A Peano-Gosper Fractal-Inspired Stretchable Electrode with Integrated Three-Directional Strain and Normal Pressure Sensing

Abstract

1. Introduction

2. Experimental Section

2.1. Materials and Equipment

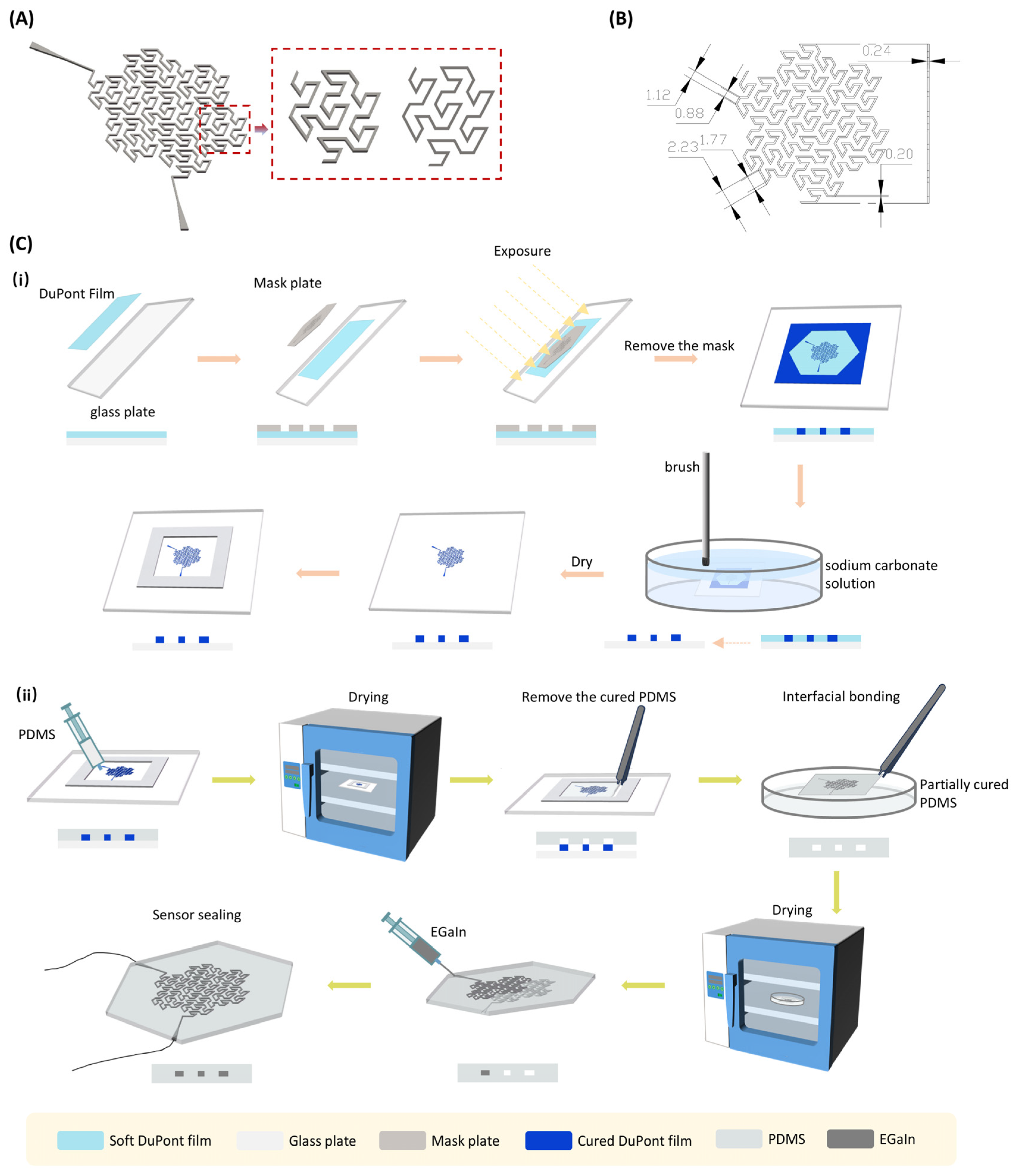

2.2. Electrode Fabrication

2.2.1. Structural Design

2.2.2. Mold Fabrication

2.2.3. Electrode Fabrication Process

2.3. Electrode Testing and Characterization

3. Results and Discussion

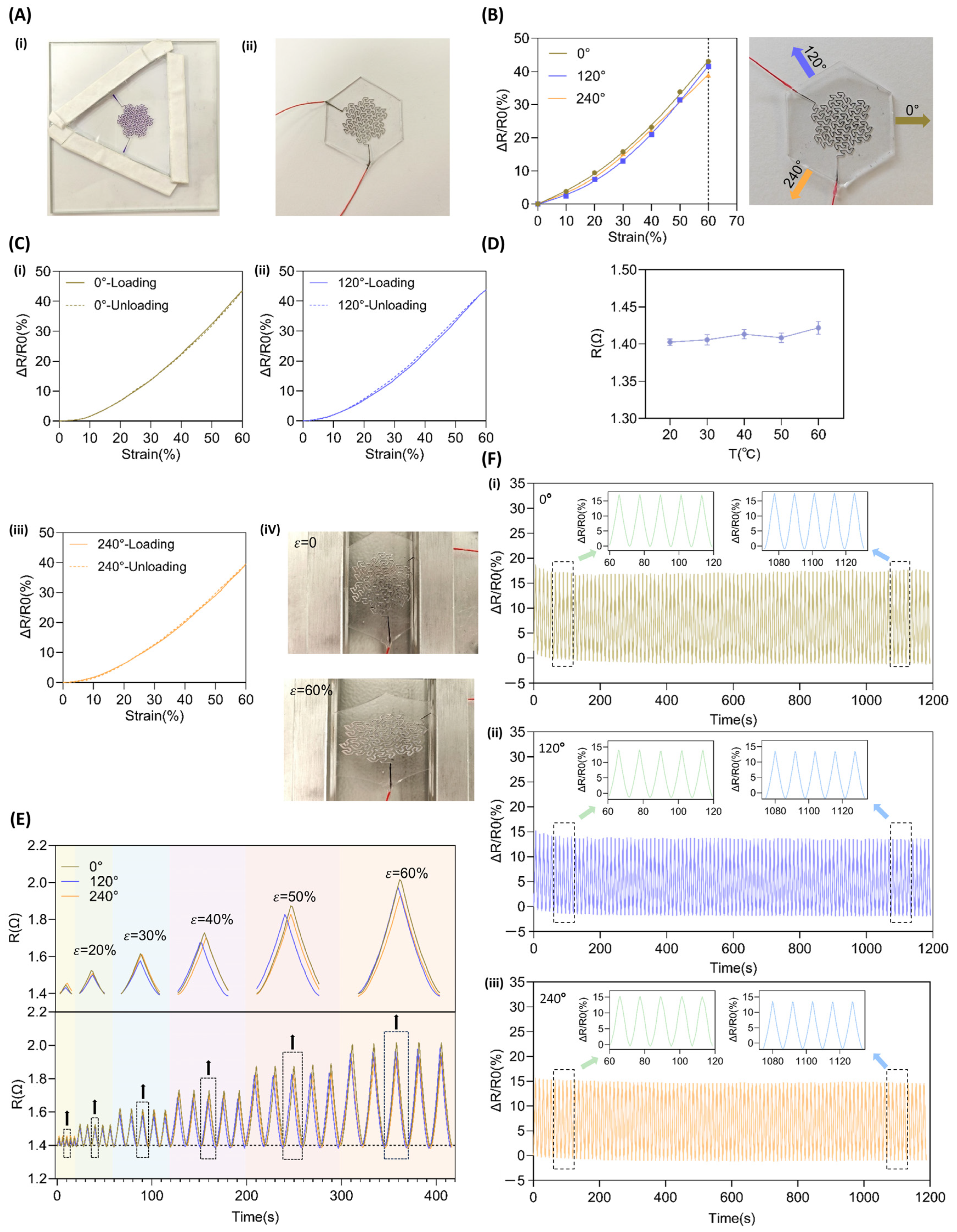

3.1. Electromechanical Stability

3.2. Cyclic Strain Stability

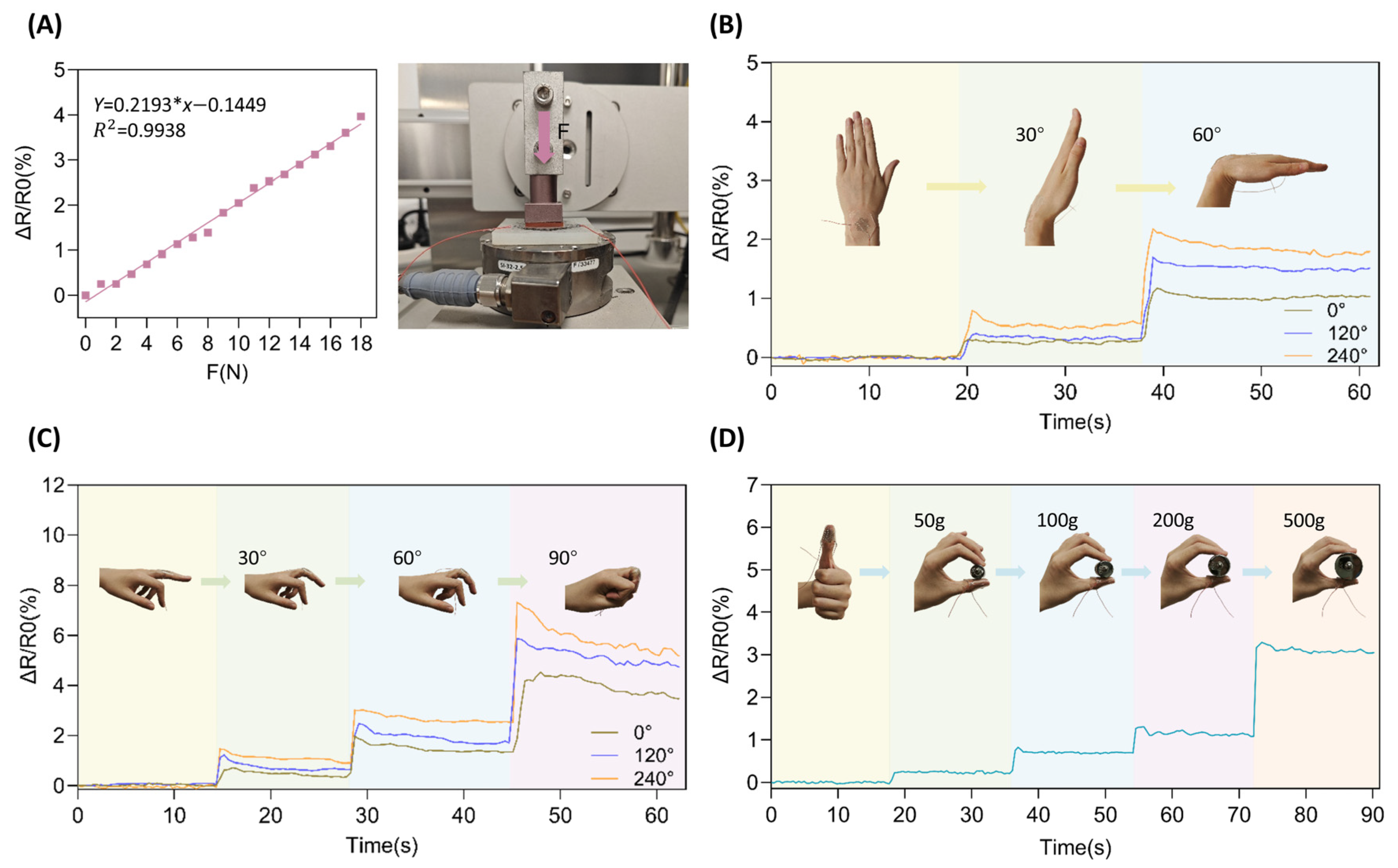

3.3. Pressure Sensitivity

4. Application Testing of Flexible Electrodes in Wearable Sensing

4.1. Joint Motion Monitoring

4.2. Fingertip Normal Pressure Monitoring

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ning, C.; Cheng, R.; Jiang, Y.; Sheng, F.; Yi, J.; Shen, S.; Zhang, Y.; Peng, X.; Dong, K.; Wang, Z.L. Helical fiber strain sensors based on triboelectric nanogenerators for self-powered human respiratory monitoring. ACS Nano 2022, 16, 2811–2821. [Google Scholar] [CrossRef] [PubMed]

- Gao, J.; Fan, Y.; Zhang, Q.; Luo, L.; Hu, X.; Li, Y.; Song, J.; Jiang, H.; Gao, X.; Zheng, L.; et al. Ultra-robust and extensible fibrous mechanical sensors for wearable smart healthcare. Adv. Mater. 2022, 34, 2107511. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Zeng, J.; Wang, C.; Feng, L.; Song, Z.; Zhao, W.; Wang, Q.; Liu, C. The application of wearable glucose sensors in point-of-care testing. Front. Bioeng. Biotechnol. 2021, 9, 774210. [Google Scholar] [CrossRef] [PubMed]

- Zhao, W.; Liu, C.; Wang, Y.; Li, K.; He, Z.; Zhou, S.; Zeng, J.; Ibrahim, O.O.; Zhang, S.; Wang, Q. A flexible substrate-free electrochemical tattoo sensor with alcohol transfer printing method for real-time monitoring of sodium ions in sweat. Sens. Actuators B Chem. 2025, 428, 137245. [Google Scholar] [CrossRef]

- Hou, C.; Xu, Z.; Qiu, W.; Wu, R.; Wang, Y.; Xu, Q.; Liu, X.Y.; Guo, W. A biodegradable and stretchable protein-based sensor as artificial electronic skin for human motion detection. Small 2019, 15, 1805084. [Google Scholar] [CrossRef]

- Shajari, S.; Ramakrishnan, S.; Karan, K.; Sudak, L.J.; Sundararaj, U. Ultrasensitive wearable sensor with novel hybrid structures of silver nanowires and carbon nanotubes in fluoroelastomer: Multi-directional sensing for human health monitoring and stretchable electronics. Appl. Mater. Today 2022, 26, 101295. [Google Scholar] [CrossRef]

- Wang, C.; Liu, C.; Shang, F.; Niu, S.; Ke, L.; Zhang, N.; Ma, B.; Li, R.; Sun, X.; Zhang, S. Tactile sensing technology in bionic skin: A review. Biosens. Bioelectron. 2023, 220, 114882. [Google Scholar] [CrossRef]

- Wang, Q.; Sun, X.; Liu, C.; Wang, C.; Zhao, W.; Zhu, Z.; Ma, S.; Zhang, S. Current development of stretchable self-powered technology based on nanomaterials toward wearable biosensors in biomedical applications. Front. Bioeng. Biotechnol. 2023, 11, 1164805. [Google Scholar] [CrossRef]

- Maurya, D.; Khaleghian, S.; Sriramdas, R.; Kumar, P.; Kishore, R.A.; Kang, M.G.; Kumar, V.; Song, H.-C.; Lee, S.-Y.; Yan, Y.; et al. 3D printed graphene-based self-powered strain sensors for smart tires in autonomous vehicles. Nat. Commun. 2020, 11, 5392. [Google Scholar] [CrossRef]

- Liu, L.; Xu, W.; Ni, Y.; Xu, Z.; Cui, B.; Liu, J.; Wei, H.; Xu, W. Stretchable neuromorphic transistor that combines multisensing and information processing for epidermal gesture recognition. ACS Nano 2022, 16, 2282–2291. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, D.; Lee, J.-H.; Chen, H.; Kim, E.; Shen, X.; Zheng, Q.; Yang, J.; Kim, J.-K. Anisotropic, wrinkled, and crack-bridging structure for ultrasensitive, highly selective multidirectional strain sensors. Nano-Micro Lett. 2021, 13, 122. [Google Scholar] [CrossRef] [PubMed]

- Yang, C.; Hou, X.; Zhang, L. Microfluidics-derived microfibers in flexible bioelectronics. Mater. Futures 2024, 3, 032401. [Google Scholar] [CrossRef]

- Bai, J.; Gu, W.; Bai, Y.; Li, Y.; Yang, L.; Fu, L.; Li, S.; Li, T.; Zhang, T. Multifunctional flexible sensor based on PU-TA@ MXene janus architecture for selective direction recognition. Adv. Mater. 2023, 35, 2302847. [Google Scholar] [CrossRef]

- Xiao, W.; Cai, X.; Jadoon, A.; Zhou, Y.; Guo, Q.; Tang, J.; Ma, X.; Wang, W.; Cai, J. High-Performance Graphene Flexible Sensors for Pulse Monitoring and Human–Machine Interaction. ACS Appl. Mater. Interfaces 2024, 16, 32445–32455. [Google Scholar] [CrossRef]

- Dong, H.; Sun, J.; Liu, X.; Jiang, X.; Lu, S. Highly sensitive and stretchable MXene/CNTs/TPU composite strain sensor with bilayer conductive structure for human motion detection. ACS Appl. Mater. Interfaces 2022, 14, 15504–15516. [Google Scholar] [CrossRef]

- He, J.; Feng, J.; Huang, B.; Duan, W.; Chen, Z.; Huang, J.; Li, B.; Zhou, Z.; Zeng, Z.; Gui, X. Multi-directional strain sensor based on carbon nanotube array for human motion monitoring and gesture recognition. Carbon 2024, 226, 119201. [Google Scholar] [CrossRef]

- Lu, Z.; Wang, J.; He, L.; Song, J.; Yang, Z.; Hammad, F.A. High-performance multidirectional flexible strain sensor for human motion and health monitoring. ACS Appl. Mater. Interfaces 2024, 16, 41409–41420. [Google Scholar] [CrossRef]

- Yang, R.; Song, H.; Zhou, Z.; Yang, S.; Tang, X.; He, J.; Liu, S.; Zeng, Z.; Yang, B.-R.; Gui, X. Ultra-sensitive, multi-directional flexible strain sensors based on an MXene film with periodic wrinkles. ACS Appl. Mater. Interfaces 2023, 15, 8345–8354. [Google Scholar] [CrossRef]

- Noushin, T.; Hossain, N.I.; Tabassum, S. Kirigami-patterned highly stable and strain insensitive sweat pH and temperature sensors for long-term wearable applications. In Proceedings of the 2022 IEEE Healthcare Innovations and Point of Care Technologies (HI-POCT), Houston, TX, USA, 10–11 March 2022; IEEE: New York, NY, USA, 2022; pp. 108–111. [Google Scholar]

- Chen, J.; Zhang, J.; Luo, Z.; Zhang, J.; Li, L.; Su, Y.; Gao, X.; Li, Y.; Tang, W.; Cao, C.; et al. Superelastic, sensitive, and low hysteresis flexible strain sensor based on wave-patterned liquid metal for human activity monitoring. ACS Appl. Mater. Interfaces 2020, 12, 22200–22211. [Google Scholar] [CrossRef]

- Luo, Y.; Fan, H.; Lai, X.; Zeng, Z.; Lan, X.; Lin, P.; Tang, L.; Wang, W.; Chen, Y.; Tang, Y. Flexible liquid metal-based microfluidic strain sensors with fractal-designed microchannels for monitoring human motion and physiological signals. Biosens. Bioelectron. 2024, 246, 115905. [Google Scholar] [CrossRef]

- Mandelbrot, B.B. Fractal geometry: What is it, and what does it do? Proc. R. Soc. Lond. A Math. Phys. Sci. 1989, 423, 3–16. [Google Scholar]

- Mandelbrot, B.B.; Aizenman, M. Fractals: Form, chance, and dimension. Phys. Today 1979, 32, 65–66. [Google Scholar] [CrossRef]

- Carpinteri, A.; Chiaia, B.; Cornetti, P. Static-kinematic duality and the principle of virtual work in the mechanics of fractal media. Comput. Methods Appl. Mech. Eng. 2001, 191, 3–19. [Google Scholar] [CrossRef]

- Han, S.; Peng, H.; Sun, Q.; Venkatesh, S.; Chung, K.; Lau, S.C.; Zhou, Y.; Roy, V.A.L. An overview of the development of flexible sensors. Adv. Mater. 2017, 29, 1700375. [Google Scholar] [CrossRef] [PubMed]

- Mandelbrot, B. How long is the coast of Britain? Statistical self-similarity and fractional dimension. Science 1967, 156, 636–638. [Google Scholar] [CrossRef]

- Falconer, K. Fractal Geometry: Mathematical Foundations and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Deane, A.E.; Keefe, L.R. Multifractal spectra in homogeneous shear flow. In Studying Turbulence Using Numerical Simulation Databases, 2. Proceedings of the 1988 Summer Program; Center for Turbulence Research: Stanford, CA, USA, 1988. [Google Scholar]

- Yu, R.; Xia, T.; Wu, B.; Yuan, J.; Ma, L.; Cheng, G.J.; Liu, F. Highly sensitive flexible piezoresistive sensor with 3D conductive network. ACS Appl. Mater. Interfaces 2020, 12, 35291–35299. [Google Scholar] [CrossRef]

- Choi, D.Y.; Kim, M.H.; Oh, Y.S.; Jung, S.-H.; Jung, J.H.; Sung, H.J.; Lee, H.W.; Lee, H.M. Highly stretchable, hysteresis-free ionic liquid-based strain sensor for precise human motion monitoring. ACS Appl. Mater. Interfaces 2017, 9, 1770–1780. [Google Scholar] [CrossRef]

- Di Tocco, J.; Presti, D.L.; Rainer, A.; Schena, E.; Massaroni, C. Silicone-textile composite resistive strain sensors for human motion-related parameters. Sensors 2022, 22, 3954. [Google Scholar] [CrossRef]

- Wang, Y.; Qin, W.; Yang, M.; Tian, Z.; Guo, W.; Sun, J.; Zhou, X.; Fei, B.; An, B.; Sun, R.; et al. High linearity, low hysteresis Ti3C2Tx MXene/AgNW/liquid metal self-healing strain sensor modulated by dynamic disulfide and hydrogen bonds. Adv. Funct. Mater. 2023, 33, 2301587. [Google Scholar] [CrossRef]

- Xu, Y.; Chen, M.; Yu, S.; Zhou, H. High-performance flexible strain sensors based on silver film wrinkles modulated by liquid PDMS substrates. RSC Adv. 2023, 13, 33697–33706. [Google Scholar] [CrossRef]

- Chang, K.; Guo, M.; Pu, L.; Dong, J.; Li, L.; Ma, P.; Huang, Y.; Liu, T. Wearable nanofibrous tactile sensors with fast response and wireless communication. Chem. Eng. J. 2023, 451, 138578. [Google Scholar] [CrossRef]

| Channel Shape | Maximum GF | Minimum DH | Minimum Hysterr | Sensing Direction | Reference |

|---|---|---|---|---|---|

| Peano-Gosper | 0.72 | 0.94% | 1.41% | Three-directional | This work |

| Wave | 2.67 | 1.02% | 9% | Unidirectional | [20] |

| Peano II | 0.84 | 3.70% | 3.11% | Bidirectional | [21] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, C.; Huang, Y.; Zhao, Z.; Li, H.; Liu, C.; Jia, Z.; Wang, Y.; Wang, Q.; Zhang, S. A Peano-Gosper Fractal-Inspired Stretchable Electrode with Integrated Three-Directional Strain and Normal Pressure Sensing. Nanomaterials 2025, 15, 1370. https://doi.org/10.3390/nano15171370

Wang C, Huang Y, Zhao Z, Li H, Liu C, Jia Z, Wang Y, Wang Q, Zhang S. A Peano-Gosper Fractal-Inspired Stretchable Electrode with Integrated Three-Directional Strain and Normal Pressure Sensing. Nanomaterials. 2025; 15(17):1370. https://doi.org/10.3390/nano15171370

Chicago/Turabian StyleWang, Chunge, Yuanyuan Huang, Zixia Zhao, Haoyu Li, Chen Liu, Zhixin Jia, Yanping Wang, Qianqian Wang, and Sheng Zhang. 2025. "A Peano-Gosper Fractal-Inspired Stretchable Electrode with Integrated Three-Directional Strain and Normal Pressure Sensing" Nanomaterials 15, no. 17: 1370. https://doi.org/10.3390/nano15171370

APA StyleWang, C., Huang, Y., Zhao, Z., Li, H., Liu, C., Jia, Z., Wang, Y., Wang, Q., & Zhang, S. (2025). A Peano-Gosper Fractal-Inspired Stretchable Electrode with Integrated Three-Directional Strain and Normal Pressure Sensing. Nanomaterials, 15(17), 1370. https://doi.org/10.3390/nano15171370