MXene-Based Chemo-Sensors and Other Sensing Devices

Abstract

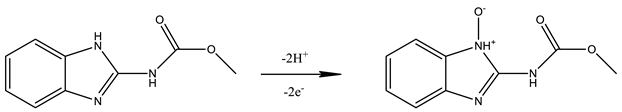

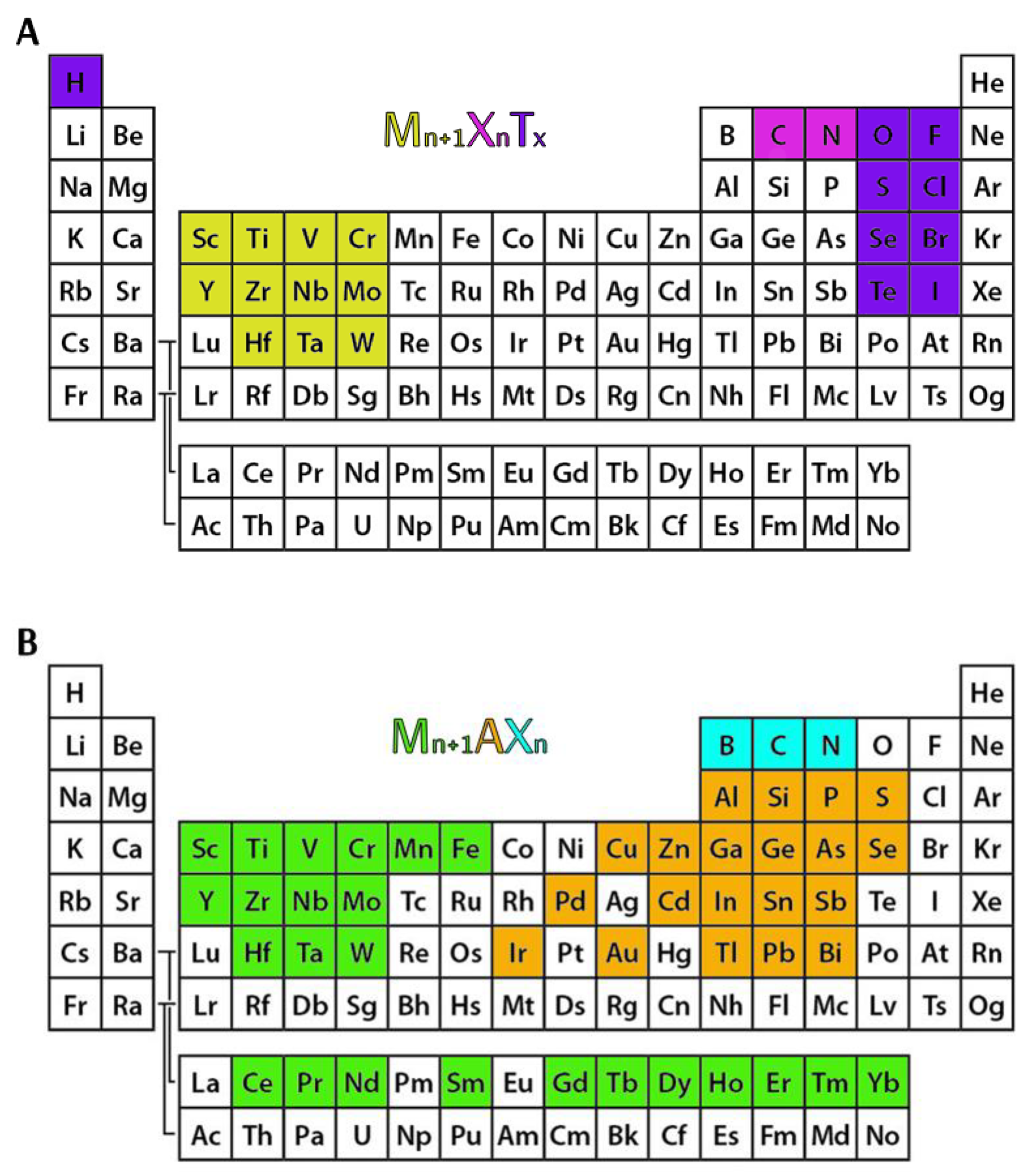

1. Introduction

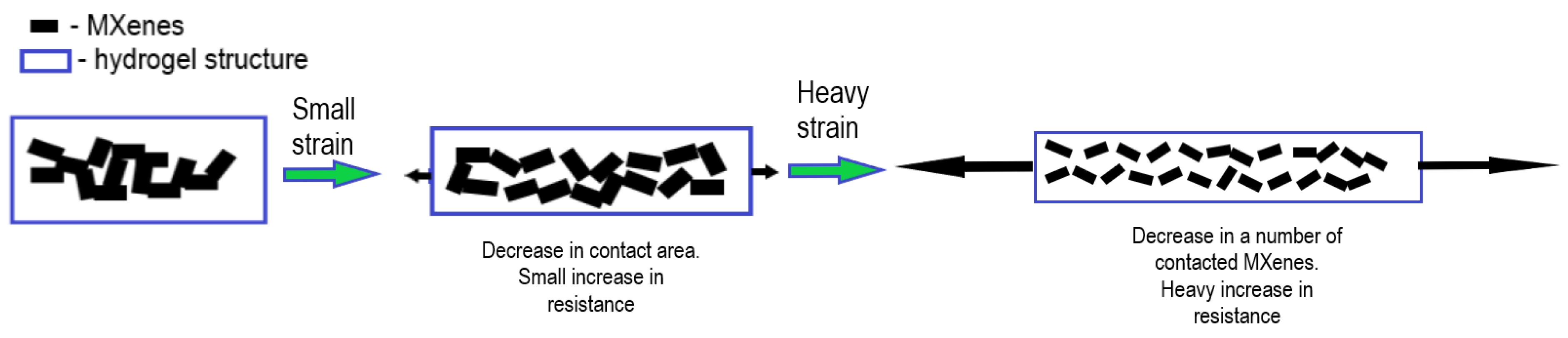

2. MXene-Based Strain Sensors

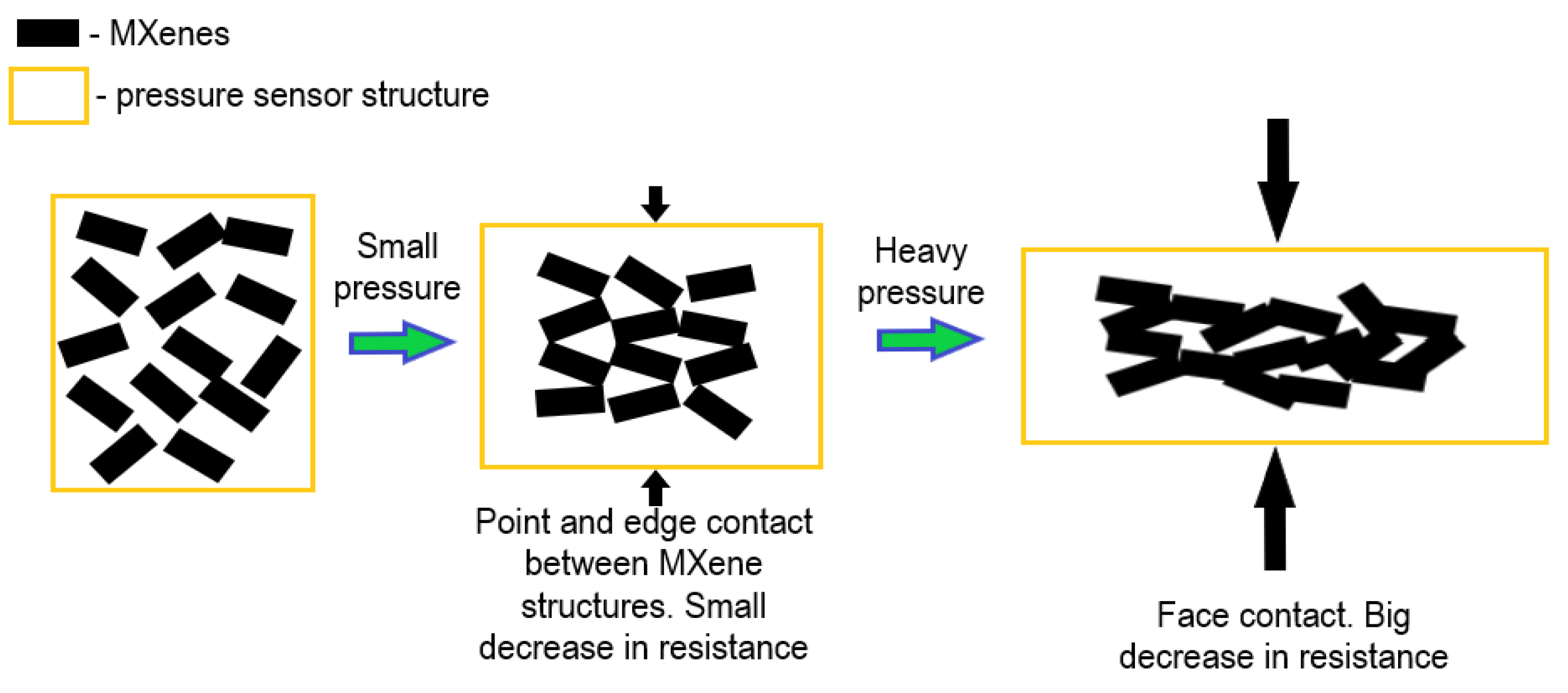

3. MXene-Based Pressure Sensors

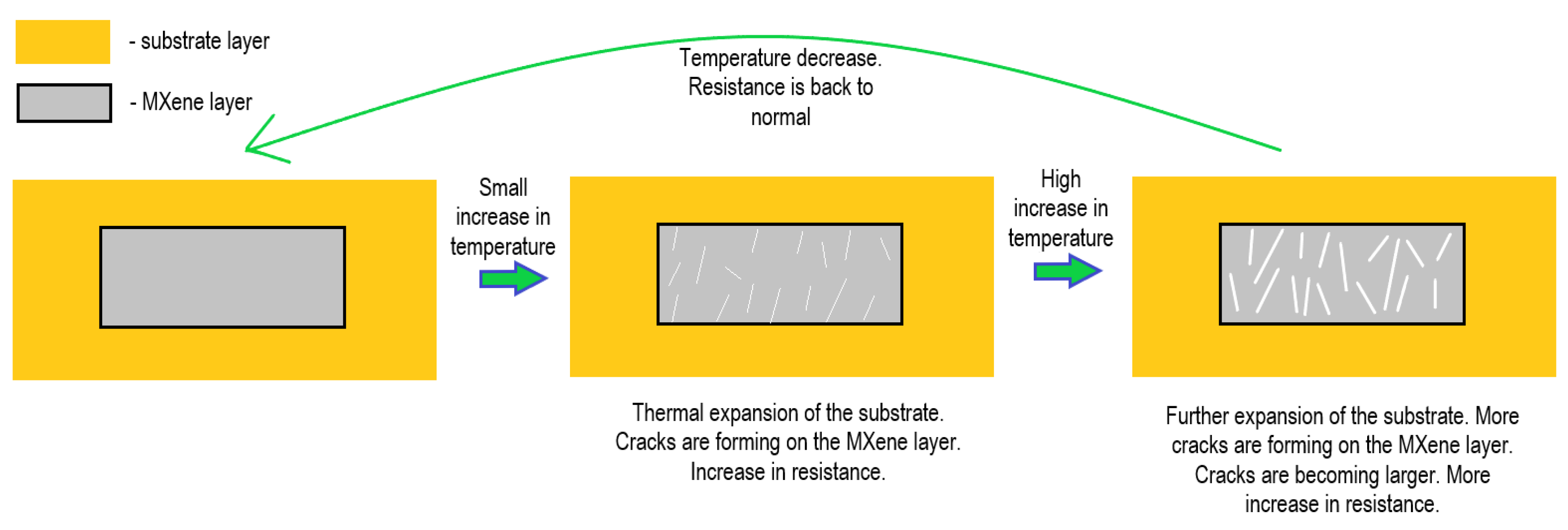

4. MXene-Based Temperature Sensors

5. MXene-Based Humidity Sensors

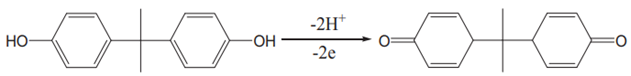

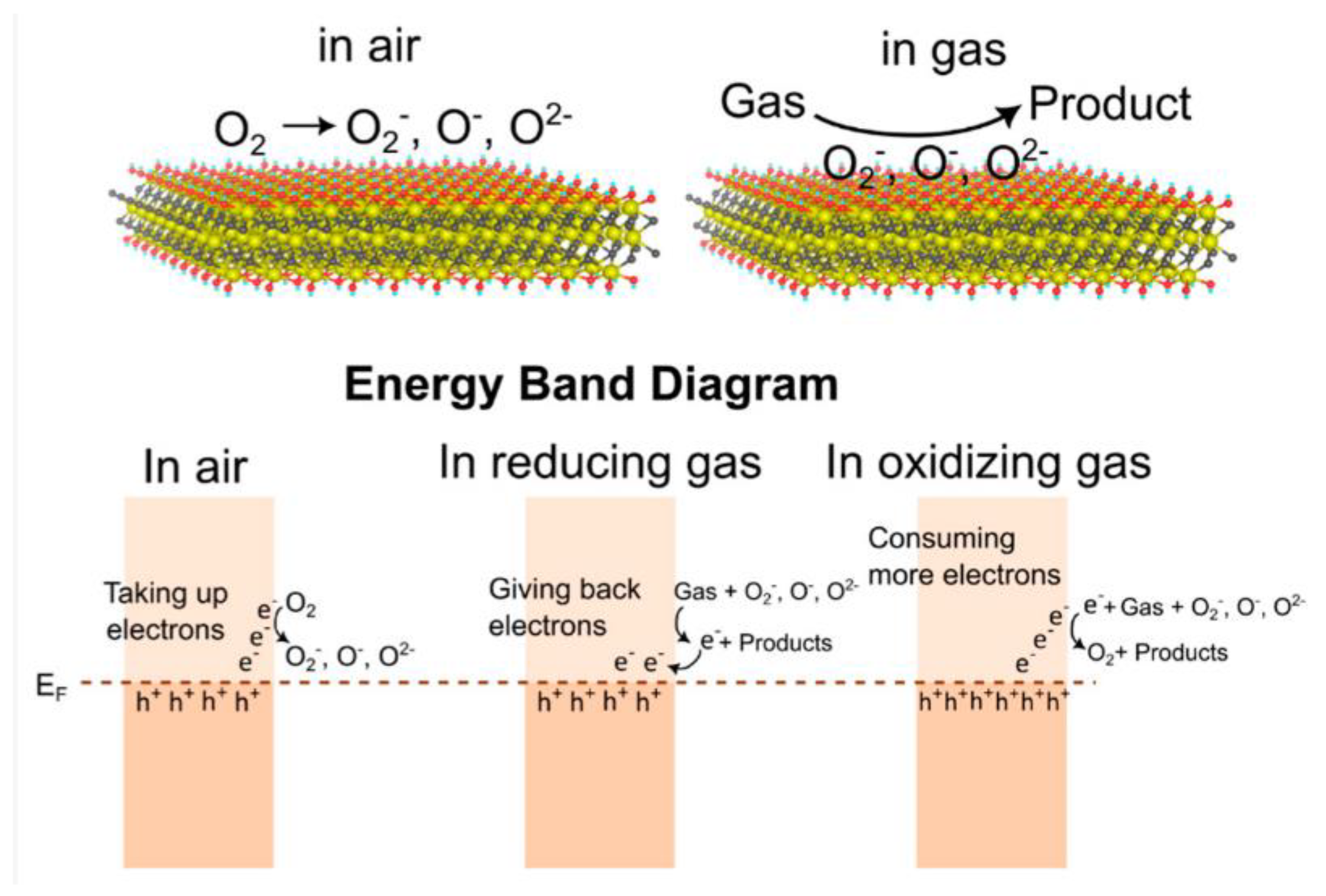

6. MXene-Based Gas Sensors

6.1. NH3 Sensing by MXene-Based Sensors

6.2. Determination of Volatile Organic Compounds (VOCs)

6.3. Other Gas Sensors Based on MXenes

7. Chemical Sensors

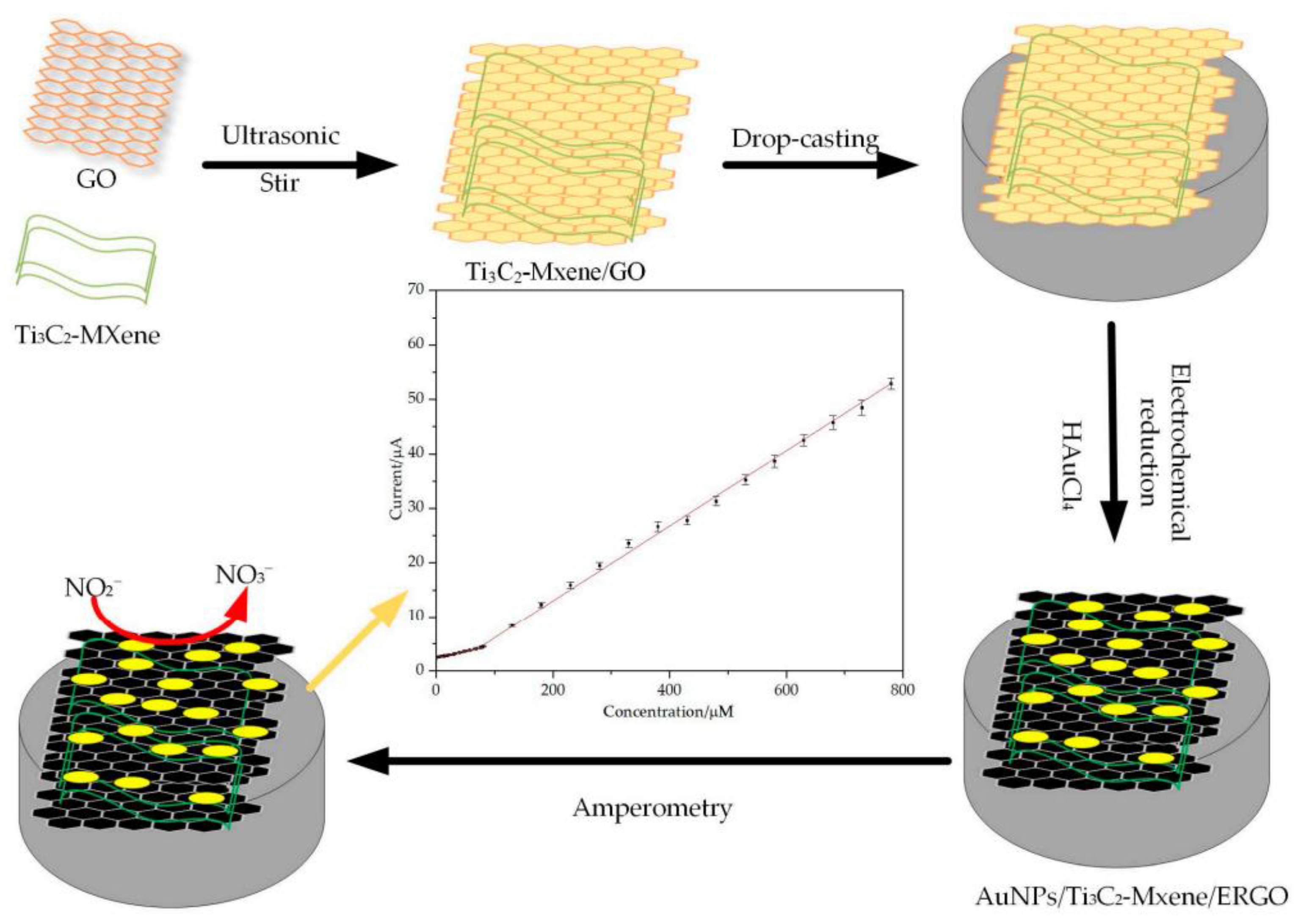

7.1. Nitrite Sensors

7.2. Hydrazine Sensors

7.3. Sensing of Phenol and Its Derivatives

7.4. Pesticide Sensors

8. Optical Sensing

9. Conclusions and Outlook

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| VOC | volatile organic compound |

| LOD | limit of detection |

| CNT | carbon nanotube |

| NW | nanowire |

| PPy | polypyrrole |

| HEC | hydroxyethyl cellulose |

| MWCNTs | multi-walled carbon nanotubes |

| TPU | thermoplastic polyurethane |

| PDMS | polydimethylsiloxane |

| PANI | polyaniline |

| PANIF | polyaniline fiber |

| P(VDF-TrFE) | poly(vinylidenefluoride-co-trifluoroethylene) |

| PVA | polyvinyl alcohol |

| CMC | sodium carboxymethylcellulose |

| TA | tannic acid |

| PVA-CA | catechol-functionalized poly(vinyl alcohol) |

| PAA | polyacrylic acid |

| PEDOT | poly(3,4-ethylenedioxythiophene) |

| PSS | poly(styrene-sulfonate) |

| ANFs | aramid nanofibers |

| ZIF-67 | zeolitic imidazolate framework-67 |

| PAN | polyacrylonitrile |

| PE | polyethylene |

| CTAB | hexadecyl trimethyl ammonium bromide |

| CMF | carbon sponge |

| PPNs | polypyrrole nanospheres |

| TPUEM | thermoplastic polyurethane electrospinning membrane |

| GO | graphene oxide |

| rGO | reduced graphene oxide |

| PS | polystyrene |

| BC | bacterial cellulose |

| CA | κ-carrageenan |

| PAM | polyacrylamide |

| PHOS | photothermal optical sensor |

| MZI | Mach–Zehnder interferometer |

| MKR | micro-fiber knot resonator |

| RH | relative humidity |

| TOCNFs | (TEMPO)-oxidized cellulose nanofibers |

| SAW | surface acoustic wave |

| MEMS | micro-electromechanical systems |

| NPs | nanoparticles |

| ERGO | electrochemically reduced graphene oxide |

| PDDA | poly(dimethyl diallyl ammonium chloride) |

| GCE | glassy carbon electrode |

| CQDs | carbon quantum dots |

| FL-Cr2CTx | few-layered two-dimensional chromium carbide |

| ZIF-8 | zeolitic imidazolate framework-8 |

| CC | carbon cloth |

| 4-CP | 4-chlorophenol |

| 4-NP | 4-nitrophenol |

| NC | nanocage |

| RSD | relative standard deviation |

| MOF | metal–organic framework |

| CBZ | carbendazim |

| CNHs | carbon nanohorns |

| CD-MOFs | cyclodextrin–metal–organic frameworks |

| PB | Prussian blue |

| ECL | electrochemiluminescence |

| PEC | photoelectrochemistry |

| CFU | Colony-forming unit |

| CRISPR | clustered regularly interspaced short palindromic repeats |

| TMB | 3,3,5,5-tetramethylbenzidine |

| SPR | surface plasmon resonance |

| SERS | surface-enhanced Raman scattering |

References

- Naguib, M.; Kurtoglu, M.; Presser, V.; Lu, J.; Niu, J.; Heon, M.; Hultman, L.; Gogotsi, Y.; Barsoum, M.W. Two-Dimensional Nanocrystals Produced by Exfoliation of Ti3AlC2. Adv. Mater. 2011, 23, 4248–4253. [Google Scholar] [CrossRef] [PubMed]

- Sun, N.; Zhu, Q.; Anasori, B.; Zhang, P.; Liu, H.; Gogotsi, Y.; Xu, B. MXene-Bonded Flexible Hard Carbon Film as Anode for Stable Na/K-Ion Storage. Adv. Funct. Mater. 2019, 29, 1906282. [Google Scholar] [CrossRef]

- Du, Y.-T.; Kan, X.; Yang, F.; Gan, L.-Y.; Schwingenschlögl, U. MXene/Graphene Heterostructures as High-Performance Electrodes for Li-Ion Batteries. ACS Appl. Mater. Interfaces 2018, 10, 32867–32873. [Google Scholar] [CrossRef]

- Zhou, Q.; Qian, K.; Fang, J.; Miao, M.; Cao, S.; Feng, X. UV-Light Modulated Ti3C2Tx MXene/g-C3N4 Heterojunction Film for Electromagnetic Interference Shielding. Compos. Part. A Appl. Sci. Manuf. 2020, 134, 105899. [Google Scholar] [CrossRef]

- Hantanasirisakul, K.; Gogotsi, Y. Electronic and Optical Properties of 2D Transition Metal Carbides and Nitrides (MXenes). Adv. Mater. 2018, 30, 1804779. [Google Scholar] [CrossRef]

- Wen, Y.; Yang, J.; Zou, H.; Fan, Y.; Li, J.; Kuang, Y.; Liu, W.; Zhang, K.; Xiong, L. 2D TiVCTx Layered Nanosheets Grown on Nickel Foam as Highly Efficient Electrocatalysts for the Hydrogen Evolution Reaction. RSC Adv. 2022, 12, 23584–23594. [Google Scholar] [CrossRef]

- Peng, J.; Chen, X.; Ong, W.-J.; Zhao, X.; Li, N. Surface and Heterointerface Engineering of 2D MXenes and Their Nanocomposites: Insights into Electro- and Photocatalysis. Chem 2019, 5, 18–50. [Google Scholar] [CrossRef]

- Lipatov, A.; Alhabeb, M.; Lu, H.; Zhao, S.; Loes, M.J.; Vorobeva, N.S.; Dall’Agnese, Y.; Gao, Y.; Gruverman, A.; Gogotsi, Y.; et al. Electrical and Elastic Properties of Individual Single-Layer Nb4C3Tx MXene Flakes. Adv. Electron. Mater. 2020, 6, 1901382. [Google Scholar] [CrossRef]

- Abdolhosseinzadeh, S.; Jiang, X.; Zhang, H.; Qiu, J.; Zhang, C. Perspectives on Solution Processing of Two-Dimensional MXenes. Mater. Today 2021, 48, 214–240. [Google Scholar] [CrossRef]

- Kamysbayev, V.; Filatov, A.S.; Hu, H.; Rui, X.; Lagunas, F.; Wang, D.; Klie, R.F.; Talapin, D.V. Covalent Surface Modifications and Superconductivity of Two-Dimensional Metal Carbide MXenes. Science 2020, 369, 979–983. [Google Scholar] [CrossRef]

- Shayesteh Zeraati, A.; Mirkhani, S.A.; Sun, P.; Naguib, M.; Braun, P.V.; Sundararaj, U. Improved Synthesis of Ti3C2Tx MXenes Resulting in Exceptional Electrical Conductivity, High Synthesis Yield, and Enhanced Capacitance. Nanoscale 2021, 13, 3572–3580. [Google Scholar] [CrossRef]

- Saravanan, P.; Rajeswari, S.; Kumar, J.A.; Rajasimman, M.; Rajamohan, N. Bibliometric Analysis and Recent Trends on MXene Research—A Comprehensive Review. Chemosphere 2022, 286, 131873. [Google Scholar] [CrossRef]

- Naguib, M.; Come, J.; Dyatkin, B.; Presser, V.; Taberna, P.-L.; Simon, P.; Barsoum, M.W.; Gogotsi, Y. MXene: A Promising Transition Metal Carbide Anode for Lithium-Ion Batteries. Electrochem. Commun. 2012, 16, 61–64. [Google Scholar] [CrossRef]

- Lim, K.R.G.; Shekhirev, M.; Wyatt, B.C.; Anasori, B.; Gogotsi, Y.; Seh, Z.W. Fundamentals of MXene Synthesis. Nat. Synth. 2022, 1, 601–614. [Google Scholar] [CrossRef]

- Wei, Y.; Zhang, P.; Soomro, R.A.; Zhu, Q.; Xu, B. Advances in the Synthesis of 2D MXenes. Adv. Mater. 2021, 33, 2103148. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.; Liu, A.; Wang, C.; Liu, F.; He, J.; Li, S.; Wang, J.; You, R.; Yan, X.; Sun, P.; et al. Improvement of Gas and Humidity Sensing Properties of Organ-like MXene by Alkaline Treatment. ACS Sens. 2019, 4, 1261–1269. [Google Scholar] [CrossRef] [PubMed]

- Caffrey, N.M. Effect of Mixed Surface Terminations on the Structural and Electrochemical Properties of Two-Dimensional Ti3C2T2 and V2CT2 MXenes Multilayers. Nanoscale 2018, 10, 13520–13530. [Google Scholar] [CrossRef]

- Seh, Z.W.; Fredrickson, K.D.; Anasori, B.; Kibsgaard, J.; Strickler, A.L.; Lukatskaya, M.R.; Gogotsi, Y.; Jaramillo, T.F.; Vojvodic, A. Two-Dimensional Molybdenum Carbide (MXene) as an Efficient Electrocatalyst for Hydrogen Evolution. ACS Energy Lett. 2016, 1, 589–594. [Google Scholar] [CrossRef]

- Rasheed, P.A.; Pandey, R.P.; Banat, F.; Hasan, S.W. Recent Advances in Niobium MXenes: Synthesis, Properties, and Emerging Applications. Matter 2022, 5, 546–572. [Google Scholar] [CrossRef]

- Jiang, L.; Zhou, D.; Yang, J.; Zhou, S.; Wang, H.; Yuan, X.; Liang, J.; Li, X.; Chen, Y.; Li, H. 2D Single- and Few-Layered MXenes: Synthesis, Applications and Perspectives. J. Mater. Chem. A Mater. 2022, 10, 13651–13672. [Google Scholar] [CrossRef]

- Pogorielov, M.; Smyrnova, K.; Kyrylenko, S.; Gogotsi, O.; Zahorodna, V.; Pogrebnjak, A. MXenes—A New Class of Two-Dimensional Materials: Structure, Properties and Potential Applications. Nanomaterials 2021, 11, 3412. [Google Scholar] [CrossRef]

- Ghidiu, M.; Naguib, M.; Shi, C.; Mashtalir, O.; Pan, L.M.; Zhang, B.; Yang, J.; Gogotsi, Y.; Billinge, S.J.L.; Barsoum, M.W. Synthesis and Characterization of Two-Dimensional Nb4C3 (MXene). Chem. Commun. 2014, 50, 9517–9520. [Google Scholar] [CrossRef]

- Lukatskaya, M.R.; Mashtalir, O.; Ren, C.E.; Dall’Agnese, Y.; Rozier, P.; Taberna, P.L.; Naguib, M.; Simon, P.; Barsoum, M.W.; Gogotsi, Y. Cation Intercalation and High Volumetric Capacitance of Two-Dimensional Titanium Carbide. Science 2013, 341, 1502–1505. [Google Scholar] [CrossRef]

- Mashtalir, O.; Naguib, M.; Dyatkin, B.; Gogotsi, Y.; Barsoum, M.W. Kinetics of Aluminum Extraction from Ti3AlC2 in Hydrofluoric Acid. Mater. Chem. Phys. 2013, 139, 147–152. [Google Scholar] [CrossRef]

- Halim, J.; Kota, S.; Lukatskaya, M.R.; Naguib, M.; Zhao, M.-Q.; Moon, E.J.; Pitock, J.; Nanda, J.; May, S.J.; Gogotsi, Y.; et al. Synthesis and Characterization of 2D Molybdenum Carbide (MXene). Adv. Funct. Mater. 2016, 26, 3118–3127. [Google Scholar] [CrossRef]

- Li, T.; Yao, L.; Liu, Q.; Gu, J.; Luo, R.; Li, J.; Yan, X.; Wang, W.; Liu, P.; Chen, B.; et al. Fluorine-Free Synthesis of High-Purity Ti3C2Tx (T=OH, O) via Alkali Treatment. Angew. Chem. Int. Ed. 2018, 57, 6115–6119. [Google Scholar] [CrossRef] [PubMed]

- Li, G.; Tan, L.; Zhang, Y.; Wu, B.; Li, L. Highly Efficiently Delaminated Single-Layered MXene Nanosheets with Large Lateral Size. Langmuir 2017, 33, 9000–9006. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Shao, H.; Lin, Z.; Lu, J.; Liu, L.; Duployer, B.; Persson, P.O.Å.; Eklund, P.; Hultman, L.; Li, M.; et al. A General Lewis Acidic Etching Route for Preparing MXenes with Enhanced Electrochemical Performance in Non-Aqueous Electrolyte. Nat. Mater. 2020, 19, 894–899. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Lu, J.; Luo, K.; Li, Y.; Chang, K.; Chen, K.; Zhou, J.; Rosen, J.; Hultman, L.; Eklund, P.; et al. Element Replacement Approach by Reaction with Lewis Acidic Molten Salts to Synthesize Nanolaminated MAX Phases and MXenes. J. Am. Chem. Soc. 2019, 141, 4730–4737. [Google Scholar] [CrossRef] [PubMed]

- Pang, S.-Y.; Wong, Y.-T.; Yuan, S.; Liu, Y.; Tsang, M.-K.; Yang, Z.; Huang, H.; Wong, W.-T.; Hao, J. Universal Strategy for HF-Free Facile and Rapid Synthesis of Two-Dimensional MXenes as Multifunctional Energy Materials. J. Am. Chem. Soc. 2019, 141, 9610–9616. [Google Scholar] [CrossRef] [PubMed]

- Yang, S.; Zhang, P.; Wang, F.; Ricciardulli, A.G.; Lohe, M.R.; Blom, P.W.M.; Feng, X. Fluoride-Free Synthesis of Two-Dimensional Titanium Carbide (MXene) Using A Binary Aqueous System. Angew. Chem. Int. Ed. 2018, 57, 15491–15495. [Google Scholar] [CrossRef]

- Shi, H.; Zhang, P.; Liu, Z.; Park, S.; Lohe, M.R.; Wu, Y.; Shaygan Nia, A.; Yang, S.; Feng, X. Ambient-Stable Two-Dimensional Titanium Carbide (MXene) Enabled by Iodine Etching. Angew. Chem. Int. Ed. 2021, 60, 8689–8693. [Google Scholar] [CrossRef] [PubMed]

- Mei, J.; Ayoko, G.A.; Hu, C.; Bell, J.M.; Sun, Z. Two-Dimensional Fluorine-Free Mesoporous Mo2C MXene via UV-Induced Selective Etching of Mo2Ga2C for Energy Storage. Sustain. Mater. Technol. 2020, 25, e00156. [Google Scholar] [CrossRef]

- Marian, M.; Song, G.C.; Wang, B.; Fuenzalida, V.M.; Krauß, S.; Merle, B.; Tremmel, S.; Wartzack, S.; Yu, J.; Rosenkranz, A. Effective Usage of 2D MXene Nanosheets as Solid Lubricant—Influence of Contact Pressure and Relative Humidity. Appl. Surf. Sci. 2020, 531, 147311. [Google Scholar] [CrossRef]

- Wang, B.; Zhou, A.; Liu, F.; Cao, J.; Wang, L.; Hu, Q. Carbon Dioxide Adsorption of Two-Dimensional Carbide MXenes. J. Adv. Ceram. 2018, 7, 237–245. [Google Scholar] [CrossRef]

- Naguib, M.; Unocic, R.R.; Armstrong, B.L.; Nanda, J. Large-Scale Delamination of Multi-Layers Transition Metal Carbides and Carbonitrides “MXenes. ” Dalton Trans. 2015, 44, 9353–9358. [Google Scholar] [CrossRef] [PubMed]

- Mashtalir, O.; Lukatskaya, M.R.; Zhao, M.-Q.; Barsoum, M.W.; Gogotsi, Y. Amine-Assisted Delamination of Nb2C MXene for Li-Ion Energy Storage Devices. Adv. Mater. 2015, 27, 3501–3506. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, J.; Wu, Y.; Huang, H.; Li, G.; Zhang, X.; Wang, Z. Surface Modified MXene Ti3C2 Multilayers by Aryl Diazonium Salts Leading to Large-Scale Delamination. Appl. Surf. Sci. 2016, 384, 287–293. [Google Scholar] [CrossRef]

- Pazniak, H.; Plugin, I.A.; Sheverdyaeva, P.M.; Rapenne, L.; Varezhnikov, A.S.; Agresti, A.; Pescetelli, S.; Moras, P.; Kostin, K.B.; Gorokhovsky, A.V.; et al. Alcohol Vapor Sensor Based on Quasi-2D Nb2O5 Derived from Oxidized Nb2CTz MXenes. Sensors 2024, 24, 38. [Google Scholar] [CrossRef]

- Jolly, S.; Paranthaman, M.P.; Naguib, M. Synthesis of Ti3C2Tz MXene from Low-Cost and Environmentally Friendly Precursors. Mater. Today Adv. 2021, 10, 100139. [Google Scholar] [CrossRef]

- Li, C.; Kota, S.; Hu, C.; Barsoum, M. On the Synthesis of Low-Cost, Titanium-Based MXenes. J. Ceram. Sci. Technol. 2016, 7, 7–10. [Google Scholar] [CrossRef]

- Ramanavicius, S.; Ramanavicius, A. Progress and Insights in the Application of MXenes as New 2D Nano-Materials Suitable for Biosensors and Biofuel Cell Design. Int. J. Mol. Sci. 2020, 21, 9224. [Google Scholar] [CrossRef]

- Guo, B.; He, S.; Yao, M.; Tan, Z.; Li, X.; Liu, M.; Yu, C.; Liang, L.; Zhao, Z.; Guo, Z.; et al. MXene-Containing Anisotropic Hydrogels Strain Sensors with Enhanced Sensing Performance for Human Motion Monitoring and Wireless Transmission. Chem. Eng. J. 2023, 461, 142099. [Google Scholar] [CrossRef]

- Yi, J.; Xianyu, Y. Gold Nanomaterials-Implemented Wearable Sensors for Healthcare Applications. Adv. Funct. Mater. 2022, 32, 2113012. [Google Scholar] [CrossRef]

- Wu, L.; Wang, L.; Guo, Z.; Luo, J.; Xue, H.; Gao, J. Durable and Multifunctional Superhydrophobic Coatings with Excellent Joule Heating and Electromagnetic Interference Shielding Performance for Flexible Sensing Electronics. ACS Appl. Mater. Interfaces 2019, 11, 34338–34347. [Google Scholar] [CrossRef] [PubMed]

- Tang, J.; Wu, Y.; Ma, S.; Yan, T.; Pan, Z. Flexible Strain Sensor Based on CNT/TPU Composite Nanofiber Yarn for Smart Sports Bandage. Compos. B Eng. 2022, 232, 109605. [Google Scholar] [CrossRef]

- Duan, Q.; Lan, B.; Lv, Y. Highly Dispersed, Adhesive Carbon Nanotube Ink for Strain and Pressure Sensors. ACS Appl. Mater. Interfaces 2022, 14, 1973–1982. [Google Scholar] [CrossRef]

- Zheng, X.; Cao, W.; Hong, X.; Zou, L.; Liu, Z.; Wang, P.; Li, C. Versatile Electronic Textile Enabled by a Mixed-Dimensional Assembly Strategy. Small 2023, 19, 2208134. [Google Scholar] [CrossRef]

- Li, X.; Zhao, B.; Qin, W.; Yang, M.; Feng, L.; Gu, C.; Tian, Z.; Liu, H.; Guo, X.; Zhang, Y.; et al. MXene Ti3C2Tx, EGaIn, and Carbon Nanotube Composites on Polyurethane Substrates for Strain Sensing, Electromagnetic Interference Shielding, and Joule Heating. ACS Appl. Nano Mater. 2023, 6, 14459–14468. [Google Scholar] [CrossRef]

- Pu, J.-H.; Zhao, X.; Zha, X.-J.; Bai, L.; Ke, K.; Bao, R.-Y.; Liu, Z.-Y.; Yang, M.-B.; Yang, W. Multilayer Structured AgNW/WPU-MXene Fiber Strain Sensors with Ultrahigh Sensitivity and a Wide Operating Range for Wearable Monitoring and Healthcare. J. Mater. Chem. A Mater. 2019, 7, 15913–15923. [Google Scholar] [CrossRef]

- Yang, Y.; Cao, Z.; He, P.; Shi, L.; Ding, G.; Wang, R.; Sun, J. Ti3C2Tx MXene-Graphene Composite Films for Wearable Strain Sensors Featured with High Sensitivity and Large Range of Linear Response. Nano Energy 2019, 66, 104134. [Google Scholar] [CrossRef]

- Cai, Y.; Shen, J.; Ge, G.; Zhang, Y.; Jin, W.; Huang, W.; Shao, J.; Yang, J.; Dong, X. Stretchable Ti3C2Tx MXene/Carbon Nanotube Composite Based Strain Sensor with Ultrahigh Sensitivity and Tunable Sensing Range. ACS Nano 2018, 12, 56–62. [Google Scholar] [CrossRef]

- Xu, X.; Chen, Y.; He, P.; Wang, S.; Ling, K.; Liu, L.; Lei, P.; Huang, X.; Zhao, H.; Cao, J.; et al. Wearable CNT/Ti3C2Tx MXene/PDMS Composite Strain Sensor with Enhanced Stability for Real-Time Human Healthcare Monitoring. Nano Res. 2021, 14, 2875–2883. [Google Scholar] [CrossRef]

- Cao, J.; Jiang, Y.; Li, X.; Yuan, X.; Zhang, J.; He, Q.; Ye, F.; Luo, G.; Guo, S.; Zhang, Y.; et al. A Flexible and Stretchable MXene/Waterborne Polyurethane Composite-Coated Fiber Strain Sensor for Wearable Motion and Healthcare Monitoring. Sensors 2024, 24, 271. [Google Scholar] [CrossRef]

- Yang, H.; Xiao, X.; Li, Z.; Li, K.; Cheng, N.; Li, S.; Low, J.H.; Jing, L.; Fu, X.; Achavananthadith, S.; et al. Wireless Ti3C2Tx MXene Strain Sensor with Ultrahigh Sensitivity and Designated Working Windows for Soft Exoskeletons. ACS Nano 2020, 14, 11860–11875. [Google Scholar] [CrossRef]

- Liao, H.; Guo, X.; Wan, P.; Yu, G. Conductive MXene Nanocomposite Organohydrogel for Flexible, Healable, Low-Temperature Tolerant Strain Sensors. Adv. Funct. Mater. 2019, 29, 1904507. [Google Scholar] [CrossRef]

- Yang, C.; Zhang, D.; Wang, D.; Luan, H.; Chen, X.; Yan, W. In Situ Polymerized MXene/Polypyrrole/Hydroxyethyl Cellulose-Based Flexible Strain Sensor Enabled by Machine Learning for Handwriting Recognition. ACS Appl. Mater. Interfaces 2023, 15, 5811–5821. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Zhou, R.; Li, D.; Zhang, L.; Ren, G.; Wang, L.; Liu, J.; Wang, D.; Tang, Z.; Lu, G.; et al. High-Performance Foam-Shaped Strain Sensor Based on Carbon Nanotubes and Ti3C2Tx MXene for the Monitoring of Human Activities. ACS Nano 2021, 15, 9690–9700. [Google Scholar] [CrossRef] [PubMed]

- Yang, K.; Yin, F.; Xia, D.; Peng, H.; Yang, J.; Yuan, W. A Highly Flexible and Multifunctional Strain Sensor Based on a Network-Structured MXene/Polyurethane Mat with Ultra-High Sensitivity and a Broad Sensing Range. Nanoscale 2019, 11, 9949–9957. [Google Scholar] [CrossRef] [PubMed]

- Chao, M.; Wang, Y.; Ma, D.; Wu, X.; Zhang, W.; Zhang, L.; Wan, P. Wearable MXene Nanocomposites-Based Strain Sensor with Tile-like Stacked Hierarchical Microstructure for Broad-Range Ultrasensitive Sensing. Nano Energy 2020, 78, 105187. [Google Scholar] [CrossRef]

- Bu, Y.; Shen, T.; Yang, W.; Yang, S.; Zhao, Y.; Liu, H.; Zheng, Y.; Liu, C.; Shen, C. Ultrasensitive Strain Sensor Based on Superhydrophobic Microcracked Conductive Ti3C2Tx MXene/Paper for Human-Motion Monitoring and E-Skin. Sci. Bull. 2021, 66, 1849–1857. [Google Scholar] [CrossRef] [PubMed]

- Fu, X.; Li, L.; Chen, S.; Xu, H.; Li, J.; Shulga, V.; Han, W. Knitted Ti3C2Tx MXene Based Fiber Strain Sensor for Human–Computer Interaction. J. Colloid. Interface Sci. 2021, 604, 643–649. [Google Scholar] [CrossRef] [PubMed]

- Kong, D.; El-Bahy, Z.M.; Algadi, H.; Li, T.; El-Bahy, S.M.; Nassan, M.A.; Li, J.; Faheim, A.A.; Li, A.; Xu, C.; et al. Highly Sensitive Strain Sensors with Wide Operation Range from Strong MXene-Composited Polyvinyl Alcohol/Sodium Carboxymethylcellulose Double Network Hydrogel. Adv. Compos. Hybrid. Mater. 2022, 5, 1976–1987. [Google Scholar] [CrossRef]

- Chae, A.; Murali, G.; Lee, S.-Y.; Gwak, J.; Kim, S.J.; Jeong, Y.J.; Kang, H.; Park, S.; Lee, A.S.; Koh, D.-Y.; et al. Highly Oxidation-Resistant and Self-Healable MXene-Based Hydrogels for Wearable Strain Sensor. Adv. Funct. Mater. 2023, 33, 2213382. [Google Scholar] [CrossRef]

- Peng, W.; Pan, X.; Liu, X.; Gao, Y.; Lu, T.; Li, J.; Xu, M.; Pan, L. A Moisture Self-Regenerative, Ultra-Low Temperature Anti-Freezing and Self-Adhesive Polyvinyl Alcohol/Polyacrylamide/CaCl2/MXene Ionotronics Hydrogel for Bionic Skin Strain Sensor. J. Colloid. Interface Sci. 2023, 634, 782–792. [Google Scholar] [CrossRef] [PubMed]

- Dong, L.; Zhou, X.; Zheng, S.; Luo, Z.; Nie, Y.; Feng, X.; Zhu, J.; Wang, Z.; Lu, X.; Mu, L. Liquid Metal @ Mxene Spring Supports Ionic Gel with Excellent Mechanical Properties for High-Sensitivity Wearable Strain Sensor. Chem. Eng. J. 2023, 458, 141370. [Google Scholar] [CrossRef]

- Liang, J.; He, J.; Xin, Y.; Gao, W.; Zeng, G.; He, X. MXene Reinforced PAA/PEDOT:PSS/MXene Conductive Hydrogel for Highly Sensitive Strain Sensors. Macromol. Mater. Eng. 2023, 308, 2200519. [Google Scholar] [CrossRef]

- Qin, W.; Geng, J.; Lin, C.; Li, G.; Peng, H.; Xue, Y.; Zhou, B.; Liu, G. Flexible Multifunctional TPU Strain Sensors with Improved Sensitivity and Wide Sensing Range Based on MXene/AgNWs. J. Mater. Sci. Mater. Electron. 2023, 34, 564. [Google Scholar] [CrossRef]

- Seesaard, T.; Wongchoosuk, C. Flexible and Stretchable Pressure Sensors: From Basic Principles to State-of-the-Art Applications. Micromachines 2023, 14, 1638. [Google Scholar] [CrossRef]

- Ma, Z.; Zhang, Y.; Zhang, K.; Deng, H.; Fu, Q. Recent Progress in Flexible Capacitive Sensors: Structures and Properties. Nano Mater. Sci. 2023, 5, 265–277. [Google Scholar] [CrossRef]

- Wu, Y.; Ma, Y.; Zheng, H.; Ramakrishna, S. Piezoelectric Materials for Flexible and Wearable Electronics: A Review. Mater. Des. 2021, 211, 110164. [Google Scholar] [CrossRef]

- Garcia, C.; Trendafilova, I.; Guzman de Villoria, R.; Sanchez del Rio, J. Self-Powered Pressure Sensor Based on the Triboelectric Effect and Its Analysis Using Dynamic Mechanical Analysis. Nano Energy 2018, 50, 401–409. [Google Scholar] [CrossRef]

- Trung, T.Q.; Lee, N.-E. Flexible and Stretchable Physical Sensor Integrated Platforms for Wearable Human-Activity Monitoringand Personal Healthcare. Adv. Mater. 2016, 28, 4338–4372. [Google Scholar] [CrossRef] [PubMed]

- Liang, G.; Ruan, Z.; Liu, Z.; Li, H.; Wang, Z.; Tang, Z.; Mo, F.; Yang, Q.; Ma, L.; Wang, D.; et al. Toward Multifunctional and Wearable Smart Skins with Energy-Harvesting, Touch-Sensing, and Exteroception-Visualizing Capabilities by an All-Polymer Design. Adv. Electron. Mater. 2019, 5, 1900553. [Google Scholar] [CrossRef]

- Fiorillo, A.S.; Critello, C.D.; Pullano, S.A. Theory, Technology and Applications of Piezoresistive Sensors: A Review. Sens. Actuators A Phys. 2018, 281, 156–175. [Google Scholar] [CrossRef]

- Li, H.; Wu, K.; Xu, Z.; Wang, Z.; Meng, Y.; Li, L. Ultrahigh-Sensitivity Piezoresistive Pressure Sensors for Detection of Tiny Pressure. ACS Appl. Mater. Interfaces 2018, 10, 20826–20834. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, L.; Zhao, L.; Wang, K.; Zheng, Y.; Yuan, Z.; Wang, D.; Fu, X.; Shen, G.; Han, W. Flexible Self-Powered Integrated Sensing System with 3D Periodic Ordered Black Phosphorus@MXene Thin-Films. Adv. Mater. 2021, 33, 2007890. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Liu, Y.; Li, Y.; Hao, Q. Development and Application of Resistance Strain Force Sensors. Sensors 2020, 20, 5826. [Google Scholar] [CrossRef]

- Wu, Z.; Wei, L.; Tang, S.; Xiong, Y.; Qin, X.; Luo, J.; Fang, J.; Wang, X. Recent Progress in Ti3C2Tx MXene-Based Flexible Pressure Sensors. ACS Nano 2021, 15, 18880–18894. [Google Scholar] [CrossRef]

- Zou, Y.; Chen, Z.; Guo, X.; Peng, Z.; Yu, C.; Zhong, W. Mechanically Robust and Elastic Graphene/Aramid Nanofiber/Polyaniline Nanotube Aerogels for Pressure Sensors. ACS Appl. Mater. Interfaces 2022, 14, 17858–17868. [Google Scholar] [CrossRef]

- Fu, X.; Li, J.; Li, D.; Zhao, L.; Yuan, Z.; Shulga, V.; Han, W.; Wang, L. MXene/ZIF-67/PAN Nanofiber Film for Ultra-Sensitive Pressure Sensors. ACS Appl. Mater. Interfaces 2022, 14, 12367–12374. [Google Scholar] [CrossRef] [PubMed]

- Lei, D.; Liu, N.; Su, T.; Zhang, Q.; Wang, L.; Ren, Z.; Gao, Y. Roles of MXene in Pressure Sensing: Preparation, Composite Structure Design, and Mechanism. Adv. Mater. 2022, 34, 2110608. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Y.; Yin, R.; Zhao, Y.; Liu, H.; Zhang, D.; Shi, X.; Zhang, B.; Liu, C.; Shen, C. Conductive MXene/Cotton Fabric Based Pressure Sensor with Both High Sensitivity and Wide Sensing Range for Human Motion Detection and E-Skin. Chem. Eng. J. 2021, 420, 127720. [Google Scholar] [CrossRef]

- Xu, Z.; Zhang, D.; Li, Z.; Du, C.; Yang, Y.; Zhang, B.; Zhao, W. Waterproof Flexible Pressure Sensors Based on Electrostatic Self-Assembled MXene/NH2-CNTs for Motion Monitoring and Electronic Skin. ACS Appl. Mater. Interfaces 2023, 15, 32569–32579. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Zhang, M.; Yang, B.; Tan, J.; Ding, X. Highly Compressible, Thermally Stable, Light-Weight, and Robust Aramid Nanofibers/Ti3AlC2 MXene Composite Aerogel for Sensitive Pressure Sensor. ACS Nano 2020, 14, 10633–10647. [Google Scholar] [CrossRef]

- Yin, T.; Cheng, Y.; Hou, Y.; Sun, L.; Ma, Y.; Su, J.; Zhang, Z.; Liu, N.; Li, L.; Gao, Y. 3D Porous Structure in MXene/PANI Foam for a High-Performance Flexible Pressure Sensor. Small 2022, 18, 2204806. [Google Scholar] [CrossRef]

- Li, G.; Sun, F.; Zhao, S.; Xu, R.; Wang, H.; Qu, L.; Tian, M. Autonomous Electroluminescent Textile for Visual Interaction and Environmental Warning. Nano Lett. 2023, 23, 8436–8444. [Google Scholar] [CrossRef]

- Guo, D.; Mu, C.; Liu, Q.; Wang, B.; Xiang, J.; Nie, A.; Zhai, K.; Shu, Y.; Xue, T.; Wen, F.; et al. Aramid Nanofiber/Polypyrrole Composite Films for Broadband EMI Shielding, Wearable Electronics, Joule Heating, and Photothermal Conversion. ACS Appl. Nano Mater. 2023, 6, 15108–15118. [Google Scholar] [CrossRef]

- Ma, Y.; Liu, N.; Li, L.; Hu, X.; Zou, Z.; Wang, J.; Luo, S.; Gao, Y. A Highly Flexible and Sensitive Piezoresistive Sensor Based on MXene with Greatly Changed Interlayer Distances. Nat. Commun. 2017, 8, 1207. [Google Scholar] [CrossRef]

- Pei, Y.; Wang, K.; Hui, Z.; Pan, H.; Zhou, J.; Sun, G. Blowing up Ti3C2TX MXene Membrane for Robust Sound Detection. Appl. Phys. Lett. 2023, 122, 083501. [Google Scholar] [CrossRef]

- Gou, G.-Y.; Li, X.-S.; Jian, J.-M.; Tian, H.; Wu, F.; Ren, J.; Geng, X.-S.; Xu, J.-D.; Qiao, Y.-C.; Yan, Z.-Y.; et al. Two-Stage Amplification of an Ultrasensitive MXene-Based Intelligent Artificial Eardrum. Sci. Adv. 2024, 8, eabn2156. [Google Scholar] [CrossRef]

- Bilibana, M.P. Electrochemical Properties of MXenes and Applications. Adv. Sens. Energy Mater. 2023, 2, 100080. [Google Scholar] [CrossRef]

- Hajian, S.; Maddipatla, D.; Narakathu, B.B.; Atashbar, M.Z. MXene-Based Flexible Sensors: A Review. Front. Sens. 2022, 3, 1006749. [Google Scholar] [CrossRef]

- Qi, Z.; Zhang, T.; Zhang, X.-D.; Xu, Q.; Cao, K.; Chen, R. MXene-Based Flexible Pressure Sensor with Piezoresistive Properties Significantly Enhanced by Atomic Layer Infiltration. Nano Mater. Sci. 2023, 5, 439–446. [Google Scholar] [CrossRef]

- Li, C.; Gu, H.; Ji, Z.; Zhang, L.; Xu, R.; Gao, J.; Jiang, Y. Hierarchically Structured MXene Nanosheets on Carbon Sponges with a Synergistic Effect of Electrostatic Adsorption and Capillary Action for Highly Sensitive Pressure Sensors. ACS Appl. Nano Mater. 2023, 6, 13482–13491. [Google Scholar] [CrossRef]

- Cheng, H.; Yang, C.; Chu, J.; Zhou, H.; Wang, C. Multifunctional Ti3C2Tx MXene/Nanospheres/Ti3C2Tx MXene/Thermoplastic Polyurethane Electrospinning Membrane Inspired by Bean Pod Structure for EMI Shielding and Pressure Sensing. Sens. Actuators A Phys. 2023, 353, 114226. [Google Scholar] [CrossRef]

- Xie, Y.; Cheng, Y.; Ma, Y.; Wang, J.; Zou, J.; Wu, H.; Yue, Y.; Li, B.; Gao, Y.; Zhang, X.; et al. 3D MXene-Based Flexible Network for High-Performance Pressure Sensor with a Wide Temperature Range. Adv. Sci. 2023, 10, 2205303. [Google Scholar] [CrossRef]

- Li, L.; Cheng, Y.; Cao, H.; Liang, Z.; Liu, Z.; Yan, S.; Li, L.; Jia, S.; Wang, J.; Gao, Y. MXene/RGO/PS Spheres Multiple Physical Networks as High-Performance Pressure Sensor. Nano Energy 2022, 95, 106986. [Google Scholar] [CrossRef]

- Yang, J.; Li, H.; Cheng, J.; He, T.; Li, J.; Wang, B. Nanocellulose Intercalation to Boost the Performance of MXene Pressure Sensor for Human Interactive Monitoring. J. Mater. Sci. 2021, 56, 13859–13873. [Google Scholar] [CrossRef]

- Cao, Z.; Yang, Y.; Zheng, Y.; Wu, W.; Xu, F.; Wang, R.; Sun, J. Highly Flexible and Sensitive Temperature Sensors Based on Ti3C2Tx (MXene) for Electronic Skin. J. Mater. Chem. A Mater. 2019, 7, 25314–25323. [Google Scholar] [CrossRef]

- Zhao, L.; Fu, X.; Xu, H.; Zheng, Y.; Han, W.; Wang, L. Tissue-Like Sodium Alginate-Coated 2D MXene-Based Flexible Temperature Sensors for Full-Range Temperature Monitoring. Adv. Mater. Technol. 2022, 7, 2101740. [Google Scholar] [CrossRef]

- Wang, Z.; Zou, X.; Yang, Z.; Wang, J.; Chen, Q.; Pei, C.; Wang, Z.; Dong, M.; Zhang, J.; Li, H.; et al. Highly Sensitive Temperature Detection Based on a Frost- and Dehydration-Resistive Ion-Doped Hydrogel-MXene Composite. ACS Appl. Mater. Interfaces 2023, 15, 35525–35533. [Google Scholar] [CrossRef]

- Liu, H.; Yang, N.; Zhang, Q.; Wang, F.; Yan, X.; Zhang, X.; Cheng, T. A High-Performance Wearable Ag/Ti3C2Tx MXene-Based Fiber Sensor for Temperature Sensing, Pressure Sensing, and Human Motion Detection. IEEE Trans. Instrum. Meas. 2022, 71, 9512608. [Google Scholar] [CrossRef]

- Saeidi-Javash, M.; Du, Y.; Zeng, M.; Wyatt, B.C.; Zhang, B.; Kempf, N.; Anasori, B.; Zhang, Y. All-Printed MXene–Graphene Nanosheet-Based Bimodal Sensors for Simultaneous Strain and Temperature Sensing. ACS Appl. Electron. Mater. 2021, 3, 2341–2348. [Google Scholar] [CrossRef]

- Zuo, Y.; Gao, Y.; Qin, S.; Wang, Z.; Zhou, D.; Li, Z.; Yu, Y.; Shao, M.; Zhang, X. Broadband Multi-Wavelength Optical Sensing Based on Photothermal Effect of 2D MXene Films. Nanophotonics 2020, 9, 123–131. [Google Scholar] [CrossRef]

- Chen, S.; Ran, J.; Zheng, T.; Wu, Q. Ultracompact MXene V2C-Improved Temperature Sensor by a Runway-Type Microfiber Knot Resonator. Nanomaterials 2023, 13, 2354. [Google Scholar] [CrossRef] [PubMed]

- Wu, Q.; Ran, J.; Zheng, T.; Wu, H.; Liao, Y.; Wang, F.; Chen, S. MXene V2C-Coated Runway-Type Microfiber Knot Resonator for an All-Optical Temperature Sensor. RSC Adv. 2023, 13, 19366–19372. [Google Scholar] [CrossRef] [PubMed]

- Yuan, X.; Zhang, M.; Wu, Y. MXene-Based Sensors for Detecting Human Physiological Information. Sens. Mater. 2020, 32, 4047–4065. [Google Scholar] [CrossRef]

- Tai, Y.; Lubineau, G. Human-Finger Electronics Based on Opposing Humidity-Resistance Responses in Carbon Nanofilms. Small 2017, 13, 1603486. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.; Wu, Z.; Xu, H.; Wu, Q.; Liu, C.; Yang, B.-R.; Gui, X.; Xie, X.; Tao, K.; Shen, Y.; et al. An Intrinsically Stretchable Humidity Sensor Based on Anti-Drying, Self-Healing and Transparent Organohydrogels. Mater. Horiz. 2019, 6, 595–603. [Google Scholar] [CrossRef]

- Wu, J.; Sun, Y.-M.; Wu, Z.; Li, X.; Wang, N.; Tao, K.; Wang, G.P. Carbon Nanocoil-Based Fast-Response and Flexible Humidity Sensor for Multifunctional Applications. ACS Appl. Mater. Interfaces 2019, 11, 4242–4251. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Yuan, X.; Lin, C.; Yang, Y.; Xu, L.; Du, X.; Xie, J.; Lin, J.; Sun, J. Achieving High Pseudocapacitance of 2D Titanium Carbide (MXene) by Cation Intercalation and Surface Modification. Adv. Energy Mater. 2017, 7, 1602725. [Google Scholar] [CrossRef]

- Célérier, S.; Hurand, S.; Garnero, C.; Morisset, S.; Benchakar, M.; Habrioux, A.; Chartier, P.; Mauchamp, V.; Findling, N.; Lanson, B.; et al. Hydration of Ti3C2Tx MXene: An Interstratification Process with Major Implications on Physical Properties. Chem. Mater. 2019, 31, 454–461. [Google Scholar] [CrossRef]

- Dai, J.; Zhang, T.; Qi, R.; Zhao, H.; Fei, T.; Lu, G. LiCl Loaded Cross-Linked Polymer Composites by Click Reaction for Humidity Sensing. Sens. Actuators B Chem. 2017, 253, 361–367. [Google Scholar] [CrossRef]

- Zhang, Z.; Huang, J.; Dong, B.; Yuan, Q.; He, Y.; Wolfbeis, O.S. Rational Tailoring of ZnSnO3/TiO2 Heterojunctions with Bioinspired Surface Wettability for High-Performance Humidity Nanosensors. Nanoscale 2015, 7, 4149–4155. [Google Scholar] [CrossRef] [PubMed]

- Muckley, E.S.; Naguib, M.; Ivanov, I.N. Multi-Modal, Ultrasensitive, Wide-Range Humidity Sensing with Ti3C2 Film. Nanoscale 2018, 10, 21689–21695. [Google Scholar] [CrossRef]

- Wu, J.; Lu, P.; Dai, J.; Zheng, C.; Zhang, T.; Yu, W.W.; Zhang, Y. High Performance Humidity Sensing Property of Ti3C2Tx MXene-Derived Ti3C2Tx/K2Ti4O9 Composites. Sens. Actuators B Chem. 2021, 326, 128969. [Google Scholar] [CrossRef]

- An, H.; Habib, T.; Shah, S.; Gao, H.; Patel, A.; Echols, I.; Zhao, X.; Radovic, M.; Green, M.J.; Lutkenhaus, J.L. Water Sorption in MXene/Polyelectrolyte Multilayers for Ultrafast Humidity Sensing. ACS Appl. Nano Mater. 2019, 2, 948–955. [Google Scholar] [CrossRef]

- Lu, Y.; Wang, M.-Y.; Wang, D.-Y.; Sun, Y.-H.; Liu, Z.-H.; Gao, R.-K.; Yu, L.-D.; Zhang, D.-Z. Flexible Impedance Sensor Based on Ti3C2Tx MXene and Graphitic Carbon Nitride Nanohybrid for Humidity-Sensing Application with Ultrahigh Response. Rare Met. 2023, 42, 2204–2213. [Google Scholar] [CrossRef]

- Han, M.; Shen, W. Nacre-Inspired Cellulose Nanofiber/MXene Flexible Composite Film with Mechanical Robustness for Humidity Sensing. Carbohydr. Polym. 2022, 298, 120109. [Google Scholar] [CrossRef]

- Li, R.; Fan, Y.; Ma, Z.; Zhang, D.; Liu, Y.; Xu, J. Controllable Preparation of Ultrathin MXene Nanosheets and Their Excellent QCM Humidity Sensing Properties Enhanced by Fluoride Doping. Microchim. Acta 2021, 188, 81. [Google Scholar] [CrossRef]

- Muckley, E.S.; Naguib, M.; Wang, H.-W.; Vlcek, L.; Osti, N.C.; Sacci, R.L.; Sang, X.; Unocic, R.R.; Xie, Y.; Tyagi, M.; et al. Multimodality of Structural, Electrical, and Gravimetric Responses of Intercalated MXenes to Water. ACS Nano 2017, 11, 11118–11126. [Google Scholar] [CrossRef]

- Li, N.; Jiang, Y.; Xiao, Y.; Meng, B.; Xing, C.; Zhang, H.; Peng, Z. A Fully Inkjet-Printed Transparent Humidity Sensor Based on a Ti3C2/Ag Hybrid for Touchless Sensing of Finger Motion. Nanoscale 2019, 11, 21522–21531. [Google Scholar] [CrossRef]

- Sun, B.; Lv, H.; Liu, Z.; Wang, J.; Bai, X.; Zhang, Y.; Chen, J.; Kan, K.; Shi, K. Co3O4@PEI/Ti3C2Tx MXene Nanocomposites for a Highly Sensitive NOx Gas Sensor with a Low Detection Limit. J. Mater. Chem. A Mater. 2021, 9, 6335–6344. [Google Scholar] [CrossRef]

- Kim, S.J.; Koh, H.-J.; Ren, C.E.; Kwon, O.; Maleski, K.; Cho, S.-Y.; Anasori, B.; Kim, C.-K.; Choi, Y.-K.; Kim, J.; et al. Metallic Ti3C2Tx MXene Gas Sensors with Ultrahigh Signal-to-Noise Ratio. ACS Nano 2018, 12, 986–993. [Google Scholar] [CrossRef]

- John, R.A.B.; Vijayan, K.; Septiani, N.L.W.; Hardiansyah, A.; Kumar, A.R.; Yuliarto, B.; Hermawan, A. Gas-Sensing Mechanisms and Performances of MXenes and MXene-Based Heterostructures. Sensors 2023, 23, 8674. [Google Scholar] [CrossRef]

- Lee, E.; VahidMohammadi, A.; Prorok, B.C.; Yoon, Y.S.; Beidaghi, M.; Kim, D.-J. Room Temperature Gas Sensing of Two-Dimensional Titanium Carbide (MXene). ACS Appl. Mater. Interfaces 2017, 9, 37184–37190. [Google Scholar] [CrossRef] [PubMed]

- Wu, M.; He, M.; Hu, Q.; Wu, Q.; Sun, G.; Xie, L.; Zhang, Z.; Zhu, Z.; Zhou, A. Ti3C2 MXene-Based Sensors with High Selectivity for NH3 Detection at Room Temperature. ACS Sens. 2019, 4, 2763–2770. [Google Scholar] [CrossRef]

- Lee, S.H.; Eom, W.; Shin, H.; Ambade, R.B.; Bang, J.H.; Kim, H.W.; Han, T.H. Room-Temperature, Highly Durable Ti3C2Tx MXene/Graphene Hybrid Fibers for NH3 Gas Sensing. ACS Appl. Mater. Interfaces 2020, 12, 10434–10442. [Google Scholar] [CrossRef] [PubMed]

- Shuvo, S.N.; Ulloa Gomez, A.M.; Mishra, A.; Chen, W.Y.; Dongare, A.M.; Stanciu, L.A. Sulfur-Doped Titanium Carbide MXenes for Room-Temperature Gas Sensing. ACS Sens. 2020, 5, 2915–2924. [Google Scholar] [CrossRef] [PubMed]

- Bhardwaj, R.; Hazra, A. MXene-Based Gas Sensors. J. Mater. Chem. C Mater. 2021, 9, 15735–15754. [Google Scholar] [CrossRef]

- Ismail, A.H.; Mohd Yahya, N.A.; Mahdi, M.A.; Yaacob, M.H.; Sulaiman, Y. Gasochromic Response of Optical Sensing Platform Integrated with Polyaniline and Poly(3,4-Ethylenedioxythiophene) Exposed to NH3 Gas. Polymer 2020, 192, 122313. [Google Scholar] [CrossRef]

- Ahamad, T.; Naushad, M.; Alshheri, S.M. Fabrication of Highly Porous N/S Doped Carbon Embedded with CuO/CuS Nanoparticles for NH3 Gas Sensing. Mater. Lett. 2020, 268, 127515. [Google Scholar] [CrossRef]

- Li, P.; Wang, B.; Qin, C.; Han, C.; Sun, L.; Wang, Y. Band-Gap-Tunable CeO2 Nanoparticles for Room-Temperature NH3 Gas Sensors. Ceram. Int. 2020, 46, 19232–19240. [Google Scholar] [CrossRef]

- Liu, M.; Ji, J.; Song, P.; Wang, J.; Wang, Q. Sensing Performance of α-Fe2O3/Ti3C2Tx MXene Nanocomposites to NH3 at Room Temperature. J. Alloys Compd. 2022, 898, 162812. [Google Scholar] [CrossRef]

- Xiao, B.; Li, Y.-C.; Yu, X.F.; Cheng, J. MXenes: Reusable Materials for NH3 Sensor or Capturer by Controlling the Charge Injection. Sens. Actuators B Chem. 2016, 235, 103–109. [Google Scholar] [CrossRef]

- Kim, S.J.; Choi, J.; Maleski, K.; Hantanasirisakul, K.; Jung, H.-T.; Gogotsi, Y.; Ahn, C.W. Interfacial Assembly of Ultrathin, Functional MXene Films. ACS Appl. Mater. Interfaces 2019, 11, 32320–32327. [Google Scholar] [CrossRef]

- Seekaew, Y.; Kamlue, S.; Wongchoosuk, C. Room-Temperature Ammonia Gas Sensor Based on Ti3C2Tx MXene/Graphene Oxide/CuO/ZnO Nanocomposite. ACS Appl. Nano Mater. 2023, 6, 9008–9020. [Google Scholar] [CrossRef]

- Gabriunaite, I.; Valiuniene, A.; Ramanavicius, S.; Ramanavicius, A. Biosensors Based on Bio-Functionalized Semiconducting Metal Oxides. Crit. Rev. Anal. Chem. 2022, 1–16. [Google Scholar] [CrossRef]

- Celiesiute, R.; Ramanaviciene, A.; Gicevicius, M.; Ramanavicius, A. Electrochromic Sensors Based on Conducting Polymers, Metal Oxides, and Coordination Complexes. Crit. Rev. Anal. Chem. 2019, 49, 195–208. [Google Scholar] [CrossRef]

- Ramanavicius, S.; Jagminas, A.; Ramanavicius, A. Gas Sensors Based on Titanium Oxides (Review). Coatings 2022, 12, 699. [Google Scholar] [CrossRef]

- Ramanavicius, S.; Ramanavicius, A. Insights in the Application of Stoichiometric and Non-Stoichiometric Titanium Oxides for the Design of Sensors for the Determination of Gases and VOCs (TiO2−x and TinO2n−1 vs. TiO2). Sensors 2020, 20, 6833. [Google Scholar] [CrossRef]

- Ramanavicius, S.; Tereshchenko, A.; Karpicz, R.; Ratautaite, V.; Bubniene, U.; Maneikis, A.; Jagminas, A.; Ramanavicius, A. TiO2−x/TiO2-Structure Based ‘Self-Heated’ Sensor for the Determination of Some Reducing Gases. Sensors 2020, 20, 74. [Google Scholar] [CrossRef] [PubMed]

- Petruleviciene, M.; Savickaja, I.; Juodkazyte, J.; Ramanavicius, A. Investigation of WO3 and BiVO4 Photoanodes for Photoelectrochemical Sensing of Xylene, Toluene and Methanol. Chemosensors 2023, 11, 552. [Google Scholar] [CrossRef]

- Ramanavičius, S.; Petrulevičienė, M.; Juodkazytė, J.; Grigucevičienė, A.; Ramanavičius, A. Selectivity of Tungsten Oxide Synthesized by Sol-Gel Method Towards Some Volatile Organic Compounds and Gaseous Materials in a Broad Range of Temperatures. Materials 2020, 13, 523. [Google Scholar] [CrossRef] [PubMed]

- Petruleviciene, M.; Juodkazyte, J.; Parvin, M.; Tereshchenko, A.; Ramanavicius, S.; Karpicz, R.; Samukaite-Bubniene, U.; Ramanavicius, A. Tuning the Photo-Luminescence Properties of WO3 Layers by the Adjustment of Layer Formation Conditions. Materials 2020, 13, 2814. [Google Scholar] [CrossRef] [PubMed]

- Liu, M.; Wang, J.; Song, P.; Ji, J.; Wang, Q. Metal-Organic Frameworks-Derived In2O3 Microtubes/Ti3C2Tx MXene Composites for NH3 Detection at Room Temperature. Sens. Actuators B Chem. 2022, 361, 131755. [Google Scholar] [CrossRef]

- Pasupuleti, K.S.; Thomas, A.M.; Vidyasagar, D.; Rao, V.N.; Yoon, S.-G.; Kim, Y.-H.; Kim, S.-G.; Kim, M.-D. ZnO@Ti3C2Tx MXene Hybrid Composite-Based Schottky-Barrier-Coated SAW Sensor for Effective Detection of Sub-Ppb-Level NH3 at Room Temperature under UV Illumination. ACS Mater. Lett. 2023, 5, 2739–2746. [Google Scholar] [CrossRef]

- Liu, M.; Sun, R.-Y.; Ding, Y.-L.; Wang, Q.; Song, P. Au/α-Fe2O3/Ti3C2Tx MXene Nanosheet Heterojunctions for High-Performance NH3 Gas Detection at Room Temperature. ACS Appl. Nano Mater. 2023, 6, 11856–11867. [Google Scholar] [CrossRef]

- Turemis, M.; Zappi, D.; Giardi, M.T.; Basile, G.; Ramanaviciene, A.; Kapralovs, A.; Ramanavicius, A.; Viter, R. ZnO/Polyaniline Composite Based Photoluminescence Sensor for the Determination of Acetic Acid Vapor. Talanta 2020, 211, 120658. [Google Scholar] [CrossRef]

- Ramanavicius, S.; Ramanavicius, A. Conducting Polymers in the Design of Biosensors and Biofuel Cells. Polymers 2021, 13, 49. [Google Scholar] [CrossRef]

- Ramanavicius, S.; Ramanavicius, A. Charge Transfer and Biocompatibility Aspects in Conducting Polymer-Based Enzymatic Biosensors and Biofuel Cells. Nanomaterials 2021, 11, 371. [Google Scholar] [CrossRef] [PubMed]

- Gicevicius, M.; Celiesiute, R.; Kucinski, J.; Ramanaviciene, A.; Bagdziunas, G.; Ramanavicius, A. Analytical Evaluation of Optical PH-Sensitivity of Polyaniline Layer Electrochemically Deposited on ITO Electrode. J. Electrochem. Soc. 2018, 165, H903. [Google Scholar] [CrossRef]

- Ramanavicius, S.; Jagminas, A.; Ramanavicius, A. Advances in Molecularly Imprinted Polymers Based Affinity Sensors (Review). Polymers 2021, 13, 974. [Google Scholar] [CrossRef] [PubMed]

- Gicevicius, M.; Kucinski, J.; Ramanaviciene, A.; Ramanavicius, A. Tuning the Optical PH Sensing Properties of Polyaniline-Based Layer by Electrochemical Copolymerization of Aniline with o-Phenylenediamine. Dye. Pigment. 2019, 170, 107457. [Google Scholar] [CrossRef]

- Ramanavicius, S.; Samukaite-Bubniene, U.; Ratautaite, V.; Bechelany, M.; Ramanavicius, A. Electrochemical Molecularly Imprinted Polymer Based Sensors for Pharmaceutical and Biomedical Applications (Review). J. Pharm. Biomed. Anal. 2022, 215, 114739. [Google Scholar] [CrossRef]

- Ramanavicius, S.; Ramanavicius, A. Development of Molecularly Imprinted Polymer Based Phase Boundaries for Sensors Design (Review). Adv. Colloid. Interface Sci. 2022, 305, 102693. [Google Scholar] [CrossRef]

- Jin, L.; Wu, C.; Wei, K.; He, L.; Gao, H.; Zhang, H.; Zhang, K.; Asiri, A.M.; Alamry, K.A.; Yang, L.; et al. Polymeric Ti3C2Tx MXene Composites for Room Temperature Ammonia Sensing. ACS Appl. Nano Mater. 2020, 3, 12071–12079. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, D.; Zhang, H.; Gong, L.; Yang, Y.; Zhao, W.; Yu, S.; Yin, Y.; Sun, D. In Situ Polymerized Polyaniline/MXene (V2C) as Building Blocks of Supercapacitor and Ammonia Sensor Self-Powered by Electromagnetic-Triboelectric Hybrid Generator. Nano Energy 2021, 88, 106242. [Google Scholar] [CrossRef]

- Li, X.; Wang, H.; Li, H.; Chen, Y.; Ni, Y.; Xia, Y. Zr3C2O2 MXene as Promising Candidate for NH3 Sensor with High Sensitivity and Selectivity at Room Temperature. Appl. Surf. Sci. 2023, 624, 157125. [Google Scholar] [CrossRef]

- Gao, X.; Zhang, T. An Overview: Facet-Dependent Metal Oxide Semiconductor Gas Sensors. Sens. Actuators B Chem. 2018, 277, 604–633. [Google Scholar] [CrossRef]

- Zhang, D.; Wu, Z.; Zong, X. Flexible and Highly Sensitive H2S Gas Sensor Based on In-Situ Polymerized SNO2/RGO/PANI Ternary Nanocomposite with Application in Halitosis Diagnosis. Sens. Actuators B Chem. 2019, 289, 32–41. [Google Scholar] [CrossRef]

- Gui, Y.; Yang, L.; Tian, K.; Zhang, H.; Fang, S. P-Type Co3O4 Nanoarrays Decorated on the Surface of n-Type Flower-like WO3 Nanosheets for High-Performance Gas Sensing. Sens. Actuators B Chem. 2019, 288, 104–112. [Google Scholar] [CrossRef]

- Xu, Y.; Ma, T.; Zheng, L.; Zhao, Y.; Liu, X.; Zhang, J. Heterostructures of Hematite-Sensitized W18O49 Hollow Spheres for Improved Acetone Detection with Ultralow Detection Limit. Sens. Actuators B Chem. 2019, 288, 432–441. [Google Scholar] [CrossRef]

- Zhang, R.; Zhou, T.; Wang, L.; Zhang, T. Metal–Organic Frameworks-Derived Hierarchical Co3O4 Structures as Efficient Sensing Materials for Acetone Detection. ACS Appl. Mater. Interfaces 2018, 10, 9765–9773. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, C. Is Breath Acetone a Biomarker of Diabetes? A Historical Review on Breath Acetone Measurements. J. Breath. Res. 2013, 7, 037109. [Google Scholar] [CrossRef] [PubMed]

- Sun, S.; Wang, M.; Chang, X.; Jiang, Y.; Zhang, D.; Wang, D.; Zhang, Y.; Lei, Y. W18O49/Ti3C2Tx Mxene Nanocomposites for Highly Sensitive Acetone Gas Sensor with Low Detection Limit. Sens. Actuators B Chem. 2020, 304, 127274. [Google Scholar] [CrossRef]

- Liu, M.; Wang, Z.; Song, P.; Yang, Z.; Wang, Q. Flexible MXene/RGO/CuO Hybrid Aerogels for High Performance Acetone Sensing at Room Temperature. Sens. Actuators B Chem. 2021, 340, 129946. [Google Scholar] [CrossRef]

- Majhi, S.M.; Ali, A.; Greish, Y.E.; El-Maghraby, H.F.; Mahmoud, S.T. V2CTX MXene-Based Hybrid Sensor with High Selectivity and Ppb-Level Detection for Acetone at Room Temperature. Sci. Rep. 2023, 13, 3114. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Zhang, G.; Wang, J.; Yuan, T.; Huang, J.; Wang, L.; Liu, Y.-N. Ru Nanoclusters Supported on Ti3C2Tx Nanosheets for Catalytic Hydrogenation of Quinolines. ACS Appl. Nano Mater. 2022, 5, 6213–6220. [Google Scholar] [CrossRef]

- Lee, J.T.; Wyatt, B.C.; Davis, G.A., Jr.; Masterson, A.N.; Pagan, A.L.; Shah, A.; Anasori, B.; Sardar, R. Covalent Surface Modification of Ti3C2Tx MXene with Chemically Active Polymeric Ligands Producing Highly Conductive and Ordered Microstructure Films. ACS Nano 2021, 15, 19600–19612. [Google Scholar] [CrossRef] [PubMed]

- Hermawan, A.; Zhang, B.; Taufik, A.; Asakura, Y.; Hasegawa, T.; Zhu, J.; Shi, P.; Yin, S. CuO Nanoparticles/Ti3C2Tx MXene Hybrid Nanocomposites for Detection of Toluene Gas. ACS Appl. Nano Mater. 2020, 3, 4755–4766. [Google Scholar] [CrossRef]

- Guo, W.; Surya, S.G.; Babar, V.; Ming, F.; Sharma, S.; Alshareef, H.N.; Schwingenschlögl, U.; Salama, K.N. Selective Toluene Detection with Mo2CTx MXene at Room Temperature. ACS Appl. Mater. Interfaces 2020, 12, 57218–57227. [Google Scholar] [CrossRef]

- Park, H.J.; Hong, S.Y.; Chun, D.H.; Kang, S.W.; Park, J.C.; Lee, D.-S. A Highly Susceptive Mesoporous Hematite Microcube Architecture for Sustainable P-Type Formaldehyde Gas Sensors. Sens. Actuators B Chem. 2019, 287, 437–444. [Google Scholar] [CrossRef]

- Fu, X.; Yang, P.; Xiao, X.; Zhou, D.; Huang, R.; Zhang, X.; Cao, F.; Xiong, J.; Hu, Y.; Tu, Y.; et al. Ultra-Fast and Highly Selective Room-Temperature Formaldehyde Gas Sensing of Pt-Decorated MoO3 Nanobelts. J. Alloys Compd. 2019, 797, 666–675. [Google Scholar] [CrossRef]

- Zhao, R.; Zhang, X.; Peng, S.; Hong, P.; Zou, T.; Wang, Z.; Xing, X.; Yang, Y.; Wang, Y. Shaddock Peels as Bio-Templates Synthesis of Cd-Doped SnO2 Nanofibers: A High Performance Formaldehyde Sensing Material. J. Alloys Compd. 2020, 813, 152170. [Google Scholar] [CrossRef]

- Shuaishuai, J.; Wan, X.; Cuimin, Z.; Feihu, L.; Bo, M.; Zili, Z. Improving the Formaldehyde Gas Sensing Performance of the ZnO/SnO2 Nanoparticles by PdO Decoration. J. Mater. Sci. Mater. Electron. 2020, 31, 684–692. [Google Scholar] [CrossRef]

- Chen, X.; Shen, Y.; Zhou, P.; Zhao, S.; Zhong, X.; Li, T.; Han, C.; Wei, D.; Meng, D. NO2 Sensing Properties of One-Pot-Synthesized ZnO Nanowires with Pd Functionalization. Sens. Actuators B Chem. 2019, 280, 151–161. [Google Scholar] [CrossRef]

- Zhang, D.; Mi, Q.; Wang, D.; Li, T. MXene/Co3O4 Composite Based Formaldehyde Sensor Driven by ZnO/MXene Nanowire Arrays Piezoelectric Nanogenerator. Sens. Actuators B Chem. 2021, 339, 129923. [Google Scholar] [CrossRef]

- Niu, G.; Zhang, M.; Wu, B.; Zhuang, Y.; Ramachandran, R.; Zhao, C.; Wang, F. Nanocomposites of Pre-Oxidized Ti3C2Tx MXene and SnO2 Nanosheets for Highly Sensitive and Stable Formaldehyde Gas Sensor. Ceram. Int. 2023, 49, 2583–2590. [Google Scholar] [CrossRef]

- Mirzaei, A.; Leonardi, S.G.; Neri, G. Detection of Hazardous Volatile Organic Compounds (VOCs) by Metal Oxide Nanostructures-Based Gas Sensors: A Review. Ceram. Int. 2016, 42, 15119–15141. [Google Scholar] [CrossRef]

- Wang, X.; Sun, K.; Li, K.; Li, X.; Gogotsi, Y. Ti3C2Tx/PEDOT:PSS Hybrid Materials for Room-Temperature Methanol Sensor. Chin. Chem. Lett. 2020, 31, 1018–1021. [Google Scholar] [CrossRef]

- Liu, M.; Wang, Z.; Song, P.; Yang, Z.; Wang, Q. In2O3 Nanocubes/Ti3C2Tx MXene Composites for Enhanced Methanol Gas Sensing Properties at Room Temperature. Ceram. Int. 2021, 47, 23028–23037. [Google Scholar] [CrossRef]

- Jiang, B.; Lu, J.; Han, W.; Sun, Y.; Wang, Y.; Cheng, P.; Zhang, H.; Wang, C.; Lu, G. Hierarchical Mesoporous Zinc Oxide Microspheres for Ethanol Gas Sensor. Sens. Actuators B Chem. 2022, 357, 131333. [Google Scholar] [CrossRef]

- Zhang, J.; Ma, S.; Wang, B.; Pei, S. Hydrothermal Synthesis of SnO2-CuO Composite Nanoparticles as a Fast-Response Ethanol Gas Sensor. J. Alloys Compd. 2021, 886, 161299. [Google Scholar] [CrossRef]

- Sharma, B.; Karuppasamy, K.; Vikraman, D.; Jo, E.-B.; Sivakumar, P.; Kim, H.-S. Porous, 3D-Hierarchical α-NiMoO4 Rectangular Nanosheets for Selective Conductometric Ethanol Gas Sensors. Sens. Actuators B Chem. 2021, 347, 130615. [Google Scholar] [CrossRef]

- Tseng, S.-F.; Chen, C.-W. Synthesis of Nanograiny SnO2 Films on Laser-Patterned Graphene/Ceramic Substrates for Low-Temperature Ethanol Gas Sensors. Ceram. Int. 2021, 47, 33498–33508. [Google Scholar] [CrossRef]

- Mao, J.N.; Hong, B.; Chen, H.D.; Gao, M.H.; Xu, J.C.; Han, Y.B.; Yang, Y.T.; Jin, H.X.; Jin, D.F.; Peng, X.L.; et al. Highly Improved Ethanol Gas Response of N-Type α-Fe2O3 Bunched Nanowires Sensor with High-Valence Donor-Doping. J. Alloys Compd. 2020, 827, 154248. [Google Scholar] [CrossRef]

- Zhang, S.; Song, P.; Sun, J.; Ding, Y.; Wang, Q. MoO3/Ti3C2Tx MXene Nanocomposites with Rapid Response for Enhanced Ethanol-Sensing at a Low Temperature. Sens. Actuators B Chem. 2023, 378, 133216. [Google Scholar] [CrossRef]

- Wang, C.; Li, R.; Feng, L.; Xu, J. The SnO2/MXene Composite Ethanol Sensor Based on MEMS Platform. Chemosensors 2022, 10, 109. [Google Scholar] [CrossRef]

- Ai, T.; Li, J.; Nie, S.; Yin, Y.; Lu, J.; Bao, S.; Yan, L. High-Performance H2 Gas Sensor Based on Mn-Doped α-Fe2O3 Polyhedrons from N, N-Dimethylformamide Assisted Hydrothermal Synthesis. Int. J. Hydrogen Energy 2022, 47, 20561–20571. [Google Scholar] [CrossRef]

- Long, Y.; Xu, H.; He, J.; Li, C.; Zhu, M. Piezoelectric Polarization of BiOCl via Capturing Mechanical Energy for Catalytic H2 Evolution. Surf. Interfaces 2022, 31, 102056. [Google Scholar] [CrossRef]

- Meng, X.; Bi, M.; Xiao, Q.; Gao, W. Ultrasensitive Gas Sensor Based on Pd/SnS2/SnO2 Nanocomposites for Rapid Detection of H2. Sens. Actuators B Chem. 2022, 359, 131612. [Google Scholar] [CrossRef]

- Zhu, S.; Tian, Q.; Wu, G.; Bian, W.; Sun, N.; Wang, X.; Li, C.; Zhang, Y.; Dou, H.; Gong, C.; et al. Highly Sensitive and Stable H2 Gas Sensor Based on P-PdO-n-WO3-Heterostructure-Homogeneously-Dispersing Thin Film. Int. J. Hydrogen Energy 2022, 47, 17821–17834. [Google Scholar] [CrossRef]

- Wang, L.; Xiao, Z.; Yao, X.; Yu, X.; Tu, S.-T.; Chen, S. Pt=Pd Separation Modified Ti3C2TX MXene for Hydrogen Detection at Room Temperature. Int. J. Hydrogen Energy 2023, 48, 30205–30217. [Google Scholar] [CrossRef]

- Xia, Y.; Zhou, L.; Yang, J.; Du, P.; Xu, L.; Wang, J. Highly Sensitive and Fast Optoelectronic Room-Temperature NO2 Gas Sensor Based on ZnO Nanorod-Assembled Macro-/Mesoporous Film. ACS Appl. Electron. Mater. 2020, 2, 580–589. [Google Scholar] [CrossRef]

- Guo, F.; Feng, C.; Zhang, Z.; Zhang, L.; Xu, C.; Zhang, C.; Lin, S.; Wu, H.; Zhang, B.; Tabusi, A.; et al. A Room-Temperature NO2 Sensor Based on Ti3C2TX MXene Modified with Sphere-like CuO. Sens. Actuators B Chem. 2023, 375, 132885. [Google Scholar] [CrossRef]

- Gasso, S.; Kaur Sohal, M.; Chand Singh, R.; Mahajan, A. NOx Sensor Based on Semiconductor Metal Oxide and MXene Nanostructures. Mater. Today Proc. 2023, 92, 632–635. [Google Scholar] [CrossRef]

- Sun, B.; Qin, F.; Jiang, L.; Gao, J.; Liu, Z.; Wang, J.; Zhang, Y.; Fan, J.; Kan, K.; Shi, K. Room-Temperature Gas Sensors Based on Three-Dimensional Co3O4/Al2O3@Ti3C2Tx MXene Nanocomposite for Highly Sensitive NOx Detection. Sens. Actuators B Chem. 2022, 368, 132206. [Google Scholar] [CrossRef]

- Kuang, D.; Wang, L.; Guo, X.; She, Y.; Du, B.; Liang, C.; Qu, W.; Sun, X.; Wu, Z.; Hu, W.; et al. Facile Hydrothermal Synthesis of Ti3C2Tx-TiO2 Nanocomposites for Gaseous Volatile Organic Compounds Detection at Room Temperature. J. Hazard. Mater. 2021, 416, 126171. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, Y.; Wang, Y.; Li, X. Humidity-Enabled Ionic Conductive Trace Carbon Dioxide Sensing of Nitrogen-Doped Ti3C2Tx MXene/Polyethyleneimine Composite Films Decorated with Reduced Graphene Oxide Nanosheets. Anal. Chem. 2020, 92, 16033–16042. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Xu, R.; Xia, Y.; Komarneni, S. Ti2CTx MXene: A Novel p-Type Sensing Material for Visible Light-Enhanced Room Temperature Methane Detection. Ceram. Int. 2021, 47, 34437–34442. [Google Scholar] [CrossRef]

- Persson, P.; Rosen, J. Current State of the Art on Tailoring the MXene Composition, Structure, and Surface Chemistry. Curr. Opin. Solid. State Mater. Sci. 2019, 23, 100774. [Google Scholar] [CrossRef]

- Rhouati, A.; Berkani, M.; Vasseghian, Y.; Golzadeh, N. MXene-Based Electrochemical Sensors for Detection of Environmental Pollutants: A Comprehensive Review. Chemosphere 2022, 291, 132921. [Google Scholar] [CrossRef]

- Park, Y.J.; Peñas-Defrutos, M.N.; Drummond, M.J.; Gordon, Z.; Kelly, O.R.; Garvey, I.J.; Gullett, K.L.; García-Melchor, M.; Fout, A.R. Secondary Coordination Sphere Influences the Formation of Fe(III)-O or Fe(III)-OH in Nitrite Reduction: A Synthetic and Computational Study. Inorg. Chem. 2022, 61, 8182–8192. [Google Scholar] [CrossRef]

- Hao, D.; Liu, Y.; Gao, S.; Arandiyan, H.; Bai, X.; Kong, Q.; Wei, W.; Shen, P.K.; Ni, B.-J. Emerging Artificial Nitrogen Cycle Processes through Novel Electrochemical and Photochemical Synthesis. Mater. Today 2021, 46, 212–233. [Google Scholar] [CrossRef]

- Hou, C.-Y.; Fu, L.-M.; Ju, W.-J.; Wu, P.-Y. Microfluidic Colorimetric System for Nitrite Detection in Foods. Chem. Eng. J. 2020, 398, 125573. [Google Scholar] [CrossRef]

- Guadagnini, L.; Tonelli, D. Carbon Electrodes Unmodified and Decorated with Silver Nanoparticles for the Determination of Nitrite, Nitrate and Iodate. Sens. Actuators B Chem. 2013, 188, 806–814. [Google Scholar] [CrossRef]

- Wang, T.; Wang, C.; Xu, X.; Li, Z.; Li, D. One-Step Electrodeposition Synthesized Aunps/Mxene/ERGO for Selectivity Nitrite Sensing. Nanomaterials 2021, 11, 1892. [Google Scholar] [CrossRef]

- Wang, Y.; Zeng, Z.; Qiao, J.; Dong, S.; Liang, Q.; Shao, S. Ultrasensitive Determination of Nitrite Based on Electrochemical Platform of AuNPs Deposited on PDDA-Modified MXene Nanosheets. Talanta 2021, 221, 121605. [Google Scholar] [CrossRef]

- Feng, X.; Han, G.; Cai, J.; Wang, X. Au@Carbon Quantum Dots-MXene Nanocomposite as an Electrochemical Sensor for Sensitive Detection of Nitrite. J. Colloid. Interface Sci. 2022, 607, 1313–1322. [Google Scholar] [CrossRef]

- Zhuang, J.; Pan, H.; Feng, W. 3D Urchin–like CoVO/MXene Nanosheet Composites for Enhanced Detection Signal of Nitrite. Sens. Actuators B Chem. 2023, 378, 133207. [Google Scholar] [CrossRef]

- Schmidt, E.W. Hydrazine and Its Derivatives: Preparation, Properties, Applications, 2 Volume Set; John Wiley & Sons: Hoboken, NJ, USA, 2001; ISBN 0471415537. [Google Scholar]

- Mackinson, F.W. Occupational Health Guidelines for Chemical Hazards. NIOSH OSHA 1981, 4, 81–123. [Google Scholar]

- Soundiraraju, B.; Raghavan, R.; George, B.K. Chromium Carbide Nanosheets Prepared by Selective Etching of Aluminum from Cr2AlC for Hydrazine Detection. ACS Appl. Nano Mater. 2020, 3, 11007–11016. [Google Scholar] [CrossRef]

- Soundiraraju, B.; Anthony, A.M.; Pandurangan, P.; George, B.K. Electrochemical Behavior of Chromium Carbide MXene Modified Electrodes: Hydrazine Sensing. Mater. Today Commun. 2022, 32, 103982. [Google Scholar] [CrossRef]

- Yao, Y.; Han, X.; Yang, X.; Zhao, J.; Chai, C. Detection of Hydrazine at MXene/ZIF-8 Nanocomposite Modified Electrode†. Chin. J. Chem. 2021, 39, 330–336. [Google Scholar] [CrossRef]

- Gul, S.; Serna, M.I.; Zahra, S.A.; Arif, N.; Iqbal, M.; Akinwande, D.; Rizwan, S. Un-Doped and Er-Adsorbed Layered Nb2C MXene for Efficient Hydrazine Sensing Application. Surf. Interfaces 2021, 24, 101074. [Google Scholar] [CrossRef]

- Yang, H.; Li, S.; Yu, H.; Zheng, F.; Lin, L.; Chen, J.; Li, Y.; Lin, Y. In Situ Construction of Hollow Carbon Spheres with N, Co, and Fe Co-Doping as Electrochemical Sensors for Simultaneous Determination of Dihydroxybenzene Isomers. Nanoscale 2019, 11, 8950–8958. [Google Scholar] [CrossRef]

- Shen, Y.; Rao, D.; Sheng, Q.; Zheng, J. Simultaneous Voltammetric Determination of Hydroquinone and Catechol by Using a Glassy Carbon Electrode Modified with Carboxy-Functionalized Carbon Nanotubes in a Chitosan Matrix and Decorated with Gold Nanoparticles. Microchim. Acta 2017, 184, 3591–3601. [Google Scholar] [CrossRef]

- Wu, L.; Lu, X.; Dhanjai; Wu, Z.-S.; Dong, Y.; Wang, X.; Zheng, S.; Chen, J. 2D Transition Metal Carbide MXene as a Robust Biosensing Platform for Enzyme Immobilization and Ultrasensitive Detection of Phenol. Biosens. Bioelectron. 2018, 107, 69–75. [Google Scholar] [CrossRef]

- Lei, L.; Li, C.; Huang, W.; Wu, K. Simultaneous Detection of 4-Chlorophenol and 4-Nitrophenol Using a Ti3C2Tx MXene Based Electrochemical Sensor. Analyst 2021, 146, 7593–7600. [Google Scholar] [CrossRef]

- Krishnamoorthy, R.; Muthumalai, K.; Nagaraja, T.; Rajendrakumar, R.T.; Das, S.R. Chemically Exfoliated Titanium Carbide MXene for Highly Sensitive Electrochemical Sensors for Detection of 4-Nitrophenols in Drinking Water. ACS Omega 2022, 7, 42644–42654. [Google Scholar] [CrossRef] [PubMed]

- Huang, R.; Liao, D.; Liu, Z.; Yu, J.; Jiang, X. Electrostatically Assembling 2D Hierarchical Nb2CTx and Zifs-Derivatives into Zn-Co-NC Nanocage for the Electrochemical Detection of 4-Nitrophenol. Sens. Actuators B Chem. 2021, 338, 129828. [Google Scholar] [CrossRef]

- Rasheed, P.A.; Pandey, R.P.; Jabbar, K.A.; Mahmoud, K.A. Platinum Nanoparticles/Ti3C2Tx (MXene) Composite for the Effectual Electrochemical Sensing of Bisphenol A in Aqueous Media. J. Electroanal. Chem. 2021, 880, 114934. [Google Scholar] [CrossRef]

- Huang, R.; Liao, D.; Chen, S.; Yu, J.; Jiang, X. A Strategy for Effective Electrochemical Detection of Hydroquinone and Catechol: Decoration of Alkalization-Intercalated Ti3C2 with MOF-Derived N-Doped Porous Carbon. Sens. Actuators B Chem. 2020, 320, 128386. [Google Scholar] [CrossRef]

- Tu, X.; Gao, F.; Ma, X.; Zou, J.; Yu, Y.; Li, M.; Qu, F.; Huang, X.; Lu, L. Mxene/Carbon Nanohorn/β-Cyclodextrin-Metal-Organic Frameworks as High-Performance Electrochemical Sensing Platform for Sensitive Detection of Carbendazim Pesticide. J. Hazard. Mater. 2020, 396, 122776. [Google Scholar] [CrossRef] [PubMed]

- Xie, Y.; Gao, F.; Tu, X.; Ma, X.; Xu, Q.; Dai, R.; Huang, X.; Yu, Y.; Lu, L. Facile Synthesis of MXene/Electrochemically Reduced Graphene Oxide Composites and Their Application for Electrochemical Sensing of Carbendazim. J. Electrochem. Soc. 2019, 166, B1673. [Google Scholar] [CrossRef]

- He, Y.; Zhou, X.; Zhou, L.; Zhang, X.; Ma, L.; Jiang, Y.; Gao, J. Self-Reducing Prussian Blue on Ti3C2Tx MXene Nanosheets as a Dual-Functional Nanohybrid for Hydrogen Peroxide and Pesticide Sensing. Ind. Eng. Chem. Res. 2020, 59, 15556–15564. [Google Scholar] [CrossRef]

- Zhao, F.; Yao, Y.; Jiang, C.; Shao, Y.; Barceló, D.; Ying, Y.; Ping, J. Self-Reduction Bimetallic Nanoparticles on Ultrathin MXene Nanosheets as Functional Platform for Pesticide Sensing. J. Hazard. Mater. 2020, 384, 121358. [Google Scholar] [CrossRef]

- Zhou, L.; Zhang, X.; Ma, L.; Gao, J.; Jiang, Y. Acetylcholinesterase/Chitosan-Transition Metal Carbides Nanocomposites-Based Biosensor for the Organophosphate Pesticides Detection. Biochem. Eng. J. 2017, 128, 243–249. [Google Scholar] [CrossRef]

- Lin, C.; Song, X.; Ye, W.; Liu, T.; Rong, M.; Niu, L. Recent Progress in Optical Sensors Based on MXenes Quantum Dots and MXenes Nanosheets. J. Anal. Test. 2023, 8, 95–113. [Google Scholar] [CrossRef]

- Wu, L.; Yuan, X.; Tang, Y.; Wageh, S.; Al-Hartomy, O.A.; Al-Sehemi, A.G.; Yang, J.; Xiang, Y.; Zhang, H.; Qin, Y. MXene Sensors Based on Optical and Electrical Sensing Signals: From Biological, Chemical, and Physical Sensing to Emerging Intelligent and Bionic Devices. PhotoniX 2023, 4, 15. [Google Scholar] [CrossRef]

- Bhardwaj, S.K.; Singh, H.; Khatri, M.; Kim, K.-H.; Bhardwaj, N. Advances in MXenes-Based Optical Biosensors: A Review. Biosens. Bioelectron. 2022, 202, 113995. [Google Scholar] [CrossRef]

- Chaudhuri, K.; Alhabeb, M.; Wang, Z.; Shalaev, V.M.; Gogotsi, Y.; Boltasseva, A. Highly Broadband Absorber Using Plasmonic Titanium Carbide (MXene). ACS Photonics 2018, 5, 1115–1122. [Google Scholar] [CrossRef]

- Li, R.; Zhang, L.; Shi, L.; Wang, P. MXene Ti3C2: An Effective 2D Light-to-Heat Conversion Material. ACS Nano 2017, 11, 3752–3759. [Google Scholar] [CrossRef]

- Cui, Y.; Yang, K.; Zhang, F.; Lyu, Y.; Zhang, Q.; Zhang, B. Ultra-Light MXene/CNTs/PI Aerogel with Neat Arrangement for Electromagnetic Wave Absorption and Photothermal Conversion. Compos. Part A Appl. Sci. Manuf. 2022, 158, 106986. [Google Scholar] [CrossRef]

- Li, W.; Miao, Y.; Zheng, Y.; Zhang, K.; Yao, J. Nb2CTx MXene Integrated Tapered Microfiber Based on Light-Controlled Light for Ultra-Sensitive and Wide-Range Hemoglobin Detection. IEEE Sens. J. 2022, 22, 11456–11462. [Google Scholar] [CrossRef]

- Kumar, A.; Verma, P.; Jindal, P. Surface Plasmon Resonance Biosensor Based on a D-Shaped Photonic Crystal Fiber Using Ti3C2Tx MXene Material. Opt. Mater. 2022, 128, 112397. [Google Scholar] [CrossRef]

- Ma, C.; Cao, Y.; Gou, X.; Zhu, J.-J. Recent Progress in Electrochemiluminescence Sensing and Imaging. Anal. Chem. 2020, 92, 431–454. [Google Scholar] [CrossRef]

- Sojic, N. Analytical Electrogenerated Chemiluminescence: From Fundamentals to Bioassays; Royal Society of Chemistry: London, UK, 2019; Volume 15, ISBN 1788014146. [Google Scholar]

- Ramanaviciene, A.; German, N.; Kausaite-Minkstimiene, A.; Voronovic, J.; Kirlyte, J.; Ramanavicius, A. Comparative Study of Surface Plasmon Resonance, Electrochemical and Electroassisted Chemiluminescence Methods Based Immunosensor for the Determination of Antibodies against Human Growth Hormone. Biosens. Bioelectron. 2012, 36, 48–55. [Google Scholar] [CrossRef]

- Ma, X.; Gao, W.; Du, F.; Yuan, F.; Yu, J.; Guan, Y.; Sojic, N.; Xu, G. Rational Design of Electrochemiluminescent Devices. ACC Chem. Res. 2021, 54, 2936–2945. [Google Scholar] [CrossRef]

- Kerr, E.; Farr, R.; Doeven, E.H.; Nai, Y.H.; Alexander, R.; Guijt, R.M.; Prieto-Simon, B.; Francis, P.S.; Dearnley, M.; Hayne, D.J.; et al. Amplification-Free Electrochemiluminescence Molecular Beacon-Based MicroRNA Sensing Using a Mobile Phone for Detection. Sens. Actuators B Chem. 2021, 330, 129261. [Google Scholar] [CrossRef]

- Daley, G.Q.; Van Etten, R.A.; Baltimore, D. Induction of Chronic Myelogenous Leukemia in Mice by the P210bcr/Abl Gene of the Philadelphia Chromosome. Science 1990, 247, 824–830. [Google Scholar] [CrossRef]

- Cheng, W.; Lin, Z.; Zhao, L.; Fan, N.; Bai, H.; Cheng, W.; Zhao, M.; Ding, S. CeO2/MXene Heterojunction-Based Ultrasensitive Electrochemiluminescence Biosensing for BCR-ABL Fusion Gene Detection Combined with Dual-Toehold Strand Displacement Reaction for Signal Amplification. Biosens. Bioelectron. 2022, 210, 114287. [Google Scholar] [CrossRef]

- Zhou, H.; Liu, J.; Xu, J.-J.; Zhang, S.; Chen, H.-Y. Chapter Two—Advances in DNA/RNA Detection Using Nanotechnology. In Advances in Clinical Chemistry; Makowski, G.S., Ed.; Elsevier: Amsterdam, The Netherlands, 2019; Volume 91, pp. 31–98. ISBN 0065-2423. [Google Scholar]

- Viter, R.; Kunene, K.; Genys, P.; Jevdokimovs, D.; Erts, D.; Sutka, A.; Bisetty, K.; Viksna, A.; Ramanaviciene, A.; Ramanavicius, A. Photoelectrochemical Bisphenol S Sensor Based on ZnO-Nanoroads Modified by Molecularly Imprinted Polypyrrole. Macromol. Chem. Phys. 2020, 221, 1900232. [Google Scholar] [CrossRef]

- Zhao, W.-W.; Xu, J.-J.; Chen, H.-Y. Photoelectrochemical Bioanalysis: The State of the Art. Chem. Soc. Rev. 2015, 44, 729–741. [Google Scholar] [CrossRef]

- Zhou, Q.; Tang, D. Recent Advances in Photoelectrochemical Biosensors for Analysis of Mycotoxins in Food. TrAC Trends Anal. Chem. 2020, 124, 115814. [Google Scholar] [CrossRef]

- Zhao, W.-W.; Xu, J.-J.; Chen, H.-Y. Photoelectrochemical DNA Biosensors. Chem. Rev. 2014, 114, 7421–7441. [Google Scholar] [CrossRef]

- Liu, F.; Zhao, J.; Liu, X.; Zhen, X.; Feng, Q.; Gu, Y.; Yang, G.; Qu, L.; Zhu, J.-J. PEC-SERS Dual-Mode Detection of Foodborne Pathogens Based on Binding-Induced DNA Walker and C3N4/MXene-Au NPs Accelerator. Anal. Chem. 2023, 95, 14297–14307. [Google Scholar] [CrossRef]

- Wang, L.; Zhu, F.; Chen, M.; Zhu, Y.; Xiao, J.; Yang, H.; Chen, X. Rapid and Visual Detection of Aflatoxin B1 in Foodstuffs Using Aptamer/G-Quadruplex DNAzyme Probe with Low Background Noise. Food Chem. 2019, 271, 581–587. [Google Scholar] [CrossRef] [PubMed]

- Viter, R.; Savchuk, M.; Iatsunskyi, I.; Pietralik, Z.; Starodub, N.; Shpyrka, N.; Ramanaviciene, A.; Ramanavicius, A. Analytical, Thermodynamical and Kinetic Characteristics of Photoluminescence Immunosensor for the Determination of Ochratoxin A. Biosens. Bioelectron. 2018, 99, 237–243. [Google Scholar] [CrossRef]

- Lu, X.; Wang, C.; Qian, J.; Ren, C.; An, K.; Wang, K. Target-Driven Switch-on Fluorescence Aptasensor for Trace Aflatoxin B1 Determination Based on Highly Fluorescent Ternary CdZnTe Quantum Dots. Anal. Chim. Acta 2019, 1047, 163–171. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.; Sun, D.-W.; Pu, H.; Wei, Q. A Novel Fluorescence Biosensor Based on CRISPR/Cas12a Integrated MXenes for Detecting Aflatoxin B1. Talanta 2023, 252, 123773. [Google Scholar] [CrossRef]

- Bandodkar, A.J.; Gutruf, P.; Choi, J.; Lee, K.; Sekine, Y.; Reeder, J.T.; Jeang, W.J.; Aranyosi, A.J.; Lee, S.P.; Model, J.B.; et al. Battery-Free, Skin-Interfaced Microfluidic/Electronic Systems for Simultaneous Electrochemical, Colorimetric, and Volumetric Analysis of Sweat. Sci. Adv. 2023, 5, eaav3294. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Kang, Z.; Kong, L.; Shi, H.; Zhang, Y.; Cui, M.; Yang, D.-P. MXene-Ti3C2/CuS Nanocomposites: Enhanced Peroxidase-like Activity and Sensitive Colorimetric Cholesterol Detection. Mater. Sci. Eng. C 2019, 104, 110000. [Google Scholar] [CrossRef]

- Zeng, Y.; Hu, R.; Wang, L.; Gu, D.; He, J.; Wu, S.-Y.; Ho, H.-P.; Li, X.; Qu, J.; Gao, B.Z.; et al. Recent Advances in Surface Plasmon Resonance Imaging: Detection Speed, Sensitivity, and Portability. Nanophotonics 2017, 6, 1017–1030. [Google Scholar] [CrossRef]

- Balciunas, D.; Plausinaitis, D.; Ratautaite, V.; Ramanaviciene, A.; Ramanavicius, A. Towards Electrochemical Surface Plasmon Resonance Sensor Based on the Molecularly Imprinted Polypyrrole for Glyphosate Sensing. Talanta 2022, 241, 123252. [Google Scholar] [CrossRef]

- Kausaite-Minkstimiene, A.; Ramanavicius, A.; Ruksnaite, J.; Ramanaviciene, A. A Surface Plasmon Resonance Immunosensor for Human Growth Hormone Based on Fragmented Antibodies. Anal. Methods 2013, 5, 4757–4763. [Google Scholar] [CrossRef]

- Zhu, X.; Gao, T. Chapter 10—Spectrometry. In Nano-Inspired Biosensors for Protein Assay with Clinical Applications; Li, G., Ed.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 237–264. ISBN 978-0-12-815053-5. [Google Scholar]

- Chen, R.; Kan, L.; Duan, F.; He, L.; Wang, M.; Cui, J.; Zhang, Z.; Zhang, Z. Surface Plasmon Resonance Aptasensor Based on Niobium Carbide MXene Quantum Dots for Nucleocapsid of SARS-CoV-2 Detection. Microchim. Acta 2021, 188, 316. [Google Scholar] [CrossRef]

- Baniukevic, J.; Hakki Boyaci, I.; Goktug Bozkurt, A.; Tamer, U.; Ramanavicius, A.; Ramanaviciene, A. Magnetic Gold Nanoparticles in SERS-Based Sandwich Immunoassay for Antigen Detection by Well Oriented Antibodies. Biosens. Bioelectron. 2013, 43, 281–288. [Google Scholar] [CrossRef]

- Liu, R.; Jiang, L.; Yu, Z.; Jing, X.; Liang, X.; Wang, D.; Yang, B.; Lu, C.; Zhou, W.; Jin, S. MXene (Ti3C2Tx)-Ag Nanocomplex as Efficient and Quantitative SERS Biosensor Platform by in-Situ PDDA Electrostatic Self-Assembly Synthesis Strategy. Sens. Actuators B Chem. 2021, 333, 129581. [Google Scholar] [CrossRef]

| Composition | Sensitivity (GF) | Test Range, Strain % | LOD, Strain % | Ref |

|---|---|---|---|---|

| Ti3C2Tx/MWCNTs/TPU | 13–363 | 0–100 | - | [58] |

| Ti3C2Tx MXene/polyurethane | 22.9–228 | 58–150 | 0.1 | [59] |

| CNT/Ti3C2Tx MXene/PDMS | 13.3 | 0–60.3 | - | [53] |

| MXene/PANIF | 97.6–2369.1 | 0–80 | 0.1538 | [60] |

| Ti3C2Tx MXene/paper | 17.4 | 0–0.6 | 0.1 | [61] |

| Ti3C2Tx MXene/P(VDF-TrFE) | 6.35–108.8 | 45–66 | - | [62] |

| PVA/CMC/TA/MXene hydrogel | 2.9 | 0–700 | 1 | [63] |

| PVA-CA-MXene hydrogel | 2.3 | 0–200 | - | [64] |

| Polyvinyl alcohol/polyacrylamide/CaCl2/MXene | 3.0 | 0–300 | - | [65] |

| Liquid metal/MXene | 7.85–15.47 | 0–400 | - | [66] |

| PAA/PEDOT:PSS/MXene hydrogel | 9–20.86 | 0–1000 | - | [67] |

| MXene/AgNWs/TPU | 33.1 | 0–120 | - | [68] |

| Composition | Sensitivity, kPa−1 | Test Range, kPa | LOD, Pa | Ref |

|---|---|---|---|---|

| MXene/CTAB/CMF | 381.91 | 0−3 | 0.1 | [95] |

| MXene/PPNs/MXene/TPUEM | 34.9–177.3 | 0–30.4 | - | [96] |

| MXene/Polyetherimide | 20 (150 °C)–80 (−5 °C) | 0–40 | 9 | [97] |

| MXene/rGO/PS | 115–224 | 0–20.65 | - | [98] |

| MXene/bacterial cellulose (BC) | 0.94–95.2 | 0–10 | 0.4 | [99] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Navitski, I.; Ramanaviciute, A.; Ramanavicius, S.; Pogorielov, M.; Ramanavicius, A. MXene-Based Chemo-Sensors and Other Sensing Devices. Nanomaterials 2024, 14, 447. https://doi.org/10.3390/nano14050447

Navitski I, Ramanaviciute A, Ramanavicius S, Pogorielov M, Ramanavicius A. MXene-Based Chemo-Sensors and Other Sensing Devices. Nanomaterials. 2024; 14(5):447. https://doi.org/10.3390/nano14050447

Chicago/Turabian StyleNavitski, Ilya, Agne Ramanaviciute, Simonas Ramanavicius, Maksym Pogorielov, and Arunas Ramanavicius. 2024. "MXene-Based Chemo-Sensors and Other Sensing Devices" Nanomaterials 14, no. 5: 447. https://doi.org/10.3390/nano14050447

APA StyleNavitski, I., Ramanaviciute, A., Ramanavicius, S., Pogorielov, M., & Ramanavicius, A. (2024). MXene-Based Chemo-Sensors and Other Sensing Devices. Nanomaterials, 14(5), 447. https://doi.org/10.3390/nano14050447