Selective DUV Femtosecond Laser Annealing for Electrical Property Modulation in NMOS Inverter

Abstract

1. Introduction

2. Experimental Methods

2.1. Fabrication of ZnON TFTs

2.2. Laser-Annealing Methods

2.3. Characteristic Measurements

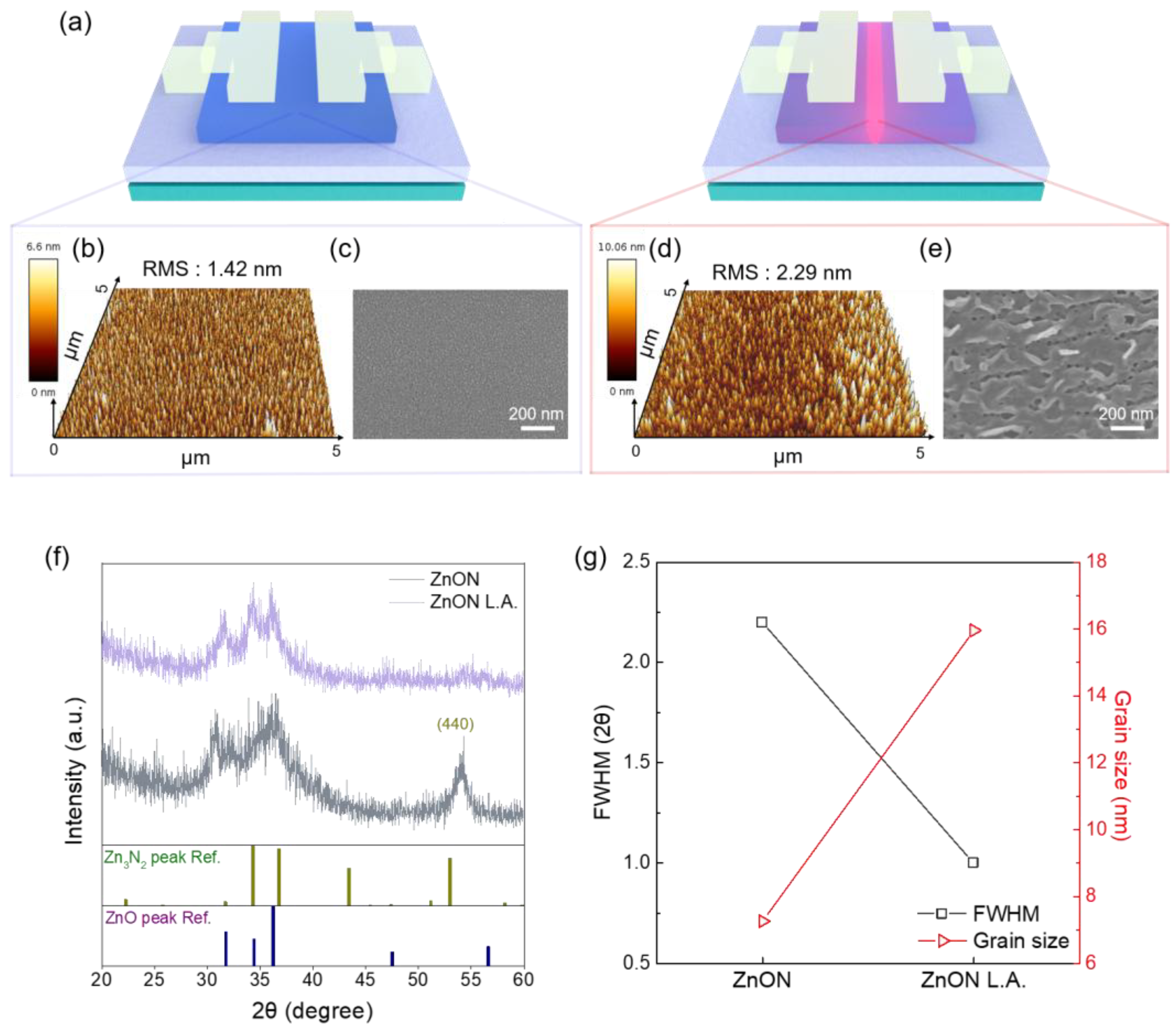

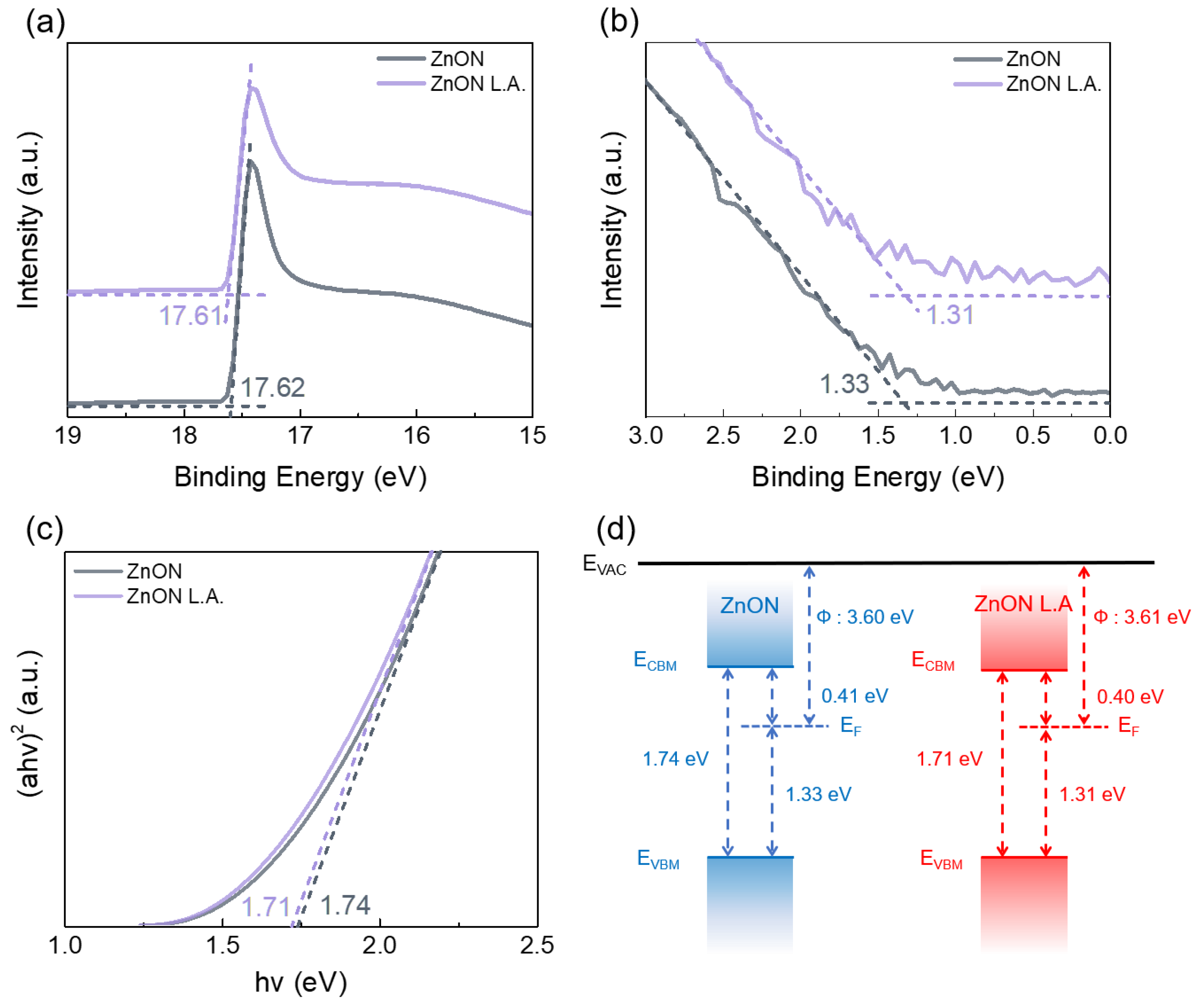

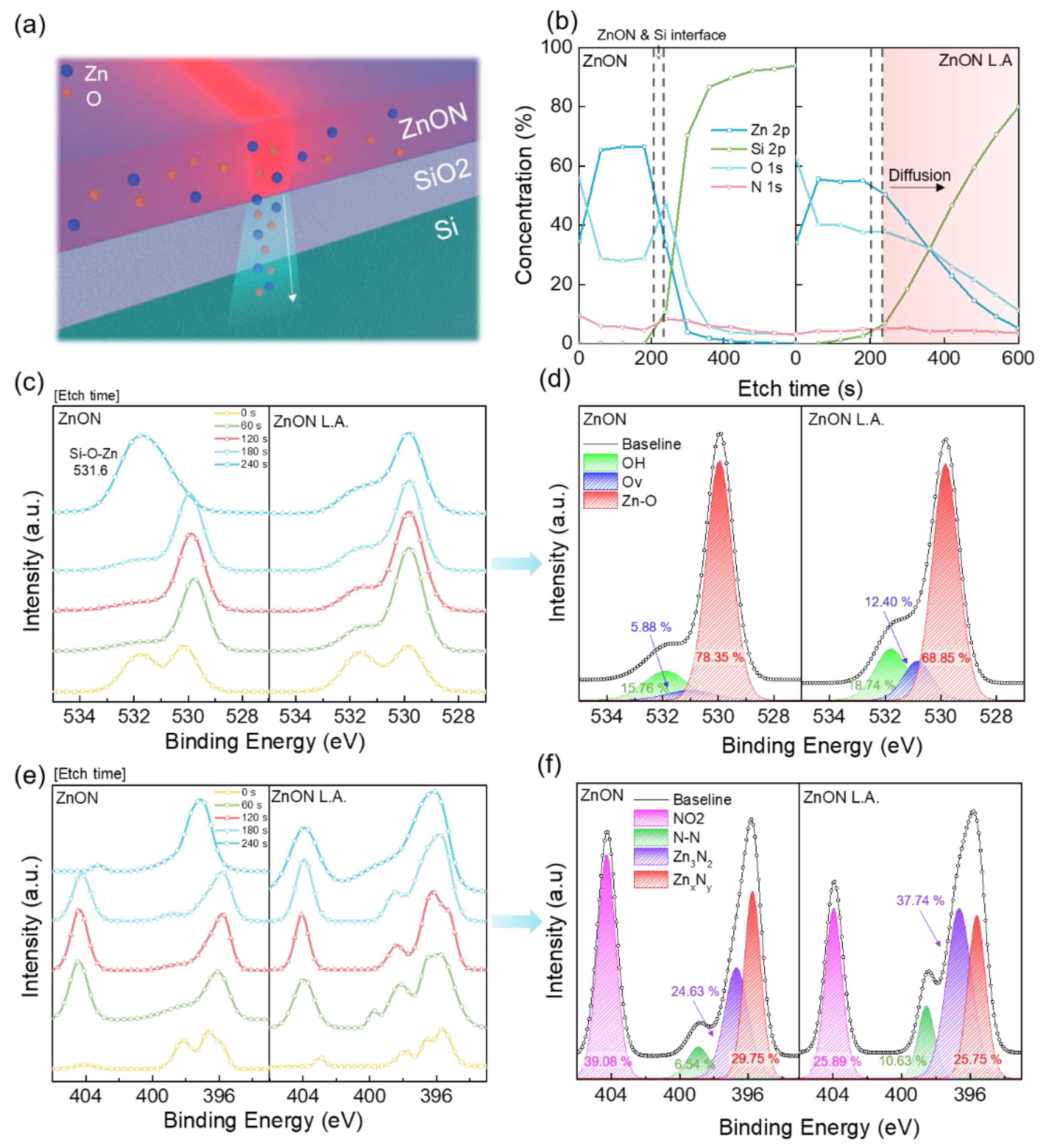

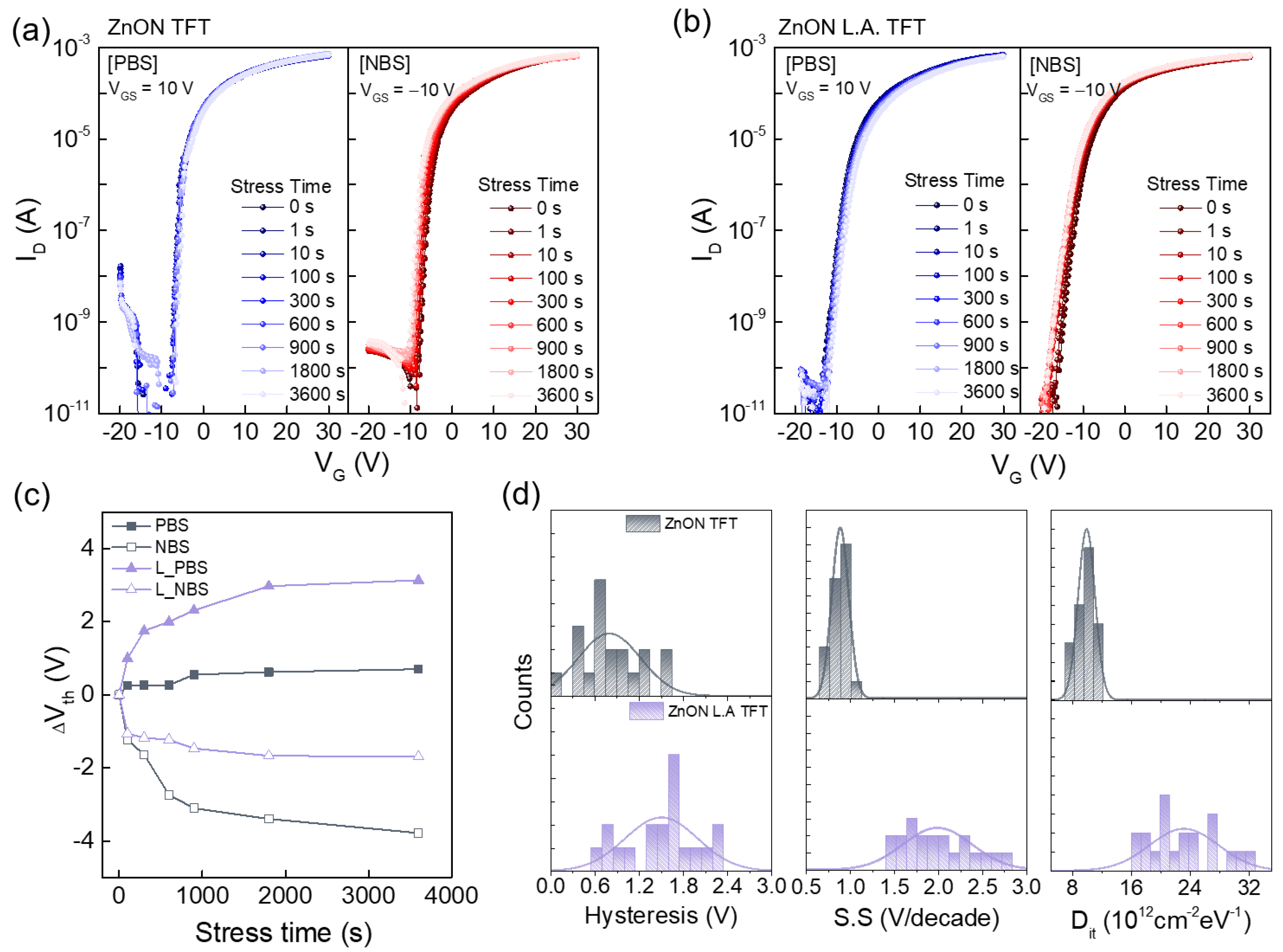

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nomura, K.; Ohta, H.; Takagi, A.; Kamiya, T.; Hirano, M.; Hosono, H. Room-temperature fabrication of transparent flexible thin-film transistors using amorphous oxide semiconductors. Nature 2004, 432, 488–492. [Google Scholar] [CrossRef]

- Park, J.S.; Maeng, W.-J.; Kim, H.-S.; Park, J.-S. Review of recent developments in amorphous oxide semiconductor thin-film transistor devices. Thin Solid Film. 2012, 520, 1679–1693. [Google Scholar] [CrossRef]

- Kamiya, T.; Nomura, K.; Hosono, H. Origin of definite Hall voltage and positive slope in mobility-donor density relation in disordered oxide semiconductors. Appl. Phys. Lett. 2010, 96, 122103. [Google Scholar] [CrossRef]

- Kamiya, T.; Hosono, H. Material characteristics and applications of transparent amorphous oxide semiconductors. NPG Asia Mater. 2010, 2, 15–22. [Google Scholar] [CrossRef]

- Kim, T.; Choi, C.H.; Hur, J.S.; Ha, D.; Kuh, B.J.; Kim, Y.; Cho, M.H.; Kim, S.; Jeong, J.K. Progress, Challenges, and Opportunities in Oxide Semiconductor Devices: A Key Building Block for Applications Ranging from Display Backplanes to 3D Integrated Semiconductor Chips. Adv. Mater. 2023, 35, 2204663. [Google Scholar] [CrossRef] [PubMed]

- Alzoubi, K.; Hamasha, M.M.; Lu, S.; Sammakia, B. Bending Fatigue Study of Sputtered ITO on Flexible Substrate. J. Disp. Technol. 2011, 7, 593–600. [Google Scholar] [CrossRef]

- Ahmed, N.M.; Sabah, F.A.; Abdulgafour, H.I.; Alsadig, A.; Sulieman, A.; Alkhoaryef, M. The effect of post annealing temperature on grain size of indium-tin-oxide for optical and electrical properties improvement. Results Phys. 2019, 13, 102159. [Google Scholar] [CrossRef]

- Klein, A. Interface Properties of Dielectric Oxides. J. Am. Ceram. Soc. 2016, 99, 369–387. [Google Scholar] [CrossRef]

- Chen, Z.; Yan, Y.; Ding, G.; Zhou, Y.; Han, S.; Zhang, M. Annealing Strategy Toward Achieving High-Performance Indium Tungsten Oxide Thin-Film Transistors by Equilibrating Oxygen Vacancy and Chemisorbed Oxygen. IEEE Trans. Electron Devices 2025, 72, 1167–1173. [Google Scholar] [CrossRef]

- Kim, H.-S.; Jeon, S.H.; Park, J.S.; Kim, T.S.; Son, K.S.; Seon, J.-B.; Seo, S.-J.; Kim, S.-J.; Lee, E.; Chung, J.G.; et al. Anion control as a strategy to achieve high-mobility and high-stability oxide thin-film transistors. Sci. Rep. 2013, 3, 1459. [Google Scholar] [CrossRef]

- Park, J.; Kim, Y.S.; Ok, K.-C.; Park, Y.C.; Kim, H.Y.; Park, J.-S.; Kim, H.-S. A study on the electron transport properties of ZnON semiconductors with respect to the relative anion content. Sci. Rep. 2016, 6, 24787. [Google Scholar] [CrossRef] [PubMed]

- Park, J.-S.; Kim, H.; Kim, I.-D. Overview of electroceramic materials for oxide semiconductor thin film transistors. J. Electroceramics 2014, 32, 117–140. [Google Scholar] [CrossRef]

- Ye, Y.; Lim, R.; White, J.M. High mobility amorphous zinc oxynitride semiconductor material for thin film transistors. J. Appl. Phys. 2009, 106, 074512. [Google Scholar] [CrossRef]

- Park, J.; Kim, Y.S.; Kim, J.H.; Park, K.; Park, Y.C.; Kim, H.-S. The effects of active layer thickness and annealing conditions on the electrical performance of ZnON thin-film transistors. J. Alloys Compd. 2016, 688, 666–671. [Google Scholar] [CrossRef]

- Lee, E.; Benayad, A.; Shin, T.; Lee, H.; Ko, D.-S.; Kim, T.S.; Son, K.S.; Ryu, M.; Jeon, S.; Park, G.-S. Nanocrystalline ZnON; High Mobility and Low Band Gap Semiconductor Material for High Performance Switch Transistor and Image Sensor Application. Sci. Rep. 2014, 4, 4948. [Google Scholar] [CrossRef]

- Ok, K.C.; Jeong, H.J.; Kim, H.S.; Park, J.S. Highly Stable ZnON Thin-Film Transistors with High Field-Effect Mobility Exceeding 50 cm2/Vs. IEEE Electron Device Lett. 2015, 36, 38–40. [Google Scholar] [CrossRef]

- Ding, X.; Yang, J.; Qin, C.; Yang, X.; Ding, T.; Zhang, J. Nitrogen-Doped ZnO Film Fabricated Via Rapid Low-Temperature Atomic Layer Deposition for High-Performance ZnON Transistors. IEEE Trans. Electron Devices 2018, 65, 3283–3290. [Google Scholar] [CrossRef]

- Jang, J.T.; Kim, H.D.; Kim, D.M.; Choi, S.J.; Kim, H.S.; Kim, D.H. Influence of Nitrogen Content on Persistent Photoconductivity in Zinc Oxynitride Thin Film Transistors. IEEE Electron Device Lett. 2020, 41, 561–564. [Google Scholar] [CrossRef]

- Ryu, M.; Kim, T.S.; Son, K.S.; Kim, H.S.; Park, J.S.; Seon, J.B.; Seo, S.J.; Kim, S.J.; Lee, E.; Lee, H.; et al. High Mobility Zinc Oxynitride-TFT with Operation Stability Under Light-Illuminated Bias-Stress Conditions for Large Area and High Resolution Display Applications. In Proceeding of the 2012 International Electron Devices Meeting, San Francisco, CA, USA, 10–13 December 2012; pp. 5.6.1–5.6.3. [Google Scholar]

- Jeong, H.; Jeong, H.S.; Kim, D.H.; Jeong, C.Y.; Kwon, H.I. Effects of Post-Deposition Thermal Annealing Temperature on Electrical Properties of ZnON Thin-Film Transistors. IEEE Electron Device Lett. 2016, 37, 747–750. [Google Scholar] [CrossRef]

- Zhang, W.; Fan, Z.; Shen, A.; Dong, C. Atmosphere Effect in Post-Annealing Treatments for Amorphous InGaZnO Thin-Film Transistors with SiOx Passivation Layers. Micromachines 2021, 12, 1551. [Google Scholar] [CrossRef]

- Tsuji, H.; Takei, T.; Nakata, M.; Miyakawa, M.; Fujisaki, Y.; Yamamoto, T. Improvement in switching characteristics and long-term stability of Zn-O-N thin-film transistors by silicon doping. AIP Adv. 2017, 7, 065120. [Google Scholar] [CrossRef]

- Nomura, K.; Kamiya, T.; Hirano, M.; Hosono, H. Origins of threshold voltage shifts in room-temperature deposited and annealed a-In–Ga–Zn–O thin-film transistors. Appl. Phys. Lett. 2009, 95, 013502. [Google Scholar] [CrossRef]

- Perrie, W.; Rushton, A.; Gill, M.; Fox, P.; O’Neill, W. Femtosecond laser micro-structuring of alumina ceramic. Appl. Surf. Sci. 2005, 248, 213–217. [Google Scholar] [CrossRef]

- Izawa, Y.; Tokita, S.; Fujita, M.; Norimatsu, T.; Izawa, Y. Ultra fast melting process in femtosecond laser crystallization of thin a-Si layer. Appl. Surf. Sci. 2009, 255, 9764–9769. [Google Scholar] [CrossRef]

- Choi, W.; Kim, H.Y.; Jeon, J.W.; Chang, W.S.; Cho, S.-H. Vibration-Assisted Femtosecond Laser Drilling with Controllable Taper Angles for AMOLED Fine Metal Mask Fabrication. Materials 2017, 10, 212. [Google Scholar] [CrossRef] [PubMed]

- Shan, F.; Sun, H.Z.; Lee, J.Y.; Pyo, S.; Kim, S.J. Improved High-Performance Solution Processed In2O3 Thin Film Transistor Fabricated by Femtosecond Laser Pre-Annealing Process. IEEE Access 2021, 9, 44453–44462. [Google Scholar] [CrossRef]

- Lee, J.Y.; Shan, F.; Kim, H.S.; Kim, S.J. Effect of Femtosecond Laser Postannealing on a-IGZO Thin-Film Transistors. IEEE Trans. Electron Devices 2021, 68, 3371–3378. [Google Scholar] [CrossRef]

- Shan, F.; Lee, J.-Y.; Zhao, H.-L.; Choi, S.G.; Koh, J.-H.; Kim, S.-J. Multi-Stacking Indium Zinc Oxide Thin-Film Transistors Post-Annealed by Femtosecond Laser. Electron. Mater. Lett. 2021, 17, 451–458. [Google Scholar] [CrossRef]

- Natoli, J.-Y.; Gallais, L.; Akhouayri, H.; Amra, C. Laser-induced damage of materials in bulk, thin-film, and liquid forms. Appl. Opt. 2002, 41, 3156–3166. [Google Scholar] [CrossRef]

- Futsuhara, M.; Yoshioka, K.; Takai, O. Optical properties of zinc oxynitride thin films. Thin Solid Film. 1998, 317, 322–325. [Google Scholar] [CrossRef]

- Gao, H.; Zhang, X.; Zhao, Y.; Yan, B. The correlation of material properties and deposition condition of ZnON thin films. AIP Adv. 2017, 7, 025111. [Google Scholar] [CrossRef]

- Ben Moussa, N.; Lajnef, M.; Jebari, N.; Villebasse, C.; Bayle, F.; Chaste, J.; Madouri, A.; Chtourou, R.; Herth, E. Synthesis of ZnO Sol–Gel Thin-Films CMOS-Compatible. RSC Adv. 2021, 11, 22723–22733. [Google Scholar] [CrossRef] [PubMed]

- Whitten, J.E. Ultraviolet Photoelectron Spectroscopy: Practical Aspects and Best Practices. Appl. Surf. Sci. Adv. 2023, 13, 100384. [Google Scholar] [CrossRef]

- Viezbicke, B.D.; Patel, S.; Davis, B.E.; Birnie III, D.P. Evaluation of the Tauc method for optical absorption edge determination: ZnO thin films as a model system. Phys. Status Solidi 2015, 252, 1700–1710. [Google Scholar] [CrossRef]

- Dementjev, A.P.; de Graaf, A.; van de Sanden, M.C.M.; Maslakov, K.I.; Naumkin, A.V.; Serov, A.A. X-Ray photoelectron spectroscopy reference data for identification of the C3N4 phase in carbon–nitrogen films. Diam. Relat. Mater. 2000, 9, 1904–1907. [Google Scholar] [CrossRef]

- Santra, B.; Pal, S.; Saha, S.; Kanjilal, A. Tailoring Structural, Chemical, and Photocatalytic Properties of ZnO@β-SiC Composites: The Effect of Annealing Temperature and Environment. ACS Omega 2023, 8, 24113–24124. [Google Scholar] [CrossRef]

- Raven, M.S. XPS and Auger LMM analysis of ZnO/Si and ZnO/SiO2 interfaces. Surf. Interface Anal. 1979, 1, 20–25. [Google Scholar] [CrossRef]

- Libsch, F.R.; Kanicki, J. Bias-stress-induced stretched-exponential time dependence of charge injection and trapping in amorphous thin-film transistors. Appl. Phys. Lett. 1993, 62, 1286–1288. [Google Scholar] [CrossRef]

- Park, J.; Jeong, H.-J.; Lee, H.-M.; Nahm, H.-H.; Park, J.-S. The resonant interaction between anions or vacancies in ZnON semiconductors and their effects on thin film device properties. Sci. Rep. 2017, 7, 2111. [Google Scholar] [CrossRef]

- Kim, H.-D.; Kim, J.H.; Park, K.; Kim, J.H.; Park, J.; Kim, Y.J.; Kim, H.-S. Effects of Fluorine Doping on the Electrical Performance of ZnON Thin-Film Transistors. ACS Appl. Mater. Interfaces 2017, 9, 24688–24695. [Google Scholar] [CrossRef]

- Jin, J.W.; Nathan, A.; Barquinha, P.; Pereira, L.; Fortunato, E.; Martins, R.; Cobb, B. Interpreting anomalies observed in oxide semiconductor TFTs under negative and positive bias stress. AIP Adv. 2016, 6, 085321. [Google Scholar] [CrossRef]

- Gu, B.-S.; Park, E.-S.; Kwon, J.-H.; Kim, M.-H. Effect of Gate Bias Stress on the Electrical Characteristics of Ferroelectric Oxide Thin-Film Transistors with Poly (Vinylidenefluoride-Trifluoroethylene). Materials 2023, 16, 2285. [Google Scholar] [CrossRef]

- Zhao, H.-L.; Tarsoly, G.; Shan, F.; Wang, X.-L.; Lee, J.-Y.; Jeong, Y.J.; Kim, S.-J. Impact of pre-annealing process on electrical properties and stability of indium zinc oxide thin-film transistors. Sci. Rep. 2022, 12, 19497. [Google Scholar] [CrossRef]

- Cui, Q.; Si, M.; Sporea, R.A.; Guo, X. Simple Noise Margin Model for Optimal Design of Unipolar Thin-Film Transistor Logic Circuits. IEEE Trans. Electron Devices 2013, 60, 1782–1785. [Google Scholar] [CrossRef]

| Parameter | μsat [cm2/Vs] | Vth [V] | On/Off Ratio | S.S [V/Dec] | Dit [cm−2eV−1] |

|---|---|---|---|---|---|

| ZnON TFT | 22.30 | −3.75 | 2.03 × 108 | 0.65 | 7.08 × 1011 |

| ZnON L.A. TFT | 21.09 | −5.80 | 1.71 × 107 | 1.61 | 1.86 × 1012 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jeong, J.H.; Lee, W.W.; Kwon, S.J.; Park, M.-K.; Cho, E.-S. Selective DUV Femtosecond Laser Annealing for Electrical Property Modulation in NMOS Inverter. Nanomaterials 2025, 15, 1247. https://doi.org/10.3390/nano15161247

Jeong JH, Lee WW, Kwon SJ, Park M-K, Cho E-S. Selective DUV Femtosecond Laser Annealing for Electrical Property Modulation in NMOS Inverter. Nanomaterials. 2025; 15(16):1247. https://doi.org/10.3390/nano15161247

Chicago/Turabian StyleJeong, Joo Hyun, Won Woo Lee, Sang Jik Kwon, Min-Kyu Park, and Eou-Sik Cho. 2025. "Selective DUV Femtosecond Laser Annealing for Electrical Property Modulation in NMOS Inverter" Nanomaterials 15, no. 16: 1247. https://doi.org/10.3390/nano15161247

APA StyleJeong, J. H., Lee, W. W., Kwon, S. J., Park, M.-K., & Cho, E.-S. (2025). Selective DUV Femtosecond Laser Annealing for Electrical Property Modulation in NMOS Inverter. Nanomaterials, 15(16), 1247. https://doi.org/10.3390/nano15161247