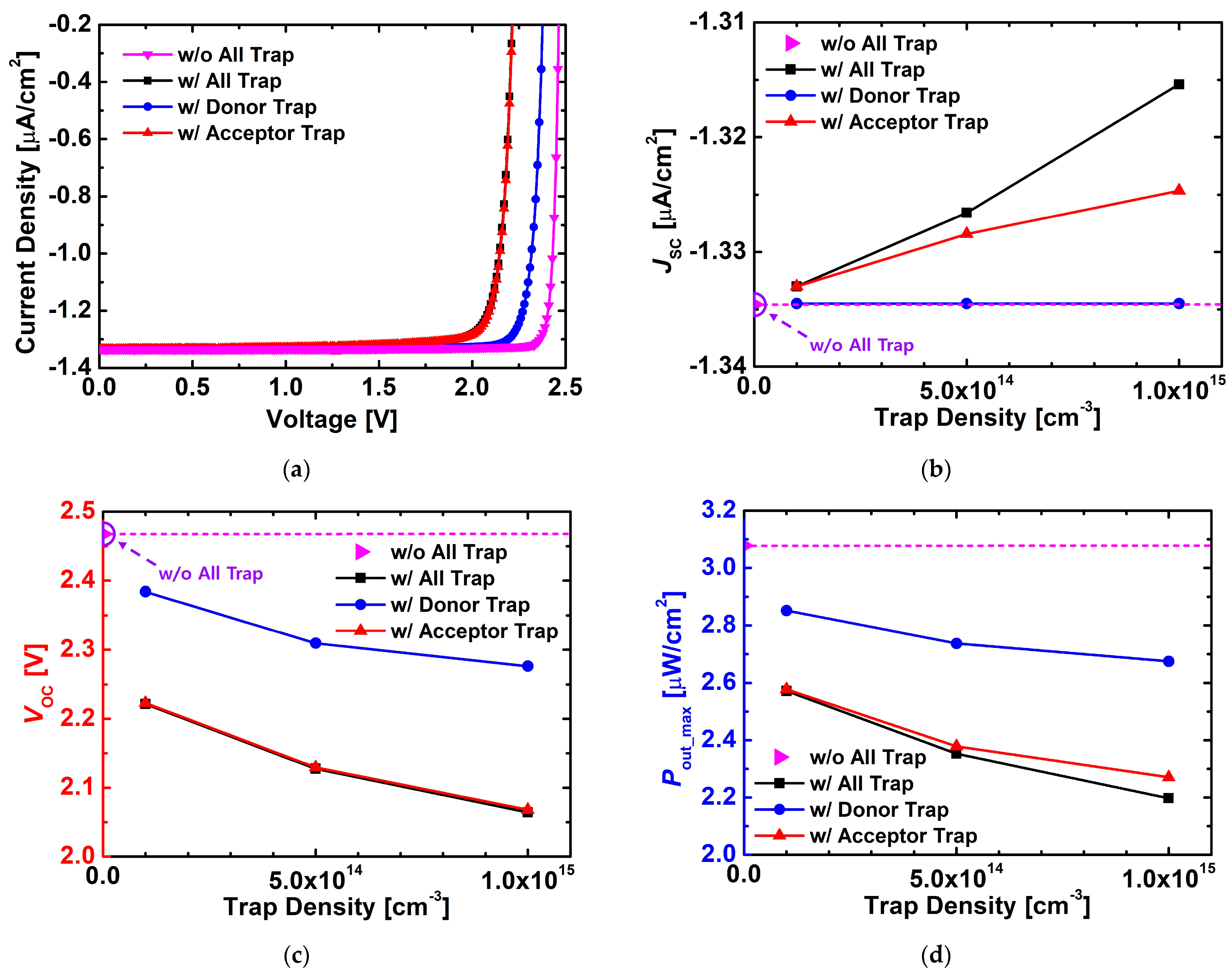

2. Device Structure and Simulation Method

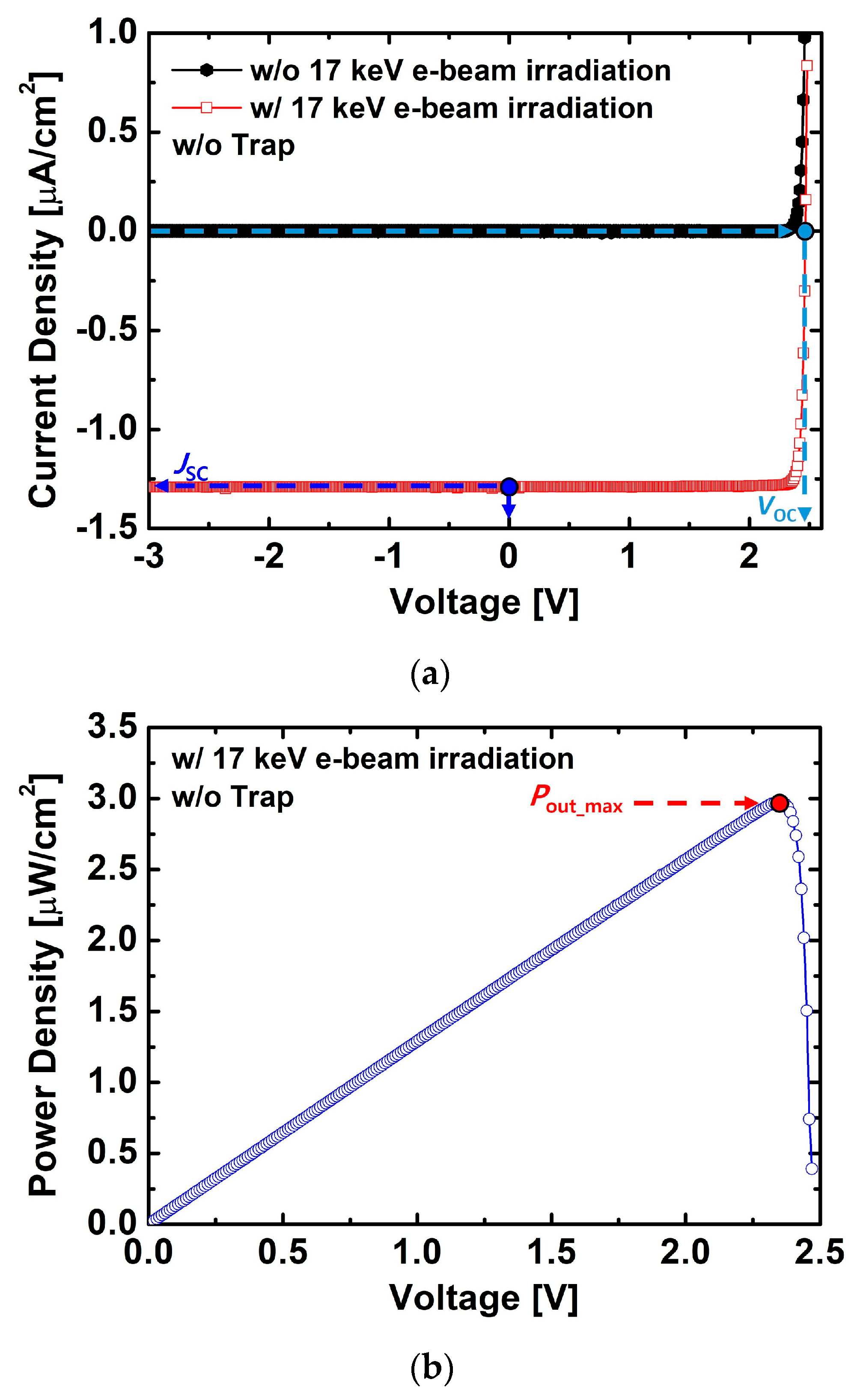

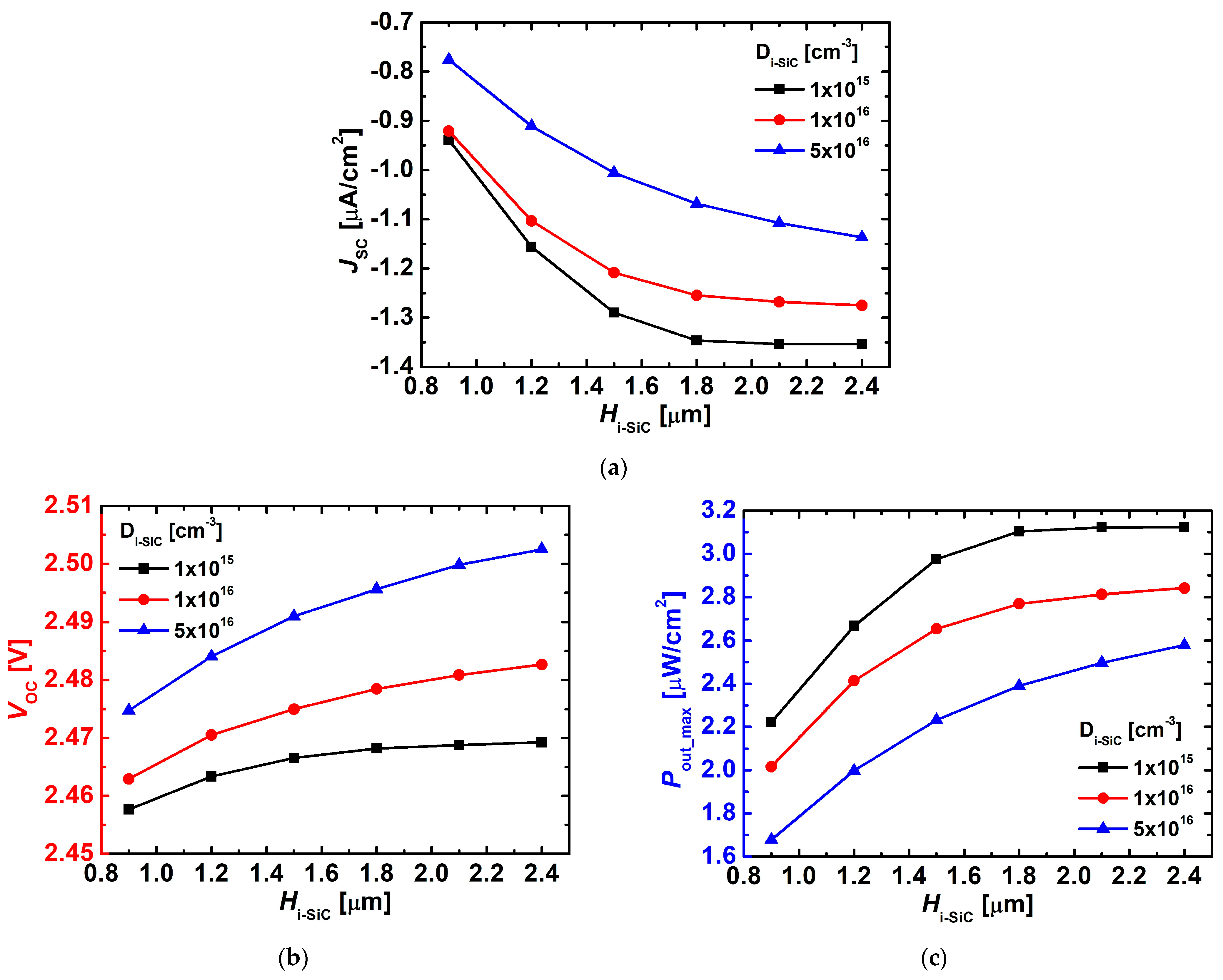

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Spencer, M.G.; Alam, T. High power direct energy conversion by nuclear batteries. Appl. Phys. Rev. 2019, 6, 031305. [Google Scholar] [CrossRef]

- Prelas, M.A.; Weaver, C.L.; Watermann, M.L.; Lukosi, E.D.; Schott, R.J.; Wisniewski, D.A. A review of nuclear batteries. Prog. Nucl. Energy 2014, 75, 117–148. [Google Scholar] [CrossRef]

- Olsen, L.C.; Cabauy, P.; Elkind, B.J. Betavoltaic power sources. Phys. Today 2012, 65, 35–38. [Google Scholar] [CrossRef]

- Ko, W.H.; Hynecek, J. Implant evaluation of a nuclear power source—Betacel battery. IEEE Trans. Biomed. Eng. 1974, 21, 238–241. [Google Scholar] [CrossRef] [PubMed]

- Spickler, J.W.; Rasor, N.S.; Kezdi, P.; Misra, S.N.; Robins, K.E.; LeBoeuf, C. Totally self-contained intracardiac pacemaker. J. Electrocardiol. 1970, 3, 325–331. [Google Scholar] [CrossRef]

- Wang, Y.; Weng, G.-M. Nuclear batteries: Potential, challenges and the future. Innov. Energy 2025, 2, 100079. [Google Scholar] [CrossRef]

- Uhm, Y.R.; Choi, B.G.; Kim, J.B.; Jeong, D.H.; Son, K.J. Study of a Betavoltaic Battery Using Electroplated Nickel-63 on Nickel Foil as a Power Source. Nucl. Eng. Technol. 2016, 48, 773–777. [Google Scholar] [CrossRef]

- Rappaport, P. The Electron-Voltaic Effect in p–n Junctions Induced by Beta-Particle Bombardment. Phys. Rev. 1954, 93, 246–247. [Google Scholar] [CrossRef]

- Butera, S.; Lioliou, G.; Barnett, A.M. Temperature effects on gallium arsenide 63Ni betavoltaic cell. Appl. Radiat. Isot. 2017, 125, 42–47. [Google Scholar] [CrossRef]

- Cheng, Z.; Chen, X.; San, H.; Feng, Z.; Liu, B. A high open-circuit voltage gallium nitride betavoltaic microbattery. J. Micromech. Microeng. 2012, 22, 074011. [Google Scholar] [CrossRef]

- Khan, M.R.; Smith, J.R.; Tompkins, R.P.; Kelley, S.; Litz, M.; Russo, J.; Leathersich, J.; Shahedipour-Sandvik, F.; Jones, K.A.; Iliadis, A. Design and characterization of GaN p–i–n diodes for betavoltaic devices. Solid-State Electron. 2017, 136, 24–29. [Google Scholar] [CrossRef]

- Munson, C.E.; Arif, M.; Streque, J.; Belahsene, S.; Martinez, A.; Ramdane, A.; El Gmili, Y.; Salvestrini, J.-P.; Voss, P.L.; Ougazzaden, A. Model of Ni-63 battery with realistic PIN structure. J. Appl. Phys. 2015, 118, 105101. [Google Scholar] [CrossRef]

- Zhang, L. Simulation and Optimization Design of SiC-Based PN Betavoltaic Microbattery Using Tritium Source. Crystals 2020, 10, 105. [Google Scholar] [CrossRef]

- Thomas, C.; Portnoff, S.; Spencer, M.G. High efficiency 4H-SiC betavoltaic power sources using tritium radioisotopes. Appl. Phys. Lett. 2016, 108, 013505. [Google Scholar] [CrossRef]

- Tudisco, S.; Altana, C.; Amaducci, S.; Ciampi, C.; Cosentino, G.; De Luca, S.; La Via, F.; Lanzalone, G.; Muoio, A.; Pasquali, G.; et al. Silicon Carbide devices for radiation detection: A review of the main performances. Nucl. Instrum. Methods Phys. Res. Sect. A-Accel. Spectrom. Dect. Assoc. Equip. 2025, 1072, 170112. [Google Scholar] [CrossRef]

- De Napoli, M. SiC Detectors: A Review on the Use of Silicon Carbide as Radiation Detection Material. Front. Phys. 2022, 10, 898833. [Google Scholar] [CrossRef]

- Lebedev, A.A.; Kozlovski, V.V.; Davydovskaya, K.S.; Levinshtein, M.E. Radiation Hardness of Silicon Carbide upon High-Temperature Electron and Proton Irradiation. Materials 2021, 14, 4976. [Google Scholar] [CrossRef]

- Holmström, E.; Nordlund, K.; Kuronen, A.; Albe, K. Threshold displacement energies in silicon calculated with density functional theory. Phys. Rev. B 2008, 78, 045202. [Google Scholar] [CrossRef]

- Sun, M.; Hu, J.; Yan, J.; Wang, L.; Zheng, Y.; Zhang, Y. Review of the Recent Progress on GaN-Based Vertical Devices. Electronics 2019, 8, 575. [Google Scholar] [CrossRef]

- Chen, N.; Gray, S.; Leach, R.; Gao, F.; Smith, M. Computational Simulation of Threshold Displacement Energies of GaAs. J. Mater. Res. 2017, 32, 1555–1562. [Google Scholar] [CrossRef]

- Lucas, G.; Pizzagalli, L.; Kermode, J.R. Ab initio Molecular Dynamics Calculations of Threshold Displacement Energies in Silicon Carbide. Phys. Rev. B 2005, 72, 045207. [Google Scholar] [CrossRef]

- Guo, P.; Song, C.; Wu, Y.-N.; Chen, S. Temperature Effect on GaN Threshold Displacement Energy Under Low-Energy Electron Beam Irradiation. Adv. Electron. Mater. 2024, 10, 2400014. [Google Scholar] [CrossRef]

- Litrico, G.; Zimbone, M.; Musumeci, P.; Calcagno, L. Defects annealing in 4H–SiC epitaxial layer probed by low temperature photoluminescence. Mater. Sci. Semicond. Process. 2012, 15, 740–743. [Google Scholar] [CrossRef]

- Hazdra, P.; Vobecký, J. Radiation defects created in n-type 4H–SiC by electron irradiation in the energy range of 1–10 MeV. Phys. Status Solidi A-Appl. Mat. 2019, 216, 1900312. [Google Scholar] [CrossRef]

- Yoon, Y.J.; Lee, J.S.; Kang, I.M.; Lee, J.-H.; Kim, D.-S. Design optimization of GaN diode with p-GaN multi-well structure for high-efficiency betavoltaic cell. Nucl. Eng. Technol. 2021, 53, 1284–1288. [Google Scholar] [CrossRef]

- Yoon, Y.J.; Lee, J.S.; Kang, I.M.; Lee, J.-H.; Kim, D.-S. Design and optimization of GaN-based betavoltaic cell for enhanced output power density. Int. J. Energy Res. 2021, 45, 799–806. [Google Scholar] [CrossRef]

- Kim, K.M.; Kim, K.H.; Kim, Y.H.; Im, J.B.; Choi, G.H.; Yoon, Y.J. Changes in the Electrical Characteristics of GaN MIS-HEMT with TMAH Process under 5 MeV and 25 MeV Proton Irradiation. J. Inst. Korean Electr. Electron. Eng. 2024, 28, 687–695. [Google Scholar] [CrossRef]

- Marek, J.; Kozarik, J.; Minarik, M.; Chvála, A.; Matus, M.; Donoval, M.; Stuchlikova, L.; Weis, M. Charge Trap States of SiC Power TrenchMOS Transistor under Repetitive Unclamped Inductive Switching Stress. Materials 2022, 15, 8230. [Google Scholar] [CrossRef] [PubMed]

- Atlas User’s Manual; Silvaco International Inc.: Santa Clara, CA, USA, 2020.

- Kimoto, T.; Cooper, J.A. Fundamentals of Silicon Carbide Technology: Growth, Characterization, Devices, and Applications; John Wiley & Sons: Singapore, 2014. [Google Scholar] [CrossRef]

- Eiting, C.J.; Krishnamoorthy, V.; Rodgers, S.; George, T.; Robertson, J.D.; Brockman, J. Demonstration of a radiation resistant, high efficiency SiC betavoltaic. Appl. Phys. Lett. 2006, 88, 064101. [Google Scholar] [CrossRef]

- Hovington, P.; Drouin, D.; Gauvin, R. CASINO: A new Monte Carlo code in C language for electron beam interaction—Part I: Description of the program. Scanning 1997, 19, 1–14. [Google Scholar] [CrossRef]

- Drouin, D.; Couture, A.R.; Joly, D.; Tastet, X.; Aimez, V.; Gauvin, R. CASINO V2.42—A Fast and Easy-to-Use Modeling Tool for Scanning Electron Microscopy and Microanalysis Users. Scanning 2007, 29, 92–101. [Google Scholar] [CrossRef] [PubMed]

- Kawahara, K.; Alfieri, G.; Kimoto, T. Detection and depth analyses of deep levels generated by ion implantation in n- and p-type 4H–SiC. J. Appl. Phys. 2009, 106, 013719. [Google Scholar] [CrossRef]

| Properties | Si | GaAs | GaN | 4H-SiC |

|---|---|---|---|---|

| Bandgap (eV) | 1.12 | 1.42 | 3.44 | 3.26 |

| Thermal Conductivity (W/cm·K) | 1.45 | 0.5 | 2.53 | 3.7 |

| Breakdown Field (MV/cm) | 0.3 | 0.4 | 3.3 | 2.0 |

| Electron Mobility (103 cm2/V·s) | 1.35 | 8.5 | 1.25 | 0.72 |

| Threshold Displacement Energy (eV) | 10–30 | 13 ± 1 (average) | 38 (Ga)/ 16 (N) | 38 (Si)/ 19 (C) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, K.M.; Kang, I.M.; Seo, J.H.; Yoon, Y.J.; Kim, K. Structural Optimization and Trap Effects on the Output Performance of 4H-SiC Betavoltaic Cell. Nanomaterials 2025, 15, 1625. https://doi.org/10.3390/nano15211625

Kim KM, Kang IM, Seo JH, Yoon YJ, Kim K. Structural Optimization and Trap Effects on the Output Performance of 4H-SiC Betavoltaic Cell. Nanomaterials. 2025; 15(21):1625. https://doi.org/10.3390/nano15211625

Chicago/Turabian StyleKim, Kyeong Min, In Man Kang, Jae Hwa Seo, Young Jun Yoon, and Kibeom Kim. 2025. "Structural Optimization and Trap Effects on the Output Performance of 4H-SiC Betavoltaic Cell" Nanomaterials 15, no. 21: 1625. https://doi.org/10.3390/nano15211625

APA StyleKim, K. M., Kang, I. M., Seo, J. H., Yoon, Y. J., & Kim, K. (2025). Structural Optimization and Trap Effects on the Output Performance of 4H-SiC Betavoltaic Cell. Nanomaterials, 15(21), 1625. https://doi.org/10.3390/nano15211625