Advancements in Superhydrophobic Paper-Based Materials: A Comprehensive Review of Modification Methods and Applications

Abstract

1. Introduction

2. Paper-Based Functional Materials

3. Applications of Paper-Based Functional Materials

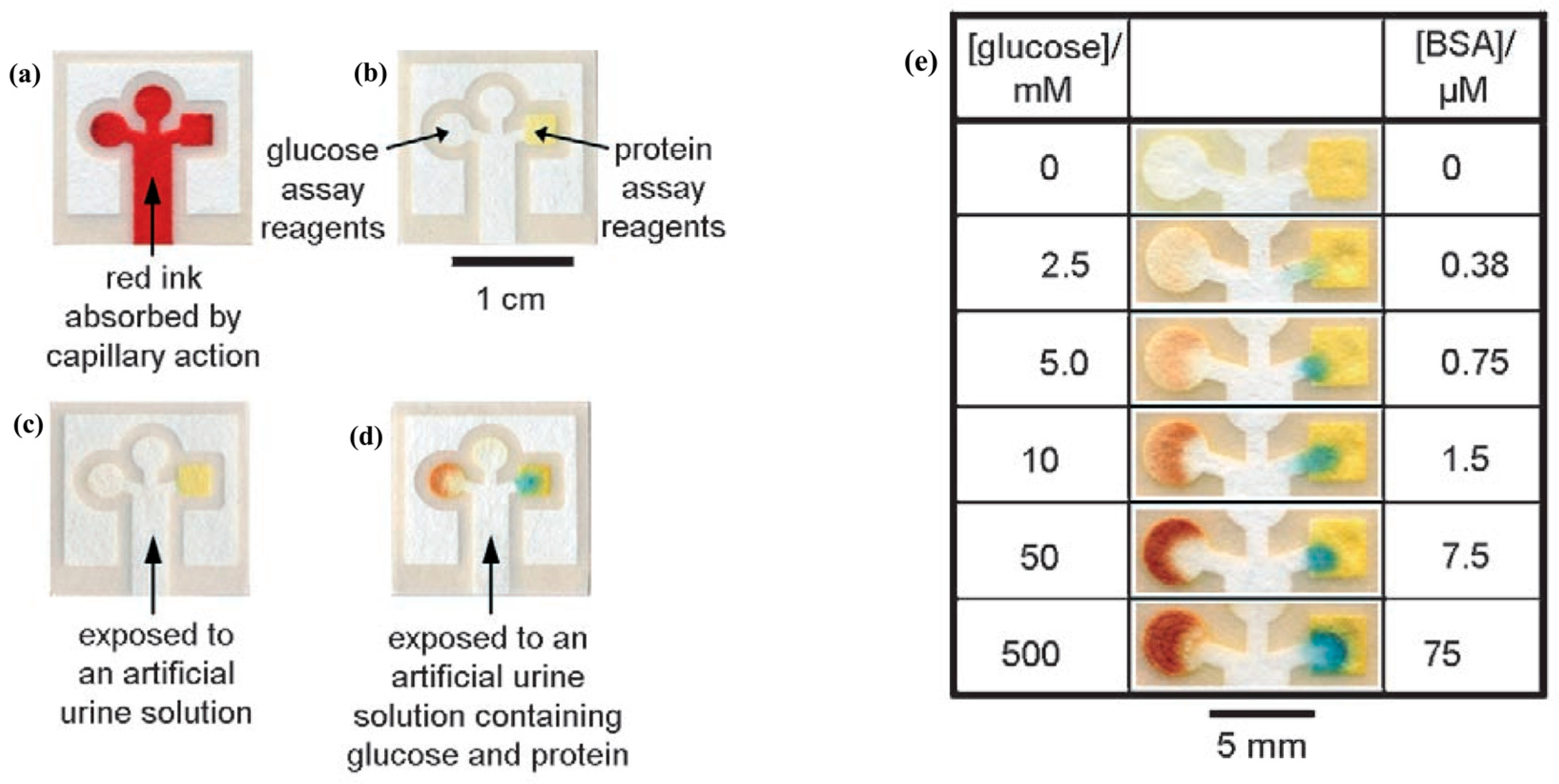

- Diagnostics

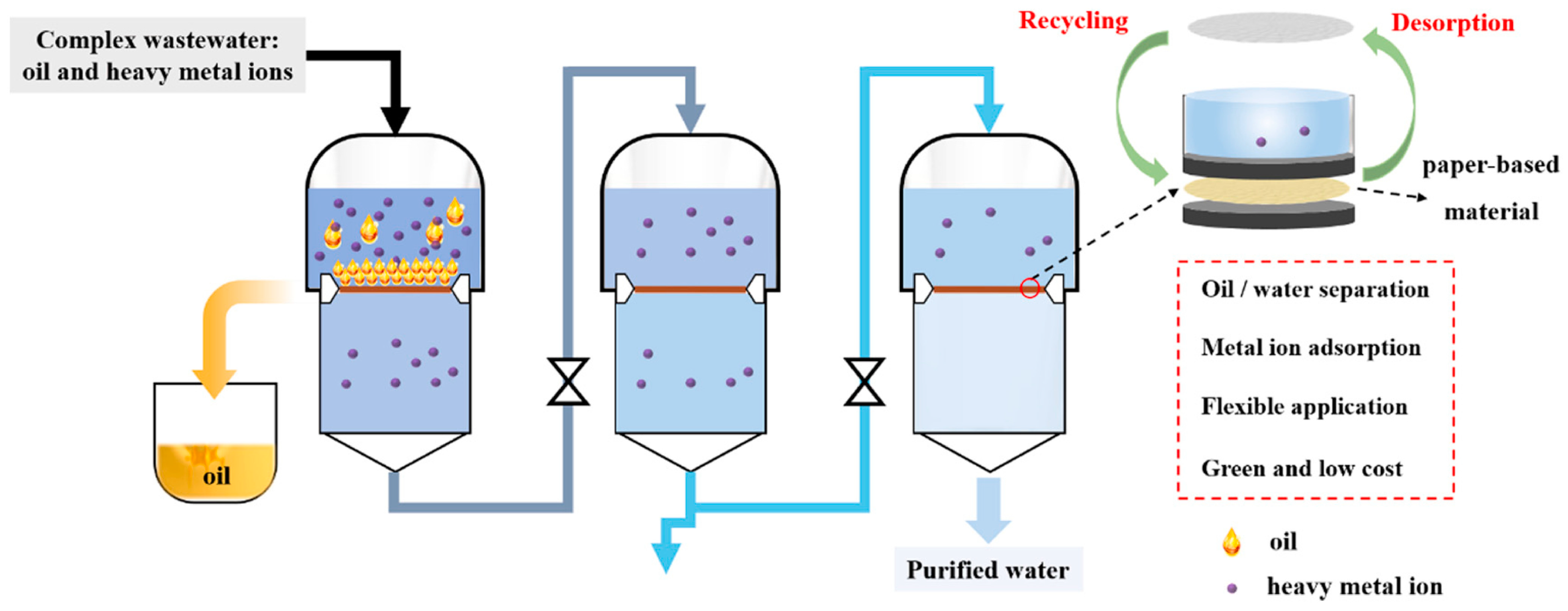

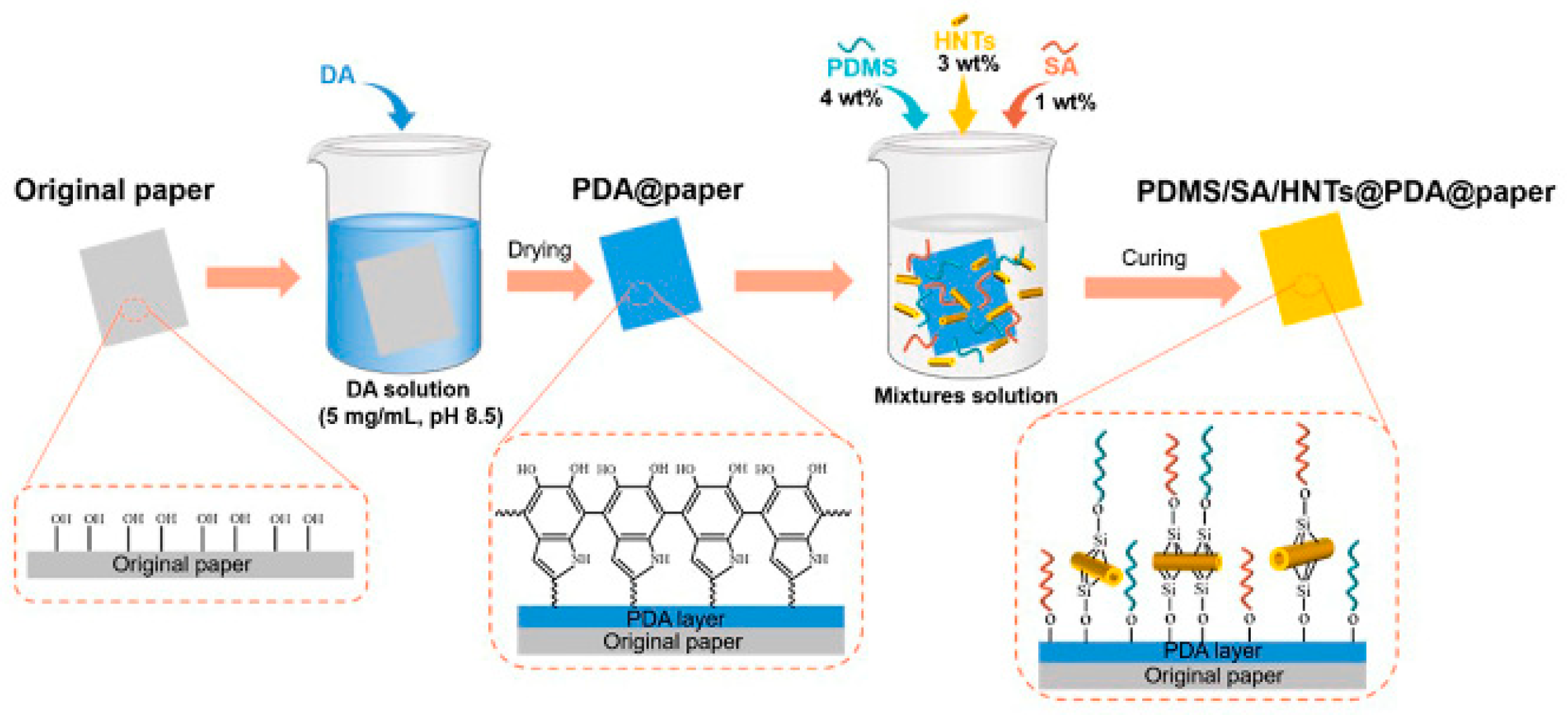

- Environmental Management

- Energy Generation

- Food Testing

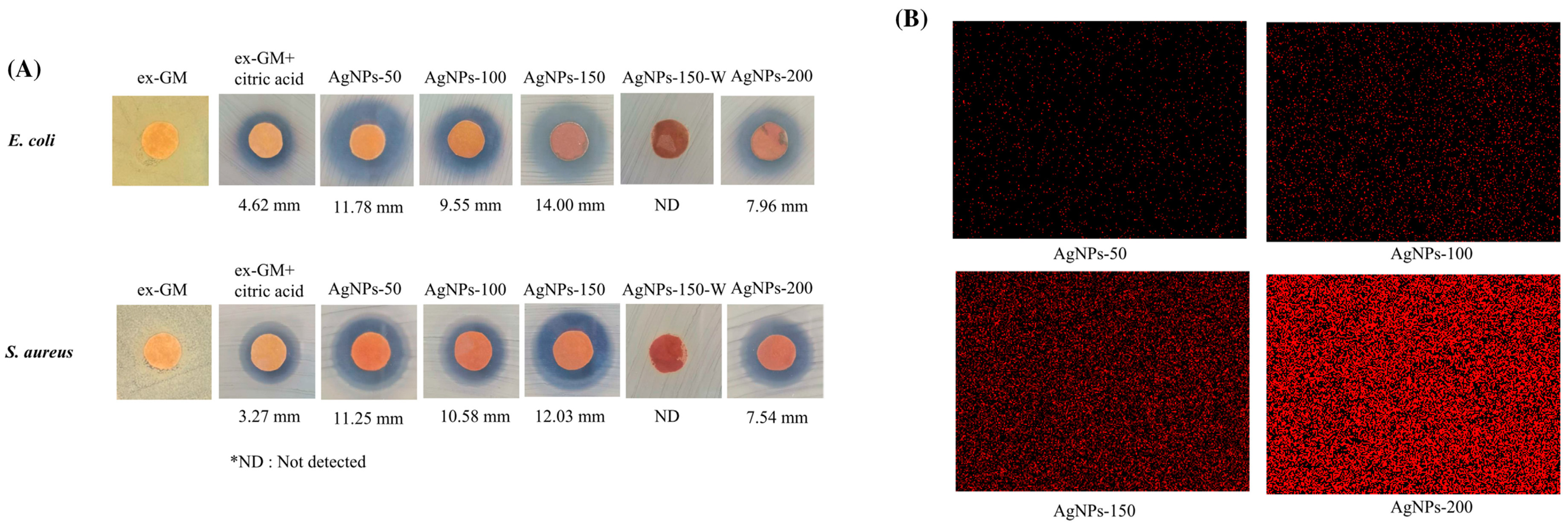

- Smart Packaging

4. Superhydrophobic Modification of Paper-Based Materials

4.1. Superhydrophobic Materials

4.2. Methods of Paper-Based Materials Superhydrophobic Modification

4.2.1. Surface Chemical Modification Technology

4.2.2. Surface Coating Technology

4.2.3. Physical Composite Technology

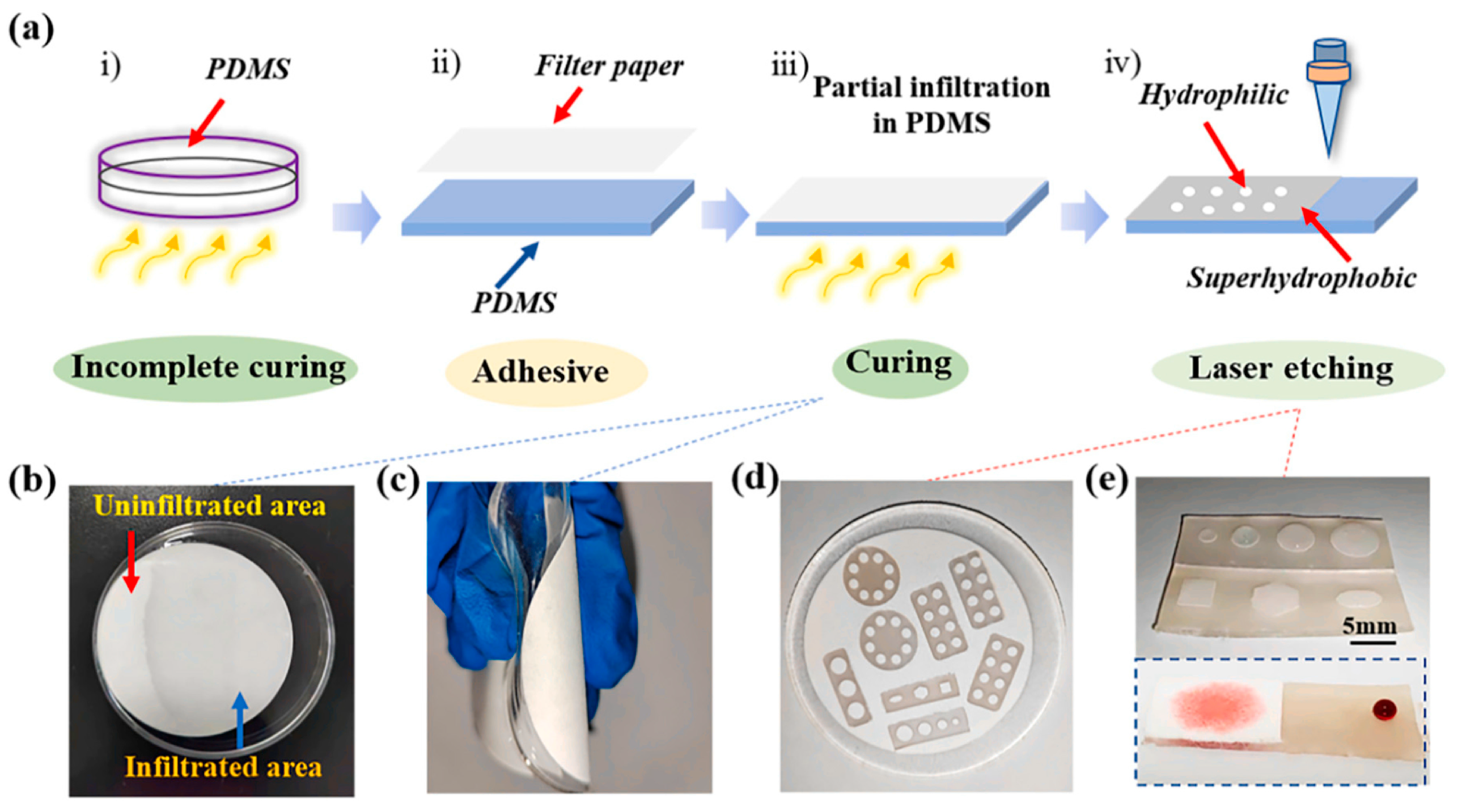

4.2.4. Laser Etching Technology

4.2.5. Other Methods

4.2.6. Comparison of Modification Methods

4.3. Application and Development of Superhydrophobic Paper-Based Materials

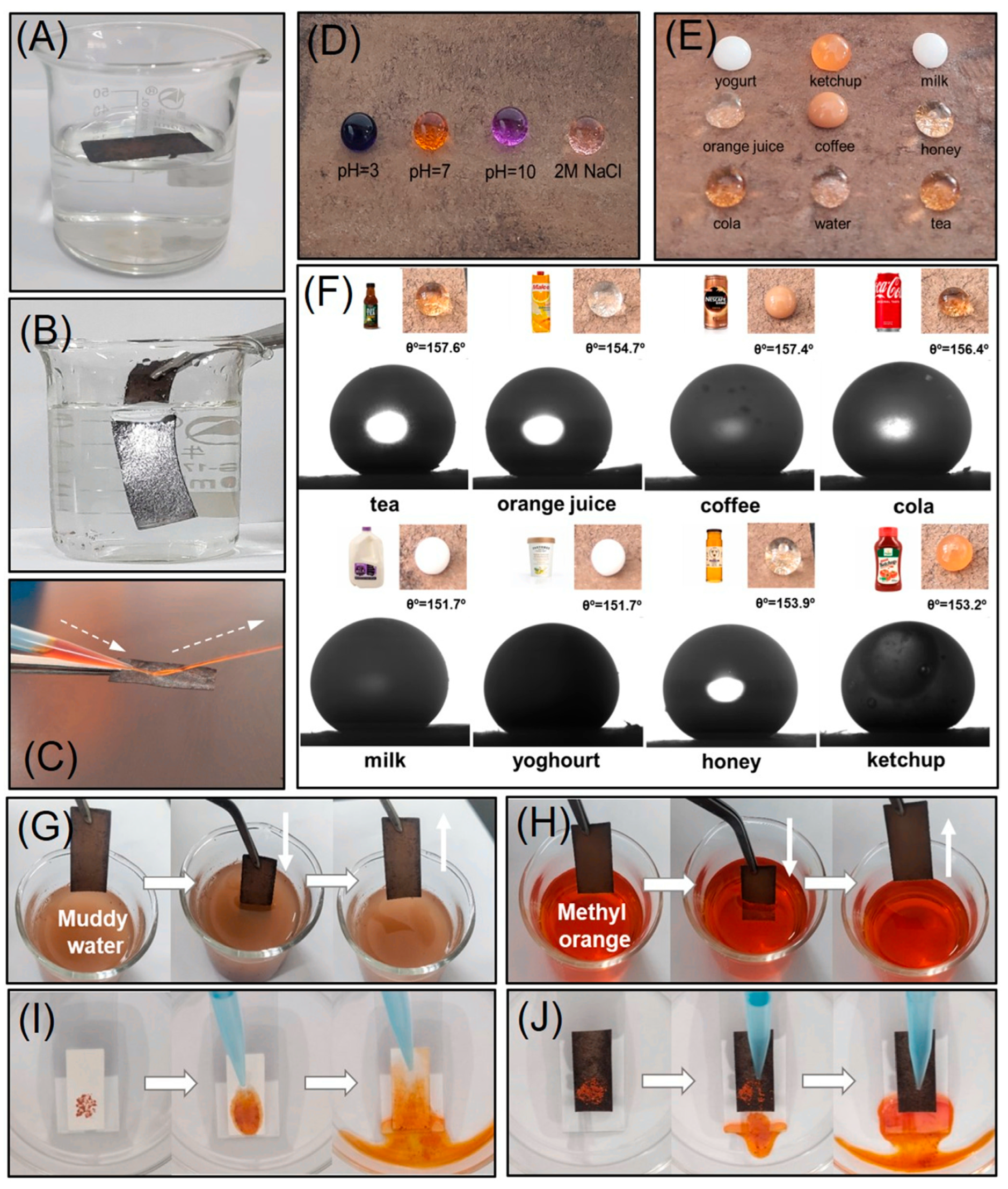

- Self-Cleaning Material

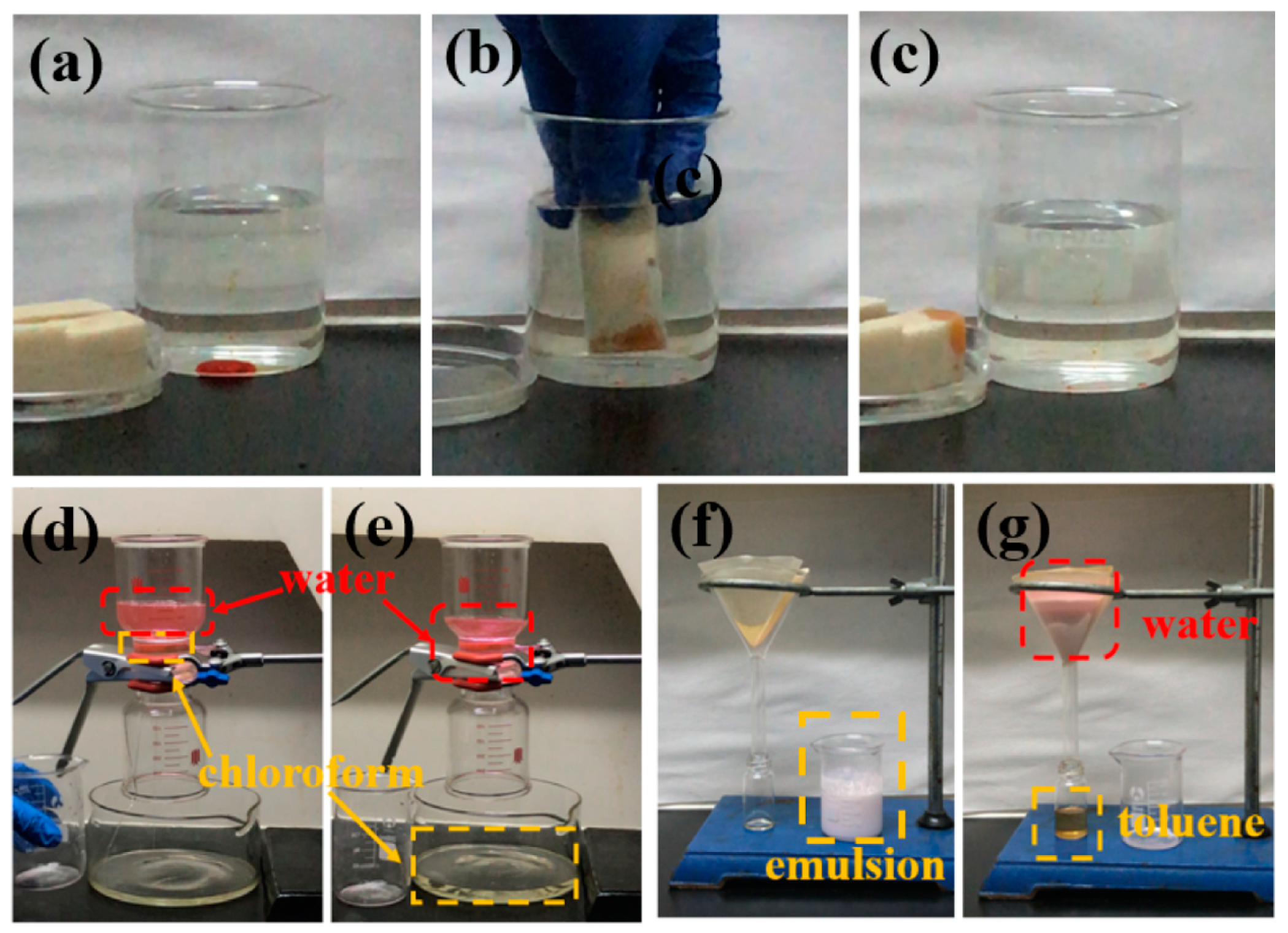

- Oil–Water Separation

- Droplet Manipulation and Paper Fluidics

- Paper-Based Sensor

5. Summary

Author Contributions

Funding

Conflicts of Interest

References

- Lafuma, A.; Quere, D. Superhydrophobic states. Nat. Mater. 2003, 2, 457–460. [Google Scholar] [CrossRef]

- Barthlott, W.; Neinhuis, C. Purity of the sacred lotus, or escape from contamination in biological surfaces. Planta 1997, 202, 1–8. [Google Scholar] [CrossRef]

- Feng, L.; Li, S.H.; Li, Y.; Li, H.; Zhai, J.; Song, Y.; Jiang, L. Super-hydrophobic surfaces: From natural to artificial. Adv. Mater. 2002, 14, 1857–1860. [Google Scholar] [CrossRef]

- Quere, D.; Reyssat, M. Non-adhesive Lotus and other hydrophobic materials. Philos. Trans. R. Soc. A 2008, 366, 1539–1556. [Google Scholar] [CrossRef] [PubMed]

- Aulin, C.; Ström, G. Multilayered alkyd resin/nanocellulose coatings for use in renewable packaging solutions with a high level of moisture resistance. Ind. Eng. Chem. Res. 2013, 52, 2582–2589. [Google Scholar] [CrossRef]

- Martinez, A.W.; Phillips, S.T.; Butte, M.J.; Whitesides, G. Patterned paper as a platform for inexpensive, low volume, portable bioassays. Angew. Chem. 2007, 46, 1318–1320. [Google Scholar] [CrossRef] [PubMed]

- Shankaregowda, S.A.; Ahmed, R.F.S.M.; Nanjegowda, C.B.; Wang, J.W.; Guan, S.; Puttaswamy, M.; Amini, A.; Zhang, Y.; Kong, D.; Sannathammegowda, K.; et al. Single-electrode triboelectric nanogenerator based on economical graphite coated paper for harvesting waste environmental energy. Nano Energy 2019, 66, 104141. [Google Scholar] [CrossRef]

- Belal, A.S.; Nady, J.E.; Shokry, A.; Ebrahim, S.; Soliman, M.; Khalil, M. Superhydrophobic functionalized cellulosic paper by copper hydroxide nanorods for oils purification. Sci. Rep. 2021, 11, 16261. [Google Scholar] [CrossRef]

- Chen, B.; Wang, Z.L. Toward a new era of sustainable energy: Advanced triboelectric nanogenerator for harvesting high entropy energy. Small 2022, 18, 2107034. [Google Scholar] [CrossRef]

- Boonruang, S.; Naksen, P.; Anutrasakda, W.; Chansaenpak, K.; Promarak, V.; Saenmuangchin, R.; Jarujamrus, P. Use of nitrogen-doped amorphous carbon nanodots (N-CNDs) as a fluorometric paper-based sensor: A new approach for sensitive determination of lead(ii) at a trace level in highly ionic matrices. Analyst 2021, 146, 3551–3560. [Google Scholar] [CrossRef]

- French, A.D. Glucose, not cellobiose, is the repeating unit of cellulose and why that is important. Cellulose 2017, 24, 4605–4609. [Google Scholar] [CrossRef]

- Li, A.; Wang, G.; Zhang, Y.; Zhang, J.; He, W.; Ren, S.; Xu, Z.; Wang, J.; Ma, Y. Preparation methods and research progress of superhydrophobic paper. Coord. Chem. Rev. 2021, 449, 214207. [Google Scholar] [CrossRef]

- Li, C.; Yun, T.; Tao, Y.; Lu, J.; Li, C.; Du, J.; Wang, H. Constructing high-density crack-microstructures within MXene interlayers for ultrasensitive and superhydrophobic cellulosic fibers-based sensors. Int. J. Biol. Macromol. 2024, 260, 129488. [Google Scholar] [CrossRef] [PubMed]

- Bu, Y.; Shen, T.; Yang, W.; Yang, S.; Zhao, Y.; Liu, H.; Zheng, Y.; Liu, C.; Shen, C. Ultrasensitive strain sensor based on superhydrophobic microcracked conductive Ti3C2Tx MXene/paper for human-motion monitoring and E-skin. Sci. Bull. 2021, 66, 1849–1857. [Google Scholar] [CrossRef]

- Li, Q.; Yang, W.; Sun, K.; Guo, Y.; Liu, H.; Liu, C.; Shen, C. Superhydrophobic flexible conductive PFDT/CB/MXene@Paper for high-efficiency EMI shielding and Joule heating applications. J. Mater. Chem. C 2022, 10, 14560–14568. [Google Scholar] [CrossRef]

- He, Z.; Li, S.; Zeng, Y.; Zhang, J.; Li, Q.; Gao, B.; Du, X.; Gu, Z. Photo-Adjustable TiO2-Paper as a Smart Substrate for Paper-Based Analytical Devices. Adv. Mater. Interfaces 2021, 9, 4. [Google Scholar] [CrossRef]

- Tang, Z.; Tian, T.; Molino, P.J.; Skvortsov, A.; Ruan, D.; Ding, J.; Li, Y. Recent Advances in Superhydrophobic Materials Development for Maritime Applications. Adv. Sci. 2024, 11, 2308152. [Google Scholar] [CrossRef]

- Hubbe, M.A.; Rojas, O.J.; Lucia, L.A.; Sain, M. Cellulosic nanocomposites: A review. Bioresources 2008, 3, 929–980. [Google Scholar]

- Moon, R.J.; Martini, A.; Nairn, J.; Simonsen, J.; Youngblood, J. Cellulose nanomaterials review: Structure, properties and nanocomposites. Chem. Soc. Rev. 2011, 40, 3941–3994. [Google Scholar] [CrossRef]

- Siro, I.; Plackett, D. Microfibrillated cellulose and new nanocomposite materials: A review. Cellulose 2010, 17, 459–494. [Google Scholar] [CrossRef]

- Spence, K.L.; Venditti, R.A.; Rojas, O.J.; Habibi, Y.; Pawlak, J.J. The effect of chemical composition on micro-fibrillated cellulose films. Cellulose 2011, 18, 1097–1111. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, L. Recent developments in superhydrophobic paper-based materials. J. Colloid. Interface Sci. 2020, 581, 772–787. [Google Scholar]

- Kim, D.H.; Kim, S.O. Superhydrophobic paper from directional deposition of silica nanoparticles onto paper surfaces. ACS Appl. Mater. Interfaces 2012, 4, 2169–2174. [Google Scholar]

- Wang, S.; Jiang, L. Definition of superhydrophobic states. Adv. Mater. 2010, 22, 511–513. [Google Scholar] [CrossRef]

- Li, X.; Yuan, Q. Durable superhydrophobic surfaces via a facile one-step process of nano-SiO2 deposition on cotton fabric. Appl. Surf. Sci. 2014, 292, 72–77. [Google Scholar]

- Lee, J.S.; Ryu, J.; Park, C.B. Bio-inspired fabrication of superhydrophobic surfaces through peptide self-assembly. Soft Matter 2009, 5, 2717–2720. [Google Scholar] [CrossRef]

- Hayden, O.; Luppa, P.B.; Min, J. Point-of-care testing-new horizons for cross-sectional technologies and decentralized application strategies. Anal. Bioanal. Chem. 2022, 414, 3161–3163. [Google Scholar] [CrossRef]

- O’Farrell, B. Evolution in Lateral Flow-Based Immunoassay Systems. In Lateral Flow Immunoassay; Wong, R., Tse, H., Eds.; Humana: New York, NY, USA, 2009; Volume 1, pp. 1–33. [Google Scholar]

- Nie, J.; Zhang, Y.; Lin, L.; Zhou, C.; Li, S.; Zhang, L.; Li, J. Low-cost fabrication of paper-based microfluidic devices by one-step plotting. Anal. Chem. 2012, 84, 6331–6335. [Google Scholar] [CrossRef] [PubMed]

- Kumar, A.; Parihar, A.; Panda, U.; Parihar, D.S. Microfluidics-Based Point-of-Care Testing (POCT) Devices in Dealing with Waves of COVID-19 Pandemic: The Emerging Solution. ACS Appl. Bio Mater. 2022, 5, 2046–2068. [Google Scholar] [CrossRef]

- Jiang, S.; Xi, J.; Dai, H.; Wu, W.; Xiao, H. Multifunctional cellulose paper-based materials and their application in complex wastewater treatment. Int. J. Biol. Macromol. 2022, 207, 414–423. [Google Scholar] [CrossRef]

- Gao, X.; Xu, T.; Shao, C.; Han, Y.; Lu, B.; Zhang, Z.; Qu, L. Electric power generation using paper materials. J. Mater. Chem. A 2019, 7, 20574–20578. [Google Scholar] [CrossRef]

- Mustafa, F.; Finny, A.S.; Kirk, K.A.; Andreescu, S. Printed paper-based (bio)sensors: Design, fabrication and applications. In Comprehensive Analytical Chemistry; Elsevier: Amsterdam, The Netherlands, 2020; Volume 89, pp. 63–89. [Google Scholar] [CrossRef]

- Cinti, S.; Basso, M.; Moscone, D.; Arduini, F. A paper-based nanomodified electrochemical biosensor for ethanol detection in beers. Anal. Chim. Acta 2017, 960, 123–130. [Google Scholar] [CrossRef] [PubMed]

- Rosati, G.; Ravarotto, M.; Scaramuzza, M.; De Toni, A.; Paccagnella, A. Silver Nanoparticles Inkjet-printed Flexible Biosensor for Rapid Label-free Antibiotic Detection in Milk. Sens. Actuators B Chem. 2018, 280, 280–289. [Google Scholar] [CrossRef]

- Natwat, S.; Artjima, O.; Natnaree, S.; Supranee, P.; Thidarut, B.; Atchara, A.; Somnuk, T.; Manunya, O.; Pornnapa, K.; Natwat, S.; et al. Green-synthesized silver nanoparticle coating on paper for antibacterial and antiviral applications. Polym. Bull. 2022, 80, 11–18. [Google Scholar]

- Boukid, F. Smart Food Packaging: An Umbrella Review of Scientific Publications. Coatings 2022, 12, 1949. [Google Scholar] [CrossRef]

- Wang, T.-S.; Sun, T.; Feng, L.; Aizenberg, J. Interfacial materials with special wettability. MRS Bull. 2013, 38, 366–371. [Google Scholar] [CrossRef]

- Neinhuis, C.; Barthlott, W. Characterization and distribution of water-repellent, self-cleaning plant surfaces. Ann. Bot. 1997, 79, 667–677. [Google Scholar] [CrossRef]

- Wang, B.; Liang, W.; Guo, Z.; Liu, W. Biomimetic super-lyophobic and super-lyophilic materials applied for oil/water separation: A new strategy beyond nature. Chem. Soc. Rev. 2015, 44, 336–361. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.; Sun, Q.; Hokkanen, M.J.; Zhang, C.; Lin, F.; Liu, Q.; Zhu, S.; Zhou, T.; Chang, Q.; He, B.; et al. Design of robust super-hydrophobic surfaces. Nature 2020, 582, 55–59. [Google Scholar] [CrossRef] [PubMed]

- Chun, D.M.; Ngo, C.V.; Lee, K.M. Fast fabrication of superhydrophobic metallic surface using nanosecond laser texturing and low-temperature annealing. CIRP Ann. 2016, 65, 519–522. [Google Scholar] [CrossRef]

- Barthwal, S.; Barthwal, S. Engineering a robust, multifunctional superhydrophobic/oleophobic microporous aluminum surface via a two-step chemical etching process. Surf. Interfaces 2024, 46, 103933. [Google Scholar] [CrossRef]

- Wu, X.; Chu, F.; Orejon, D.; Mouterde, T. Superhydrophobic surfaces: Fundamentals, manufacture, and applications. Appl. Phys. Lett. 2024, 124, 020401.1–020401.3. [Google Scholar] [CrossRef]

- Yang, Y.; Shan, L.; Shen, H.; Qiu, J. Manufacturing of robust superhydrophobic Wood surfaces based on PEG–Functionalized SiO2/PVA/PAA/Fluoropolymer hybrid transparent coating. Prog. Org. Coat. 2021, 154, 106186. [Google Scholar] [CrossRef]

- Niu, H.; Luo, S.; Yao, X.; Li, T.; Ai, M.; Zhou, R.; Wang, H.; Wan, L.; Du, Y.; Hu, L.; et al. review of transparent superhydrophobic materials and their research in the field of photovoltaic dust removal. Mater. Sci. Semicond. Process. 2023, 166, 20230117. [Google Scholar] [CrossRef]

- Huajaikaew, E.; Piroonpan, T.; Booncharoen, K.; Pasanphan, W. Comb-like poly(dodecyl methacrylate) modified SiO2 nanoparticles as nanohybrid coatings: Electron beam grafting and tuning superhydrophobic/water-repellent surface studies. Prog. Org. Coat. 2022, 163, 106658. [Google Scholar] [CrossRef]

- Wang, B.; Wang, C.; Weng, D.; Lazarus, M.; Yan, D.; Liu, X. Replenishment of the Gas in a Hydrophobically-Structured Surface by Mass Transfer at the Liquid-Gas Interface for Improving the Stability of Entrapped Gas. Micromachines 2022, 13, 1893. [Google Scholar] [CrossRef]

- He, Q.; Du, Z.; Jia, Y.; Liu, Y.; Xu, Z.; Xu, Y.; Li, A. Preparation of superhydrophobic conductive micro/nano-graphite/PDMS films on paper by simple spraying method. J. Appl. Polym. Sci. 2024, 141, e55160. [Google Scholar] [CrossRef]

- Wang, L.; Wang, K.; Liu, M.; Wu, Y.; Zheng, H. Eco-friendly bionic superwetting Janus membranes prepared from paper-based laser-induced graphene for photothermal anti-icing and on-demand oil–water separation. Sep. Purif. Technol. 2025, 356, 129859. [Google Scholar] [CrossRef]

- Zhang, X.; Ding, J.; Chen, H.; Fu, H.; Xu, J. Superhydrophobic and environmentally friendly bovine bone biomass based cellulose membrane for oil-water separation. Int. J. Biol. Macromol. 2024, 280, 135677. [Google Scholar] [CrossRef]

- Wang, Q.; Xie, D.; Chen, J.; Liu, G.; Yu, M. Superhydrophobic paper fabricated via nanostructured titanium dioxide-functionalized wood cellulose fibers. J. Mater. Sci. 2020, 55, 7084–7094. [Google Scholar] [CrossRef]

- Jiang, X.; Li, Q.; Li, X.; Meng, Y.; Ling, Z.; Ji, Z.; Chen, F. Preparation and Characterization of Degradable Cellulose−Based Paper with Superhydrophobic, Antibacterial, and Barrier Properties for Food Packaging. Int. J. Mol. Sci. 2022, 23, 11158. [Google Scholar] [CrossRef] [PubMed]

- Yu, F.; Wang, K.; Li, H.; Peng, L. Superhydrophobic and ethylene scavenging paper doped with halloysite nanotubes for food packaging applications. Colloids Surf. A Physicochem. Eng. Asp. 2023, 656, 130457. [Google Scholar] [CrossRef]

- Yang, R.L.; Zhu, Y.J.; Qin, D.D.; Xiong, Z.C. Light-Operated Dual-Mode Propulsion at the Liquid/Air Interface Using Flexible, Superhydrophobic, and Thermally Stable Photothermal Paper. ACS Appl. Mater. Interfaces 2020, 12, 1339–1347. [Google Scholar] [CrossRef]

- Sudarsan, S.; Shetty, P.; Chinnappan, R.; Mani, N.K. Tuning Hydrophobicity of Paper Substrates for Effective Colorimetric detection of Glucose and Nucleic acids. Anal. Bioanal. Chem. 2023, 415, 6449–6460. [Google Scholar] [CrossRef] [PubMed]

- Yuan, Y.; Xiaowen, Z.; Lin, Y. Facile construction of durable superhydrophobic cellulose paper for oil–water separation. Cellulose 2023, 30, 3255–3265. [Google Scholar]

- Zhang, T.; Wang, D.; Liu, R.; Xie, Y.; Li, J.; Wang, L. A Coral Reef-like Structure Fabricated on Cellulose Paper for Simultaneous Oil-Water Separation and Electromagnetic Shielding Protection. ACS Omega 2020, 5, 18105–18113. [Google Scholar] [CrossRef]

- Omotayo, A.; Philani, M. Kirigami paper-based colorimetric immunosensor integrating smartphone readout for determination of humoral autoantibody immune response. Microchem. J. 2022, 178, 107427. [Google Scholar]

- Kim, Y.R.; Kim, M.P.; Park, J.; Lee, Y.; Ghosh, S.K.; Kim, J.; Kang, D.; Ko, H. Binary Spiky/Spherical Nanoparticle Films with Hierarchical Micro/Nanostructures for High-Performance Flexible Pressure Sensors. ACS Appl. Mater. Interfaces 2020, 12, 37643–37654. [Google Scholar] [CrossRef]

- Wang, C.; Quan, J.; Liu, L.; Cao, P.; Ding, K.; Ding, Y.; Jia, X.; Yan, D.; Lin, N.; Duan, J. A rigid–soft hybrid paper-based flexible pressure sensor with an ultrawide working range and frequency bandwidth. J. Mater. Chem. A 2024, 23, 12. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, H.; Cheng, Y.; Zhang, L.; Shen, W. Superhydrophobic surfaces with dual-scale roughness and water vapor-barrier property for sustainable liquid packaging applications. Cellulose 2024, 29, 9777–9790. [Google Scholar] [CrossRef]

- He, Q.; Du, Z.; Jia, Y.; Liu, Y.; Xu, Z.; Xu, Y.; Li, A. Preparation of superhydrophobic conductive CNT/PDMS film on paper by foam spraying method. Colloids Surf. A Physicochem. Eng. Asp. 2022, 648, 129327. [Google Scholar]

- Wang, Y.; Yue, G.; Li, D.; Hou, L.; Zhao, X.; Cui, Z.; Bai, J.; Wang, N.; Zhao, Y. A Robust Carbon Nanotube and PVDF-HFP Nanofiber Composite Superwettability Membrane for High-Efficiency Emulsion Separation. Macromol. Rapid Commun. 2020, 41, 2000089. [Google Scholar] [CrossRef]

- Xiang, H.; Wang, B.; Zhong, M.; Liu, W.; Yu, D.; Wang, Y.; Tam, K.C.; Zhou, G.; Zhang, Z. Sustainable and Versatile Superhydrophobic Cellulose Nanocrystals. ACS Sustain. Chem. Eng. 2022, 10, 5939–5948. [Google Scholar] [CrossRef]

- Li, A.; Wang, J.; Ren, S.; Zhang, J.; Zhang, X.; Zhang, Y. Preparation of superhydrophobic paper mulch and study on its Anti-UV Performance. J. Saudi Chem. Soc. 2021, 25, 101322. [Google Scholar] [CrossRef]

- Ma, X.; Zhu, Z.; Zhang, H.; Tian, S.; Li, X.; Fan, H.; Fu, S. Superhydrophobic and deacidified cellulose/CaCO3-derived granular coating toward historic paper preservation. Int. J. Biol. Macromol. 2022, 207, 232–241. [Google Scholar] [CrossRef] [PubMed]

- Yang, R.; Liu, B.; Yu, F.; Li, H.; Zhuang, Y. Superhydrophobic cellulose paper with sustained antibacterial activity prepared by in-situ growth of carvacrol-loaded zinc-based metal organic framework nanorods for food packaging application. Int. J. Biol. Macromol. 2023, 234, 123712. [Google Scholar] [CrossRef]

- Yu, X.; Wang, Q.; Fu, L.; Shen, G.; Zhang, W.; Yang, R.; Sun, K.; Lv, F.; Fan, S. Superhydrophobic meta-aramid papers prepared by the surface-embedded spray coating strategy. Appl. Surf. Sci. 2024, 648, 159044. [Google Scholar] [CrossRef]

- Thangjitsirisin, K.; Seeharaj, P.; Choengchan, N. Superhydrophobic eggshell for fabrication of hydrophobic barrier of paper-based analytical device for colorimetric determination of ammonium ion in water. Microchem. J. 2024, 200, 110464. [Google Scholar] [CrossRef]

- Xiang, H.; Li, Z.; Wang, W.; Wu, H.; Zhou, H.; Ni, Y.; Liu, H. Enabling a Paper-Based Flexible Sensor to Work under Water with Exceptional Long-Term Durability through Biomimetic Reassembling of Nanomaterials from Natural Wood. ACS Sustain. Chem. Eng. 2023, 11, 8667–8674. [Google Scholar] [CrossRef]

- Wan, J.; Xu, J.; Zhu, S.; Li, J.; Wang, B.; Zeng, J.; Li, J.; Chen, K. Eco-Friendly Superhydrophobic Composites with Thermostability, UV Resistance, and Coating Transparency. ACS Appl. Mater. Interfaces 2021, 12, 61681–61692. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Wang, B.; Li, J.; Ying, G.; Chen, K. High-strength and super-hydrophobic multilayered paper based on nano-silica coating and micro-fibrillated cellulose. Carbohydr. Polym. 2022, 288, 119371. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, X.; Chen, J.; Zhang, Z.; Feng, L. Functional toner for office laser printer and its application for printing of paper-based superwettable patterns and devices. Sci. Rep. 2023, 13, 12592. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Teng, R.; Fu, C.; Wang, R.; Chen, Z.; Li, W.; Liu, S. Design and Synthesis of a Robust and Multifunctional Superhydrophobic Coating with a Three-Dimensional Network Structure on a Paper-Based Material. ACS Appl. Mater. Interfaces 2024, 16, 37111–37121. [Google Scholar] [CrossRef]

- Li, X.; Chen, X.; Zhao, C.; Luo, X.; Jiang, Y.; Zhu, J.; Zhang, H. Fabrication and Research of Superhydrophobic Paper for Oil-Water Separation. Mater. Chem. Phys. 2023, 304, 127808. [Google Scholar] [CrossRef]

- Ning, S.; Tian, G.; Yang, F. Bionic Silanized Cellulose Superhydrophobic Paper for Efficient Oil-Water Separation. Sep. Purif. Technol. 2025, 353, 128523. [Google Scholar] [CrossRef]

- Yun, T.; Du, J.; Ji, X.; Tao, Y.; Cheng, Y.; Lv, Y.; Lu, J.; Wang, H. Waterproof and Ultrasensitive Paper-Based Wearable Strain/Pressure Sensor from Carbon Black/Multilayer Graphene/Carboxymethyl Cellulose Composite. Carbohydr. Polym. 2023, 313, 120898. [Google Scholar] [CrossRef] [PubMed]

- Nie, S.; Guo, H.; Lu, Y.; Zhuo, J.; Mo, J.; Wang, Z.L. Superhydrophobic Cellulose Paper-Based Triboelectric Nanogenerator for Water Drop Energy Harvesting. Adv. Mater. Technol. 2020, 5, 454. [Google Scholar] [CrossRef]

- Bandyopadhyay, S.; Santra, S.; Das, S.; Mukherjee, R.; Chakraborty, S. Non-wetting Liquid-Infused Slippery Paper. Langmuir 2021, 37, 46. [Google Scholar] [CrossRef] [PubMed]

- Breuer, C.; Cordt, C.; Hiller, B.; Geissler, A.; Biesalski, M. Using Paper as a Biomimetic Fog Harvesting Material. Adv. Mater. Interfaces 2024, 11, 8. [Google Scholar] [CrossRef]

- Wang, H.; Chen, R.; Zhang, F.; Yu, Z.; Wang, Y.; Tang, Z.; Yang, L.; Tang, X.; Xiong, B. Superhydrophobic Paper-Based Microfluidic Field-Effect Transistor Biosensor Functionalized with Semiconducting Single-Walled Carbon Nanotube and DNAzyme for Hypocalcemia Diagnosis. Int. J. Mol. Sci. 2022, 23, 7799. [Google Scholar] [CrossRef] [PubMed]

- Fan, Y.; Li, S.; Wei, D.; Hou, J.; Fang, Z.; Han, Z.; Liu, Y. Flexible bioinspired PDMS-paper based surface with hybrid wettability for droplet collection and detection. Prog. Org. Coat. 2022, 170, 106988. [Google Scholar] [CrossRef]

- Tan, W.; Aruna; Xu, Z.; Zhang, L.; Shen, W. Trace analysis on chromium (VI) in water by pre-concentration using a superhydrophobic surface and rapid sensing using a chemical-responsive adhesive tape. Talanta 2020, 218, 121116. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; Jiao, Z.; Zhang, J.; Wang, Y.; Zhang, C.; Meng, X.; Jiang, X.; Niu, S.; Han, Z.; Ren, L. Bioinspired, Superhydrophobic, and Paper-Based Strain Sensors for Wearable and Underwater Applications. ACS Appl. Mater. Interfaces 2020, 13, 1967–1978. [Google Scholar] [CrossRef]

- Cai, L.; Yongquan, Q.; Xiao, L.; Niu, L.; Xinyu, X.; Kai, A.; Mengxue, H.; Songhe, L.; Changsheng, L. Synergistic Reinforced Superhydrophobic Paper with Green, Durability, and Antifouling Function. Appl. Surf. Sci. 2022, 579, 152144. [Google Scholar]

- Liu, L.; Meng, X.; Zhang, C.; Chen, Y.; Sun, T.; Lu, Z.; Zhang, J.; Niu, S.; Han, Z.; Duan, J.-A. A multifunctional flexible sensor with coupling bionic microstructures inspired by nature. J. Mater. Chem. C 2022, 10, 11296–11306. [Google Scholar] [CrossRef]

- Jinming, W.; Jun, X.; Shiyun, Z.; Bin, W.; Jun, L.; Guangdong, Y.; Kefu, C. Flexible Biomimetic Materials with Excellent Photothermal Performance and Superhydrophobicity. J. Colloid. Interface Sci. 2023, 629, 581–590. [Google Scholar]

- Huang, Y.; Wang, W.; Chang, S.; Bao, A.; Liu, Y.; Li, R.; Xiong, J. A Waterproof Flexible Paper-Based Thermoelectric Generator for Humidity and Underwater Environments. Materials 2024, 17, 2338. [Google Scholar] [CrossRef]

- Rofman, B.; Naddaf, R.; Bar-Dolev, M.; Gefen, T.; Ben-Assa, N.; GevaZatorsky, N.; Bercovici, M. Automated Device for Multi-Stage Paper-Based Assays Enabled by an Electroosmotic Pumping Valve. Lab Chip 2022, 22, 4511–4520. [Google Scholar] [CrossRef]

- Yun, T.; Tao, Y.; Li, Q.; Cheng, Y.; Lu, J.; Lv, Y.; Du, J.; Wang, H. Superhydrophobic Modification of Cellulosic Paper-Based Materials: Fabrication, Properties, and Versatile Applications. Carbohydr. Polym. 2023, 305, 120570. [Google Scholar] [CrossRef]

- Zhang, L.; Zhou, A.G.; Sun, B.R.; Chen, K.S.; Yu, H.Z. Functional and Versatile Superhydrophobic Coatings via Stoichiometric Silanization. Nat. Commun. 2021, 12, 982. [Google Scholar] [CrossRef]

| Method | Description | Advantages/Disadvantages | References |

|---|---|---|---|

| Surface Chemical Modification Technology | This process transforms the chemical composition and micro/nanostructure of paper surfaces to create superhydrophobic properties. | Allows precise control over surface properties at the molecular level, crucial for specific wettability or reactivity. The chemical modification process can be complex, requiring specific chemicals and reaction conditions. Higher safety requirements for the environment and operators. | [12,13,17,23,39,47,48,49,50,51,52,53,54,55,56,57,58,59] |

| Surface Coating Technology | Involves applying a layer onto the paper to impart new characteristics. | Versatile and can be used to create functional surfaces with tailored properties for specific applications. Significantly broadens the application scope of paper-based materials. The adhesion and durability of the coating may be an issue. The selection and preparation of the coating material are critical and can affect the final performance. | [14,15,62,63,64,65,66,67,68,69,70] |

| Physical Composite Technology | Combines different materials to create a composite with improved properties. | Leverages the synergistic effects of material combinations to achieve performance that surpasses individual components. Enables the integration of superhydrophobic surfaces with other functionalities. The fabrication process can be complex, requiring precise control of the proportion and mixing of different components. The compatibility and interfacial bonding between different materials can affect the overall performance of the material. | [71,72,73,74,75,76,77,78,79,80,81] |

| Laser Etching Technology | Uses laser precision to create micro- and nanostructures on paper surfaces. | Allows for high-precision, customized manufacturing of paper-based analytical devices with specific channel dimensions and patterns. A more sustainable option as it does not rely on harsh chemicals. Requires professional laser equipment and operation skills. The etching process may cause some damage to the internal structure of the paper. | [16,83,84] |

| Other Methods | Various innovative techniques that are generally based on improvements of the previously mentioned methods or their binary combinations. | Provides more innovative ideas and methods for achieving multifunctional integration. Offers the potential to develop more environmentally adaptable and practical superhydrophobic paper-based materials. These methods are relatively new and may still be in the research and exploration phase, with immature processes. The universality and reproducibility of some methods need further verification. | [85,86,87,88,89,90] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, Y.; Ban, S.; Xu, Z.; Sun, J.; Ning, Z. Advancements in Superhydrophobic Paper-Based Materials: A Comprehensive Review of Modification Methods and Applications. Nanomaterials 2025, 15, 107. https://doi.org/10.3390/nano15020107

Tang Y, Ban S, Xu Z, Sun J, Ning Z. Advancements in Superhydrophobic Paper-Based Materials: A Comprehensive Review of Modification Methods and Applications. Nanomaterials. 2025; 15(2):107. https://doi.org/10.3390/nano15020107

Chicago/Turabian StyleTang, Yin, Shouwei Ban, Zhihan Xu, Jing Sun, and Zhenxin Ning. 2025. "Advancements in Superhydrophobic Paper-Based Materials: A Comprehensive Review of Modification Methods and Applications" Nanomaterials 15, no. 2: 107. https://doi.org/10.3390/nano15020107

APA StyleTang, Y., Ban, S., Xu, Z., Sun, J., & Ning, Z. (2025). Advancements in Superhydrophobic Paper-Based Materials: A Comprehensive Review of Modification Methods and Applications. Nanomaterials, 15(2), 107. https://doi.org/10.3390/nano15020107