Visible-Light-Driven Degradation of Chloramphenicol Using CeO2 Nanoparticles Prepared by a Supercritical CO2 Route: A Proof of Concept

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Micronization of Ce(acac)3

2.3. Characterization Methods

2.4. Photocatalysts Preparation

- CeO2 from non-micronized precursor calcined at 450 °C (CeO2-NM)

- CeO2 from SAS-micronized precursor calcined at 450 °C (CeO2-SAS 450 °C)

- CeO2 from SAS-micronized precursor calcined at 600 °C (CeO2-SAS 600 °C)

- CeO2 from SAS-micronized precursor calcined at 800 °C (CeO2-SAS 800 °C)

2.5. Photocatalytic Experiments

3. Results and Discussion

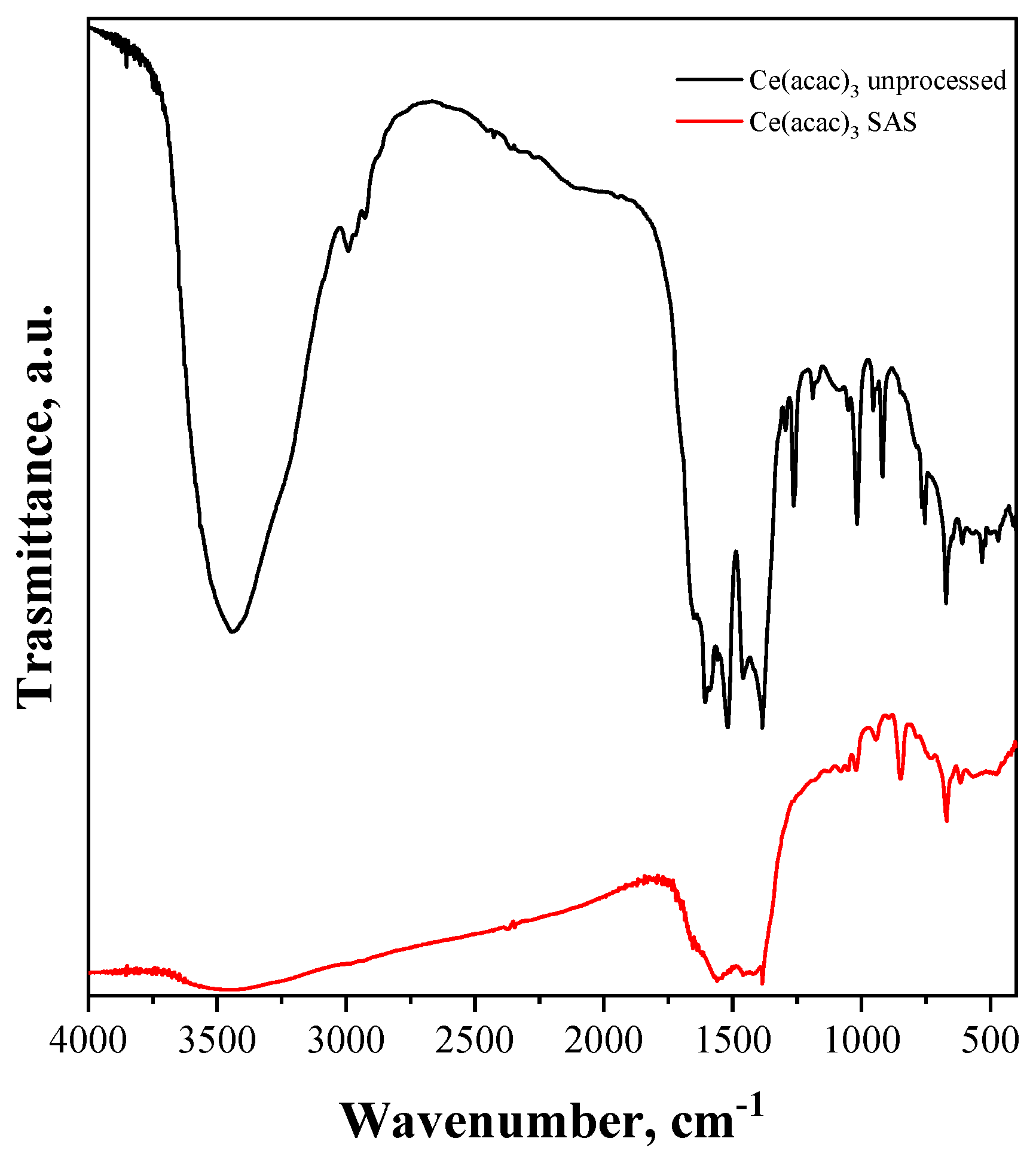

3.1. Characterization of Ce(acac)3 Micronized Particles Produced by SAS Process

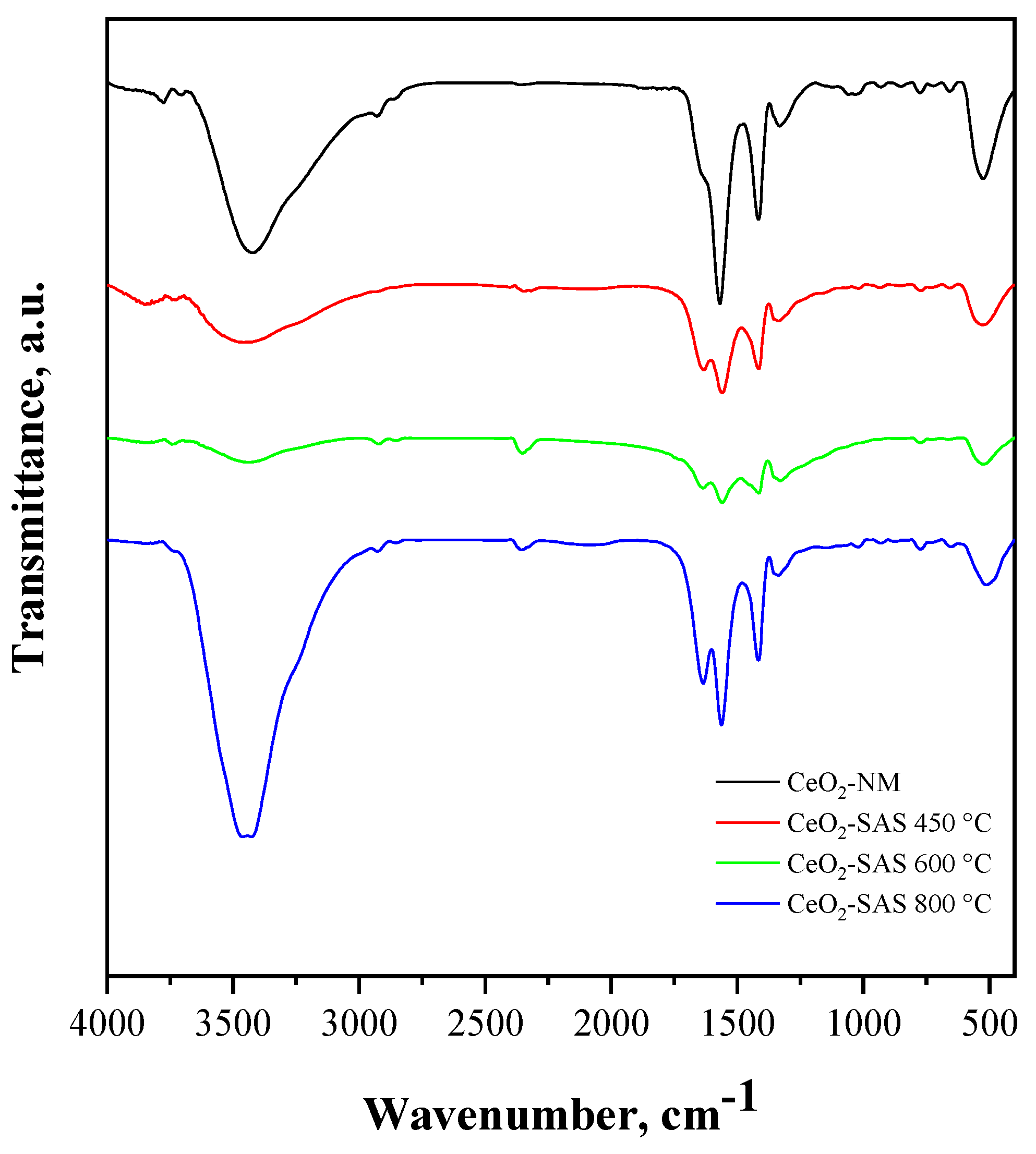

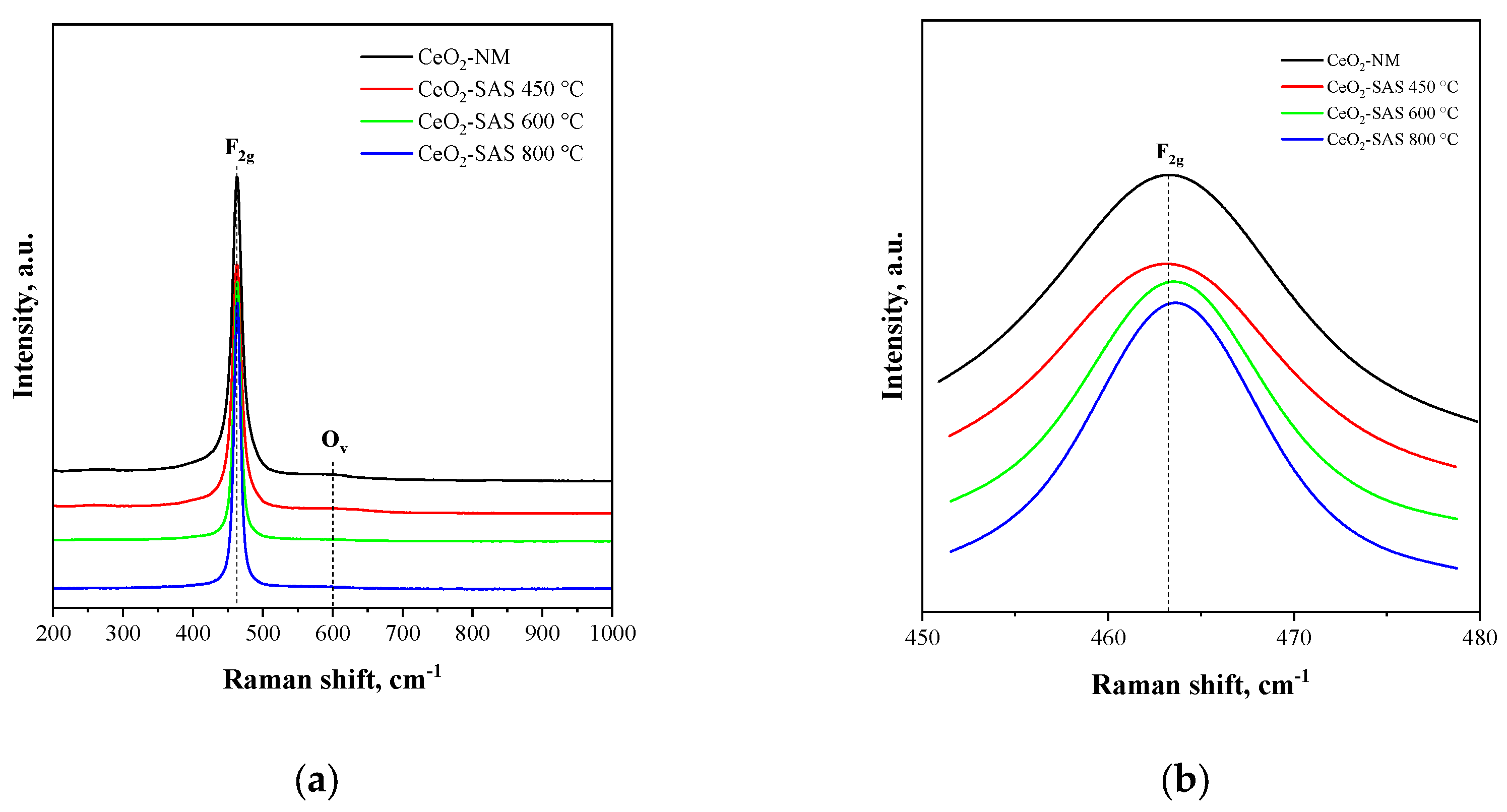

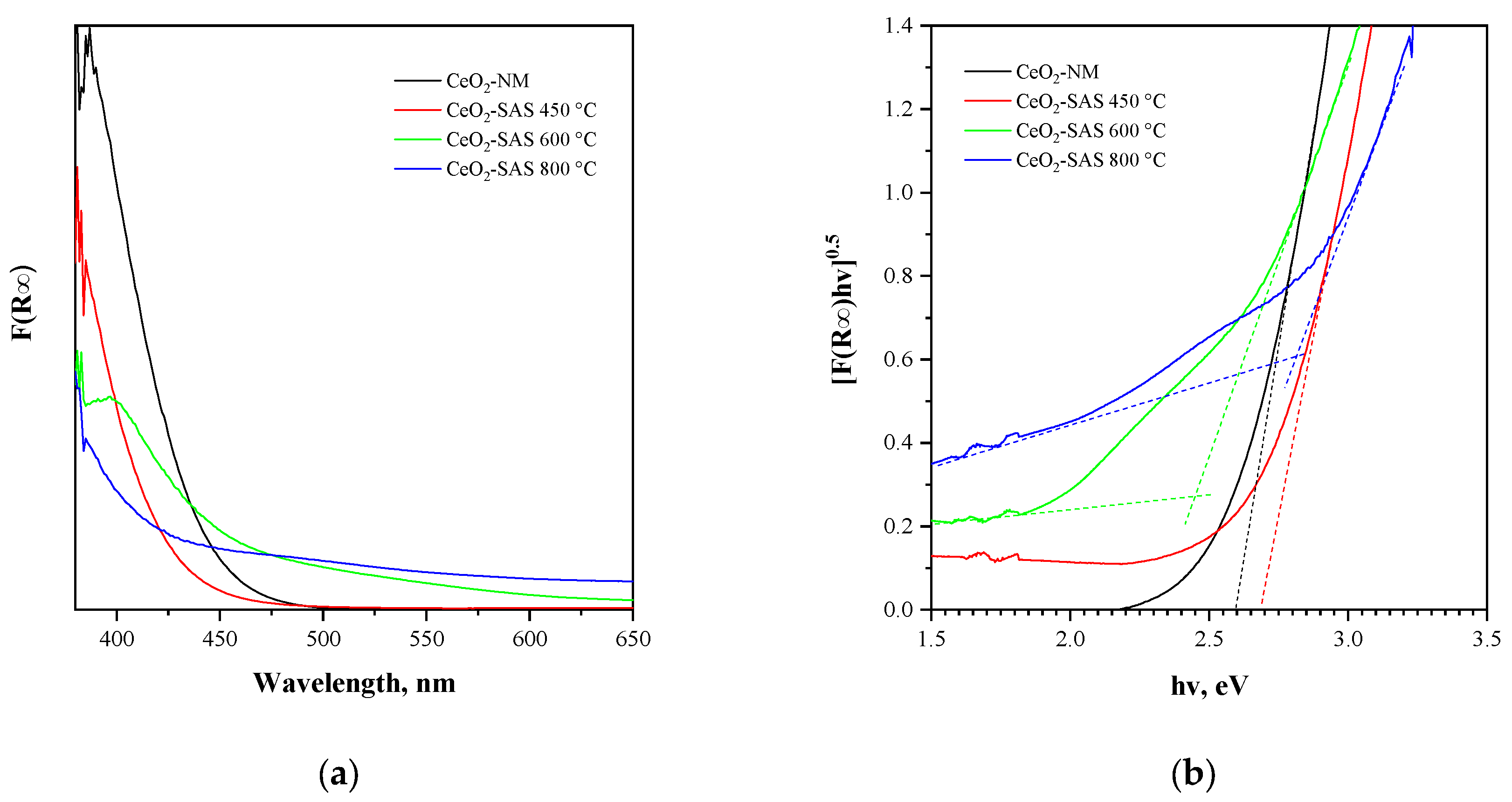

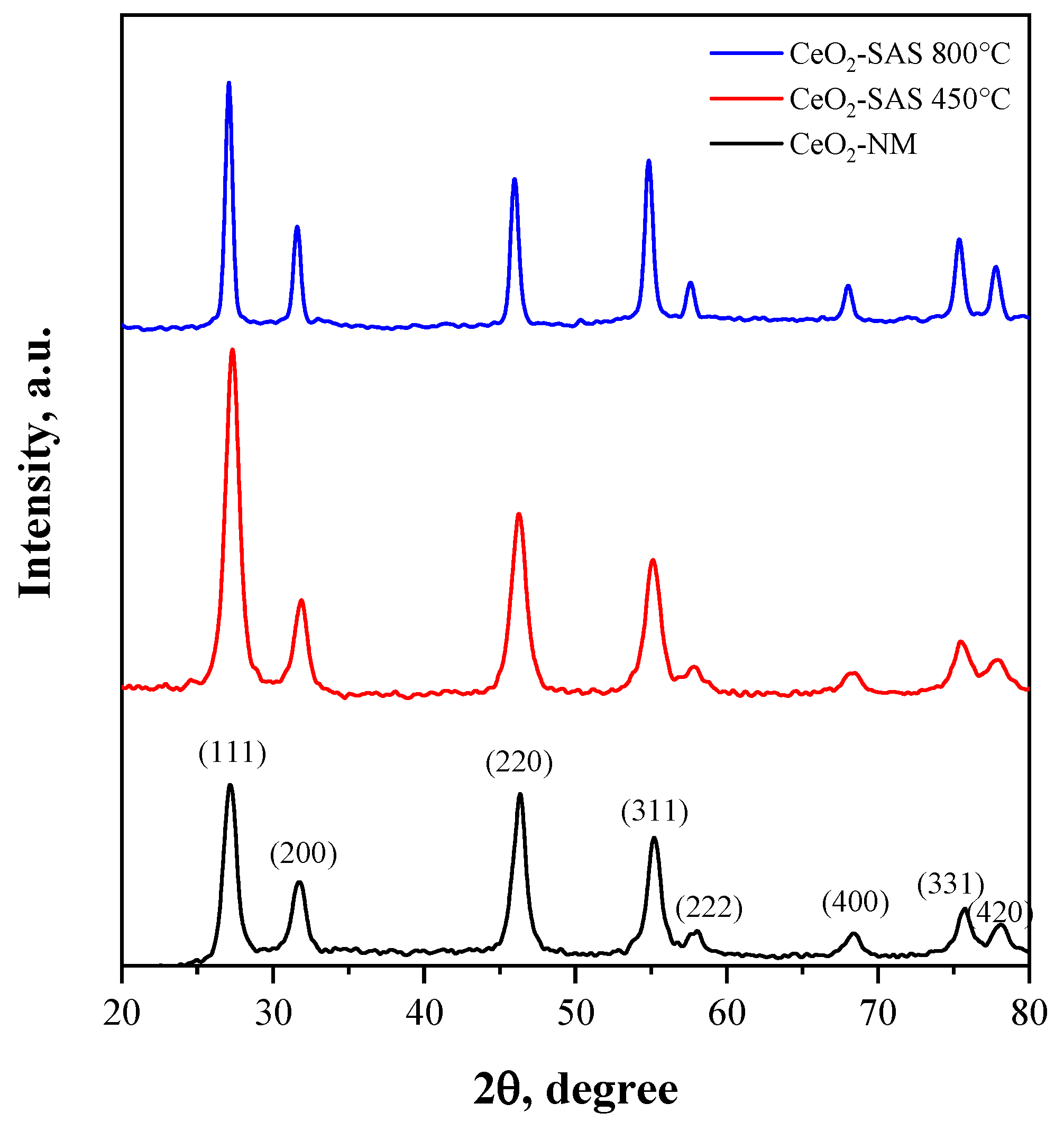

3.2. Characterization of CeO2 Particles from Thermal Annealing of Ce(acac)3 Micronized Particles

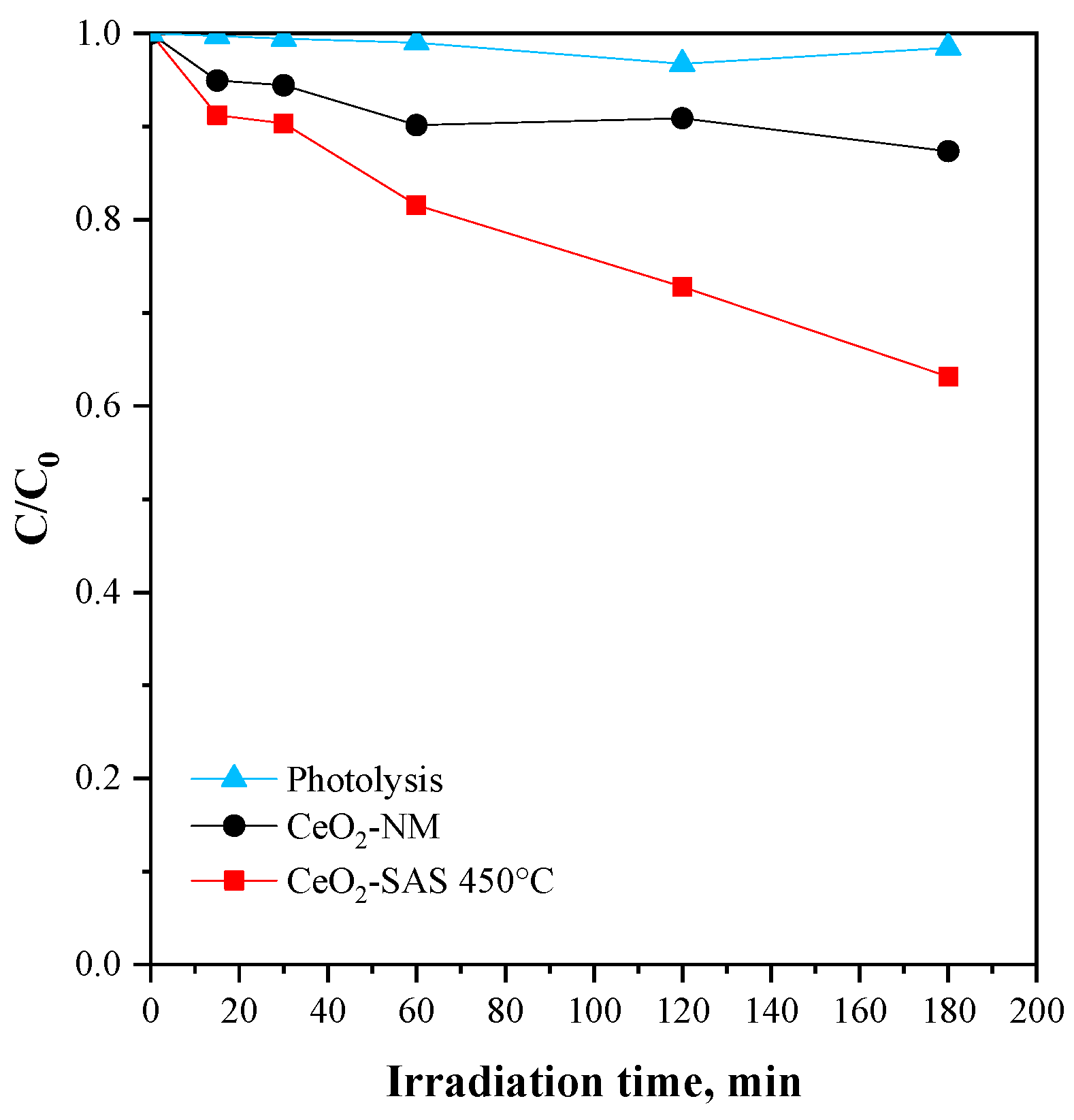

3.3. Photocatalytic Activity Results

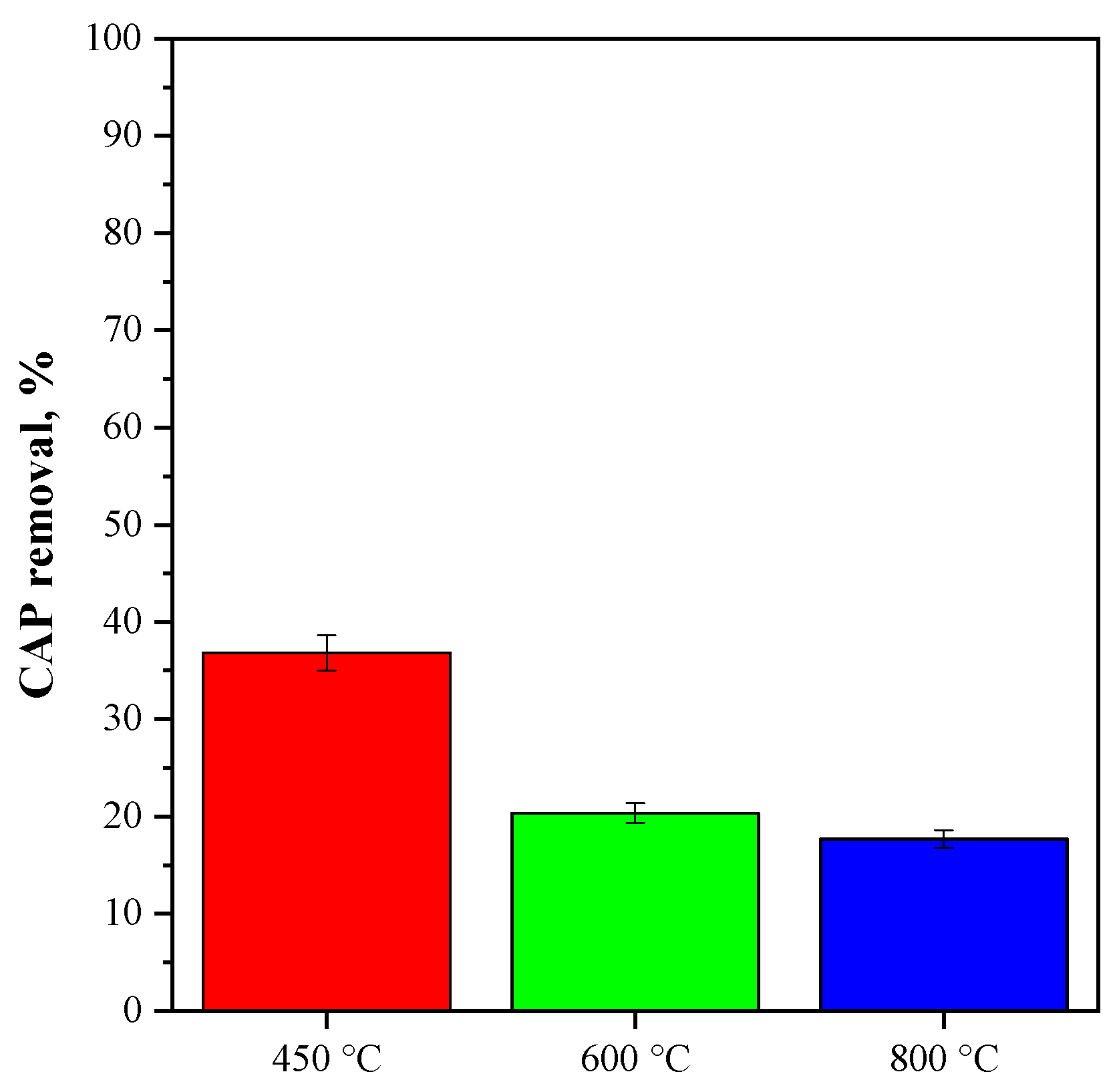

3.3.1. Effect of Annealing Temperature on CeO2-SAS Photocatalysts

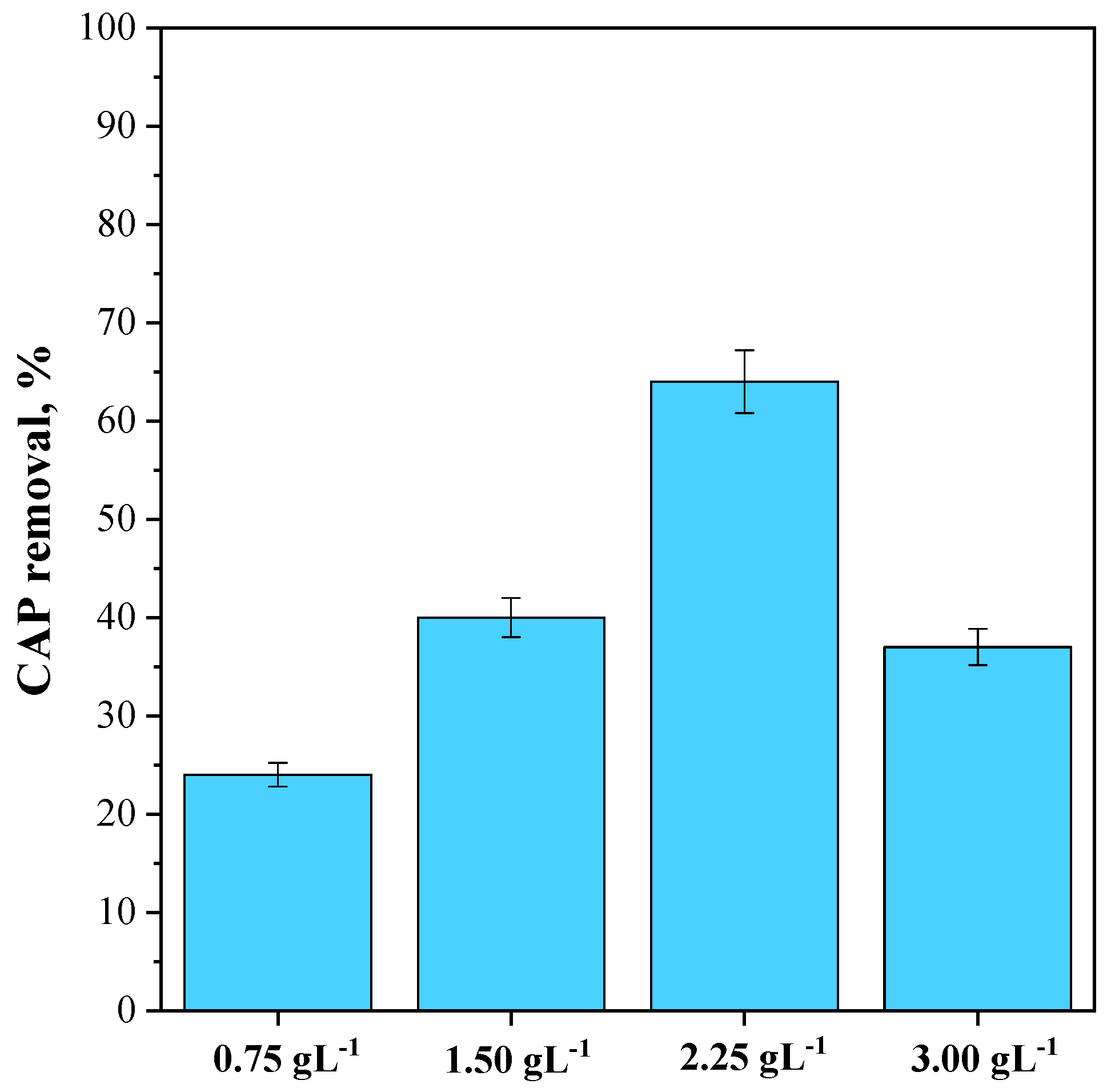

3.3.2. Effect of CeO2-SAS 450 °C Dosage on CAP Photocatalytic Degradation

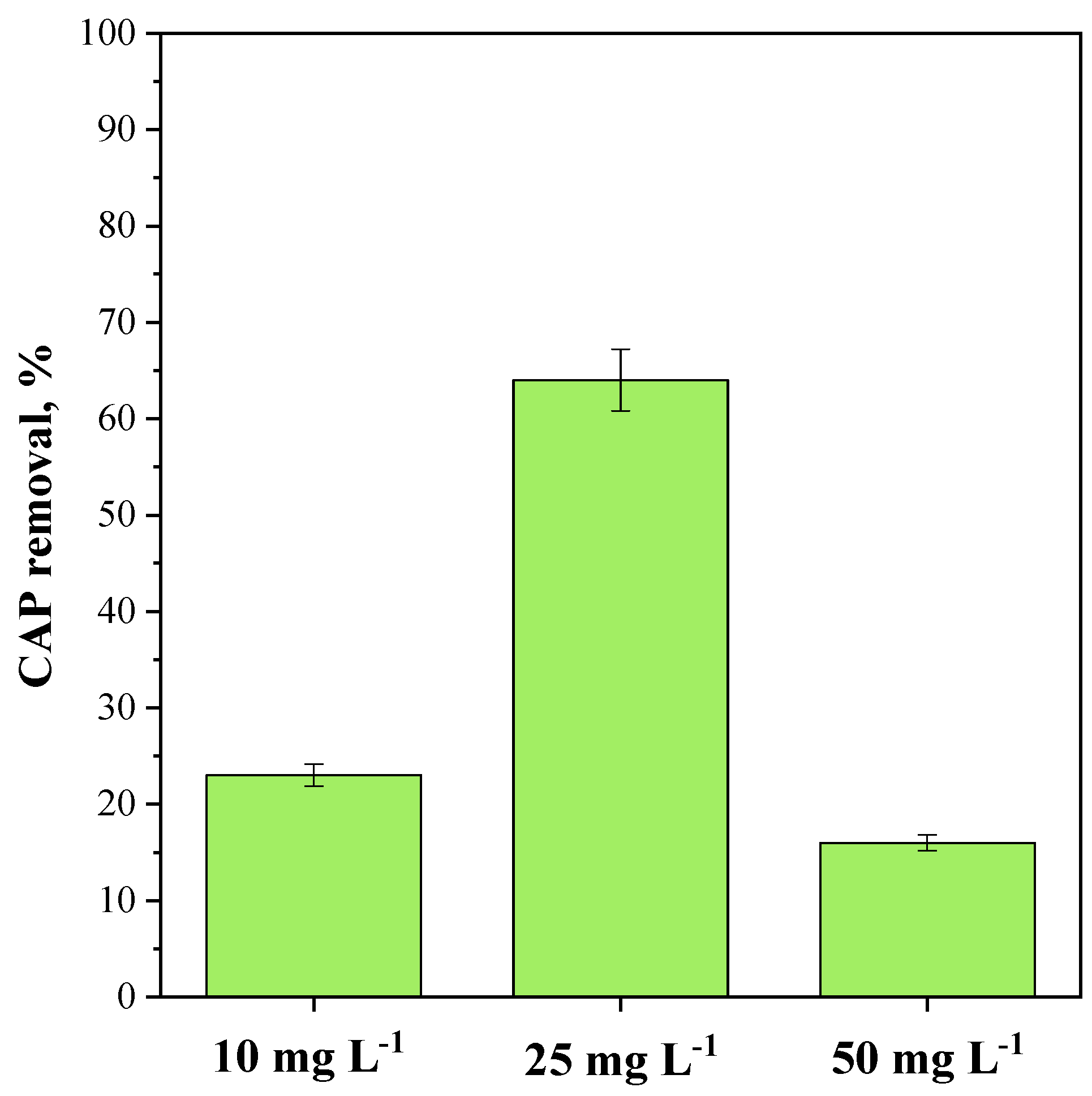

3.3.3. Influence of CAP Initial Concentration on CeO2-SAS 450 °C Photocatalytic Performance

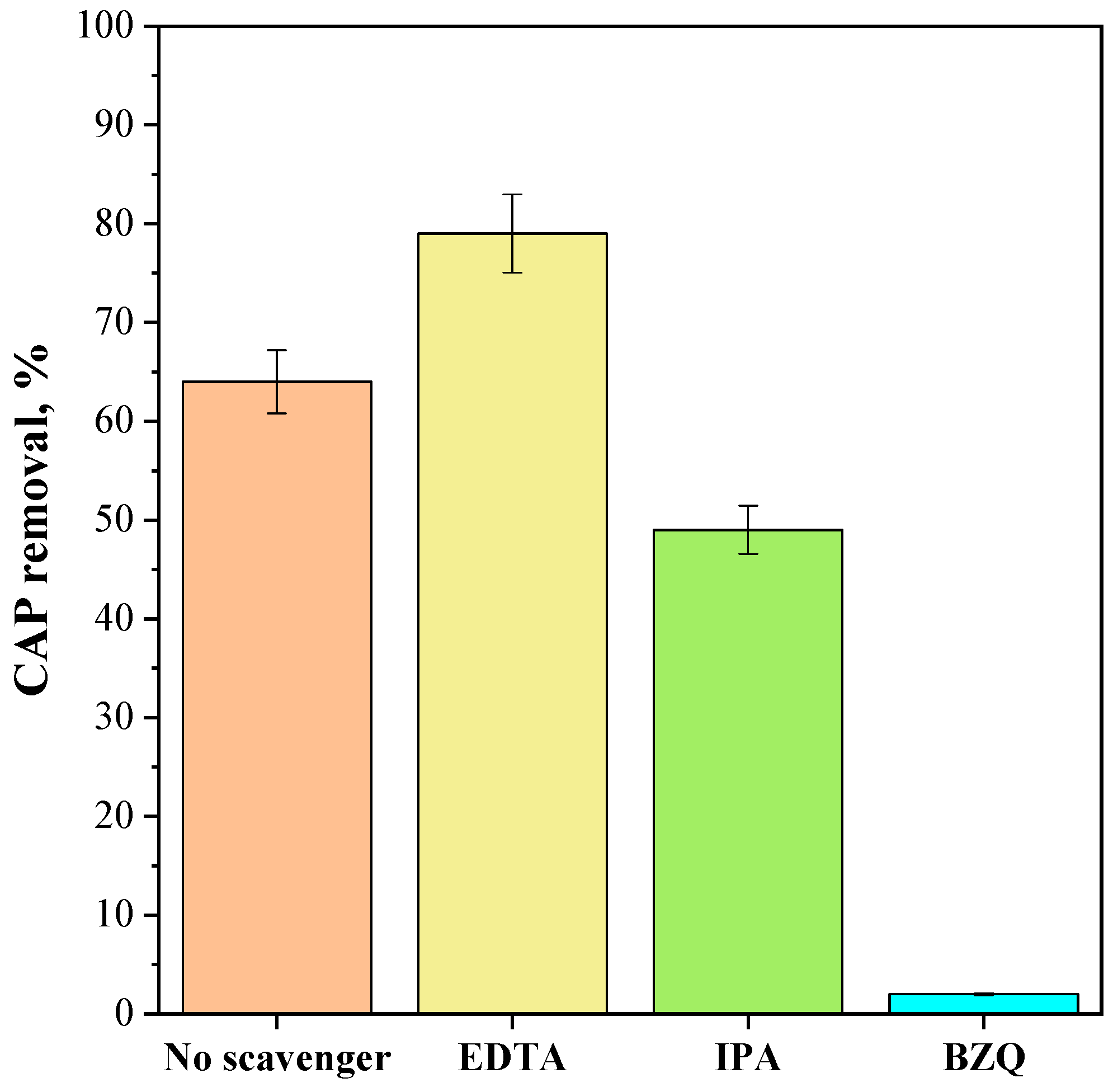

3.3.4. Role of Reactive Oxygen Species (ROS) on CAP Photodegradation Catalyzed by CeO2-SAS 450 °C

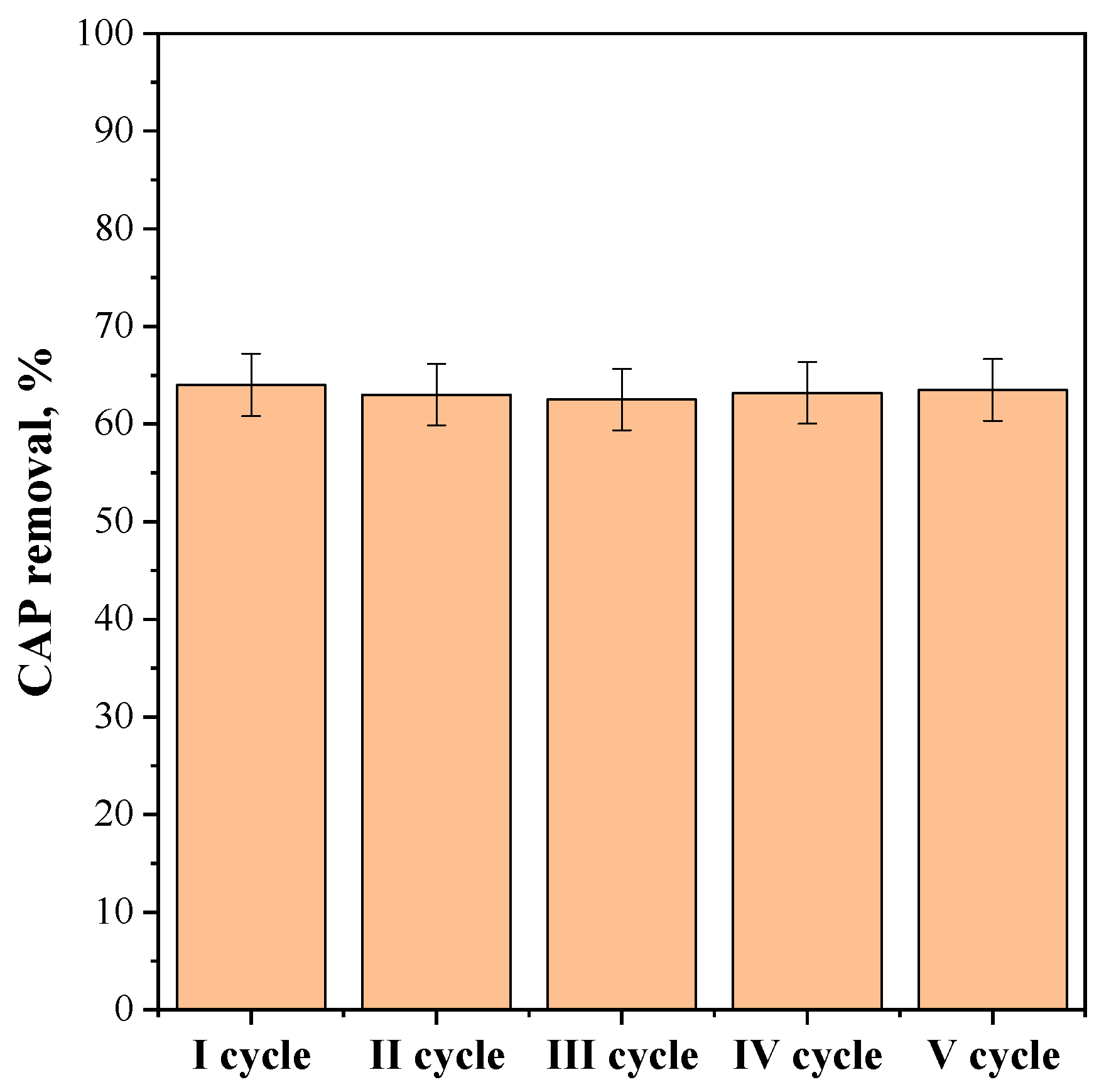

3.3.5. Stability Tests on CeO2-SAS 450 °C Photocatalyst

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ribeiro da Cunha, B.; Fonseca, L.P.; Calado, C.R. Antibiotic discovery: Where have we come from, where do we go? Antibiotics 2019, 8, 45. [Google Scholar] [CrossRef] [PubMed]

- Tiwari, B.; Sellamuthu, B.; Ouarda, Y.; Drogui, P.; Tyagi, R.D.; Buelna, G. Review on fate and mechanism of removal of pharmaceutical pollutants from wastewater using biological approach. Bioresour. Technol. 2017, 224, 1–12. [Google Scholar] [CrossRef]

- Uluseker, C.; Kaster, K.M.; Thorsen, K.; Basiry, D.; Shobana, S.; Jain, M.; Kumar, G.; Kommedal, R.; Pala-Ozkok, I. A review on occurrence and spread of antibiotic resistance in wastewaters and in wastewater treatment plants: Mechanisms and perspectives. Front. Microbiol. 2021, 12, 717809. [Google Scholar] [CrossRef] [PubMed]

- Välitalo, P.; Kruglova, A.; Mikola, A.; Vahala, R. Toxicological impacts of antibiotics on aquatic micro-organisms: A mini-review. Int. J. Hyg. Environ. Health 2017, 220, 558–569. [Google Scholar] [CrossRef]

- Kovalakova, P.; Cizmas, L.; McDonald, T.J.; Marsalek, B.; Feng, M.; Sharma, V.K. Occurrence and toxicity of antibiotics in the aquatic environment: A review. Chemosphere 2020, 251, 126351. [Google Scholar] [CrossRef] [PubMed]

- Kumar, K.; Gupta, S.C.; Chander, Y.; Singh, A.K. Antibiotic use in agriculture and its impact on the terrestrial environment. Adv. Agron. 2005, 87, 1–54. [Google Scholar]

- Balbi, H.J. Chloramphenicol: A review. Pediatr. Rev. 2004, 25, 284–288. [Google Scholar] [CrossRef]

- Weisberger, A.S.; Wessler, S.; Avioli, L.V. Mechanisms of action of chloramphenicol. JAMA 1969, 209, 97–103. [Google Scholar] [CrossRef]

- Chu, W.; Krasner, S.W.; Gao, N.; Templeton, M.R.; Yin, D. Contribution of the antibiotic chloramphenicol and its analogues as precursors of dichloroacetamide and other disinfection byproducts in drinking water. Environ. Sci. Technol. 2016, 50, 388–396. [Google Scholar] [CrossRef]

- Falyouna, O.; Maamoun, I.; Ghosh, S.; Malloum, A.; Othmani, A.; Eljamal, O.; Amen, T.W.; Oroke, A.; Bornman, C.; Ahmadi, S. Sustainable technologies for the removal of Chloramphenicol from pharmaceutical industries Effluent: A critical review. J. Mol. Liq. 2022, 368, 120726. [Google Scholar] [CrossRef]

- Nguyen, L.M.; Nguyen, N.T.T.; Nguyen, T.T.T.; Nguyen, T.T.; Nguyen, D.T.C.; Tran, T.V. Occurrence, toxicity and adsorptive removal of the chloramphenicol antibiotic in water: A review. Environ. Chem. Lett. 2022, 20, 1929–1963. [Google Scholar] [CrossRef]

- Lin, J.; Zhang, K.; Jiang, L.; Hou, J.; Yu, X.; Feng, M.; Ye, C. Removal of chloramphenicol antibiotics in natural and engineered water systems: Review of reaction mechanisms and product toxicity. Sci. Total Environ. 2022, 850, 158059. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Cao, Z.; Yuan, Z.; Zhang, J.; Guo, X.; Yang, Y.; He, F.; Zhao, Y.; Xu, J. Insight into the kinetics and mechanism of removal of aqueous chlorinated nitroaromatic antibiotic chloramphenicol by nanoscale zero-valent iron. Chem. Eng. J. 2018, 334, 508–518. [Google Scholar] [CrossRef]

- Singh, A.; Ramachandran, S.K.; Gumpu, M.B.; Zsuzsanna, L.; Veréb, G.; Kertész, S.; Gangasalam, A. Titanium dioxide doped hydroxyapatite incorporated photocatalytic membranes for the degradation of chloramphenicol antibiotic in water. J. Chem. Technol. Biotechnol. 2021, 96, 1057–1066. [Google Scholar] [CrossRef]

- Chen, Y.; Yang, J.; Zeng, L.; Zhu, M. Recent progress on the removal of antibiotic pollutants using photocatalytic oxidation process. Crit. Rev. Environ. Sci. Technol. 2022, 52, 1401–1448. [Google Scholar] [CrossRef]

- Kokkinos, P.; Venieri, D.; Mantzavinos, D. Advanced oxidation processes for water and wastewater viral disinfection. A systematic review. Food Environ. Virol. 2021, 13, 283–302. [Google Scholar] [CrossRef]

- Hodges, B.C.; Cates, E.L.; Kim, J.-H. Challenges and prospects of advanced oxidation water treatment processes using catalytic nanomaterials. Nat. Nanotechnol. 2018, 13, 642–650. [Google Scholar] [CrossRef]

- Mukherjee, J.; Lodh, B.K.; Sharma, R.; Mahata, N.; Shah, M.P.; Mandal, S.; Ghanta, S.; Bhunia, B. Advanced oxidation process for the treatment of industrial wastewater: A review on strategies, mechanisms, bottlenecks and prospects. Chemosphere 2023, 345, 140473. [Google Scholar] [CrossRef]

- Vaiano, V.; Sacco, O.; Sannino, D.; Ciambelli, P. Process intensification in the removal of organic pollutants from wastewater using innovative photocatalysts obtained coupling Zinc Sulfide based phosphors with nitrogen doped semiconductors. J. Clean. Prod. 2015, 100, 208–211. [Google Scholar] [CrossRef]

- Sacco, O.; Franco, P.; De Marco, I.; Vaiano, V.; Callone, E.; Ceccato, R.; Parrino, F. Photocatalytic activity of Eu-doped ZnO prepared by supercritical antisolvent precipitation route: When defects become virtues. J. Mater. Sci. Technol. 2022, 112, 49–58. [Google Scholar] [CrossRef]

- Pirilä, M.; Saouabe, M.; Ojala, S.; Rathnayake, B.; Drault, F.; Valtanen, A.; Huuhtanen, M.; Brahmi, R.; Keiski, R.L. Photocatalytic degradation of organic pollutants in wastewater. Top. Catal. 2015, 58, 1085–1099. [Google Scholar] [CrossRef]

- Dong, C.; Fang, W.; Yi, Q.; Zhang, J. A comprehensive review on reactive oxygen species (ROS) in advanced oxidation processes (AOPs). Chemosphere 2022, 308, 136205. [Google Scholar] [CrossRef]

- Zhang, J.; Tian, B.; Wang, L.; Xing, M.; Lei, J. Photocatalysis. In Lecture Notes in Chemistry; Springer: Singapore, 2018; pp. 1–17. [Google Scholar]

- Lu, Y.; Cai, Y.; Zhang, S.; Zhuang, L.; Hu, B.; Wang, S.; Chen, J.; Wang, X. Application of biochar-based photocatalysts for adsorption-(photo) degradation/reduction of environmental contaminants: Mechanism, challenges and perspective. Biochar 2022, 4, 45. [Google Scholar] [CrossRef]

- Abebe, B.; Murthy, H.A.; Amare, E. Summary on adsorption and photocatalysis for pollutant remediation: Mini review. J. Encapsul. Adsorpt. Sci. 2018, 8, 225–255. [Google Scholar] [CrossRef]

- Qumar, U.; Hassan, J.Z.; Bhatti, R.A.; Raza, A.; Nazir, G.; Nabgan, W.; Ikram, M. Photocatalysis vs adsorption by metal oxide nanoparticles. J. Mater. Sci. Technol. 2022, 131, 122–166. [Google Scholar] [CrossRef]

- Bruckmann, F.S.; Schnorr, C.; Oviedo, L.R.; Knani, S.; Silva, L.F.; Silva, W.L.; Dotto, G.L.; Bohn Rhoden, C.R. Adsorption and photocatalytic degradation of pesticides into nanocomposites: A review. Molecules 2022, 27, 6261. [Google Scholar] [CrossRef] [PubMed]

- Mancuso, A.; Kiani, A.; Sacco, O.; Lettieri, M.; Fittipaldi, R.; Vaiano, V.; Acocella, M.R.; Venditto, V. Ball–milled TiO2/biochar hybrid system as a heterogeneous photocatalyst for tannery dyes removal in aqueous solution. J. Mol. Liq. 2024, 399, 124357. [Google Scholar] [CrossRef]

- Chatzitakis, A.; Berberidou, C.; Paspaltsis, I.; Kyriakou, G.; Sklaviadis, T.; Poulios, I. Photocatalytic degradation and drug activity reduction of chloramphenicol. Water Res. 2008, 42, 386–394. [Google Scholar] [CrossRef]

- Lofrano, G.; Libralato, G.; Adinolfi, R.; Siciliano, A.; Iannece, P.; Guida, M.; Giugni, M.; Ghirardini, A.V.; Carotenuto, M. Photocatalytic degradation of the antibiotic chloramphenicol and effluent toxicity effects. Ecotoxicol. Environ. Saf. 2016, 123, 65–71. [Google Scholar] [CrossRef]

- Giri, A.S.; Golder, A.K. Mechanism and identification of reaction byproducts for the degradation of Chloramphenicol drug in heterogeneous photocatalytic process. Groundw. Sustain. Dev. 2018, 7, 343–347. [Google Scholar] [CrossRef]

- Zhang, Y.; Shao, Y.; Gao, N.; Gao, Y.; Chu, W.; Li, S.; Wang, Y.; Xu, S. Kinetics and by-products formation of chloramphenicol (CAP) using chlorination and photocatalytic oxidation. Chem. Eng. J. 2018, 333, 85–91. [Google Scholar] [CrossRef]

- Arora, I.; Chawla, H.; Chandra, A.; Sagadevan, S.; Garg, S. Advances in the strategies for enhancing the photocatalytic activity of TiO2: Conversion from UV-light active to visible-light active photocatalyst. Inorg. Chem. Commun. 2022, 143, 109700. [Google Scholar] [CrossRef]

- Kumar, S.G.; Devi, L.G. Review on modified TiO2 photocatalysis under UV/visible light: Selected results and related mechanisms on interfacial charge carrier transfer dynamics. J. Phys. Chem. A 2011, 115, 13211–13241. [Google Scholar] [CrossRef] [PubMed]

- Etacheri, V.; Di Valentin, C.; Schneider, J.; Bahnemann, D.; Pillai, S.C. Visible-light activation of TiO2 photocatalysts: Advances in theory and experiments. J. Photochem. Photobiol. C Photochem. Rev. 2015, 25, 1–29. [Google Scholar] [CrossRef]

- Magalhaes, P.; Andrade, L.; Nunes, O.C.; Mendes, A. Titanium dioxide photocatalysis: Fundamentals and application on photoinactivation. Rev. Adv. Mater. Sci. 2017, 51, 91–129. [Google Scholar]

- Chien, C.-W.; Dhenadhayalan, N.; Lin, K.-C. Implementation of visible light-driven photocatalytic degradation of antibiotic chloramphenicol using Bi2S3/ZrO2 and Bi2WO6/ZrO2 heteronanostructures. J. Environ. Chem. Eng. 2023, 11, 110613. [Google Scholar] [CrossRef]

- Leeladevi, K.; Kumar, J.V.; Arunpandian, M.; Thiruppathi, M.; Nagarajan, E. Investigation on photocatalytic degradation of hazardous chloramphenicol drug and amaranth dye by SmVO4 decorated g-C3N4 nanocomposites. Mater. Sci. Semicond. Process. 2021, 123, 105563. [Google Scholar] [CrossRef]

- Wang, T.; Shi, H.; Kumar, A.; Zhang, D.; Wang, H.; Wang, S.; Zheng, J. Efficient visible-light photocatalysis of chloramphenicol using novel engineered biochar-based Ti-doped Bi2WO6 composite: Mechanisms, degradation pathways, and applications. Sep. Purif. Technol. 2024, 332, 125780. [Google Scholar] [CrossRef]

- Wu, Y.; Mao, S.; Liu, C.; Pei, F.; Wang, F.; Hao, Q.; Xia, M.; Lei, W. Enhanced degradation of chloramphenicol through peroxymonosulfate and visible light over Z-scheme Photocatalysts: Synergetic performance and mechanism insights. J. Colloid Interface Sci. 2022, 608, 322–333. [Google Scholar] [CrossRef] [PubMed]

- Zhu, C.-Z.; Tian, Q.-H.; Wang, B.-H.; Xu, M.-T.; Jin, Q.-J.; Zhang, Z.-Y.; Le, S.-K.; Wu, Y.; Wei, Y.-C.; Xu, H.-T. Application of modified cerium dioxide for photocatalytic air pollution purification. Rare Met. 2024, 43, 5473–5486. [Google Scholar] [CrossRef]

- Huang, X.; Zhang, K.; Peng, B.; Wang, G.; Muhler, M.; Wang, F. Ceria-based materials for thermocatalytic and photocatalytic organic synthesis. ACS Catal. 2021, 11, 9618–9678. [Google Scholar] [CrossRef]

- Zhao, W.; Dong, Q.; Sun, C.; Xia, D.; Huang, H.; Yang, G.; Wang, G.; Leung, D.Y. A novel Au/g-C3N4 nanosheets/CeO2 hollow nanospheres plasmonic heterojunction photocatalysts for the photocatalytic reduction of hexavalent chromium and oxidation of oxytetracycline hydrochloride. Chem. Eng. J. 2021, 409, 128185. [Google Scholar] [CrossRef]

- Choudhury, B.; Chetri, P.; Choudhury, A. Oxygen defects and formation of Ce3+ affecting the photocatalytic performance of CeO2 nanoparticles. RSC Adv. 2014, 4, 4663–4671. [Google Scholar] [CrossRef]

- Tran, D.P.; Pham, M.-T.; Bui, X.-T.; Wang, Y.-F.; You, S.-J. CeO2 as a photocatalytic material for CO2 conversion: A review. Sol. Energy 2022, 240, 443–466. [Google Scholar] [CrossRef]

- Kusmierek, E. A CeO2 semiconductor as a photocatalytic and photoelectrocatalytic material for the remediation of pollutants in industrial wastewater: A review. Catalysts 2020, 10, 1435. [Google Scholar] [CrossRef]

- Yan, Y.-Q.; Wu, Y.; Wu, Y.-H.; Weng, Z.; Liu, S.-J.; Liu, Z.-G.; Lu, K.-Q.; Han, B. Recent Developments of CeO2-based Photocatalysts: Synthesis and Photocatalytic Applications. Chemsuschem 2024, 17, e202301778. [Google Scholar] [CrossRef]

- Roggenbuck, J.; Schäfer, H.; Tsoncheva, T.; Minchev, C.; Hanss, J.; Tiemann, M. Mesoporous CeO2: Synthesis by nanocasting, characterisation and catalytic properties. Microporous Mesoporous Mater. 2007, 101, 335–341. [Google Scholar] [CrossRef]

- Hu, C.; Zhang, Z.; Liu, H.; Gao, P.; Wang, Z.L. Direct synthesis and structure characterization of ultrafine CeO2 nanoparticles. Nanotechnology 2006, 17, 5983. [Google Scholar] [CrossRef]

- Pundir, S.; Priya, R.; Singh, K.; Kaur, H.; Choudhary, P. A systematic study on synthesis of CeO2 nanoparticles by various routes. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Mohali, India, 23–24 June 2023; p. 012030. [Google Scholar]

- Tabernero, A.; Guastaferro, M.; Gonzalez-Garcinuno, A.; Misol, A.; Baldino, L.; Cardea, S.; del Valle, E.M.; Reverchon, E. The viscoelastic behavior of the precursor hydrogels can modify aerogel properties. J. Supercrit. Fluids 2022, 184, 105563. [Google Scholar] [CrossRef]

- Guastaferro, M.; Cardea, S.; Baldino, L.; Reverchon, E. Cellulose acetate nanocarrier production by supercritical assisted electrospray. Chem. Eng. Trans. 2021, 87, 391–396. [Google Scholar]

- Franco, P.; Sacco, O.; Vaiano, V.; De Marco, I. Supercritical carbon dioxide-based processes in photocatalytic applications. Molecules 2021, 26, 2640. [Google Scholar] [CrossRef] [PubMed]

- Iannaco, M.C.; Mottola, S.; Vaiano, V.; Iervolino, G.; De Marco, I. CeO2-CuO composites prepared via supercritical antisolvent precipitation for photocatalytic hydrogen production from lactic acid aqueous solution. J. CO2 Util. 2024, 85, 102878. [Google Scholar] [CrossRef]

- De Marco, I.; Reverchon, E. Supercritical antisolvent micronization of cyclodextrins. Powder Technol. 2008, 183, 239–246. [Google Scholar] [CrossRef]

- Franco, P.; Navarra, W.; Sacco, O.; De Marco, I.; Mancuso, A.; Vaiano, V.; Venditto, V. Photocatalytic degradation of atrazine under visible light using Gd-doped ZnO prepared by supercritical antisolvent precipitation route. Catal. Today 2022, 397, 240–248. [Google Scholar] [CrossRef]

- Prosapio, V.; Reverchon, E.; De Marco, I. Coprecipitation of polyvinylpyrrolidone/β-carotene by supercritical antisolvent processing. Ind. Eng. Chem. Res. 2015, 54, 11568–11575. [Google Scholar] [CrossRef]

- Franco, P.; Sacco, O.; De Marco, I.; Vaiano, V. Zinc oxide nanoparticles obtained by supercritical antisolvent precipitation for the photocatalytic degradation of crystal violet dye. Catalysts 2019, 9, 346. [Google Scholar] [CrossRef]

- Shen, H.-Y.; Jiang, H.-L. Screening, determination and confirmation of chloramphenicol in seafood, meat and honey using ELISA, HPLC–UVD, GC–ECD, GC–MS–EI–SIM and GCMS–NCI–SIM methods. Anal. Chim. Acta 2005, 535, 33–41. [Google Scholar] [CrossRef]

- Zagaynov, I.; Kutsev, S. Formation of mesoporous nanocrystalline ceria from cerium nitrate, acetate or acetylacetonate. Appl. Nanosci. 2014, 4, 339–345. [Google Scholar] [CrossRef]

- Tang, Z.-R.; Edwards, J.K.; Bartley, J.K.; Taylor, S.H.; Carley, A.F.; Herzing, A.A.; Kiely, C.J.; Hutchings, G.J. Nanocrystalline cerium oxide produced by supercritical antisolvent precipitation as a support for high-activity gold catalysts. J. Catal. 2007, 249, 208–219. [Google Scholar] [CrossRef]

- Chen, W.; Li, F.; Yu, J. Combustion synthesis and characterization of nanocrystalline CeO2-based powders via ethylene glycol–nitrate process. Mater. Lett. 2006, 60, 57–62. [Google Scholar] [CrossRef]

- Bolis, V.; Magnacca, G.; Cerrato, G.; Morterra, C. Microcalorimetric and IR-spectroscopic study of the room temperature adsorption of CO2 on pure and sulphated t-ZrO2. Thermochim. Acta 2001, 379, 147–161. [Google Scholar] [CrossRef]

- Heydari, H.; Gholivand, M.B. A novel high-performance supercapacitor based on high-quality CeO2/nitrogen-doped reduced graphene oxide nanocomposite. Appl. Phys. A 2017, 123, 187. [Google Scholar] [CrossRef]

- Kumar, E.; Selvarajan, P.; Balasubramanian, K. Preparation and studies of cerium dioxide (CeO2) nanoparticles by microwave-assisted solution method. Recent Res. Sci. Technol. 2010, 2, 37–41. [Google Scholar]

- Gupta, S.; Tomar, S.; Choi, J.H.; Jeong, H.; Lee, S.-C.; Bhattacharjee, S. Controlling Moisture for Enhanced Ozone Decomposition: A Study of Water Effects on CeO2 Surfaces and Catalytic Activity. J. Phys. Chem. C 2024, 128, 5889–5899. [Google Scholar] [CrossRef]

- Schaub, R.; Thostrup, P.; Lopez, N.; Lægsgaard, E.; Stensgaard, I.; Nørskov, J.K.; Besenbacher, F. Oxygen vacancies as active sites for water dissociation on rutile TiO2 (110). Phys. Rev. Lett. 2001, 87, 266104. [Google Scholar] [CrossRef] [PubMed]

- Daniel, M.; Loridant, S. Probing reoxidation sites by in situ Raman spectroscopy: Differences between reduced CeO2 and Pt/CeO2. J. Raman Spectrosc. 2012, 43, 1312–1319. [Google Scholar] [CrossRef]

- Sun, S.; Mao, D.; Yu, J. Enhanced CO oxidation activity of CuO/CeO2 catalyst prepared by surfactant-assisted impregnation method. J. Rare Earths 2015, 33, 1268–1274. [Google Scholar] [CrossRef]

- Wang, J.; Shi, X.; Chen, L.; Li, H.; Mao, M.; Zhang, G.; Yi, H.; Fu, M.; Ye, D.; Wu, J. Enhanced performance of low Pt loading amount on Pt-CeO2 catalysts prepared by adsorption method for catalytic ozonation of toluene. Appl. Catal. A Gen. 2021, 625, 118342. [Google Scholar] [CrossRef]

- Wang, X.; Fu, K.; Wen, X.; Qi, S.; Tong, G.; Wang, X.; Wu, W. Oxygen vacancy boosted microwave absorption in CeO2 hollow nanospheres. Appl. Surf. Sci. 2022, 598, 153826. [Google Scholar] [CrossRef]

- Wang, H.-F.; Li, H.-Y.; Gong, X.-Q.; Guo, Y.-L.; Lu, G.-Z.; Hu, P. Oxygen vacancy formation in CeO2 and Ce1−xZrxO2 solid solutions: Electron localization, electrostatic potential and structural relaxation. Phys. Chem. Chem. Phys. 2012, 14, 16521–16535. [Google Scholar] [CrossRef]

- Bagcivan, A.; Aktas, S.; Yildirim, Y.; Polat, O.; Sobola, D.; Sen, C.; Caglar, Y.; Caglar, M. Structural and Optical Evolution in CeO2 Films Induced by Aluminum Doping: A Comprehensive Study. Ceram. Int. 2024, in press. [Google Scholar] [CrossRef]

- Kamboj, V.; Raychowdhury, S. Unusual Hydrogen-mediated Oxidation in Doped Ceria Systems: Operando Insights. ChemRxiv 2024. [Google Scholar] [CrossRef]

- Xu, Y.; Zhou, Y.; Li, Y.; Liu, Y.; Ding, Z. Advances in Cerium Dioxide Nanomaterials: Synthesis Strategies, Property Modulation, and Multifunctional Applications. J. Environ. Chem. Eng. 2024, 12, 113719. [Google Scholar] [CrossRef]

- Fifere, N.; Airinei, A.; Dobromir, M.; Sacarescu, L.; Dunca, S.I. Revealing the effect of synthesis conditions on the structural, optical, and antibacterial properties of cerium oxide nanoparticles. Nanomaterials 2021, 11, 2596. [Google Scholar] [CrossRef]

- Ye, T.; Qu, G.; Song, Y.; Huang, D. Experimental study of the phase relationships in the CeO2–Gd2O3 system at 1200 °C to 1600 °C in air. Mater. Chem. Phys. 2023, 295, 127126. [Google Scholar] [CrossRef]

- Vaiano, V.; Sacco, O.; Sannino, D.; Navarra, W.; Daniel, C.; Venditto, V. Influence of aggregate size on photoactivity of N-doped TiO2 particles in aqueous suspensions under visible light irradiation. J. Photochem. Photobiol. A Chem. 2017, 336, 191–197. [Google Scholar] [CrossRef]

- Cheng, Z.; Zhang, L.; Jin, N.; Zhu, Y.; Chen, L.; Yang, Q.; Yan, M.; Ma, X.; Wang, X. Effect of calcination temperature on the performance of hexaaluminate supported CeO2 for chemical looping dry reforming. Fuel Process. Technol. 2021, 218, 106873. [Google Scholar] [CrossRef]

- Liu, Z.-G.; Chai, S.-H.; Binder, A.; Li, Y.-Y.; Ji, L.-T.; Dai, S. Influence of calcination temperature on the structure and catalytic performance of CuOx−CoOy−CeO2 ternary mixed oxide for CO oxidation. Appl. Catal. A Gen. 2013, 451, 282–288. [Google Scholar] [CrossRef]

- Choudhury, B.; Chetri, P.; Choudhury, A. Annealing temperature and oxygen-vacancy-dependent variation of lattice strain, band gap and luminescence properties of CeO2 nanoparticles. J. Exp. Nanosci. 2015, 10, 103–114. [Google Scholar] [CrossRef]

- Maksimchuk, P.; Seminko, V.; Bespalova, I.; Masalov, A. Role of shallow electronic traps formed by oxygen vacancies in formation of luminescent properties of CeO2−x nanocrystals. Funct. Mater. 2014, 21, 152–157. [Google Scholar] [CrossRef][Green Version]

- Li, Z.; Yang, W.; Xie, L.; Li, Y.; Liu, Y.; Sun, Y.; Bu, Y.; Mi, X.; Zhan, S.; Hu, W. Prominent role of oxygen vacancy for superoxide radical and hydroxyl radical formation to promote electro-Fenton like reaction by W-doped CeO2 composites. Appl. Surf. Sci. 2021, 549, 149262. [Google Scholar] [CrossRef]

- Wei, X.; Li, K.; Zhang, X.; Tong, Q.; Ji, J.; Cai, Y.; Gao, B.; Zou, W.; Dong, L. CeO2 nanosheets with anion-induced oxygen vacancies for promoting photocatalytic toluene mineralization: Toluene adsorption and reactive oxygen species. Appl. Catal. B Environ. 2022, 317, 121694. [Google Scholar] [CrossRef]

- Wang, K.; Chang, Y.; Lv, L.; Long, Y. Effect of annealing temperature on oxygen vacancy concentrations of nanocrystalline CeO2 film. Appl. Surf. Sci. 2015, 351, 164–168. [Google Scholar] [CrossRef]

- Li, G.; Lv, L.; Fan, H.; Ma, J.; Li, Y.; Wan, Y.; Zhao, X. Effect of the agglomeration of TiO2 nanoparticles on their photocatalytic performance in the aqueous phase. J. Colloid Interface Sci. 2010, 348, 342–347. [Google Scholar] [CrossRef] [PubMed]

- Mancuso, A.; Sacco, O.; Vaiano, V.; Bonelli, B.; Esposito, S.; Freyria, F.S.; Blangetti, N.; Sannino, D. Visible light-driven photocatalytic activity and kinetics of Fe-doped TiO2 prepared by a three-block copolymer templating approach. Materials 2021, 14, 3105. [Google Scholar] [CrossRef]

- Bahnemann, W.; Muneer, M.; Haque, M. Titanium dioxide-mediated photocatalysed degradation of few selected organic pollutants in aqueous suspensions. Catal. Today 2007, 124, 133–148. [Google Scholar] [CrossRef]

- Pavel, M.; Anastasescu, C.; State, R.-N.; Vasile, A.; Papa, F.; Balint, I. Photocatalytic degradation of organic and inorganic pollutants to harmless end products: Assessment of practical application potential for water and air cleaning. Catalysts 2023, 13, 380. [Google Scholar] [CrossRef]

- Shah, B.R.; Patel, U.D. Mechanistic aspects of photocatalytic degradation of Lindane by TiO2 in the presence of Oxalic acid and EDTA as hole-scavengers. J. Environ. Chem. Eng. 2021, 9, 105458. [Google Scholar] [CrossRef]

- Martín-Gómez, J.; Pérez-Losada, M.; López-Tenllado, F.J.; Hidalgo-Carrillo, J.; Herrera-Beurnio, M.C.; Estévez, R.; Marinas, A.; Urbano, F.J. Insight into the reaction mechanism of photocatalytic production of solketal. Catal. Today 2024, 429, 114506. [Google Scholar] [CrossRef]

- Mancuso, A.; Sacco, O.; Mottola, S.; Pragliola, S.; Moretta, A.; Vaiano, V.; De Marco, I. Synthesis of Fe-doped ZnO by supercritical antisolvent precipitation for the degradation of azo dyes under visible light. Inorganica Chim. Acta 2023, 549, 121407. [Google Scholar] [CrossRef]

- Mottola, S.; Mancuso, A.; Sacco, O.; De Marco, I.; Vaiano, V. Photocatalytic performance assessment of Fe-N co-doped TiO2/β-cyclodextrin hybrid systems prepared by supercritical antisolvent micronization for organic dyes removal. J. Supercrit. Fluids 2023, 201, 106005. [Google Scholar] [CrossRef]

| Photocatalyst | Ov/F2g (-) | Band Gap (eV) |

|---|---|---|

| CeO2-NM | 0.0268 | 2.60 |

| CeO2-SAS 450 °C | 0.0280 | 2.70 |

| CeO2-SAS 600 °C | 0.0120 | 2.45 |

| CeO2-SAS 800 °C | 0.0096 | 2.80 |

| Photocatalyst | Crystallite Size (nm) | SSA (m2 g−1) |

|---|---|---|

| CeO2-NM | 8 | 43 |

| CeO2-SAS 450 °C | 9 | 34 |

| CeO2-SAS 800 °C | 17 | 8 |

| Photocatalyst | Dh (nm) | PdI (-) |

|---|---|---|

| CeO2-NM | 621.6 | 0.463 |

| CeO2-SAS 450 °C | 313.8 | 0.337 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Iannaco, M.C.; Mancuso, A.; Mottola, S.; Pipolo, A.; Vaiano, V.; De Marco, I. Visible-Light-Driven Degradation of Chloramphenicol Using CeO2 Nanoparticles Prepared by a Supercritical CO2 Route: A Proof of Concept. Nanomaterials 2025, 15, 102. https://doi.org/10.3390/nano15020102

Iannaco MC, Mancuso A, Mottola S, Pipolo A, Vaiano V, De Marco I. Visible-Light-Driven Degradation of Chloramphenicol Using CeO2 Nanoparticles Prepared by a Supercritical CO2 Route: A Proof of Concept. Nanomaterials. 2025; 15(2):102. https://doi.org/10.3390/nano15020102

Chicago/Turabian StyleIannaco, Maria Chiara, Antonietta Mancuso, Stefania Mottola, Andrea Pipolo, Vincenzo Vaiano, and Iolanda De Marco. 2025. "Visible-Light-Driven Degradation of Chloramphenicol Using CeO2 Nanoparticles Prepared by a Supercritical CO2 Route: A Proof of Concept" Nanomaterials 15, no. 2: 102. https://doi.org/10.3390/nano15020102

APA StyleIannaco, M. C., Mancuso, A., Mottola, S., Pipolo, A., Vaiano, V., & De Marco, I. (2025). Visible-Light-Driven Degradation of Chloramphenicol Using CeO2 Nanoparticles Prepared by a Supercritical CO2 Route: A Proof of Concept. Nanomaterials, 15(2), 102. https://doi.org/10.3390/nano15020102