Enhancement of the Surface Morphology of (Bi0.4Sb0.6)2Te3 Thin Films by In Situ Thermal Annealing

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

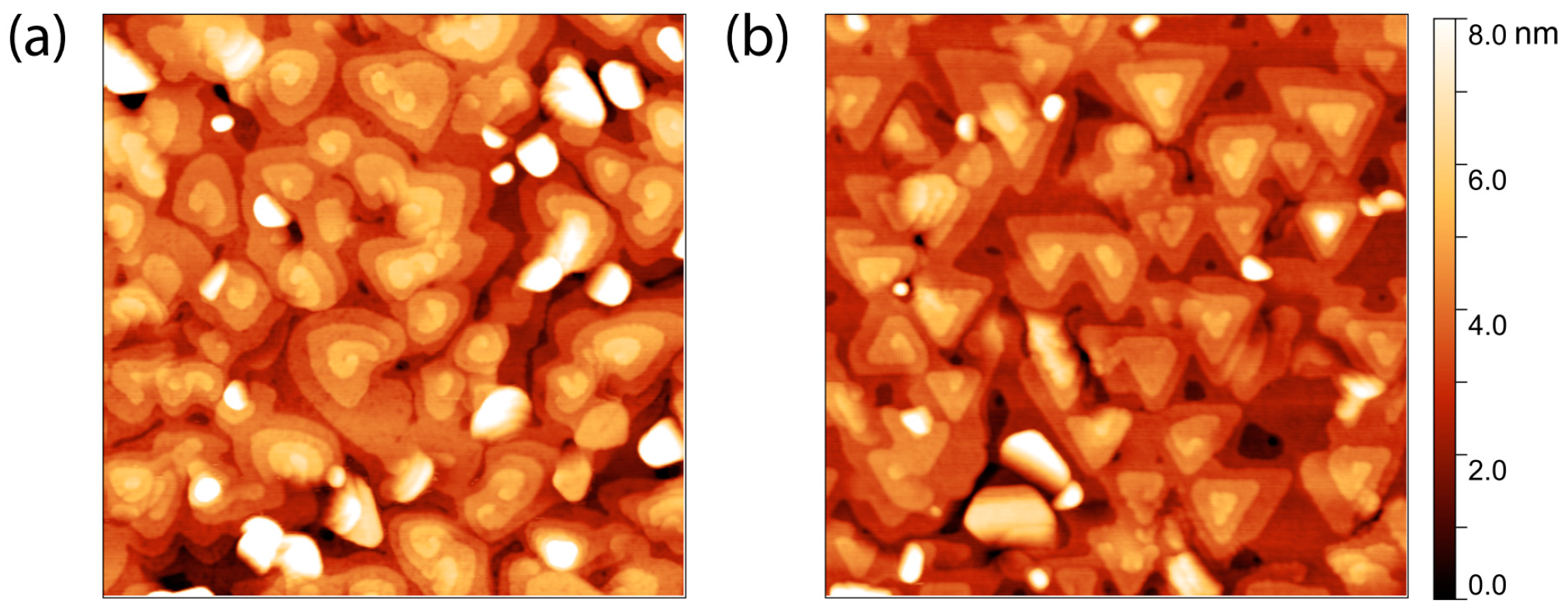

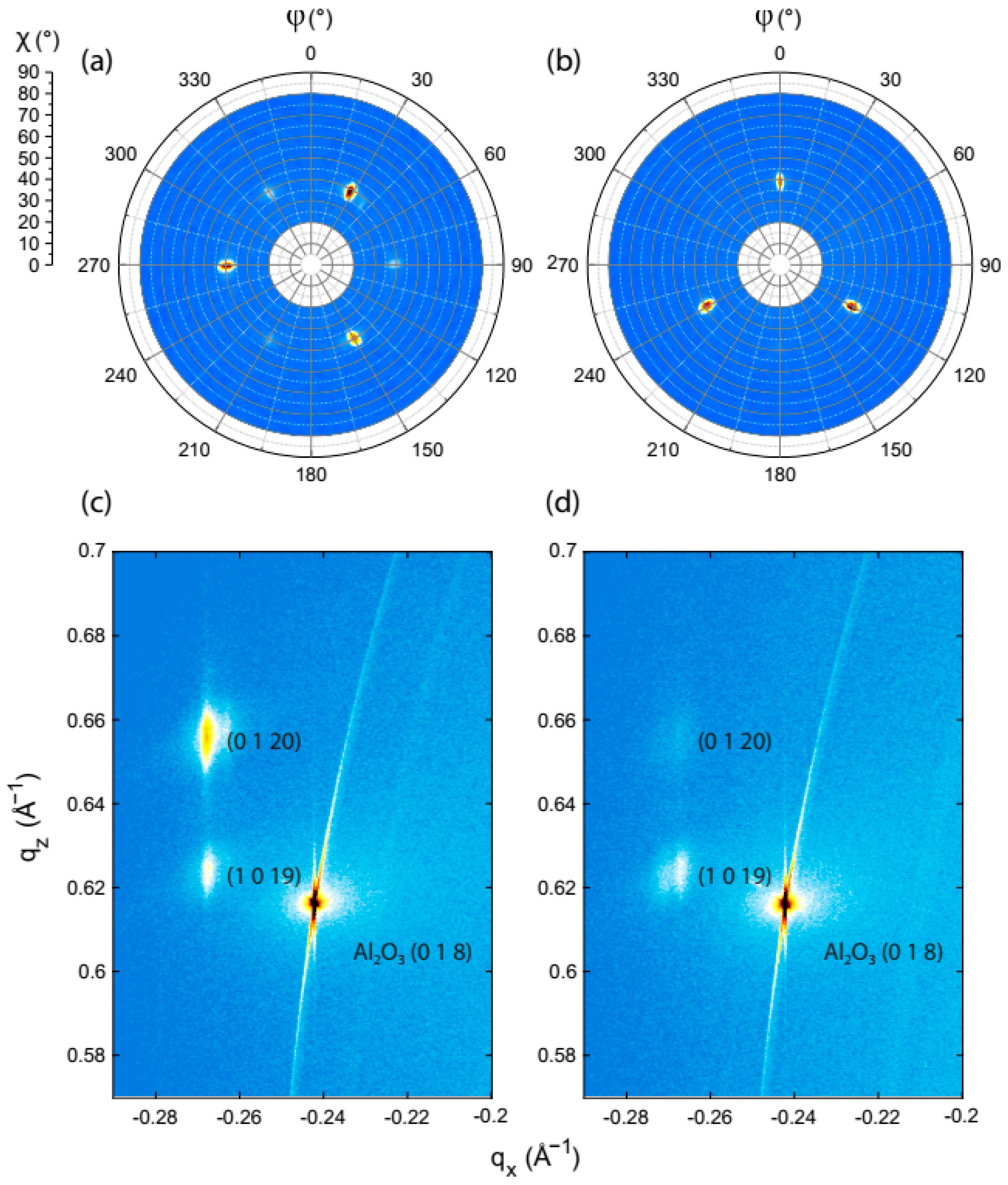

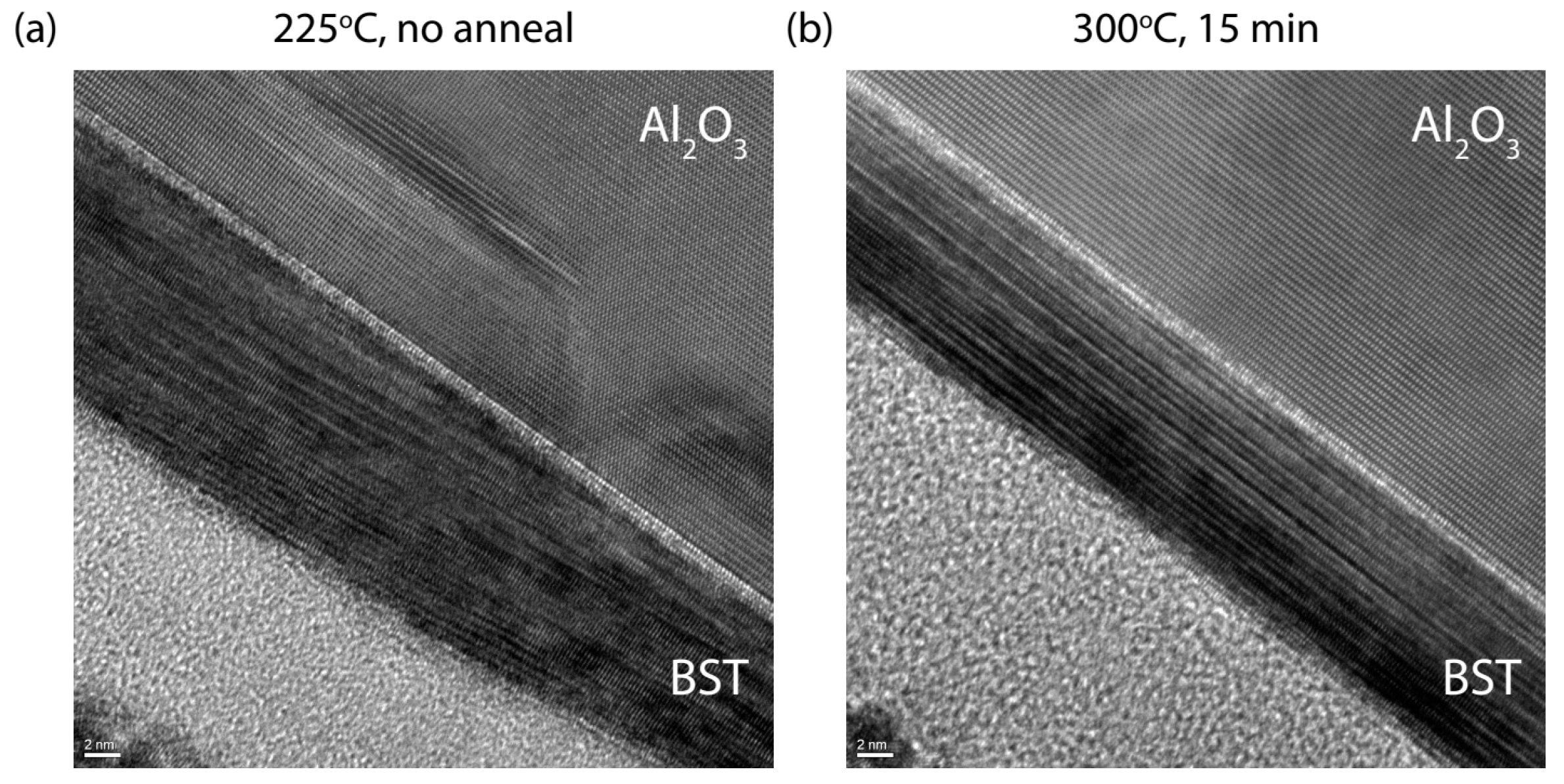

3.1. Characterization of Pristine BST Films

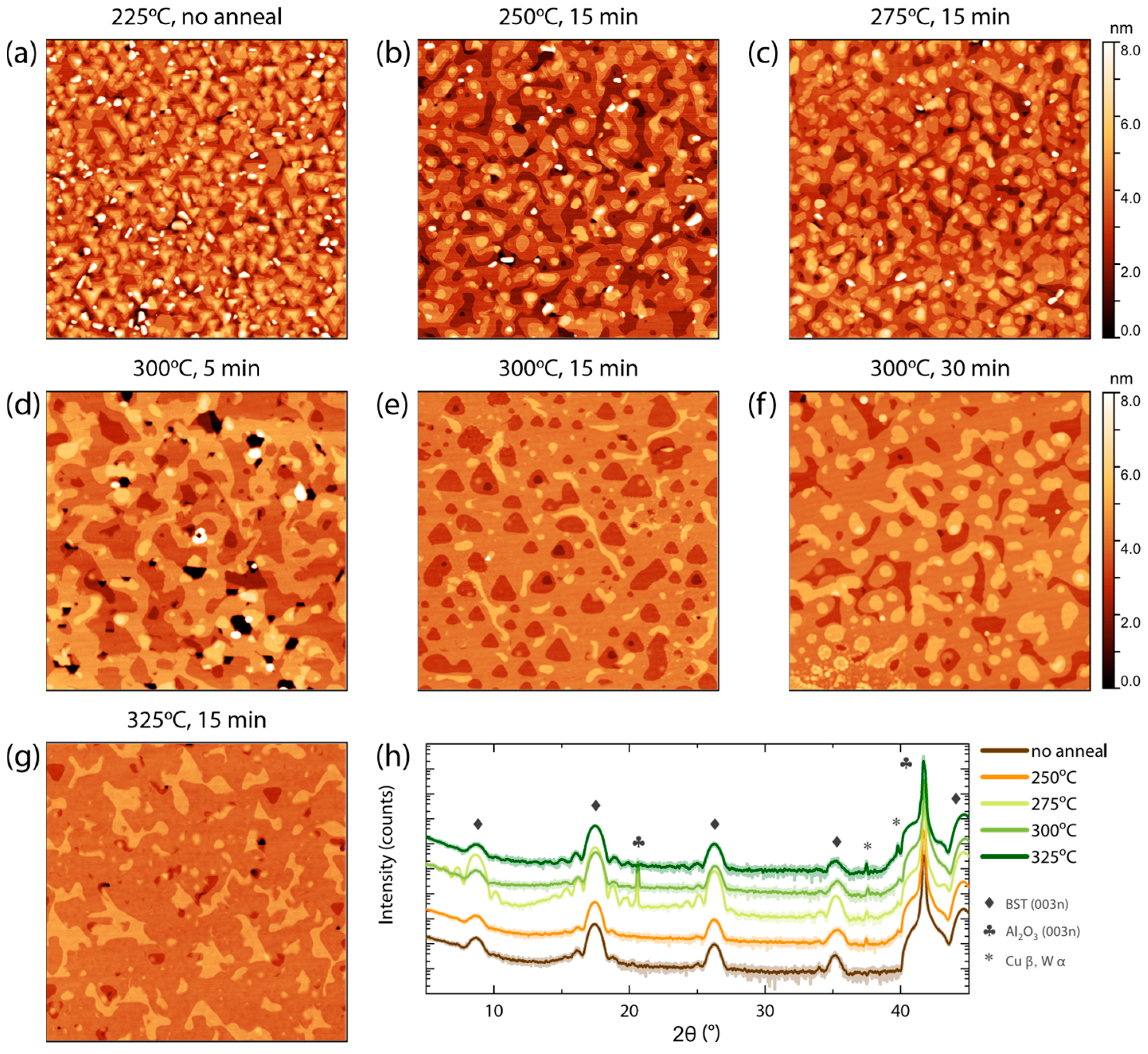

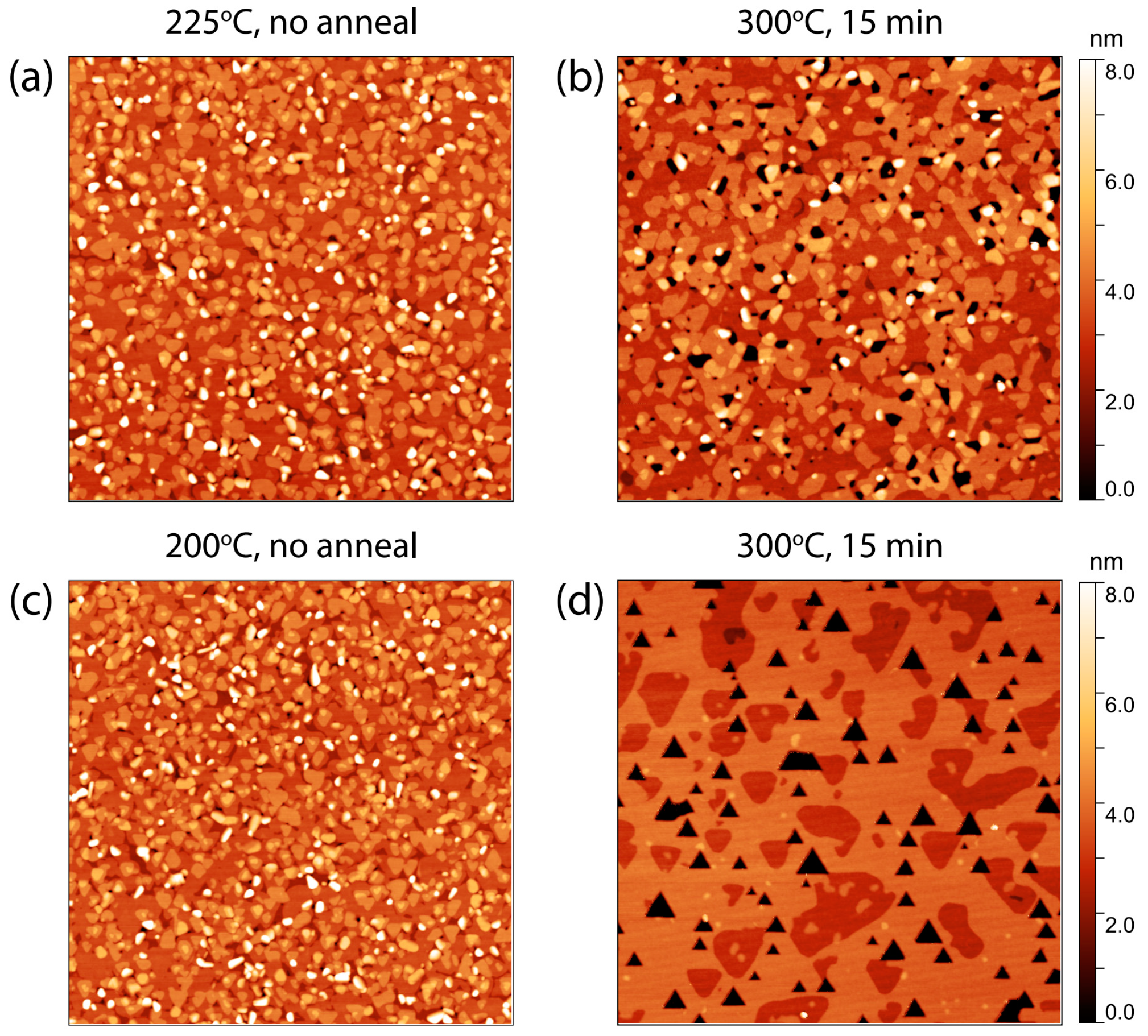

3.2. Effect of Post-Annealing Temperature

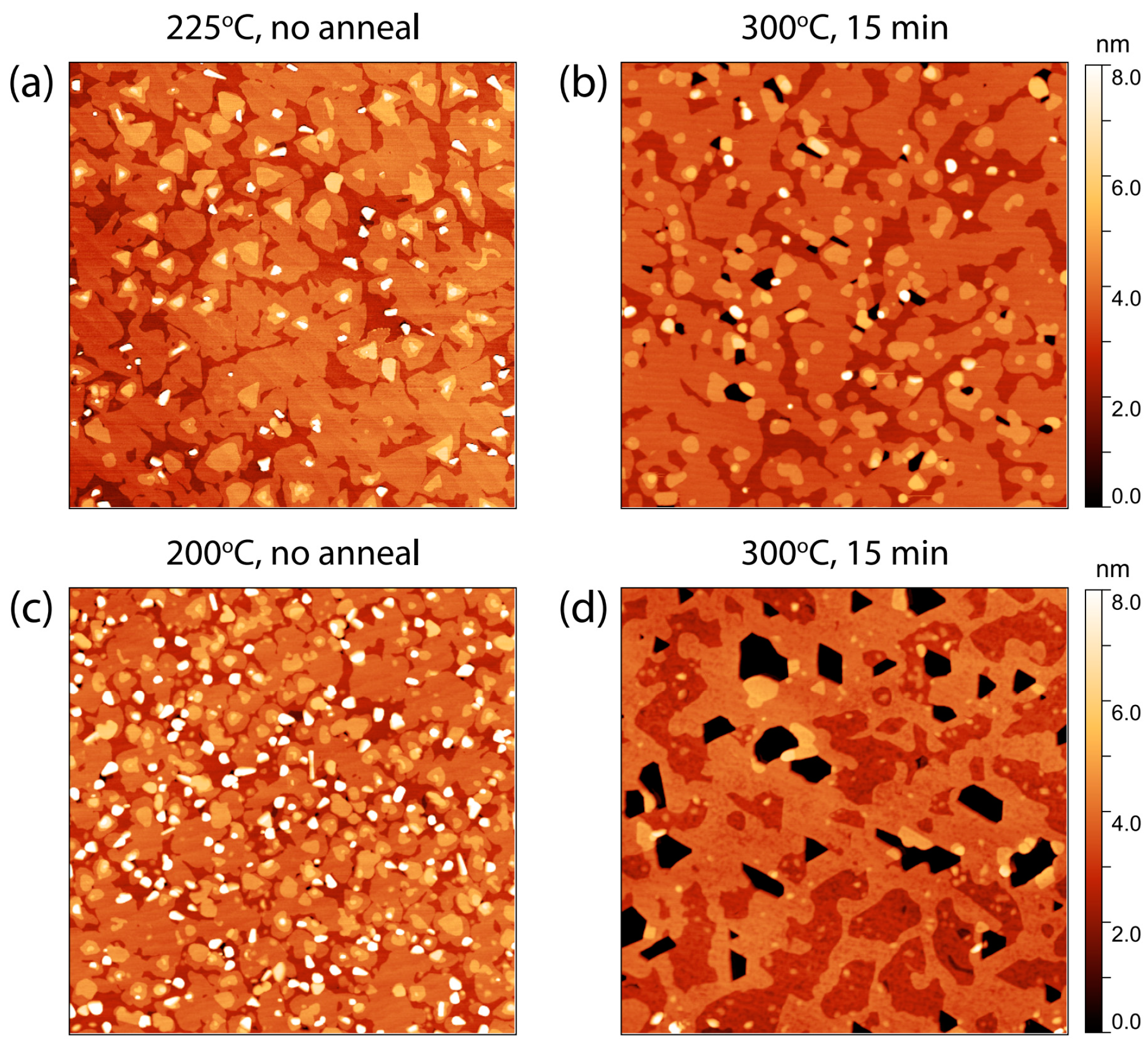

3.3. Post-Annealing of Ultrathin Films

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yue, C.; Jiang, S.; Zhu, H.; Chen, L.; Sun, Q.; Zhang, D.W. Device applications of synthetic topological insulator nanostructures. Electronics 2018, 7, 225. [Google Scholar] [CrossRef]

- He, M.; Sun, H.; He, Q.L. Topological insulator: Spintronics and quantum computations. Front. Phys. 2019, 14, 43401. [Google Scholar] [CrossRef]

- Linder, J.; Yokoyama, T.; Sudbø, A. Anomalous finite size effects on surface states in the topological insulator Bi2Se3. Phys. Rev. B—Condens. Matter Mater. Phys. 2009, 80, 205401. [Google Scholar] [CrossRef]

- Liu, C.-X.; Zhang, H.; Yan, B.; Qi, X.-L.; Frauenheim, T.; Dai, X.; Fang, Z.; Zhang, S.-C. Oscillatory crossover from two-dimensional to three-dimensional topological insulators. Phys. Rev. B—Condens. Matter Mater. Phys. 2010, 81, 2–5. [Google Scholar] [CrossRef]

- Asmar, M.M.; Sheehy, D.E.; Vekhter, I. Topological phases of topological-insulator thin films. Phys. Rev. B 2018, 97, 075419. [Google Scholar] [CrossRef]

- Jalil, A.R.; Schüffelgen, P.; Valencia, H.; Schleenvoigt, M.; Ringkamp, C.; Mussler, G.; Luysberg, M.; Mayer, J.; Grützmacher, D. Selective Area Epitaxy of Quasi-1-Dimensional Topological Nanostructures and Networks. Nanomaterials 2023, 13, 354. [Google Scholar] [CrossRef]

- Yadav, J.; Anoop, M.; Singh, R.; Yadav, N.; Rao, N.S.; Singh, F.; Jain, A.; Ichikawa, T.; Awasthi, K.; Kumar, M. A reversible tuning of Fermi level in BiSbTe3 thin films through ion implantation. Mater. Lett. 2022, 306, 130923. [Google Scholar] [CrossRef]

- Yüzüak, G.D.; Çiçek, M.M.; Elerman, Y.; Yüzüak, E. Enhancing the power factor of p-type BiSbTe films via deposited with/without Cr seed layer. J. Alloys Compd. 2021, 886, 161263. [Google Scholar] [CrossRef]

- Yu, W.; van Toan, N.; Li, Y.J.; Wang, Z.; Ono, T.; Wang, R. Morphological Analysis and Properties Evaluation of Electrodeposited Thick BiSbTe Films with Cooperative Interactions among Multiple Additives. J. Electrochem. Soc. 2021, 168, 022505. [Google Scholar] [CrossRef]

- Fu, L.; Park, K.; Kim, S.-I.; Kim, B.; Song, H.Y.; Choi, W.; Kim, Y.-M.; Hwang, J.-Y.; Lee, K.H.; Kim, S.W. High-Performance Bismuth Antimony Telluride Thermoelectric Membrane on Curved and Flexible Supports. ACS Energy Lett. 2021, 6, 2378–2385. [Google Scholar] [CrossRef]

- Liu, W.; Endicott, L.; Stoica, V.A.; Chi, H.; Clarke, R.; Uher, C. High-quality ultra-flat BiSbTe3films grown by MBE. J. Cryst. Growth 2015, 410, 23–29. [Google Scholar] [CrossRef]

- He, L.; Kou, X.; Lang, M.; Choi, E.S.; Jiang, Y.; Nie, T.; Jiang, W.; Fan, Y.; Wang, Y.; Xiu, F.; et al. Evidence of the two surface states of (Bi0.53Sb0.47)2Te3 films grown by van der Waals epitaxy. Sci. Rep. 2013, 3, 3406. [Google Scholar] [CrossRef] [PubMed]

- Shimizu, S.; Yoshimi, R.; Hatano, T.; Takahashi, K.S.; Tsukazaki, A.; Kawasaki, M.; Iwasa, Y.; Tokura, Y. Gate control of surface transport in MBE-grown topological insulator (Bi1−xSbx)2Te3 thin films. Phys. Rev. B—Condens. Matter Mater. Phys. 2012, 86, 045319. [Google Scholar] [CrossRef]

- Weyrich, C.; Drögeler, M.; Kampmeier, J.; Eschbach, M.; Mussler, G.; Merzenich, T.; Stoica, T.; Batov, I.E.; Schubert, J.; Plucinski, L.; et al. Growth, characterization, and transport properties of ternary (Bi1−xSbx)2Te3 topological insulator layers. J. Phys. Condens. Matter 2016, 28, 495501. [Google Scholar] [CrossRef] [PubMed]

- He, X.; Guan, T.; Wang, X.; Feng, B.; Cheng, P.; Chen, L.; Li, Y.; Wu, K. Highly tunable electron transport in epitaxial topological insulator (Bi1−xSbx)2Te3 thin films. Appl. Phys. Lett. 2012, 101, 123111. [Google Scholar] [CrossRef]

- Mulder, L.; Wielens, D.H.; Birkhölzer, Y.A.; Brinkman, A.; Concepción, O. Revisiting the van der Waals Epitaxy in the Case of (Bi0.4Sb0.6)2Te3 Thin Films on Dissimilar Substrates. Nanomaterials 2022, 12, 1790. [Google Scholar] [CrossRef]

- Kampmeier, J.; Borisova, S.; Plucinski, L.; Luysberg, M.; Mussler, G.; Grützmacher, D. Suppressing twin domains in molecular beam epitaxy grown Bi2Te3 topological insulator thin films. Cryst. Growth Des. 2015, 15, 390–394. [Google Scholar] [CrossRef]

- Höfer, K. All In Situ Ultra-High Vacuum Study of Bi2Te3 Topological Insulator Thin Filmss. Ph.D. Thesis, The Technische Universität Dresden, Dresden, Germany, 2017. [Google Scholar]

- Tarakina, N.V.; Schreyeck, S.; Luysberg, M.; Grauer, S.; Schumacher, C.; Karczewski, G.; Brunner, K.; Gould, C.; Buhmann, H.; Dunin-Borkowski, R.E.; et al. Suppressing Twin Formation in Bi2Se3 Thin Films. Adv. Mater. Interfaces 2014, 1, 1400134. [Google Scholar] [CrossRef]

- Guo, X.; Xu, Z.J.; Liu, H.C.; Zhao, B.; Dai, X.Q.; He, H.T.; Wang, J.N.; Liu, H.J.; Ho, W.K.; Xie, M.H. Single domain Bi2Se3 films grown on InP(111)A by molecular-beam epitaxy. Appl. Phys. Lett. 2013, 102, 151604. [Google Scholar] [CrossRef]

- Li, H.D.; Wang, Z.Y.; Kan, X.; Guo, X.; He, H.T.; Wang, Z.; Wang, J.N.; Wong, T.L.; Wang, N.; Xie, M.H. The van der Waals epitaxy of Bi2Se3 on the vicinal Si(111) surface: An approach for preparing high-quality thin films of a topological insulator. New J. Phys. 2010, 12, 103038. [Google Scholar] [CrossRef]

- Kim, K.-C.; Lee, J.; Kim, B.K.; Choi, W.Y.; Chang, H.J.; Won, S.O.; Kwon, B.; Kim, S.K.; Hyun, D.-B.; Kim, H.J.; et al. Free-electron creation at the 60° twin boundary in Bi2Te3. Nat. Commun. 2016, 7, 12449. [Google Scholar] [CrossRef]

- Ngabonziza, P.; Heimbuch, R.; de Jong, N.; Klaassen, R.A.; Stehno, M.P.; Snelder, M.; Solmaz, A.; Ramankutty, S.V.; Frantzeskakis, E.; van Heumen, E.; et al. In situ spectroscopy of intrinsic Bi2Te3 topological insulator thin films and impact of extrinsic defects. Phys. Rev. B—Condens. Matter Mater. Phys. 2015, 92, 035405. [Google Scholar] [CrossRef]

- Harrison, S.E.; Li, S.; Huo, Y.; Zhou, B.; Chen, Y.L.; Harris, J.S. Two-step growth of high quality Bi2Te3 thin films on Al2O3 (0001) by molecular beam epitaxy. Appl. Phys. Lett. 2013, 102, 171906. [Google Scholar] [CrossRef]

- Degen, T.; Sadki, M.; Bron, E.; König, U.; Nénert, G. The high score suite. Powder Diffr. 2014, 29, S13–S18. [Google Scholar] [CrossRef]

- Richardella, A.; Kandala, A.; Lee, J.S.; Samarth, N. Characterizing the structure of topological insulator thin films. APL Mater. 2015, 3, 083303. [Google Scholar] [CrossRef]

- Winnerlein, M.; Schreyeck, S.; Grauer, S.; Rosenberger, S.; Fijalkowski, K.M.; Gould, C.; Brunner, K.; Molenkamp, L.W. Epitaxy and structural properties of (V,Bi,Sb)2Te3 layers exhibiting the quantum anomalous Hall effect. Phys. Rev. Mater. 2017, 1, 011201. [Google Scholar] [CrossRef]

- Mu, X.; Zhou, H.; He, D.; Zhao, W.; Wei, P.; Zhu, W.; Nie, X.; Liu, H.; Zhang, Q. Enhanced electrical properties of stoichiometric Bi0.5Sb1.5Te3 film with high-crystallinity via layer-by-layer in-situ Growth. Nano Energy 2017, 33, 55–64. [Google Scholar] [CrossRef]

- Liao, Z.; Brahlek, M.; Ok, J.M.; Nuckols, L.; Sharma, Y.; Lu, Q.; Zhang, Y.; Lee, H.N. Pulsed-laser epitaxy of topological insulator Bi2Te3 thin films. APL Mater. 2019, 7, 041101. [Google Scholar] [CrossRef]

- Richardella, A.; Zhang, D.M.; Lee, J.S.; Koser, A.; Rench, D.W.; Yeats, A.; Buckley, B.B.; Awschalom, D.D.; Samarth, N. Coherent heteroepitaxy of Bi2Se3 on GaAs (111)B. Appl. Phys. Lett. 2010, 97, 262104. [Google Scholar] [CrossRef]

- Chen, J.; Qin, H.J.; Yang, F.; Liu, J.; Guan, T.; Qu, F.M.; Zhang, G.H.; Shi, J.R.; Xie, X.C.; Yang, C.L.; et al. Gate-voltage control of chemical potential and weak antilocalization in Bi2Se3. Phys. Rev. Lett. 2010, 105, 176602. [Google Scholar] [CrossRef]

- Liu, Y.; Weinert, M.; Li, L. Spiral growth without dislocations: Molecular beam epitaxy of the topological insulator Bi2Se3 on epitaxial graphene/SiC(0001). Phys. Rev. Lett. 2012, 108, 115501. [Google Scholar] [CrossRef] [PubMed]

- He, L.; Kou, X.; Wang, K.L. Review of 3D topological insulator thin-film growth by molecular beam epitaxy and potential applications. Phys. Status Solidi—Rapid Res. Lett. 2013, 7, 50–63. [Google Scholar] [CrossRef]

- Fornari, C.I.; Rappl, P.H.O.; Morelhão, S.L.; Fornari, G.; Travelho, J.S.; de Castro, S.; Pirralho, M.J.P.; Pena, F.S.; Peres, M.L.; Abramof, E. Structural defects and electronic phase diagram of topological insulator bismuth telluride epitaxial films. Mater. Res. Express 2018, 5, 116410. [Google Scholar] [CrossRef]

- Krumrain, J.; Mussler, G.; Borisova, S.; Stoica, T.; Plucinski, L.; Schneider, C.; Grützmacher, D. MBE growth optimization of topological insulator Bi2Te3 films. J. Cryst. Growth 2011, 324, 115–118. [Google Scholar] [CrossRef]

- Reed, T.B. Free Energy of Formation of Binary Compounds: An Atlas of Charts for High-Temperature Chemical Calculations. 1971; p. 81. Available online: https://openlibrary.org/works/OL853093W/Free_energy_of_formation_of_binary_compounds (accessed on 9 February 2023).

- Ueda, K.; Hadate, Y.; Suzuki, K.; Asano, H. Fabrication of high-quality epitaxial Bi1-xSbx films by two-step growth using molecular beam epitaxy. Thin Solid Films 2020, 713, 138361. [Google Scholar] [CrossRef]

- Pereira, V.M.; Wu, C.-N.; Höfer, K.; Choa, A.; Knight, C.-A.; Swanson, J.; Becker, C.; Komarek, A.C.; Rata, A.D.; Rößler, S.; et al. Challenges of Topological Insulator Research: Bi2Te3 Thin Films and Magnetic Heterostructures. Phys. Status Solidi 2021, 258, 2000346. [Google Scholar] [CrossRef]

- Ferhat, M.; Tedenac, J.C.; Nagao, J. Mechanisms of spiral growth in Bi2Te3 thin films grown by the hot-wall-epitaxy technique. J. Cryst. Growth 2000, 218, 250–258. [Google Scholar] [CrossRef]

- Mulder, L. Pushing a Topological Insulator to Its Ultrathin Limit. Ph.D. Thesis, University of Twente, Enschede, The Netherlands, 2021. [Google Scholar] [CrossRef]

| Tanneal (°C) | tanneal (min) | f (%) | hc (nm) | σ (nm) |

|---|---|---|---|---|

| - | - | 2.3 ± 0.3 | 7.0 ± 1.3 | 1.15 ± 0.1 |

| 250 | 15 | 1.3 ± 0.1 | 6.3 ± 0.2 | 1.06 ± 0.03 |

| 275 | 15 | 0.7 ± 0.3 | 6.5 ± 0.6 | 1.00 ± 0.04 |

| 300 | 5 | 0.8 ± 0.6 | 6.9 ± 1.2 | 1.43 ± 0.11 |

| 300 | 15 | - * | - * | 0.63 ± 0.01 |

| 300 | 30 | - * | -* | 0.68 ± 0.03 |

| 325 | 15 | -* | -* | 0.49 ± 0.02 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mulder, L.; van de Glind, H.; Brinkman, A.; Concepción, O. Enhancement of the Surface Morphology of (Bi0.4Sb0.6)2Te3 Thin Films by In Situ Thermal Annealing. Nanomaterials 2023, 13, 763. https://doi.org/10.3390/nano13040763

Mulder L, van de Glind H, Brinkman A, Concepción O. Enhancement of the Surface Morphology of (Bi0.4Sb0.6)2Te3 Thin Films by In Situ Thermal Annealing. Nanomaterials. 2023; 13(4):763. https://doi.org/10.3390/nano13040763

Chicago/Turabian StyleMulder, Liesbeth, Hanne van de Glind, Alexander Brinkman, and Omar Concepción. 2023. "Enhancement of the Surface Morphology of (Bi0.4Sb0.6)2Te3 Thin Films by In Situ Thermal Annealing" Nanomaterials 13, no. 4: 763. https://doi.org/10.3390/nano13040763

APA StyleMulder, L., van de Glind, H., Brinkman, A., & Concepción, O. (2023). Enhancement of the Surface Morphology of (Bi0.4Sb0.6)2Te3 Thin Films by In Situ Thermal Annealing. Nanomaterials, 13(4), 763. https://doi.org/10.3390/nano13040763