Interfacial Charge Transfer Mechanism and Output Characteristics of Identical-Material Triboelectric Nanogenerators

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials of I-TENG

2.2. The Methods of I-TENG Electrical Property Measurement and Material Surface Potential Measurement

3. Results and Discussion

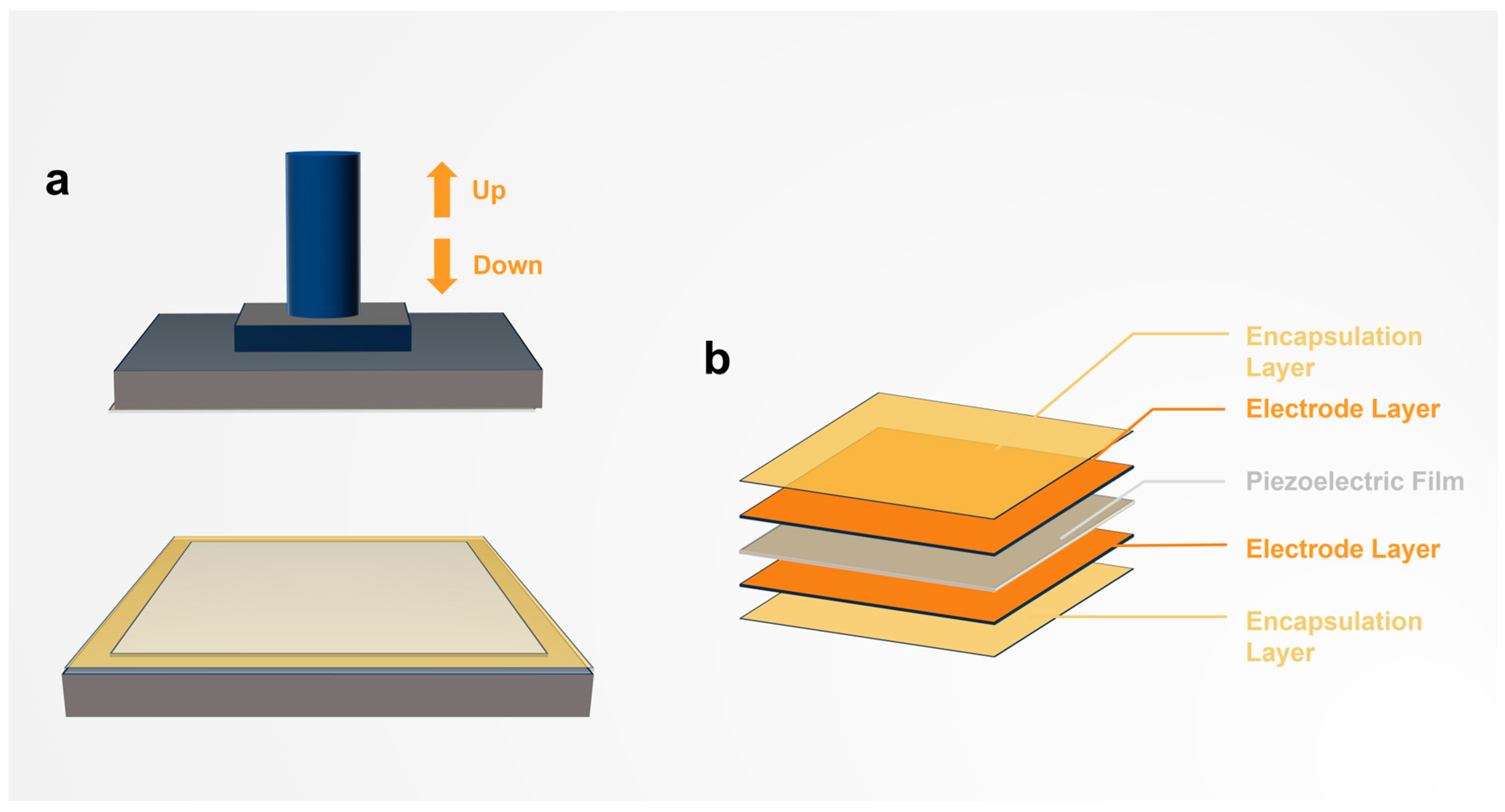

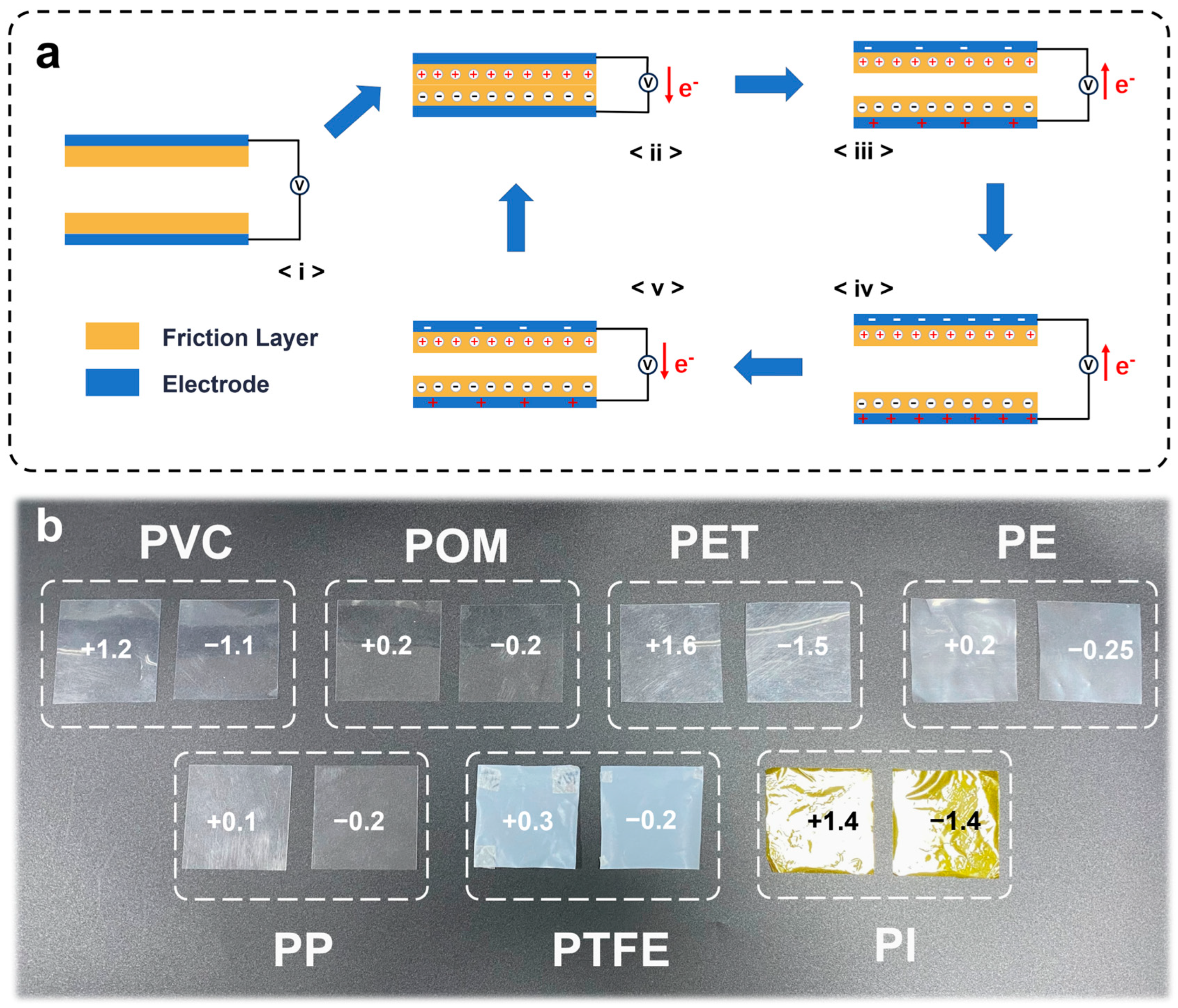

3.1. Self-Friction Effect of Identical Materials and Basic Principle of I-TENG

3.2. Study on Effect Mechanism of Self-Friction of Identical Materials

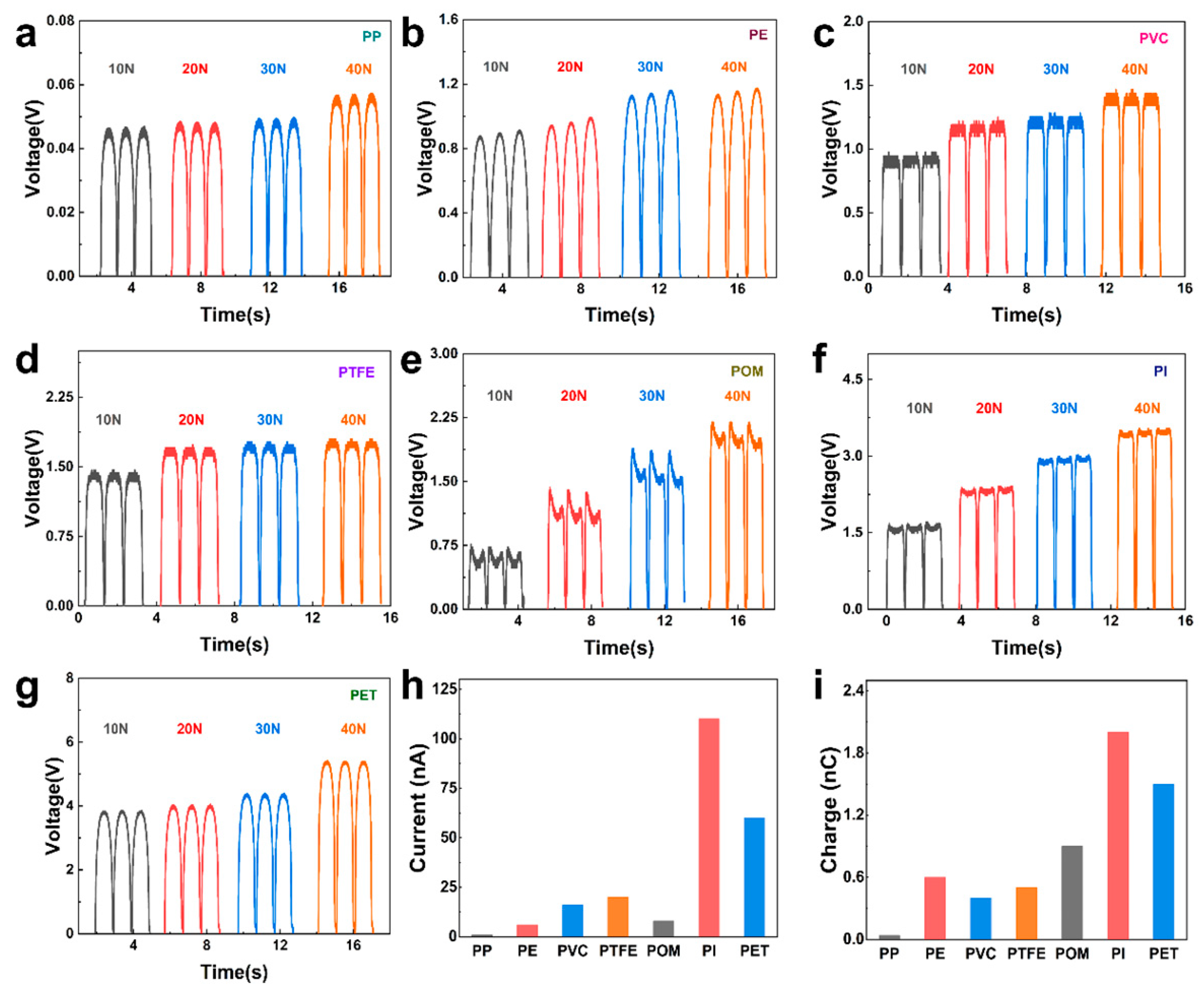

3.3. Output Properties of I-TENG for Different Polymer Materials

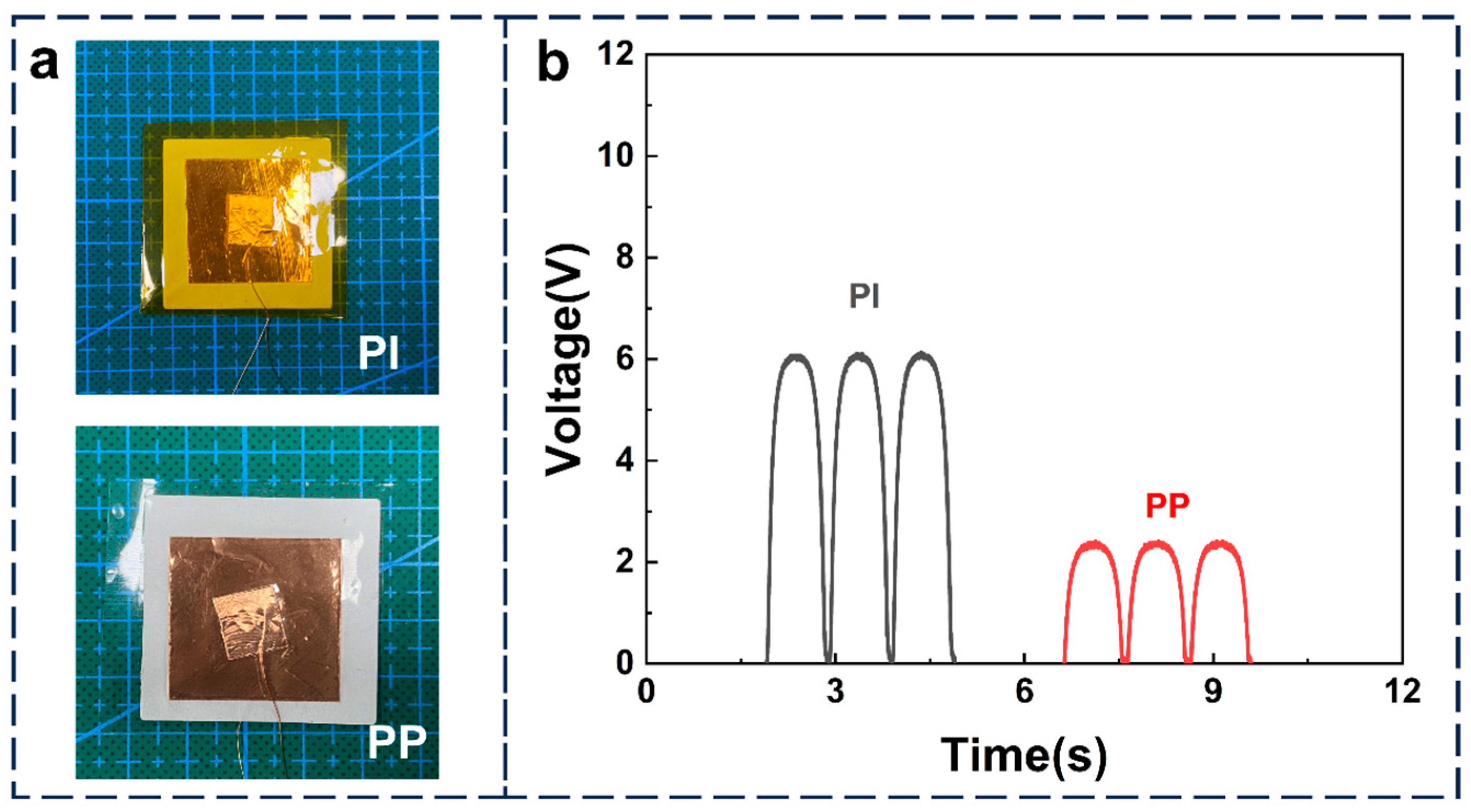

3.4. The Application of Polypropylene (PP) Materials in Piezoelectric Testing

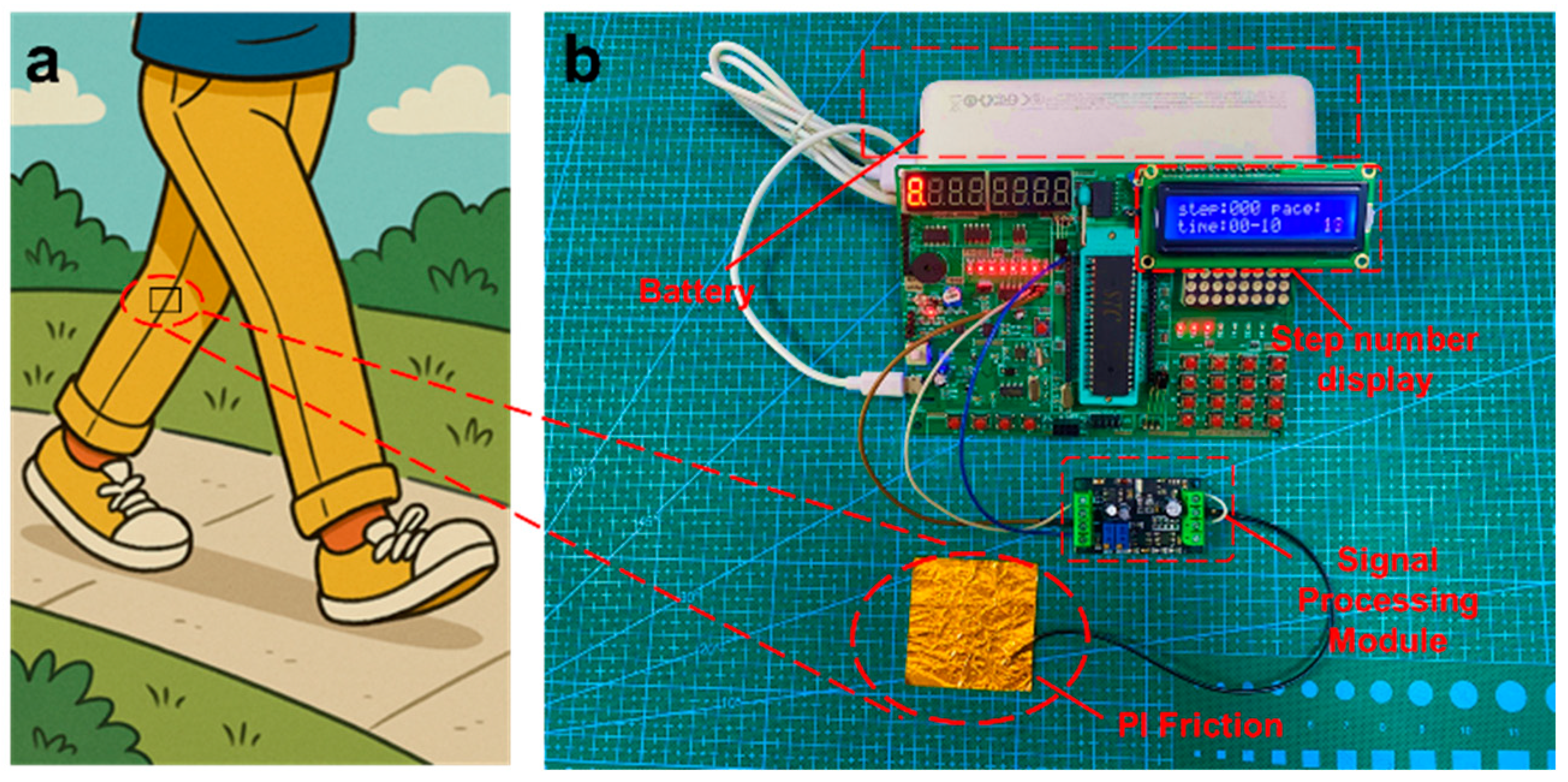

3.5. The Application of I-TENG in Self-Powered Stride Sensors

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Imani, I.M.; Kim, H.S.; Lee, M.; Kim, S.-B.; Song, S.-M.; Lee, D.-G.; Hwang, J.-H.; Lee, J.; Suh, I.-Y.; Kim, S.-W.; et al. A Body Conformal Ultrasound Receiver for Efficient and Stable Wireless Power Transfer in Deep Percutaneous Charging. Adv. Mater. 2025, 2419264. [Google Scholar] [CrossRef] [PubMed]

- Hao, Y.; Wen, J.; Gao, X.; Nan, D.; Pan, J.; Yang, Y.; Chen, B.; Wang, Z.L. Self-Rebound Cambered Triboelectric Nanogenerator Array for Self-Powered Sensing in Kinematic Analytics. ACS Nano 2022, 16, 1271–1279. [Google Scholar] [CrossRef]

- Lei, H.; Xiao, J.; Chen, Y.; Jiang, J.; Xu, R.; Wen, Z.; Dong, B.; Sun, X. Bamboo-inspired self-powered triboelectric sensor for touch sensing and sitting posture monitoring. Nano Energy 2022, 91, 106670. [Google Scholar] [CrossRef]

- Luo, J.; Wang, Z.; Xu, L.; Wang, A.C.; Han, K.; Jiang, T.; Lai, Q.; Bai, Y.; Tang, W.; Fan, F.R.; et al. Flexible and durable wood-based triboelectric nanogenerators for self-powered sensing in athletic big data analytics. Nat. Commun. 2019, 10, 5147. [Google Scholar] [CrossRef]

- Xiang, H.; Peng, L.; Yang, Q.; Wang, Z.L.; Cao, X. Triboelectric nanogenerator for high-entropy energy, self-powered sensors, and popular education. Sci. Adv. 2024, 10, eads2291. [Google Scholar] [CrossRef] [PubMed]

- Xu, W.; Huang, L.-B.; Wong, M.-C.; Chen, L.; Bai, G.; Hao, J. Self-Powered Sensors: Environmentally Friendly Hydrogel-Based Triboelectric Nanogenerators for Versatile Energy Harvesting and Self-Powered Sensors. Adv. Energy Mater. 2017, 7, 1601529. [Google Scholar] [CrossRef]

- Zhang, B.; Zhang, S.; Li, W.; Gao, Q.; Zhao, D.; Wang, Z.L.; Cheng, T. Self-Powered Sensing for Smart Agriculture by Electromagnetic–Triboelectric Hybrid Generator. ACS Nano 2021, 15, 20278–20286. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Liu, L.; Zhou, L.; Yin, X.; Wei, X.; Hu, Y.; Liu, Y.; Chen, S.; Wang, J.; Wang, Z.L. Self-Powered Sensor for Quantifying Ocean Surface Water Waves Based on Triboelectric Nanogenerator. ACS Nano 2020, 14, 7092–7100. [Google Scholar] [CrossRef]

- Zhang, W.; Chen, X.; Zhao, J.; Wang, X.; Li, X.; Liu, T.; Luo, B.; Qin, Y.; Zhang, S.; Chi, M.; et al. Cellulose template-based triboelectric nanogenerators for self-powered sensing at high humidity. Nano Energy 2023, 108, 108196. [Google Scholar] [CrossRef]

- Kavarthapu, V.S.; Paranjape, M.V.; Manchi, P.; Kurakula, A.; Lee, J.K.; Graham, S.A.; Yu, J.S. Wireless Alerts and Data Monitoring from BNNO-MWCNTs/PDMS Composite Film-Based TENG Integrated Inhaler for Smart Healthcare Application. Small 2024, 20, 2403218. [Google Scholar] [CrossRef]

- Manchi, P.; Paranjape, M.V.; Kurakula, A.; Graham, S.A.; Kavarthapu, V.S.; Yu, J.S. PDA-Ag/TiO2 Nanoparticles-Loaded Electrospun Nylon Composite Nanofibrous Film-Based Triboelectric Nanogenerators for Wearable Biomechanical Energy Harvesting and Multifunctional Sensors. Adv. Funct. Mater. 2025, 35, 2416018. [Google Scholar] [CrossRef]

- Kurakula, A.; Graham, S.A.; Paranjape, M.V.; Manchi, P.; Kavarthapu, V.S.; Yu, J.S. Multimodal Energy Generation and Intruder Sensing Platform via Aluminum Titanate/Poly-Glucosamine Composite Film-Based Hybrid Nanogenerators. Adv. Funct. Mater. 2024, 34, 2307462. [Google Scholar] [CrossRef]

- Manchi, P.; Graham, S.A.; Patnam, H.; Paranjape, M.V.; Yu, J.S. High-Efficiency Poly(Vinylidene Fluoride-Co-Hexafluoropropylene) Loaded 3D Marigold Flower-Like Bismuth Tungstate Triboelectric Films for Mechanical Energy Harvesting and Sensing Applications. Small 2022, 18, 2200822. [Google Scholar] [CrossRef]

- Paranjape, M.V.; Manchi, P.; Kurakula, A.; Kavarthapu, V.S.; Lee, J.K.; Graham, S.A.; Yu, J.S. Generalized utilization of energy harvesting ability of TENG for concurrent energy storage and motion sensing application with effective external circuitry. Nano Energy 2024, 129, 109983. [Google Scholar] [CrossRef]

- Manchi, P.; Graham, S.A.; Patnam, H.; Alluri, N.R.; Kim, S.-J.; Yu, J.S. LiTaO3-Based Flexible Piezoelectric Nanogenerators for Mechanical Energy Harvesting. ACS Appl. Mater. Interfaces 2021, 13, 46526–46536. [Google Scholar] [CrossRef]

- Li, X.; Zhang, D.; Zhang, D.; Li, Z.; Wu, H.; Zhou, Y.; Wang, B.; Guo, H.; Peng, Y. Solid-Liquid Triboelectric Nanogenerator Based on Vortex-Induced Resonance. Nanomaterials 2023, 13, 1036. [Google Scholar] [CrossRef]

- Liang, X.; Liu, S.; Lin, S.; Yang, H.; Jiang, T.; Wang, Z.L. Liquid–Solid Triboelectric Nanogenerator Arrays Based on Dynamic Electric-Double-Layer for Harvesting Water Wave Energy. Adv. Energy Mater. 2023, 13, 2300571. [Google Scholar] [CrossRef]

- Wang, D.; Zhang, D.; Tang, M.; Zhang, H.; Sun, T.; Yang, C.; Mao, R.; Li, K.; Wang, J. Ethylene chlorotrifluoroethylene/hydrogel-based liquid-solid triboelectric nanogenerator driven self-powered MXene-based sensor system for marine environmental monitoring. Nano Energy 2022, 100, 107509. [Google Scholar] [CrossRef]

- Wang, Y.; Guo, H.; Liao, J.; Qin, Y.; Ali, A.; Li, C. Solid-Liquid triboelectric nanogenerator based on curvature effect for harvesting mechanical and wave energy. Chem. Eng. J. 2023, 476, 146571. [Google Scholar] [CrossRef]

- Zhai, H.; Ding, S.; Chen, X.; Wu, Y.; Wang, Z.L. Advances in solid–solid contacting triboelectric nanogenerator for ocean energy harvesting. Mater. Today 2023, 65, 166–188. [Google Scholar] [CrossRef]

- Zhang, X.; Yu, M.; Ma, Z.; Ouyang, H.; Zou, Y.; Zhang, S.L.; Niu, H.; Pan, X.; Xu, M.; Li, Z.; et al. Self-Powered Distributed Water Level Sensors Based on Liquid–Solid Triboelectric Nanogenerators for Ship Draft Detecting. Adv. Funct. Mater. 2019, 29, 1900327. [Google Scholar] [CrossRef]

- Cheng, J.; Zhang, X.; Jia, T.; Wu, Q.; Dong, Y.; Wang, D. Triboelectric nanogenerator with a seesaw structure for harvesting ocean energy. Nano Energy 2022, 102, 107622. [Google Scholar] [CrossRef]

- Jung, H.; Ouro-Koura, H.; Salalila, A.; Salalila, M.; Deng, Z.D. Frequency-multiplied cylindrical triboelectric nanogenerator for harvesting low frequency wave energy to power ocean observation system. Nano Energy 2022, 99, 107365. [Google Scholar] [CrossRef]

- Kim, J.-S.; Kim, J.; Kim, J.-N.; Ahn, J.; Jeong, J.-H.; Park, I.; Kim, D.; Oh, I.-K. Collectively Exhaustive Hybrid Triboelectric Nanogenerator Based on Flow-Induced Impacting-Sliding Cylinder for Ocean Energy Harvesting. Adv. Energy Mater. 2022, 12, 2103076. [Google Scholar] [CrossRef]

- Liu, W.; Wang, X.; Yang, L.; Wang, Y.; Xu, H.; Sun, Y.; Nan, Y.; Sun, C.; Zhou, H.; Huang, Y. Swing Origami-Structure-Based Triboelectric Nanogenerator for Harvesting Blue Energy toward Marine Environmental Applications. Adv. Sci. 2024, 11, 2401578. [Google Scholar] [CrossRef]

- Pang, H.; Feng, Y.; An, J.; Chen, P.; Han, J.; Jiang, T.; Wang, Z.L. Segmented Swing-Structured Fur-Based Triboelectric Nanogenerator for Harvesting Blue Energy toward Marine Environmental Applications. Adv. Funct. Mater. 2021, 31, 2106398. [Google Scholar] [CrossRef]

- Zhang, C.; Yang, S.; Dai, X.; Tu, Y.; Du, Z.; Wu, X.; Huang, Y.; Fan, J.; Hong, Z.; Jiang, T.; et al. Hybridized triboelectric-electromagnetic nanogenerators for efficient harvesting of wave energy for self-powered ocean buoy. Nano Energy 2024, 128, 109929. [Google Scholar] [CrossRef]

- Zhao, C.; Liu, D.; Wang, Y.; Hu, Z.; Zhang, Q.; Zhang, Z.; Wang, H.; Du, T.; Zou, Y.; Yuan, H.; et al. Highly-stretchable rope-like triboelectric nanogenerator for self-powered monitoring in marine structures. Nano Energy 2022, 94, 106926. [Google Scholar] [CrossRef]

- Xu, C.; Zhang, B.; Wang, A.C.; Zou, H.; Liu, G.; Ding, W.; Wu, C.; Ma, M.; Feng, P.; Wang, Z.L.; et al. Contact-Electrification between Two Identical Materials: Curvature Effect. ACS Nano 2019, 13, 2034–2041. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, L.-X.; Ma, S.-J.; Li, M.-J.; Zhang, X.-L.; Zheng, G.; Liang, Z.; Li, R.; Dong, H.; Zhang, J.; Long, Y.-Z. Interfacial Charge Transfer Mechanism and Output Characteristics of Identical-Material Triboelectric Nanogenerators. Nanomaterials 2025, 15, 708. https://doi.org/10.3390/nano15100708

Wu L-X, Ma S-J, Li M-J, Zhang X-L, Zheng G, Liang Z, Li R, Dong H, Zhang J, Long Y-Z. Interfacial Charge Transfer Mechanism and Output Characteristics of Identical-Material Triboelectric Nanogenerators. Nanomaterials. 2025; 15(10):708. https://doi.org/10.3390/nano15100708

Chicago/Turabian StyleWu, Lin-Xin, Shi-Jia Ma, Meng-Jie Li, Xian-Lei Zhang, Gang Zheng, Zheng Liang, Ru Li, Hao Dong, Jun Zhang, and Yun-Ze Long. 2025. "Interfacial Charge Transfer Mechanism and Output Characteristics of Identical-Material Triboelectric Nanogenerators" Nanomaterials 15, no. 10: 708. https://doi.org/10.3390/nano15100708

APA StyleWu, L.-X., Ma, S.-J., Li, M.-J., Zhang, X.-L., Zheng, G., Liang, Z., Li, R., Dong, H., Zhang, J., & Long, Y.-Z. (2025). Interfacial Charge Transfer Mechanism and Output Characteristics of Identical-Material Triboelectric Nanogenerators. Nanomaterials, 15(10), 708. https://doi.org/10.3390/nano15100708