Study on Regulation Mechanism of Heat Transport at Aluminum Nitride/Graphene/Silicon Carbide Heterogeneous Interface

Abstract

1. Introduction

2. Materials and Methods

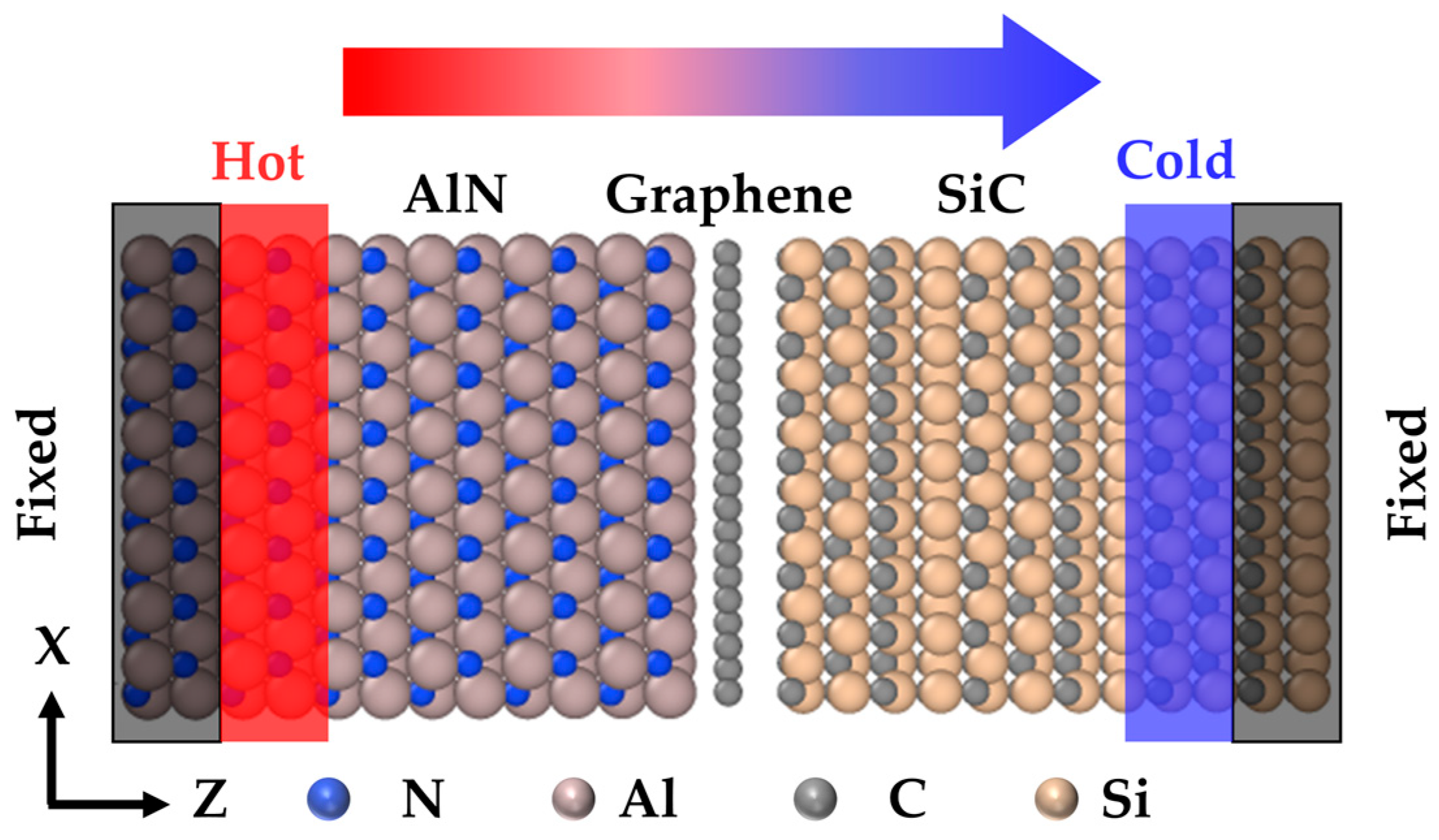

2.1. Modeling

2.2. Simulation Process

3. Results

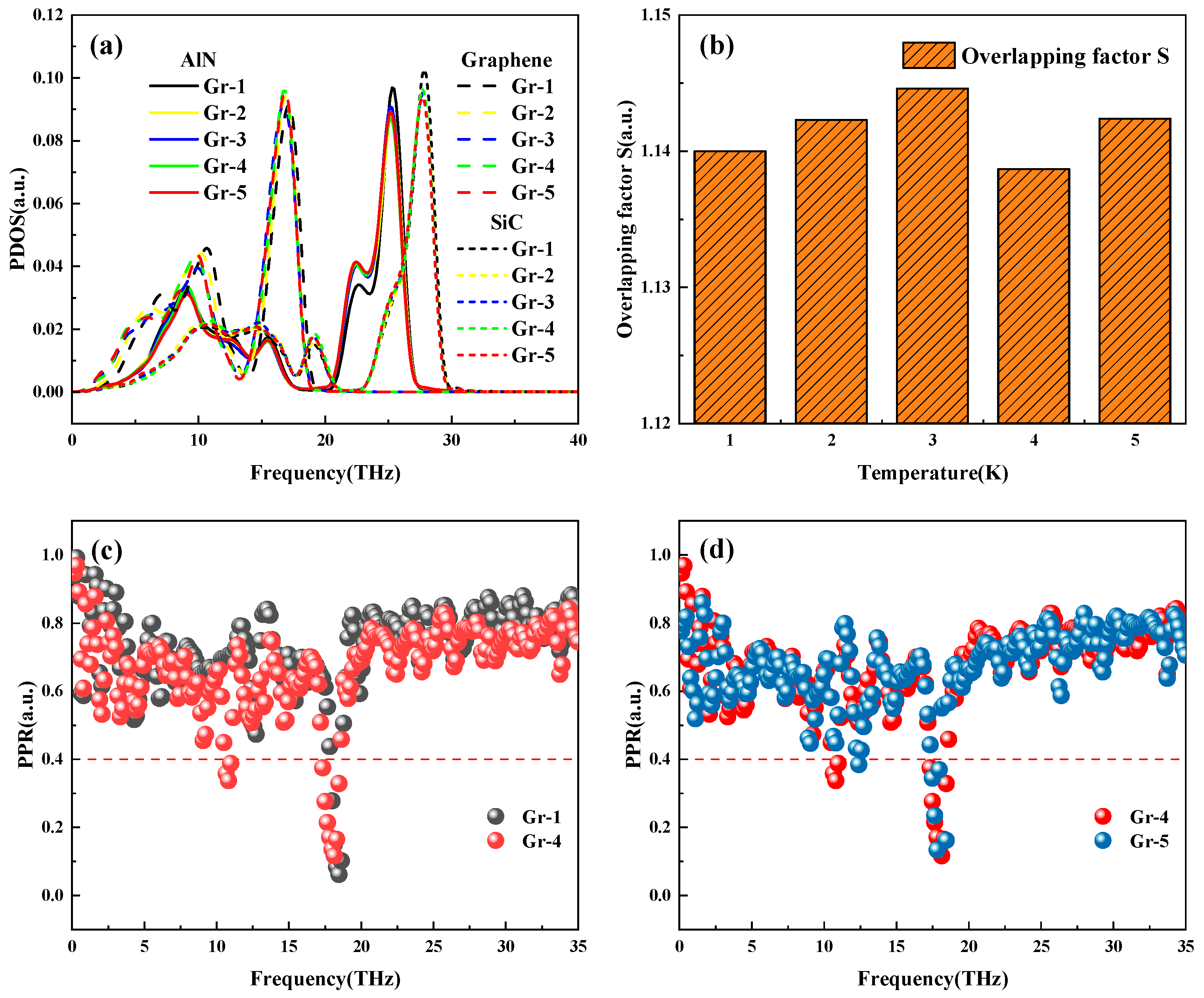

3.1. Temperature Effects

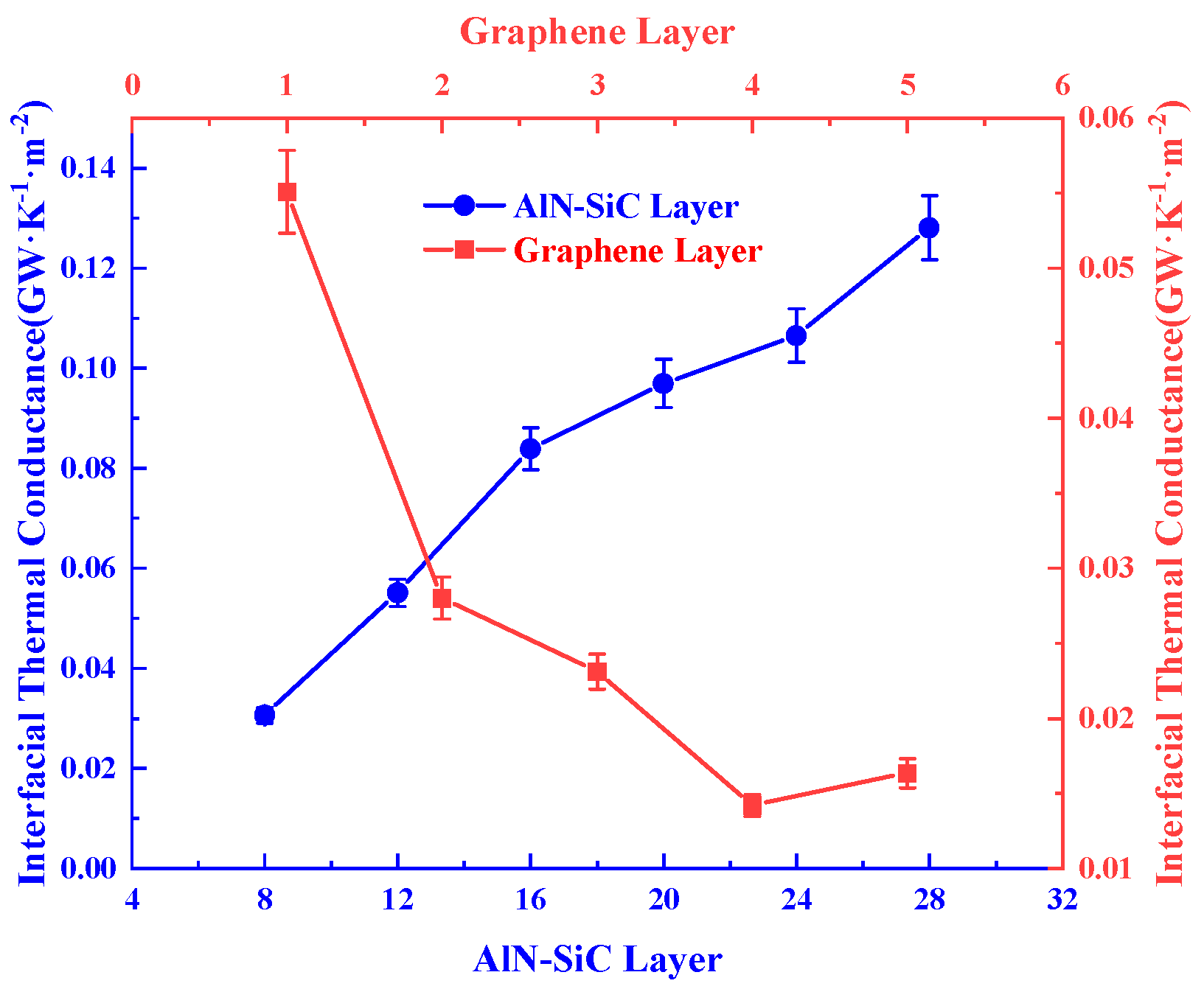

3.2. Dimensional Effects

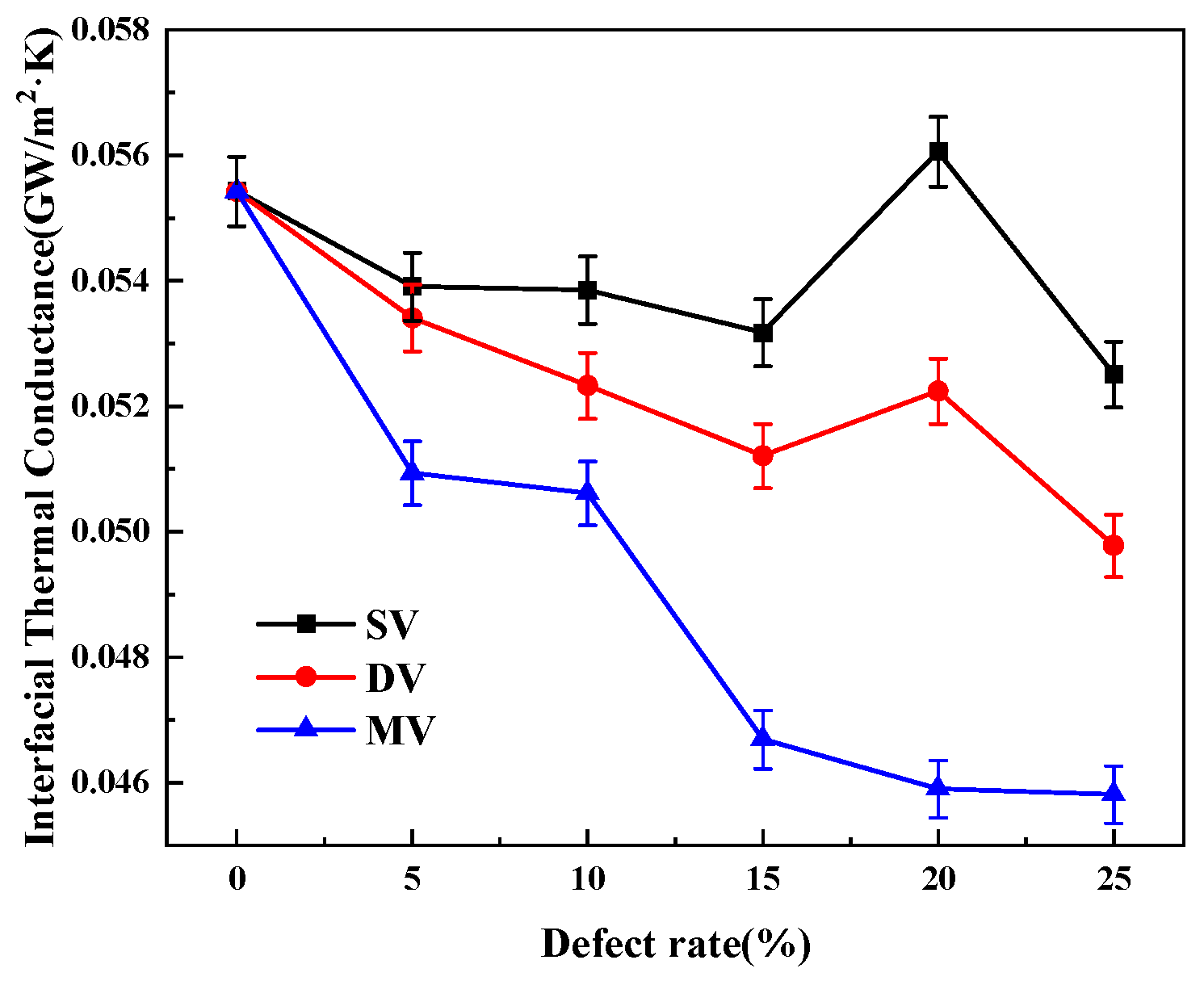

3.3. Impact of Defects

4. Conclusions

- The significant increase in ITC with increasing temperature is attributed to the fact that more phonons are excited at high temperatures, which enhances the interfacial phonon coupling and improves the thermal transport capacity, and the interfacial thermal conductance increases with the coupling strength factor.

- The size of the heterostructure has an essential effect on the ITC; the increase in the number of AlN/SiC layers increases the interfacial thermal conductance, which is due to the rise in the number of layers effectively reducing the interfacial scattering and improving the phonon transport efficiency across the interface. In contrast, the increase in the number of graphene layers exacerbates the localization effect of the phonons, resulting in a continuous decrease in the ITC up to 4 layers. The increase in the ITC at 5 layers is due to the transition of the phonons from localized to the delocalized mode, increasing the heat transfer phonons.

- Structural defects in graphene usually weaken the interfacial thermal conductivity. Still, when the single vacancy defect rate reaches 20%, there may be a localized rebound in ITC, which may be related to the optimization of phonon mode matching at a specific defect concentration. The most important reason for this condition in the double vacancy defect concentration is the transition of the phonons from the localized to the delocalized state at this concentration of defects, which makes the heat-transferring phonon increase, and consequently, the ITC is enlarged.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Moore, A.L.; Shi, L. Emerging challenges and materials for thermal management of electronics. Mater. Today 2014, 17, 163–174. [Google Scholar] [CrossRef]

- Sun, Z.; Yu, H.; Feng, Y.; Feng, W. Application and Development of Smart Thermally Conductive Fiber Materials. Nanomaterials 2024, 14, 154. [Google Scholar] [CrossRef] [PubMed]

- Olabi, A.G.; Maghrabie, H.M.; Adhari, O.H.K.; Sayed, E.T.; Yousef, B.A.; Salameh, T.; Kamil, M.; Abdelkareem, M.A. Battery Thermal Management Systems: Recent Progress and Challenges. Int. J. Thermofluids 2022, 15, 100171. [Google Scholar] [CrossRef]

- Lin, H.; Jian, Q.; Bai, X.; Li, D.; Huang, Z.; Huang, W.; Feng, S.; Cheng, Z. Recent advances in thermal conductivity and thermal applications of graphene and its derivatives nanofluids. Appl. Therm. Eng. 2023, 218, 119176. [Google Scholar] [CrossRef]

- Geim, A.K.; Novoselov, K.S. The rise of graphene. Nat. Mater. 2007, 6, 183–191. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Fal′Ko, V.I.; Colombo, L.; Gellert, P.R.; Schwab, M.G.; Kim, K. A roadmap for graphene. Nature 2012, 490, 192–200. [Google Scholar] [CrossRef] [PubMed]

- Liu, D. Investigation on thermal conductivity of graphene/Si heterostructure with different defect ratios and sizes. Phys. Lett. A 2020, 384, 126077. [Google Scholar] [CrossRef]

- Lin, C.; Rao, Z. Thermal conductivity enhancement of paraffin by adding boron nitride nanostructures: A molecular dynamics study. Appl. Therm. Eng. 2017, 110, 1411–1419. [Google Scholar] [CrossRef]

- Wang, Z.; Bi, K.; Guan, H.; Wang, J. Thermal Transport between Graphene Sheets and SiC Substrate by Molecular-Dynamical Calculation. J. Mater. 2014, 2014, 479808. [Google Scholar] [CrossRef]

- Li, R.; Hussain, K.; Liao, M.E.; Huynh, K.; Bin Hoque, S.; Wyant, S.; Koh, Y.R.; Xu, Z.; Wang, Y.; Luccioni, D.P.; et al. Enhanced thermal boundary conductance across GaN/SiC interfaces with AlN transition layers. ACS Appl. Mater. Interfaces 2024, 16, 8109–8118. [Google Scholar] [CrossRef]

- Yang, B.; Tang, Y.; Xin, Z.; Zheng, H.; Qi, D.; Zhang, N.; Tang, Y.; Wu, X. Modulation of the interfacial thermal resistances of the w-AlN/Graphene/3C-SiC interface by nanoscale nonplanar feature structures. Appl. Surf. Sci. 2024, 659, 159905. [Google Scholar] [CrossRef]

- Hu, M.; Poulikakos, D. Graphene mediated thermal resistance reduction at strongly coupled interfaces. Int. J. Heat Mass Transf. 2013, 62, 205–213. [Google Scholar] [CrossRef]

- Yang, B.; Yang, H.; Li, T.; Yang, J.; Yang, P. Thermal transport at 6H-SiC/graphene buffer layer/GaN heterogeneous interface. Appl. Surf. Sci. 2021, 536, 147828. [Google Scholar] [CrossRef]

- Tao, L.; Theruvakkattil Sreenivasan, S.; Shahsavari, R. Interlaced, nanostructured interface with graphene buffer layer reduces thermal boundary resistance in nano/microelectronic systems. ACS Appl. Mater. Interfaces 2017, 9, 989–998. [Google Scholar] [CrossRef]

- Yang, B.; Wang, J.; Yang, Z.; Xin, Z.; Zhang, N.; Zheng, H.; Wu, X. Thermal transport mechanism of AlN/SiG/3C-SiC typical heterostructures. Mater. Today Phys. 2023, 30, 100948. [Google Scholar] [CrossRef]

- Yang, B.; Peng, C.; Song, M.; Tang, Y.; Wu, Y.; Wu, X.; Zheng, H. Thermal Transport of AlN/Graphene/3C-SiC Typical Heterostructures with Different Crystallinities of Graphene. ACS Appl. Mater. Interfaces 2022, 15, 2384–2395. [Google Scholar] [CrossRef]

- Tian, S.; Wu, T.; Hu, S.; Ma, D.; Zhang, L. Boosting phonon transport across AlN/SiC interface by fast annealing amorphous layers. Appl. Phys. Lett. 2024, 124, 042202. [Google Scholar] [CrossRef]

- Al Balushi, Z.Y.; Miyagi, T.; Lin, Y.C.; Wang, K.; Calderin, L.; Bhimanapati, G.; Redwing, J.M.; Robinson, J.A. The impact of graphene properties on GaN and AlN nucleation. Surf. Sci. 2015, 634, 81–88. [Google Scholar] [CrossRef]

- Xu, Y.; Cao, B.; Li, Z.; Cai, D.; Zhang, Y.; Ren, G.; Wang, J.; Shi, L.; Wang, C.; Xu, K. Growth model of van der Waals epitaxy of films: A case of AlN films on multilayer graphene/SiC. ACS Appl. Mater. Interfaces 2017, 9, 44001–44009. [Google Scholar] [CrossRef]

- Bao, W.; Wang, Z.; Hu, B.; Tang, D. Thermal transport across graphene/GaN and MoS2/GaN interfaces. Int. J. Heat Mass Transf. 2023, 201, 123569. [Google Scholar] [CrossRef]

- Bao, W.; Wang, Z.; Tang, D. Phonon transport across GaN/AlN interface: Interfacial phonon modes and phonon local non-equilibrium analysis. Int. J. Heat Mass Transf. 2022, 183, 122090. [Google Scholar] [CrossRef]

- Wang, J.; Shen, Y.; Yang, P. Multilayered Graphene/ZnO heterostructure interfaces to improve thermal transfer. Compos. Commun. 2023, 40, 101616. [Google Scholar] [CrossRef]

- Freitas, R.; Asta, M.; De Koning, M. Nonequilibrium free-energy calculation of solids using LAMMPS. Comput. Mater. Sci. 2016, 112, 333–341. [Google Scholar] [CrossRef]

- Stukowski, A. Visualization and analysis of atomistic simulation data with OVITO-the Open Visualization Tool. Model. Simul. Mater. Sci. Eng. 2009, 18, 015012. [Google Scholar] [CrossRef]

- Tungare, M.; Shi, Y.; Tripathi, N.; Suvarna, P.; Shahedipour-Sandvik, F. A Tersoff-based interatomic potential for wurtzite AlN. Phys. Status Solidi (A) 2011, 208, 1569–1572. [Google Scholar] [CrossRef]

- Erhart, P.; Albe, K. Analytical potential for atomistic simulations of silicon, carbon, and silicon carbide. Phys. Rev. B-Condens. Matter Mater. Phys. 2005, 71, 035211. [Google Scholar] [CrossRef]

- Stuart, S.J.; Tutein, A.B.; Harrison, J.A. A reactive potential for hydrocarbons with intermolecular interactions. J. Chem. Phys. 2000, 112, 6472–6486. [Google Scholar] [CrossRef]

- Liu, D.-J.; Hu, Z.-L.; Zhou, F.; Wang, P.-B.; Wang, Z.-D.; Li, T. Interfacial thermal conductance of gallium nitride/graphene/diamond heterostructure based on molecular dynamics simulation. Acta Phys. Sin. 2024, 73, 150202. [Google Scholar] [CrossRef]

- Hu, M.; Poulikakos, D. Si/Ge Superlattice Nanowires with Ultralow Thermal Conductivity. Nano Lett. 2012, 12, 5487–5494. [Google Scholar] [CrossRef]

- Liu, D.-J.; Wang, S.-M.; Yang, P. Thermal property of graphene/silicon carbide heterostructure by molecular dynamics simulation. Acta Phys. Sin. 2021, 70, 187302. [Google Scholar] [CrossRef]

- Farago, O. Langevin thermostat for robust configurational and kinetic sampling. Phys. A: Stat. Mech. Its Appl. 2019, 534, 122210. [Google Scholar] [CrossRef]

- Khosravian, N.; Samani, M.K.; Loh, G.C.; Chen, G.C.K.; Baillargeat, D.; Tay, B.K. Molecular dynamic simulation of diamond/silicon interfacial thermal conductance. J. Appl. Phys. 2013, 113, 024907. [Google Scholar] [CrossRef]

- Yang, Y.; Ma, J.; Yang, J.; Zhang, Y. Molecular dynamics simulation on in-plane thermal conductivity of graphene/hexagonal boron nitride van der Waals heterostructures. ACS Appl. Mater. Interfaces 2022, 14, 45742–45751. [Google Scholar] [CrossRef]

- Liang, T.; Zhou, M.; Zhang, P.; Yuan, P.; Yang, D. Multilayer in-plane graphene/hexagonal boron nitride heterostructures: Insights into the interfacial thermal transport properties. Int. J. Heat Mass Transf. 2020, 151, 119395. [Google Scholar] [CrossRef]

- Guo, Y.; Bescond, M.; Zhang, Z.; Xiong, S.; Hirakawa, K.; Nomura, M.; Volz, S. Thermal conductivity minimum of graded superlattices due to phonon localization. APL Mater. 2021; 9, 091104. [Google Scholar]

- Liu, Y.; Qiu, L.; Liu, J.; Feng, Y. Enhancing thermal transport across diamond/graphene heterostructure interface. Int. J. Heat Mass Transf. 2023, 209, 124123. [Google Scholar] [CrossRef]

- Yin, K.; Shi, L.; Ma, X.; Zhong, Y.; Li, M.; He, X. Thermal Conductivity of 3C/4H-SiC Nanowires by Molecular Dynamics Simulation. Nanomaterials 2023, 13, 2196. [Google Scholar] [CrossRef]

- Wu, S.; Wang, J.; Xie, H.; Guo, Z. Interfacial thermal conductance across graphene/MoS2 van der Waals heterostructures. Energies 2020, 13, 5851. [Google Scholar] [CrossRef]

- Hong, Y.; Zhang, J.; Zeng, X.C. Interlayer thermal conductance within a phosphorene and graphene bilayer. Nanoscale 2016, 8, 19211–19218. [Google Scholar] [CrossRef]

- Wei, N.; Zhou, C.; Li, Z.; Ou, B.; Zhao, K.; Yu, P.; Li, S.; Zhao, J. Thermal conductivity of Aluminum/Graphene metal-matrix composites: From the thermal boundary conductance to thermal regulation. Mater. Today Commun. 2022, 30, 103147. [Google Scholar] [CrossRef]

- Hoque, M.S.B.; Koh, Y.R.; Zare, S.; Liao, M.E.; Huynh, K.; Goorsky, M.S.; Liu, Z.; Shi, J.; Graham, S.; Luo, T.; et al. Experimental observation of ballistic to diffusive transition in phonon thermal transport of AlN thin films. Appl. Phys. Lett. 2024, 125. [Google Scholar]

- Watari, K.; Ishizaki, K.; Tsuchiya, F. Phonon scattering and thermal conduction mechanisms of sintered aluminum nitride ceramics. J. Mater. Sci. 1993, 28, 3709–3714. [Google Scholar] [CrossRef]

- Xu, R.L.; Muñoz Rojo, M.; Islam, S.M.; Sood, A.; Vareskic, B.; Katre, A.; Mingo, N.; Goodson, K.E.; Xing, H.G.; Jena, D.; et al. Thermal conductivity of crystalline AlN and the influence of atomic-scale defects. J. Appl. Phys. 2019, 126. [Google Scholar] [CrossRef]

- Ghosh, S.; Bao, W.; Nika, D.L.; Subrina, S.; Pokatilov, E.P.; Lau, C.N.; Balandin, A.A. Dimensional crossover of thermal transport in few-layer graphene. Nat. Mater. 2010, 9, 555–558. [Google Scholar] [CrossRef]

- Yuan, X.; Li, D.; Yang, B.; Gao, W.; Ge, D.; Yang, P. Thermal transport of graphene and graphene nanoribbon: A summary review. Int. J. Mater. Struct. Integr. 2017, 11, 193–204. [Google Scholar] [CrossRef]

- Khan, A.I.; Paul, R.; Subrina, S. Thermal transport in graphene/stanene hetero-bilayer nanostructures with vacancies: An equilibrium molecular dynamics study. RSC Adv. 2017, 7, 44780–44787. [Google Scholar] [CrossRef]

- Liu, X.; Gao, J.; Zhang, G.; Zhang, Y.W. Design of phosphorene/graphene heterojunctions for high and tunable interfacial thermal conductance. Nanoscale 2018, 10, 19854–19862. [Google Scholar] [CrossRef]

| Orientations | Aluminum Nitride | Graphene | Silicon Carbide | |||

|---|---|---|---|---|---|---|

| Original Cell Parameters (Å) | Enlargement Factor | Original Cell Parameters (Å) | Enlargement Factor | Original Cell Parameters (Å) | Enlargement Factor | |

| X | 5.419 | 7 | 4.260 | 9 | 5.330 | 7 |

| Y | 3.129 | 8 | 2.460 | 10 | 3.070 | 8 |

| Z | 2.508 | 6 | - | - | 2.512 | 6 |

| Parameters | ε (eV) | σ (Å) |

|---|---|---|

| Al-C | 0.030755 | 3.010 |

| Al-Si | 0.011300 | 3.118 |

| Si-N | 0.012705 | 3.375 |

| N-C | 0.003690 | 3.346 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, D.; Wang, P.; Hu, Z.; Fu, J.; Qin, W.; Yu, J.; Zhang, Y.; Yang, B.; Tang, Y. Study on Regulation Mechanism of Heat Transport at Aluminum Nitride/Graphene/Silicon Carbide Heterogeneous Interface. Nanomaterials 2025, 15, 928. https://doi.org/10.3390/nano15120928

Liu D, Wang P, Hu Z, Fu J, Qin W, Yu J, Zhang Y, Yang B, Tang Y. Study on Regulation Mechanism of Heat Transport at Aluminum Nitride/Graphene/Silicon Carbide Heterogeneous Interface. Nanomaterials. 2025; 15(12):928. https://doi.org/10.3390/nano15120928

Chicago/Turabian StyleLiu, Dongjing, Pengbo Wang, Zhiliang Hu, Jia Fu, Wei Qin, Jianbin Yu, Yangyang Zhang, Bing Yang, and Yunqing Tang. 2025. "Study on Regulation Mechanism of Heat Transport at Aluminum Nitride/Graphene/Silicon Carbide Heterogeneous Interface" Nanomaterials 15, no. 12: 928. https://doi.org/10.3390/nano15120928

APA StyleLiu, D., Wang, P., Hu, Z., Fu, J., Qin, W., Yu, J., Zhang, Y., Yang, B., & Tang, Y. (2025). Study on Regulation Mechanism of Heat Transport at Aluminum Nitride/Graphene/Silicon Carbide Heterogeneous Interface. Nanomaterials, 15(12), 928. https://doi.org/10.3390/nano15120928