Mechanical and Shape Memory Properties of Additively Manufactured Polyurethane (PU)/Halloysite Nanotube (HNT) Nanocomposites

Abstract

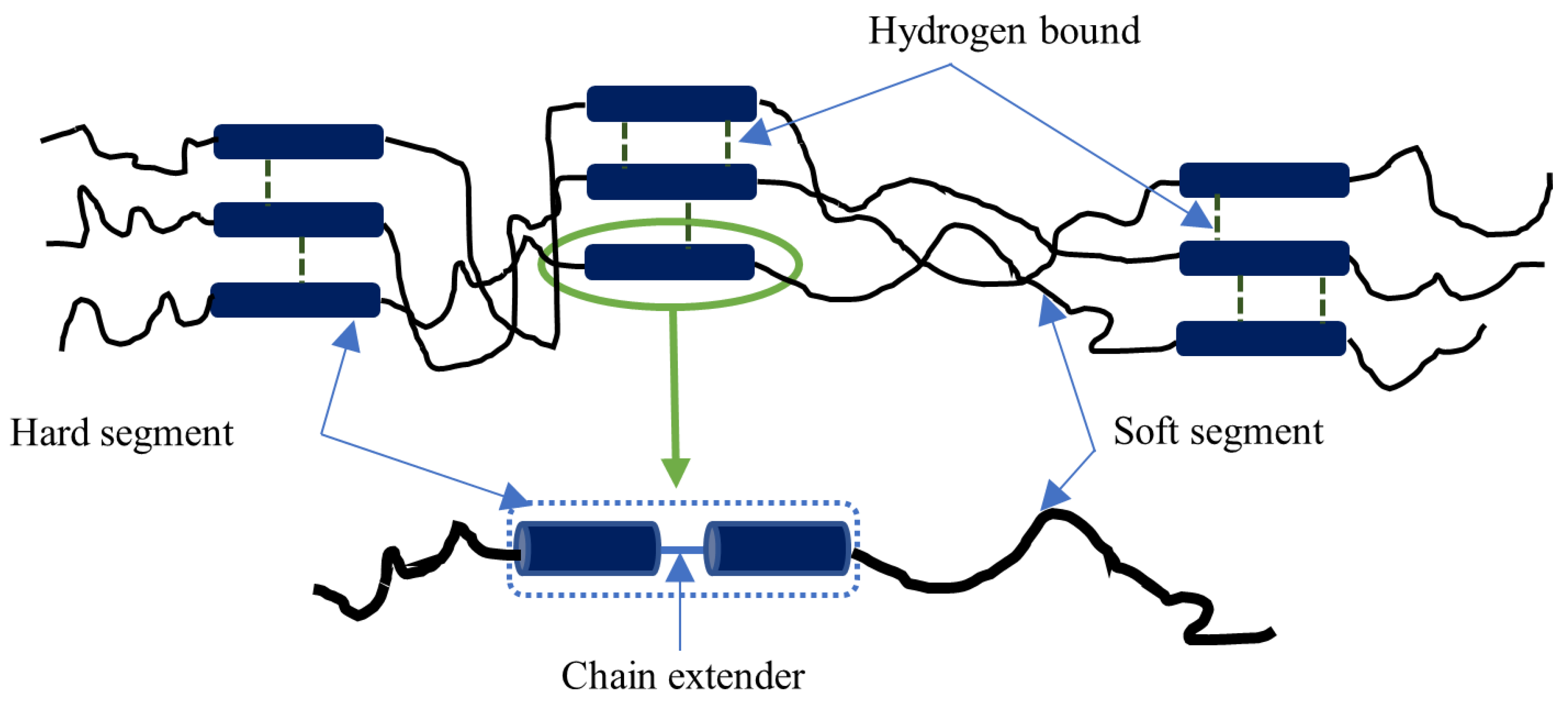

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

2.3. Tensile Tests

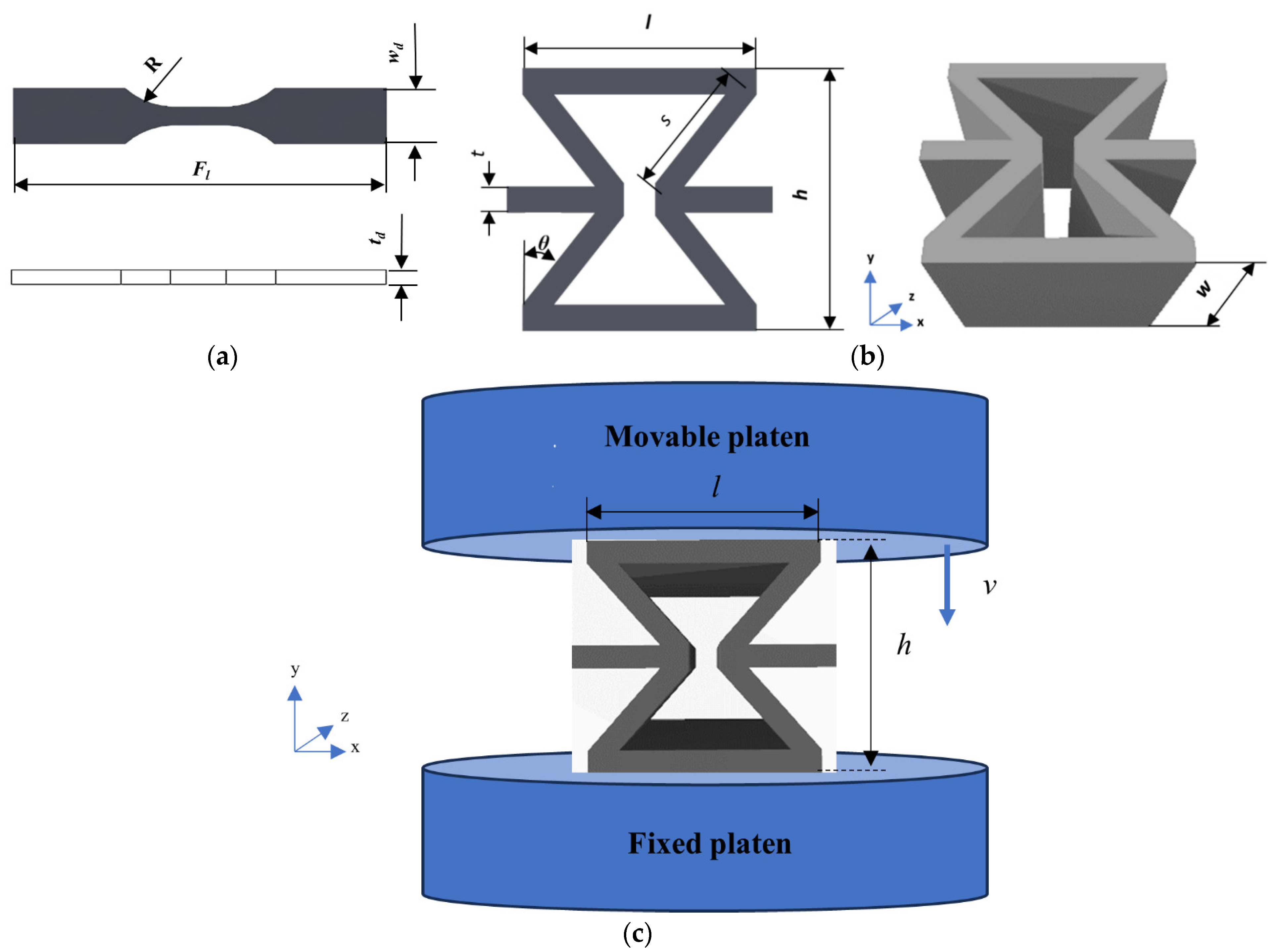

2.4. Compressive Tests

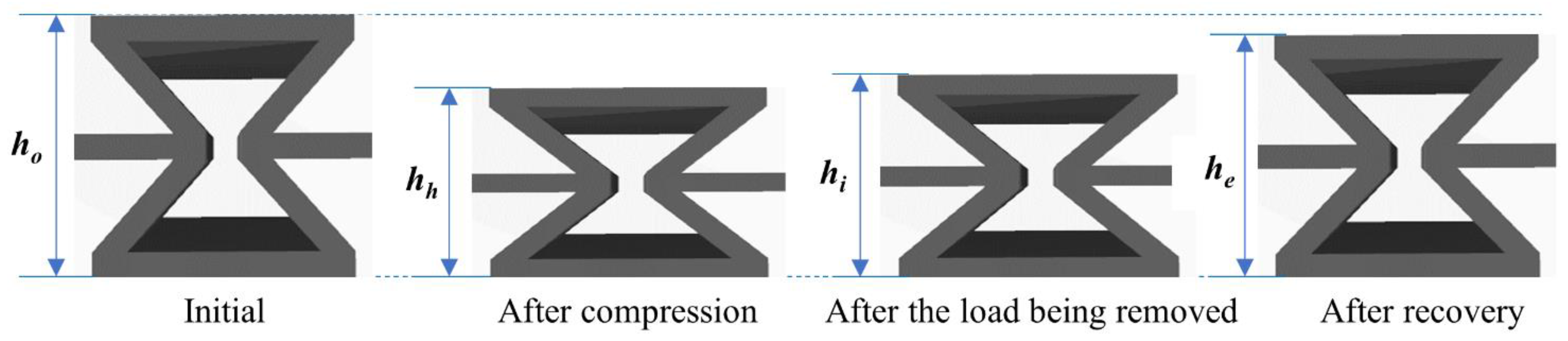

2.5. Shape Memory Tests

2.6. Material Characterisation

2.7. Statistical Analysis

3. Result and Discussion

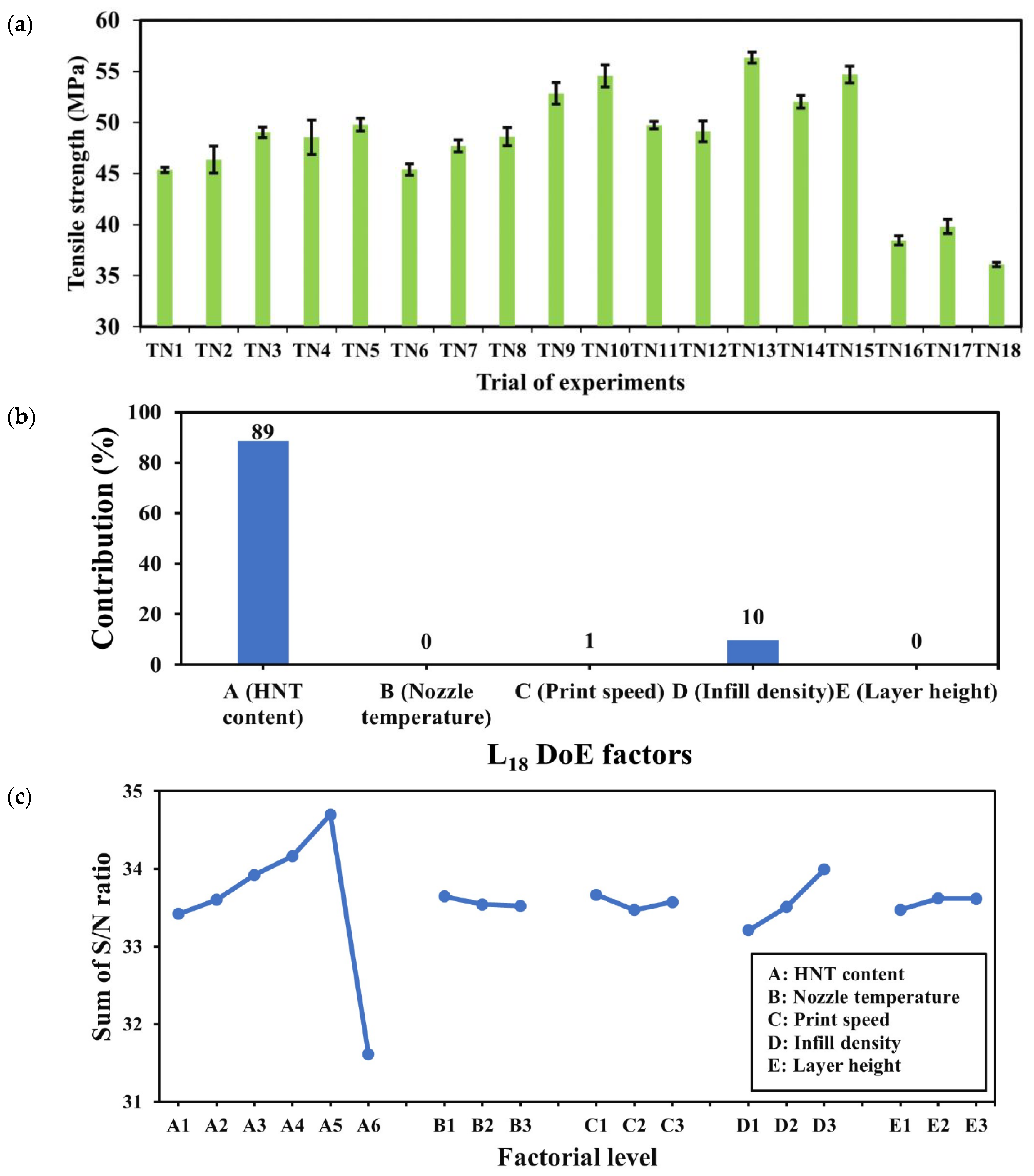

3.1. Tensile Properties

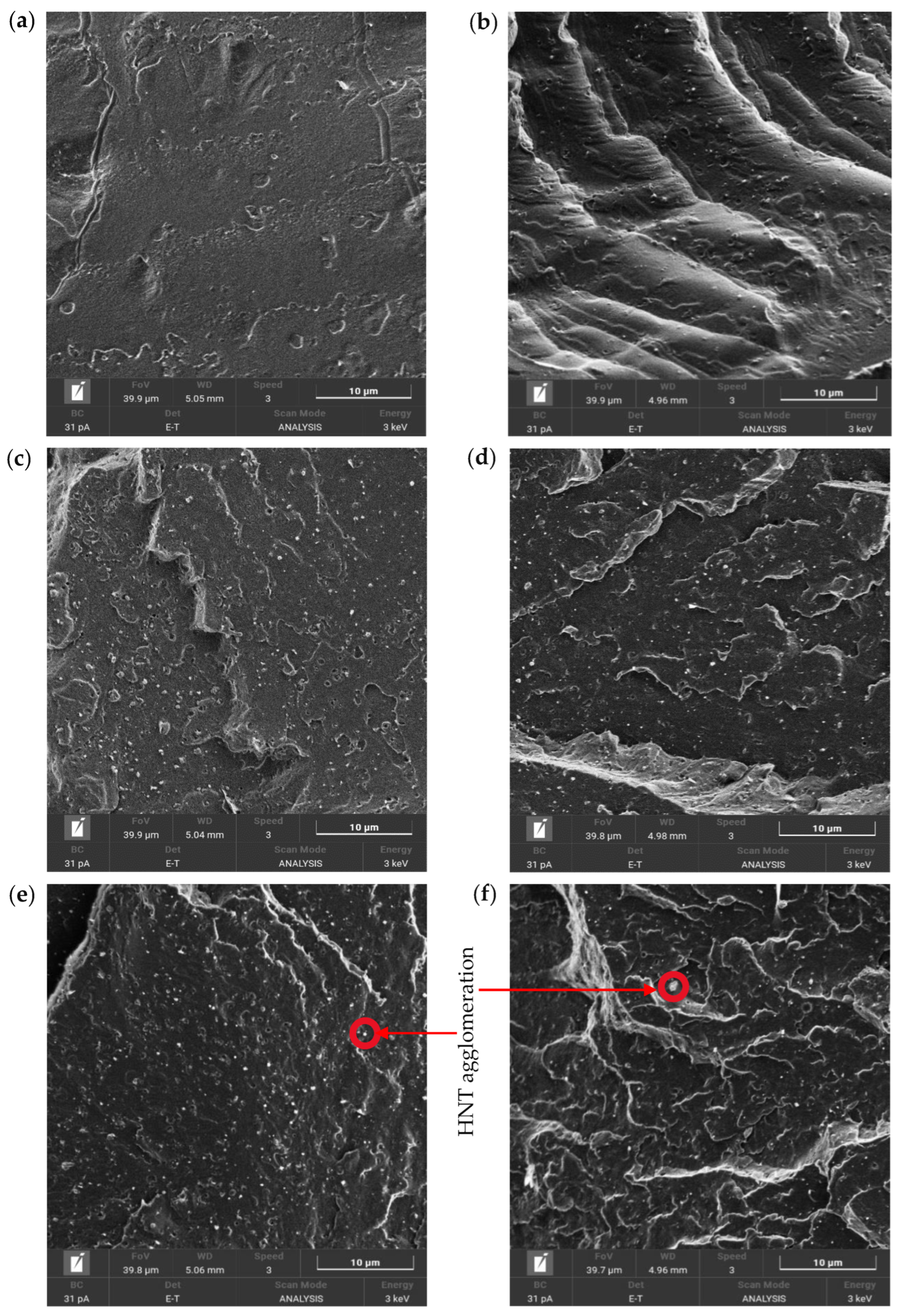

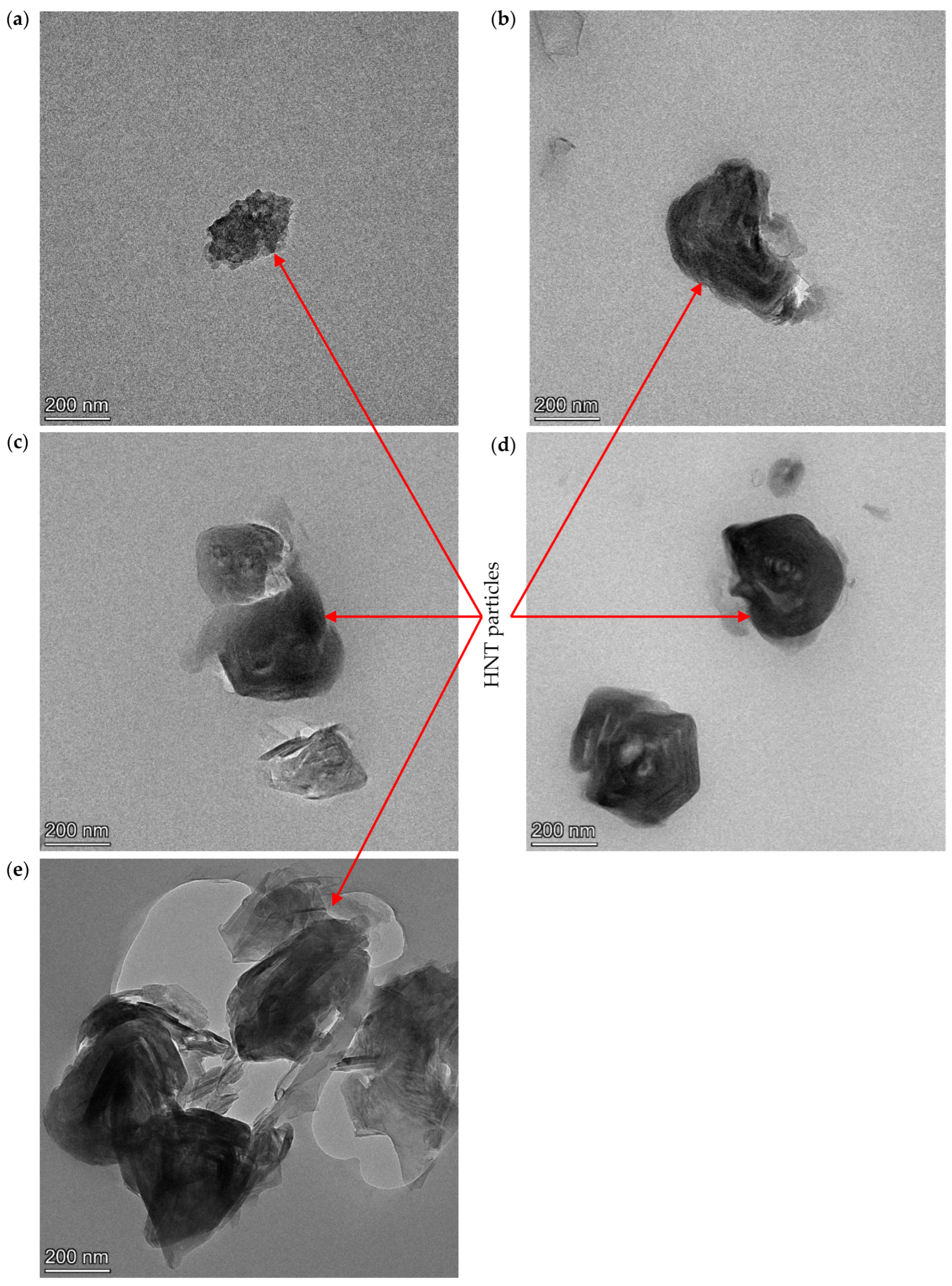

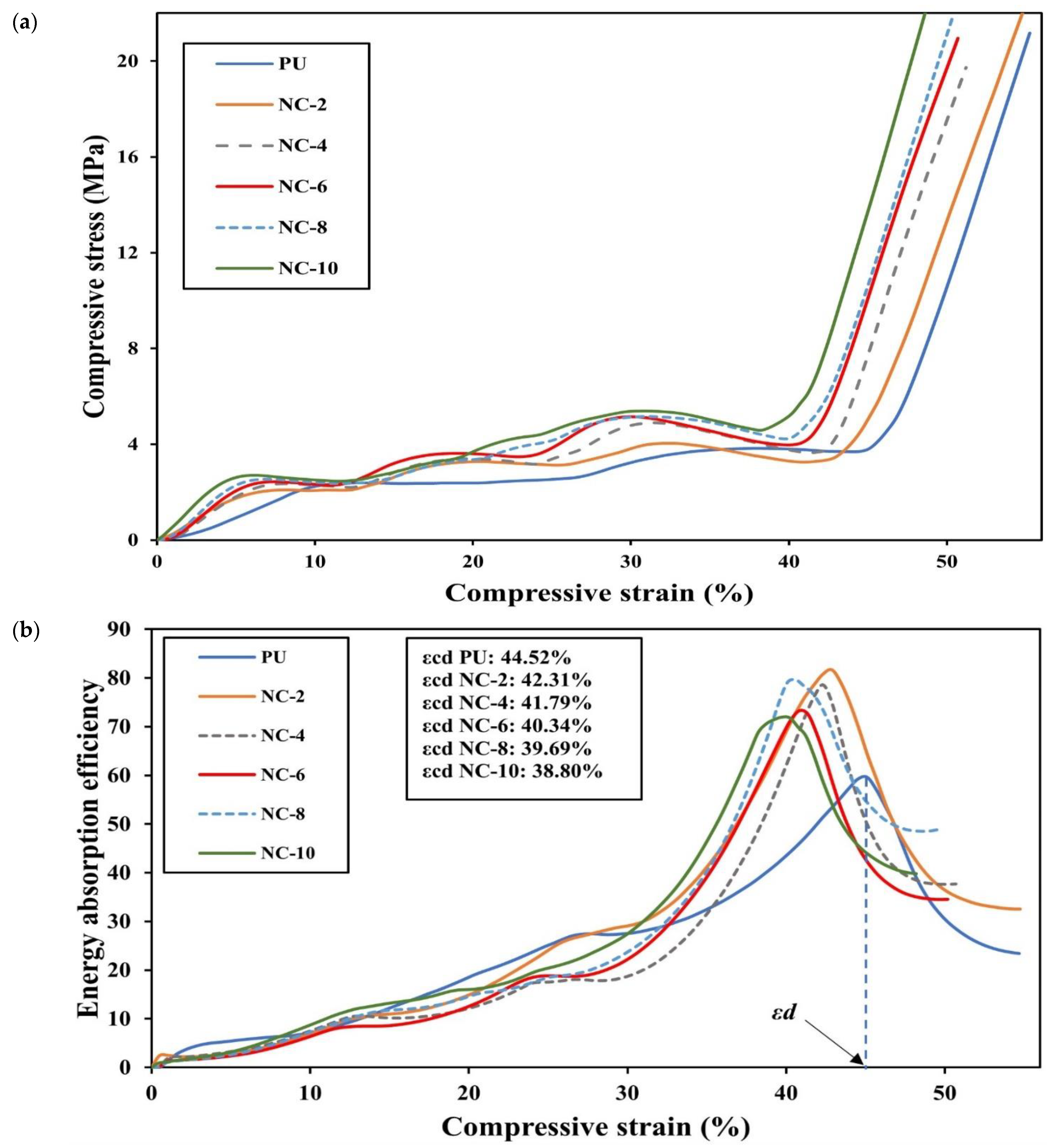

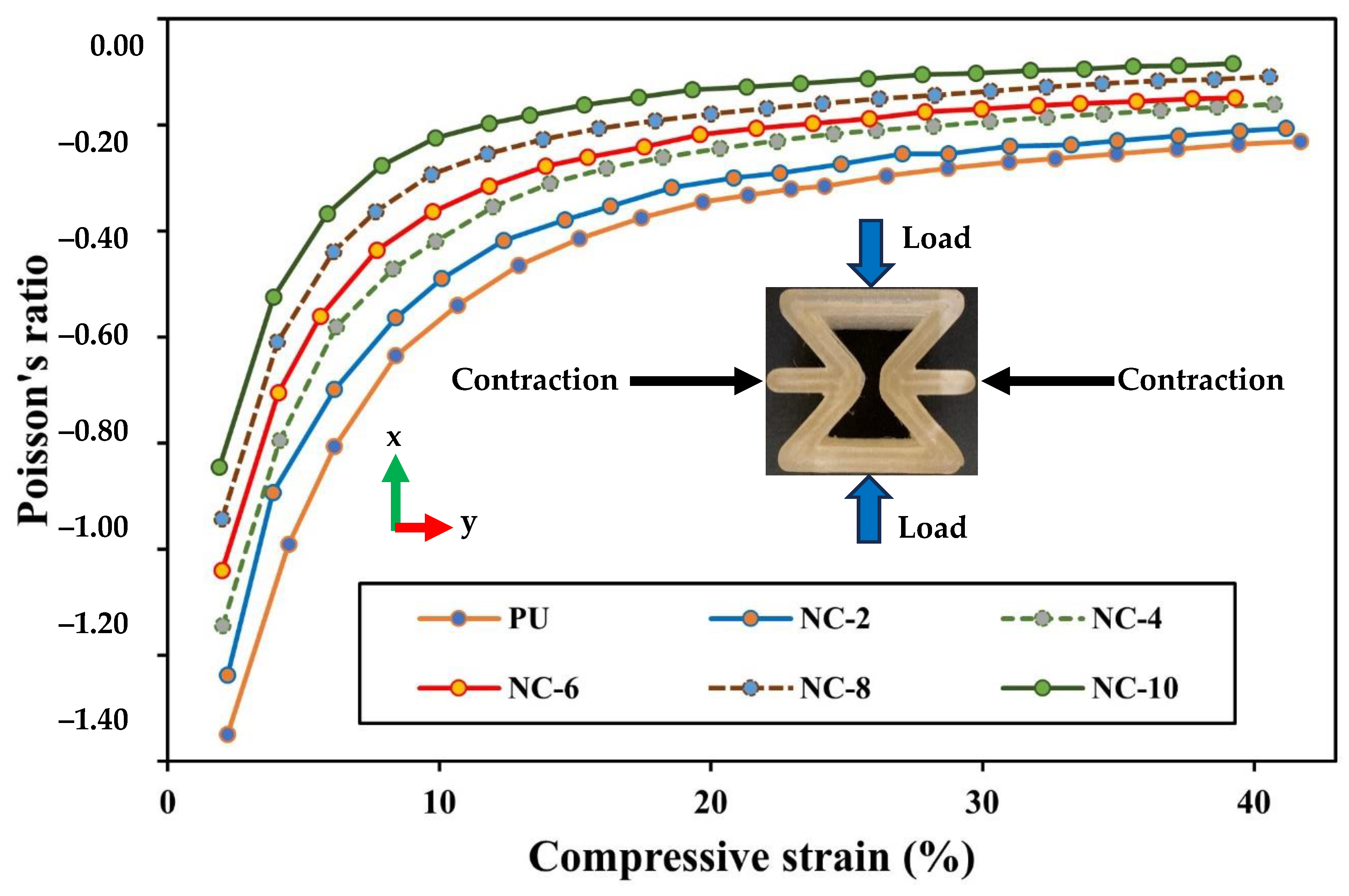

3.2. Compressive Properties

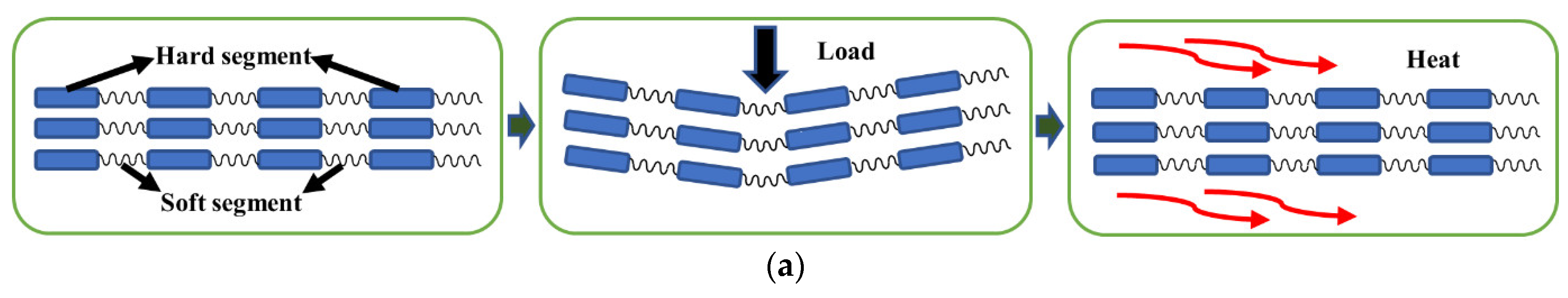

3.3. Shape Memory Properties

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- He, Y.; Xie, D.; Zhang, X. The structure, microphase-separated morphology, and property of polyurethanes and polyureas. J. Mater. Sci. 2014, 49, 7339–7352. [Google Scholar] [CrossRef]

- Chen, Q.; Mangadlao, J.D.; Wallat, J.; De Leon, A.; Pokorski, J.K.; Advincula, R.C. 3D printing biocompatible polyurethane/poly(lactic acid)/graphene oxide nanocomposites: Anisotropic properties. ACS Appl. Mater. Interf. 2017, 9, 4015–4023. [Google Scholar] [CrossRef] [PubMed]

- Joo, H.; Cho, S. Comparative studies on polyurethane composites filled with polyaniline and graphene for DLP-type 3D printing. Polymers 2020, 12, 67. [Google Scholar] [CrossRef] [PubMed]

- Tao, Y.; Shao, J.; Li, P.; Shi, S.Q. Application of a thermoplastic polyurethane/polylactic acid composite filament for 3D-printed personalized orthosis. Mater. Technol. 2019, 53, 71–76. [Google Scholar] [CrossRef]

- 5 Lathers, S.; La Belle, J. Additive manufactured biomimicking actuator with shape memory polymer composite for prosthetic actuators. 3D Print Addit. Manuf. 2017, 4, 201–213. [Google Scholar] [CrossRef]

- Li, Z.; Wang, Z.; Gan, X.; Fu, D.; Fei, G.; Xia, H. Selective laser sintering 3D printing: A way to Construct 3D electrically conductive segregated network in polymer matrix. Macromol. Mater. Eng. 2017, 302, 1700211. [Google Scholar] [CrossRef]

- Christ, J.F.; Hohimer, C.J.; Aliheidari, N.; Ameli, A.; Mo, C.; Potschke, P. 3D printing of highly elastic strain sensors using polyurethane/multiwall carbon nanotube composites. Proc. SPIE 2017, 101168, 70–76. [Google Scholar] [CrossRef]

- Hernandez, R.; Weksler, J.; Padsalgikar, A.; Runt, J. In vitro oxidation of high polydimethylsiloxane content biomedical polyurethanes: Correlation with the microstructure. J. Biomed. Mater. Res. A 2008, 87, 546–556. Available online: https://pubmed.ncbi.nlm.nih.gov/18186070 (accessed on 3 February 2023). [CrossRef]

- Driffield, M.; Bradley, E.L.; Castle, L. A method of test for residual isophorone diisocyanate trimer in new polyester–polyurethane coatings on light metal packaging using liquid chromatography with tandem mass spectrometric detection. J. Chromatogr. A 2007, 1141, 61–66. Available online: https://pubmed.ncbi.nlm.nih.gov/17178416 (accessed on 3 February 2023). [CrossRef]

- Aneja, A.; Wilkes, G.L.; Rightor, E.G. Study of slabstock flexible polyurethane foams based on varied toluene diisocyanate isomer ratios. J. Polym. Sci. B Polym. Phys. 2003, 41, 258–268. [Google Scholar] [CrossRef]

- Tzounis, L.; Petousis, M.; Grammatikos, S.; Vidakis, N. 3D printed thermoelectric polyurethane/multiwalled carbon nanotube nanocomposites: A novel approach towards the fabrication of flexible and stretchable organic thermoelectrics. Materials 2020, 13, 2879. [Google Scholar] [CrossRef]

- Nugroho, W.T.; Dong, Y.; Pramanik, A.; Leng, J.; Ramakrishna, S. Smart polyurethane composites for 3D or 4D printing: General-purpose use, sustainability and shape memory effect. Compos. B Eng. 2021, 223, 109104. [Google Scholar] [CrossRef]

- Xiang, D.; Zhang, X.; Li, Y.; Harkin-Jones, E.; Zheng, Y.; Wang, L.; Zhao, C.; Wang, P. Enhanced performance of 3D printed highly elastic strain sensors of carbon nanotube/thermoplastic polyurethane nanocomposites via non-covalent interactions. Compos. B Eng. 2019, 176, 107250. [Google Scholar] [CrossRef]

- Kandiyil, J.; Vasudevan, S.; Athiyanathil, S. Efficient selective methylene blue adsorption by polyurethane/montmorillonite-based antifouling electrospun composite membranes. J. Appl. Polym. Sci. 2022, 140, e53464. [Google Scholar] [CrossRef]

- Maamoun, A.; Elkhateeb, A.; Zulfiqar, S. Halloysite-decorated mechanically robust polyurethane nanocomposite foams for acoustic relevance. Indust. Eng. Chem. Res. 2022, 61, 17937–17949. [Google Scholar] [CrossRef]

- Ozturk, M.; Baran, T.; Mehmet, T. Experimental and numerical investigation of conventional and stiffened re-entrant cell structures under compression. J. Brazilian Mech. Eng. 2022, 44, 593. [Google Scholar] [CrossRef]

- Lakes, R. Design considerations for materials with negative Poisson’s ratios. J. Mech. Des. 1993, 115, 696–700. [Google Scholar] [CrossRef]

- Li, T.; Chen, Y.; Hu, X.; Li, Y.; Wang, L. Exploiting negative Poisson’s ratio to design 3D-printed composites with enhanced mechanical properties. Mater. Des. 2018, 142, 247–258. [Google Scholar] [CrossRef]

- Attard, D.; Farrugia, P.; Gatt, R.; Grima, J. Starchirals-A novel class of auxetic hierarchal structures. Int. J. Mech. Sci. 2020, 179, 105631. [Google Scholar] [CrossRef]

- Xu, J.; Wu, Y.; Wang, L.; Li, J.; Yang, Y.; Tian, Y.; Gong, Z.; Zhang, P.; Nutt, S.; Yin, S. Compressive properties of hollow lattice truss reinforced honeycombs (Honeytubes) by additive manufacturing: Patterning and tube alignment effects. Mater. Des. 2018, 156, 446–457. [Google Scholar] [CrossRef]

- Despeisse, M.; Ford, S. The role of additive manufacturing in improving resource efficiency and sustainability. In Advances in Production Management Systems: Innovative Production Management Towards Sustainable Growth: IFIP WG 5.7 International Conference, APMS 2015, Tokyo, Japan, 7–9 September 2015; Springer: Cham, Switzerland, 2015; pp. 129–136. [Google Scholar] [CrossRef]

- Rao, R. How GE Is Using 3D Printing to Unleash the Biggest Revolution in Large-Scale Manufacturing in over a Century. In TechRepublic 2016. Available online: https://www.techrepublic.com/resource-library/downloads/manufacturing-in-over-a-century (accessed on 10 February 2023).

- Murali, A.; Vakkattil, M.A.; Parameswaran, R. Investigating the effect of processing on mechanical behavior of 3D fused deposition modelling printed polylactic acid. J. Mater. Eng. Perform. 2023, 32, 1089–1102. [Google Scholar] [CrossRef]

- Kokcu, I.; Eryildiz, M.; Altan, M.; Ertugrul, M.I.; Odabas, S. Scaffold fabrication from drug loaded HNT reinforced polylactic acid by FDM for biomedical applications. Polym. Compos. 2022, 44, 2138–2152. [Google Scholar] [CrossRef]

- Lv, Q.; Peng, Z.; Meng, Y.; Pei, H.; Chen, Y.; Ivanaov, E.; Kotsilkova, R. Three-dimensional printing to fabricate graphene-modified polyolefin elastomer flexible composites with tailorable porous structures for Electromagnetic interference shielding and thermal management application. Ind. Eng. Chem. Res. 2022, 61, 16733–16746. [Google Scholar] [CrossRef]

- Mrowka, M.; Szymiczek, M.; Machoczek, T.; Pawlyta, M. Influence of the halloysite nanotube (HNT) addition on selected mechanical and biological properties of thermoplastic polyurethane. Materials 2021, 14, 3625. [Google Scholar] [CrossRef] [PubMed]

- Mahunaki, M.P.; Asl, V.H.; Mamaqani, H.R.; Koosha, M.; Yazdi, M. Halloysite-reinforced thermoplastic polyurethane nanocomposites: Physico-mechanical, rheological, and thermal investigations. Polym. Compos. 2020, 41, 3260–3270. [Google Scholar] [CrossRef]

- Prasanthi, L.; Bora, B.R.; Raidongia, K.; Datta, K.K.R. Fluorinated graphene nanosheet supported halloysite nanoarchitectonics: Super-wetting coatings for efficient and recyclable oil sorption. Sep. Purif. Technol. 2021, 301, 122049. [Google Scholar] [CrossRef]

- Sulong, A.B.; Gaaz, T.S.; Sahari, J. Mechanical and physical properties of injection molded halloysite nanotubes-thermoplastic polyurethane nanocomposites. Proc-Soc. Behav. Sci. 2015, 195, 2748–2752. [Google Scholar] [CrossRef]

- Gaaz, T.S.; Sulong, A.B.; Ansari, M.N.M.; Kadhum, A.A.H.; Al-Amiery, A.A.; Al-Furjan, M.S.H. Effect of halloysite nanotubes loading on thermo-mechanical and morphological properties of polyurethane nanocomposites. Mater. Technol. 2017, 32, 430–442. [Google Scholar] [CrossRef]

- Aguiar, R.; Petel, O.; Miller, R. Effect of a halloysite-polyurethane nanocomposite interlayer on the ballistic performance of laminate transparent armour. Compos. C Open Access 2022, 7, 100231. [Google Scholar] [CrossRef]

- SMP Technologies, Shape Memory Polymer. 2021. Available online: http://www2.smptechno.com/en/smp/ (accessed on 25 June 2023).

- Imerys, Halloysite. 2021. Available online: https://www.imerys.com/minerals/halloysite (accessed on 25 June 2023).

- Du, M.; Guo, B.; Jia, D. Newly emerging applications of halloysite nanotubes: A review. Polym. Int. 2010, 59, 574–582. [Google Scholar] [CrossRef]

- Nugroho, W.T.; Dong, Y.; Pramanik, A.; Zhang, Z.; Ramakrishna, S. Co-influence of nanofiller content and 3D printing parameters on mechanical properties of thermoplastic polyurethane (TPU)/halloysite nanotube (HNT) nanocomposites. Nanomaterials 2023, 13, 1975. [Google Scholar] [CrossRef] [PubMed]

- ASTM D638; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM D790-17; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM C365; Standard Test Method for Flatwise Compressive Properties of Sandwich Cores. ASTM International: West Conshohocken, PA, USA, 2022.

- Alomarah, A.; Masood, S.H.; Sbarski, I.; Faisal, B.; Gao, Z.; Ruan, D. Compressive properties of 3D printed auxetic structures: Experimental and numerical studies. Vir. Phys. Prot. 2019, 15, 1–21. [Google Scholar] [CrossRef]

- Dong, Z.; Li, Y.; Zhao, T.; Wu, W.; Xiao, D.; Liang, J. Experimental and numerical studies on the compressive mechanical properties of the metallic auxetic reentrant honeycomb. Mater. Des. 2019, 182, 108036. [Google Scholar] [CrossRef]

- Shen, J.; Lu, G.; Ruan, D. Compressive Behaviour of Closed-Cell Aluminium Foams at High Strain Rates. Compos. B Eng. 2010, 41, 678–685. [Google Scholar] [CrossRef]

- Onck, P.R.; Andrews, E.W.; Gibson, L.J. Size Effects in Ductile Cellular Solids. Part I: Modeling. Int. J. Mech. Sci. 2001, 43, 681–699. [Google Scholar] [CrossRef]

- Ingrole, A.; Hao, A.; Liang, R. Design and modeling of auxetic and hybrid honeycomb structures for in-plane property enhancement. Mater. Des. 2017, 117, 72–83. [Google Scholar] [CrossRef]

- Bitzer, T. Honeycomb Technology: Material Design, Manufacturing Applications and Testing; Chapman & Hall: London, UK, 2012. [Google Scholar] [CrossRef]

- Chow, L.; Yick, K.; Wong, K.; Leung, M.; Sun, Y.; Kwan, M.; Ning, K.; Yu, A.; Yip, J.; Chan, Y.; et al. 3D printing auxetic architectures for hypertrophic scar. Macromol. Mater. Eng. 2022, 307, 2100866. [Google Scholar] [CrossRef]

- Shunmugesh, K.; Panneerselvam, K. Multi-performance optimization of drilling carbon fiber reinforced polymer using Taguchi: Membership function. Trans. Indian Inst Metals 2018, 71, 1615–1627. [Google Scholar] [CrossRef]

- Ross, P. Taguchi Techniques for Quality Engineering, Loss Function, Orthogonal Experiments, Parameter and Tolerance Design; McGraw-Hill: New York, NY, USA, 1988. [Google Scholar]

- Quinn, G.; Keough, M. Experimental Design and Data Analysis for Biologists; Cambridge University Press: Cambridge, UK, 2002. [Google Scholar] [CrossRef]

- Park, S. Robust Design and Analysis for Quality Engineering; Chapman & Hall: London, UK, 1996. [Google Scholar]

- Chie, S.; Mansor, N.; Keat, Y.; Ai, T.; Leng, T.; Wei, K. Effect of printing parameters on characteristic and properties PLA/Fe2O3 and CPLA/Fe2O3 composites using FDM techniques. Pap. Present. AIP Conf. Proc. 2022, 2541, 050005. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Korlos, A.; Velidakis, E.; Mountakis, N.; Charou, C.; Myftari, A. Strain rate sensitivity of polycarbonate and thermoplastic polyurethane for various 3D printing temperatures and layer heights. Polymers 2021, 13, 2752. [Google Scholar] [CrossRef]

- Wang, J.; Yang, B.; Lin, X.; Gao, L.; Liu, T.; Lu, Y.; Wang, R. Research of TPU materials for 3D printing aiming at non-pneumatic tires by FDM method. Polymers 2020, 12, 2492. [Google Scholar] [CrossRef] [PubMed]

- Namathoti, S.; Vakkalagadda, M. Mechanical and shape recovery characterization of MWCNTs/HNTs-reinforced thermal-responsive shape-memory polymer nanocomposites. Polymers 2023, 15, 710. [Google Scholar] [CrossRef]

- Nie, K.; Ji, N.; Xu, J.; Guo, M.; Wang, Y.; Xu, X. Fast and efficient removal of dyes and Cr(VI) ion from wastewater using halloysite nanotubes-covalently coated polyurethane sponges. J. Env. Chem. Eng. 2022, 10, 108308. [Google Scholar] [CrossRef]

- Lorusso, C.; Vergaro, V.; Conciauro, F.; Ciccarella, G.; Congedo, P. Thermal and mechanical performance of rigid polyurethane foam added with commercial nanoparticles. Engineering 2017, 7, 1847980416684117. [Google Scholar] [CrossRef]

- Salaman, A.; Obaidi, A.; Takriff, M. Enhancing morphology and compression properties of halloysite reinforced polyurethane nanocomposites using injection-moulding technique. Res. Phys. 2019, 14, 102507. [Google Scholar] [CrossRef]

- El-baky, M.; Hegazy, D.; Hassan, M.; Kamel, M. Potentiality of halloysite nanoclay on crashworthiness performance of polymer composite tubular elements. J. Compos. Mater. 2022, 56, 1901–1919. [Google Scholar] [CrossRef]

- Ye, Y.; Chen, H.; Wu, J.; Chan, C.M. Evaluation on the thermal and mechanical properties of HNT-toughened epoxy/carbon fibre composites. Compos. B Eng. 2011, 42, 2145–2150. [Google Scholar] [CrossRef]

- Silva, F.; Sachse, S.; Njuguna, J. Energy absorption characteristics of nano-composite conical structures. Paper presented at IOP Conf. Series: Mater. Sci. Eng. 2012, 40, 012020. [Google Scholar] [CrossRef]

- Park, Y.; Kim, J. The Effect of Negative Poisson’s Ratio Polyurethane Scaffolds for Articular Cartilage Tissue Engineering Applications. Adv. Mater. Sci. Eng. 2013, 853289. [Google Scholar] [CrossRef]

- Abdullah, S.; Jumahat, A.; Abdullah, N.; Frormann, L. Determination of shape fixity and shape recovery rate of carbon nanotube-filled shape memory polymer nanocomposites. Proc. Eng. 2012, 41, 1641–1646. [Google Scholar] [CrossRef]

- Mohammadzadeh, F.; Haddadi-Asl, V.; Balzade, Z.; Sahebi, J.I. Switch section and halloysite nanotube role in the phase separation behavior of shape-memory thermoplastic polyurethane. Polym. Compos. 2020, 41, 2625–2633. [Google Scholar] [CrossRef]

- Koerner, H.; Price, G.; Pearce, N.; Alexander, M.; Vaia, R. Remotely actuated polymer nanocomposites--stress-recovery of carbon-nanotube-filled thermoplastic elastomers. Nat. Mater. 2004, 3, 115–120. [Google Scholar] [CrossRef] [PubMed]

| Physical Properties | Mechanical Properties | Thermal Properties | |||

|---|---|---|---|---|---|

| Melt viscosity (Pa·s at 215 °C) | 3310 | Young’s modulus (MPa) | 729 | Glass transition temperature (°C) | 45 |

| Tensile strength at break (MPa) | 41.4 | ||||

| Ultimate elongation (%) | 600 | ||||

| Shore D hardness | 72 | ||||

| Property | Value |

|---|---|

| Moisture content (%) | 3.0 |

| Specific gravity | 2.55 |

| pH (aqueous slurry at 20% solids) | 3.5–4.5 |

| Surface area [Brunauer–Emmett–Teller (BET)] (m2/g) | 25 |

| Linear shrinkage (dried at 110 °C) (%) | 3.8 |

| Modulus of rupture (dried at 110 °C) (MPa) | 2.9 |

| Exp. | Factor | |||||

|---|---|---|---|---|---|---|

| Symbol | A HNT Content wt% | B Nozzle Temperature °C | C Print Speed mm/s | D Infill Density % | E Layer Height mm | |

| 1 | TN1 | 0 | 210 | 10 | 40 | 0.2 |

| 2 | TN2 | 0 | 220 | 20 | 70 | 0.3 |

| 3 | TN3 | 0 | 230 | 30 | 100 | 0.4 |

| 4 | TN4 | 2 | 210 | 10 | 70 | 0.3 |

| 5 | TN5 | 2 | 220 | 20 | 100 | 0.4 |

| 6 | TN6 | 2 | 230 | 30 | 40 | 0.2 |

| 7 | TN7 | 4 | 210 | 20 | 40 | 0.4 |

| 8 | TN8 | 4 | 220 | 30 | 70 | 0.2 |

| 9 | TN9 | 4 | 230 | 10 | 100 | 0.3 |

| 10 | TN10 | 6 | 210 | 30 | 100 | 0.3 |

| 11 | TN11 | 6 | 220 | 10 | 40 | 0.4 |

| 12 | TN12 | 6 | 230 | 20 | 70 | 0.2 |

| 13 | TN13 | 8 | 210 | 20 | 100 | 0.2 |

| 14 | TN14 | 8 | 220 | 30 | 40 | 0.3 |

| 15 | TN15 | 8 | 230 | 10 | 70 | 0.4 |

| 16 | TN16 | 10 | 210 | 30 | 70 | 0.4 |

| 17 | TN17 | 10 | 220 | 10 | 100 | 0.2 |

| 18 | TN18 | 10 | 230 | 20 | 40 | 0.3 |

| Parameter | Specific Parameter | Setting |

|---|---|---|

| Quality | Shell thickness (mm) | 1.6 |

| Initial layer thickness (mm) | 0.5 | |

| Initial layer line width (%) | 120 | |

| Top surface quality | precise | |

| Fill | Bottom/top thickness (mm) | 1.2 |

| Infill interface density | dense | |

| Infill type | triangle | |

| Infill overlap (%) | 15 | |

| Temperature | Bed temperature (°C) | 55 |

| Speed | Travel speed (mm/s) | 150 |

| Bottom layer speed (mm/s) | 15 | |

| Infill speed (mm/s) | 30 | |

| Filament | Flow (%) | 115 |

| Retraction | Speed (mm/s) | 30 |

| Distance (mm) | 5 | |

| Minimum travel (mm) | 1.5 | |

| Minimal extrusion before retracting (mm) | 0.005 |

| Required Tests | Sample Type | Number of Tested Samples |

|---|---|---|

| Tensile tests | Dog-bone (ASTM D638 type V) | 5 |

| Three-point bending tests | Strip-like (ASTM D790-17) | 3 |

| Compressive tests | Re-entrant | 3 |

| Shape memory tests | Strip-like (ASTM D790-17) | 3 |

| Re-entrant | 3 |

| Parameter | Setting |

|---|---|

| Nozzle temperature (°C) | 210 |

| Print speed (mm/s) | 10 |

| Infill density (%) | 100 |

| Layer height (mm) | 0.4 |

| Sample | Trendline Function | R2 |

|---|---|---|

| PU | σ(ε) = 8 × 10−7 ε5 − 9 × 10−5 ε4 + 3.9 × 10−3 ε3 − 7.42 × 10−2 ε2 + 0.6982 ε − 0.7198 | 0.99 |

| NC-2wt%HNTs | σ(ε) = 3 × 10−7 ε5 − 2 × 10−5 ε4 + 6 × 10−4 ε3 − 6.3 × 10−3 ε2 + 0.202 ε + 0.3514 | 0.98 |

| NC-4wt%HNTs | σ(ε) = 1 × 10−6 ε5 − 1 × 10−4 ε4 + 4.57 × 10−3 ε3 − 9.2 × 10−2 ε2 + 0.8067 ε − 0.4499 | 0.98 |

| NC-6wt%HNTs | σ(ε) = 1 × 10−6 ε5 − 1 × 10−4 ε4 + 4.2 × 10−3 ε3 − 7.25 × 10−2 ε2 + 0.6331 ε − 0.1783 | 0.98 |

| NC-8wt%HNTs | σ(ε) = 2 × 10−6 ε5 − 1.735 × 10−4 ε4 + 6.4 × 10−3 ε3 − 0.1043 ε2 + 0.8216 ε − 0.2194 | 0.98 |

| NC-10wt%HNTs | σ(ε) = 2 × 10−6 ε5 − 1.92 × 10−4 ε4 + 7.5 × 10−3 ε3 − 0.1213 ε2 + 0.8986 ε + 0.0102 | 0.99 |

| Sample | Integration Result of Trendline Function F(x) |

|---|---|

| PU | σ′(ε) = 1.33 × 10−7 ε6 − 1.8 × 10−5 ε5 + 0.975 × 10−3 ε4 − 2.473 × 10−2 ε3 + 0.3491 ε2 − 0.7198 ε + 0.2781 |

| NC-2wt% HNTs | σ′(ε) = 0.5 × 10−7 ε6 − 0.4 × 10−5 ε5 + 1.5 × 10−4 ε4 − 2.1 × 10−3 ε3 + 0.101 ε2 + 0.3514 ε + 0.1057 |

| NC-4wt% HNTs | σ′(ε) = 0.167 × 10−6 ε6 − 0.2 × 10−4 ε5 + 1.1425 × 10−3 ε4 − 3.067 × 10−2 ε3 + 4.0335 × 10−2 ε2 − 0.4499 ε + 0.1253 |

| NC-6wt% HNTs | σ′(ε) = 0.167 × 10−6 ε6 − 0.2 × 10−4 ε5 + 1.04 × 10−3 ε4 − 2.4167 × 10−2 ε3 + 0.3165 ε2 − 0.1783 ε + 0.0192 |

| NC-8wt% HNTs | σ′(ε) = 0.33 × 10−6 ε6 − 0.347 × 10−4 ε5 + 1.6 × 10−3 ε4 − 0.035 ε3 + 0.4108 ε2 − 0.2194 ε + 0.0221 |

| NC-10wt% HNTs | σ′(ε) = 0.33 × 10−6 ε6 − 0.384 × 10−4 ε5 + 1.875 × 10−3 ε4 − 0.0404 × 10−2 ε3 + 0.4493 ε2 + 0.0102 ε + 0.1018 |

| Sample | Density of PU ρs (kg/m3) | Density of RE Structure ρ (kg/m3) |

|---|---|---|

| PU | 1200 | 467.49 |

| NC-2 | 1205 | 469.43 |

| NC-4 | 1210 | 471.38 |

| NC-6 | 1215 | 473.33 |

| NC-8 | 1218 | 474.50 |

| NC-10 | 1222 | 476.06 |

| HNT Addition (wt%) | Compressive Strength (MPa) | Compressive Modulus (GPa) | SEA (kJ/kg) |

|---|---|---|---|

| 0 | 3.88 ± 0.036 | 0.28 ± 0.011 | 0.44 ± 0.026 |

| 2 | 4.11 ± 0.090 | 0.35 ± 0.022 | 0.57 ± 0.015 |

| 4 | 4.96 ± 0.029 | 0.50 ± 0.010 | 0.64 ± 0.006 |

| 6 | 5.14 ± 0.035 | 0.54 ± 0.010 | 0.65 ± 0.012 |

| 8 | 5.18 ± 0.009 | 0.61 ± 0.014 | 0.70 ± 0.007 |

| 10 | 5.20 ± 0.106 | 0.63 ± 0.013 | 0.76 ± 0.034 |

| HNT Addition (wt%) | Shape Fixity Ratio Rf (%) | Shape Recovery Ratio Rr (%) | Recovery Time (min) |

|---|---|---|---|

| 0 | 80.21 | 99.09 | 3.45 |

| 2 | 83.38 | 98.66 | 4.04 |

| 4 | 85.19 | 97.23 | 4.29 |

| 6 | 86.96 | 95.58 | 4.66 |

| 8 | 88.97 | 93.42 | 4.87 |

| 10 | 89.50 | 90.27 | 5.02 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nugroho, W.T.; Dong, Y.; Pramanik, A. Mechanical and Shape Memory Properties of Additively Manufactured Polyurethane (PU)/Halloysite Nanotube (HNT) Nanocomposites. Nanomaterials 2024, 14, 1373. https://doi.org/10.3390/nano14161373

Nugroho WT, Dong Y, Pramanik A. Mechanical and Shape Memory Properties of Additively Manufactured Polyurethane (PU)/Halloysite Nanotube (HNT) Nanocomposites. Nanomaterials. 2024; 14(16):1373. https://doi.org/10.3390/nano14161373

Chicago/Turabian StyleNugroho, Wendy Triadji, Yu Dong, and Alokesh Pramanik. 2024. "Mechanical and Shape Memory Properties of Additively Manufactured Polyurethane (PU)/Halloysite Nanotube (HNT) Nanocomposites" Nanomaterials 14, no. 16: 1373. https://doi.org/10.3390/nano14161373

APA StyleNugroho, W. T., Dong, Y., & Pramanik, A. (2024). Mechanical and Shape Memory Properties of Additively Manufactured Polyurethane (PU)/Halloysite Nanotube (HNT) Nanocomposites. Nanomaterials, 14(16), 1373. https://doi.org/10.3390/nano14161373