Magnetic Shape Memory Nanocomposites Assembled with High Speed High Pressure Torsion

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Severe Plastic Deformation with High-Speed High-Pressure Torsion

3.2. Optical Microscopy

3.3. SEM Investigation of MSMC Composites

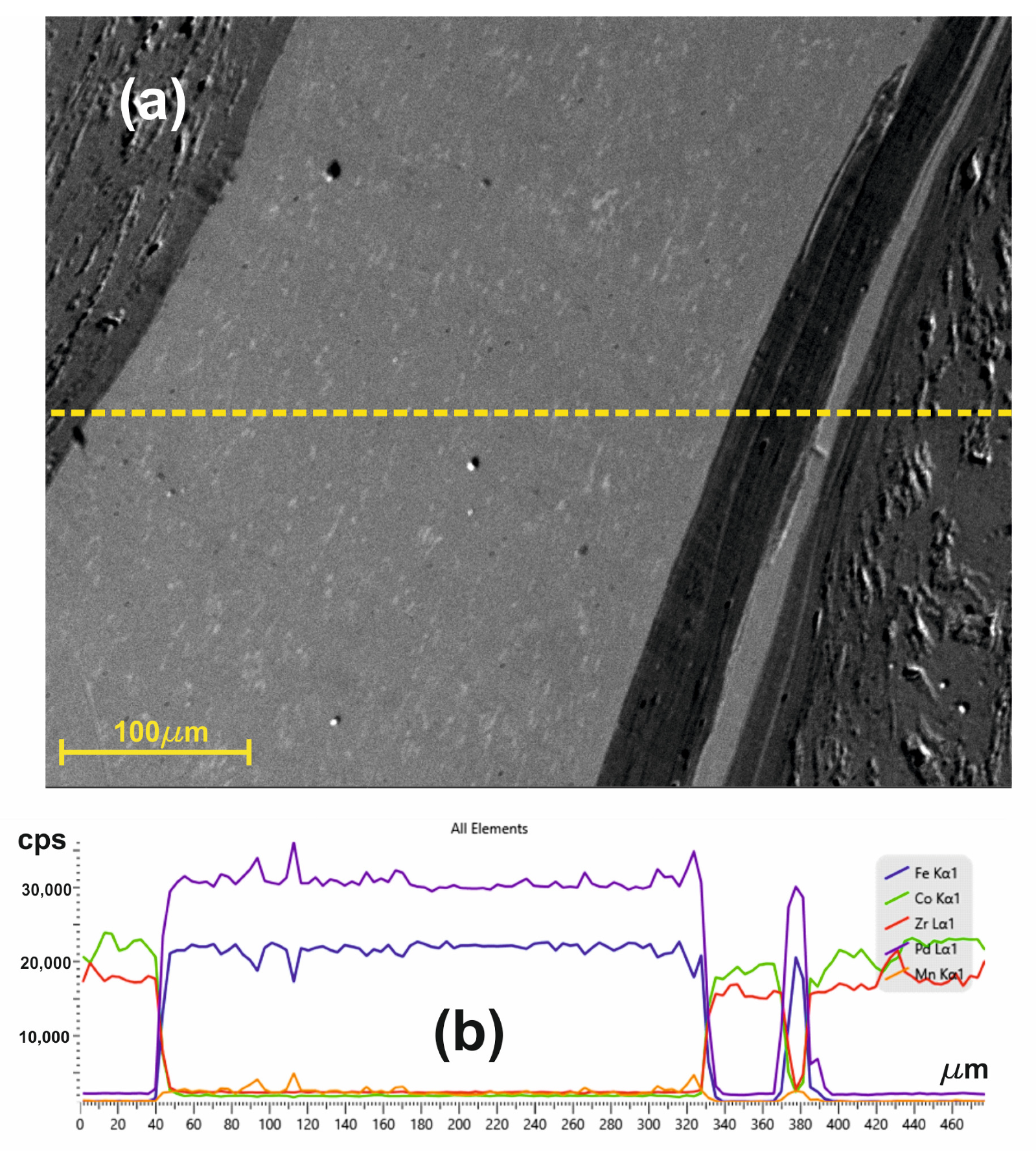

3.4. SEM-EDS Analysis

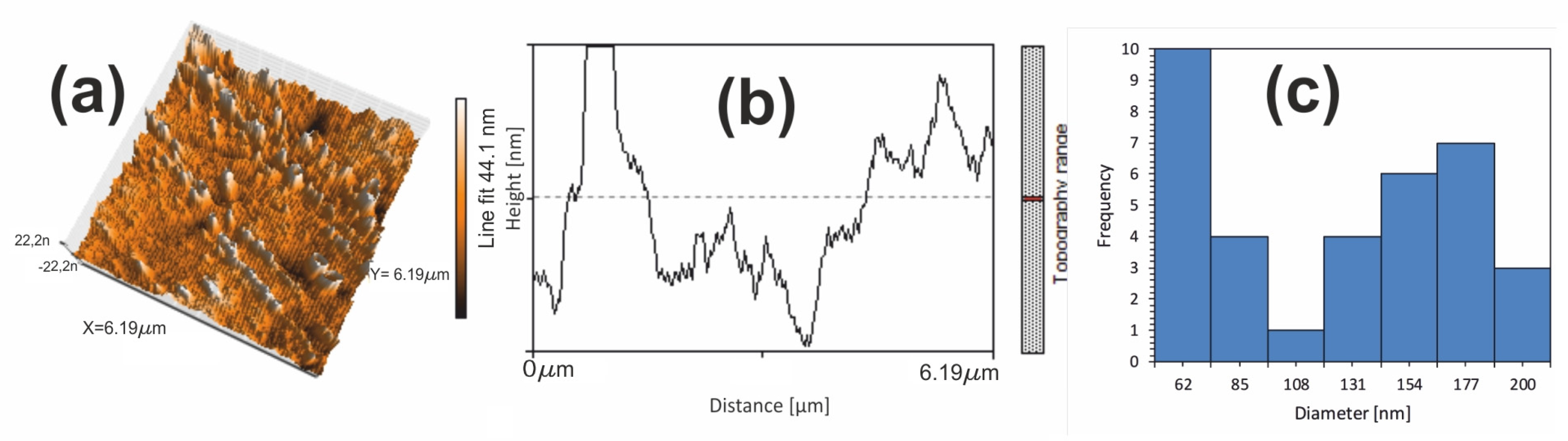

3.5. AFM Study of CoZr/NiFeGaAl Multilayered Composite

3.6. Mechanical Properties of MSMCs

4. Conclusions

- The HSHPT severe plastic deformation technique was successfully used to fabricate novel multilayered magnetic shape memory composites. The manufactured multilayered metallic composites are composed of a Co87Zr13 magnetic alloy and one of the two soft ferromagnetic shape memory alloys, FePd30Mn3 or Ni55Fe20Ga25.

- The initial cast magnetic alloys were subjected to HSHPT with the same deformation degree (ε = 0.46) in disks. The second step was fabricating the MSMCs from the initial disks with 2.46 and 3.97–3.98 logarithmic deformation degrees. The resulting composites demonstrate strong metallurgical joining of all dissimilar magnetic layers.

- The difference between the hardness values of layers was involved in the consolidation process of the composites. The softer layers, which are more ductile, formed distinct layers. The harder layers determined fragmentation and interpenetration of layers into multilayered composites.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Karthik, G.M.; Asghari-Rad, P.; Sathiyamoorthi, P.; Zargaran, A.; Kim, E.S.; Kim, T.S.; Kim, H.S. Architectured multi-metal CoCrFeMnNi-Inconel 718 lamellar composite by high-pressure torsion. Scr. Mater. 2021, 195, 113722. [Google Scholar] [CrossRef]

- Bazarnik, P.; Bartkowska, A.; Romelczyk-Baishya, B.; Adamczyk-Cieślak, B.; Dai, J.; Huang, Y.; Lewandowska, M.; Langdon, T.G. Superior strength of tri-layered Al–Cu–Al nano-composites processed by high-pressure torsion. J. Alloys Compd. 2020, 846, 156380. [Google Scholar] [CrossRef]

- Xiong, R.; Kwon, H.; Karthik, G.M.; Gu, G.H.; Asghari-Rad, P.; Son, S.; Kim, E.S.; Kim, H.S. Novel multi-metal stainless steel (316L)/high-modulus steel (Fe-TiB2) composite with enhanced specific modulus and strength using high-pressure torsion. Mater. Lett. 2021, 303, 130510. [Google Scholar] [CrossRef]

- Nitheeshwaran, K.; Padmanathan, T.; Sakthi Vignesh, S.M.; Shri Anantha Sayan, M.; Phanibhushana, M.V. Study of microstructure and mechanical properties of metal matrix composites subjected to severe plastic deformation—A review. Mater. Today Proc. 2021, 46, 799–805. [Google Scholar] [CrossRef]

- Castro, M.M.; Montoro, L.A.; Isaac, A.; Kawasaki, M.; Figueiredo, R.B. Mechanical mixing of Mg and Zn using high-pressure torsion. J. Alloys Compd. 2021, 869, 159302. [Google Scholar] [CrossRef]

- Sundeev, R.V.; Shalimova, A.V.; Rogachev, S.O.; Chernogorova, O.P.; Glezer, A.M.; Ovcharov, A.V.; Karateev, I.A. Role of structural changes in the composite consolidation from dissimilar layers upon high-pressure torsion. Mater. Lett. 2023, 331, 15–18. [Google Scholar] [CrossRef]

- Qiao, X.; Li, X.; Zhang, X.; Chen, Y.; Zheng, M.; Golovin, I.S.; Gao, N.; Starink, M.J. Intermetallics formed at interface of ultrafine grained Al/Mg bi-layered disks processed by high pressure torsion at room temperature. Mater. Lett. 2016, 181, 187–190. [Google Scholar] [CrossRef]

- Gurǎu, G.; Gurǎu, C.; Potecaşu, O.; Alexandru, P.; Bujoreanu, L.G. Novel high-speed high pressure torsion technology for obtaining Fe-Mn-Si-Cr shape memory alloy active elements. J. Mater. Eng. Perform. 2014, 23, 2396–2402. [Google Scholar] [CrossRef]

- Gurau, G.; Gurau, C.; Fernandes, F.M.B.; Alexandru, P.; Sampath, V.; Marin, M.; Galbinasu, B.M. Structural Characteristics of Multilayered Ni-Ti Nanocomposite Fabricated by High Speed High Pressure Torsion (HSHPT). Metals 2020, 10, 1629. [Google Scholar] [CrossRef]

- Rogachev, S.O.; Khatkevich, V.M.; Sundeev, R.V. High strength in layered metal composites obtained by high-pressure torsion. Mater. Lett. 2021, 303, 130567. [Google Scholar] [CrossRef]

- Danilenko, V.N.; Kiekkuzhina, L.U.; Parkhimovich, N.Y.; Khafizova, E.D.; Gunderov, D.V. Cu-Al metal matrix composite fabricated by accumulative HPT. Mater. Lett. 2021, 300, 130240. [Google Scholar] [CrossRef]

- Zhu, M.; Xu, Z.; Yu, J.; Liu, X.; Wang, K.; Gu, J.; Chang, Y.; Zhao, Y.; Wang, L.; Ma, M.; et al. Mechanical properties and microstructure evolution of VGCNF reinforced 7075Al composite during high pressure torsion. Mater. Sci. Eng. A 2023, 878, 145225. [Google Scholar] [CrossRef]

- Sánchez-Alarcos, V.; Recarte, V.; Pérez-Landazábal, J.I.; González, M.A.; Rodríguez-Velamazán, J.A. Effect of Mn addition on the structural and magnetic properties of Fe-Pd ferromagnetic shape memory alloys. Acta Mater. 2009, 57, 4224–4232. [Google Scholar] [CrossRef]

- Gruner, M.E.; Hamann, S.; Brunken, H.; Ludwig, A.; Entel, P. Compositional trends and magnetic excitations in binary and ternary Fe-Pd-X magnetic shape memory alloys. J. Alloys Compd. 2013, 577, 333–337. [Google Scholar] [CrossRef]

- Xiao, F.; Fukuda, T. Shape memory effect associated with successive FCC-FCT-BCT martensitic transformation in single-crystalline Fe-Pd alloy. Materialia 2021, 16, 100685. [Google Scholar] [CrossRef]

- Bonifacich, F.G.; Pérez-Landazábal, J.I.; Lambri, O.A.; Bozzano, P.B.; Sánchez-Alarcos, V.; García, J.A.; Zelada, G.I.; Recarte, V.; Cuello, G.J. Influence of thermal treatments on the mechanical properties and the martensitic transformation in Fe-Pd-Mn ferromagnetic shape memory alloy. Mater. Sci. Eng. A 2017, 683, 164–171. [Google Scholar] [CrossRef]

- Yu, H.J.; Zu, X.T.; Fu, H.; Zhang, X.Y.; Wang, Z.G. Effect of annealing and heating/cooling rate on the transformation temperatures of NiFeGa alloy. J. Alloys Compd. 2009, 470, 237–240. [Google Scholar] [CrossRef]

- Yu, H.J.; Fu, H.; Wang, Z.G.; Zu, X.T. Effect of Ge addition on the martensitic transformation temperatures of Ni-Fe-Ga alloys. Mater. Sci. Eng. A 2009, 507, 37–41. [Google Scholar] [CrossRef]

- Popescu, B.; Gurau, C.; Gurau, G.; Tolea, M.; Sofronie, M.; Tolea, F. Martensitic Transformation and Magnetic Properties of Ni57Fe18Ga25 Shape Memory Alloy Subjected to Severe Plastic Deformation. Trans. Indian Inst. Met. 2021, 74, 2491–2498. [Google Scholar] [CrossRef]

- Popescu, B.; Palade, P.; Sofronie, M.; Kuncser, A.; Gurau, C.; Gurau, G.; Tolea, F. Effects of the Severe Plastic Deformation on the Magnetic Properties of Zr13Co87 Ribbons. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2022, 53, 172–178. [Google Scholar] [CrossRef]

- Fan, Y.; Ding, J.; Liao, K.; Huang, H.; Xiong, E. Experimental study on performance of Ti-Ni shape memory alloy composite suspension damping system. Constr. Build. Mater. 2022, 346, 128377. [Google Scholar] [CrossRef]

- Qin, F.; Chen, F.; Hou, J.; Lu, W.; Chen, S.; Li, J. Strong resistance to shear instability in multilayered metallic composites by nanoscale amorphous-BCC crystalline interfaces. Mater. Sci. Eng. A 2024, 891, 145919. [Google Scholar] [CrossRef]

- Gangil, N.; Siddiquee, A.N.; Maheshwari, S. Towards applications, processing and advancements in shape memory alloy and its composites. J. Manuf. Process. 2020, 59, 205–222. [Google Scholar] [CrossRef]

- Huang, G.Q.; Yan, Y.F.; Wu, J.; Shen, Y.F.; Gerlich, A.P. Microstructure and mechanical properties of fine-grained aluminum matrix composite reinforced with nitinol shape memory alloy particulates produced by underwater friction stir processing. J. Alloys Compd. 2019, 786, 257–271. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gurau, C.; Tolea, F.; Cimpoesu, N.; Sofronie, M.; Cantaragiu Ceoromila, A.; Stefanescu, C.; Gurau, G. Magnetic Shape Memory Nanocomposites Assembled with High Speed High Pressure Torsion. Nanomaterials 2024, 14, 405. https://doi.org/10.3390/nano14050405

Gurau C, Tolea F, Cimpoesu N, Sofronie M, Cantaragiu Ceoromila A, Stefanescu C, Gurau G. Magnetic Shape Memory Nanocomposites Assembled with High Speed High Pressure Torsion. Nanomaterials. 2024; 14(5):405. https://doi.org/10.3390/nano14050405

Chicago/Turabian StyleGurau, Carmela, Felicia Tolea, Nicanor Cimpoesu, Mihaela Sofronie, Alina Cantaragiu Ceoromila, Cristian Stefanescu, and Gheorghe Gurau. 2024. "Magnetic Shape Memory Nanocomposites Assembled with High Speed High Pressure Torsion" Nanomaterials 14, no. 5: 405. https://doi.org/10.3390/nano14050405

APA StyleGurau, C., Tolea, F., Cimpoesu, N., Sofronie, M., Cantaragiu Ceoromila, A., Stefanescu, C., & Gurau, G. (2024). Magnetic Shape Memory Nanocomposites Assembled with High Speed High Pressure Torsion. Nanomaterials, 14(5), 405. https://doi.org/10.3390/nano14050405