MOF-Enhanced Aluminosilicate Ceramic Membranes Using Non-Firing Processes for Pesticide Filtration and Phytochrome Removal

Abstract

:1. Introduction

2. Materials and Methods

2.1. Reagents

2.2. Instrumentation and Analytical Conditions

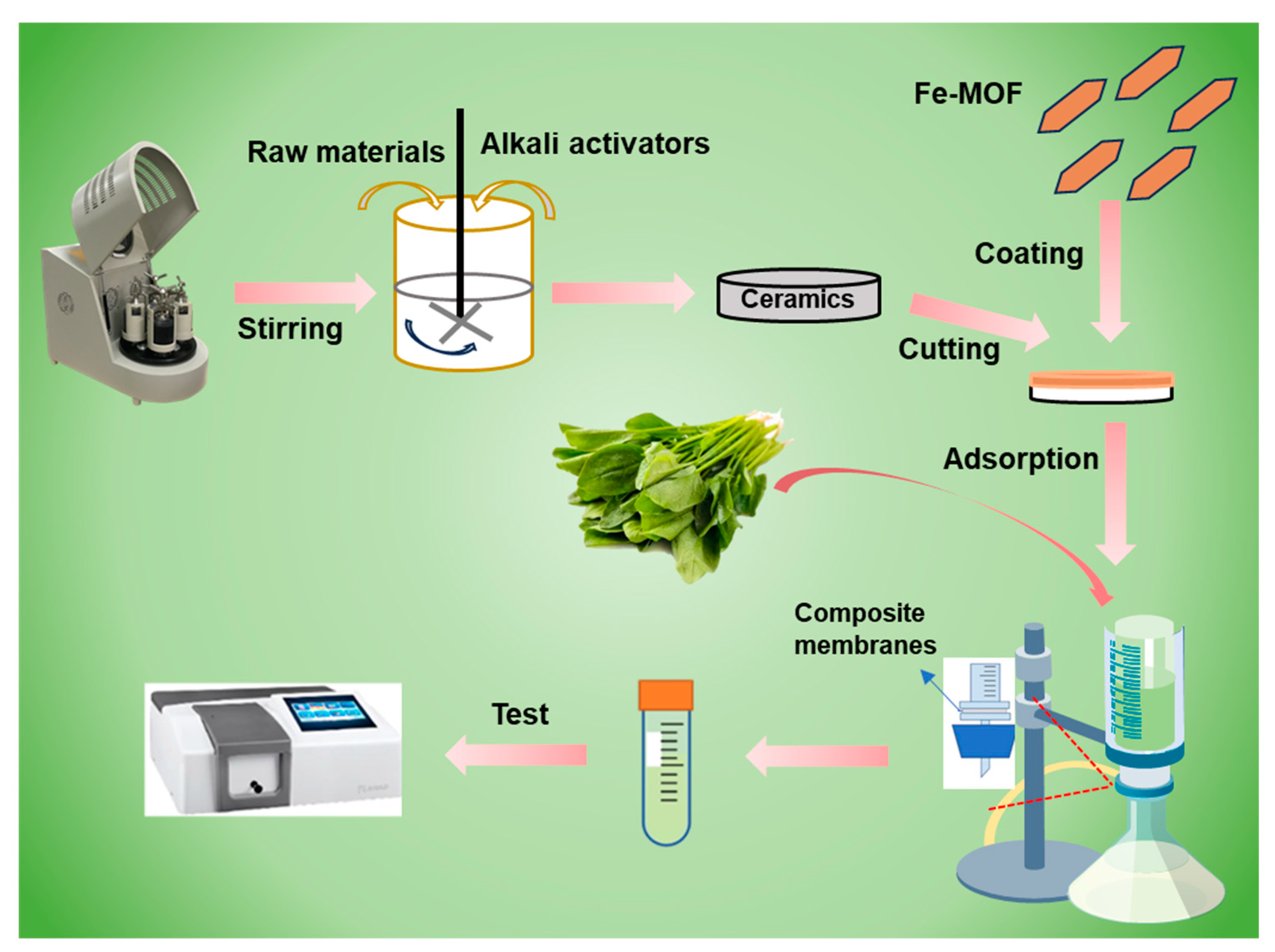

2.3. Preparation of Non-Firing Aluminosilicate Ceramic Membranes

2.4. Preparation of Fe-MOF

2.5. Preparation of Fe-MOF/Non-Firing Aluminosilicate Membranes

2.6. Application of Fe-MOF/Non-Firing Aluminosilicate Membranes for Phytochromes Removal

- A663: absorbance of the solution at 663 nm;

- A645: absorbance of the solution at 645 nm;

- C0: initial concentration of phytochromes (mg/L);

- Ce: remaining concentration of phytochromes (mg/L).

3. Results and Discussion

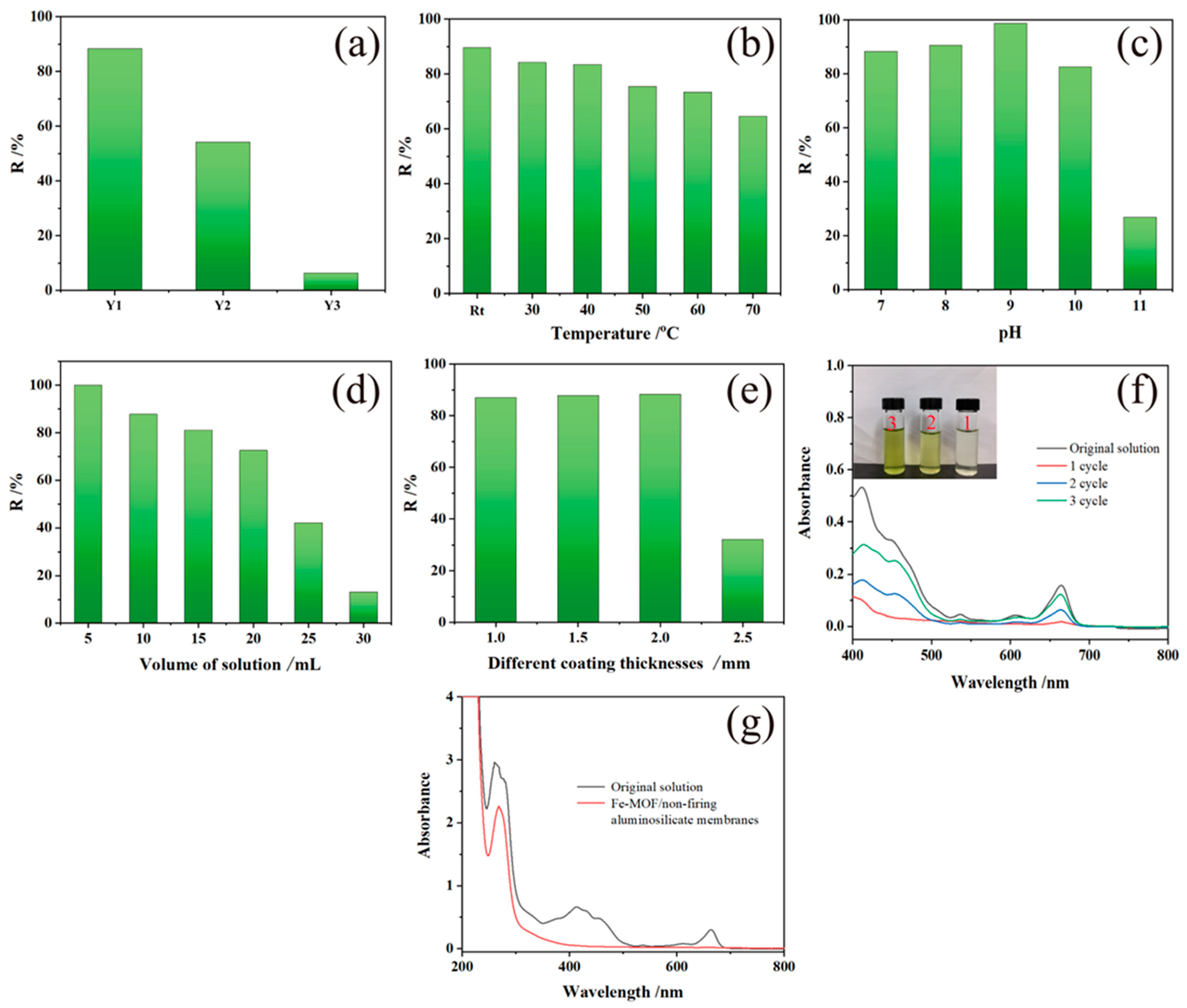

3.1. Preparation of Fe-MOF/Non-Firing Aluminosilicate Membranes and Adsorption Performance Testing

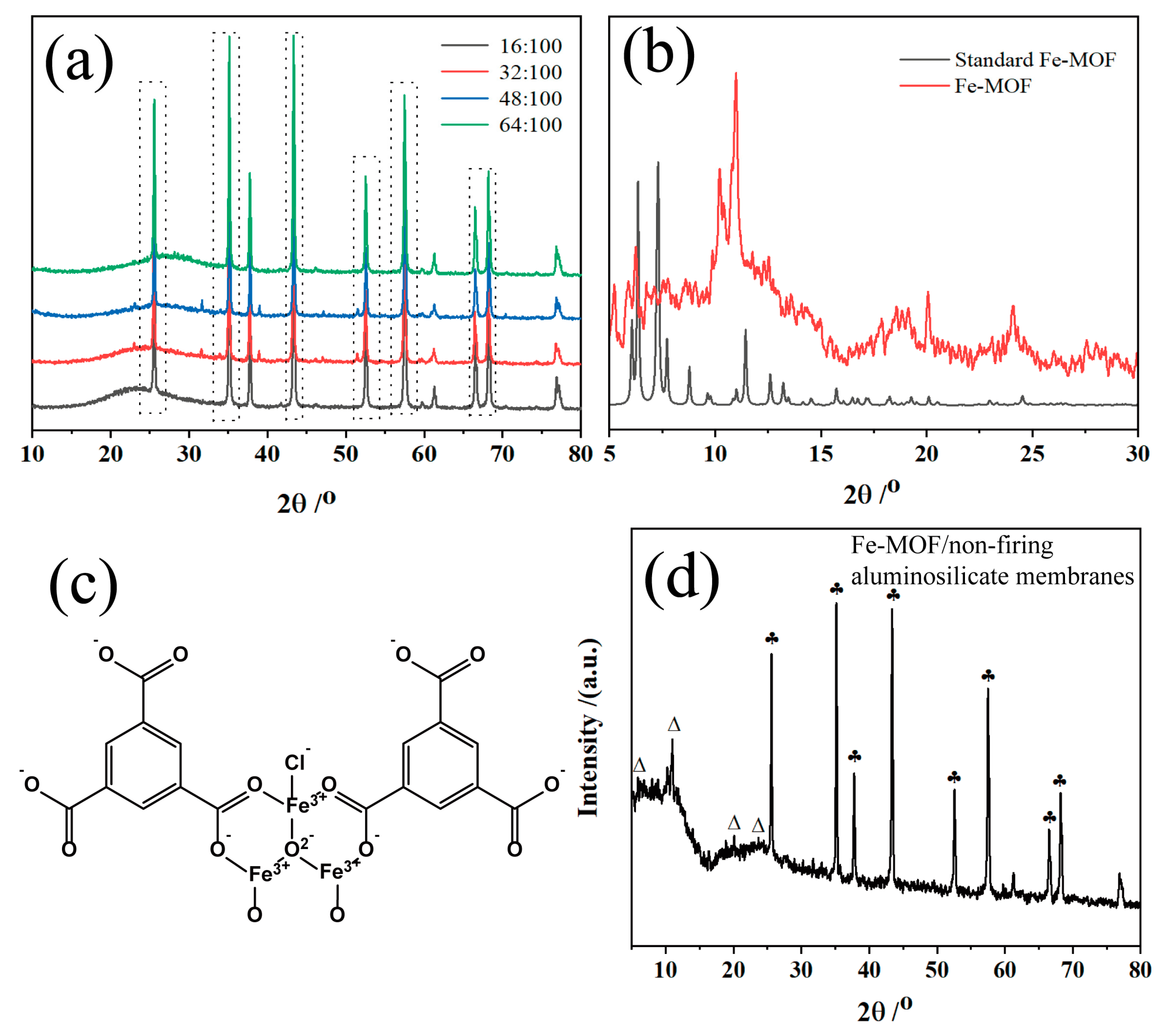

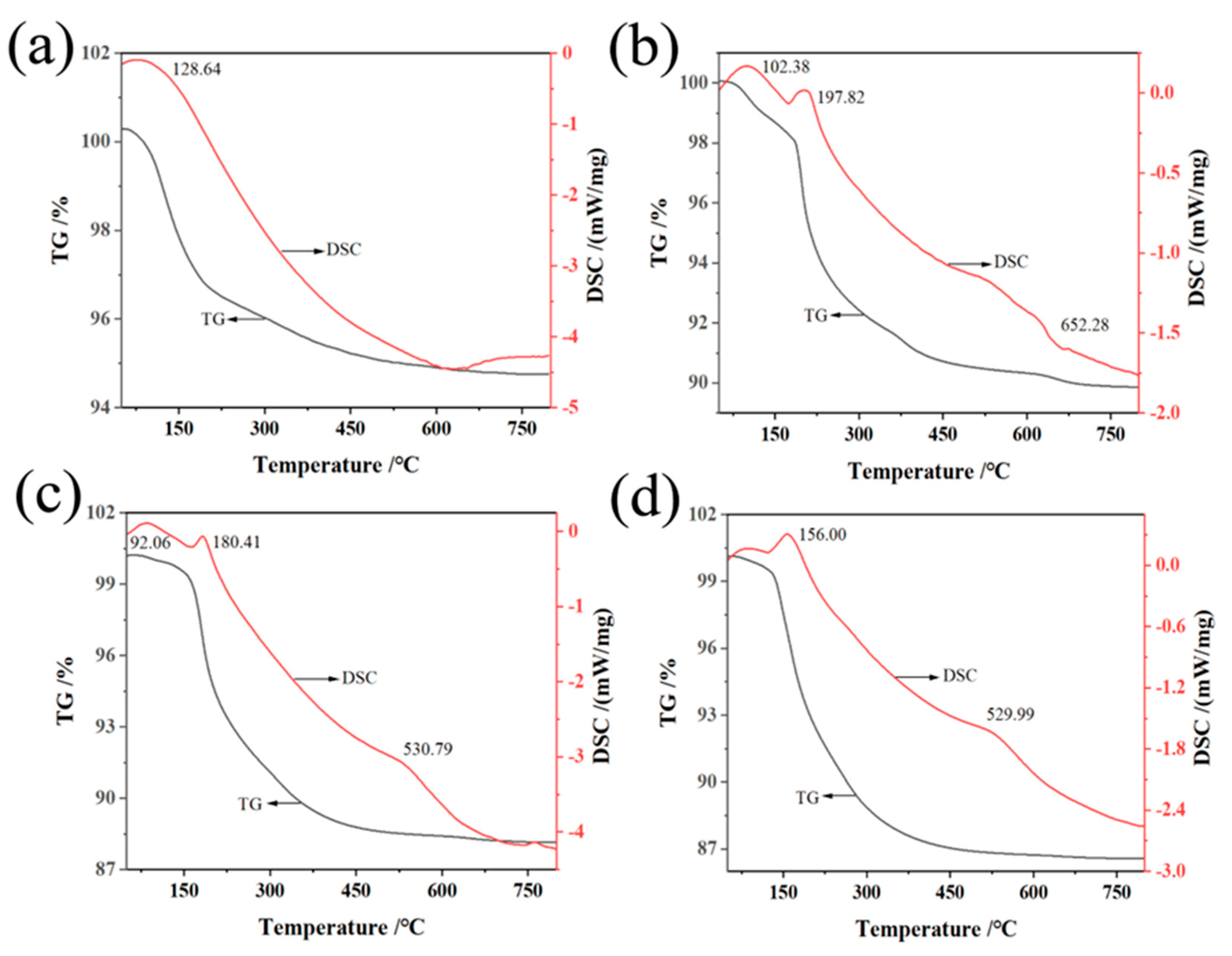

3.2. Characterization of Microscopic Morphology and Material Composition

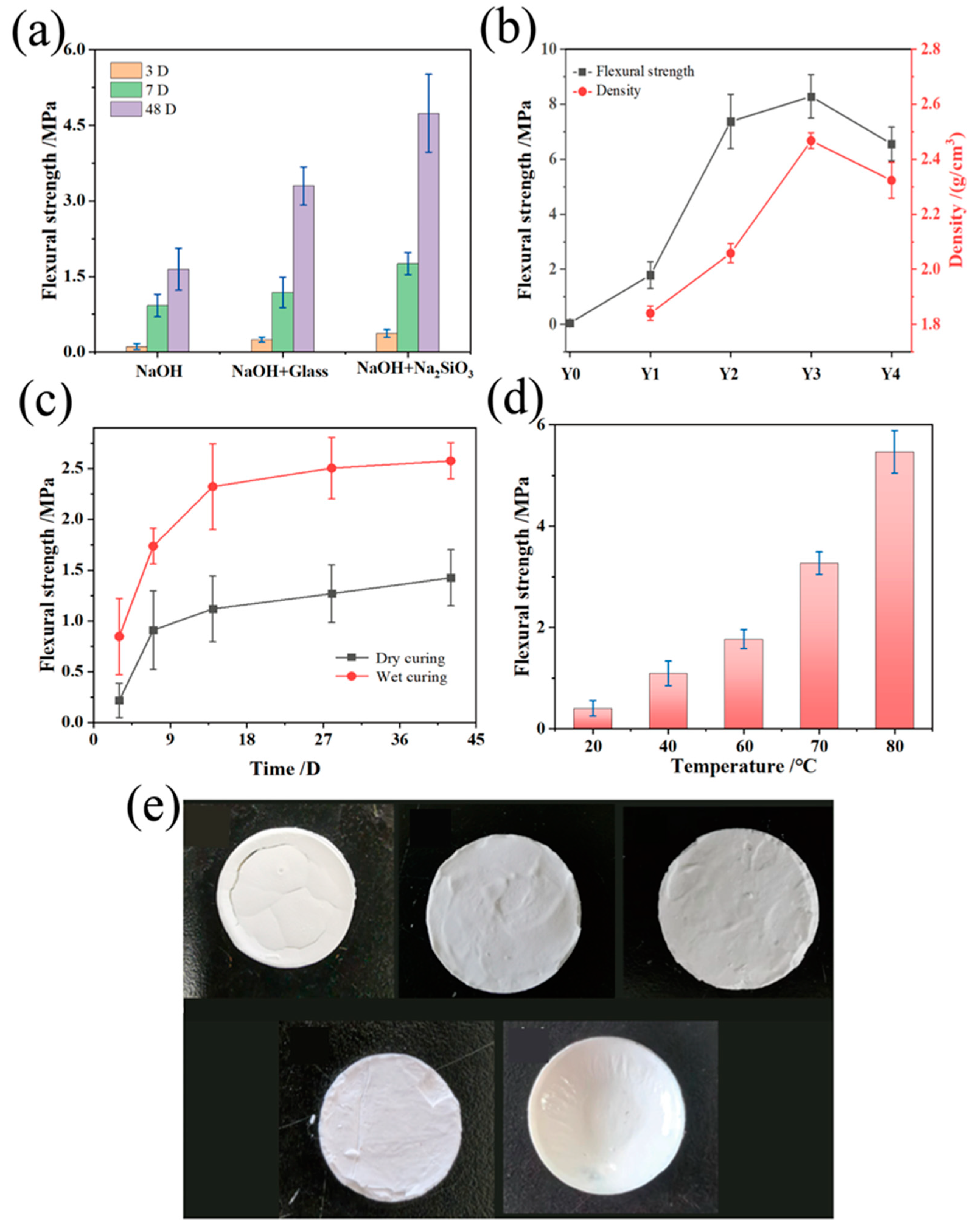

3.3. Characterization of Mechanical Properties

3.4. Characterization of Adsorption Properties

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, D.; Mei, H.; Liu, L.; Zhang, J. The effect of heating rate on sintering mechanism of alumina nanoparticles. J. Am. Ceram. Soc. 2022, 105, 7149–7158. [Google Scholar] [CrossRef]

- Nakashima, Y.; Razavi-Khosroshahi, H.; Ishida, H.; Takai, C.; Fuji, M. Non-firing ceramics: Activation of silica powder surface by a planetary ball milling. Adv. Powder Technol. 2019, 30, 461–465. [Google Scholar] [CrossRef]

- Xin, Y.; Peng, S.; Chen, J.X.; Yang, Z.J.; Zhang, J.Y. Continuous flow synthesis of porous materials. Chin. Chem. Lett. 2020, 31, 1448–1461. [Google Scholar] [CrossRef]

- Huang, H.H.; Wang, Q.; Wu, L.; Li, M.X. The Luminescence Characteristics of Alumina Ceramic Powder by the Low Temperature Combustion Synthesis. Spectrosc. Spectr. Anal. 2018, 38, 2676–2680. [Google Scholar]

- Ghosh, D.; Banda, M.; Akurati, S.; Kang, H.; Fakharizadeh, V.O. On the brittle fracture characteristics of lamella walls of ice-templated sintered alumina scaffolds and effects of platelets. Scr. Mater. 2017, 138, 139–144. [Google Scholar] [CrossRef]

- He, W.; Ai, Y.; Liang, B.; Chen, W.; Liu, C. Effects of La2O3 and Nb2O5 dopants on the microstructural development and fracture toughness of Al2O3 ceramic. Mater. Sci. Eng. A 2018, 723, 134–140. [Google Scholar] [CrossRef]

- Wu, J.; Zhang, C.; Xu, X.; Liu, X.; Zhou, S. Preparation and characterization of alumina/calcium-hexaluminate ceramic composites from ferrotitanium slag. J. Eur. Ceram. Soc. 2020, 40, 4265–4275. [Google Scholar] [CrossRef]

- Lu, J.; Zhang, Z.; Li, Y.; Liu, Z. Effect of alumina source on the densification, phase evolution, and strengthening of sintered mullite-based ceramics from milled coal fly ash. Constr. Build. Mater. 2019, 229, 116851. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, J.Y.; Zhang, Z.Q.; Zhao, L.P.; Li, M.; Li, M.J.; Zhao, D.; Zhong, G.Q.; Hu, X.D.; Zhang, X.J.; et al. Mechanochemical synthesis of nanostructured and composite oxide ceramics: From mechanisms to tailored properties. Int. J. Appl. Ceram. Technol. 2024, 21, 616–654. [Google Scholar] [CrossRef]

- Ghasali, E.; Alizadeh, M.; Shirvanimoghaddam, K.; Mirzajany, R.; Niazmand, M.; Faeghi-Nia, A.; Ebadzadeh, T. Porous and non-porous alumina reinforced magnesium matrix composite through microwave and spark plasma sintering processes. Mater. Chem. Phys. 2018, 212, 252–259. [Google Scholar] [CrossRef]

- Chen, Z.; Xu, Z.; Cui, F.; Zhang, J.; Sun, X.; Shang, Y.; Guo, R.; Liu, N.; Cai, S.; Zheng, C. Direct ink writing of cordierite ceramics with low thermal expansion coefficient. J. Eur. Ceram. Soc. 2022, 42, 1685–1693. [Google Scholar] [CrossRef]

- Liu, N.; Sun, X.; Chen, Z.; Xu, Z.; Dai, N.; Shi, G.; Cai, S.; Lv, X.; Zheng, C. Direct ink writing of dense alumina ceramics prepared by rapid sintering. Ceram. Int. 2022, 48, 30767–30778. [Google Scholar] [CrossRef]

- Chen, Z.; Sun, X.; Shang, Y.; Xiong, K.; Xu, Z.; Guo, R.; Cai, S.; Zheng, C. Dense ceramics with complex shape fabricated by 3D printing: A review. J. Adv. Ceram. 2021, 10, 195–218. [Google Scholar] [CrossRef]

- Pinargote, N.W.S.; Smirnov, A.; Peretyagin, N.; Seleznev, A.; Peretyagin, P. Direct Ink Writing Technology (3D Printing) of Graphene-Based Ceramic Nanocomposites: A Review. Nanomaterials 2020, 10, 1300. [Google Scholar] [CrossRef] [PubMed]

- Ren, X.; Lv, X.; Chen, Z.; Zhang, P.; Hu, X.; Mei, X. Preparation of Ag Nanoclusters-Modified Non-Sintered Silica Ceramic-Like Nanosheet for Removing Dyes and Bacteria from Water. Int. J. Nanomed. 2021, 16, 895–904. [Google Scholar] [CrossRef] [PubMed]

- Nakashima, Y.; Razavi-Khosroshahi, H.; Takai, C.; Fuji, M. Non-firing ceramics: Effect of adsorbed water on surface activation of silica powder via ball milling treatment. Adv. Powder Technol. 2019, 30, 1160–1164. [Google Scholar] [CrossRef]

- Razavi-Khosroshahi, H.; Sato, T.; Fuji, M. Non-firing solidification: A new room temperature ceramics processing. Adv. Powder Technol. 2020, 31, 2020–2024. [Google Scholar] [CrossRef]

- Ghayour, H.; Abdellahi, M.; Bahmanpour, M. Optimization of the high energy ball-milling: Modeling and parametric study. Powder Technol. 2016, 291, 7–13. [Google Scholar] [CrossRef]

- Thi Thu, H.T.; Shirai, T.; Fuji, M. An advanced fabrication route for alkali silicate glass by non-firing process. Adv. Powder Technol. 2014, 25, 360–364. [Google Scholar] [CrossRef]

- Hien, T.T.T.; Shirai, T.; Fuji, M.; Bhandarkar, S. Mechanochemical Treatment of Amorphous Silica Powder for Glasses without Firing. J. Am. Ceram. Soc. 2013, 96, 3708–3711. [Google Scholar] [CrossRef]

- Hristova, M.; Lesov, I.; Mihaylov, L.; Denkov, N.; Tcholakova, S. Role of particle size on the cohesive strength of non-sintered (green) ceramics. Colloids Surf. A-Physicochem. Eng. Asp. 2023, 658, 130653. [Google Scholar] [CrossRef]

- Razavi-Khosroshahi, H.; Ishida, H.; Fuji, M. High-strength non-firing ceramics by mechanochemical treatment. Adv. Powder Technol. 2020, 31, 4672–4678. [Google Scholar] [CrossRef]

- Xu, J.Y.; Li, M.J.; Zhao, D.; Zhong, G.Q.; Sun, Y.; Hu, X.D.; Sun, J.F.; Li, X.Y.; Zhu, W.J.; Li, M.; et al. Research and Application Progress of Geopolymers in Adsorption: A Review. Nanomaterials 2022, 12, 3002. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Xiong, K.Z.; Sun, Z.Q.; Lv, Y.; Zhao, Y.M.; Zhang, H.; Sun, X.H.; Xu, Z.K.; Zheng, C.M. Strength degradation of alumina fiber: Irreversible phase transition after high-temperature treatment. Ceram. Int. 2021, 47, 24582–24588. [Google Scholar] [CrossRef]

- Xu, Z.K.; Sun, X.H.; Xiong, K.Z.; Chen, Z.; Shang, Y.P.; Guo, R.S.; Cai, S.; Zheng, C.M. A review of the research progress on the interface between oxide fiber and oxide ceramic matrix. Ceram. Int. 2021, 47, 5896–5908. [Google Scholar] [CrossRef]

- Yu, H.N.; Xia, H.C.; Zhang, J.N.; He, J.; Guo, S.Y.; Xu, Q. Fabrication of Fe-doped Co-MOF with mesoporous structure for the optimization of supercapacitor performances. Chin. Chem. Lett. 2018, 29, 834–836. [Google Scholar] [CrossRef]

- Liu, M.J.; Liu, Y.; Liu, X.R.; Chu, C.C.; Yao, D.C.; Mao, S. Modification strategies on 2D Ni-Fe MOF-based catalysts in peroxydisulfate activation for efficient organic pollutant removal. Chin. Chem. Lett. 2023, 34, 107708. [Google Scholar] [CrossRef]

- Tang, J.T.; Wang, J.L. Metal Organic Framework with Coordinatively Unsaturated Sites as Efficient Fenton-like Catalyst for Enhanced Degradation of Sulfamethazine. Environ. Sci. Technol. 2018, 52, 5367–5377. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.Y.; Gao, Y.Y.; Wei, S.; Chen, P.; Gu, D.D.; Fu, B.; Chen, M.H. Plasma modification of Fe-MOF for efficient organic pollutants removal. J. Solid State Chem. 2021, 302, 122350. [Google Scholar] [CrossRef]

- Ye, G.Y.; He, Q.; Liu, S.Q.; Zhao, K.M.; Su, Y.K.; Zhu, W.W.; Huang, R.J.; He, Z. Cage-confinement of gas-phase ferrocene in zeolitic imidazolate frameworks to synthesize high-loading and atomically dispersed Fe-N codoped carbon for efficient oxygen reduction reaction. J. Mater. Chem. A 2019, 7, 16508–16515. [Google Scholar] [CrossRef]

- Ren, W.; Gao, J.; Lei, C.; Xie, Y.; Cai, Y.; Ni, Q.; Yao, J. Recyclable metal-organic framework/cellulose aerogels for activating peroxymonosulfate to degrade organic pollutants. Chem. Eng. J. 2018, 349, 766–774. [Google Scholar] [CrossRef]

- Zhou, X.; Liu, G.Q.; Zhang, H.W.; Li, Y.; Cai, W.P. Porous zeolite imidazole framework-wrapped urchin-like Au-Ag nanocrystals for SERS detection of trace hexachlorocyclohexane pesticides via efficient enrichment. J. Hazard. Mater. 2019, 368, 429–435. [Google Scholar] [CrossRef] [PubMed]

- Sun, K.; Lyu, Q.; Zheng, X.; Liu, R.; Tang, C.Y.; Zhao, M.; Dong, Y. Enhanced water treatment performance of ceramic-based forward osmosis membranes via MOF interlayer. Water Res. 2024, 254, 121395. [Google Scholar] [CrossRef] [PubMed]

- Usman, J.; Abba, S.I.; Baig, N.; Abu-Zahra, N.; Hasan, S.W.; Aljundi, I.H. Design and Machine Learning Prediction of In Situ Grown PDA-Stabilized MOF (UiO-66-NH2) Membrane for Low-Pressure Separation of Emulsified Oily Wastewater. ACS Appl. Mater. Interfaces 2024, 16, 16271–16289. [Google Scholar] [CrossRef] [PubMed]

- Torrez-Herrera, J.J.; Korili, S.A.; Gil, A. Development of ceramic-MOF filters from aluminum saline slags for capturing CO2. Powder Technol. 2023, 429, 118962. [Google Scholar] [CrossRef]

- Singh, H.; Raj, S.; Bhattacharya, J. Sustainable treatment of the dye wastewater generated from unorganized small-scale units using an economical ceramic clay-bimetallic MOF filter. J. Water Process Eng. 2023, 56, 104381. [Google Scholar] [CrossRef]

- Salazar-Aguilar, A.D.; Quintanilla, A.; López, P.; Martínez, C.; Vega-Díaz, S.M.; Casas, J.A.; Miranzo, P.; Osendi, M.I.; Belmonte, M. 3D-Printed Fe/γ-Al2O3 Monoliths from MOF-Based Boehmite Inks for the Catalytic Hydroxylation of Phenol. ACS Appl. Mater. Interfaces 2022, 14, 920–932. [Google Scholar] [CrossRef] [PubMed]

- Kong, C.L.; Du, H.B.; Chen, L.; Chen, B.L. Nanoscale MOF/organosilica membranes on tubular ceramic substrates for highly selective gas separation. Energy Environ. Sci. 2017, 10, 1812–1819. [Google Scholar] [CrossRef]

- Li, W.; Jiang, H.X.; Cui, M.F.; Wang, R.; Tang, A.N.; Kong, D.M. SiO2 templates-derived hierarchical porous COFs sample pretreatment tool for non-targeted analysis of chemicals in foods. J. Hazard. Mater. 2022, 432, 128705. [Google Scholar] [CrossRef]

- Stara, A.; Bellinvia, R.; Velisek, J.; Strouhova, A.; Kouba, A.; Faggio, C. Acute exposure of common yabby (Cherax destructor) to the neonicotinoid pesticide. Sci. Total Environ. 2019, 665, 718–723. [Google Scholar] [CrossRef]

- Farré, M.; Picó, Y.; Barceló, D. Direct Peel Monitoring of Xenobiotics in Fruit by Direct Analysis in Real Time Coupled to a Linear Quadrupole Ion Trap-Orbitrap Mass Spectrometer. Anal. Chem. 2013, 85, 2638–2644. [Google Scholar] [CrossRef] [PubMed]

- Reddy, A.V.B.; Moniruzzaman, M.; Aminabhavi, T.M. Polychlorinated biphenyls (PCBs) in the environment: Recent updates on sampling, pretreatment, cleanup technologies and their analysis. Chem. Eng. J. 2019, 358, 1186–1207. [Google Scholar] [CrossRef]

- Lv, W.J.; Wang, L.C.; Xuan, Q.H.; Zhao, X.J.; Liu, X.Y.; Shi, X.Z.; Xu, G.W. Pseudotargeted Method Based on Parallel Column Two-Dimensional Liquid Chromatography-Mass Spectrometry for Broad Coverage of Metabolome and Lipidome. Anal. Chem. 2020, 92, 6043–6050. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Jiang, H.X.; Geng, Y.; Wang, X.H.; Gao, R.Z.; Tang, A.N.; Kong, D.M. Facile Removal of Phytochromes and Efficient Recovery of Pesticides Using Heteropore Covalent Organic Framework-Based Magnetic Nanospheres and Electrospun Films. ACS Appl. Mater. Interfaces 2020, 12, 20922–20932. [Google Scholar] [CrossRef] [PubMed]

- Eliche-Quesada, D.; Sandalio-Pérez, J.A.; Martínez-Martínez, S.; Pérez-Villarejo, L.; Sánchez-Soto, P.J. Investigation of use of coal fly ash in eco-friendly construction materials: Fired clay bricks and silica-calcareous non fired bricks. Ceram. Int. 2018, 44, 4400–4412. [Google Scholar] [CrossRef]

- Nakashima, Y.; Fukushima, M.; Hyuga, H. Preparation of porous diatomite ceramics by an alkali treatment near room temperature. J. Eur. Ceram. Soc. 2021, 41, 849–855. [Google Scholar] [CrossRef]

- Xia, L.; Yang, J.N.; Su, R.H.; Zhou, W.J.; Zhang, Y.S.; Zhong, Y.H.; Huang, S.M.; Chen, Y.L.; Li, G.K. Recent Progress in Fast Sample Preparation Techniques. Anal. Chem. 2020, 92, 34–48. [Google Scholar] [CrossRef]

- Song, G.Q.; Wang, Z.Q.; Wang, L.; Li, G.R.; Huang, M.J.; Yin, F.X. Preparation of MOF(Fe) and its catalytic activity for oxygen reduction reaction in an alkaline electrolyte. Chin. J. Catal. 2014, 35, 185–195. [Google Scholar] [CrossRef]

- Jin, Y.; Qi, Y.; Tang, C.; Shao, B. Hierarchical micro- and mesoporous metal–organic framework-based magnetic nanospheres for the nontargeted analysis of chemical hazards in vegetables. J. Mater. Chem. A 2021, 9, 9056–9065. [Google Scholar] [CrossRef]

- Guesh, K.; Caiuby, C.A.D.; Mayoral, A.; Díaz-García, M.; Díaz, I.; Sanchez-Sanchez, M. Sustainable Preparation of MIL-100(Fe) and Its Photocatalytic Behavior in the Degradation of Methyl Orange in Water. Cryst. Growth Des. 2017, 17, 1806–1813. [Google Scholar] [CrossRef]

- Tian, K.V.; Mahmoud, M.Z.; Cozza, P.; Licoccia, S.; Fang, D.C.; Di Tommaso, D.; Chass, G.A.; Greaves, G.N. Periodic vs. molecular cluster approaches to resolving glass structure and properties: Anorthite a case study. J. Non-Cryst. Solids 2016, 451, 138–145. [Google Scholar] [CrossRef]

- Yuen, W.; Qi, Z. Research progress on prepartion of MOF-derived porous carbon materials through pyrolysis. Chin. Sci. Bull. 2018, 63, 2246–2263. [Google Scholar] [CrossRef]

- Bai, C.Y.; Li, H.Q.; Bernardo, E.; Colombo, P. Waste-to-resource preparation of glass-containing foams from geopolymers. Ceram. Int. 2019, 45, 7196–7202. [Google Scholar] [CrossRef]

- Tchakouté, H.K.; Rüscher, C.H.; Hinsch, M.; Djobo, J.N.Y.; Kamseu, E.; Leonelli, C. Utilization of sodium waterglass from sugar cane bagasse ash as a new alternative hardener for producing metakaolin-based geopolymer cement. Chem. Der Erde-Geochem. 2017, 77, 257–266. [Google Scholar] [CrossRef]

- Granizo, M.L.; Blanco-Varela, M.T.; Palomo, A. Influence of the starting kaolin on alkali-activated materials based on metakaolin. Study of the reaction parameters by isothermal conduction calorimetry. J. Mater. Sci. 2000, 35, 6309–6315. [Google Scholar] [CrossRef]

- Rovnaník, P. Effect of curing temperature on the development of hard structure of metakaolin-based geopolymer. Constr. Build. Mater. 2010, 24, 1176–1183. [Google Scholar] [CrossRef]

- Hui-Teng, N.; Heah, C.Y.; Liew, Y.M.; Abdullah, M.M.A.; Hun, K.E.; Razi, H.M.; Yong-Sing, N. Formulation, mechanical properties and phase analysis of fly ash geopolymer with ladle furnace slag replacement. J. Mater. Res. Technol. -JmrT 2021, 12, 1212–1226. [Google Scholar] [CrossRef]

- Xie, Q.Y.; Li, Y.; Lv, Z.L.; Zhou, H.; Yang, X.J.; Chen, J.; Guo, H. Effective Adsorption and Removal of Phosphate from Aqueous Solutions and Eutrophic Water by Fe-based MOFs of MIL-101. Sci. Rep. 2017, 7, 3316. [Google Scholar] [CrossRef] [PubMed]

- Arenillas, A.; Pevida, C.; Rubiera, F.; Palacios, J.M.; Navarrete, R.; Denoyel, R.; Rouquerol, J.; Pis, J.J. Surface characterisation of synthetic coal chars made from model compounds. Carbon 2004, 42, 1345–1350. [Google Scholar] [CrossRef]

- Lowell, S.; Shields, J.E. Powder Surface Area and Porosity; Springer Science & Business Media: Berlin/Heidelberg, Germany, 1984. [Google Scholar]

- Sabbatini, A.; Vidal, L.; Pettinari, C.; Sobrados, I.; Rossignol, S. Control of shaping and thermal resistance of metakaolin-based geopolymers. Mater. Des. 2017, 116, 374–385. [Google Scholar] [CrossRef]

| Sample Number | Al2O3/SiO2 Molar Ratio | NaOH/SiO2 Molar Ratio | Sodium Silicate Form | Conservation Methods | Curing Temperature(°C) | BET Surface Area (m2/g) | Pore Size (nm) |

|---|---|---|---|---|---|---|---|

| Y1 | 1 | 16:100 | Powder | Wet curing | 60 | 28.2 | 38.1 |

| Y2 | 1 | 32:100 | Powder | Wet curing | 60 | 1.7 | 41.8 |

| Y3 | 1 | 48:100 | Powder | Wet curing | 60 | 0.6 | 37.3 |

| Y4 | 1 | 64:100 | Powder | Wet curing | 60 | 0.1 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, L.; Xu, J.; Li, M.; Ji, Y.; Sun, Y.; Zhang, Z.; Hu, X.; Peng, Z.; Wang, Y.; Zheng, C.; et al. MOF-Enhanced Aluminosilicate Ceramic Membranes Using Non-Firing Processes for Pesticide Filtration and Phytochrome Removal. Nanomaterials 2024, 14, 944. https://doi.org/10.3390/nano14110944

Zhao L, Xu J, Li M, Ji Y, Sun Y, Zhang Z, Hu X, Peng Z, Wang Y, Zheng C, et al. MOF-Enhanced Aluminosilicate Ceramic Membranes Using Non-Firing Processes for Pesticide Filtration and Phytochrome Removal. Nanomaterials. 2024; 14(11):944. https://doi.org/10.3390/nano14110944

Chicago/Turabian StyleZhao, Liping, Jinyun Xu, Ming Li, Yanyan Ji, Yu Sun, Ziqi Zhang, Xudong Hu, Zhe Peng, Yicong Wang, Chunming Zheng, and et al. 2024. "MOF-Enhanced Aluminosilicate Ceramic Membranes Using Non-Firing Processes for Pesticide Filtration and Phytochrome Removal" Nanomaterials 14, no. 11: 944. https://doi.org/10.3390/nano14110944

APA StyleZhao, L., Xu, J., Li, M., Ji, Y., Sun, Y., Zhang, Z., Hu, X., Peng, Z., Wang, Y., Zheng, C., & Sun, X. (2024). MOF-Enhanced Aluminosilicate Ceramic Membranes Using Non-Firing Processes for Pesticide Filtration and Phytochrome Removal. Nanomaterials, 14(11), 944. https://doi.org/10.3390/nano14110944