Multi-Bit Resistive Random-Access Memory Based on Two-Dimensional MoO3 Layers

Abstract

1. Introduction

2. Methods

2.1. Preparation of α-MoO3 Crystals and Thin Flakes

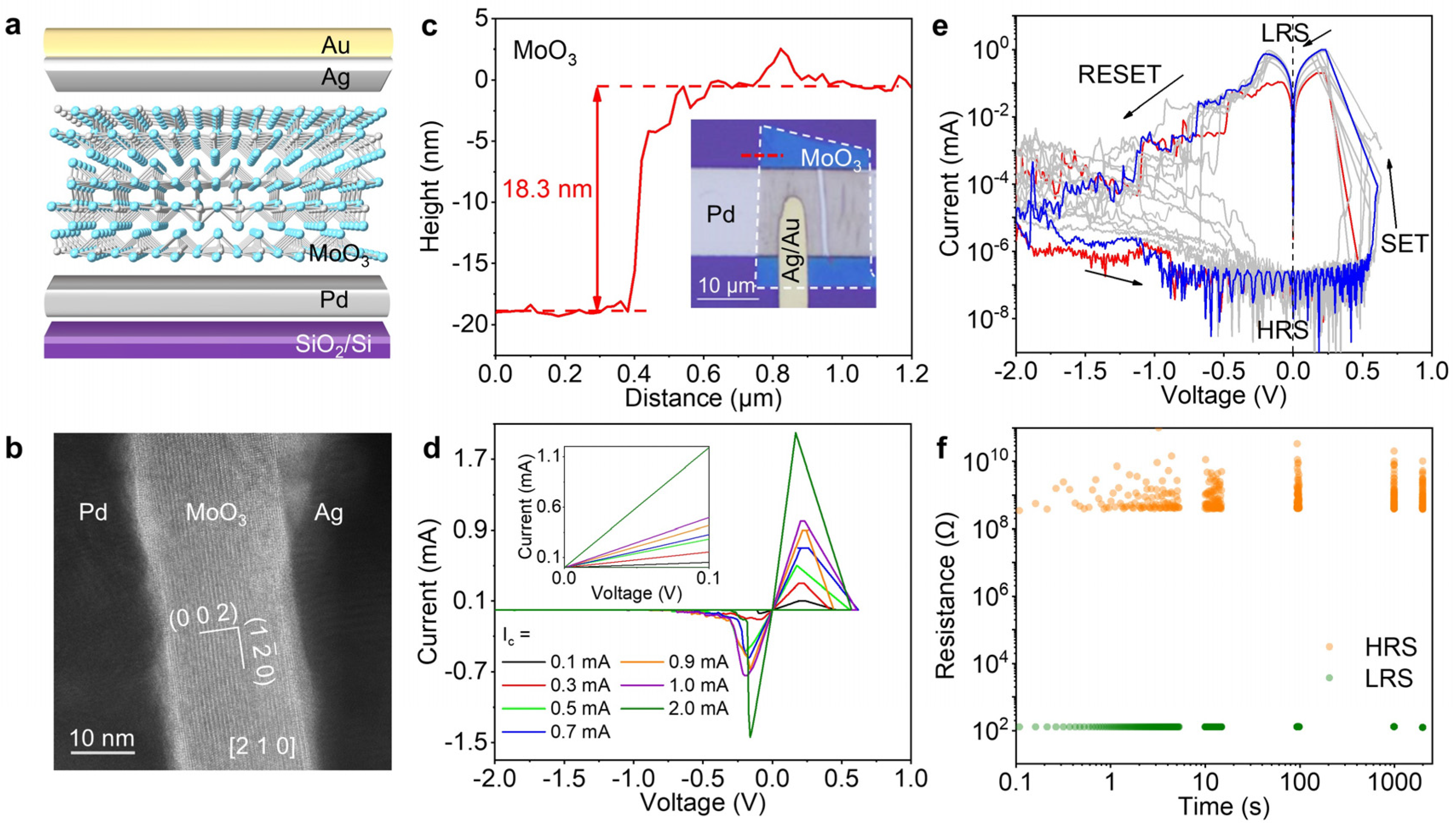

2.2. Fabrication of Pd-MoO3-Ag Devices

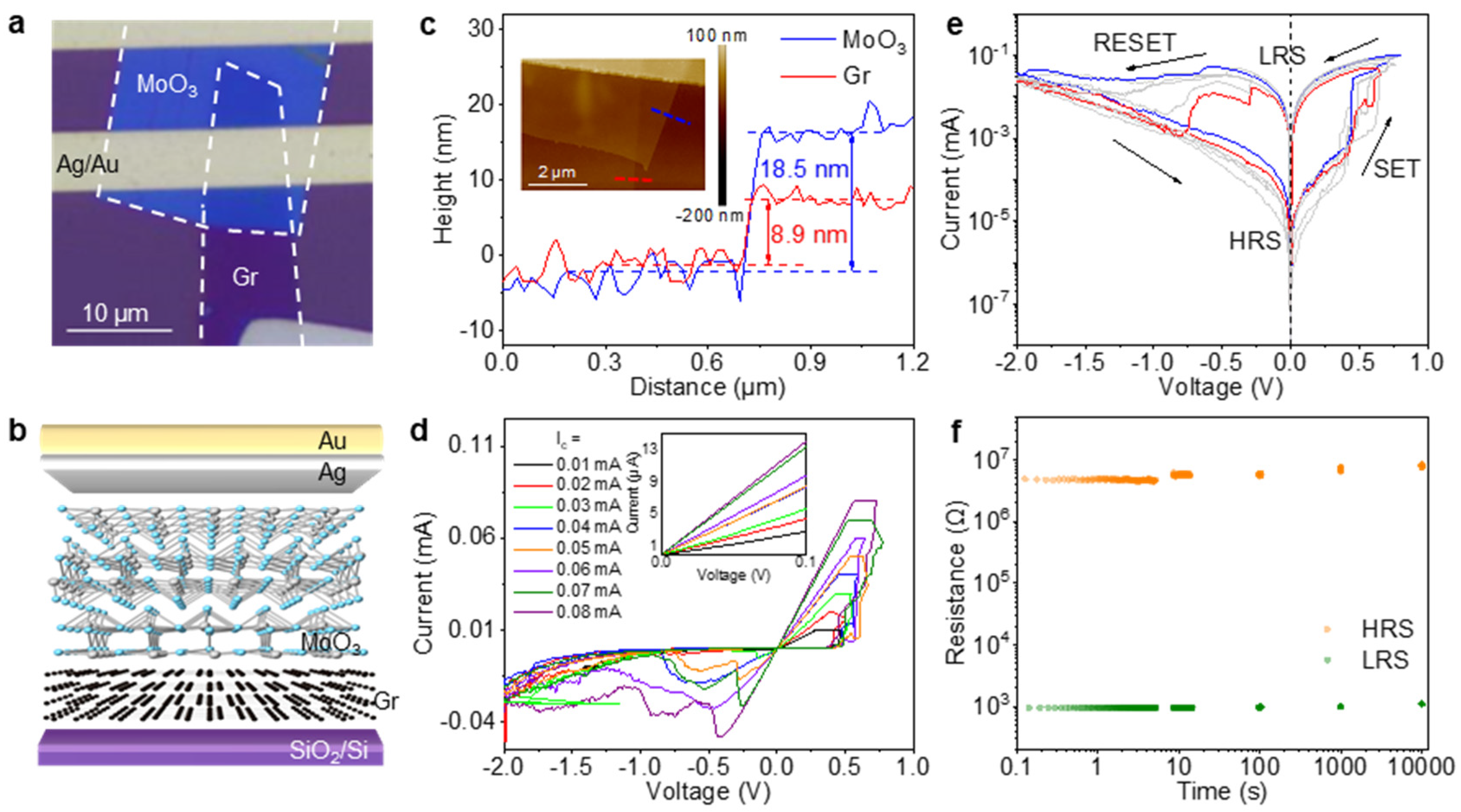

2.3. Fabrication of Gr-MoO3-Ag Devices

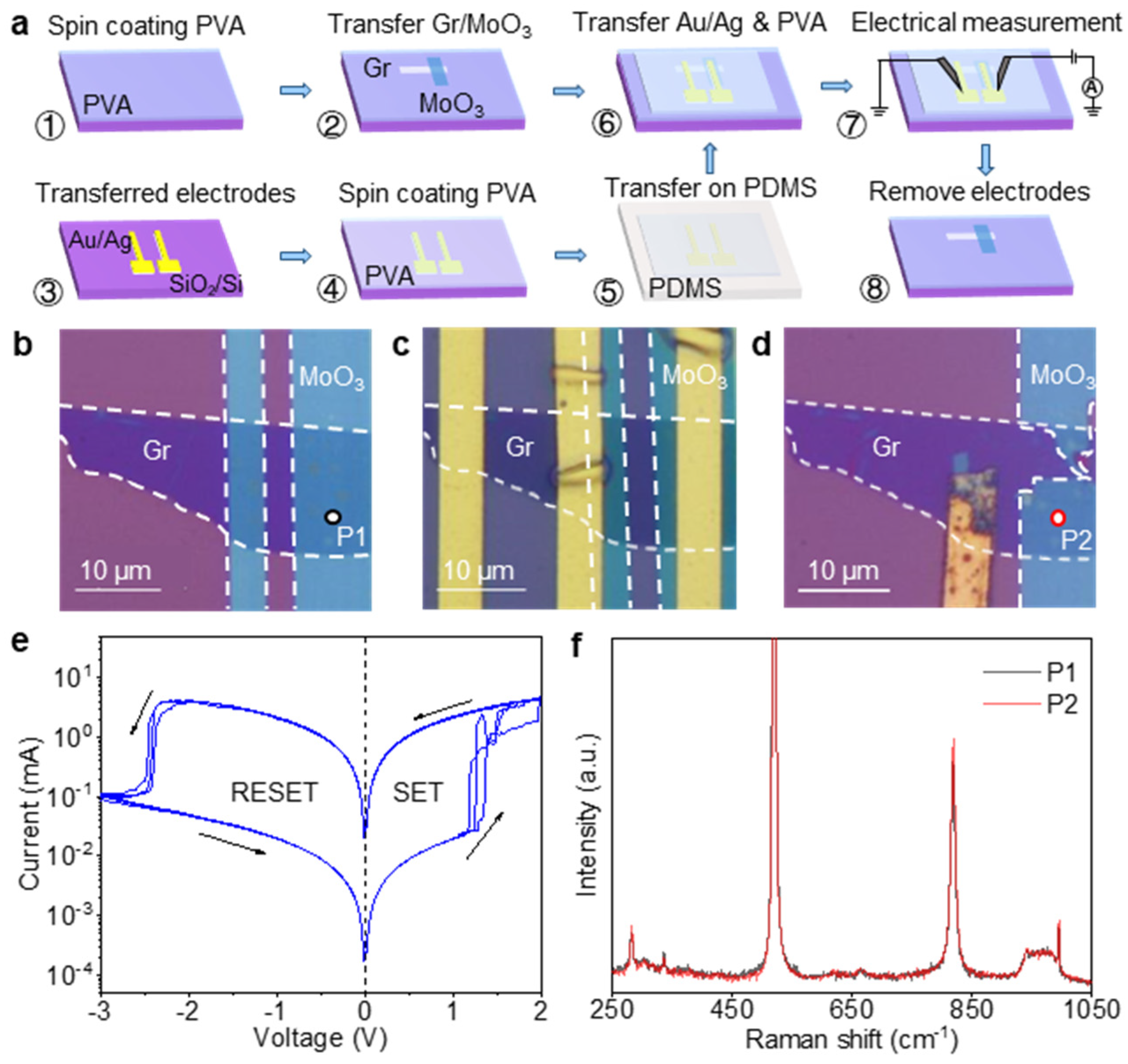

2.4. Fabrication of Detachable Devices

2.5. Characterizations

3. Results and Discussion

3.1. Characterizations of α-MoO3

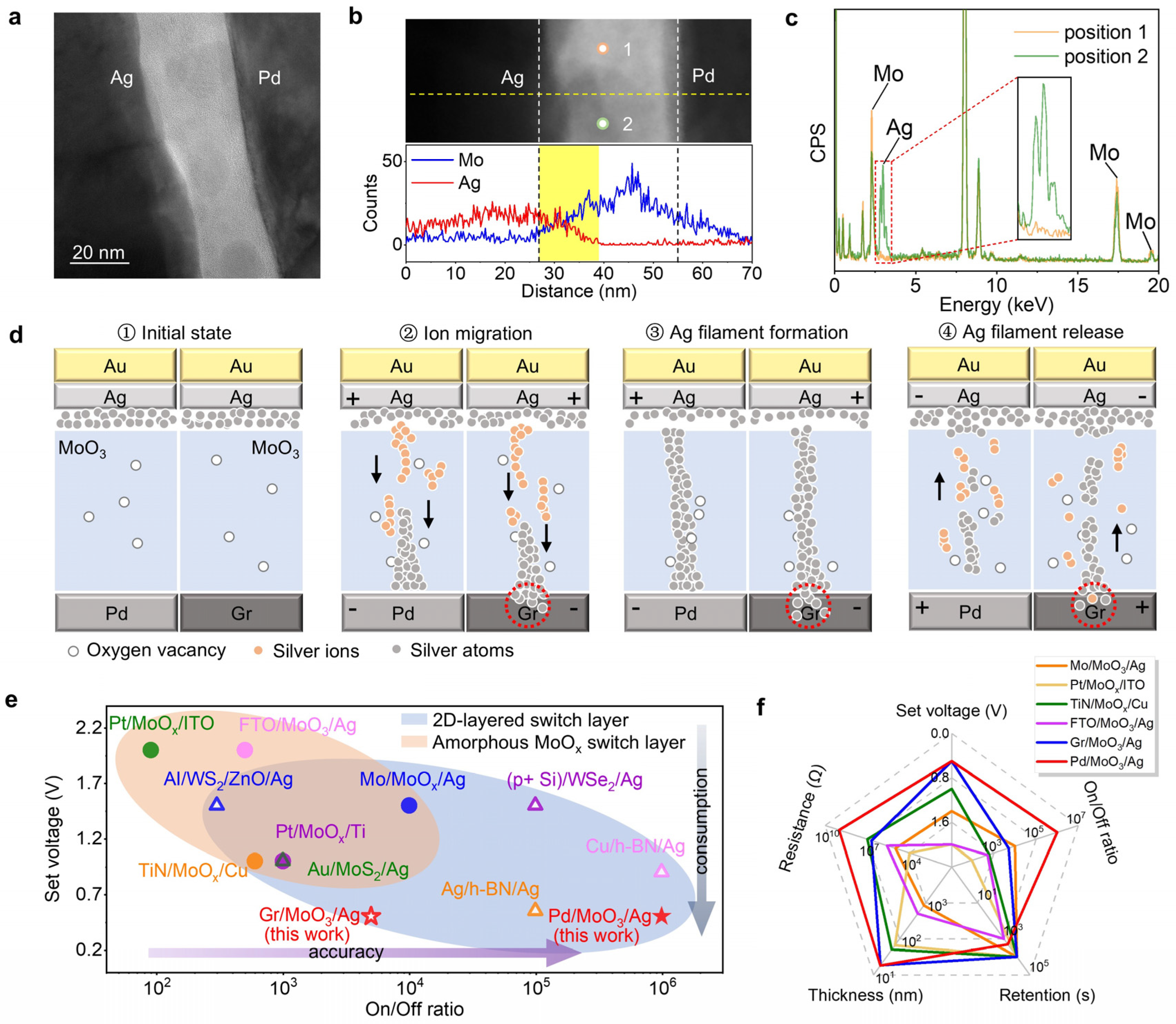

3.2. Fabrication and Resistive Switching Performance of RRAM

3.3. Analysis of Device Operating Mechanisms

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yadav, D. Machine learning: Trends, perspective, and prospects. Science 2020, 349, 255–260. [Google Scholar]

- Pan, F.; Gao, S.; Chen, C.; Song, C.; Zeng, F. Recent progress in resistive random access memories: Materials, switching mechanisms, and performance. Mater. Sci. Eng. R Rep. 2014, 83, 1–59. [Google Scholar] [CrossRef]

- Menzel, S.; Böttger, U.; Wimmer, M.; Salinga, M. Physics of the switching kinetics in resistive memories. Adv. Funct. Mater. 2015, 25, 6306–6325. [Google Scholar] [CrossRef]

- Wu, H.; Wang, X.H.; Gao, B.; Deng, N.; Lu, Z.; Haukness, B.; Bronner, G.; Qian, H. Resistive random access memory for future information processing system. Proc. IEEE 2017, 105, 1770–1789. [Google Scholar] [CrossRef]

- Chang, T.C.; Chang, K.C.; Tsai, T.M.; Chu, T.J.; Sze, S.M. Resistance random access memory. Mater. Today 2016, 19, 254–264. [Google Scholar] [CrossRef]

- Chen, Z.; Huang, W.; Zhao, W.; Hou, C.; Ma, C.; Liu, C.; Sun, H.; Yin, Y.; Li, X. Ultrafast multilevel switching in Au/YIG/n-Si RRAM. Adv. Electron. Mater. 2019, 5, 1800418. [Google Scholar] [CrossRef]

- Cario, L.; Vaju, C.; Corraze, B.; Guiot, V.; Janod, E. Electric-field-induced resistive switching in a family of Mott insulators: Towards a new class of RRAM memories. Adv. Mater. 2010, 22, 5193–5197. [Google Scholar] [CrossRef]

- Wu, M.C.; Ting, Y.H.; Chen, J.Y.; Wu, W.W. Low power consumption nanofilamentary ECM and VCM cells in a single sidewall of high-density VRRAM arrays. Adv. Sci. 2019, 6, 1902363. [Google Scholar] [CrossRef]

- Xie, M.; Jia, Y.; Nie, C.; Liu, Z.; Tang, A.; Fan, S.; Liang, X.; Jiang, L.; He, Z.; Yang, R. Monolithic 3D integration of 2D transistors and vertical RRAMs in 1T-4R structure for high-density memory. Nat. Commun. 2023, 14, 5952. [Google Scholar] [CrossRef]

- Jian, J.; Dong, P.; Jian, Z.; Zhao, T.; Miao, C.; Chang, H.; Chen, J.; Chen, Y.-F.; Feng, H.; Sorli, B. Ultralow-power RRAM with a high switching ratio based on the large van der Waals interstice radius of TMDs. ACS Nano 2022, 16, 20445–20456. [Google Scholar] [CrossRef]

- Han, S.W.; Shin, S.; Lee, C.T.; Shin, M.W. Laser-modulated formation of conduction path for the achievement of ultra-low switching voltage in resistive random-access memory (RRAM). Nano Energy 2023, 117, 108886. [Google Scholar] [CrossRef]

- Xie, W.; Bai, J.; Li, Y.; Qin, F.; Wang, D. Interface characteristic and performance optimization mechanism for HfOx-based RRAM devices. Appl. Surf. Sci. 2025, 680, 161291. [Google Scholar] [CrossRef]

- Ranjan, A.; Xu, H.; Wang, C.; Molina, J.; Wu, X.; Zhang, H.; Sun, L.; Chu, J.; Pey, K.L. Probing resistive switching in HfO2/Al2O3 bilayer oxides using in-situ transmission electron microscopy. Appl. Mater. Today 2023, 31, 101739. [Google Scholar] [CrossRef]

- Yeh, K.; Shih, P.; Hsu, K.; Cheng, W.; Chu, S. Yttrium doping effects on the resistive random access memory characteristics of sputtered HfOx films and mechanism investigations. ACS Appl. Electron. Mater. 2025, 7, 1802–1811. [Google Scholar] [CrossRef]

- Zaffora, A.; Cho, D.Y.; Lee, K.S.; Di Quarto, F.; Waser, R.; Santamaria, M.; Valov, I. Electrochemical tantalum oxide for resistive switching memories. Adv. Mater. 2017, 29, 1703357. [Google Scholar] [CrossRef]

- Song, Y.W.; Chang, Y.H.; Choi, J.; Song, M.K.; Yoon, J.H.; Lee, S.; Jung, S.Y.; Ham, W.; Park, J.M.; Kim, H.S.; et al. Doping modulated ion hopping in tantalum oxide based resistive switching memory for linear and stable switching dynamics. Appl. Surf. Sci. 2023, 631, 157356. [Google Scholar] [CrossRef]

- Lee, T.S.; Lee, N.J.; Abbas, H.; Lee, H.H.; Yoon, T.S.; Kang, C.J. Compliance current-controlled conducting filament formation in tantalum oxide-based RRAM devices with different top electrodes. ACS Appl. Electron. Mater. 2020, 2, 1154–1161. [Google Scholar] [CrossRef]

- Carta, D.; Salaoru, I.; Khiat, A.; Regoutz, A.; Mitterbauer, C.; Harrison, N.M.; Prodromakis, T. Investigation of the switching mechanism in TiO2-based RRAM: A two-dimensional EDX approach. ACS Appl. Mater. Interfaces 2016, 8, 19605–19611. [Google Scholar] [CrossRef]

- Kim, M.; Wang, Y.; Kim, D.E.; Shao, Q.; Lee, H.S.; Park, H.H. Resistive switching properties for fluorine doped titania fabricated using atomic layer deposition. APL Mater. 2022, 10, 031105. [Google Scholar] [CrossRef]

- Swathi, S.P.; Angappane, S. Low power multilevel resistive switching in titanium oxide-based RRAM devices by interface engineering. J. Sci. Adv. Mater. Devices 2021, 6, 601–610. [Google Scholar] [CrossRef]

- Dias, C.; Ventura, J. Understanding the Influence of Metal Oxide Layer Thickness and Defects on Resistive Switching Behavior Through Numerical Modeling. Phys. Status Solidi 2023, 220, 2200730. [Google Scholar] [CrossRef]

- Lee, J.; Yang, K.; Kwon, J.Y.; Kim, J.E.; Han, D.I.; Lee, D.H.; Yoon, J.H.; Park, M.H. Role of oxygen vacancies in ferroelectric or resistive switching hafnium oxide. Nano Converg. 2023, 10, 55. [Google Scholar] [CrossRef]

- Wan, W.; Kubendran, R.; Schaefer, C.; Eryilmaz, S.B.; Zhang, W.; Wu, D.; Deiss, S.; Raina, P.; Qian, H.; Gao, B.; et al. A compute-in-memory chip based on resistive random-access memory. Nature 2022, 608, 504–512. [Google Scholar] [CrossRef] [PubMed]

- Hadke, S.; Kang, M.-A.; Sangwan, V.K.; Hersam, M.C. Two-Dimensional Materials for Brain-Inspired Computing Hardware. Chem. Rev. 2025, 125, 835–932. [Google Scholar] [CrossRef]

- Li, M.; Liu, H.; Zhao, R.; Yang, F.-S.; Chen, M.; Zhuo, Y.; Zhou, C.; Wang, H.; Lin, Y.-F.; Yang, J.J. Imperfection-enabled memristive switching in van der Waals materials. Nat. Electron. 2023, 6, 491–505. [Google Scholar] [CrossRef]

- Li, X.D.; Chen, N.K.; Wang, B.Q.; Niu, M.; Xu, M.; Miao, X.; Li, X.B. Resistive memory devices at the thinnest limit: Progress and challenges. Adv. Mater. 2024, 36, 2307951. [Google Scholar] [CrossRef]

- De Castro, I.A.; Datta, R.S.; Ou, J.Z.; Castellanos-Gomez, A.; Sriram, S.; Daeneke, T.; Kalantar-zadeh, K. Molybdenum oxides-from fundamentals to functionality. Adv. Mater. 2017, 29, 1701619. [Google Scholar] [CrossRef]

- Minakshi, M.; Mitchell, D.R.G.; Baur, C.; Chable, J.; Barlow, A.J.; Fichtner, M.; Banerjee, A.; Chakraborty, S.; Ahuja, R. Phase evolution in calcium molybdate nanoparticles as a function of synthesis temperature and its electrochemical effect on energy storage. Nanoscale Adv. 2019, 1, 565–580. [Google Scholar] [CrossRef]

- Minakshi, M.; Mitchell, D.R.G.; Munnangi, A.R.; Barlow, A.J.; Fichtner, M. New insights into the electrochemistry of magnesium molybdate hierarchical architectures for high performance sodium devices. Nanoscale 2018, 10, 13277–13288. [Google Scholar] [CrossRef]

- Li, T.; Jiang, W.; Wu, Y.; Zhou, L.; Ye, H.; Geng, Y.; Hu, M.; Liu, K.; Wang, R.; Sun, Y. Controlled fabrication of metallic MoO2 nanosheets towards high-performance p-type 2D transistors. Small 2024, 20, 2403118. [Google Scholar] [CrossRef]

- Holler, B.A.; Crowley, K.; Berger, M.H.; Gao, X.P. 2D semiconductor transistors with van der Waals oxide MoO3 as integrated high-κ gate dielectric. Adv. Electron. Mater. 2020, 6, 2000635. [Google Scholar] [CrossRef]

- Gong, Y.; Zhao, Y.; Zhou, Z.; Li, D.; Mao, H.; Bao, Q.; Zhang, Y.; Wang, G.P. Polarized Raman scattering of in-plane anisotropic phonon modes in α-MoO3. Adv. Opt. Mater. 2022, 10, 2200038. [Google Scholar] [CrossRef]

- Zhu, Y.; Murali, S.; Cai, W.; Li, X.; Suk, J.W.; Potts, J.R.; Ruoff, R.S. Graphene and graphene oxide: Synthesis, properties, and applications. Adv. Mater. 2010, 22, 3906–3924. [Google Scholar] [CrossRef] [PubMed]

- Tao, Q.; Wu, R.; Li, Q.; Kong, L.; Chen, Y.; Jiang, J.; Lu, Z.; Li, B.; Li, W.; Li, Z.; et al. Reconfigurable electronics by disassembling and reassembling van der Waals heterostructures. Nat. Commun. 2021, 12, 1825. [Google Scholar] [CrossRef]

- Li, Y.; Xiong, Y.; Zhang, X.; Yin, L.; Yu, Y.; Wang, H.; Liao, L.; He, J. Memristors with analogue switching and high on/off ratios using a van der Waals metallic cathode. Nat. Electron. 2025, 8, 36–45. [Google Scholar] [CrossRef]

- Dong, X.; Sun, H.; Lai, X.; Yang, F.; Ma, T.; Zhang, X.; Chen, J.; Zhao, Y.; Chen, J.; Zhang, X.; et al. MoOx synaptic memristor with programmable multilevel conductance for reliable neuromorphic hardware. J. Phys. Chem. Lett. 2024, 15, 3668–3676. [Google Scholar] [CrossRef]

- Zhao, J.; Zheng, S.; Zhou, L.; Mi, W.; Ding, Y.; Wang, M. An artificial optoelectronic synapse based on MoOx film. Nanotechnology 2023, 34, 145201. [Google Scholar] [CrossRef]

- Arita, M.; Ohno, Y.; Murakami, Y.; Takamizawa, K.; Tsurumaki-Fukuchi, A.; Takahashi, Y. Microstructural transitions in resistive random access memory composed of molybdenum oxide with copper during switching cycles. Nanoscale 2016, 8, 14754–14766. [Google Scholar] [CrossRef] [PubMed]

- Rahman, F.; Ahmed, T.; Walia, S.; Mayes, E.; Sriram, S.; Bhaskaran, M.; Balendhran, S. Reversible resistive switching behaviour in CVD grown, large area MoOx. Nanoscale 2018, 10, 19711–19719. [Google Scholar] [CrossRef]

- Yang, C.S.; Shang, D.S.; Chai, Y.S.; Yan, L.Q.; Shen, B.G.; Sun, Y. Moisture effects on the electrochemical reaction and resistance switching at Ag/molybdenum oxide interfaces. Phys. Chem. Chem. Phys. 2016, 18, 12466–12475. [Google Scholar] [CrossRef]

- Zhao, X.; Fan, Z.; Xu, H.; Wang, Z.; Xu, J.; Ma, J.; Liu, Y. Reversible alternation between bipolar and unipolar resistive switching in Ag/MoS2/Au structure for multilevel flexible memory. J. Mater. Chem. C 2018, 6, 7195–7200. [Google Scholar] [CrossRef]

- Yang, S.J.; Liang, L.; Lee, Y.; Gu, Y.; Fatheema, J.; Kutagulla, S.; Kim, D.; Kim, M.; Kim, S.; Akinwande, D. Volatile and nonvolatile resistive switching coexistence in conductive point hexagonal boron nitride monolayer. ACS Nano 2024, 18, 3313–3322. [Google Scholar] [CrossRef]

- Kumar, M.; Ban, D.K.; Kim, S.M.; Kim, J.; Wong, C.P. Vertically aligned WS2 layers for high-performing memristors and artificial synapses. Adv. Electron. Mater. 2019, 5, 1900467. [Google Scholar] [CrossRef]

- Chaudhary, M.; Yang, T.Y.; Chen, C.T.; Lai, P.C.; Hsu, Y.C.; Peng, Y.R.; Kumar, A.; Lee, C.H.; Chueh, Y.L. Emulating neuromorphic and in-memory computing utilizing defect engineering in 2D-layered WSeOx and WSe2 thin films by plasma-assisted selenization process. Adv. Funct. Mater. 2023, 33, 2303697. [Google Scholar] [CrossRef]

- Rao, A.; Sanjay, S.; Dey, V.; Ahmadi, M.; Yadav, P.; Venugopalrao, A.; Bhat, N.; Kooi, B.; Raghavan, S.; Nukala, P. Realizing avalanche criticality in neuromorphic networks on a 2D hBN platform. Mater. Horiz. 2023, 10, 5235–5245. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, C.; Li, E.; Gao, C.; Wang, R.; Liu, Y.; Liu, F.; Shi, W.; Yuan, Y.; Sun, J.; et al. Ultralow Off-state current and multilevel resistance state in van der Waals heterostructure memristors. Adv. Funct. Mater. 2024, 34, 2309642. [Google Scholar] [CrossRef]

- Yin, L.; Cheng, R.; Wang, Z.; Wang, F.; Sendeku, M.G.; Wen, Y.; Zhan, X.; He, J. Two-dimensional unipolar memristors with logic and memory functions. Nano Lett. 2020, 20, 4144–4152. [Google Scholar] [CrossRef]

- Mao, J.Y.; Wu, S.; Ding, G.; Wang, Z.P.; Qian, F.S.; Yang, J.Q.; Zhou, Y.; Han, S.T. A van der Waals integrated damage-free memristor based on layered 2d hexagonal boron nitride. Small 2022, 18, 2106253. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, H.; Cheng, S.; Guo, F.; Jie, W.; Hao, J. Tunable resistive switching in 2D MXene Ti3C2 nanosheets for non-volatile memory and neuromorphic computing. ACS Appl. Mater. Interfaces 2022, 14, 44614–44621. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, K.; Jiang, W.; Zhou, L.; Zhou, Y.; Hu, M.; Geng, Y.; Zhang, Y.; Qiao, Y.; Wang, R.; Sun, Y. Multi-Bit Resistive Random-Access Memory Based on Two-Dimensional MoO3 Layers. Nanomaterials 2025, 15, 1033. https://doi.org/10.3390/nano15131033

Liu K, Jiang W, Zhou L, Zhou Y, Hu M, Geng Y, Zhang Y, Qiao Y, Wang R, Sun Y. Multi-Bit Resistive Random-Access Memory Based on Two-Dimensional MoO3 Layers. Nanomaterials. 2025; 15(13):1033. https://doi.org/10.3390/nano15131033

Chicago/Turabian StyleLiu, Kai, Wengui Jiang, Liang Zhou, Yinkang Zhou, Minghui Hu, Yuchen Geng, Yiyuan Zhang, Yi Qiao, Rongming Wang, and Yinghui Sun. 2025. "Multi-Bit Resistive Random-Access Memory Based on Two-Dimensional MoO3 Layers" Nanomaterials 15, no. 13: 1033. https://doi.org/10.3390/nano15131033

APA StyleLiu, K., Jiang, W., Zhou, L., Zhou, Y., Hu, M., Geng, Y., Zhang, Y., Qiao, Y., Wang, R., & Sun, Y. (2025). Multi-Bit Resistive Random-Access Memory Based on Two-Dimensional MoO3 Layers. Nanomaterials, 15(13), 1033. https://doi.org/10.3390/nano15131033